Buoy system

A buoy and buoy chamber technology, applied in the field of buoy systems, can solve the problems of unfavorable buoy integration monitoring equipment, large size of buoy module, unfavorable transportation and loading and unloading, etc., to achieve convenient transportation and loading and unloading, simplify the production process, and optimize the internal space structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

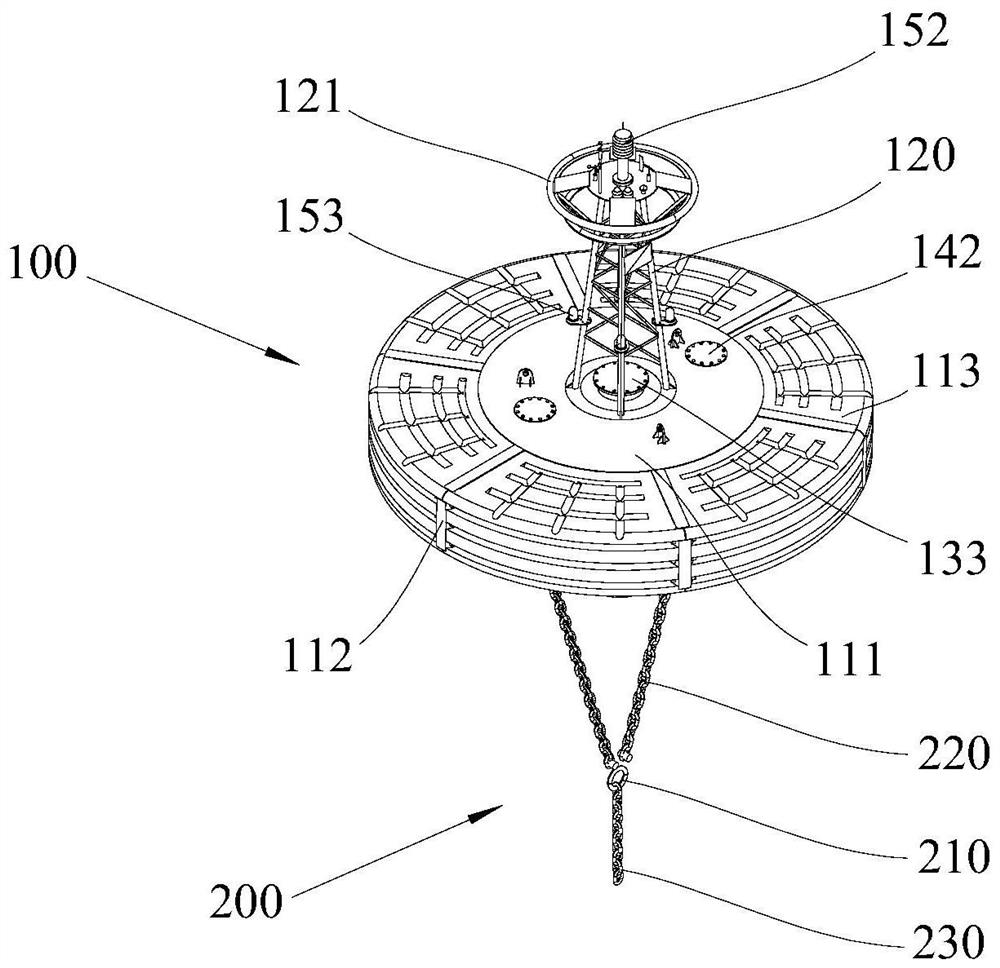

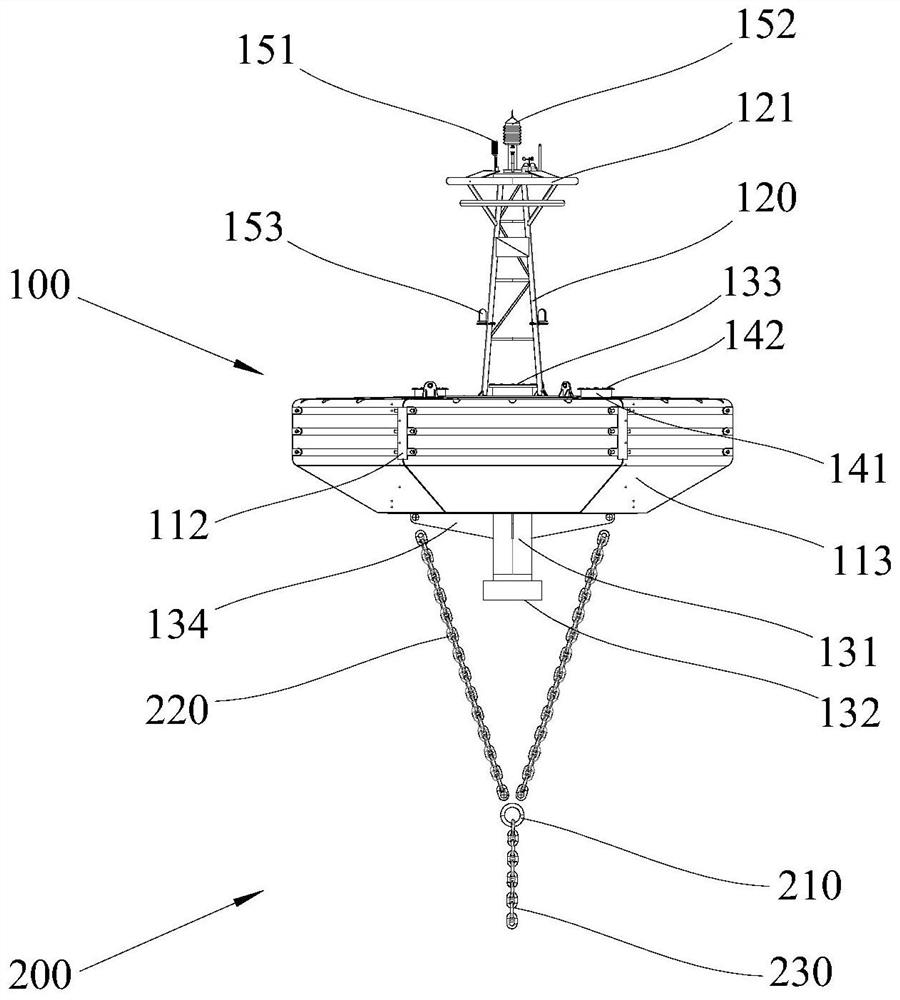

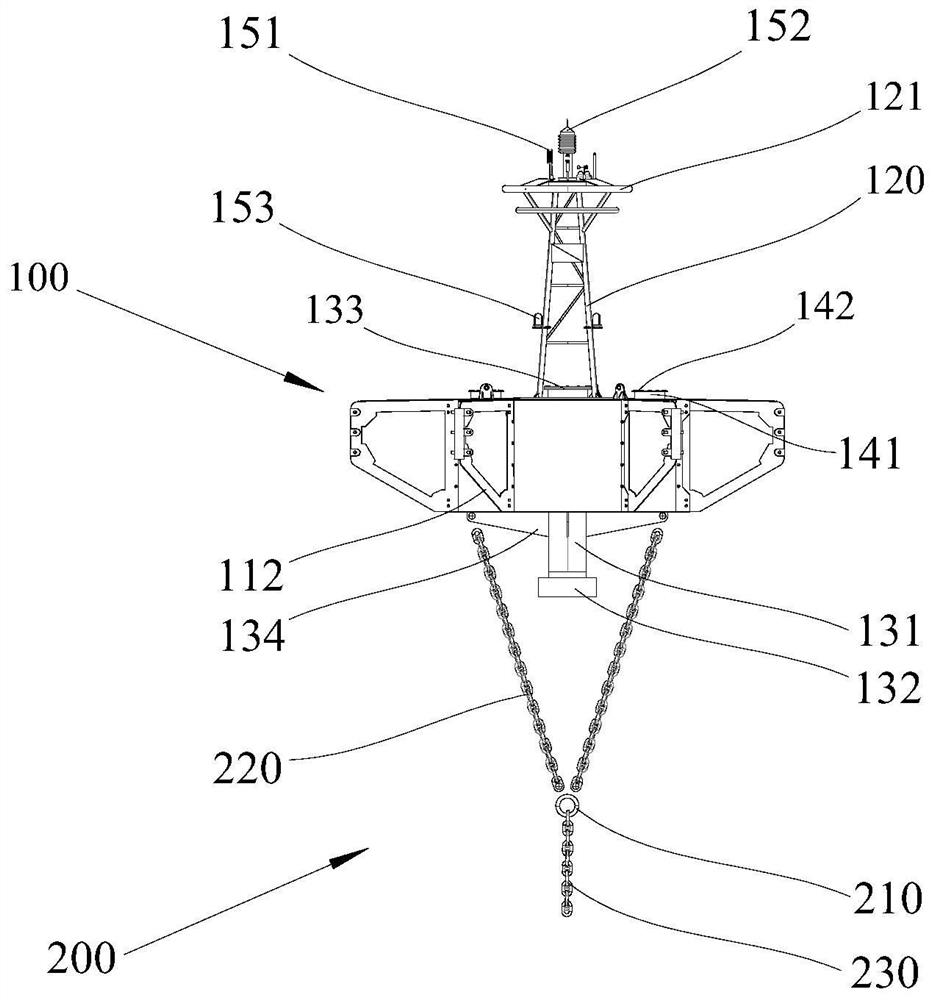

[0041] Such as Figure 1 to Figure 3 As shown, a buoy system provided in this embodiment includes a buoy body 100 and an anchoring device 200 .

[0042] The buoy body 100 includes: a main cabin 111, a mast 120, several brackets 112 and several outer wall components 113, the bottom of the main cabin 111 is provided with the mooring device 200, and the mast 120 is arranged on the main cabin 111 above, in this embodiment, the bracket 112 and the outer wall assembly 113 are made of stainless steel, as shown in the figure, the number of the bracket 112 and the outer wall assembly 113 are 6, and the bracket 112 surrounds the main cabin The body 111 is arranged on the side, and the outer wall assembly 113 is fixed on the bracket 112 through the fastener 113 on the bracket 112, and is fixed on the outer side of the main cabin body 111, and is connected with the bracket 112 and the main cabin body. The sides of 111 form a closed buoyancy chamber to provide buoyancy for the main cabin ...

Embodiment 2

[0052] The difference between this embodiment and Embodiment 1 is that the mooring device 200 chooses a mixed anchor rope structure instead of a full anchor chain structure, and one or more sections of cables are connected in the middle of the anchor chain 220, and the cables are connected to the anchor chain through a connecting member. The anchor chain 220 is connected, and the connecting member includes a cable sheath, an anti-pressure washer and at least one cable fixer. The section of the cable sheath is a curved tube, and a wear-resistant bushing and Reinforce the connecting plate, an anti-extrusion washer is arranged at the lower end of the cable sheath, a cable knot is arranged after the cable passes through the two through holes of the cable sheath and the anti-extrusion washer, and cables are fixed at intervals below the cable knot Device and cable knot, the end of cable below the last cable fixer and the cable body are provided with an end cable knot. The buoy main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com