Patents

Literature

188results about How to "Guaranteed pressure balance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dilution sampling system and sampling method of fixed source particles and volatile organic compounds

InactiveCN103091134AImprove mixing uniformityShorten the lengthWithdrawing sample devicesStop timeAutomatic control

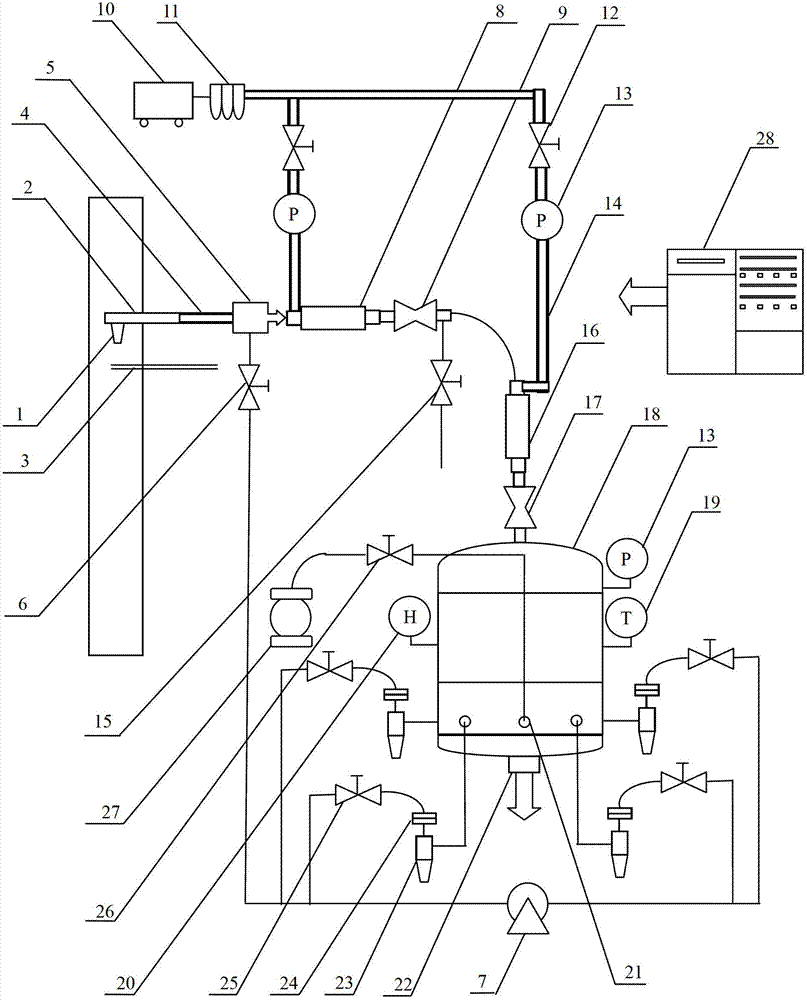

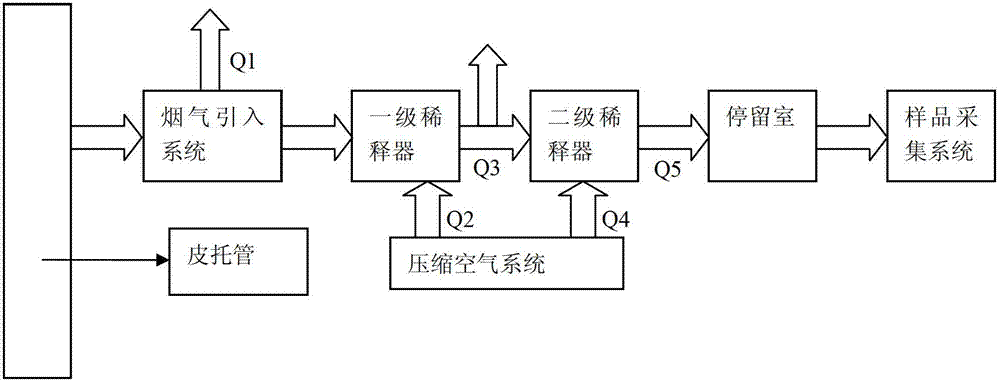

The invention discloses a dilution sampling system and a sampling method of fixed source particles and volatile organic compounds, and belongs to the technical field of environmental monitoring. The dilution sampling system comprises a smoke introducing system, a diluting system, a stopping chamber, a sample collection system and a control and data collection system. The system can simulate the nucleation, condensation and coagulation processes of the fixed source smoke after being discharged to the atmosphere, can adopt a grain size classification sampling method of atmospheric particulate matters to sample the particulate matters, can adopt the atmospheric volatile organic matter sampling method to sample the volatile organic matters, and can realize the dynamic control of dilution ratio and the dynamic stopping time. Each part of the system has the advantages of high integration, high stability, automation in control, and easiness in operation.

Owner:BEIJING UNIV OF TECH

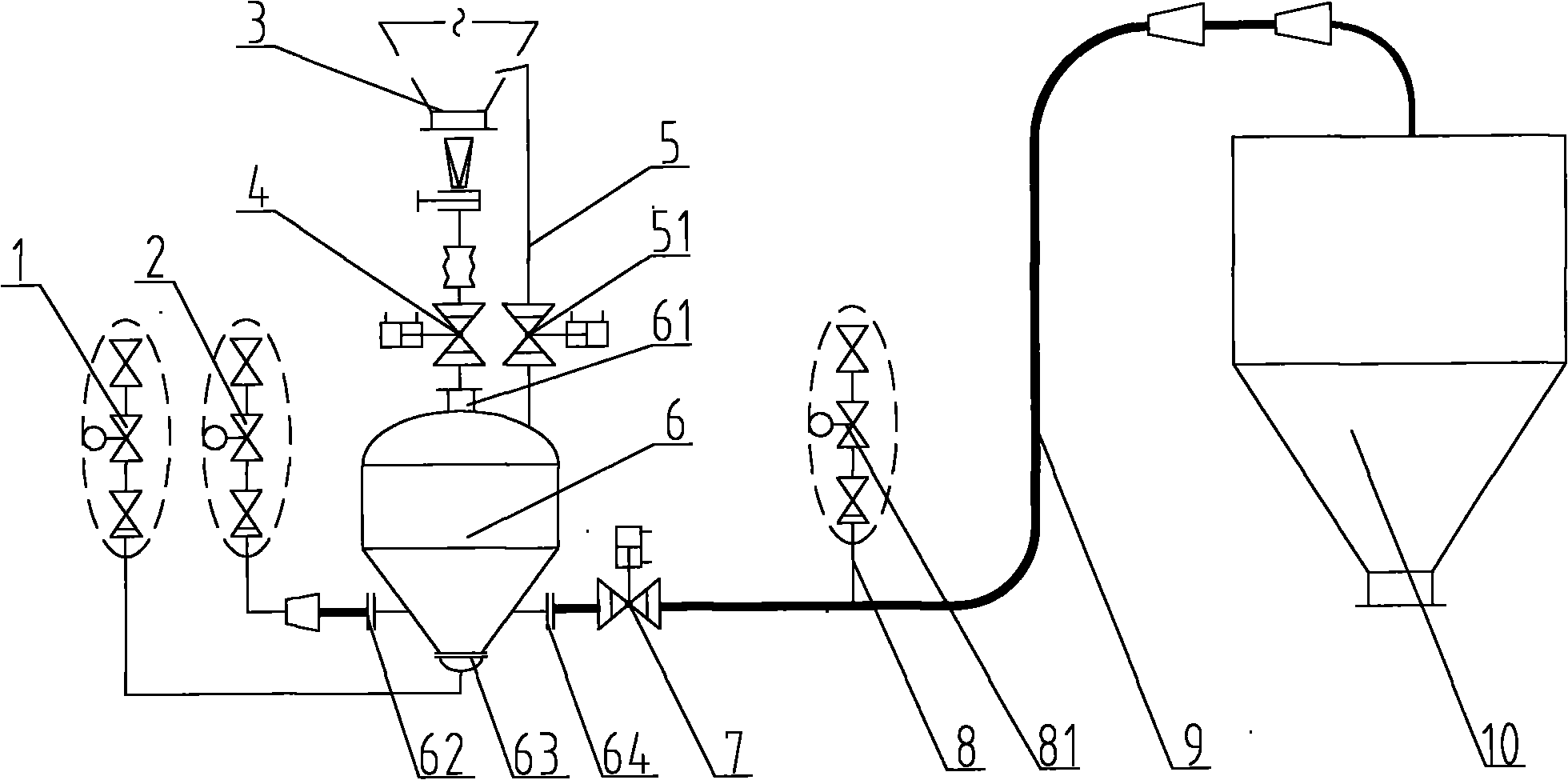

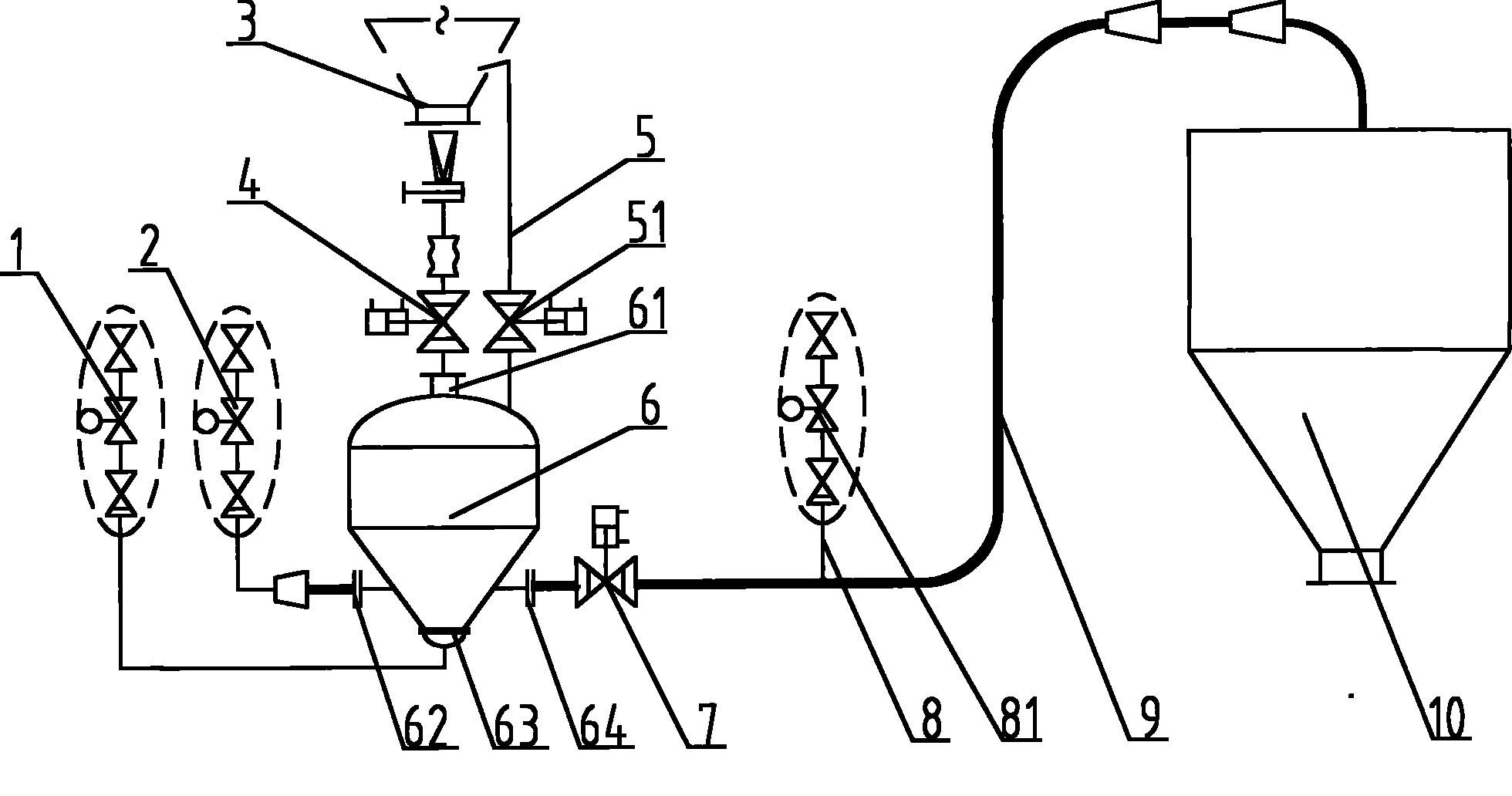

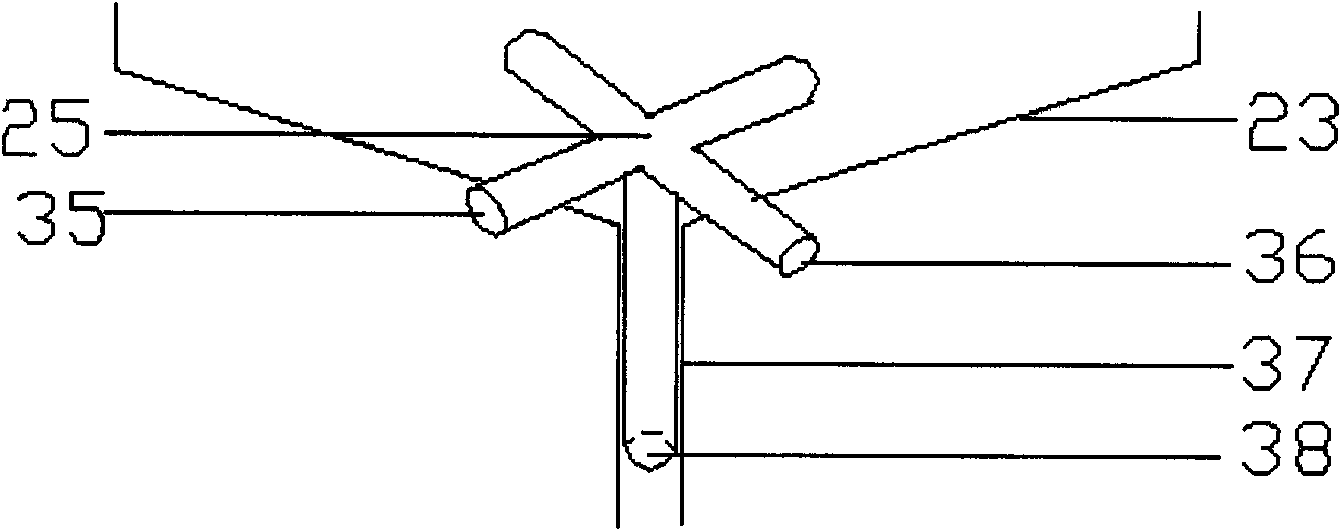

Pneumatic conveyer

The invention discloses a pneumatic conveying device, which comprises a bin pump and a delivery duct. The driving air inlet of the bin pump is connected with a bin pump cone and is in the same central line with the discharging hole of the bin pump. The diameter of the delivery duct is increased gradually. The device also comprises at least one air make-up duct. The air make-up duct is provided with a plurality of openings circumferentially distributed along the inner wall of the delivery duct. The opening direction is consistent with the flowing direction of a solid-gas mixture. The working process comprises three steps, namely feeding, fluidifying and adjusting the flow rate of the solid-gas mixture. Air is introduced into the delivery duct by the air make-up duct to adjust pressure in the delivery duct and adjust the flow velocity of solid-gas mixture so as to ensure that the solid-gas mixture has proper flow velocity, thus lowering the wear rate of the delivery duct, reducing the possibility of delivery duct blockage, and ensuring the working reliability of the pneumatic conveyer.

Owner:FUJIAN LONGKING

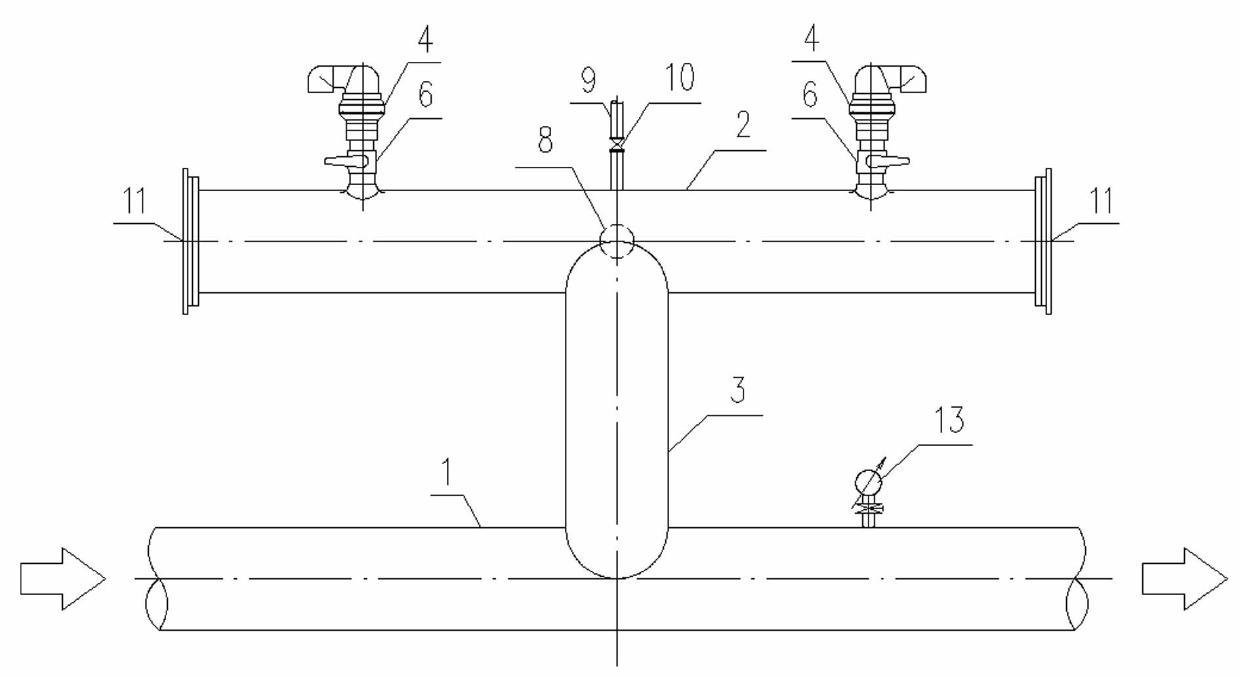

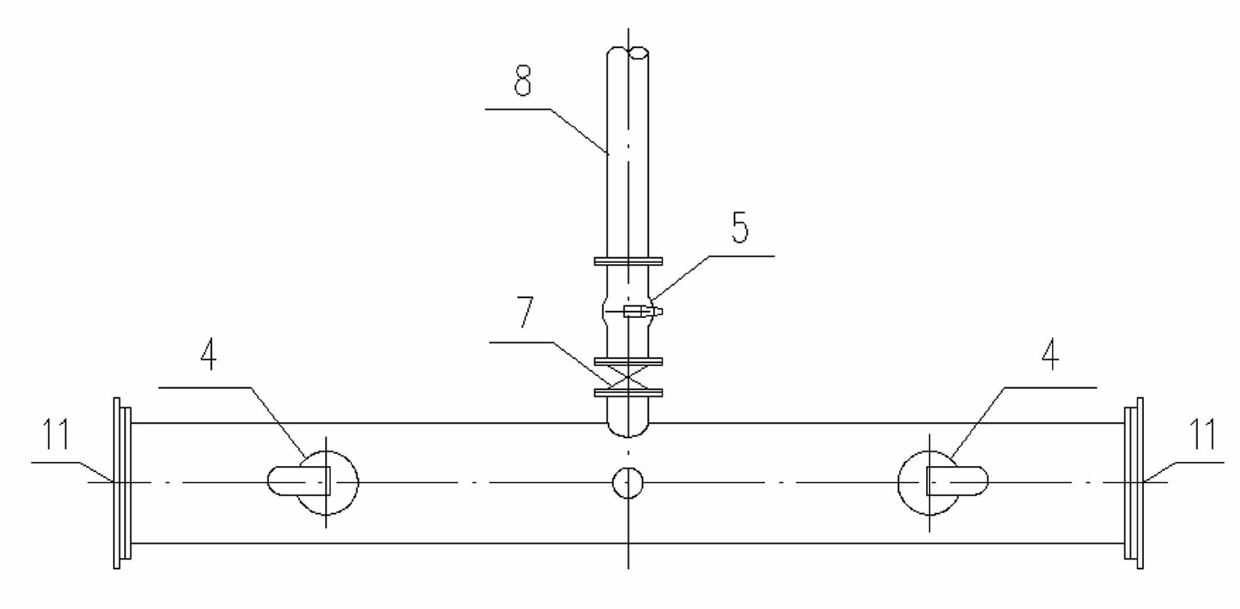

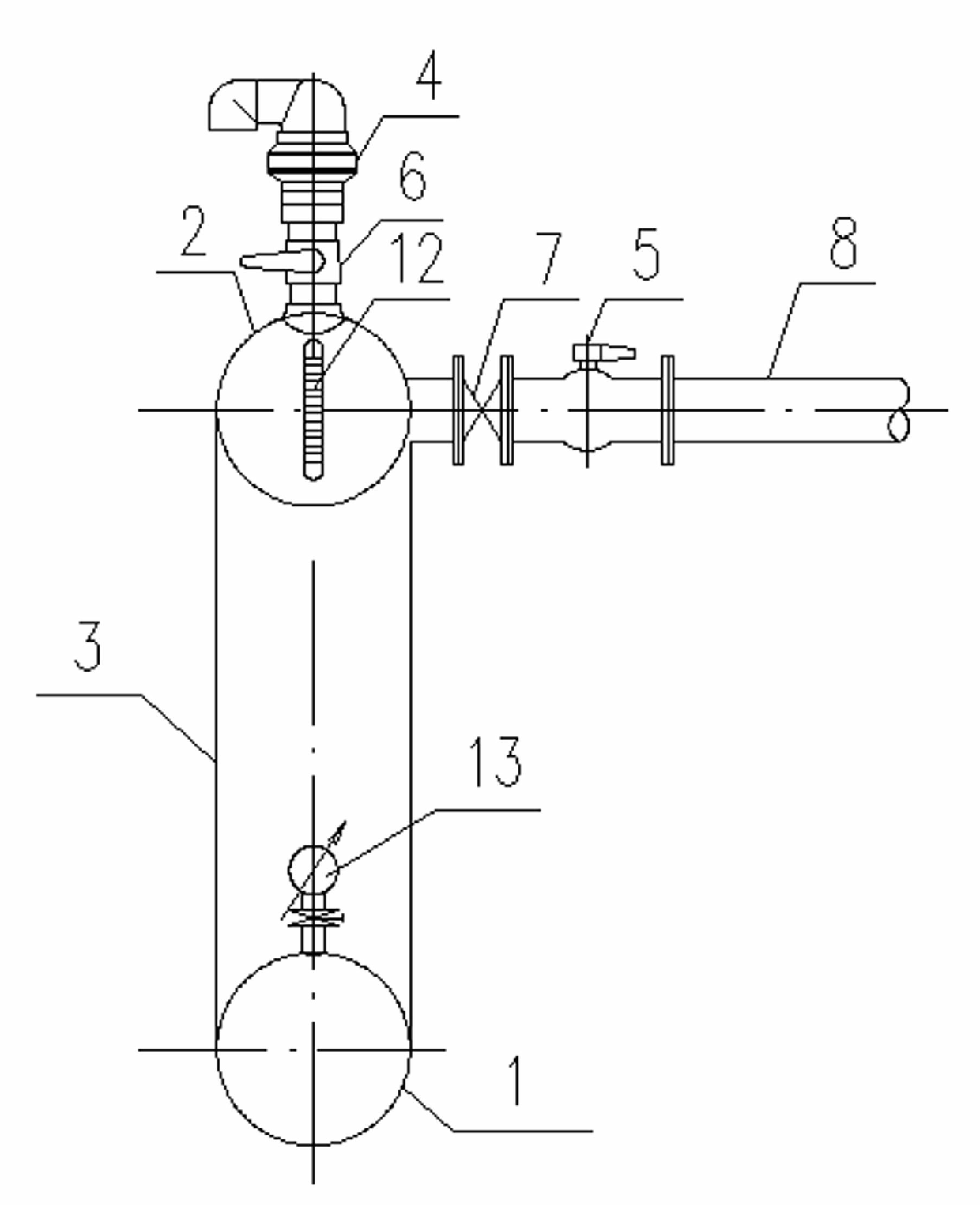

Protecting device for forward water hammer

ActiveCN102606842AEffective protectionEffective weakeningPipe elementsAutomatic controlControl system

The invention discloses a protecting device for a forward water hammer, which comprises a main body device and an automatic control system, wherein the main body device comprises a straight pipe, a buffer pipe, a connection pipe, an air valve, a pressure fluctuation pre-stop valve, a drain pipe, an air supply pipe and an air supply gate valve; the two ends of the buffer pipe are sealed and blocked; the buffer pipe is above the straight pipe; a lateral wall at the middle part of the buffer pipe is connected with the lateral wall at the middle pipe of the straight pipe through a connection pipe; the air valve is arranged on the buffer pipe; the drain pipe is arranged on the lateral wall of the buffer pipe through the pressure fluctuation pre-stop valve; the air supply pipe is arranged on the lateral wall of the buffer pipe through the air supply gate valve; the automatic control system comprises a pressure transmitter, a control box, a control cable and a signal cable; the pressure transmitter is arranged at a water outlet end of the straight pipe, and the pressure transmitter and the pressure fluctuation pre-stop valve are respectively connected with the control box through the signal cable and the control cable. According to the protecting device for the forward water hammer, the forward water hammer is effectively protected or weakened; particularly, the protecting device forthe forward water hammer is suitable for a long-distance water pipeline, and has the characteristics of being effective in protection, simple in structure, easy in production, convenient in installation, safe and stable, small in floor area, less in investment and the like.

