Pneumatic conveyer

A technology of pneumatic conveying and conveying pipelines, which is applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc., which can solve the problems of difficult to meet the needs of conveying materials, unfavorable solid-gas mixture, unfavorable discharge speed, etc., and achieve high work efficiency. Efficiency, maintenance of reliability, effect of reducing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

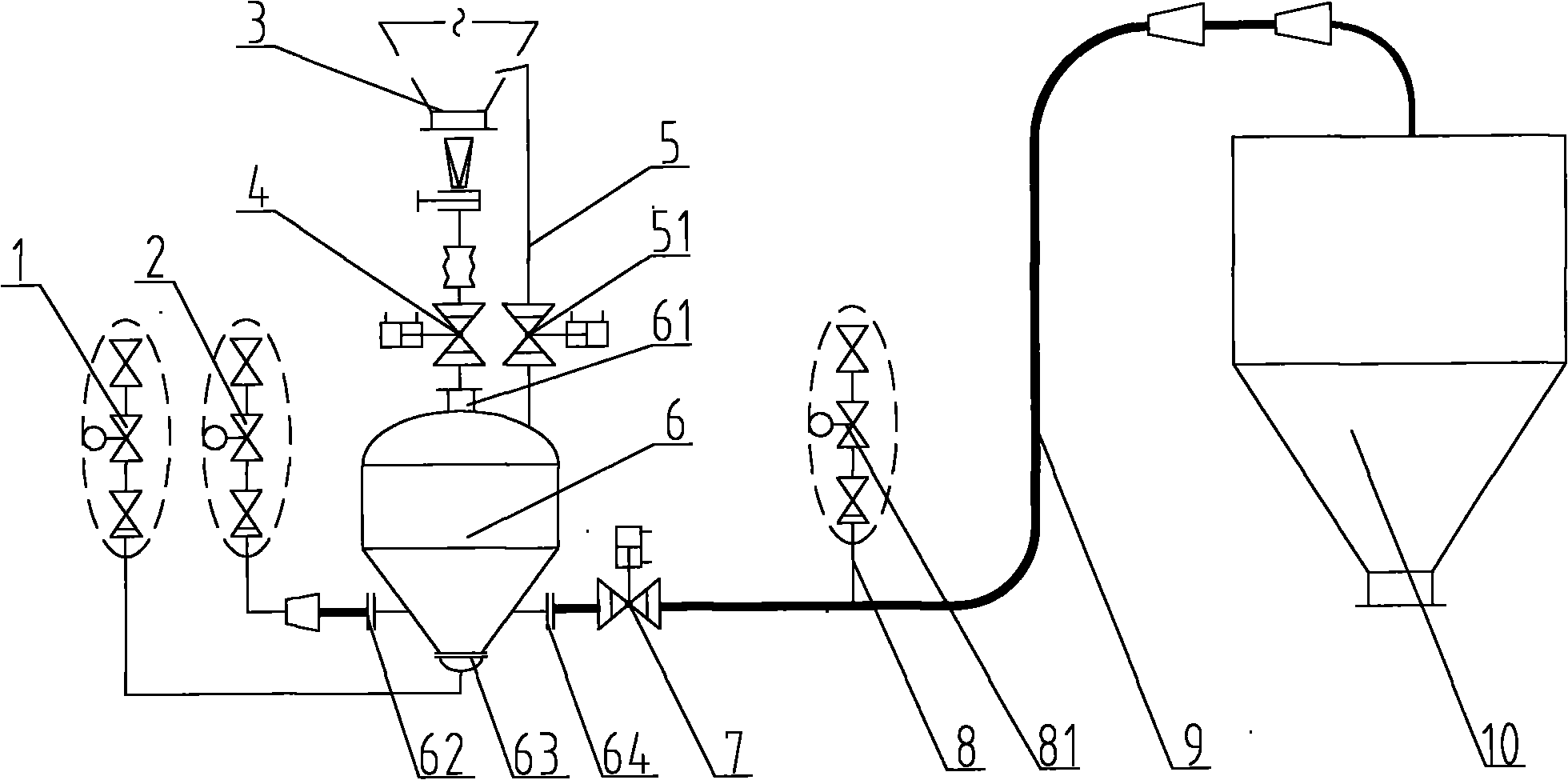

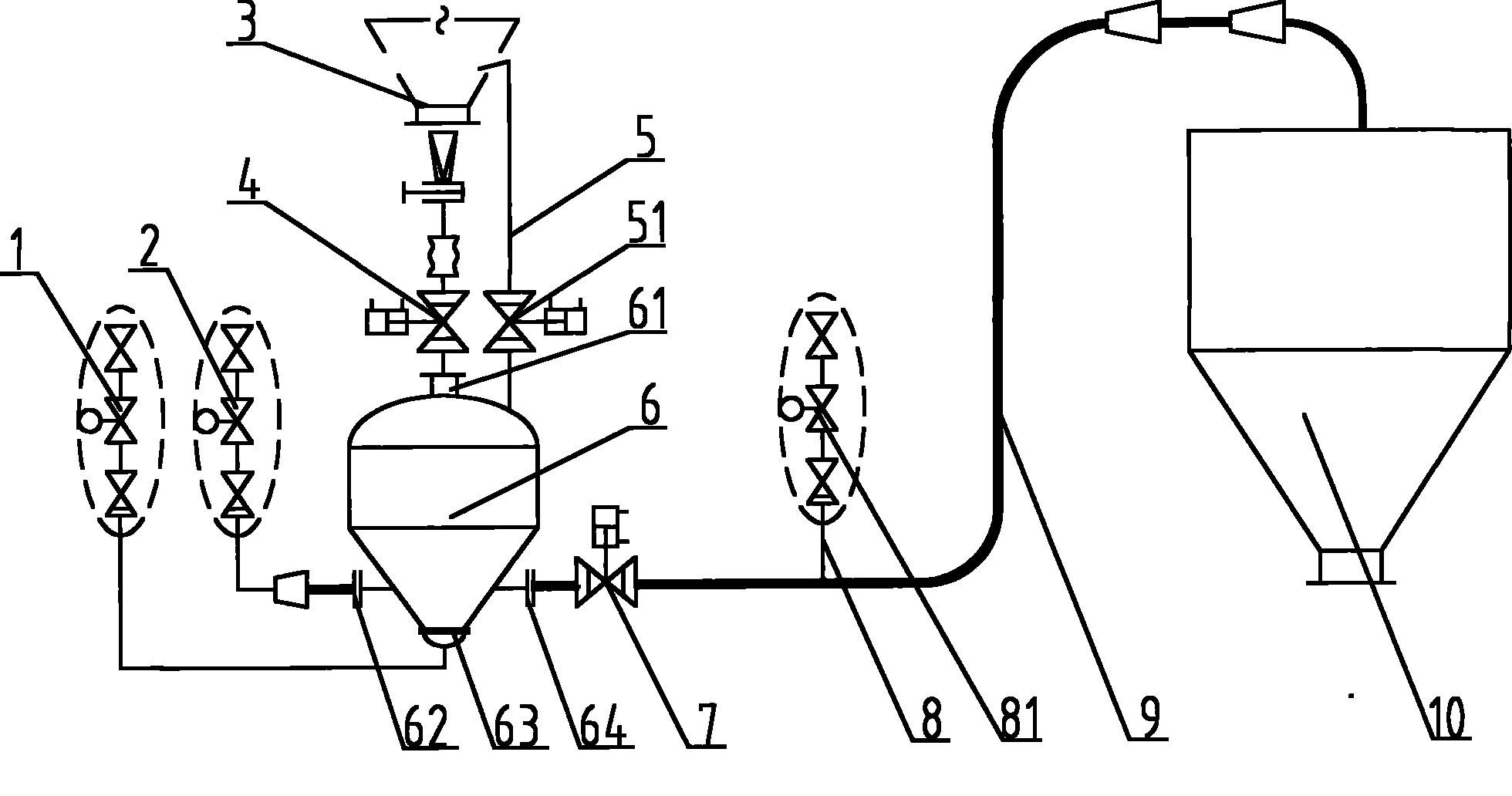

[0034] The pneumatic conveying device provided in Embodiment 1 includes a bin pump 6 , a conveying pipeline 9 and an air supply pipeline 8 . Wherein, the warehouse pump 6 has a material inlet 61 , a driving air inlet 62 , a fluidization air inlet 63 and a material outlet 64 .

[0035]The material to be transported stored in the initial bin 3 can reach the bin pump 6 through the feed port 61 . In this example, the warehouse pump 6 is located below the initial warehouse 3, and the feed port 61 is opposite to the discharge port of the initial warehouse 3, and the two are connected through the feed valve 4, and the opening and closing of the feed valve 4 can be controlled. The communication state between the initial bin 3 and the bin pump 6, so as to realize the control of the feed. The benefit of the location of the bin pump 6 below the initial bin 3 is that the material can flow into the bin pump 6 smoothly through the feed port 61 by utilizing the action of gravity. In order ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com