Patents

Literature

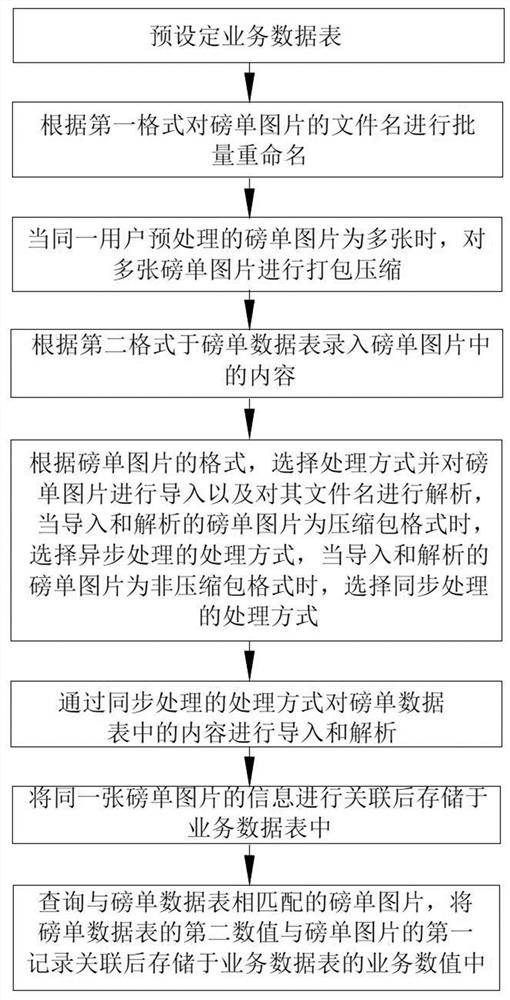

51results about How to "Pressure effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Powered watercraft