Owner:中国市政工程西北设计研究院有限公司

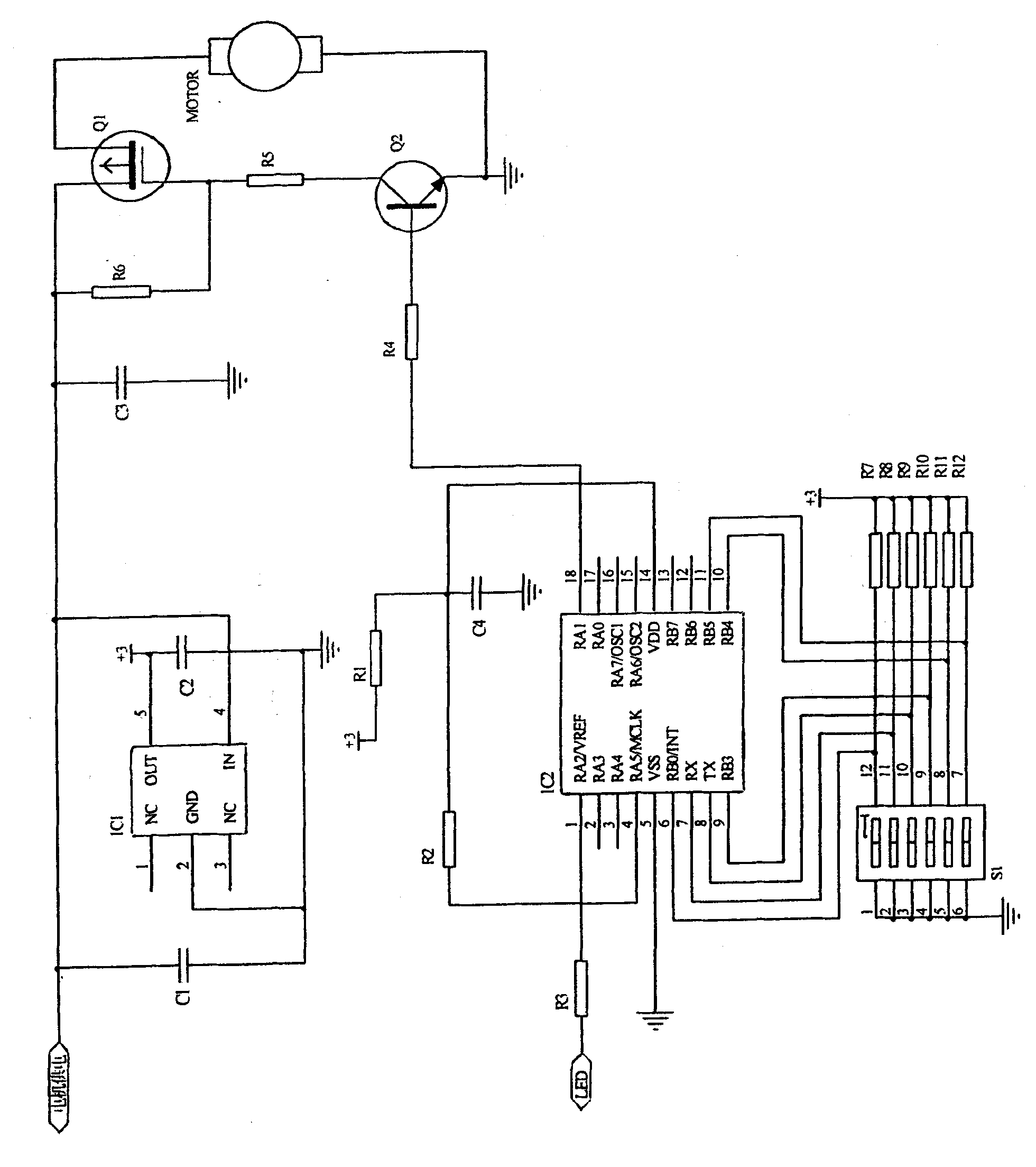

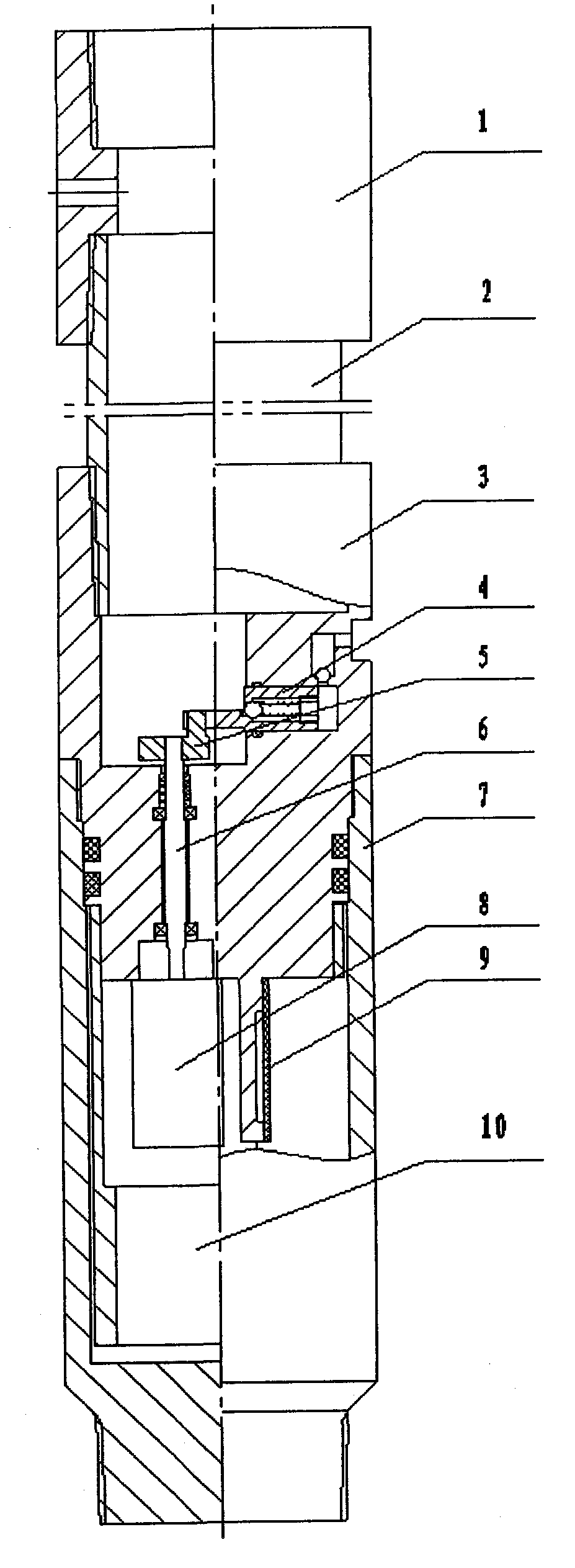

Automatic quantitative dosing device under oil well

InactiveCN102155205AReduce workloadInjected smoothlyCleaning apparatusFluid removalMicrocontrollerStart time

The invention relates to an automatic quantitative dosing device under an oil well. In the device, the upper part of a charging pipe is connected with a communicating joint, and the lower part of the charging pipe is connected with a pump body joint of a dosing pump; a piston rod of the dosing pump is connected with a cam, a connecting rod and a motor in sequence; the motor is connected with a control circuit and a battery; a singlechip IC2 of the control circuit is connected with a dial switch S1; a triode Q2 is connected with a triode Q1; the Q1 is connected with the motor; and a power supply is connected with the triode Q1 through a voltage regulating chip IC1. The motor starting time interval and every dosing amount can be set according to the total dosing amount of the oil well, the piston rod of the dosing pump reciprocates to spray a liquid medicine into the annular space of an oil sleeve during dosing, and the dosing pump stops working and waits for the next dosing time when a designed medicine amount is reached so that automatic timing and quantitative continuous dosing are realized. The automatic quantitative dosing device has a high automatic degree, a good dosing effect, low construction cost and high long-term working reliability, and is easy to operate; and underground dosing can be realized without detaching an instrument or performing pipe column operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

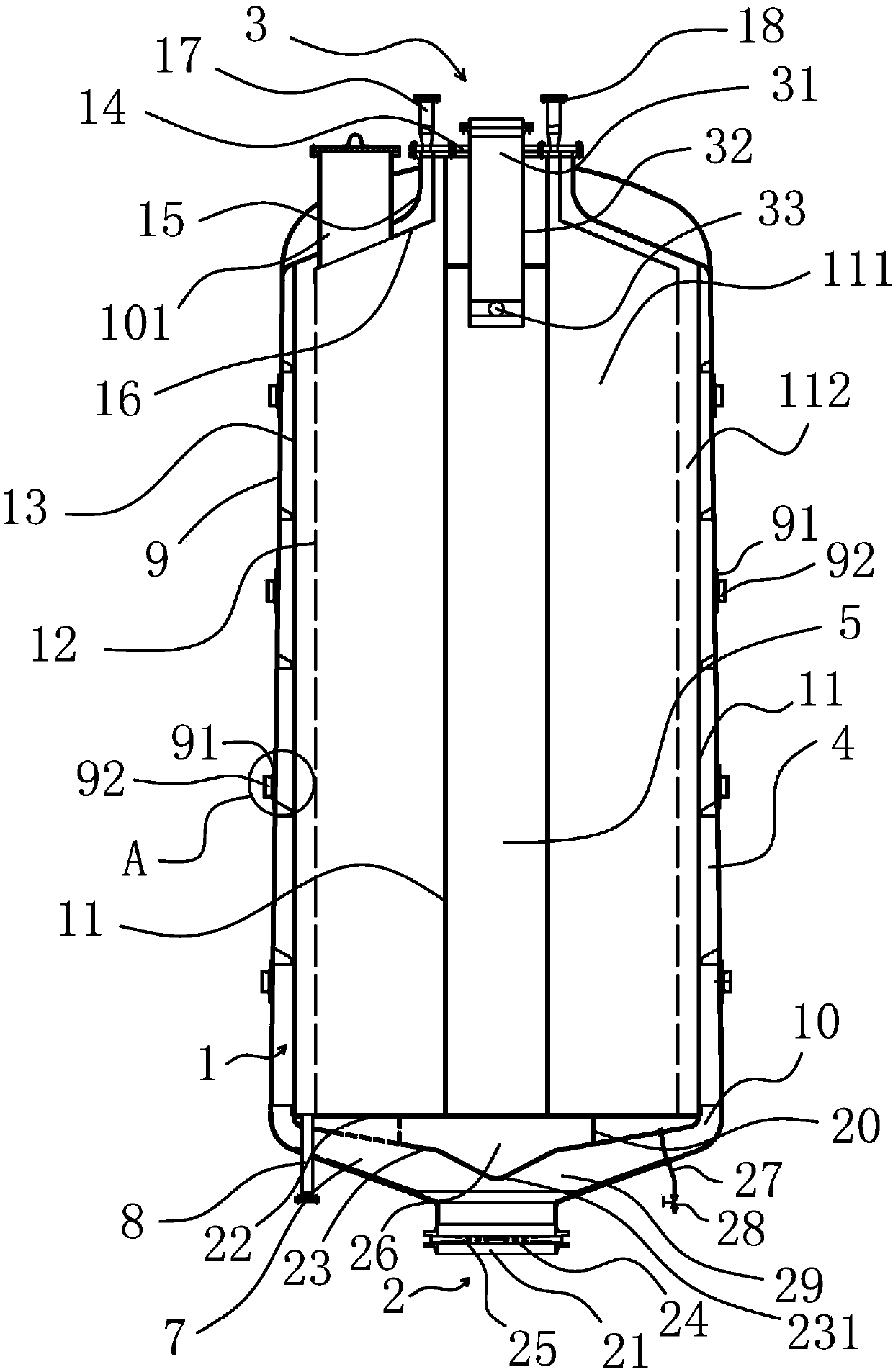

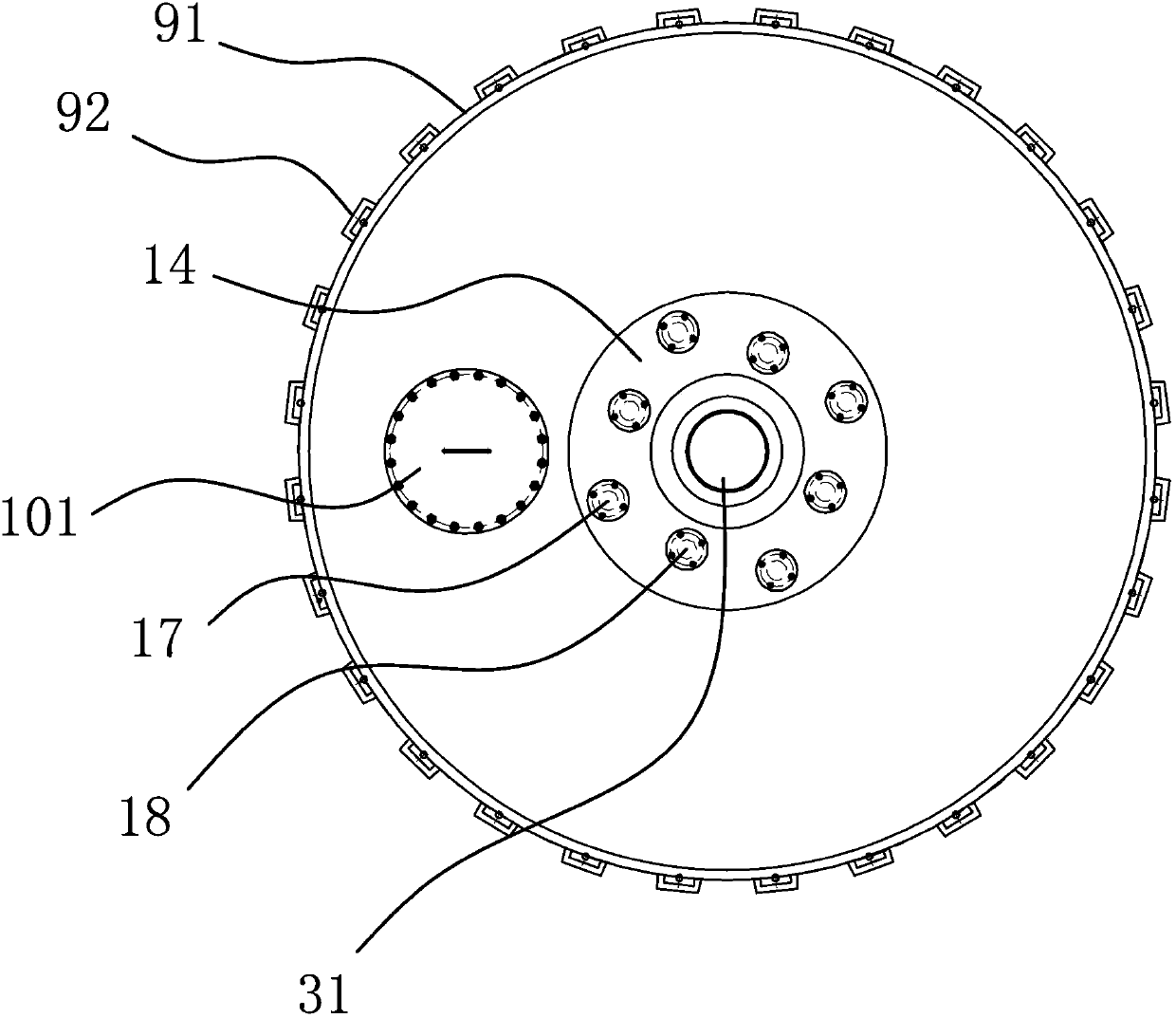

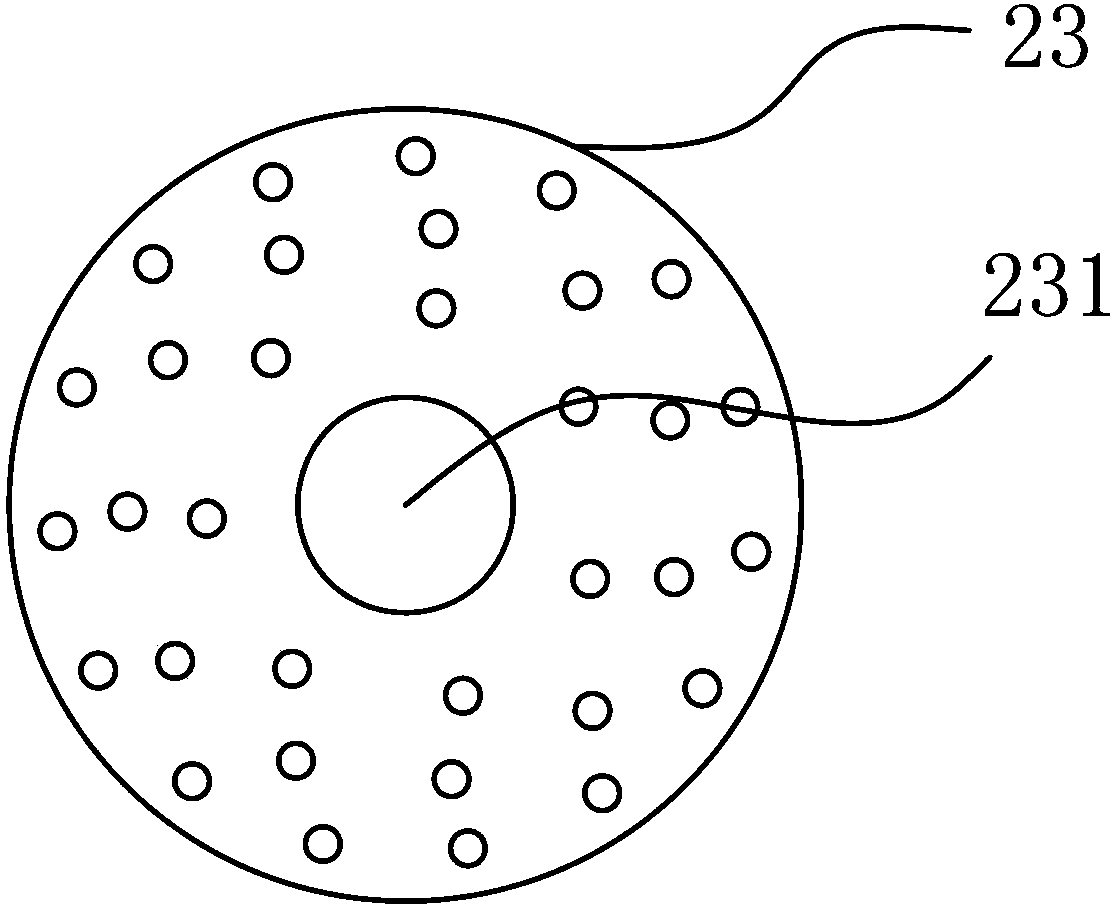

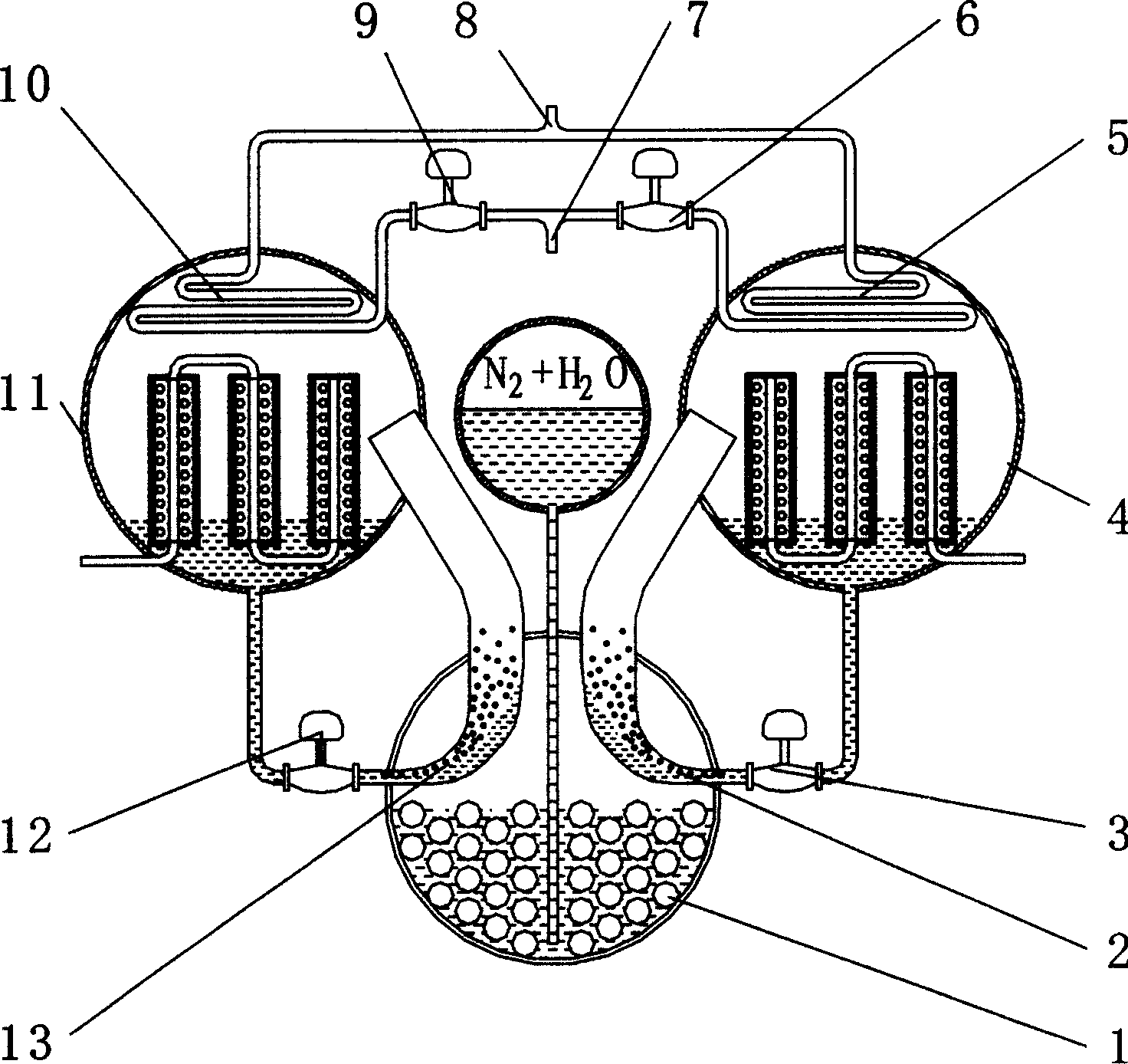

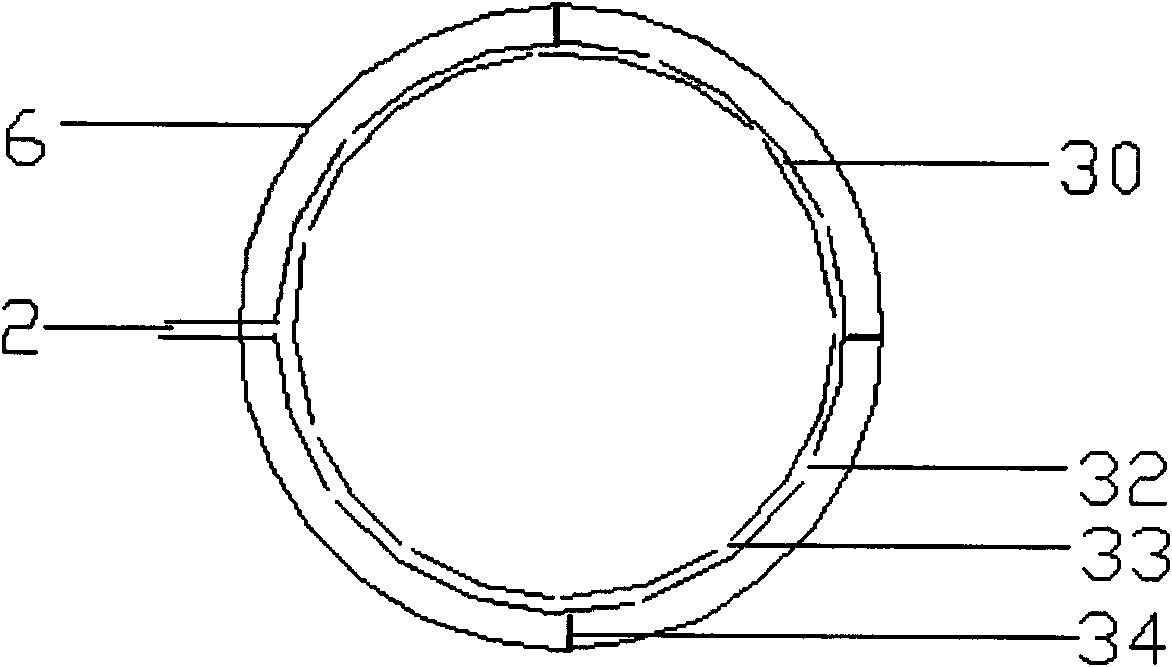

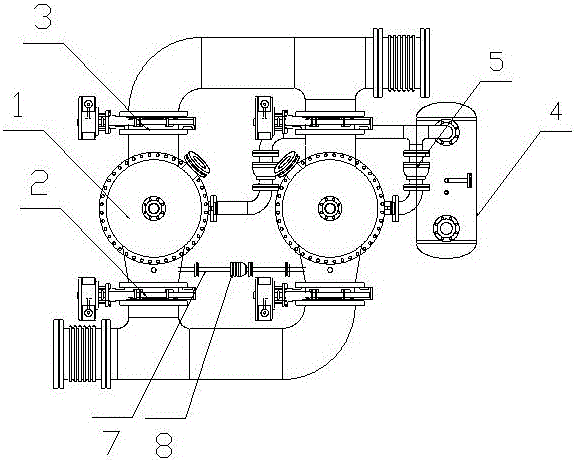

Radial oxygen production adsorption tower

ActiveCN103357243AUniform adsorptionImprove adsorption efficiencyDispersed particle separationOxygen preparationDiameter ratioMechanical equipment

The invention provides a radial oxygen production adsorption tower, belongs to the technical field of mechanical equipment, and solves the technical problems of too small height-diameter ratio, too large occupied floor space, non-uniform adsorption and the like in the prior art. The oxygen production adsorption tower comprises a cylindrical tower body, an gas inlet assembly disposed at the bottom of the tower body, an gas outlet assembly disposed at the top of the adsorption assembly, an adsorption assembly disposed in the tower body and a circular gas transportation cavity formed between the inner wall of the tower body and the outer wall of the adsorption wall, wherein the gas inlet assembly is provided with a circular gas vent disposed at the periphery of the lower end of the adsorption assembly; the circular gas vent is communicated with the gas transportation cavity; a gas flow can be transported to the adsorption assembly radially by the gas transportation cavity; two ends of the adsorption assembly are sealed; the center of the adsorption assembly is provided with a gas collection channel for collecting finished product oxygen; the lower end of the gas collection channel is sealed; and the upper end of the gas collection channel is communicated with the gas outlet assembly. The radial oxygen production adsorption tower has the advantages of uniform adsorption, high adsorption efficiency, small occupied floor space, large-scale designability, etc.

Owner:杭州普菲科空分设备有限公司

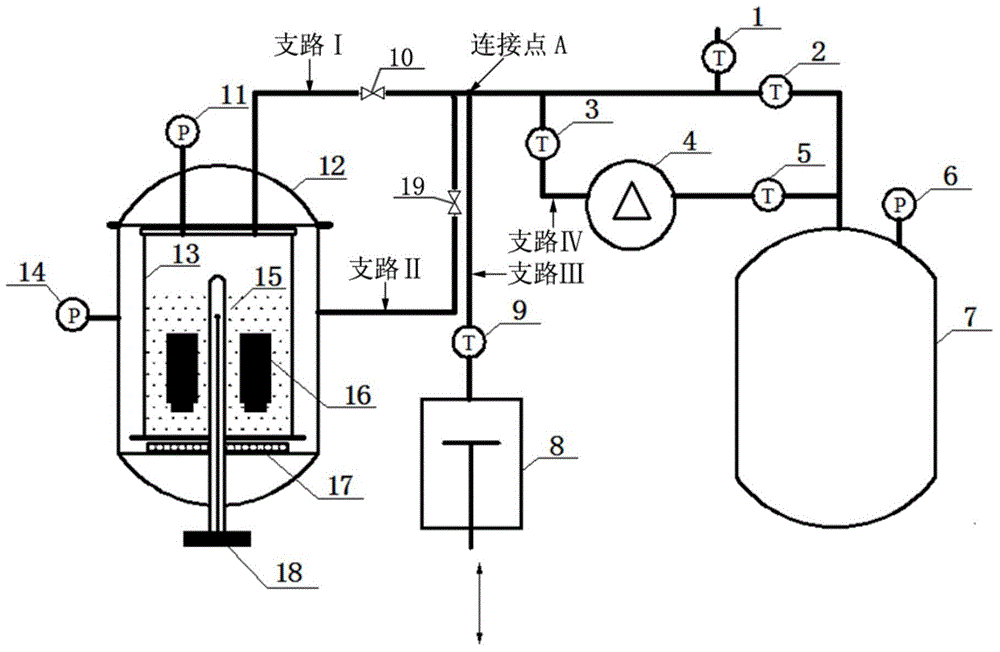

High-temperature high-pressure core-removing device and core-removing method for alumina-based ceramic core

The invention discloses a high-temperature high-pressure core-removing device and core-removing method for an alumina-based ceramic core, pertaining to the technical field of high-temperature alloy castings. A main body part of the core-removing device is composed of a pressure-tolerant kettle body and a reaction charging basket. A nitrogen compressor and a nitrogen storage tank are used for supercharging, releasing pressure and gas recovery of the core-removing device. Heating coils are used for increasing temperature of the core-removing device. A pressure regulator is used for providing alternative high pressure required by the core-removing device. A gas flow regulator is used for controlling gas flow and pressure of all pipelines. A KOH water solution with 55-80% of concentration is used as core-removing liquid at the temperature ranging from 350 to 410 DEG C. During the process of removing a mold core, alternating pressure with 15-25 MPa is applied or constant pressure with 22-25 MPa is applied. The high-temperature high-pressure core-removing device and core-removing method for the alumina-based ceramic core have following beneficial effects: the alumina-based ceramic core of a gas turbine blade can be smoothly removed; and alumina-based ceramic cores of other high-temperature alloy castings can be removed.

