Waste heat driven composite alternating heat pipe generator

A compound alternating current generator technology, which is applied in the field of compound alternating heat pipe generators, can solve problems such as corrosion in the heating section of heat pipes, achieve the effects of ensuring pressure balance, enhancing heat transfer performance, and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

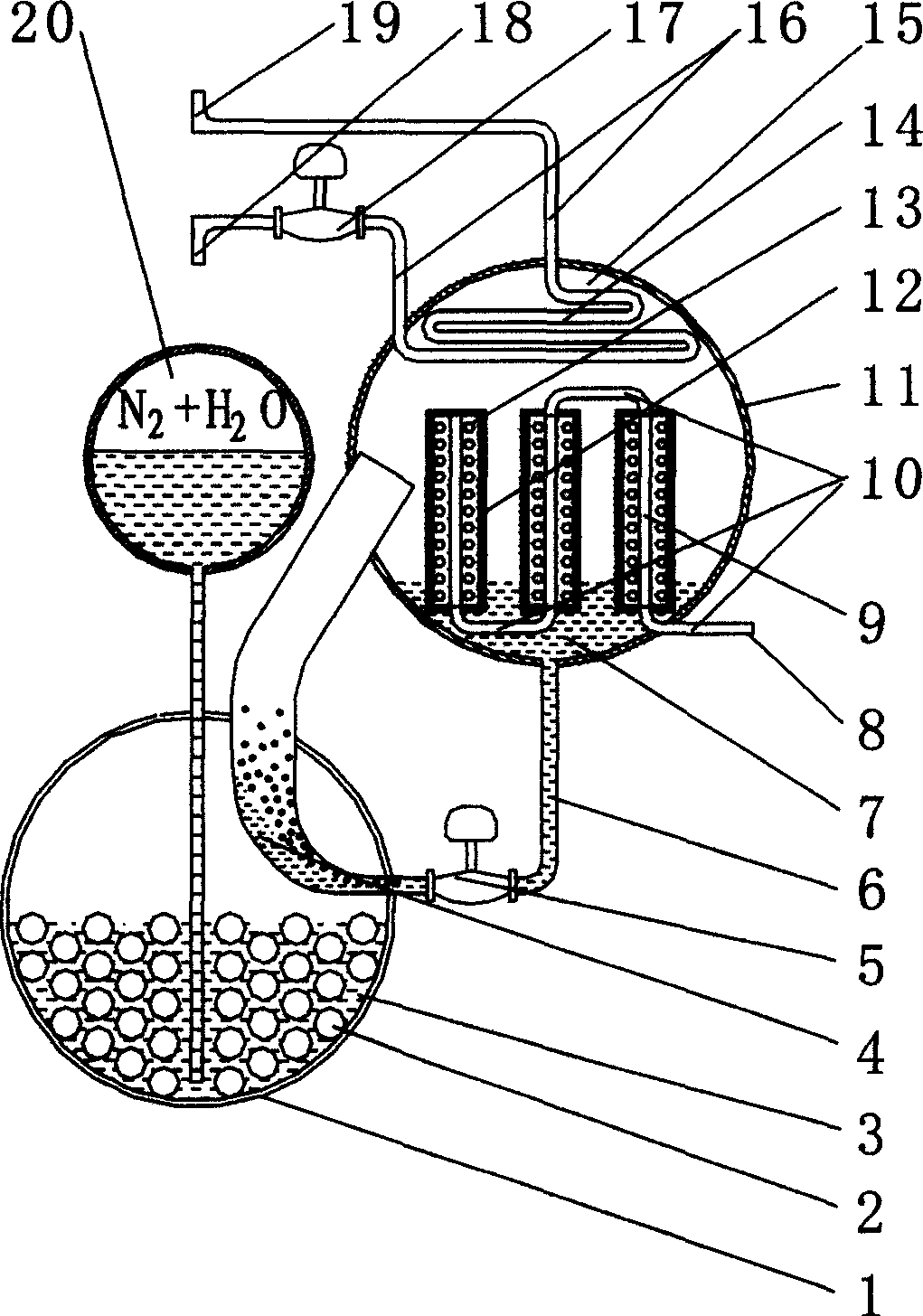

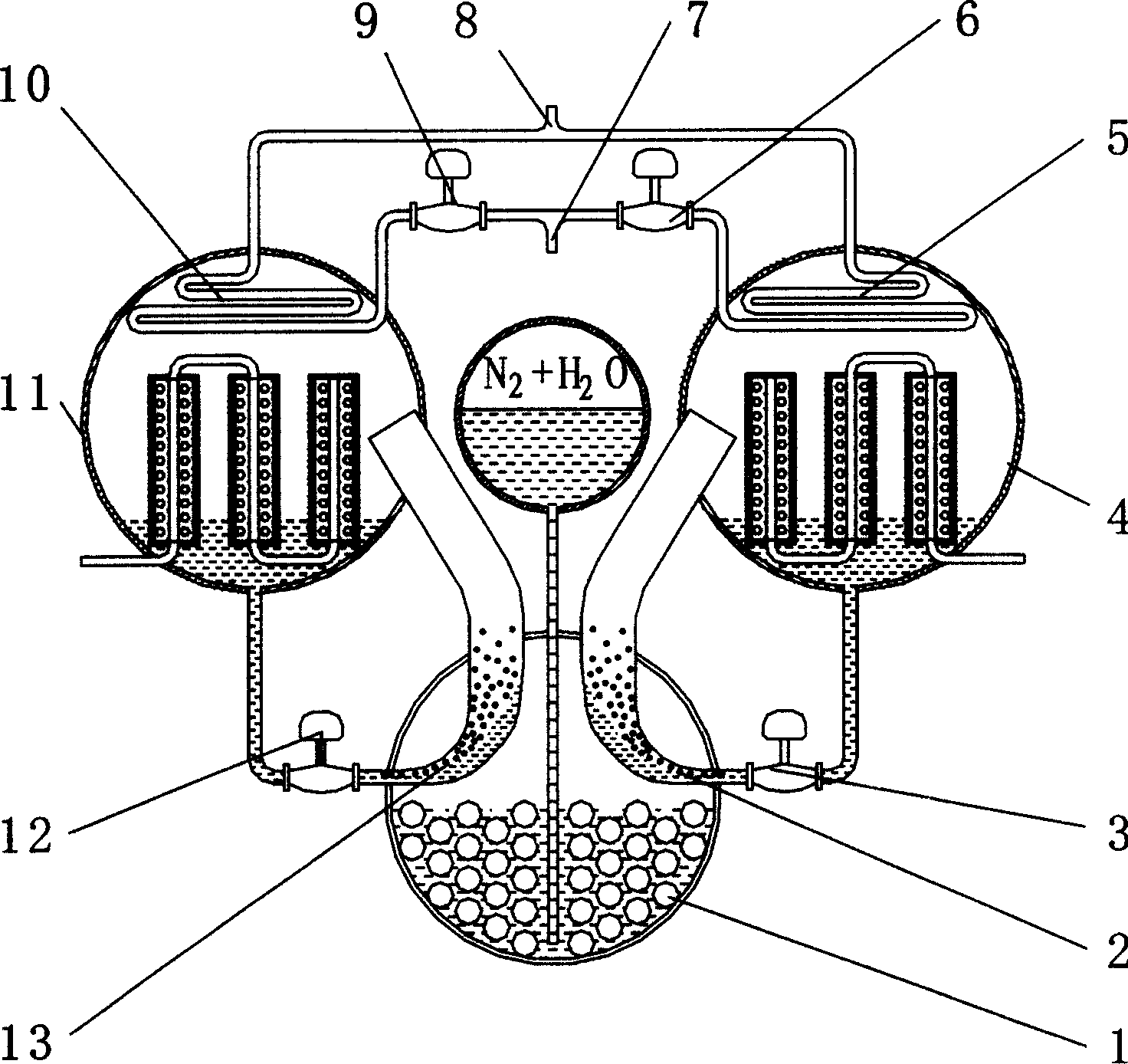

[0015] Such as figure 1 As shown, the present invention includes: flue gas heating steam boiler 1, flue gas heating pipeline 2, steam generator 3, steam regenerator / heat pipe heating section 4, heat pipe solenoid valve 5, heat pipe down section 6, heat pipe working fluid section 7. Ammonia adsorption / desorption port 8, ammonia mass transfer pipeline 9, ammonia pipeline 10, adsorption bed 11, adsorption unit tube 12, adsorbent 13, sea water condenser 14, heat pipe condensation section 15, sea water pipeline 16 , Sea water valve 17, sea water inlet 18, sea water outlet 19, pressure control air storage chamber 20. The connection method is as follows: the flue gas heating pipe 2 is located at the lower part of the flue gas heating steam boiler 1, and the inside of the pipe is filled with flue gas. The outer space of the flue gas heating pipe 2 constitutes the steam generator 3, which uses water as the medium and the steam regenerator / The lower part of the heat pipe heating section 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com