Thermal insulation building material prepared from amino modified SiO2 aerogel in cooperation with solid waste carbonization and method

An amino modification, aerogel technology, applied in the field of building insulation materials, can solve the problem of low utilization rate of resources, and achieve the effects of excellent CO2 adsorption capacity, excellent mechanical properties, and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

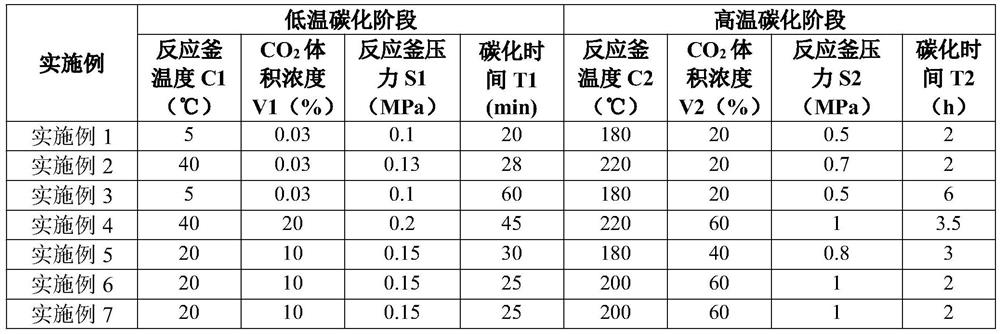

[0034] The present invention will be further described in detail below in conjunction with specific embodiments.

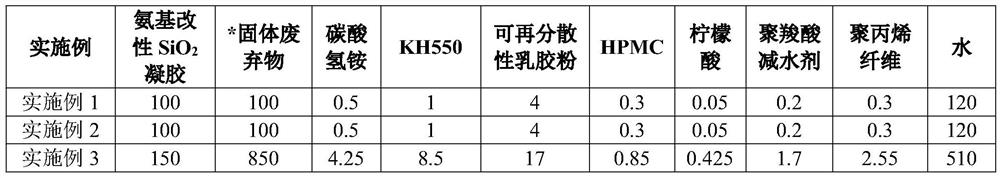

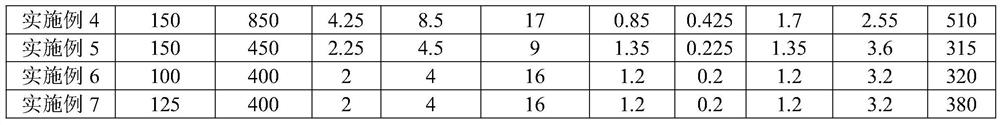

[0035] Amino-modified SiO 2 The thermal insulation building material prepared by aerogel synergistic solid waste carbonization is composed of the following raw materials in parts by weight: amino-modified SiO 2 100-150 parts of airgel, 100-850 parts of solid waste, 0.5-4.25 parts of carbonization activator, 1-8.5 parts of silane coupling agent, 4-17 parts of organic binder, 0.3-1.35 parts of thickener, 0.05-0.425 parts of retarder, 0.2-1.7 parts of water reducing agent, 0.3-3.6 parts of fiber, 120-510 parts of water.

[0036] The solid waste is rich in Ca 2+ solid waste, including steel slag, desulfurized gypsum, phosphogypsum, fly ash, sulfur-fixed ash, denitration fly ash, or a mixture of several of them mixed in any proportion. The solid waste is steel slag, desulfurized gypsum , fly ash, and the mass ratio of steel slag, desulfurized gypsum, and fly ash is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com