Owner:SHENYANG RES INST OF FOUNDRY

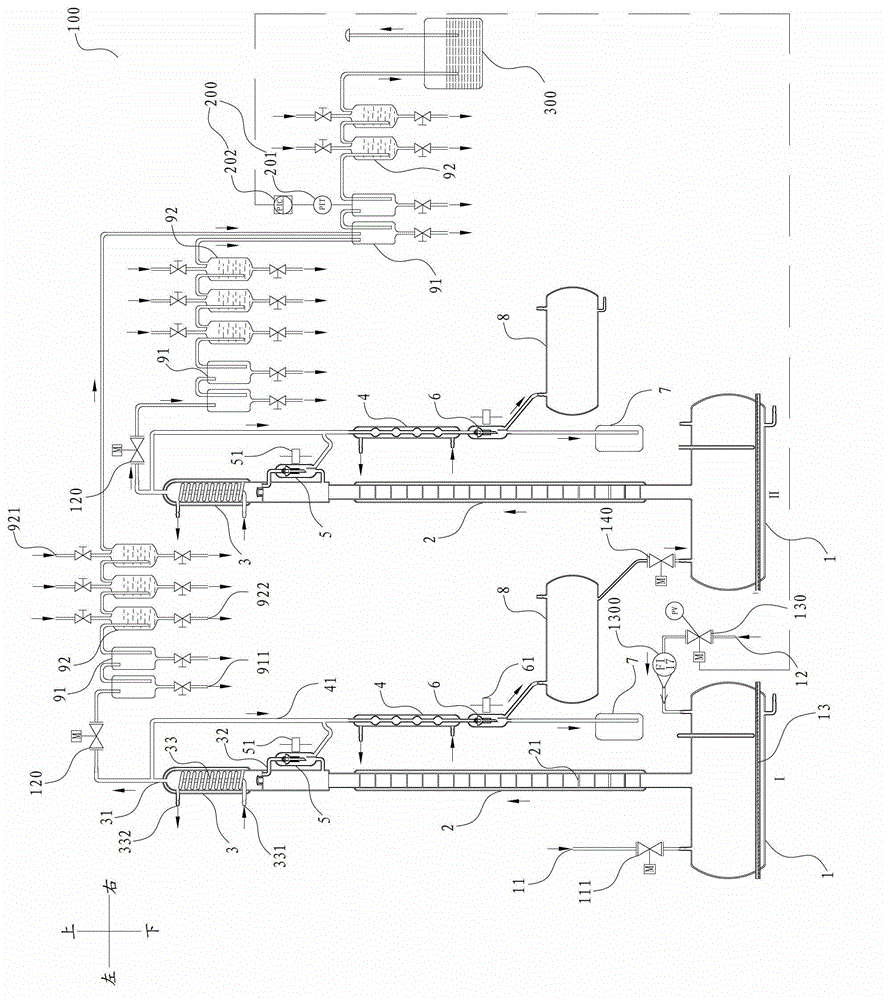

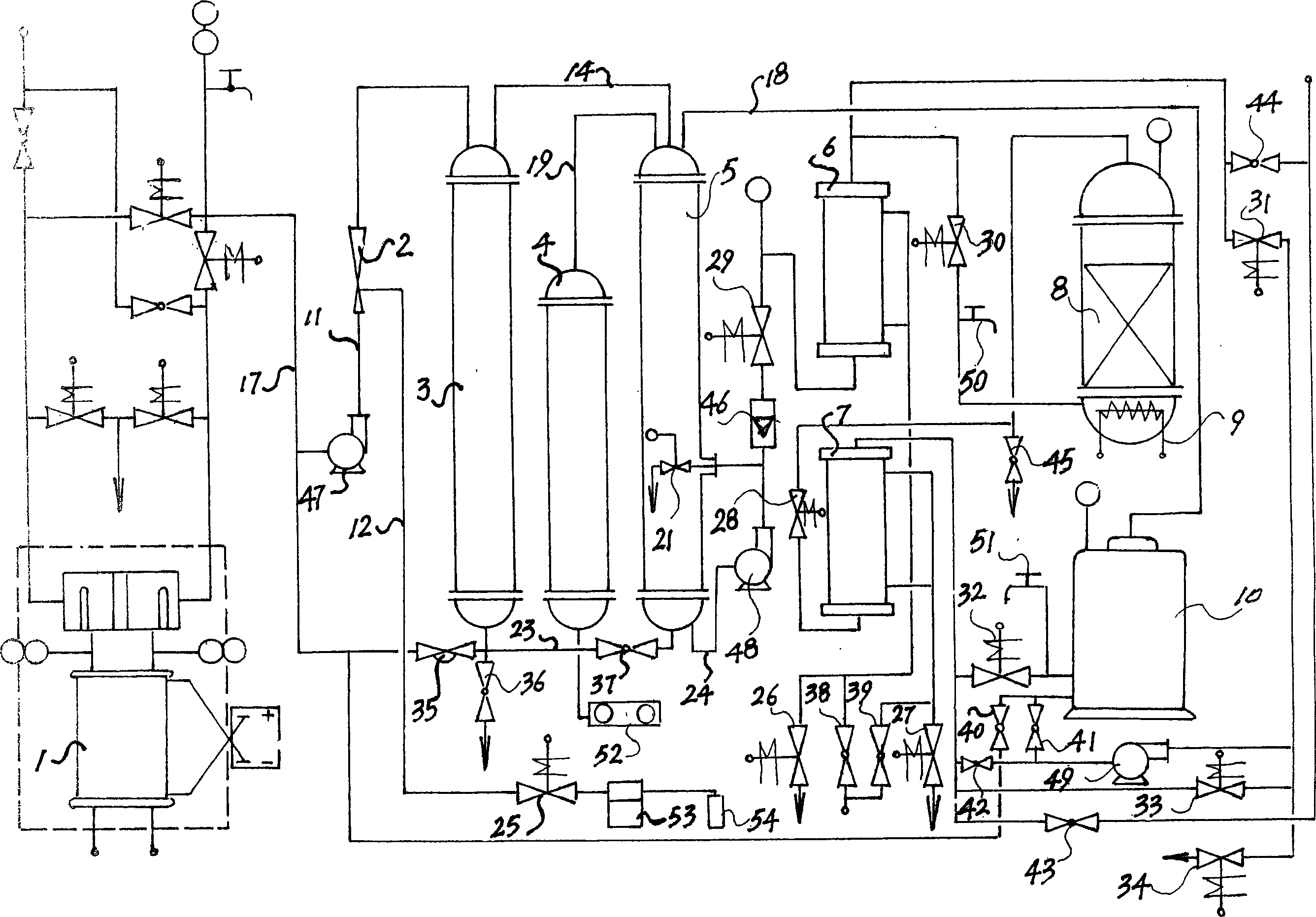

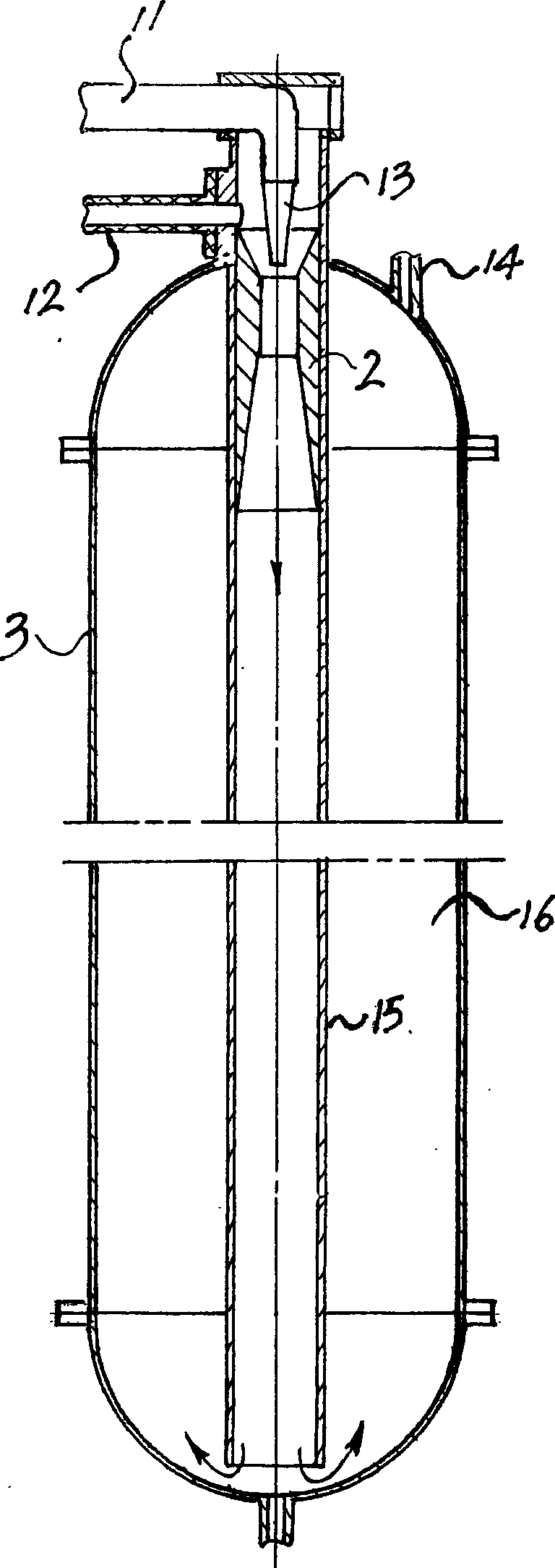

Production system of germanium tetrachloride for optical fiber

ActiveCN102976395AImprove distillation purityIsolated entryGermanium halidesEngineeringProcess engineering

The invention provides a production system of germanium tetrachloride for optical fiber. The production system of germanium tetrachloride for the optical fiber comprises at least two rectification units. The rectification units are connected with each other in series. Each of the rectification units comprises a rectifying still, a rectifying tower, a primary condensing tower, a secondary condensing tower, a discharging head, a primary exhaust gas absorption device, a secondary exhaust gas absorption device and a exhaust gas treatment device. The secondary exhaust gas absorption device is communicated with the primary exhaust gas absorption device. The exhaust gas treatment device is communicated with the secondary exhaust gas absorption device. The production system of germanium tetrachloride for the optical fiber improves the rectifying purity of the germanium tetrachloride for the optical fiber enormously by arranging a plurality of rectification units and improves the reliability of the sealing and maintains the pressure balance in the system by arranging the primary exhaust gas absorption device and the secondary exhaust gas absorption device and can evacuate the exhaust gas finally produced by the production system through the exhaust gas treatment device by arranging the exhaust gas treatment device.

