Energy-saving environment-friendly circulation type waste gas treatment method applied to paint spraying and paint baking process

A technology for waste gas treatment, energy saving and environmental protection, applied in the field of paint spraying and baking, can solve the problems of low concentration, environmental pollution, incompleteness, etc., and achieve the effect of clean air and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

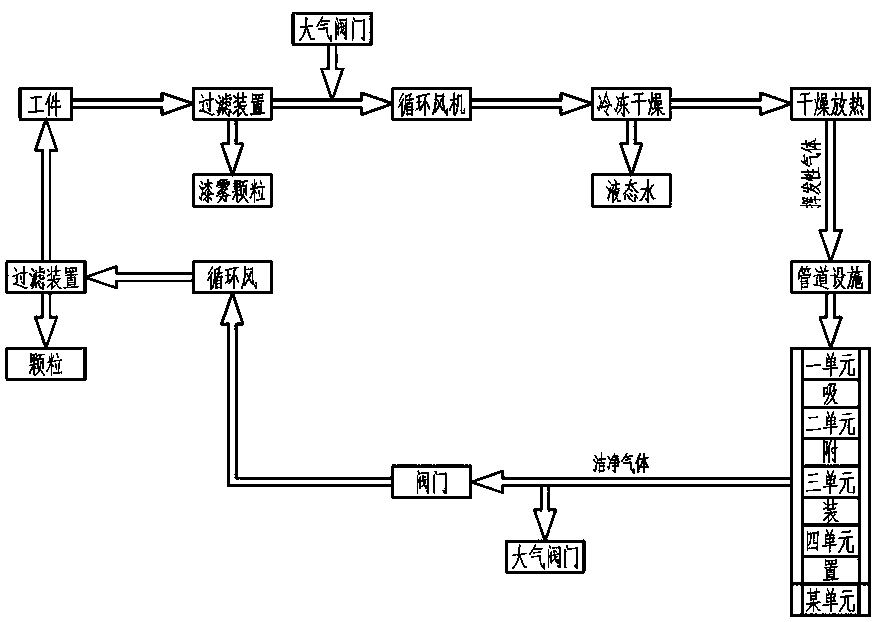

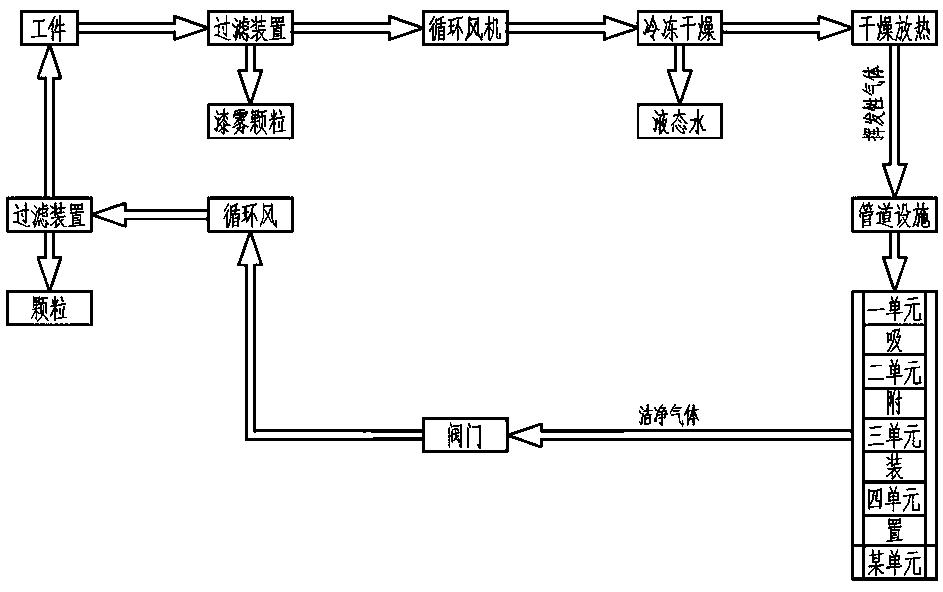

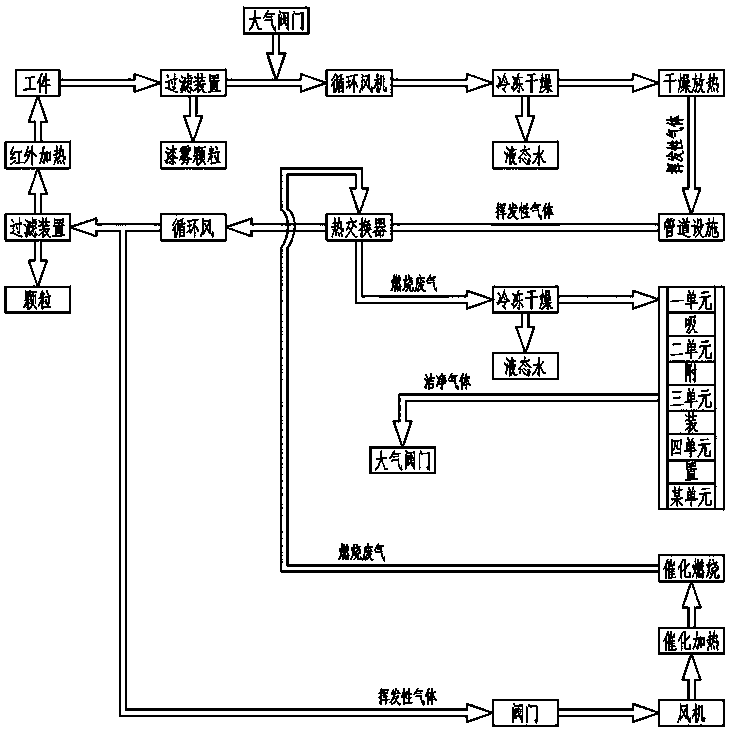

[0048] The energy-saving and environment-friendly circulating waste gas treatment method applied to the painting and baking process described in this embodiment includes waste gas treatment in the painting stage, waste gas treatment in the leveling stage, and waste gas treatment in the drying stage. The waste gas treatment in the painting stage: place the workpiece in the spraying room for Spraying, use ventilation equipment to take away the waste gas in the spraying room, and filter, dry and absorb the taken away waste gas, and the treated gas flows back into the spraying room to form a circulating air flow; waste gas treatment in the leveling stage: workpiece painting After completion, enter the leveling stage, use the ventilation equipment to take away the waste gas in the leveling chamber, and filter, dry and absorb the waste gas taken away, and the treated gas returns to the leveling chamber to form a circulating air flow; Exhaust gas treatment in the drying stage: After t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com