Device and method for carbonizing straw

A straw carbonization and carbonization furnace technology, which is applied in special forms of dry distillation, petroleum industry, biofuels, etc. Large-scale production, full utilization of raw materials, and high carbonization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

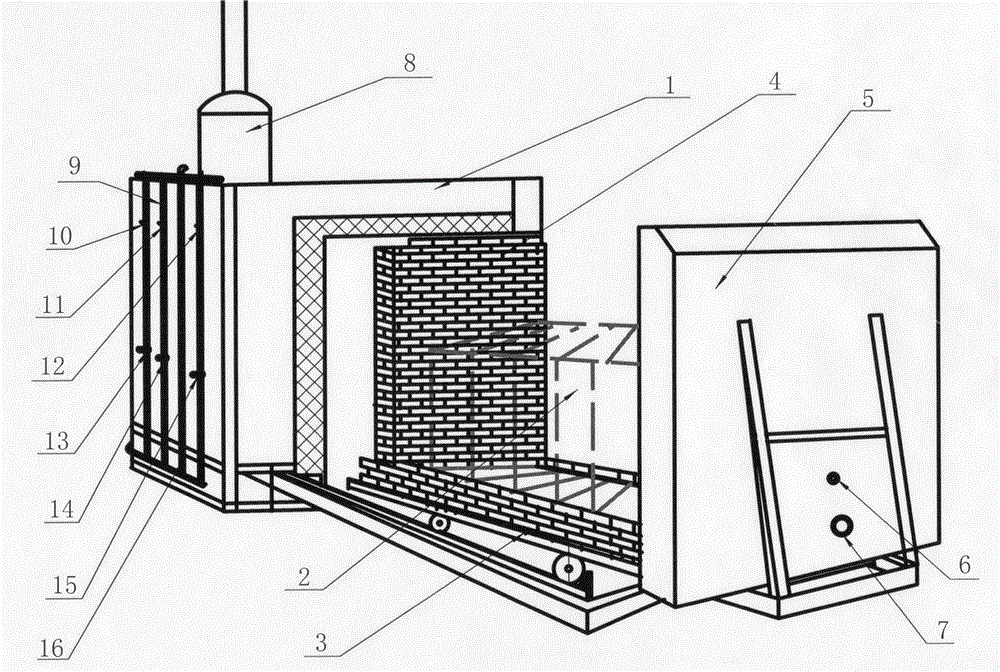

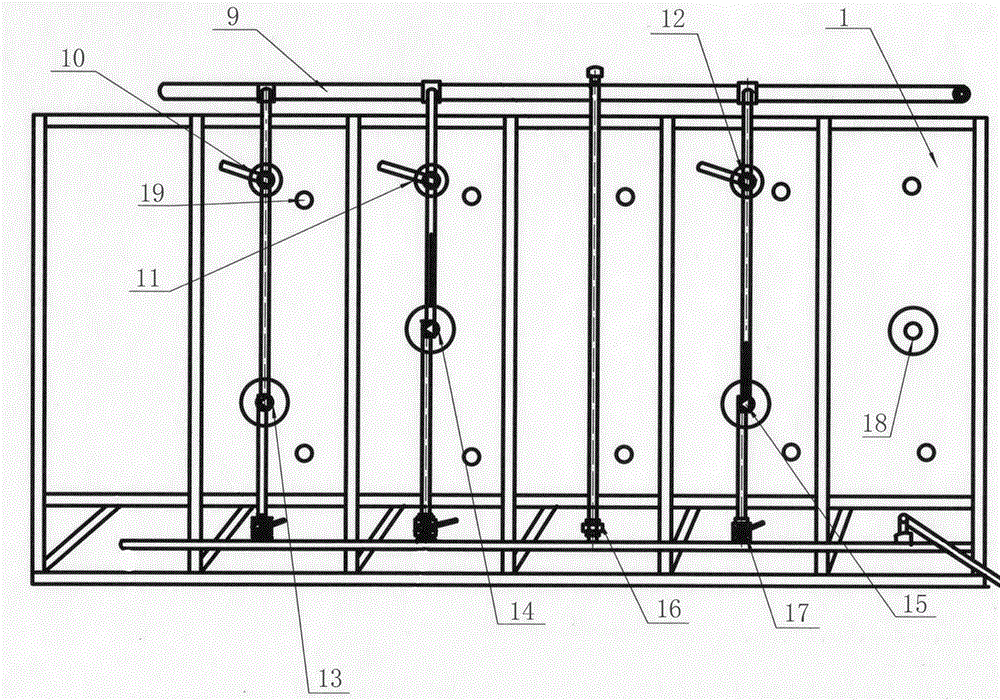

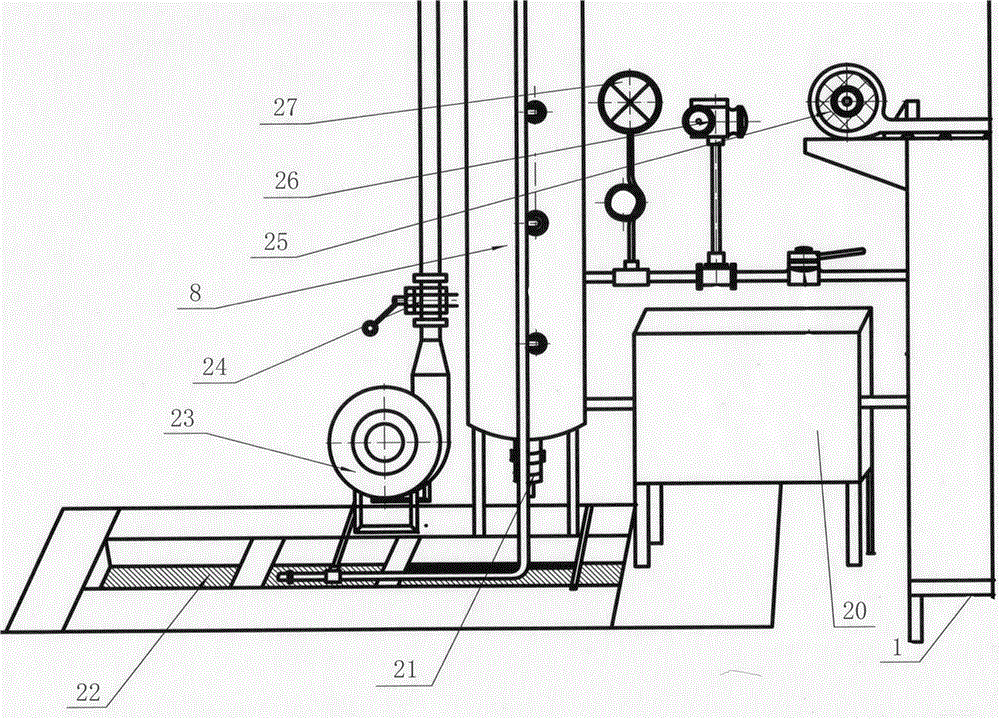

[0033] Example 1 A straw carbonization device, see figure 1 , figure 1 , image 3 , including a tunnel kiln type carbonization furnace body 1, a heating unit, a dust collection and processing unit, a certain number of sintering bins 2 with a certain degree of air permeability, and a track-type loader that matches the hearth of the carbonization furnace body 1 Feeding car 3, sintering material box 2 (made of stainless steel material) is placed in the track-type loading car 3; the heating unit includes a torch arranged in the hearth of the carbonization furnace body, and the torch and gas source (digester, gas storage tank) connected gas pipeline 16, and the gas-supporting pipeline 12 that connects the flame gun 13, 14, 15 with the gas-supporting source; the dust collection and processing unit includes a spray collector, Sewage collection pool 22, the spray collector includes induced draft fan 23, spray tower 8, and circulating water pool 20 connected in sequence; a flame in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com