Owner:云南驰宏国际锗业有限公司

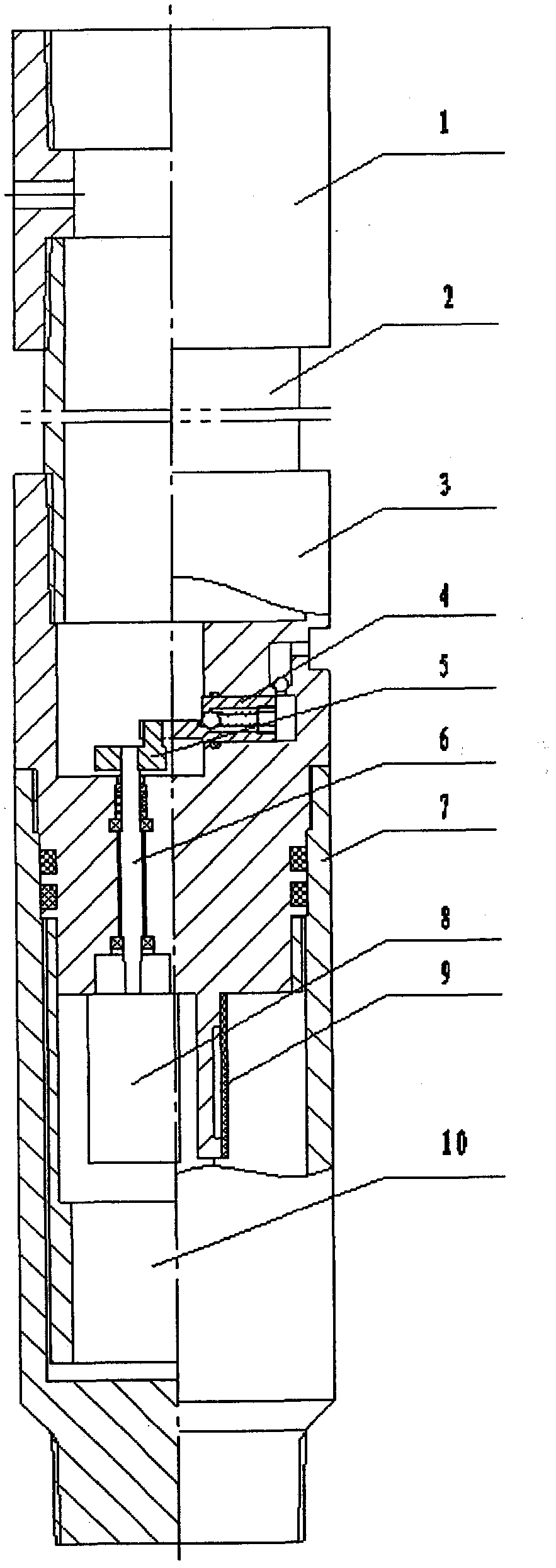

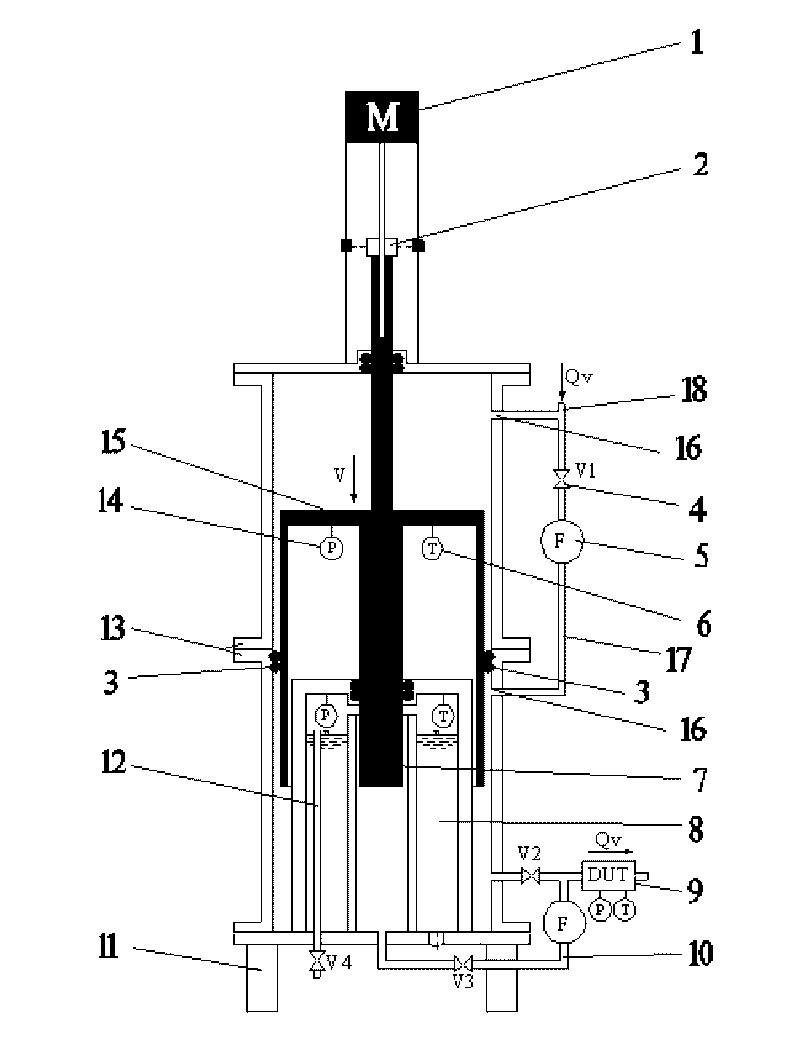

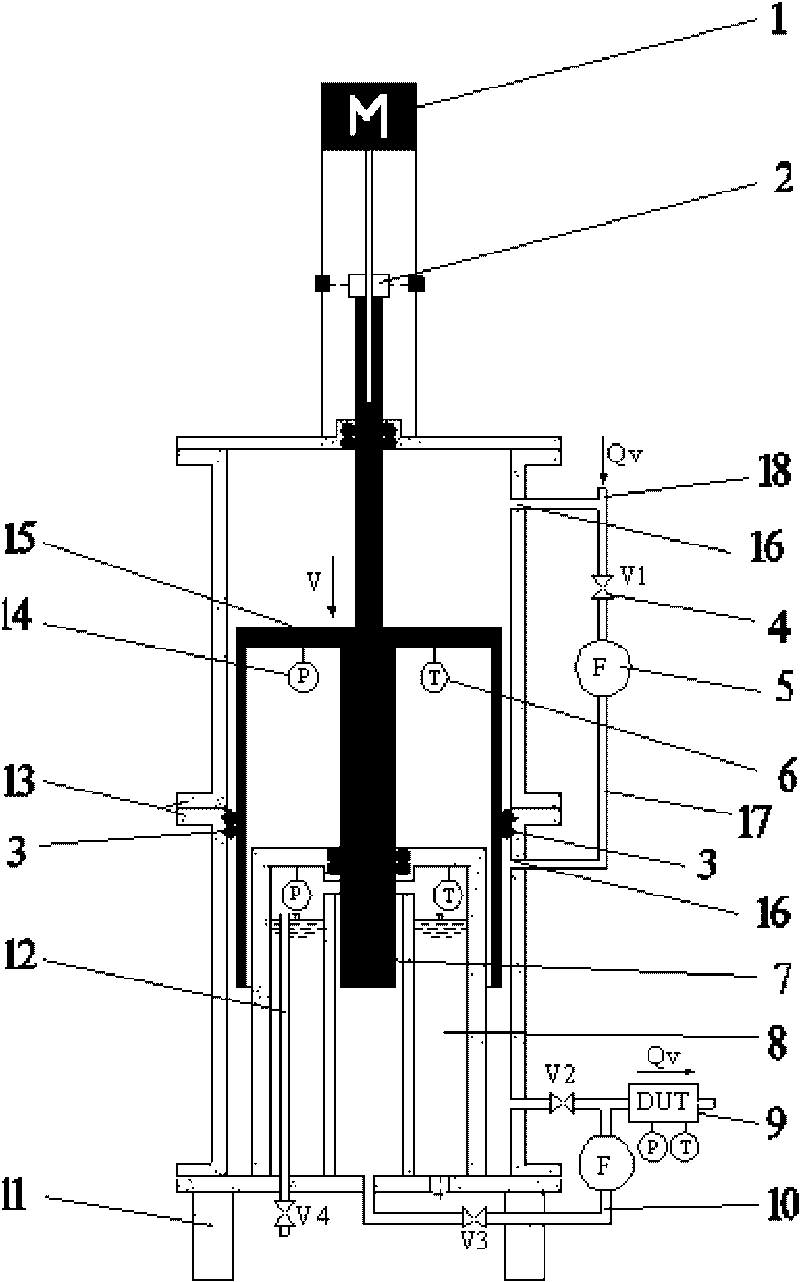

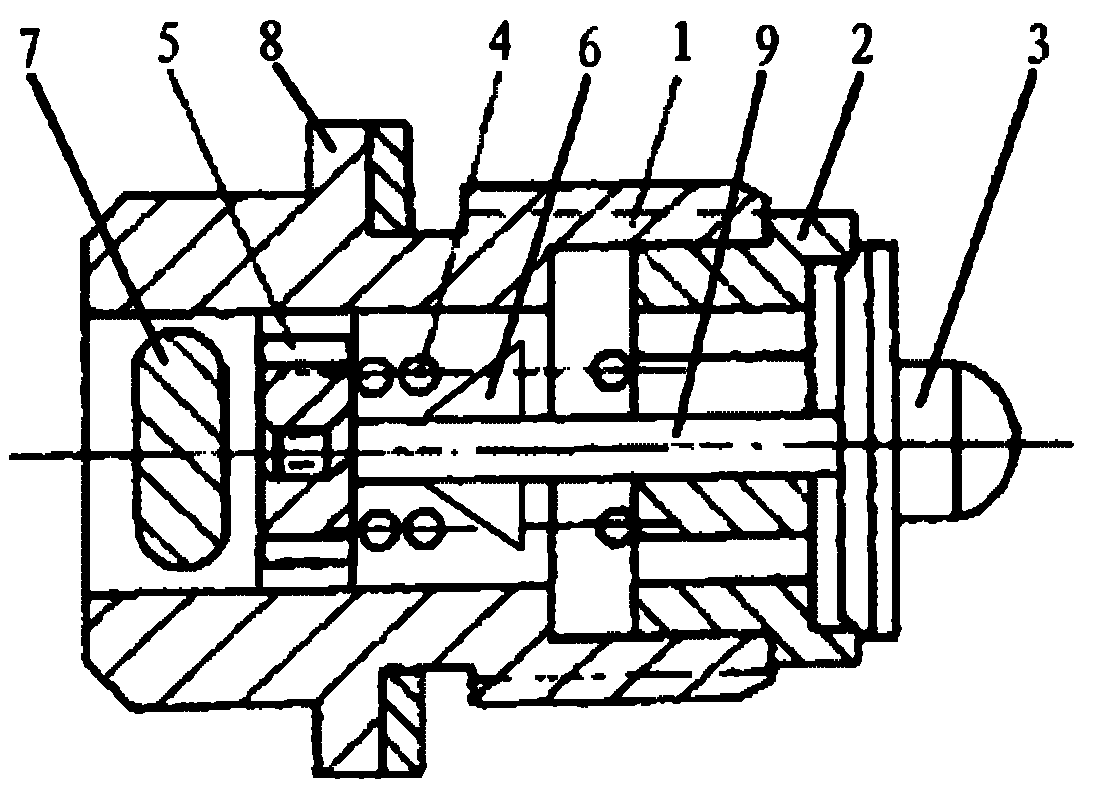

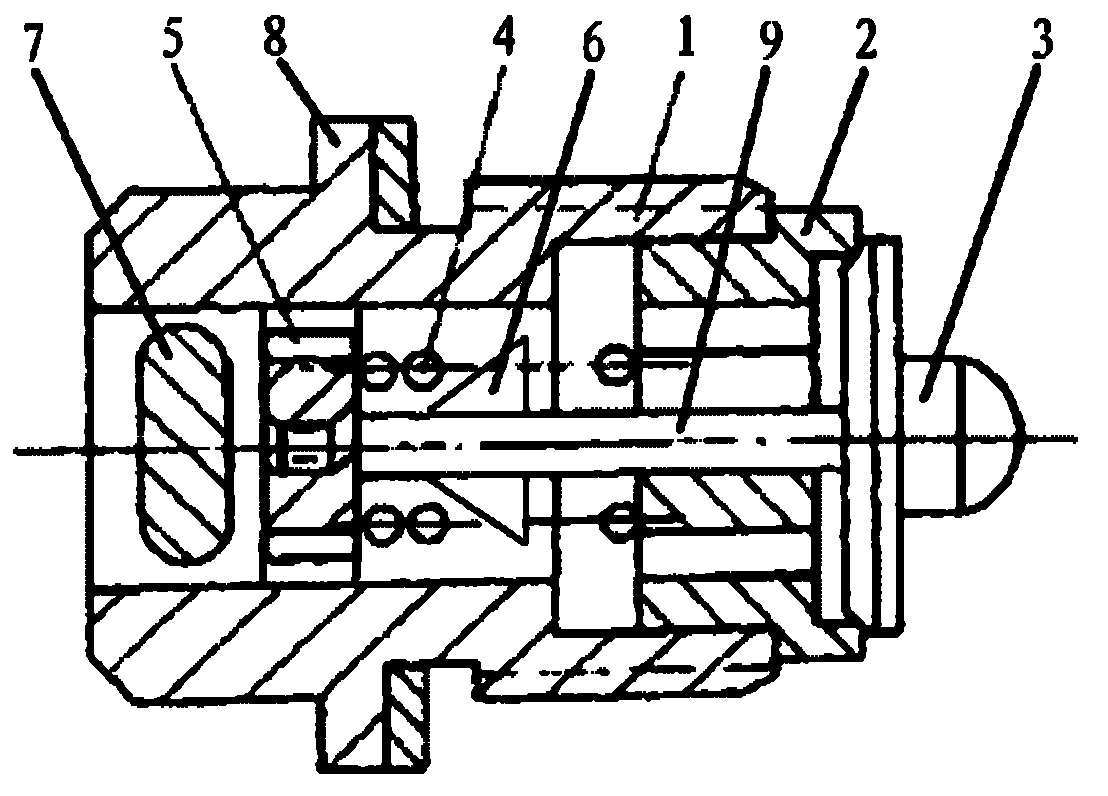

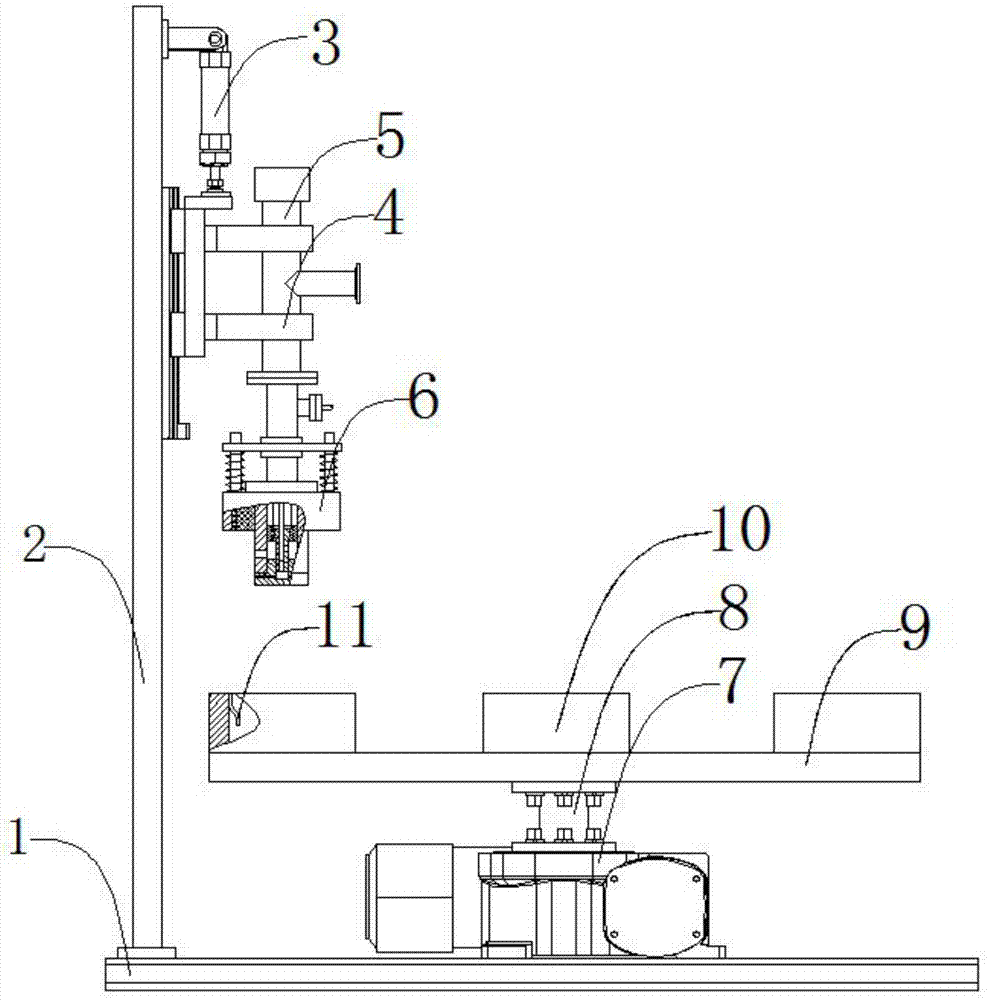

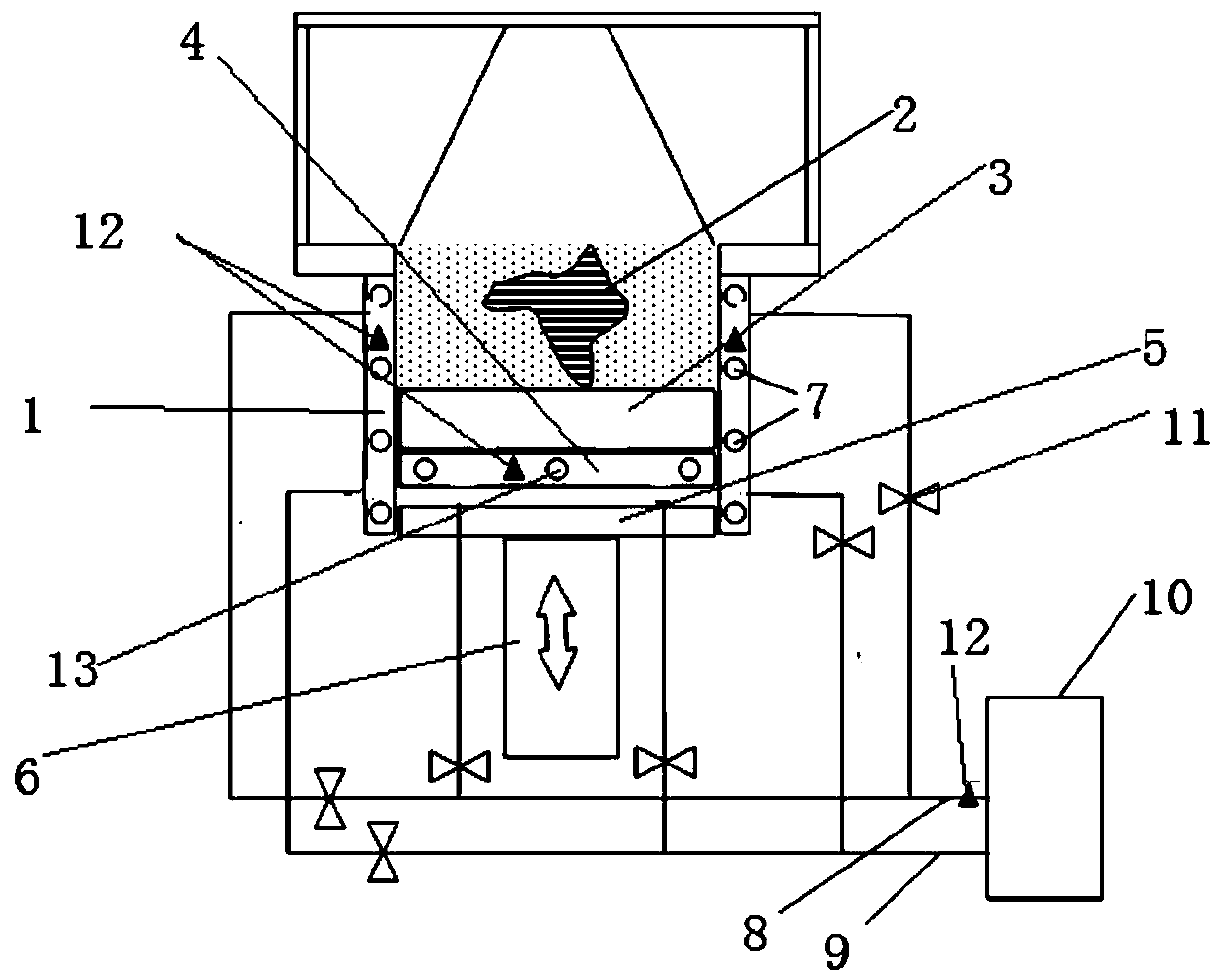

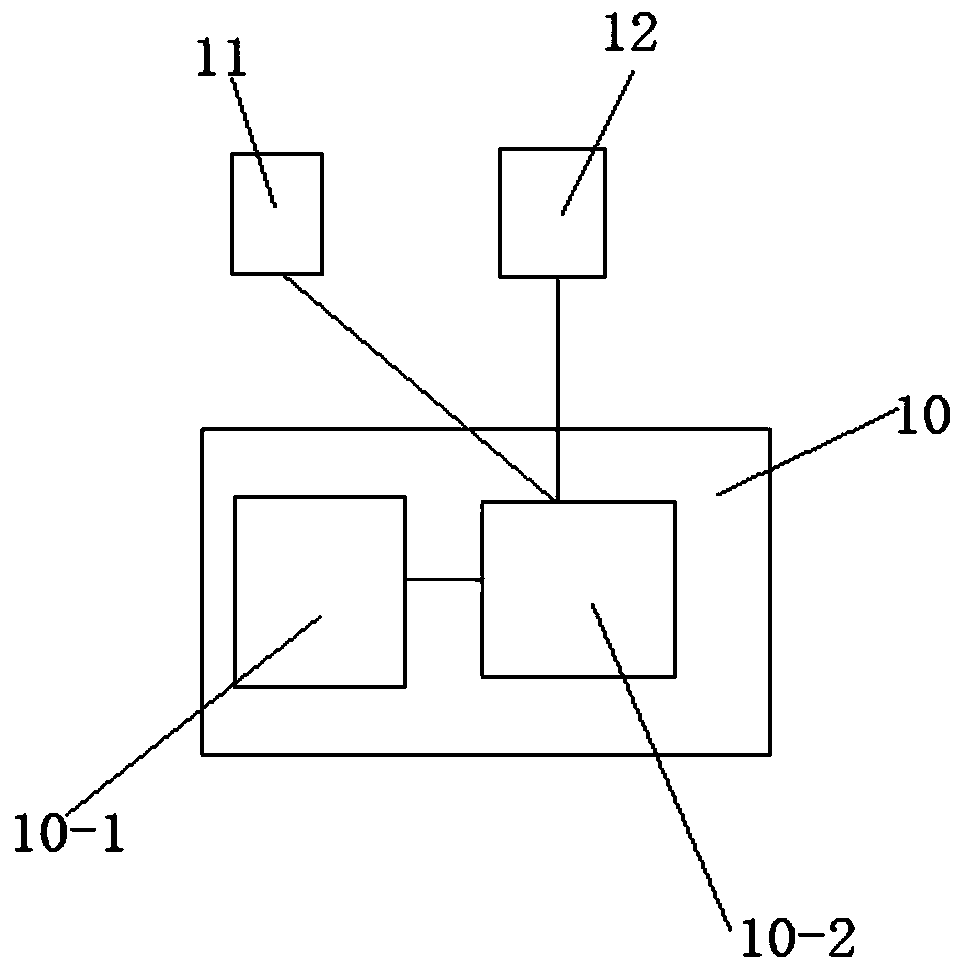

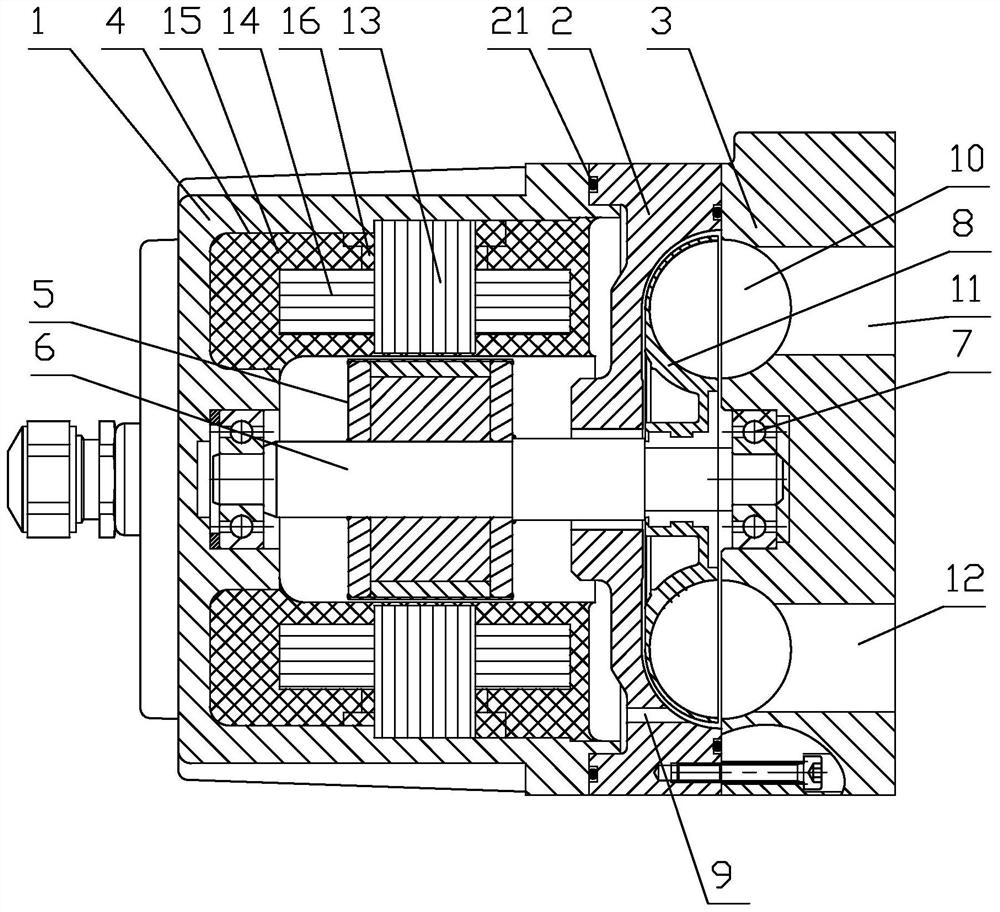

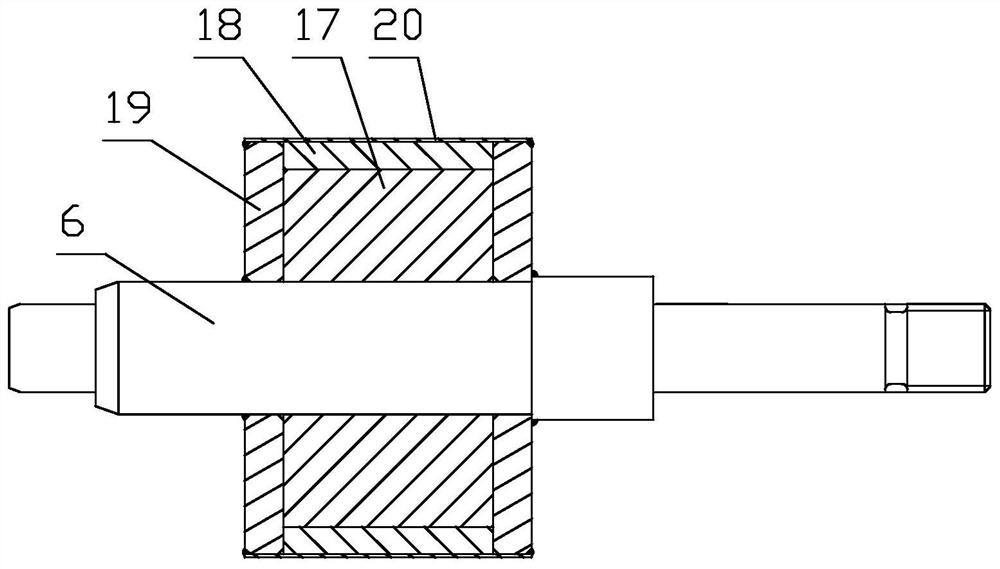

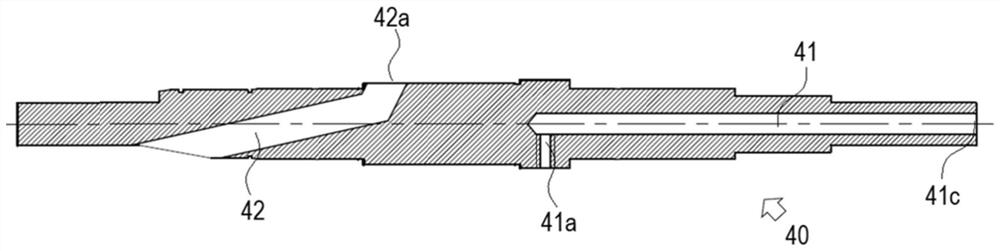

Gas flow calibrating device based on bell shape-column shape dual piston structure

InactiveCN101762307AGuaranteed pressure balanceLow powerTesting/calibration apparatusMotor driveControl system

The invention relates to a gas flow test device based on piston working principle. The existing device is suitable for large flow test, but is inconvenient to use and inaccurate in measuring result when measuring small flow. The invention comprises a frame, a cylinder, a motor and a measurement and control system, wherein the cylinder, the motor and the measurement and control system are arranged on the frame and the motor drives the piston in the cylinder. The invention is characterized in that the piston is of bell shape, a column-shaped piston is formed at the middle of the bell-shaped piston, the cylinder comprises an inner gas chamber and an outer gas chamber, the column-shaped piston is inserted into the inner gas chamber, the inner gas chamber and the outer gas chamber are connected via a gas outlet pipe arranged outside the cylinder, the gas outlet pipe is connected with a detected flowmeter, the inner gas chamber and the outer gas chamber are respectively connected with an external gas duct, and the gas duct and the gas outlet pipe are respectively provided with a flow controller. The invention is designed to optimize chamber structure in the cylinder to match with the dual pistons, and measurement is realized by selecting the corresponding piston according to different measurement need, thus improving measurement accuracy and expanding application range.

Owner:ZHEJIANG MEASUREMENT SCI RES INST

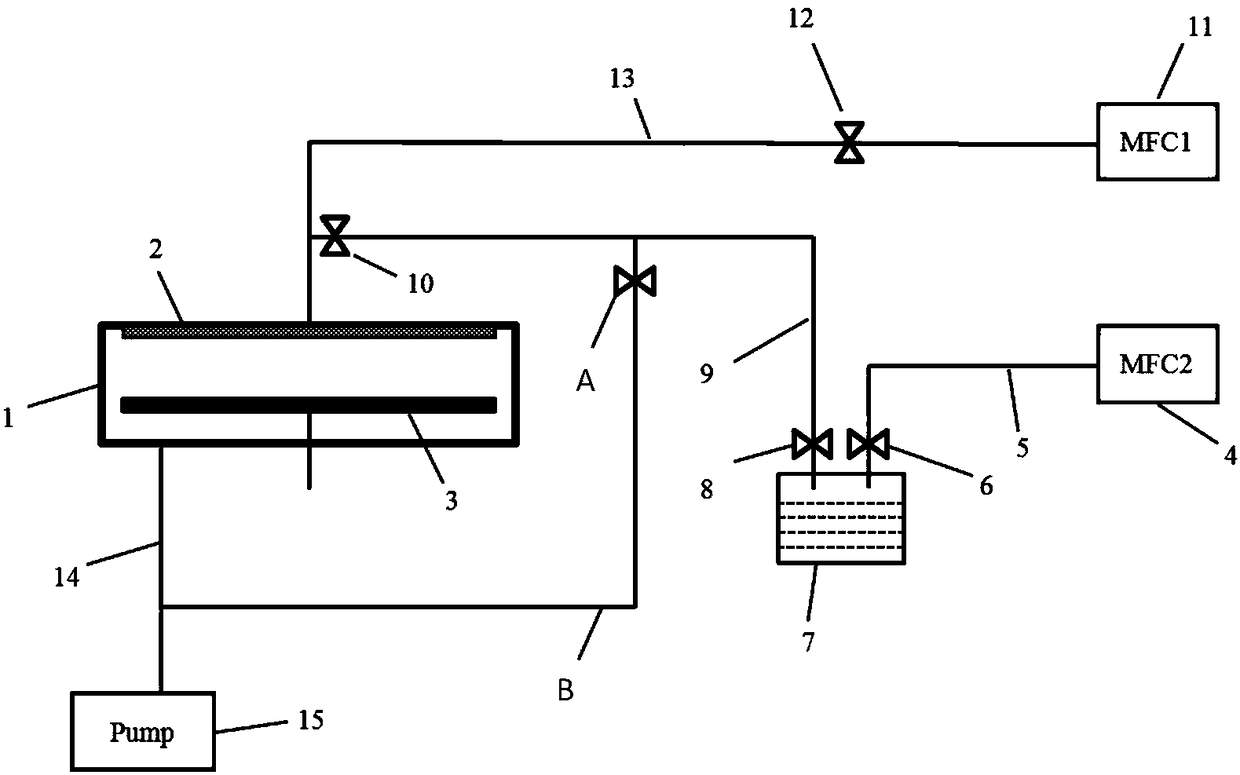

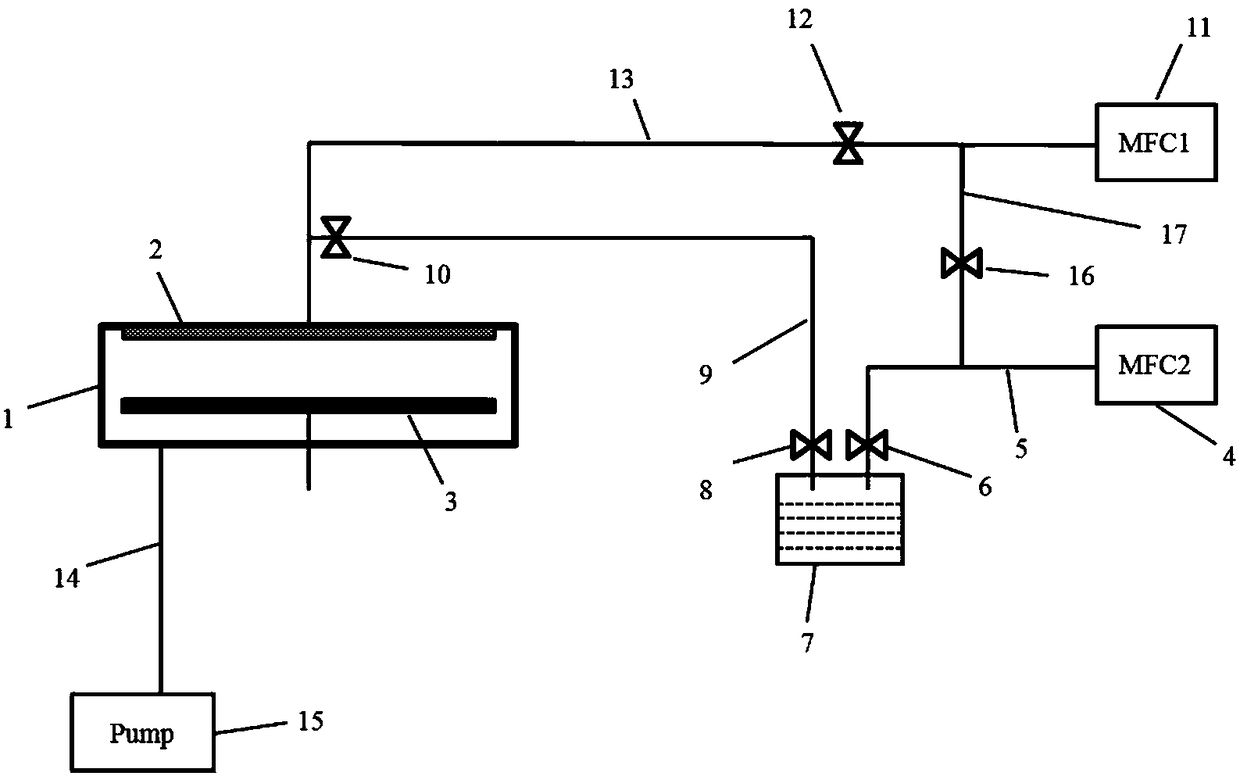

Atomic layer deposition system

ActiveCN109321896AReduce wasteGuaranteed pressure balanceChemical vapor deposition coatingProduct gasEngineering

The invention provides an atomic layer deposition system. The atomic layer deposition system is characterized in that a precursor source is connected with one end of a carrier gas pipeline and one endof a precursor gas pipeline, carrier gas in the carrier gas pipeline passes through the carrier gas pipeline and flows through the precursor source, the carrier gas carries precursor and flows alongthe precursor gas pipeline, one end of a dilution gas pipeline is connected with a reaction chamber, the other end of the precursor gas pipeline is connected to the side, close to the reaction chamber, of the dilution gas pipeline, and therefore, the carrier gas carrying precursor is mixed with the dilution gas, passes through one end of the dilution gas pipeline and flows into the reaction chamber; one end of a pressure balance pipeline is connected with the dilution gas pipeline, and the other end of the pressure balance pipeline is connected with the carrier gas pipeline, so that when precursor gas is not conveyed into the reaction chamber, carrier gas flows to the dilution gas pipeline from the carrier gas pipeline, waste of precursor is reduced, meanwhile, the carrier gas is mixed with the dilution gas and then enters the reaction chamber, and pressure balance and technology stability of the reaction chamber are ensured.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

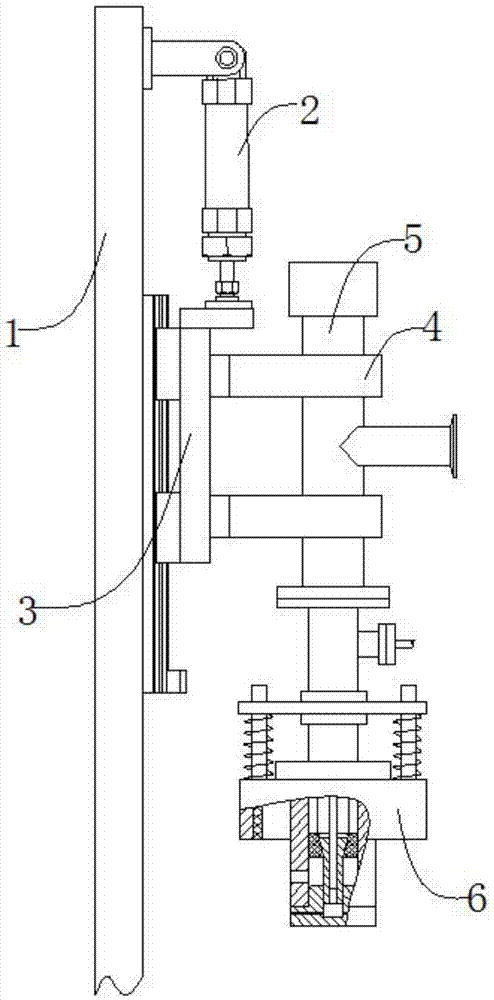

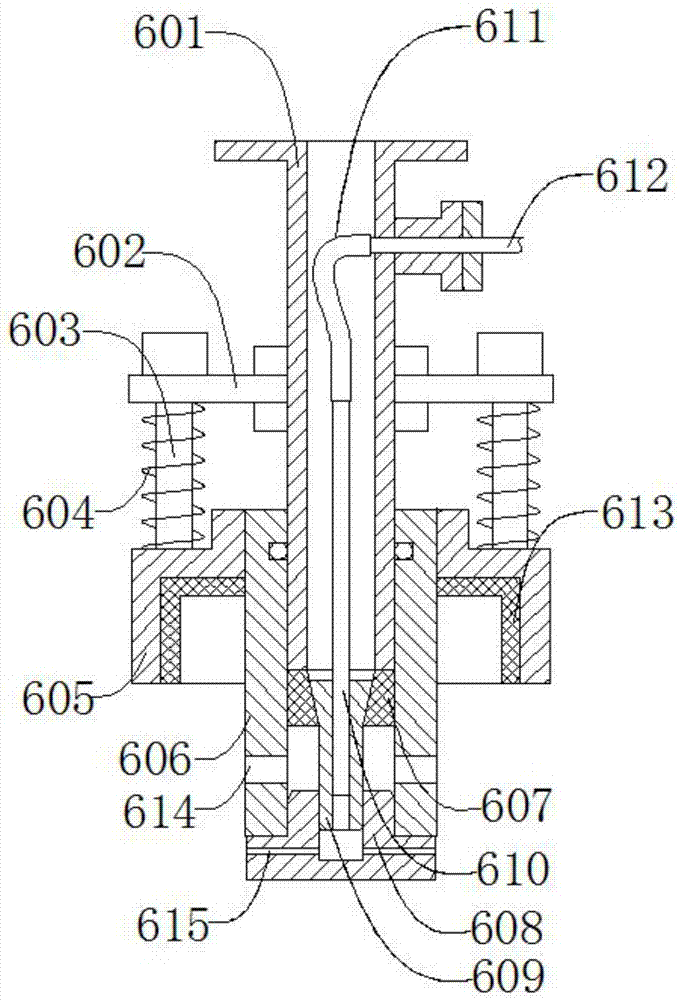

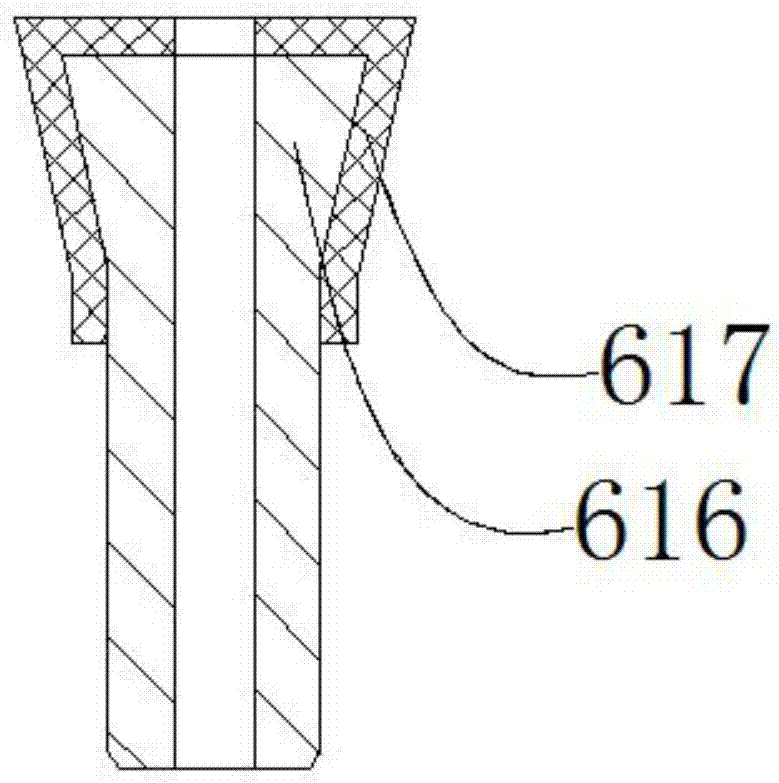

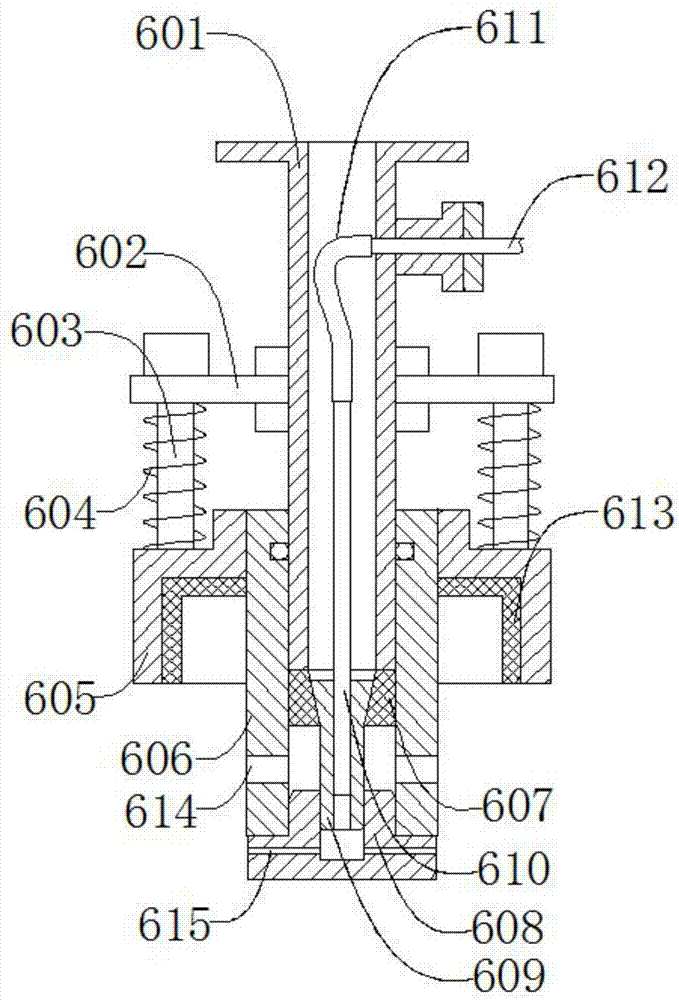

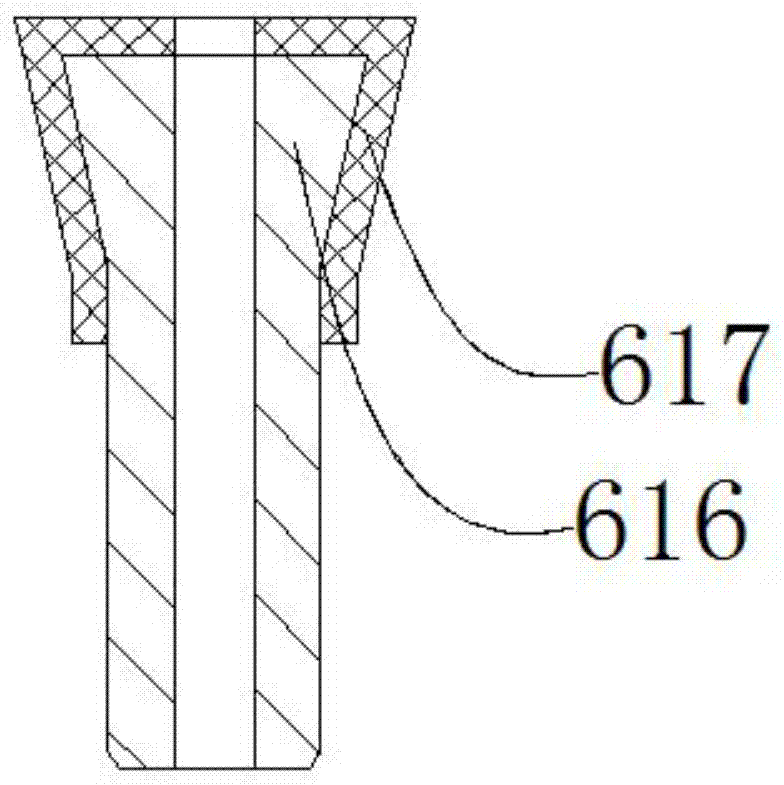

Splash-proof liquid fertilizer filling mechanism

PendingCN107445130AEvenly filledPrevent splashLiquid bottlingAgricultural engineeringWorking environment

The invention discloses a splash-proof liquid fertilizer filling mechanism. The splash-proof liquid fertilizer filling mechanism comprises an upright frame, a cylinder, a sliding seat, a hoop, a liquid inlet main pipe and a filling head. The filling head further comprises an inner pipe, a guide plate, a guide rod, a spring, a sealing cover, an outer pipe, a sealing seat, a plug, a sealing head, an air pipe, a rubber air pipe and an inserting pipe. When a packaging bottle is located under the filing head, the cylinder pushes the hoop fixedly connected with the sliding seat to move downwardly so as to push the filling head fixedly connected with a filling pipe to move downwardly so that the outer pipe can be inserted into the packaging bottle, and a bottle opening of the packaging bottle is wrapped with the sealing cover for filling; and after filling is completed, the cylinder is reset, the spring is reset, and a conical hole formed in the sealing seat is attached to a sealing cover arranged on the sealing head, so that a filling channel is blocked. The device mechanism is simple, the sealed filling head is driven by the cylinder to move downwardly and extend into the packaging bottle for filling, liquid fertilizer is effectively prevented from splashing, the waste of raw materials is prevented, and meanwhile the working environment is protected against damage.

Owner:SUQIAN WOLVBAO ORGANIC AGRI DEV

Air safety valve with drying cylinder structure

InactiveCN102444734AGuaranteed pressure balanceGood effectEqualizing valvesSafety valvesInternal pressureAir safety

An air safety valve with a drying cylinder structure comprises a valve seat, a cylindrical valve rod and a valve core, wherein a connecting end of the valve seat is provided with a limiting block, the valve core is installed on a valve seat insert connected onto the valve seat through threads, and the center in the valve core is fixedly connected with the cylindrical valve rod. The tail end of the cylindrical valve rod is provided with a pressure adjusting valve block, a pressure spring is sleeved outside the cylindrical valve rod, a baffle block is arranged on the inner wall of the valve seat at the front end of the pressure adjusting valve block, and a triangular air hole is arranged on the lateral wall of the valve seat and located on the inner side of the pressure adjusting valve block. The air safety valve with the drying cylinder structure has the advantages that the pretightening force of the pressure spring at the position of the valve rod is adjustable, and a work pressure interval of the whole safety vale can be adjusted through adjustment of the pretightening force of the pressure spring; the triangular air hole enables the safety valve to release pressure more quickly with bigger pressure in the pressure releasing process, and pressure balance in a drying cylinder controlled by the safety valve can be quickly guaranteed.

Owner:蒋春霞

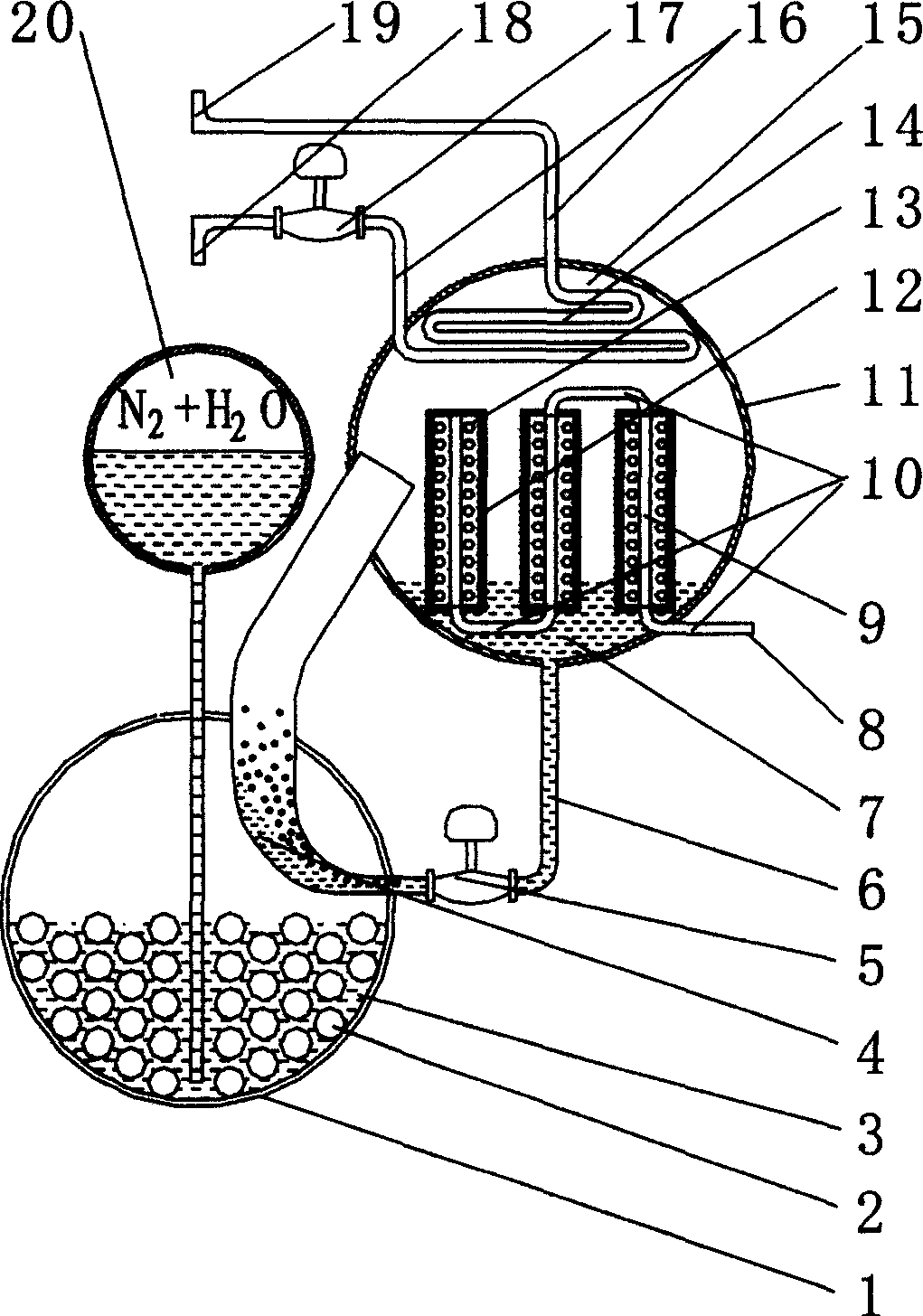

Waste heat driven composite alternating heat pipe generator

The invention relates to a kind of generator droved by remnant heat energy with compound and pulsant heating-pipeline, being used in the field of adsorbent ice-making on the boat. The smoke and gas heating pipeline is located at the bottom of the steam boiler, and the out space of the pipeline forms the steam generator. The segment for steam-regenerating is connected to the katabatic segment of heating-pipeline, linking to the adsorbent platform. The battery valve of heating-pipeline is installed between the katabatic segment of heating-pipeline and the heating pipeline. The katabatic segment of heating-pipeline is connected to the heating pipeline. The adsorbent segment is located in the inside of the adsorbent platform. The pipeline for ammonia gas is weld to the adsorbent segment. Linking to the pipeline of ammonia medium. The export of adsorb and segregating ammonia is the external equipment of the ammonia pipeline. The adsorbent is in the adsorbent segment. Cold-producing tube for seawater is located in the adsorbent segment, and the pipeline for seawater is connected to it. The entrance and output for seawater is linking to the Cold-producing tube via seawater pipeline. The bottom of the pressure-controlling room is connected to the bottom of the steam generator.