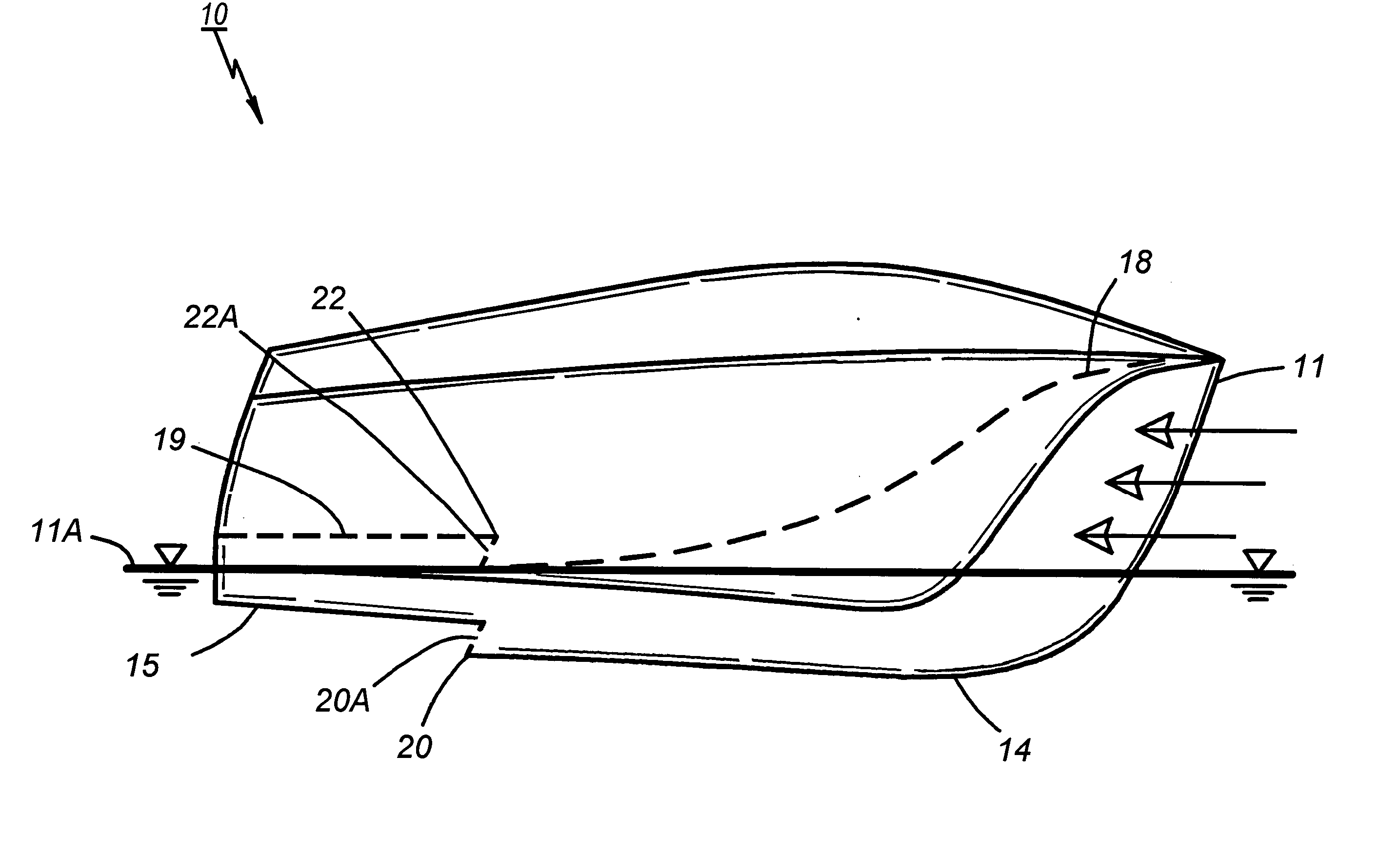

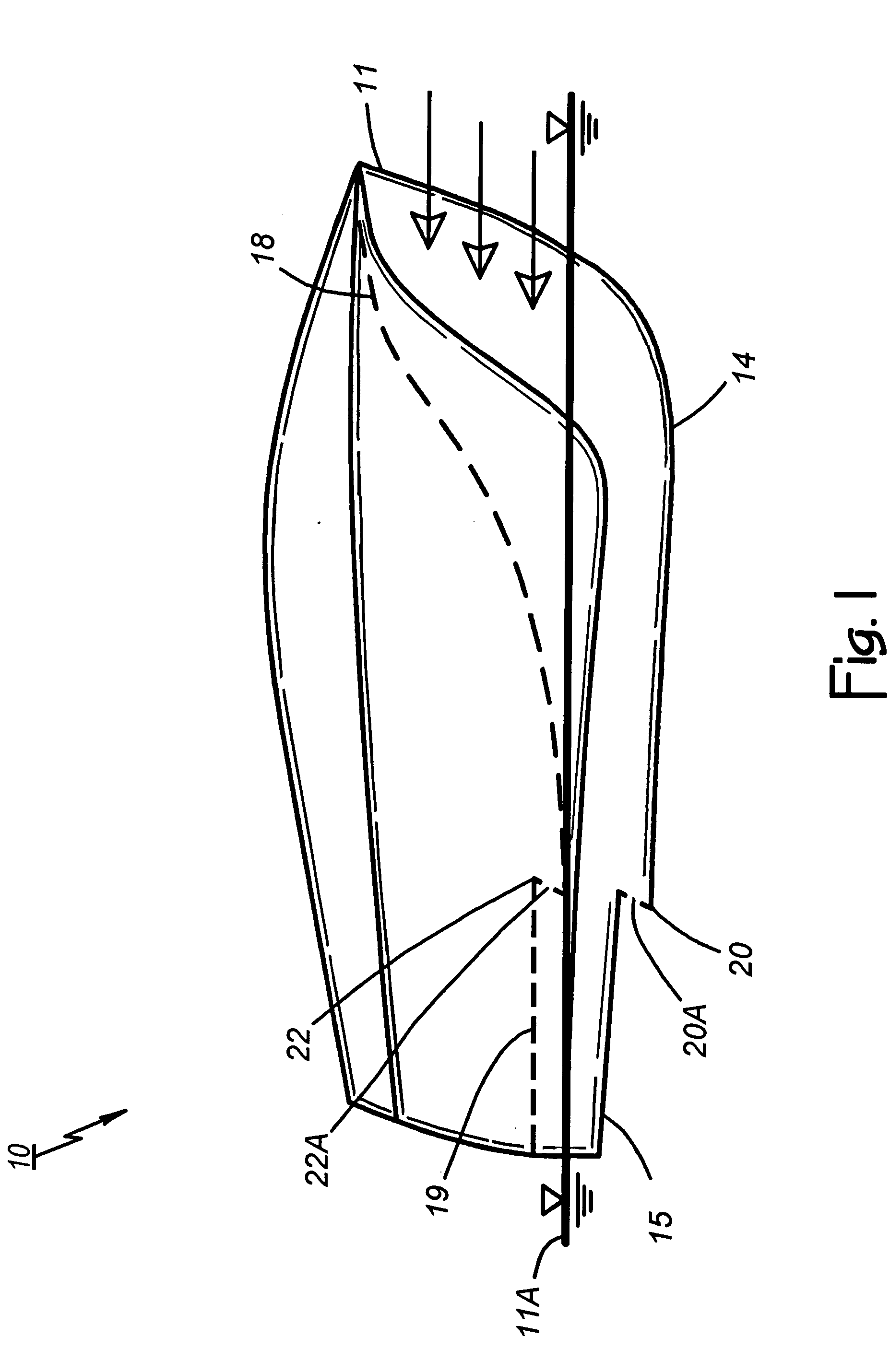

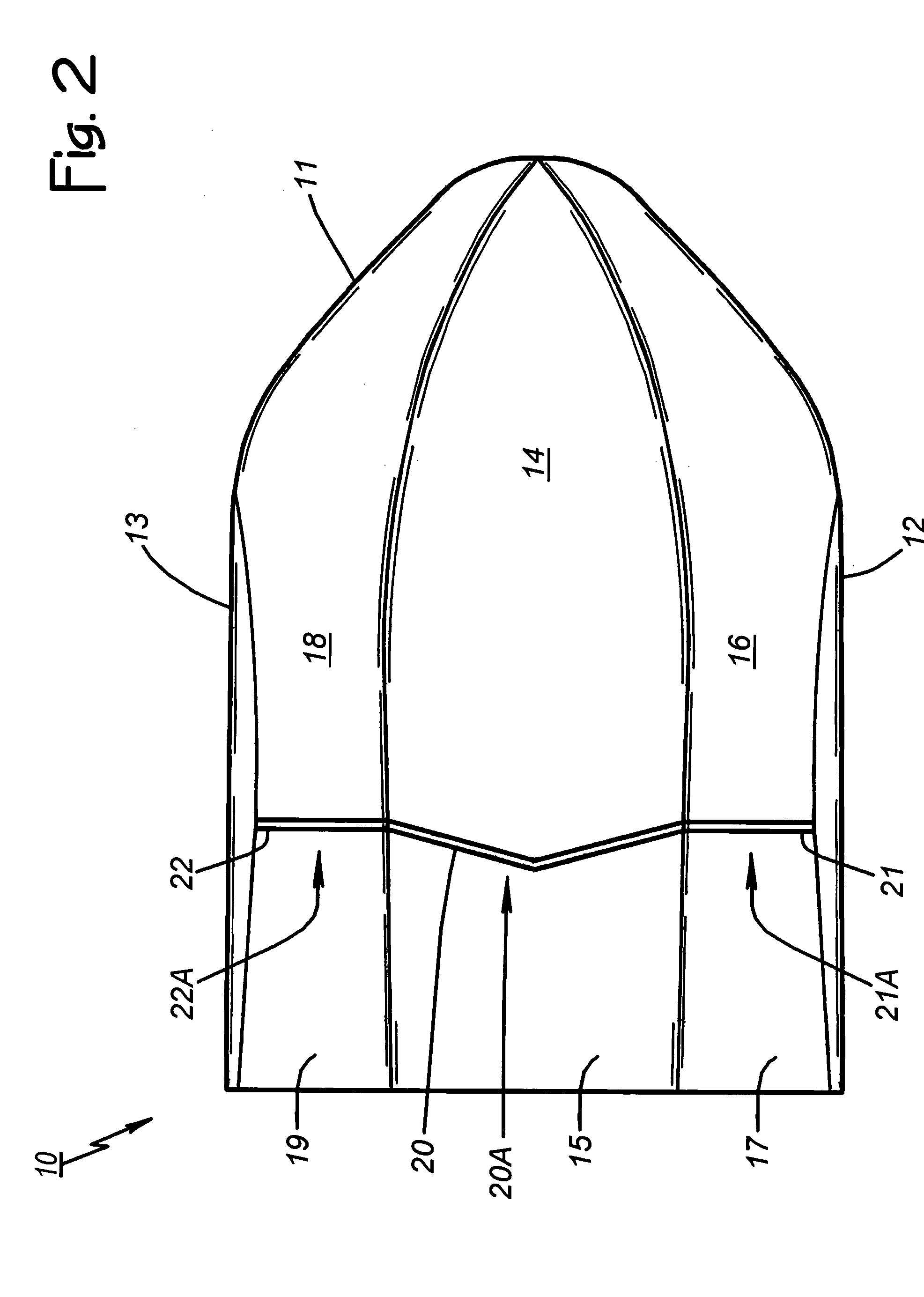

InactiveUS20050016435A1Reduce frictional resistanceReduce back pressureWatercraft hull designFloating buildingsPowered watercraft

A watercraft includes at least one hull having at least one planing surface, at least one vertical step in the planing surface, and an onboard propulsion engine. An exhaust-venting system is provided for venting exhaust from the onboard propulsion engine at the vertical step in the planing surface while under way in order to introduce gas along the planing surface. The hull of one embodiment takes the form of an M-shaped boat hull. The invention also applies to any of various other watercraft hulls, including watercraft with multiple hulls such that each of the multiple hulls includes one or more planing surfaces with one or more vertical steps at which exhaust is vented.

