Evaporation device for condensation, freezing and deodorization of grease

An evaporation device and deodorization technology, which is applied in the direction of edible oil/fat, fat oil/fat refining, application, etc., can solve the problems of evaporator tube blockage, reduce work efficiency, vacuum degree fluctuation and influence, etc., to ensure the smooth discharge of sewage , Improve work efficiency and ensure normal results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

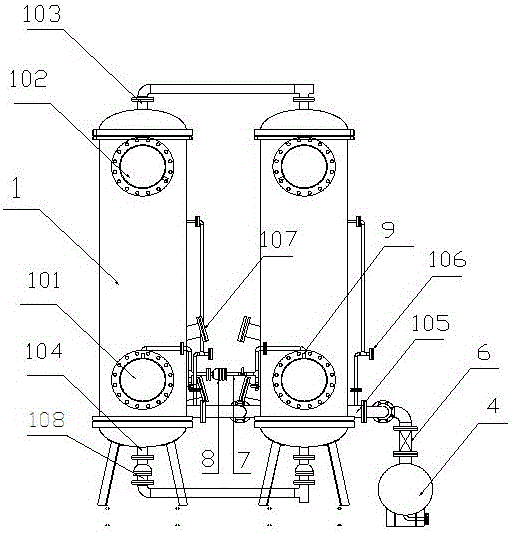

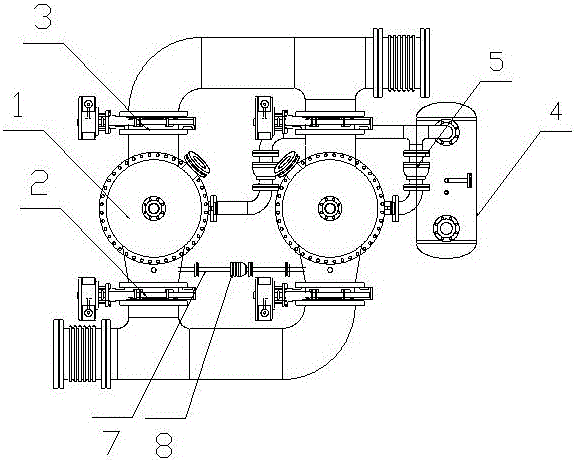

[0023] see figure 1 — figure 2 , the present invention relates to an evaporation device for condensation, freezing and deodorization of grease, comprising two evaporators 1, an air inlet 101 is opened at the lower part of the two evaporators 1, and two air inlets 101 are provided with The air intake butterfly valve 2 can select the working evaporator 1 by opening and closing the intake air butterfly valve 2. The air inlet 101 is connected with the system air outlet that needs to be deodorized. Air outlet 102, two air outlets 102 are provided with air outlet pneumatic butterfly valve 3, the top and bottom of the evaporator 1 are respectively provided with a cooling water outlet 103 and a cooling water inlet 104, the cooling water outlet 103 and cooling water The inlet 104 is respectively connected with the inlet and outlet of the condensing unit, a pneumatic ball valve 108 is installed at the cooling water inlet 104, and a sewage outlet 105 is arranged at the lower part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com