Owner:SHANGHAI JIAO TONG UNIV

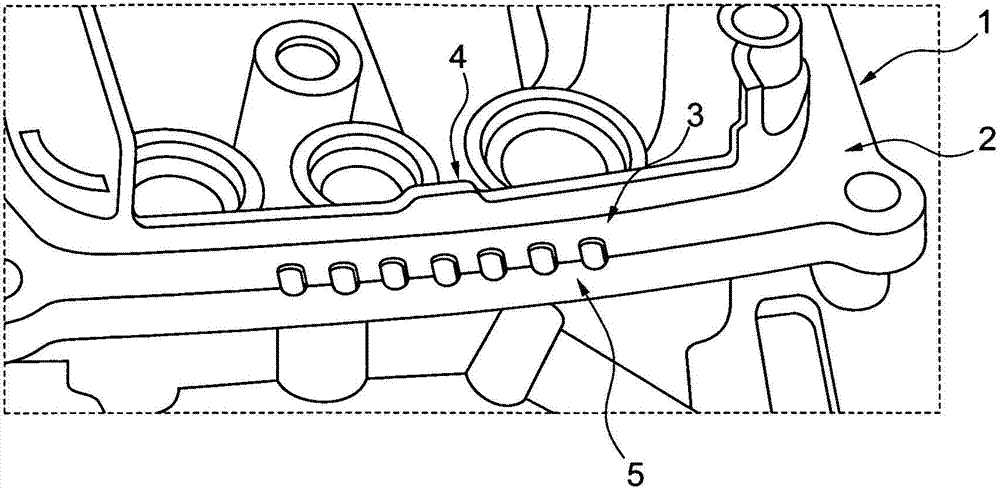

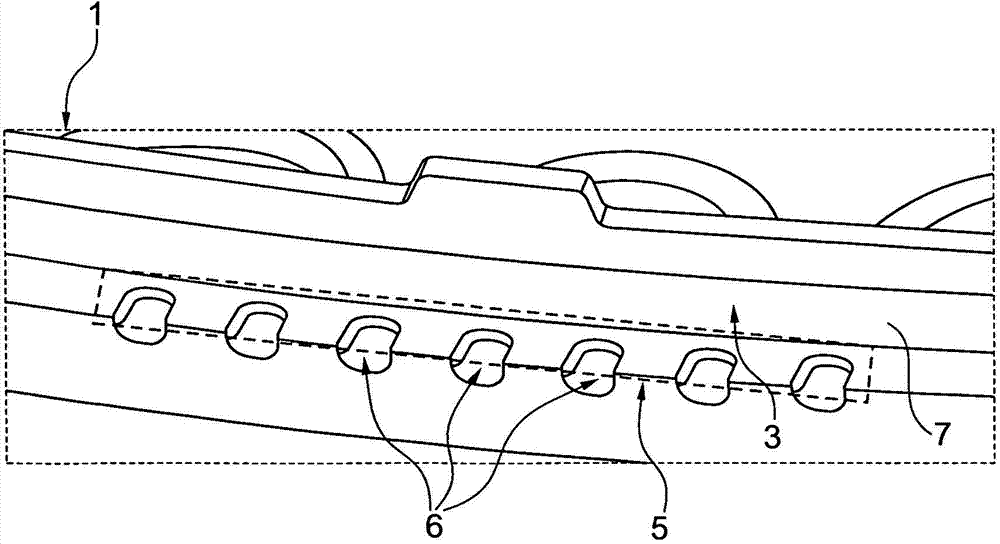

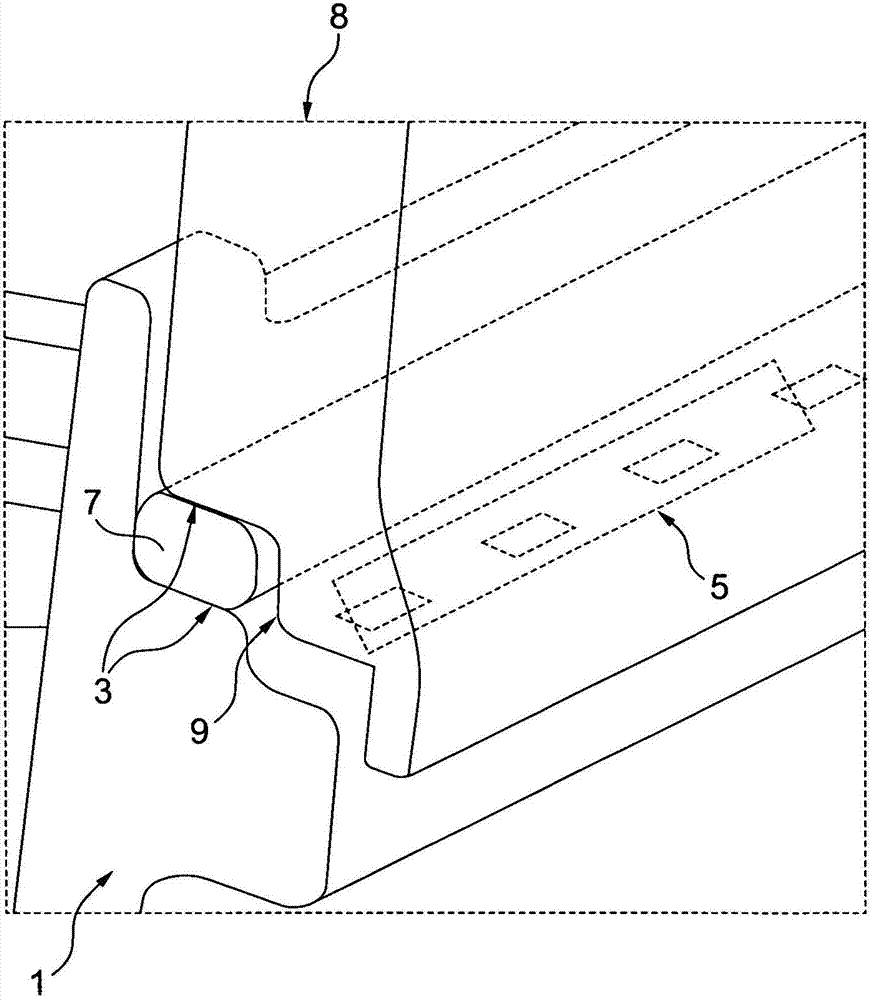

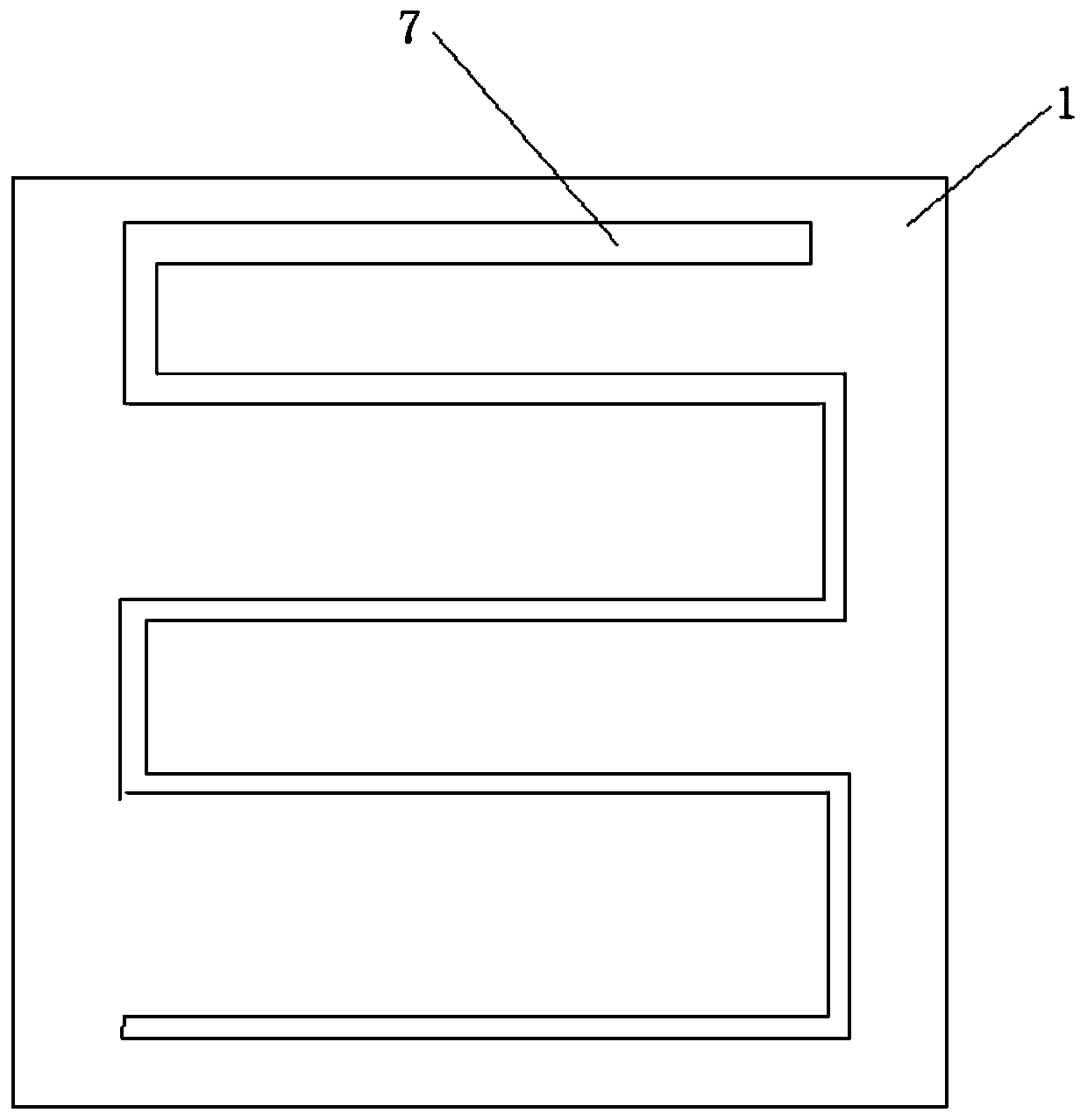

Housing having a deformation area for pressure equalization and arrangement of a sealing element in the housing

ActiveCN102860147AGuaranteed pressure balanceNo indeterminate gapsCasings/cabinets/drawers detailsHermetically-sealed casingsEngineeringEqualization

The invention relates to a housing for accommodating at least one technical functional unit. A first housing part (1) is connected to a second housing part (8) by means of a sealing element (7) along a sealing surface (3), which adjoins a support surface, which is integrally connected to the sealing surface, on the outside. At least one housing part (8) has an elastically deformable deformation area in order to compensate pressure fluctuations. Thus, the housing part (8) can be moved together with the sealing element (7) in the contact plane from the sealing surface (3) to the support surface so that pressure equalization is accomplished by means of the groove-shaped openings of the support surface, which allow for flow under the sealing element (7). According to the invention, the sealing element (7) is covered at the outer periphery thereof by a projection (9) of the second housing part (8). The second housing part supports the return of the sealing element (7) after a displacement for the purpose of the pressure equalization.

Owner:ZF CV SYST EURO BV

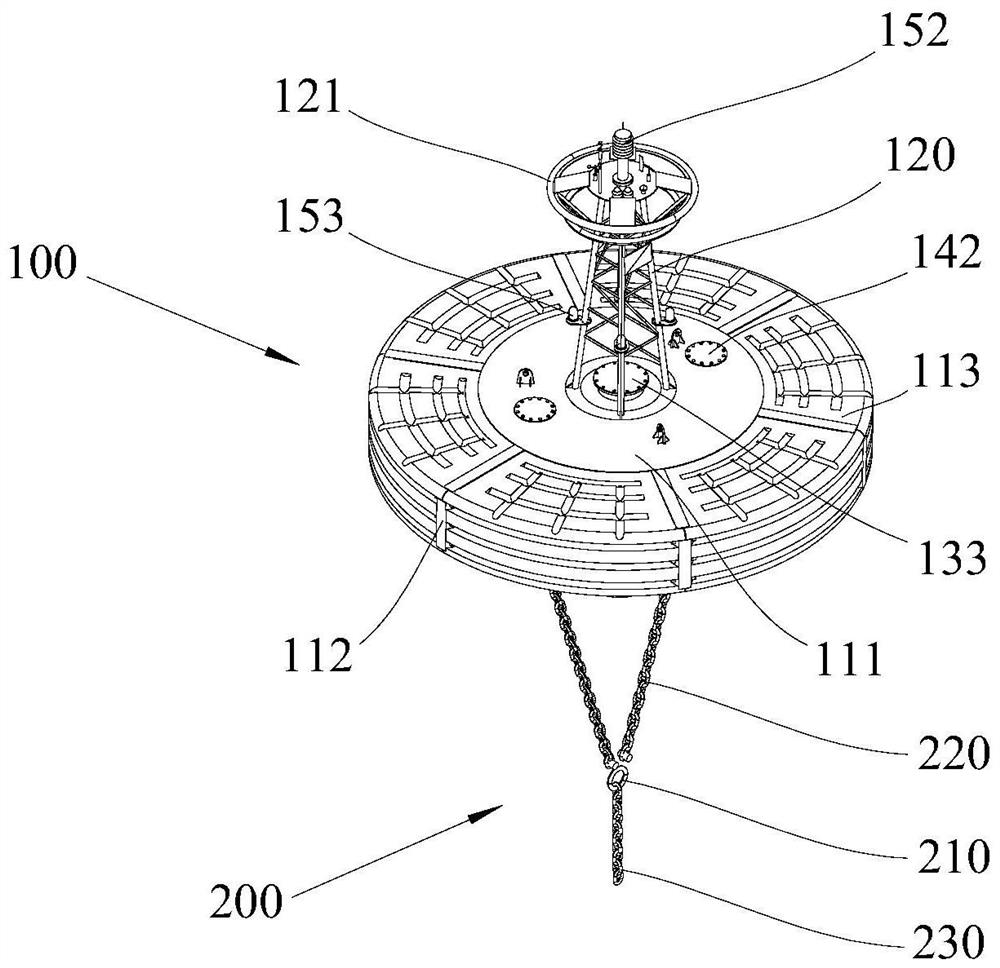

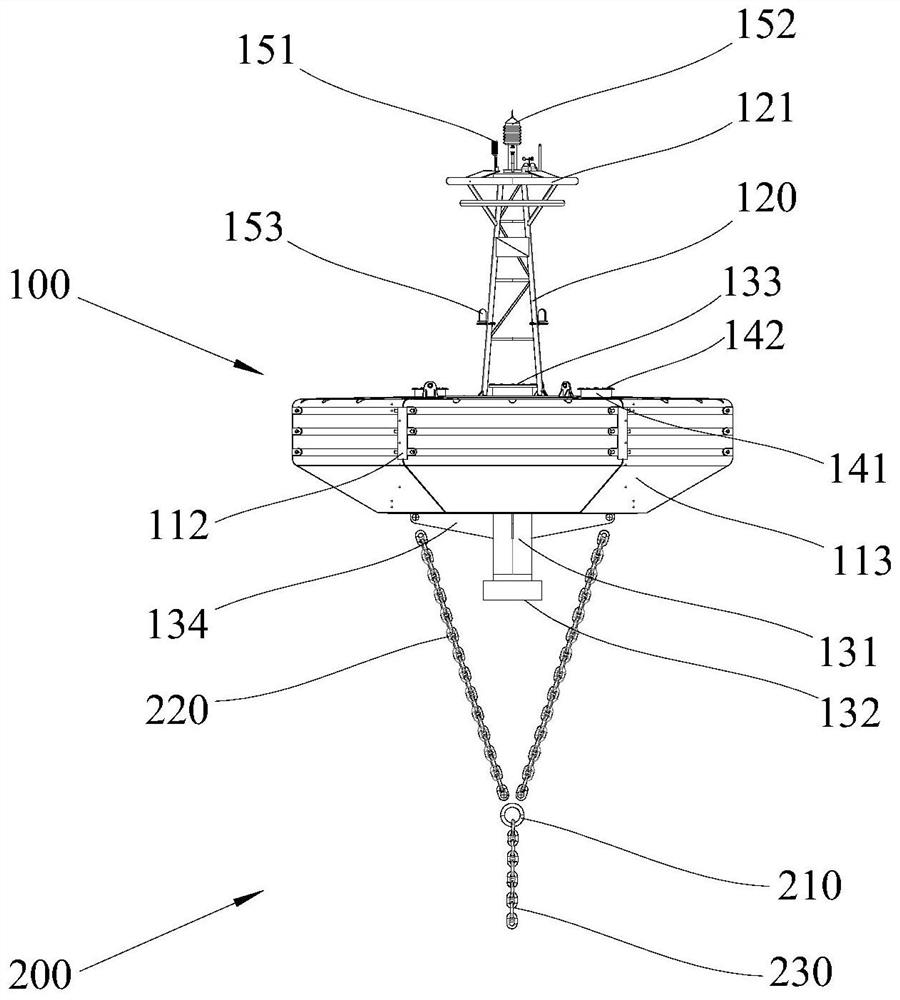

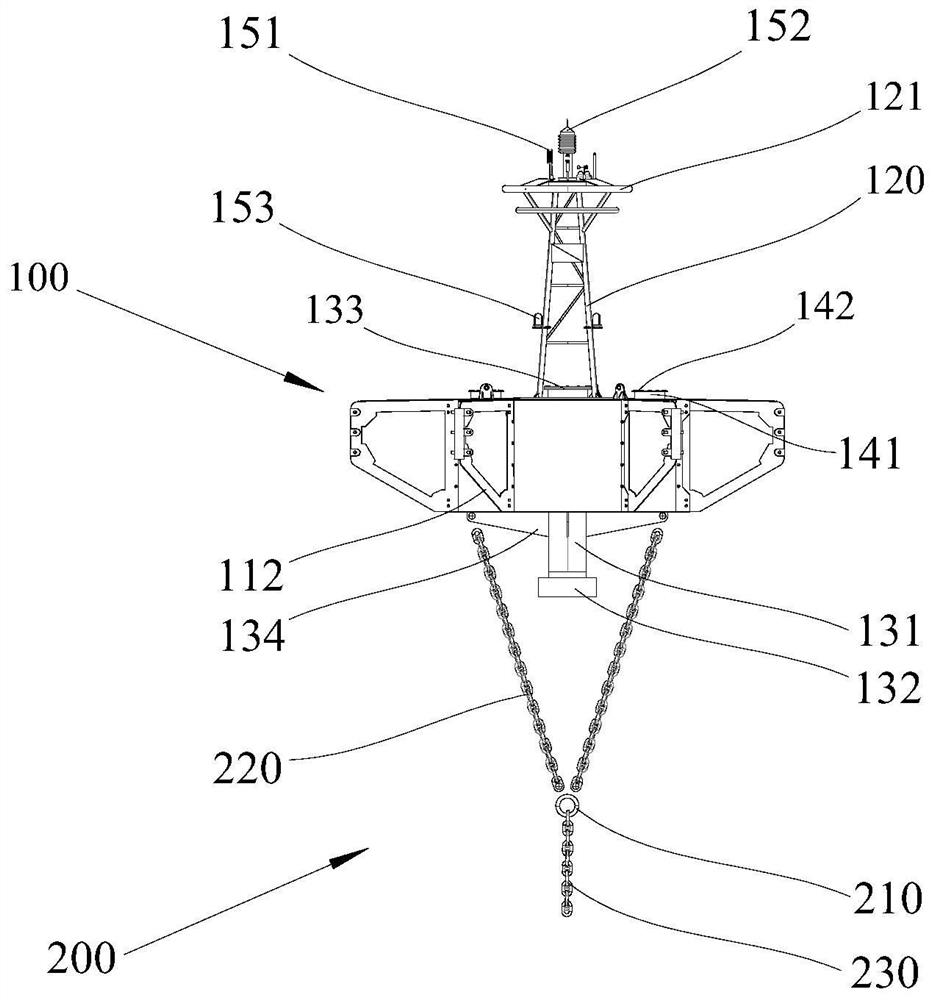

Buoy system

The present invention relates to a buoy system. The buoy system comprises: a buoy body; and an anchoring device, which is arranged below the buoy body and used for stabilizing the buoy body. The buoybody comprises a main cabin body, wherein the anchoring device is arranged at the bottom of the main cabin body; masts, which are arranged on a plurality of brackets above the main cabin body and surround the side surface of the main cabin body; and a plurality of outer wall assemblies, which are fixed to the brackets and fixed to the outer side edge of the main cabin body, wherein a closed floating chamber is defined by the outer wall assemblies, the brackets and the side face of the main cabin body. Structural modularization is achieved, the production process is simplified, transportation,loading and unloading are convenient, small and medium-sized fishing boats and engineering ships can be used for throwing and recycling, the ship using cost is reduced, the internal space structure ofthe buoy is optimized, various devices can be installed in the buoy, and the monitoring requirement is met.

Owner:国家海洋局南海调查技术中心 +2

Rotary liquid fertilizer filling device

InactiveCN107500234AStable deliveryContinuous deliveryLiquid bottlingAgricultural engineeringWorking environment

The invention discloses a rotary liquid fertilizer filling device. The device comprises a base, a vertical frame, a cylinder, a sliding seat, a main liquid feeding pipe, a filling head, a cutting device, a rotating shaft, a rotating plate, a positioning seat and a spring sheet, wherein a packing bottle is inserted into the positioning seat and automatically aligned through the spring sheet; then the rotating shaft is driven by the cutting device to rotate to drive the positioning seat which is fixedly connected with the rotating platform to rotate; when the packing bottle in the positioning seat is positioned under the filling head, a filling tube which is fixedly connected with the sliding seat is pushed by the cylinder to downwards move so as to push the filling head to downwards move to rotate and fill, thus finishing filling. The device is simple in structure; the packing bottle is continuously and accurately conveyed as the cutting device rotates; a small area is needed; in addition, the packing bottle conveying accuracy is high; meanwhile, the filling head is driven by the cylinder to downwards move and extend into the packing bottle to fill in a sealing manner, so that liquid fertilizer can be effectively prevented from splashing, and the raw material waste is prevented, and as a result, the working environment is prevented from being damaged.