Owner:M SHIP

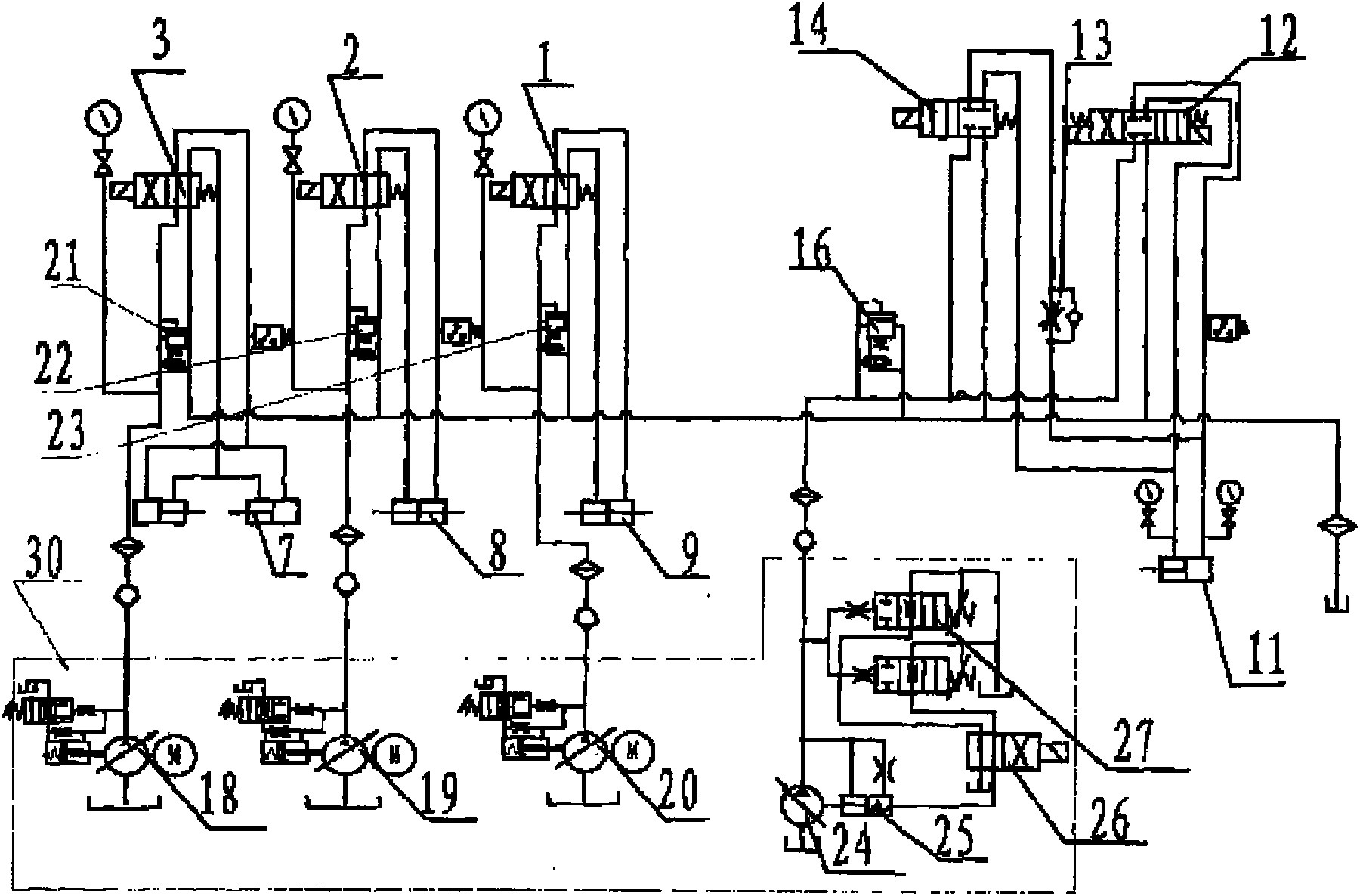

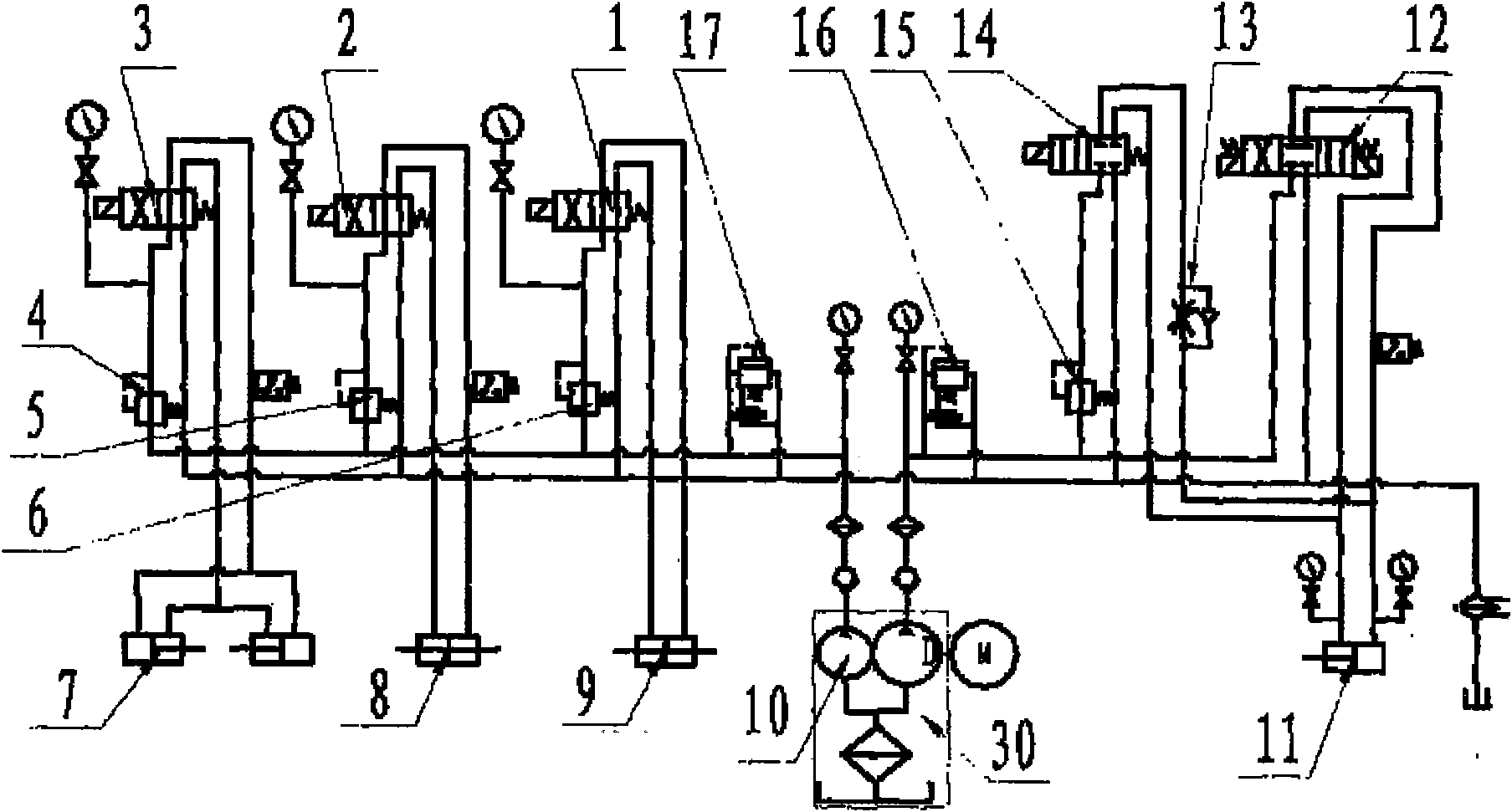

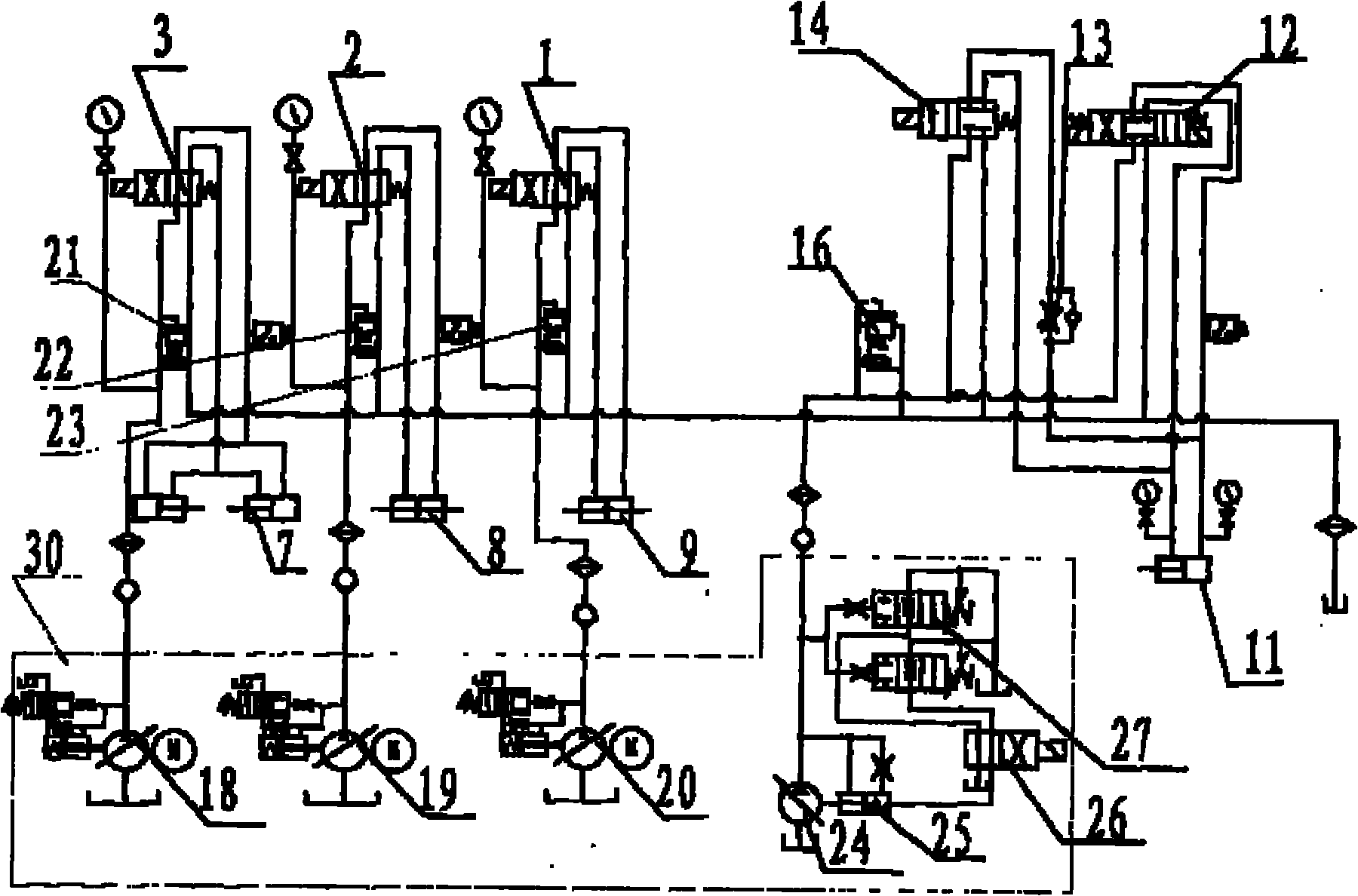

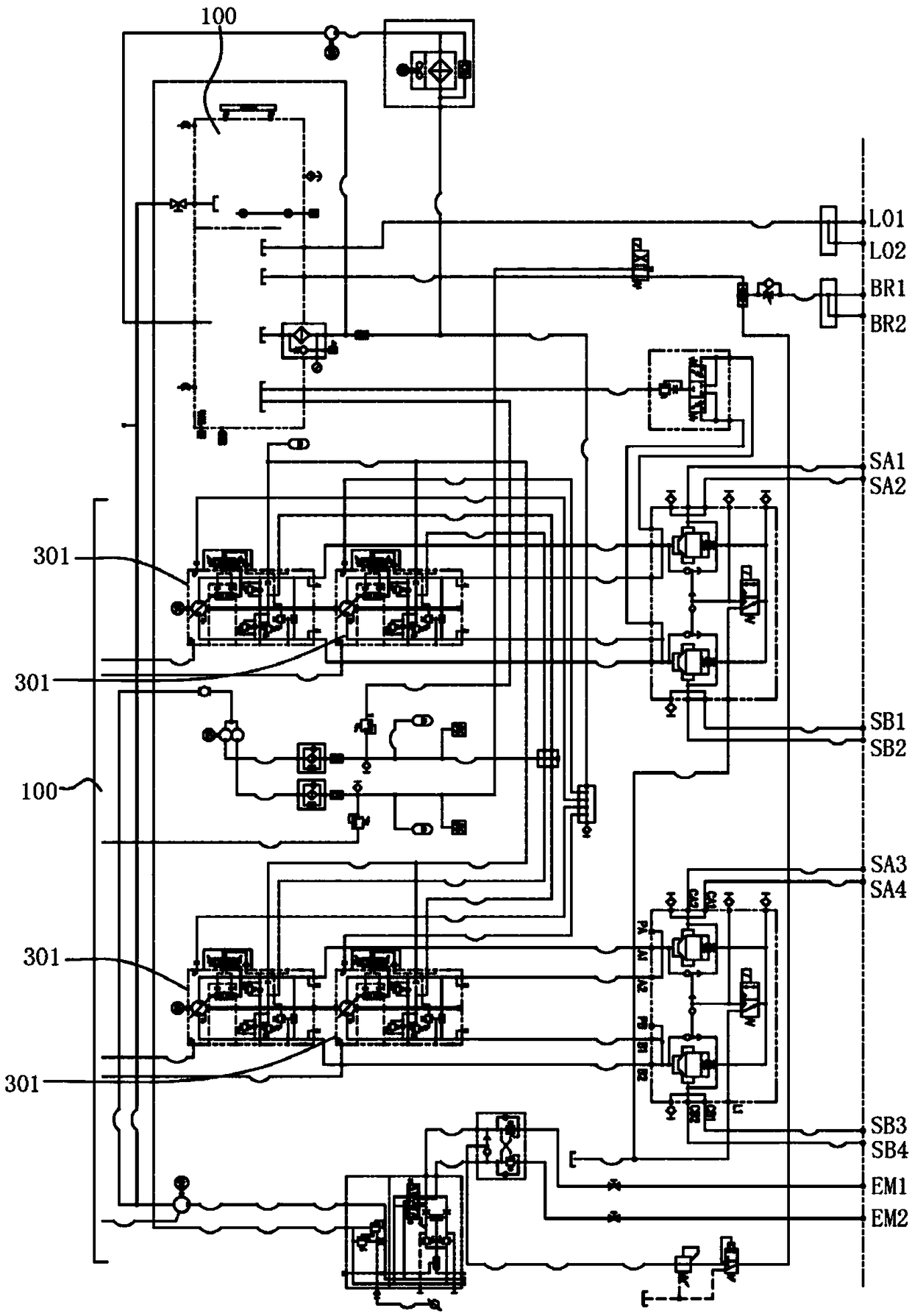

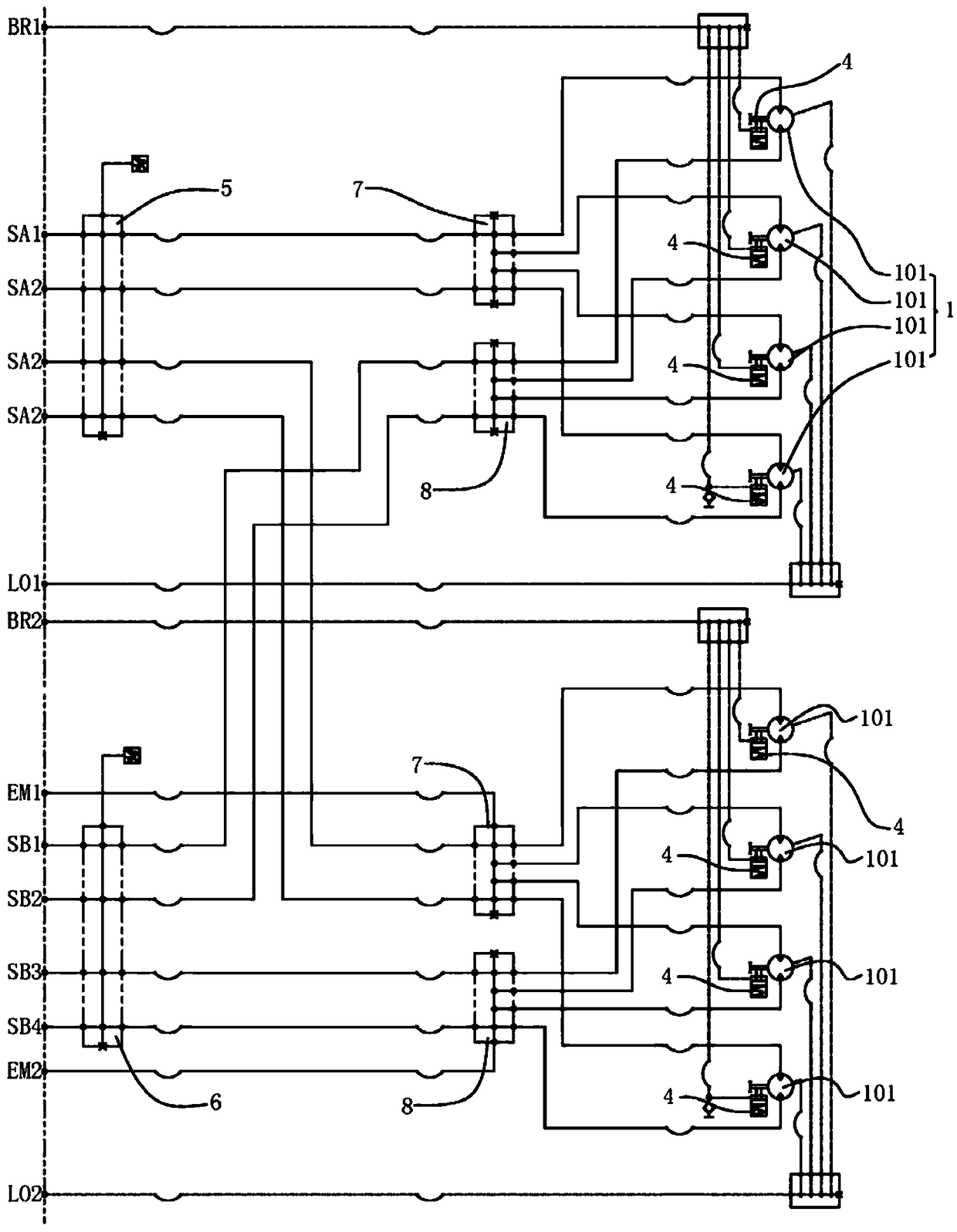

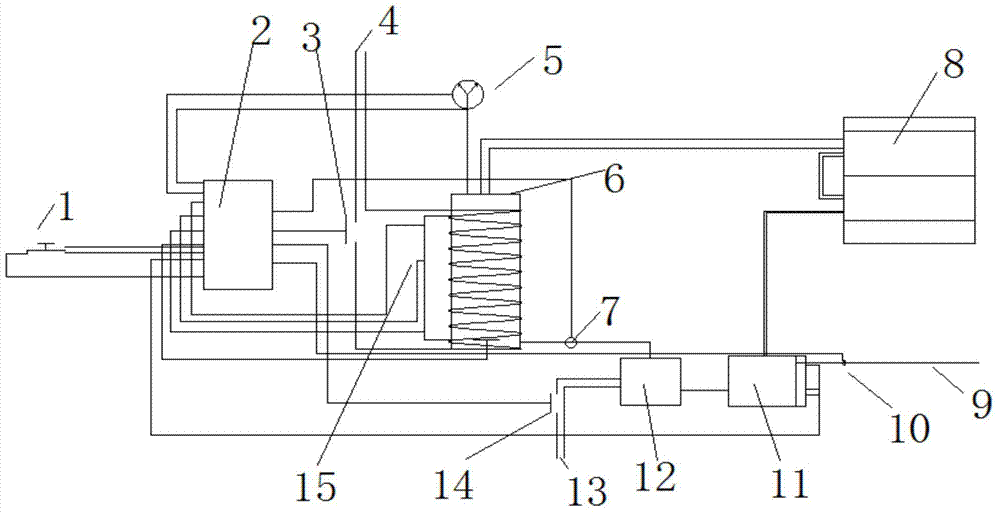

Hydraulic control system of friction welding machine

InactiveCN101934425AStable jobWork lessServomotorsNon-electric welding apparatusControl theoryRelief valve

The invention discloses a hydraulic control system of a friction welding machine, comprising a two-position four-way reversing valve, a pressure-reducing valve, an oil cylinder, a three-position four-way reversing valve, a flow speed control valve, an electromagnetic relief valve and a pump source device. The hydraulic control system of the friction welding machine is characterized in that the pump source device comprises three constant-pressure variable pumps and a two-stage constant-pressure variable pump, pressure oil needed for activating a movable clamp oil cylinder, a rotary clamp oil cylinder and a clutch brake oil cylinder is respectively provided by the three constant-pressure variable pumps, and pressure oil needed for activating a pushing oil cylinder is provided by the two-stage constant-pressure variable pump. With respect to the pump source device, the combination of the three constant-pressure variable pumps and the two-stage constant-pressure variable pump is adopted to provide system oil pressure instead of a duplex constant delivery pump so as to reduce the power consumption of the system, stabilize the oil temperature and finally enable the hydraulic control system to stably operate. By measurement, in a C450-type friction welding machine adopting the hydraulic control system, the average power consumption of a circulating hydraulic system in a friction welding process is decreased by 50 percent from 874 KJ of the prior art to 436 KJ.

