Gas flow calibrating device based on bell shape-column shape dual piston structure

A gas flow and calibration device technology, which is applied in the direction of testing/calibration devices, measuring devices, liquid/fluid solid measurement, etc., can solve problems affecting measurement accuracy, inaccurate measurement results, and single structure, so as to improve measurement accuracy and expand Scope of application, effect of reducing motor power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The substantive features of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

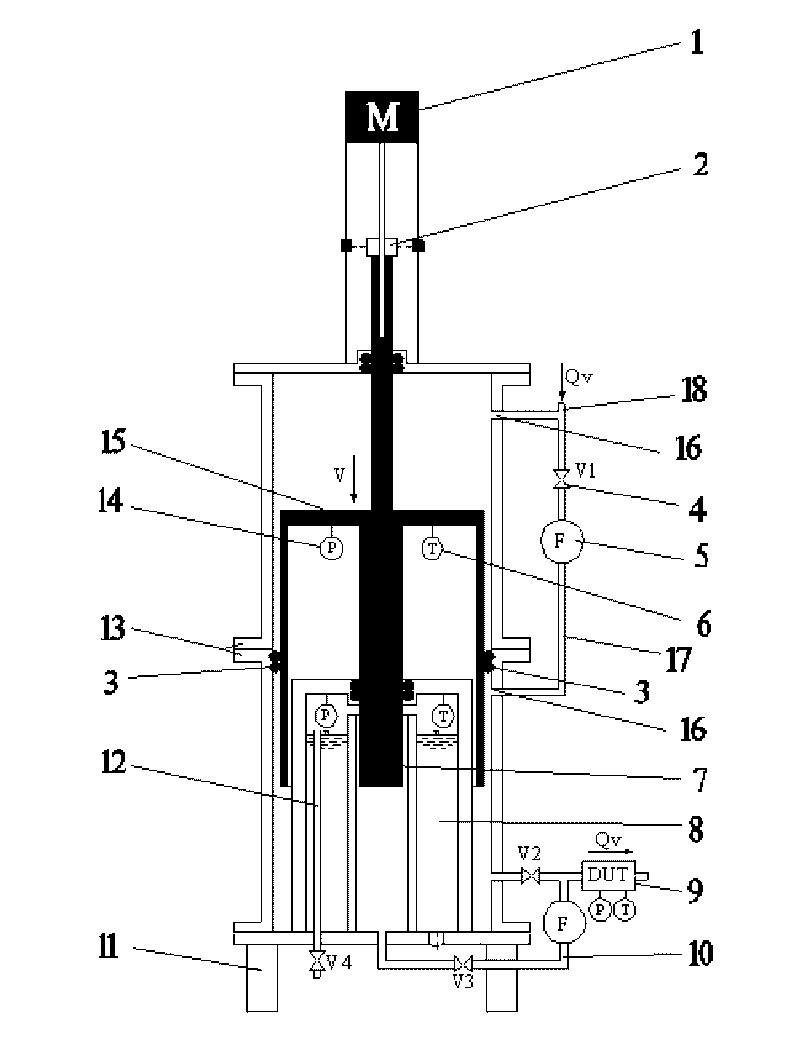

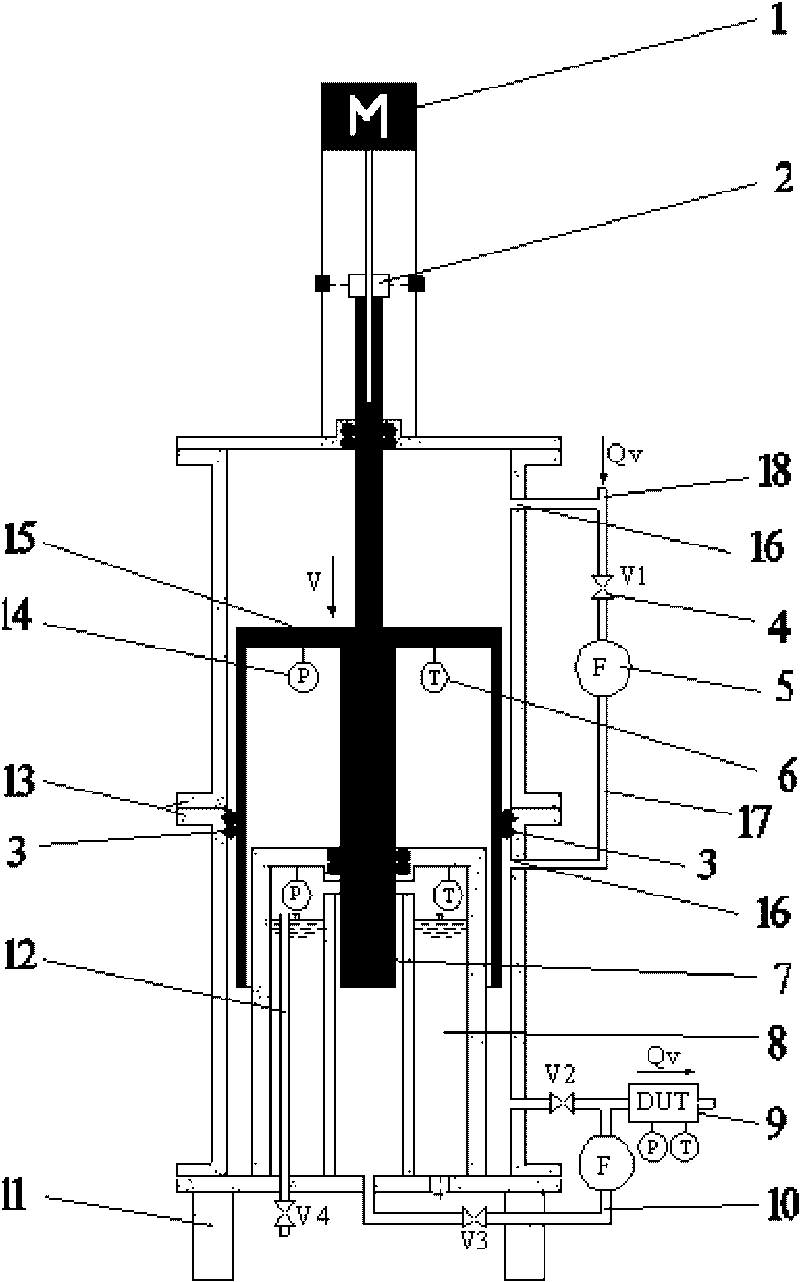

[0019] Such as figure 2 The shown gas flow calibration device based on the bell-column double-piston structure is mainly composed of a frame 11, a cylinder 13 on the frame 11, and a measurement and control system. The bar assembly 2 is connected to drive the piston in the cylinder to move up and down. The piston is a bell-shaped piston 15 as a whole, which forms a cylindrical piston 7 along the central axis of the bell-shaped piston 15. The inside of the cylinder 13 forms two air chambers inside and outside, and the inner air chamber is also separated to form three connected cavities. The cylindrical piston 7 Inserted into the middle cavity, white oil 8 is packaged in the cavities on both sides, and the inner air chamber air guide tube 12 of the flow controller 4 is connected outside the cavity on one side. The ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com