Owner:SUQIAN WOLVBAO ORGANIC AGRI DEV

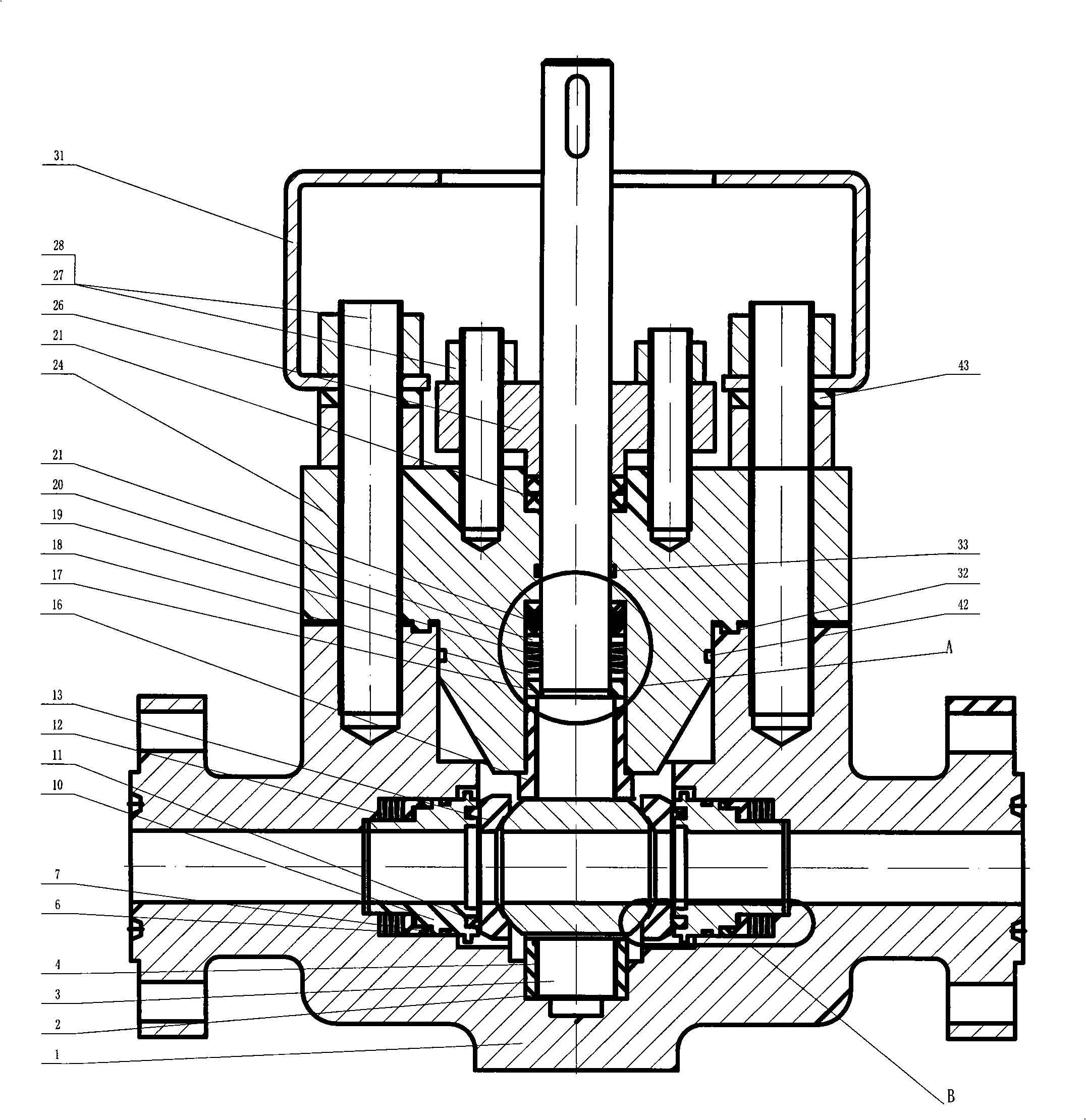

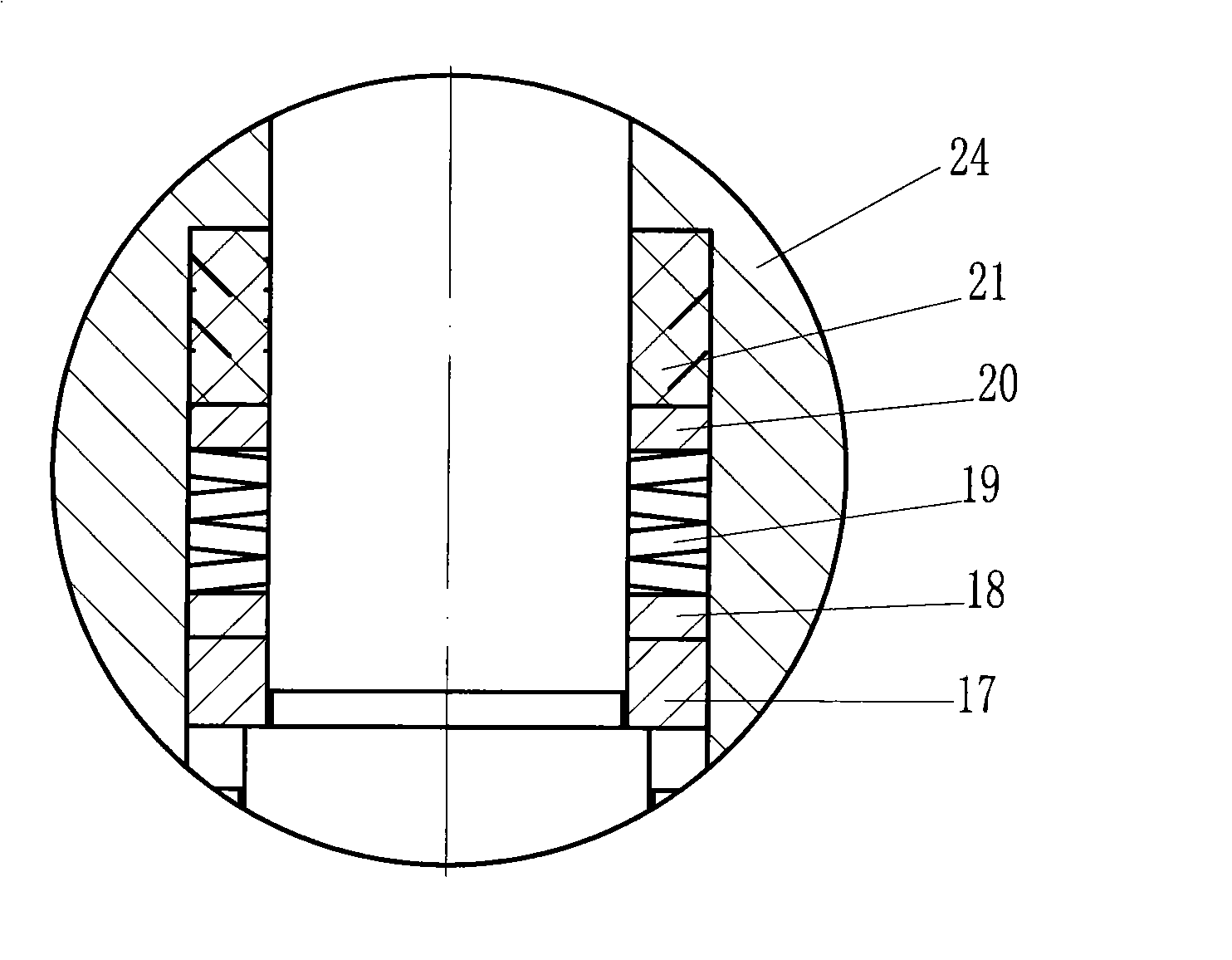

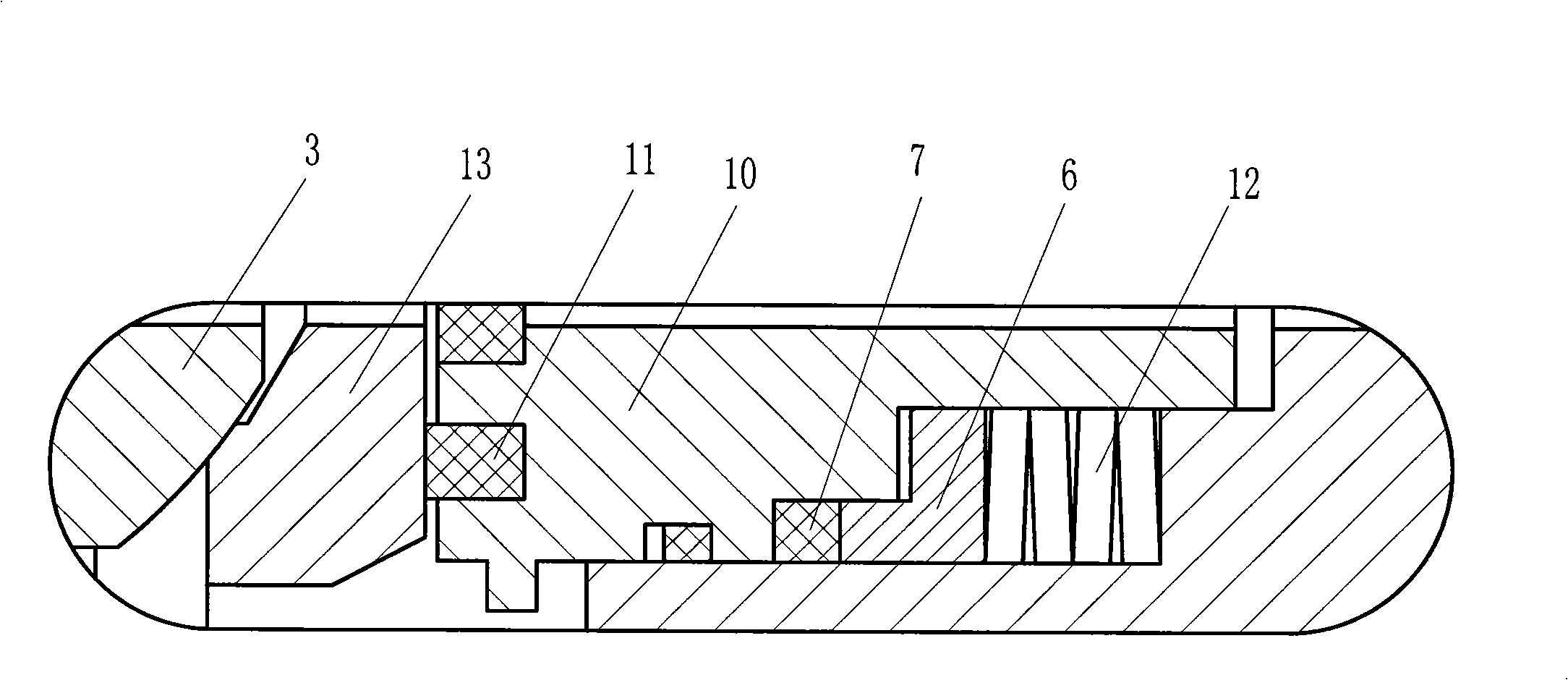

Integral top mounting type ultra-high pressure and ultra low temperature hard seal ball valve

ActiveCN101349354ALarge opening torqueGuaranteed sealing performanceSpindle sealingsPlug valvesUltra high pressureFilling materials

Disclosed is an internal top-mounting type super-high pressure super-low temperature hard sealing ball valve, which is mainly composed of a valve body (1), a valve cover (24), a ball body with a handle (3), a valve seat (13), a rear valve seat (10), a valve rod bearing seat (16) and the like. The ball body with a handle (3) placed in the valve body (1) penetrates through the center of the valve cover (24), and the ball body with a handle (3) is enabled to rotate 90 degrees by an external force to realize the opening and the closing of pipes. The sphere sealing is realized by that two sides of the ball body with a handle (3) hold the rear valve seat (10) and the valve seat (13), and a valve seat spring (12) elastically pushes and presses the ball body with a handle (3). The sealing of a valve rod employs a unique three-ply sealing structure of a self-sealing preloading device, which can guarantee sealing under low pressure, and under the action of high pressure, medium pressure action realizes self-sealing for a bearing ring (17), thereby avoiding that filling material sealing needs the high-strength pressure, and the torque becomes extremely large when the valve rod is opened.

Owner:JIANGSU JIULONG VALVE MFG

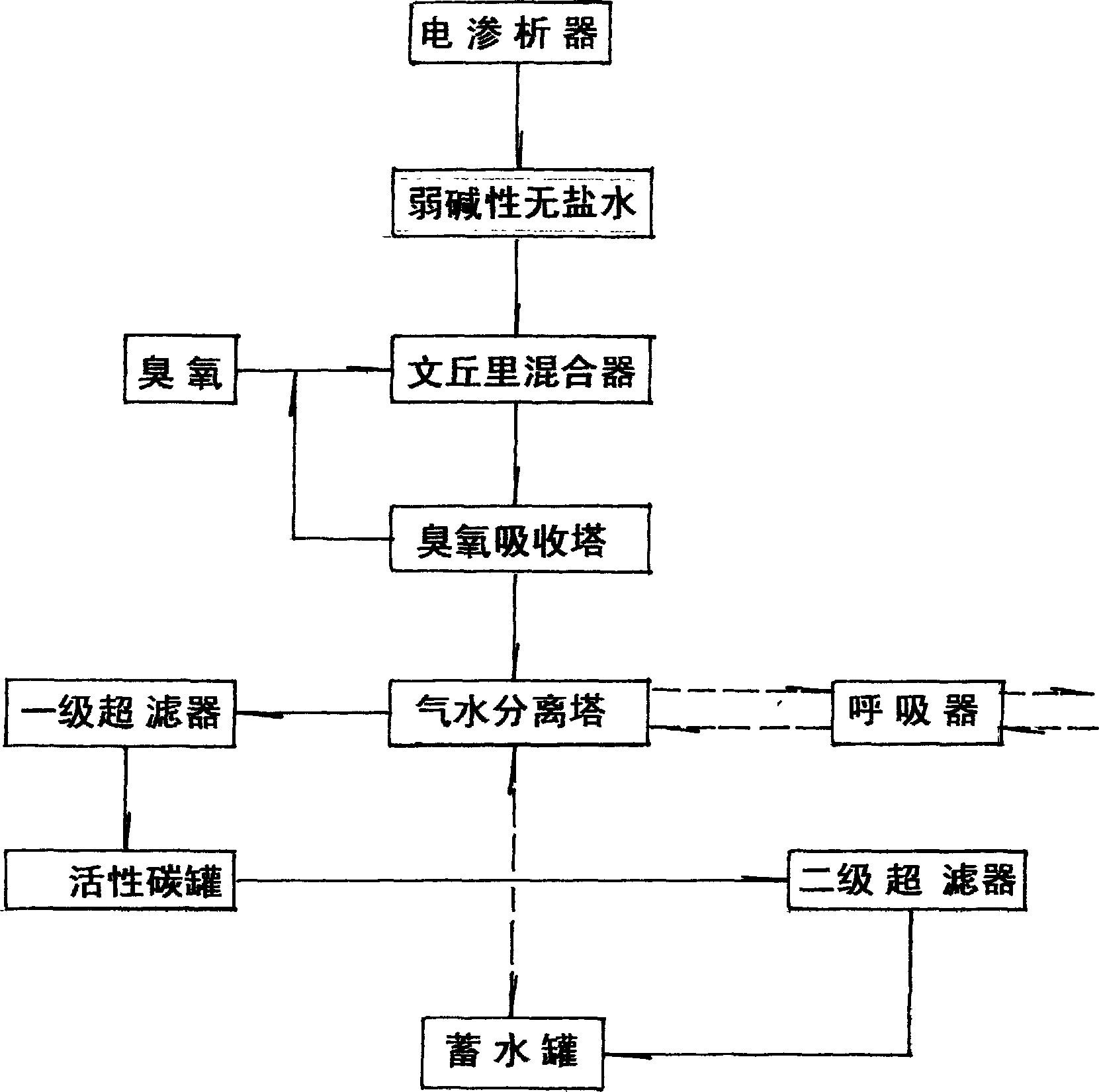

Post treating method and its device for producing weak alkaline high purity drinking water

InactiveCN1821127AEfficient killingExtend the life cycleWater/sewage treatment by irradiationDispersed particle separationForeign matterOzone Sterilization

The present invention relates to post treating method and device for producing weak alkaline high purity drinking water. Weak alkaline no-salt water and ozone gas are made to enter first to the Venturi mixer and ozone absorption tower for ozone sterilization and then to a gas-water separating tower to separate out and exhaust ozone containing gas; and the separated water is filtered in the first stage filter to eliminate microbe and suspended matter, active carbon tank to eliminate organic matter and bad smell, and the second stage filter to eliminate residue and obtain weak alkaline high purity drinking water. The whole process is completed inside one closed system with balanced pressure to eliminate foreign matters effectively.

Owner:唐战和

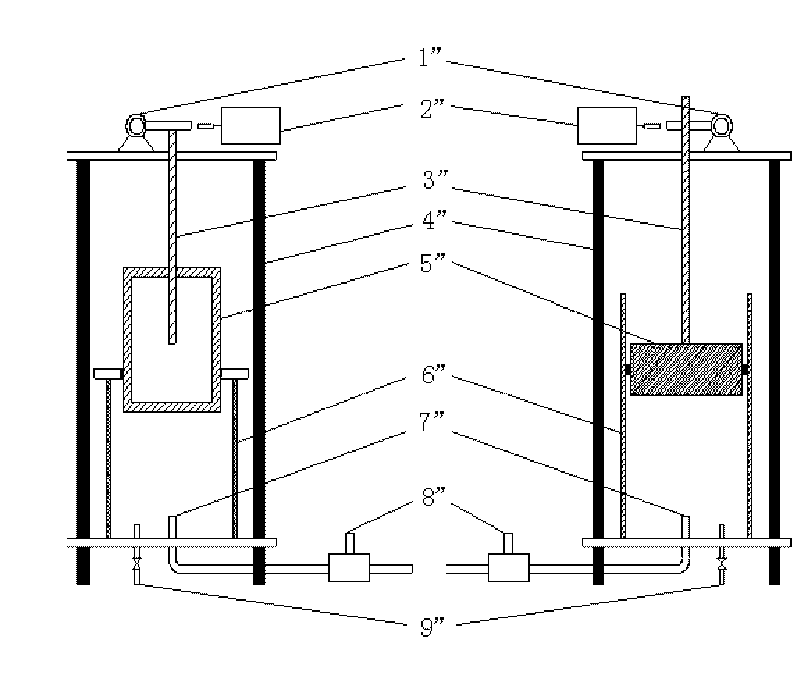

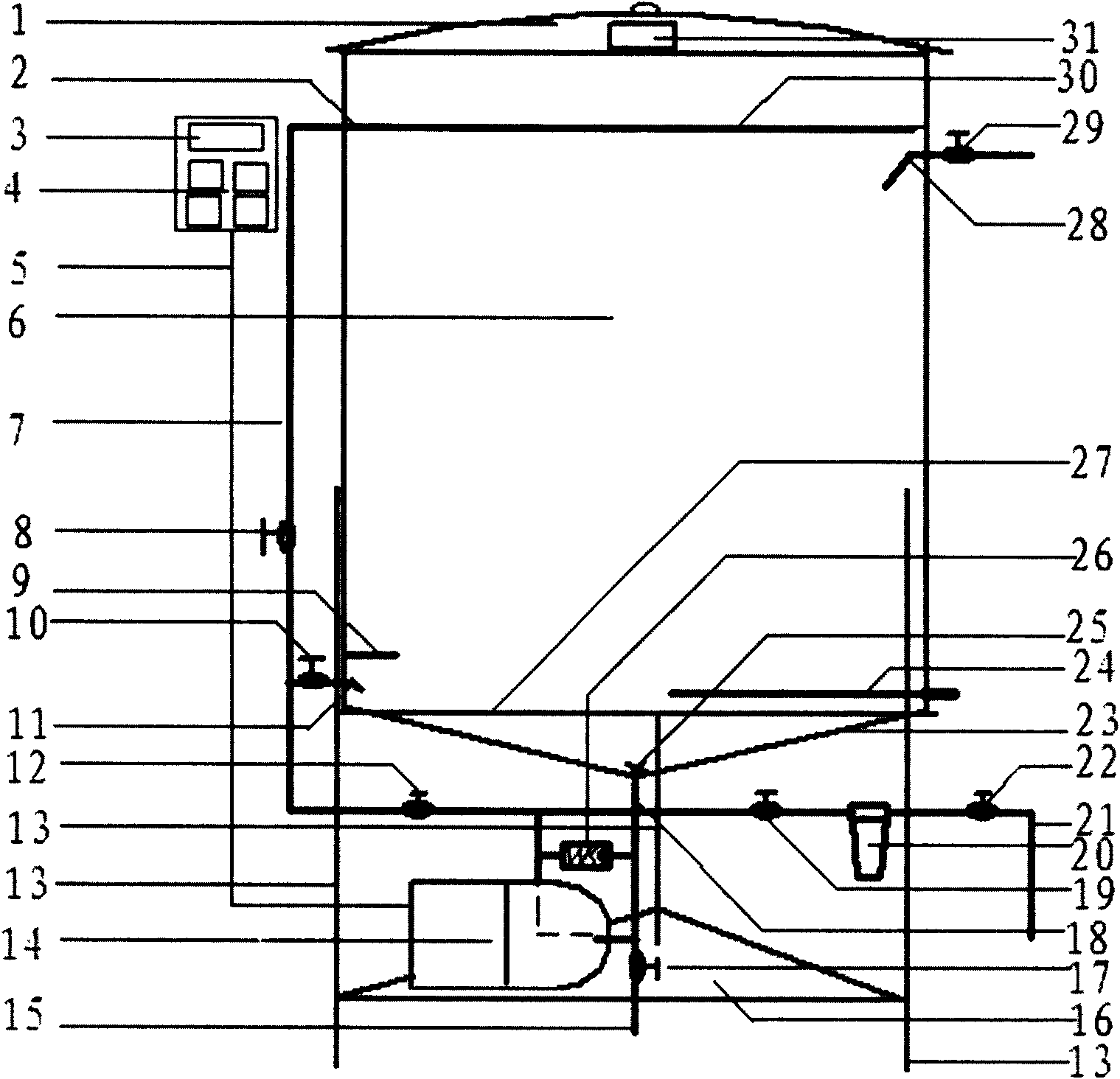

Manual preparation device of kidney dialysis liquid

The invention discloses a manual preparation device of kidney dialysis liquid, comprising a tripod, a liquid preparation bucket, a circulating pump, a control plate, a filter, valves, an automatic reducing valve, a temperature control system and a connecting line. The device is characterized in that the liquid preparation bucket is arranged above the tripod, the top of the bucket is provided with a cover, and the bottom point of the bucket is provided with a multi-way pipe; the lower part in the bucket is provided with a heating rod and a temperature sensor, and the upper part in the bucket is provided with an annular bucket flashing line; the circulating pump below the liquid preparation bucket, and the liquid preparation bucket and the circulating pump are connected by the line; the filter is arranged on the output line; the automatic reducing valve is arranged between the outlet and inlet of the circulating pump; the lines are provided with a plurality of valves which control the flow direction of liquid; and the control plate controls the temperature of the liquid and the working condition of the circulating pump. The device is invented based on the characteristic of the blood purification work, and the inconvenience of the manual preparation of kidney dialysis liquid is solved. The device provided by the invention has the advantages of novel structure and simple construction, and is convenient for use, and is particularly suitable for the preparation of the dialysis solution in the blood purification center of medical unit.

Owner:刘思波

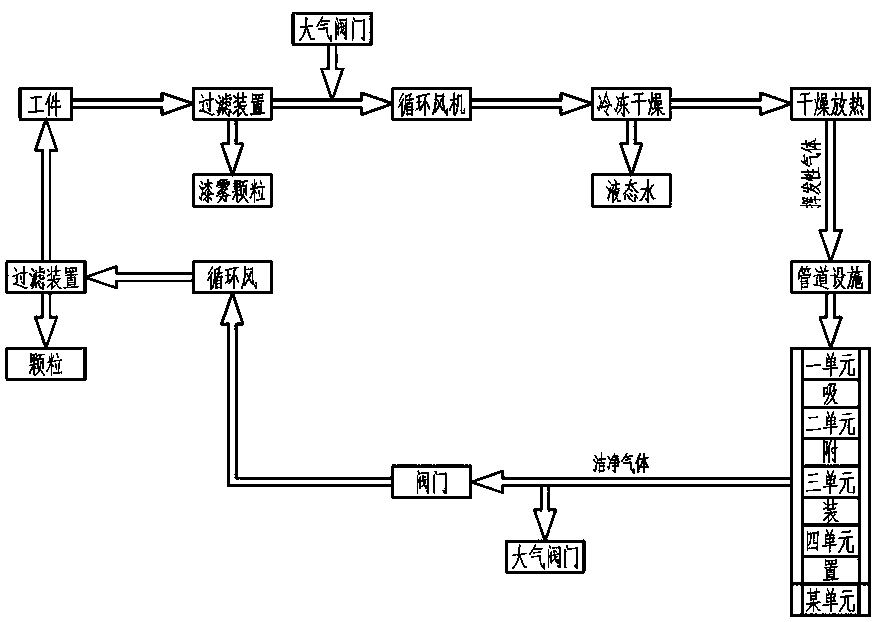

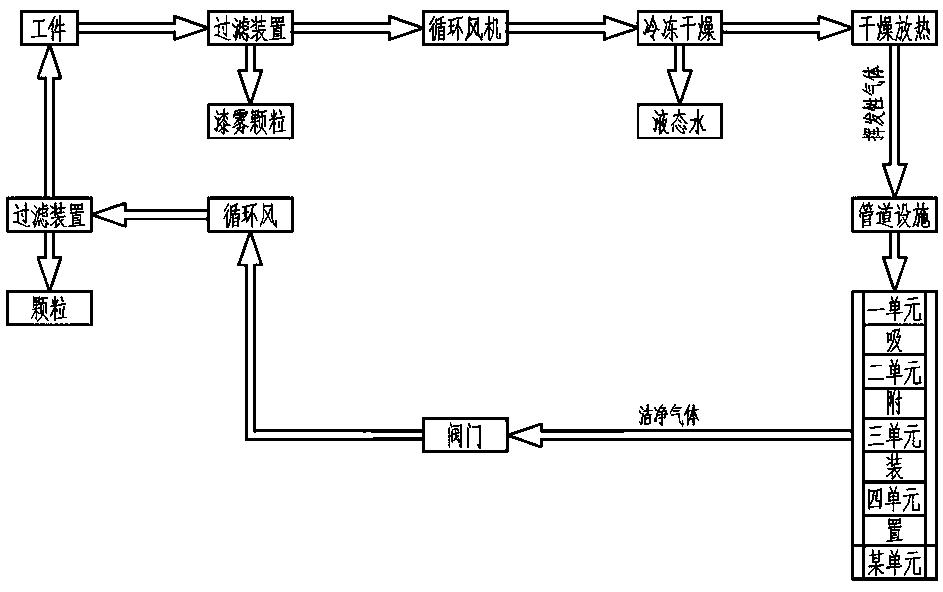

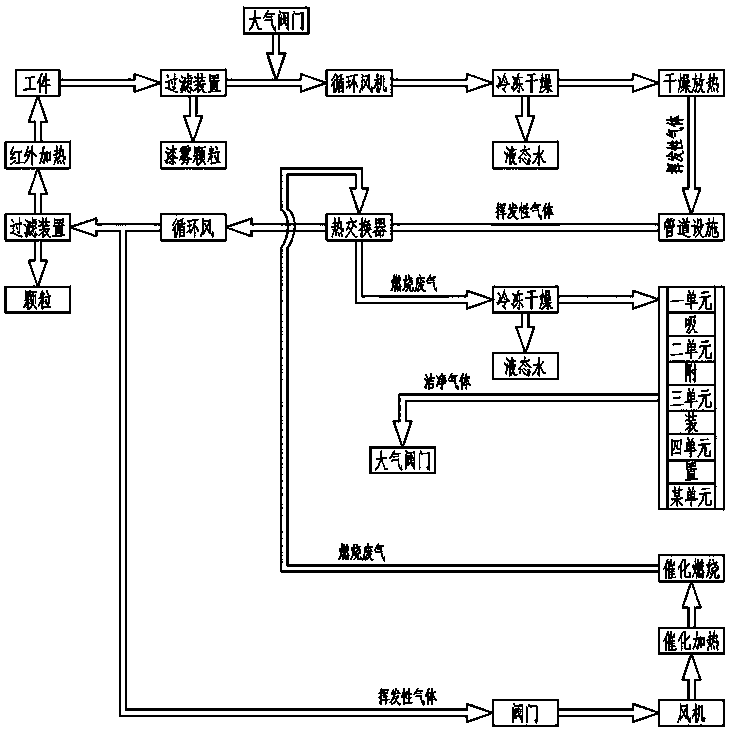

Energy-saving environment-friendly circulation type waste gas treatment method applied to paint spraying and paint baking process

ActiveCN108079738AAchieve recyclingAvoid affecting the painting and baking operation, or even polluting the workpieceGas treatmentDispersed particle filtrationHigh concentrationEnvironmental resistance

The invention discloses an energy-saving environment-friendly circulation type waste gas treatment method applied to a paint spraying and paint baking process. The method comprises the steps of paintspraying stage waste gas treatment, levelling stage waste gas treatment and drying stage waste gas treatment; during the drying stage waste gas treatment, after the levelling is completed, the operation enters the drying stage; waste gas in a drying chamber is taken away by gas exchange equipment; the taken waste gas is filtered and dried; the treated waste gas flows back into the drying chamber to form circulation airflow; when the concentration of organic volatile gas is high, and is lower than the lower explosive limit by 25 percent, a small part of high-concentration waste gas is extractedfrom the circulation airflow; heating and low-temperature catalytic oxidation are performed to form high-temperature combustion waste gas; after the high-temperature combustion waste gas and most circulation airflow are subjected to heat exchange, freeze drying and adsorption are performed; the waste gas is exhausted into atmosphere after reaching the standard. After the method is used, the wastegas can be thoroughly treated as much as possible; the discharging total quantity is reduced to the greatest degree; the resource utilization rate is improved; the effects of energy saving and environment protection are really achieved.

Owner:王理

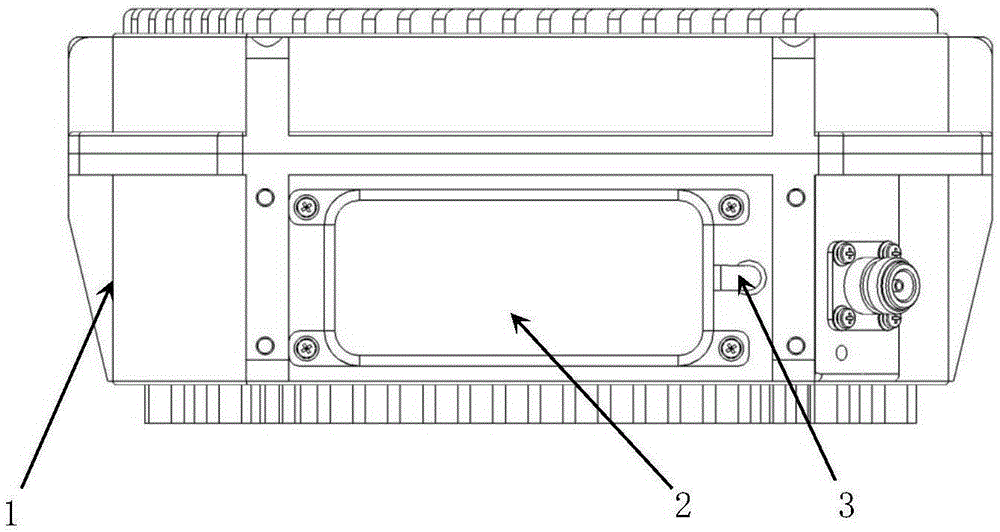

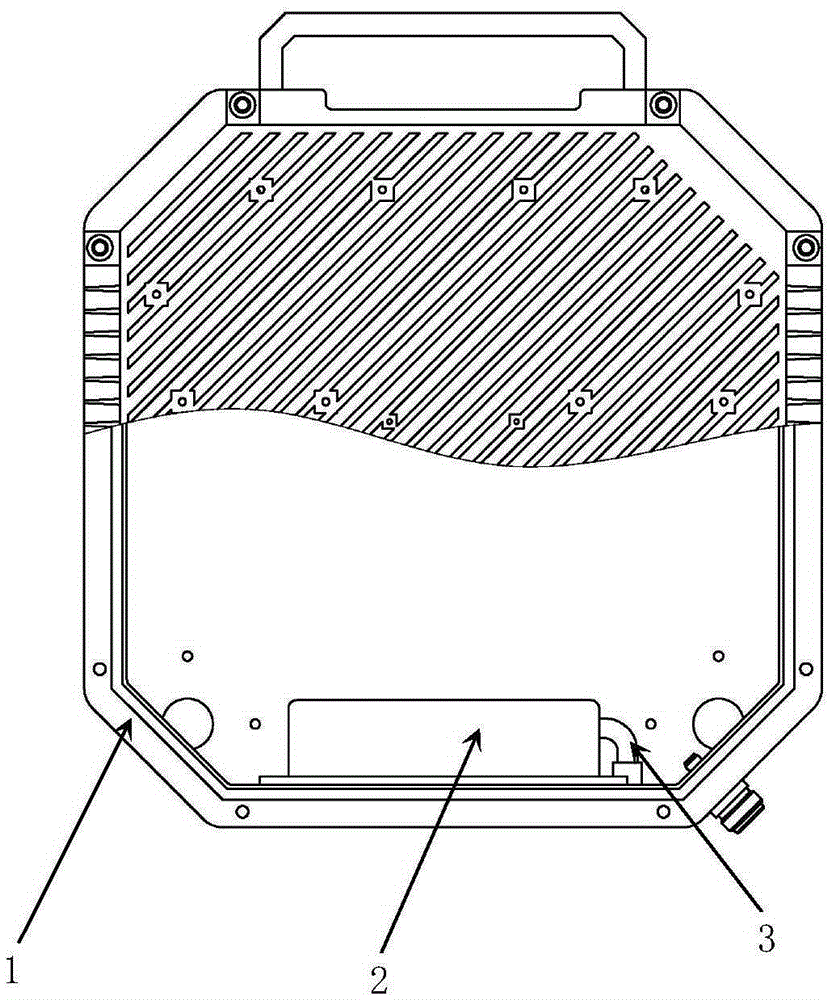

Sealing cabinet capable of balancing pressure in self-manner

InactiveCN105246284AAvoid damagePlay a protective effectCasings/cabinets/drawers detailsHermetically-sealed casingsKey pressingEngineering

The invention discloses a sealing cabinet capable of balancing pressure in a self-manner, which is mainly used for guaranteeing to balance the pressure inside and outside the sealing cabinet, isolating the gas exchange inside and outside of the cabinet and protecting the internal members. The part of the prior art usually adopts a sealing cabinet mode, and when the device is in a live working condition in the high temperature environment or in the low temperature environment, an atmosphere pressure difference is generated between the inside and the outside of the sealing cabinet, so that the strength of the sealing cabinet and the pressure resistance levels of the film button, the liquid crystal display or other members are needed to be improved. The sealing cabinet disclosed by the invention employs a combination mode of an air bag to cooperating with a vent pipeline, and integrates the balance of the inside and the outside pressure of the sealing cabinet, and utilizes the temperature to change the pressure. The pressure acts on the gas and then enables the air bag to automatically inflate and deflate, which can automatically adjust the air pressure of the inside and outside of the sealing cabinet. The sealing cabinet which is capable of balancing pressure in the self-manner and is provided with a specially-produced air bag is characterized by sealing and waterproof, electromagnetic shielding, simple structure, and good versatility.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

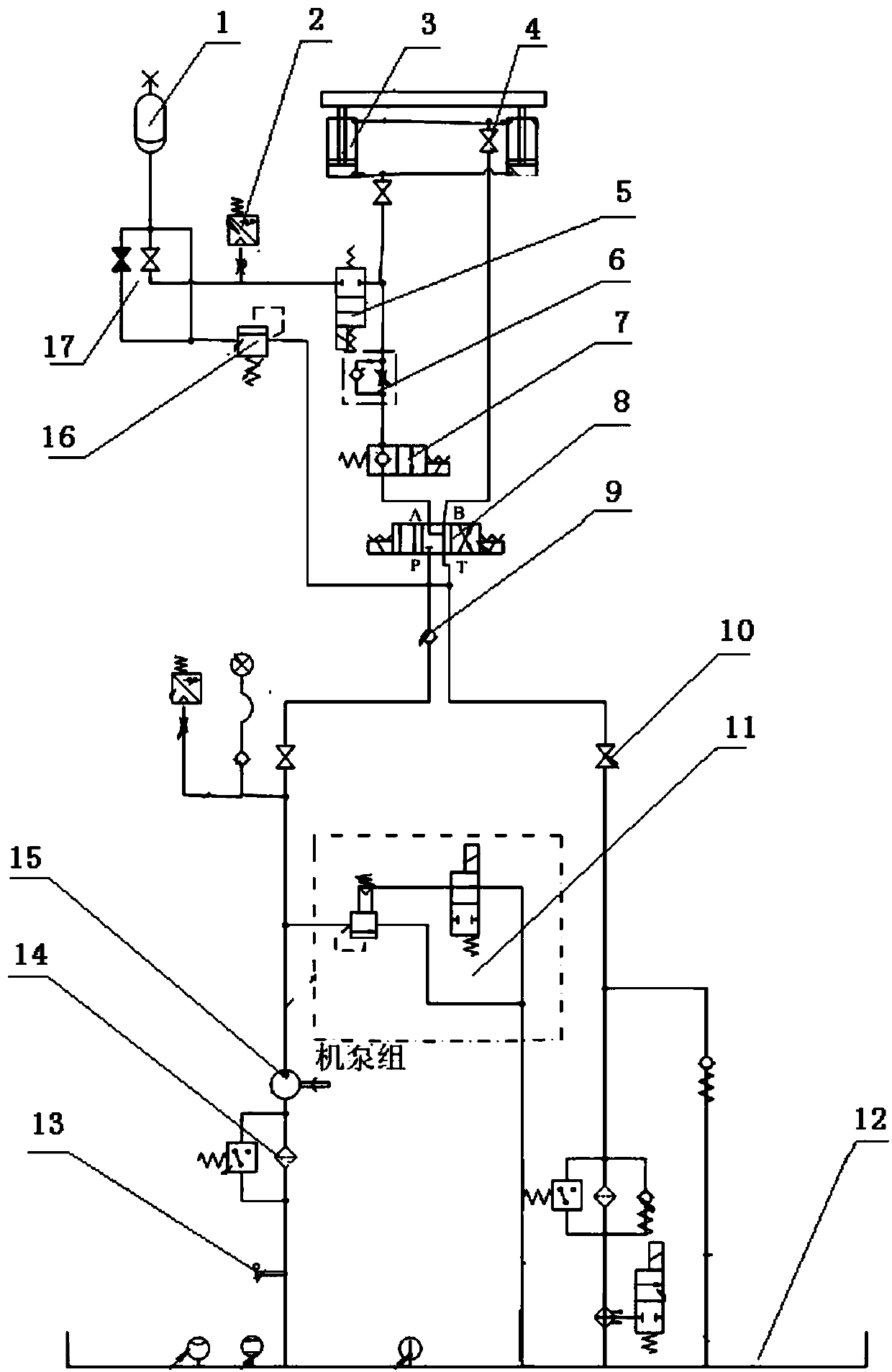

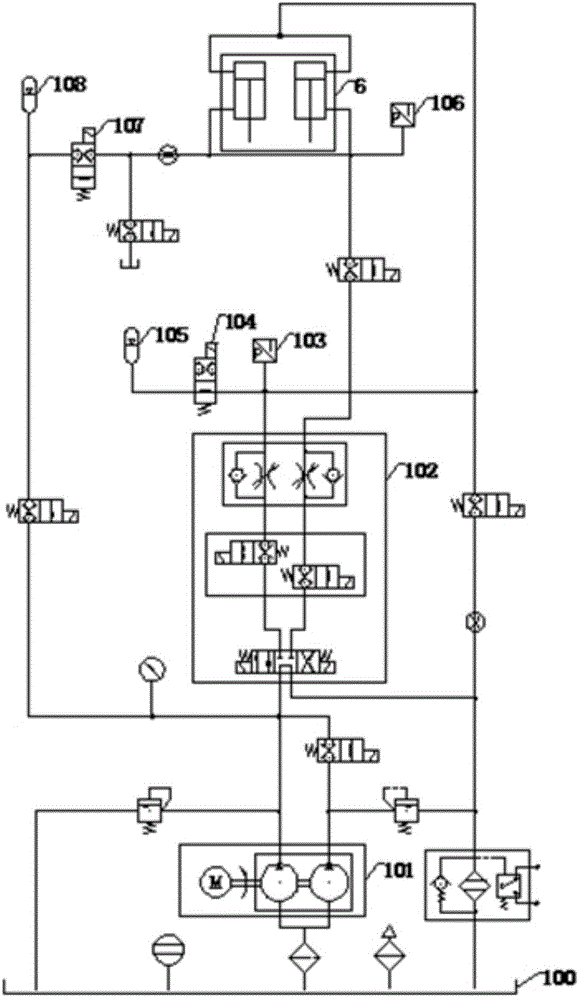

Energy-saving hydraulic servo control system for tyre vulcanizer opening and closing mold

InactiveCN107605814ASave energyRelieve stressFluid-pressure actuator safetyServomotorsCheck valveSupply energy

The invention relates to an energy-saving hydraulic servo control system for a tyre vulcanizer opening and closing mold. The energy-saving hydraulic servo control system comprises an opening and closing mold unit and an energy supply unit which are connected through an oil path. The opening and closing mold unit comprises an oil cylinder, a one-way two-position two-way electromagnetic directionalvalve and an electro-hydraulic directional valve, wherein a rodless cavity oil path of the oil cylinder is provided with a one-way throttling valve and the one-way two-position two-way electromagneticdirectional valve sequentially; the electro-hydraulic directional valve is installed at the bottom of the oil path of the oil cylinder; check valves are installed in the positions, close to the oil cylinder, of a rod cavity oil path and the rodless cavity oil path; and an energy storage oil path is installed on the rodless cavity oil path of the oil cylinder and sequentially provided with a two-position two-way electromagnetic directional valve, a pressure sensor, an energy accumulator, a two-way gate valve and an overflow valve. According to the energy-saving hydraulic servo control system for the tyre vulcanizer opening and closing mold, the electromagnetic overflow valve is opened when the pressure of the system is too high, the effect that the pressure of the whole system is balancedis ensured, the pressure of the system is prevented from being too high, the electromagnetic overflow valve is opened for unloading when the pressure is too high, and the safety is high.

Owner:天津瀚福精密液压技术有限公司

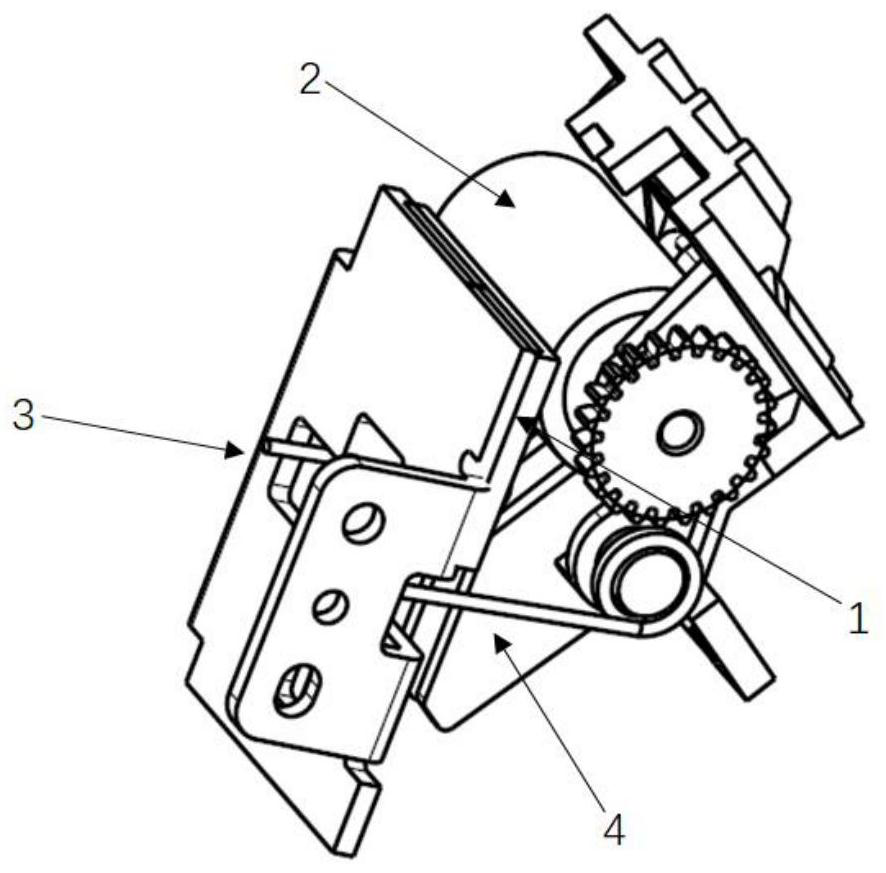

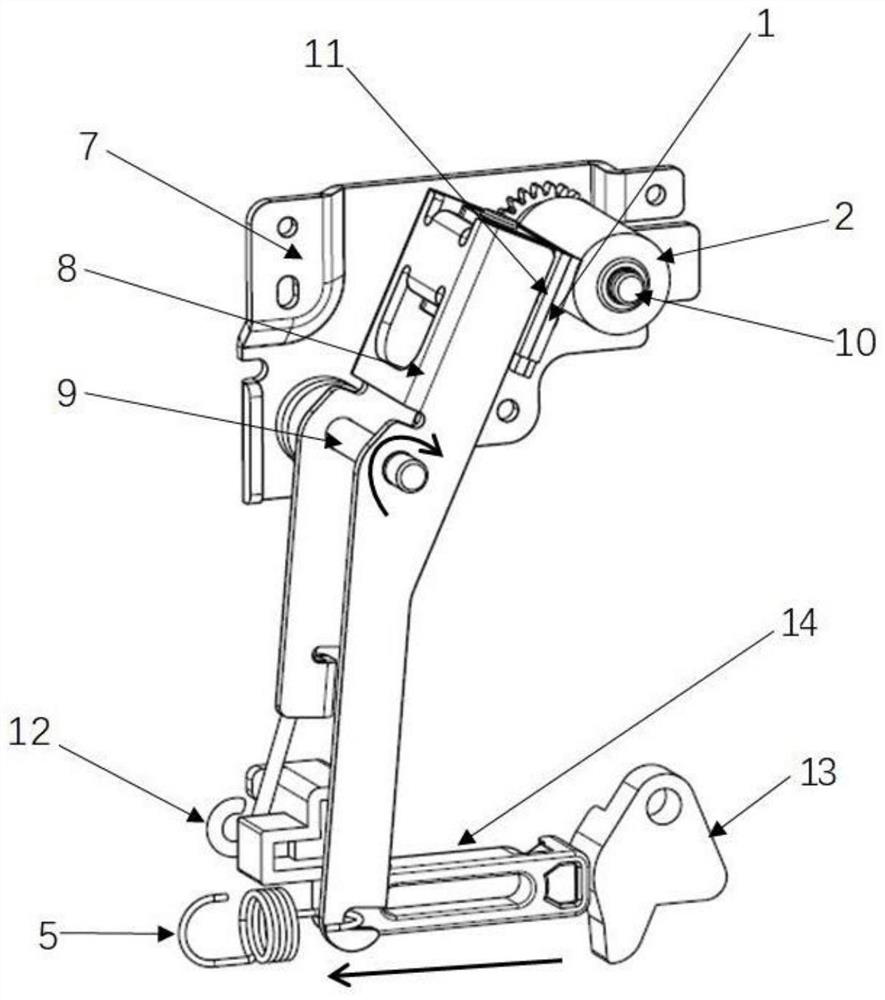

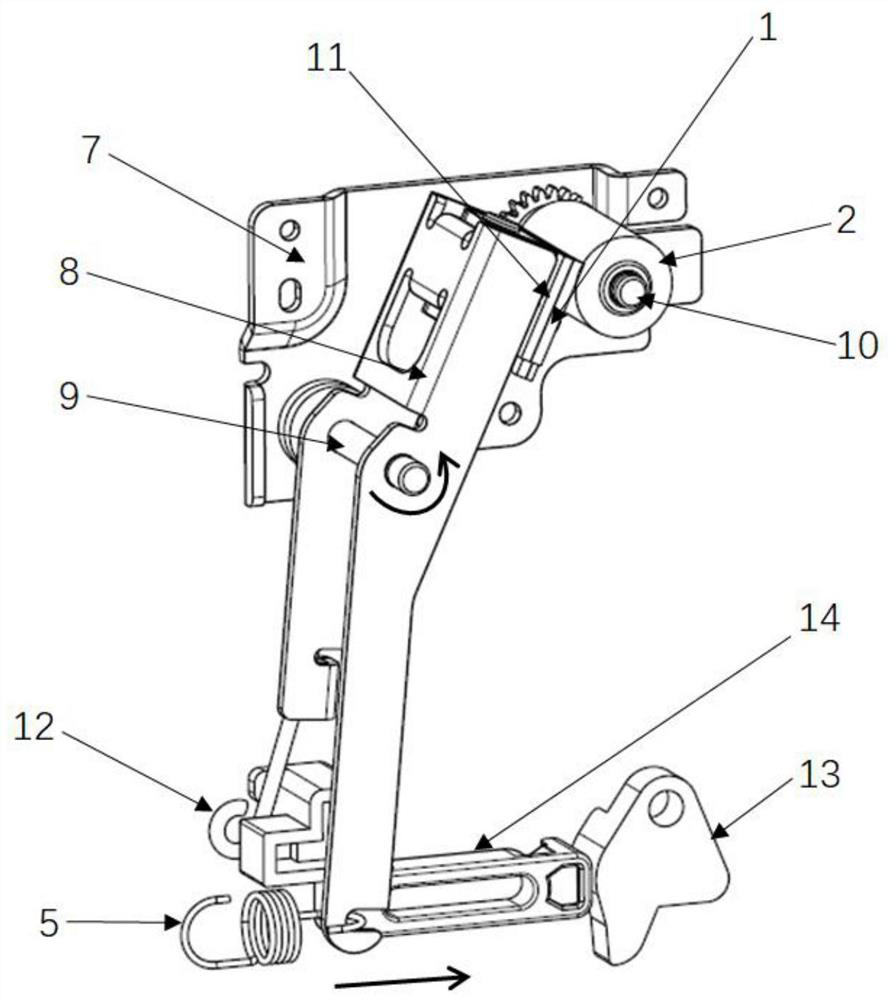

Printing head self-adaptive structure of intelligent label printer

The invention relates to a printing head self-adaptive structure of an intelligent label printer. The printing head self-adaptive structure comprises a poking rod, a sliding block, a decompression torsional spring, a pressurizing spring, a printing module framework back plate, a rotating plate, a rubber covered roller, a heat dissipation plate and a printing head which are arranged in a printer body, the heat dissipation plate is a bent plate and comprises a first connecting part used for being connected with a rotating plate and a second connecting part used for being connected with a printing head, the first connecting part is fixed to the rotating plate through a rotating shaft, and the second connecting part is tightly attached to the printing head and fixedly connected with the printing head. In the pressurizing process of the printing head, factors such as parallelism of the heat dissipation plate and the rubber covered roller do not need to be considered, point contact after being pressed is self-adaptive to line contact, a pressed point is a midpoint of the line contact, and pressure balance of the printing head and the rubber covered roller at all positions of the contactposition is guaranteed.

Owner:WUHAN JINGCHEN INTELLIGENT IDENTIFICATION TECH CO LTD

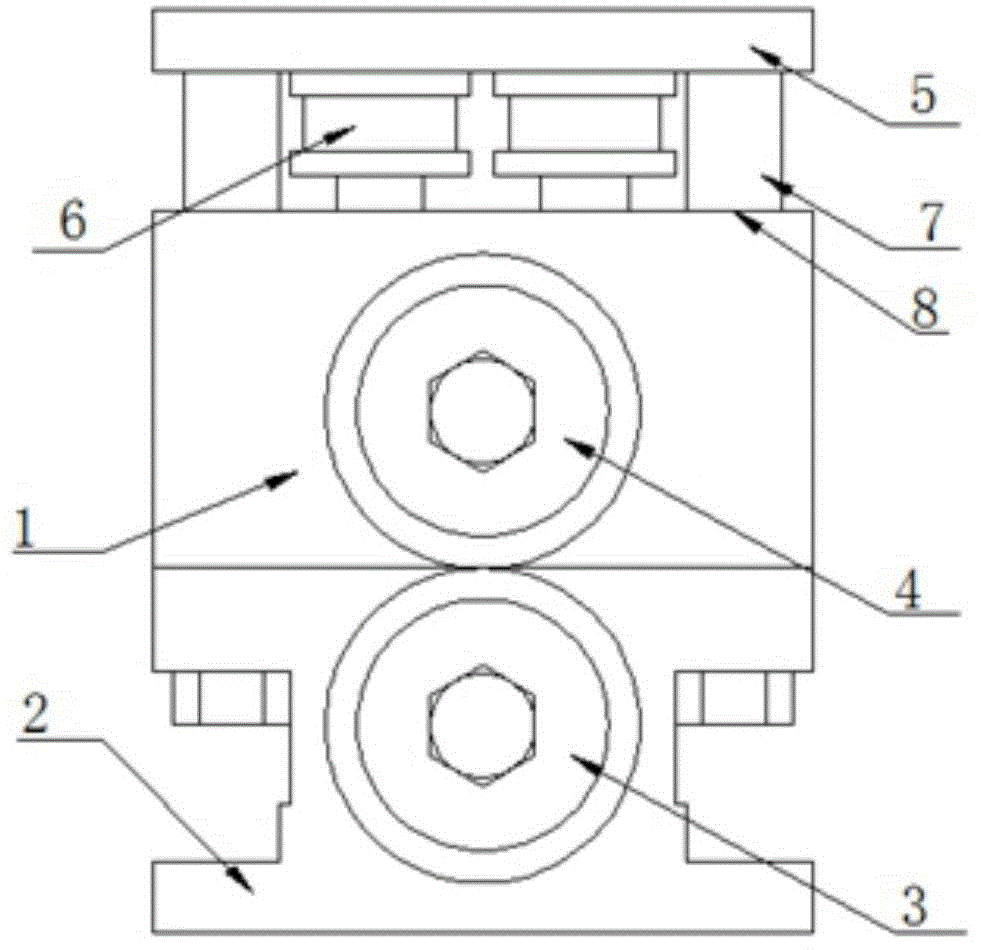

Extrusion device for dry type granulator

ActiveCN104383849AGuaranteed pressure balanceAutomatically adjust the gapGranulation by material expressionGranulation by pressingFuel tankHydraulic pump

The invention relates to an extrusion device for a dry type granulator. The extrusion device comprises an upper tank body, a lower tank body, an extrusion wheel 1, an extrusion wheel 2, a hydraulic cylinder block, a hydraulic cylinder and a hydraulic control system, wherein the hydraulic cylinder block is assembled above the lower tank body; the upper tank body is arranged between the lower tank body and the hydraulic cylinder block; the extrusion wheel 1 is assembled on the lower tank body; the extrusion wheel 2 is assembled on the upper tank body; one end of the hydraulic cylinder is assembled on the hydraulic cylinder block; the other end of the hydraulic cylinder is connected with the upper tank body; the hydraulic cylinder is provided with an oil inlet end 1 and an oil inlet end 2; the hydraulic control system comprises an oil tank, a hydraulic pump and a direction valve, which are sequentially connected in series; the direction valve is connected with the oil inlet end 1 and the oil inlet end 2; a branch circuit composed of a pressure transmitter, a control valve and an energy accumulator is connected between the hydraulic cylinder and the direction valve in parallel; the pressure transmitter is used for collecting the pressure of the hydraulic cylinder and feeding the pressure back to the control valve; and the control valve is used for controlling opening and closing of the energy accumulator to supplement or release the pressure of hydraulic oil, thus automatic pressure supplement and automatic clearance adjustment of the extrusion device are achieved; and the extruded material is relatively uniform in thickness and compactness.

Owner:CHANGZHOU YIBU DRYING EQUIP

Method for removing inorganic salt in L-alanine fermented material liquid

ActiveCN106631854AReduce energy consumptionReduce the burden onOrganic compound preparationAmino-carboxyl compound preparationMagnesium saltPhosphate

The invention discloses a method for removing inorganic salt in L-alanine fermented material liquid. The method comprises the steps that the L-alanine fermented material liquid is filtered; thalli and macromolecular protein in the fermented liquid are removed; L-alanine ultrafiltration clear liquid is obtained; the respective water injection flow rate of a fresh water pump, a concentrated water pump and an electrode water pump is controlled, so that the pressure balance in a fresh water chamber, a concentrated water chamber and an electrode water chamber is ensured; the L-alanine ultrafiltration clear liquid is subjected to electrodialytic treatment under the constant current density condition until the membrane pack voltage is stabilized to be 30 to 50V; the electrical conductivity of L-alanine fermented clear liquid is 3000 to 10000 muS / cm; when the L-alanine loss rate is 8 to 12 percent, the electrodialysis is finished. The method has the advantages that the electrodialysis is used for treating material liquid in the process of producing L-alanine by a fermentation method; saline matters such as ammonium salt, phosphate, calcium salt and magnesium salt can be effectively removed, so that the purity and the quality of L-alanine products are improved.

Owner:QINHUANGDAO HUAHENG BIOENG CO LTD

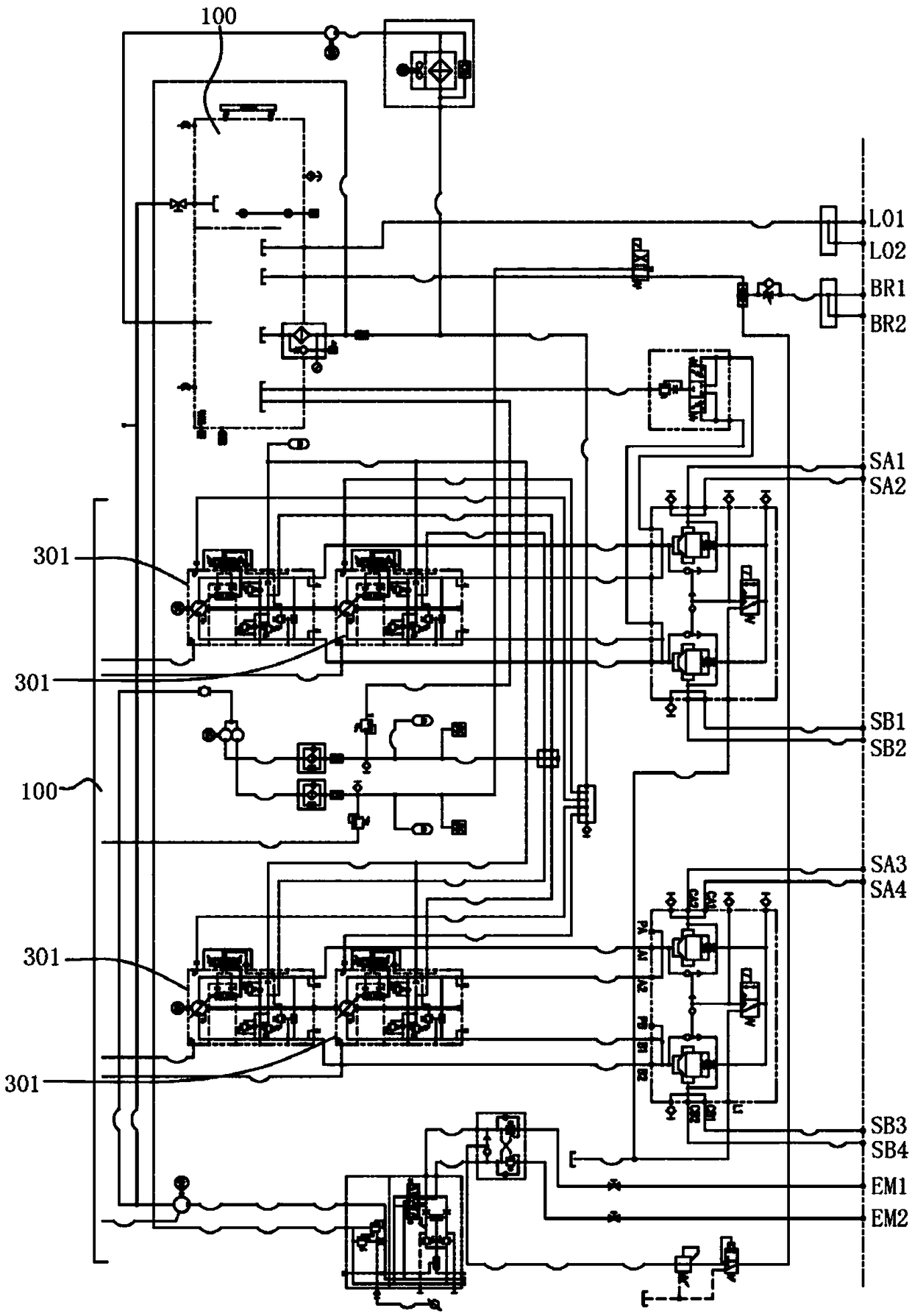

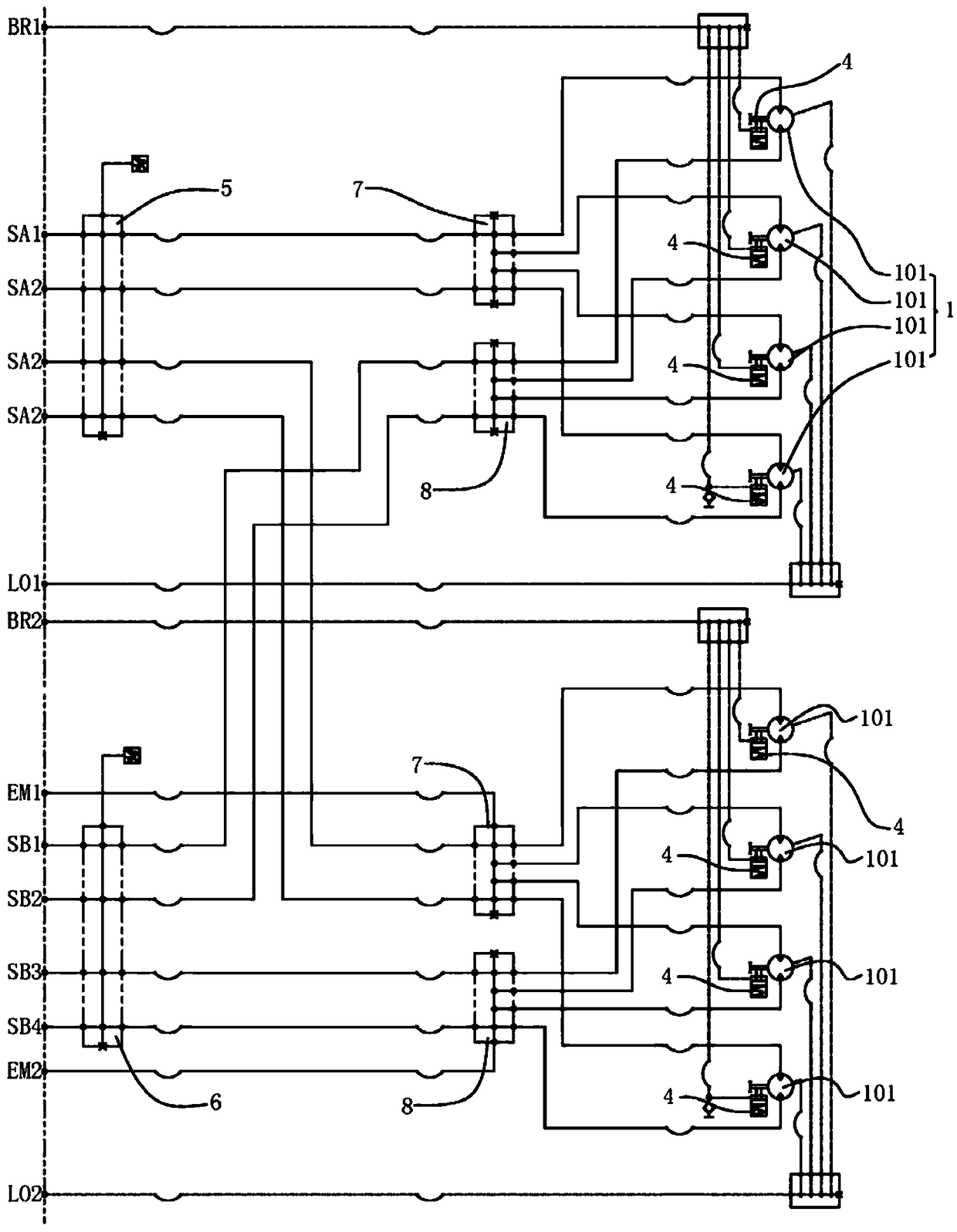

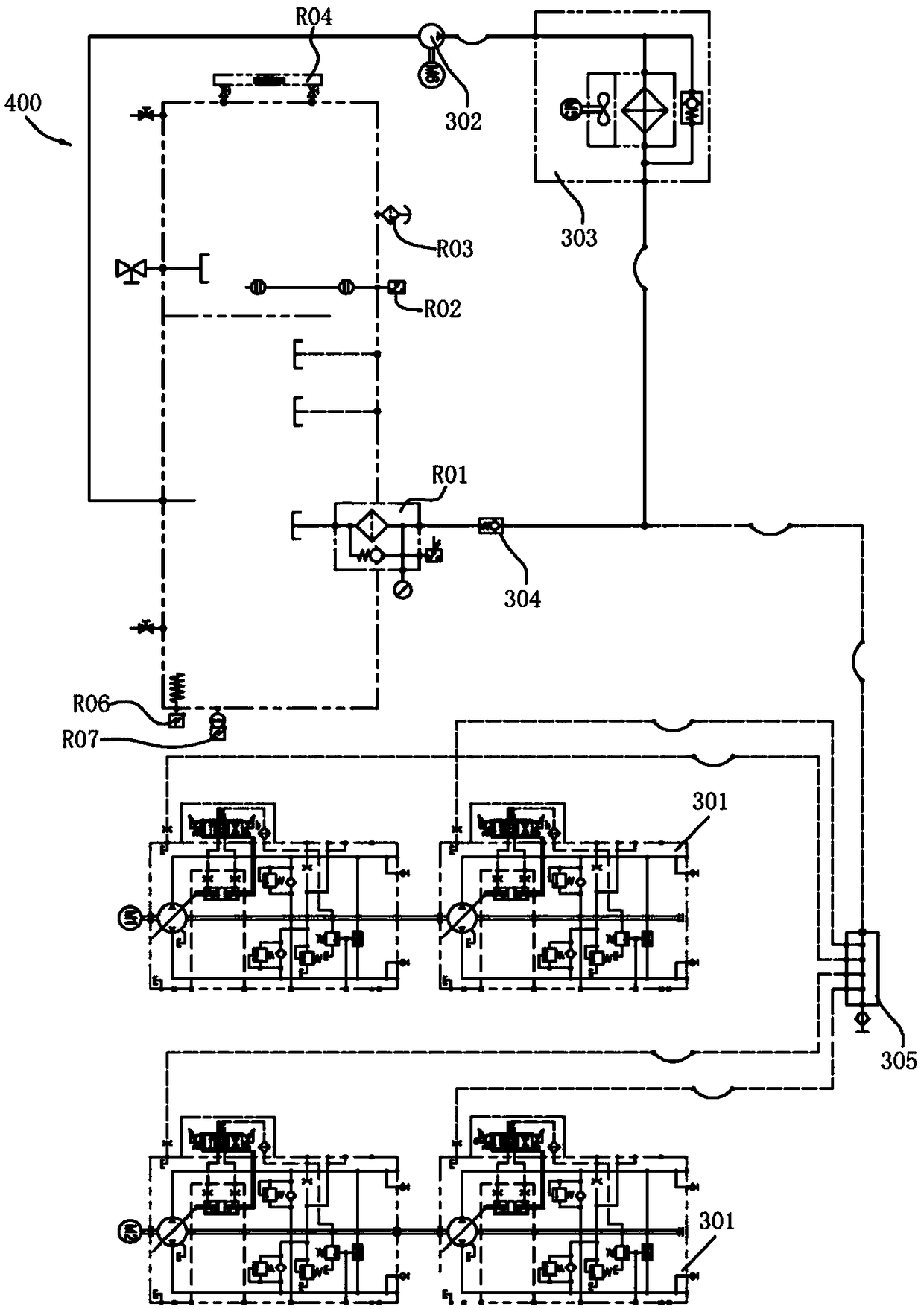

Hydraulic system of crane and working method

PendingCN109292630AGuaranteed to workPressure effectFluid-pressure actuator safetyServomotor componentsFuel tankHydraulic pump

The invention relates to a crane, and particularly relates to a hydraulic system of a crane for vessel operation and a working method. The hydraulic system of the crane comprises a fuel tank, a gyrating system for driving a gyrating platform, a brake system, a cooling system for decreasing the oil temperature, an oil supplementing system for supplementing oil, and an emergency gyrating system which is started in case of fault. According to the hydraulic system of the crane and the working method, the gyrating system is a closed hydraulic system, so that the energy utilization rate is high; theoil supplementing system is arranged and used for supplementing consumed hydraulic oil of the closed hydraulic system; a brake shuttle valve is arranged in the brake system; a normal brake system isconnected to a brake oil channel of a hydraulic emergency system, thus realizing a two-input and one-output brake system, and as a result, the safety is improved; the cooling system is arranged and used for cooling a hydraulic pump set, so that the probability of failure of the hydraulic pump set can be reduced; and the hydraulic emergency system is provided, so that the safety of the crane is improved.

Owner:SOUTH CHINA MARINE MACHINERY

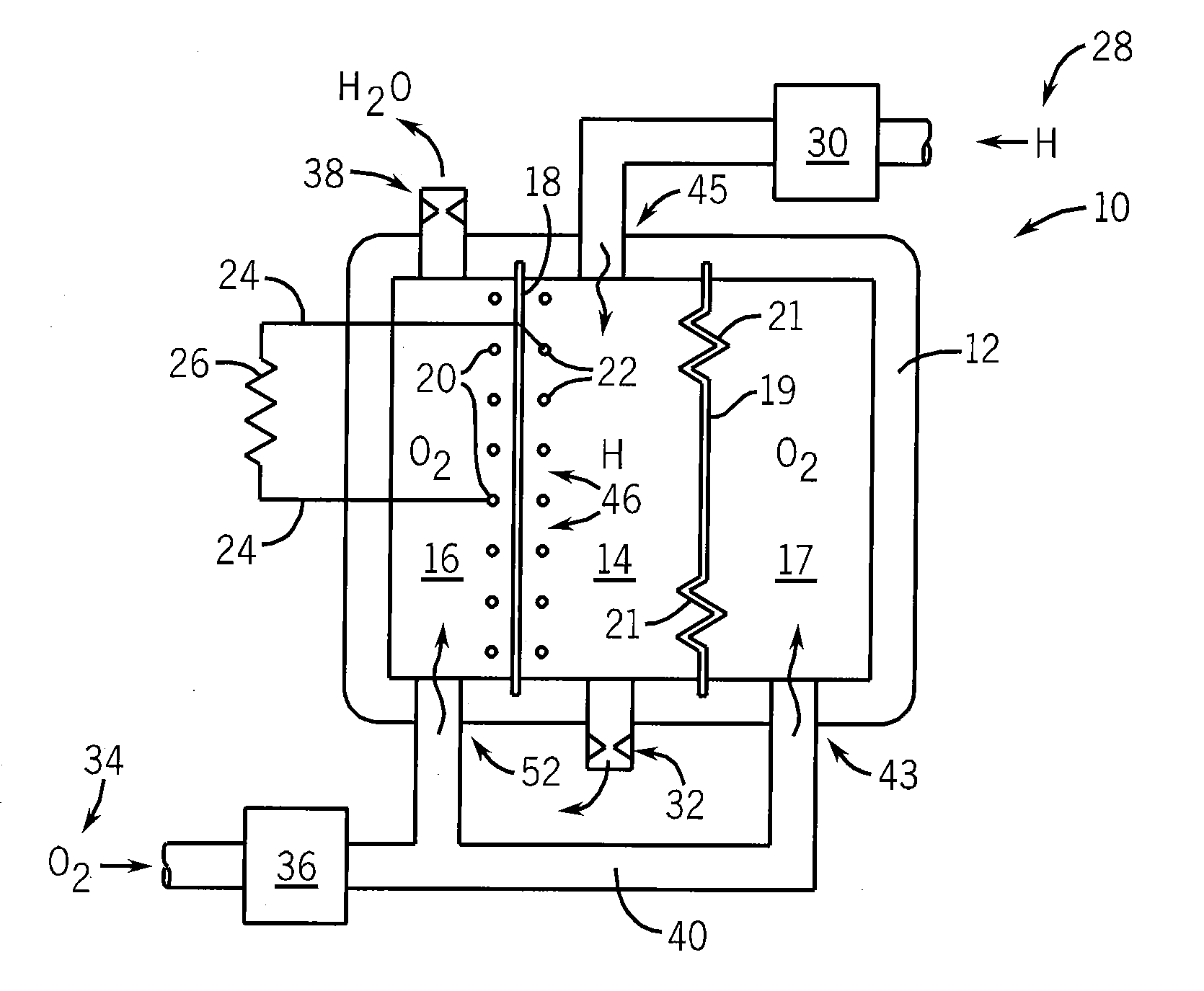

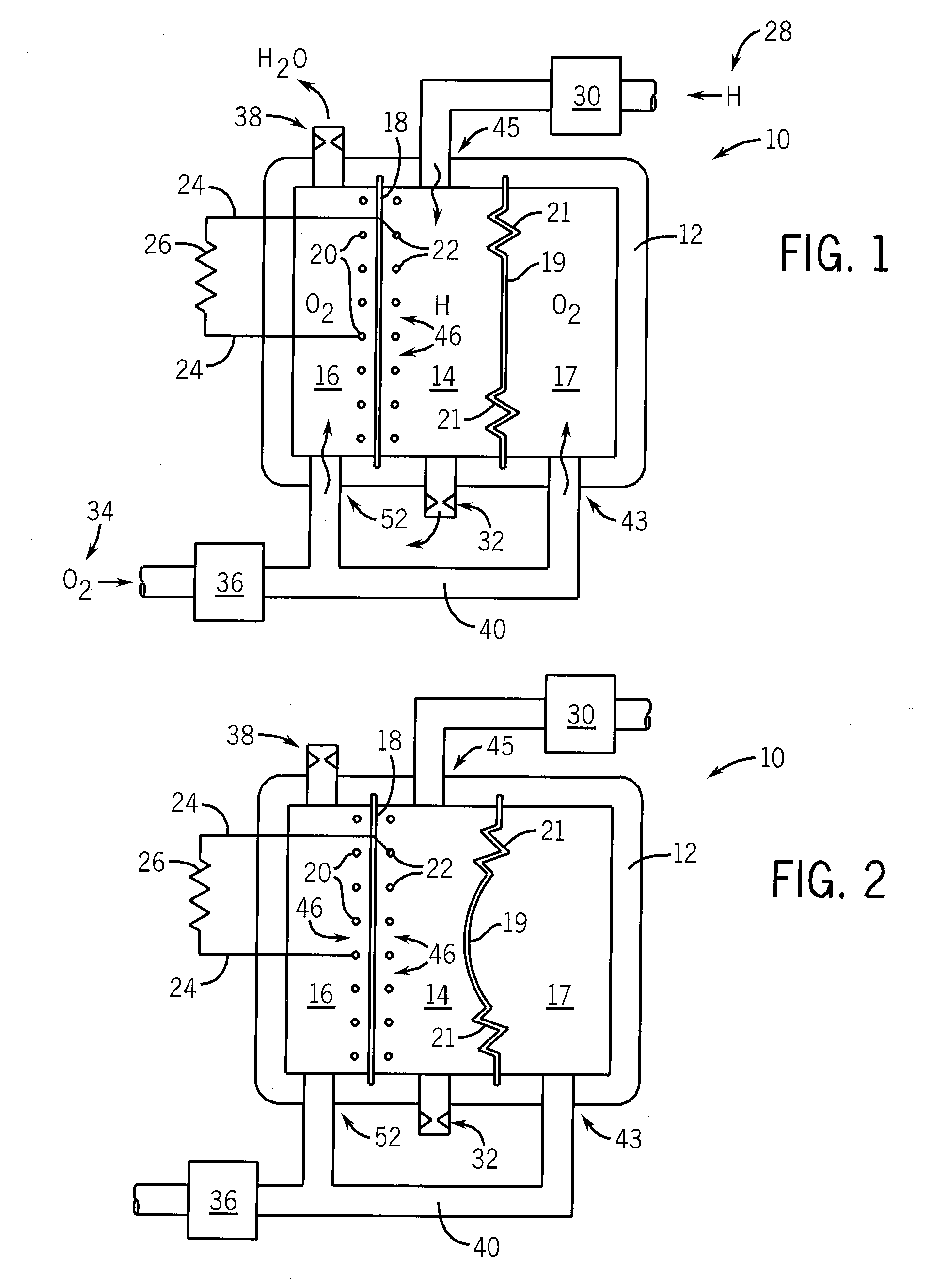

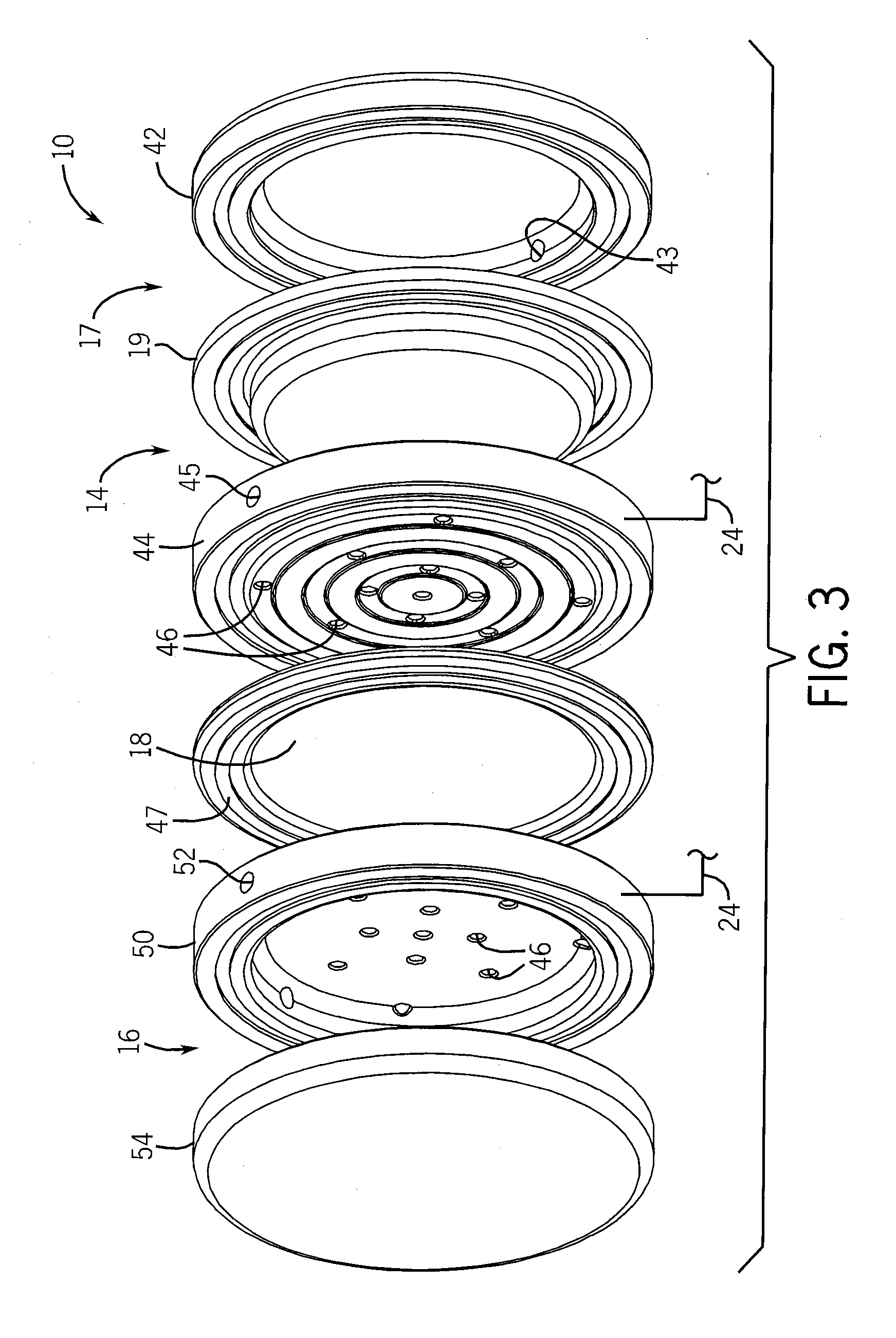

Fuel Cell with Rapid Pressure Balancing

InactiveUS20120070754A1Simple fabrication techniqueSimple but high-speed auto balancing of pressureFuel cell auxillariesSolid electrolyte fuel cellsMembrane configurationEngineering

A fuel cell provides for rapid pressure equalization across the proton exchange membrane by means of an expansion chamber on one side of the proton exchange membrane, the expansion chamber communicating with the gas on the other side of the membrane. Changes in size of the expansion chamber adjust pressure more rapidly than external control of flow rates.

Owner:WISYS TECH FOUND

Powder preheating device for SLM equipment and working method thereof

PendingCN109967738AGuaranteed pressure balanceAchieve consistencyAdditive manufacturing apparatusIncreasing energy efficiencyMetal powderHeating temperature

The invention discloses a powder preheating device for SLM equipment. The powder preheating device for the SLM equipment comprises a forming cylinder, a Z-axis lifting forming frame is arranged in theforming cylinder, a heat insulation plate is arranged on the upper surface of the Z-axis lifting forming frame, a heating plate is arranged on the upper surface of the heat insulation plate, and a substrate is arranged on the upper surface of the heating plate; and the powder preheating device for the SLM equipment further comprises a liquid heating temperature control device, a forming cylinderinner flow channel is embedded into the side wall of the forming cylinder, the two ends of the forming cylinder inner flow channel are connected with an inlet and an outlet of the liquid heating temperature control device, a heating flow channel is embedded into the substrate or the heating plate, and the two ends of the heating flow channel are also connected with the inlet and the outlet of theliquid heating temperature control device. According to the powder preheating device for the SLM equipment, a liquid heating mode is adopted, safe constant-temperature heating can be achieved, and a short circuit and the risk that metal powder is detonated to cause explosion are avoided. The invention further discloses a working method of the powder preheating device.

Owner:XIAN BRIGHT ADDTIVE TECH CO LTD

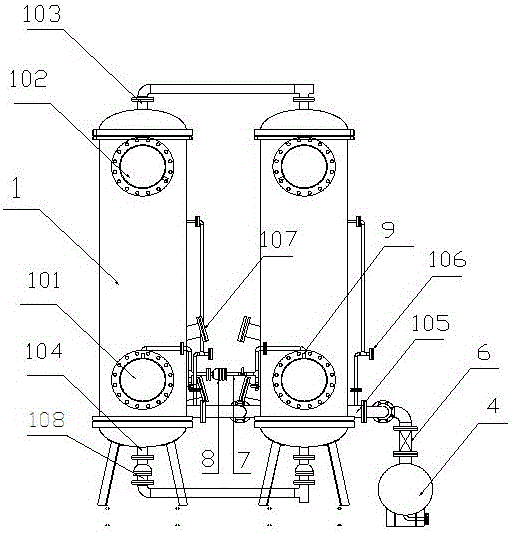

Evaporation device for condensation, freezing and deodorization of grease

ActiveCN104277910BExtended service lifeGuaranteed pressure balanceFatty-oils/fats refiningEdible oils/fatsEnergy consumptionWaste management

The invention relates to an evaporating device for condensing, freezing and deodorizing oil and fat. The evaporating device comprises at least two evaporators (1); air inlets (101) are formed in the lower parts of the two evaporators (1) and are connected with an air outlet of a system to be deodorized; air outlets (102) are formed in the upper parts of the two evaporators (1) and are connected with an air inlet of a roots liquid ring vacuum unit (13) through pipelines; a cooling water outlet (103) and a cooling water inlet (104) are respectively formed in the top and bottom of each evaporator (1); and the cooling water outlets (103) and the cooling water inlets (104) are respectively connected with an inlet and an outlet of a condensing unit. By using the evaporating device, the heat exchange effects of the evaporators can be improved, the work efficiency of the whole vacuum equipment can be increased, the energy consumption can be reduced, and the enterprise cost can be reduced.

Owner:JIANGYIN TIANTIAN VACUUM EQUIP

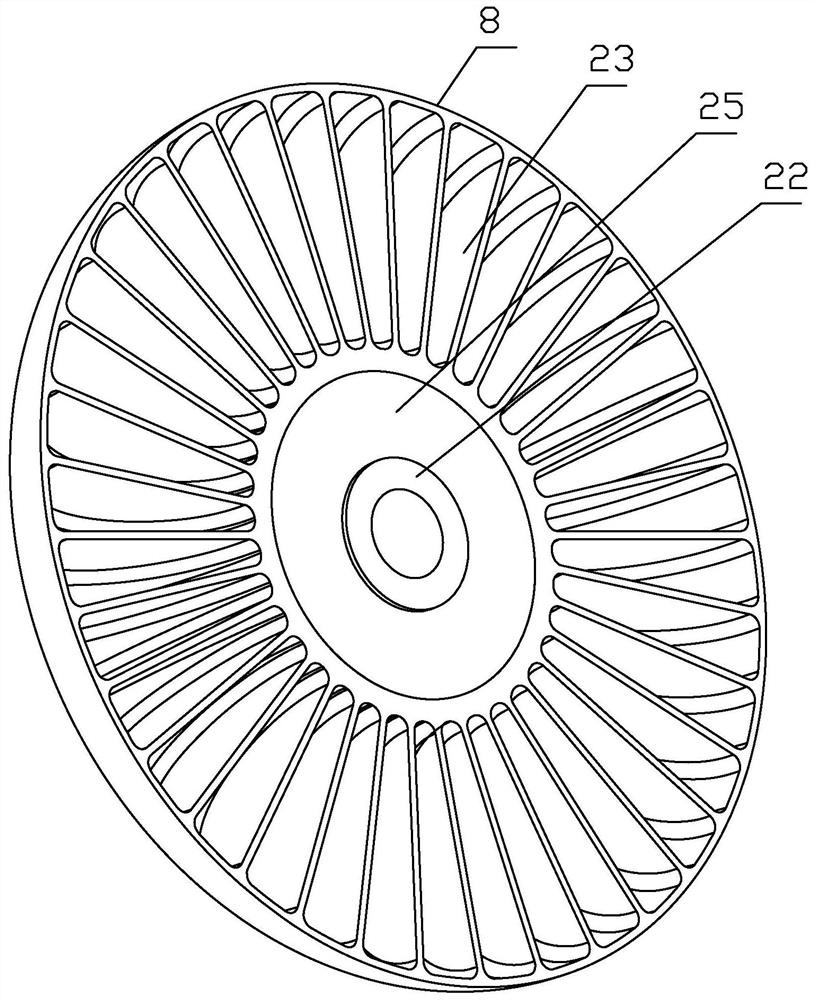

Anti-corrosion and anti-explosion vortex type hydrogen circulating pump

ActiveCN113323894AAvoid hydrogen embrittlement and hydrogen corrosionGuaranteed normal rotationPump componentsCooling/ventillation arrangementImpellerElectric machine

Disclosed is an anti-corrosion and anti-explosion vortex type hydrogen circulating pump, comprising a motor shell, an impeller shell and a bearing seat which are connected, wherein a motor cavity is formed between the motor shell and the impeller shell, an encapsulation stator, an anti-corrosion rotor and a motor shaft are arranged in the motor cavity, the two ends of the motor shaft are supported through bearings installed on the motor shell and the bearing seat, the motor shaft is in clearance fit with the impeller shell and used for keeping pressure balance between a motor cavity and a pressurizing cavity. An impeller installed on the motor shaft is arranged in the pressurizing cavity, a communicating hole for communicating the motor cavity with the pressurizing cavity is formed in the bottom of the impeller shell, an annular flow channel is formed in the bearing seat, and an air inlet and an air outlet which communicate with the annular flow channel are formed in the bearing seat. The axial balance force of the motor shaft is good, the operation is more stable and reliable, the encapsulation stator is anti-corrosion and anti-explosion, the anti-corrosion rotor is high in corrosion resistance, hydrogen embrittlement and hydrogen corrosion of the outer surfaces and the interiors of the encapsulation stator and the anti-corrosion rotor caused by hydrogen-containing mixed gas are avoided, and normal work of the hydrogen circulating pump is guaranteed.

Owner:YANTAI DONGDE IND CO LTD

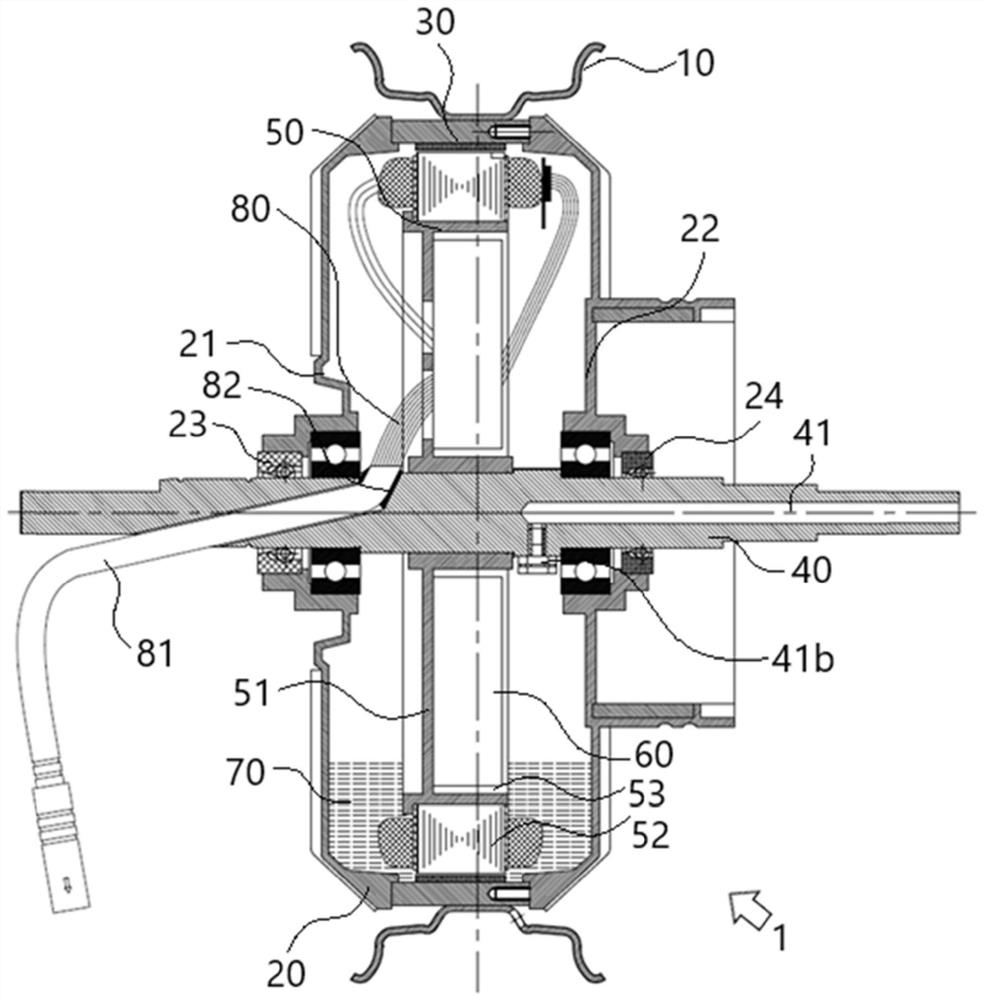

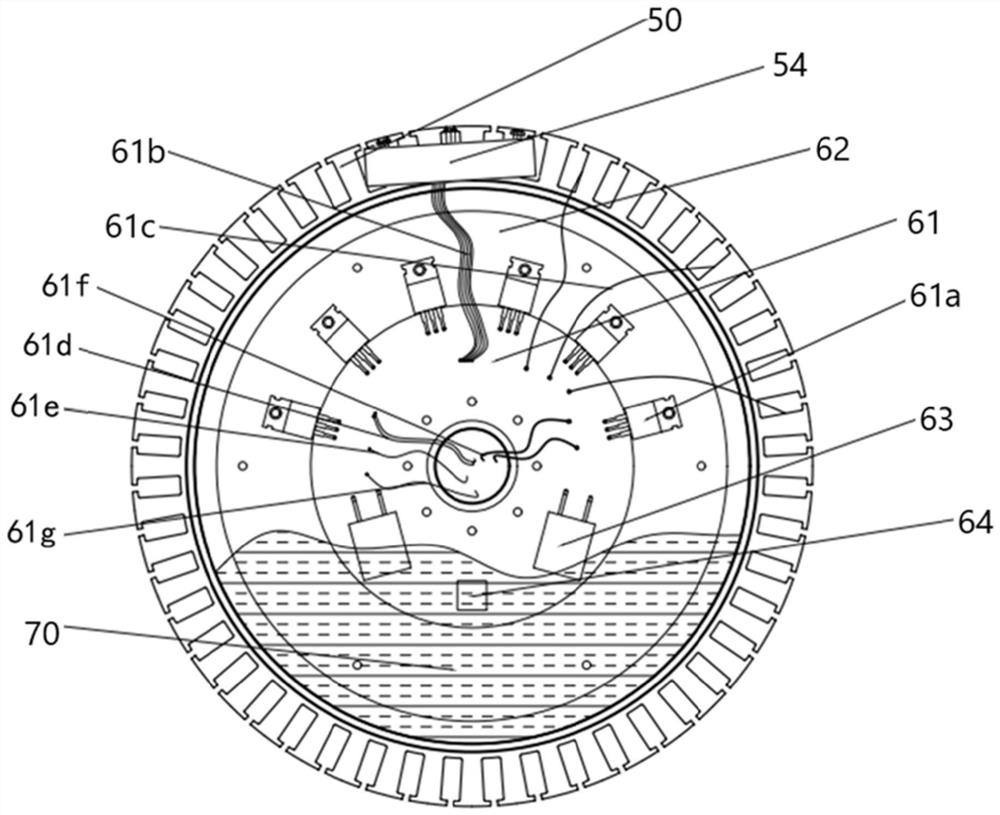

Motor controller integrated assembly for electric vehicle and electric vehicle with motor controller integrated assembly

PendingCN113726088AOptimize installation layout spaceSimple connection structureAssociation with control/drive circuitsElectric machinesPermanent magnet rotorElectric machine

The invention discloses a motor controller integrated assembly for an electric vehicle and the electric vehicle with the motor controller integrated assembly. The motor controller integrated assembly comprises a permanent magnet rotor assembly which is integrated with an electric vehicle hub and a motor shell, and a stator assembly which is located at the inner periphery of the permanent magnet rotor assembly and is integrated with a motor shaft, a controller used for achieving driving control over the motor is installed on the end face of the stator assembly, the motor shell is provided with a liquid injection opening used for injecting insulating cooling liquid, meanwhile, an air duct extending from the interior of the motor shell to the exterior of the motor shell is arranged in the motor shaft, and an air duct port located in the motor shell is connected with an air vent valve. According to the motor controller integrated assembly, the heat dissipation problem of the motor controller integrated assembly for the electric vehicle is effectively solved, so that the application process of the motor controller integrated assembly for the electric vehicle is powerfully promoted, and standardization and series modularization of motor controller products are achieved.

Owner:WUXI SINE POWER TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com