Owner:SHANGHAI HUGONG ELECTRIC WELDING MACHINE MFG

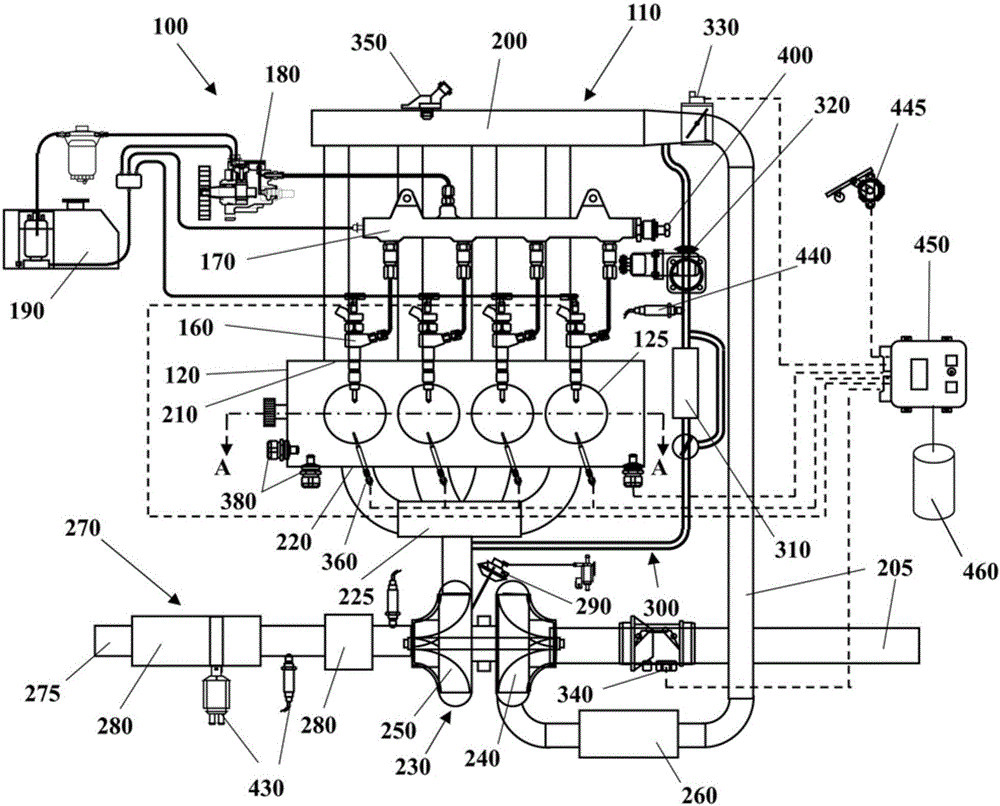

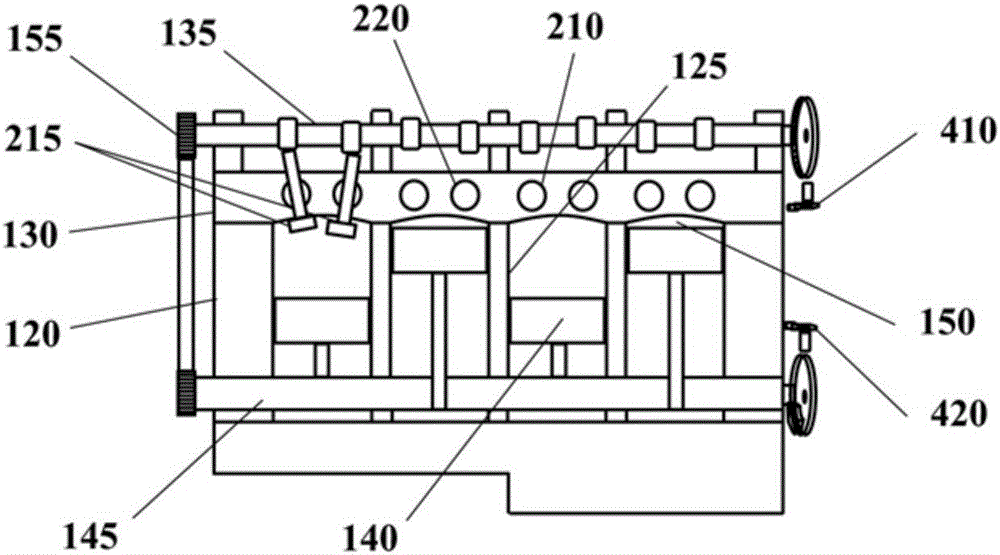

Method of operating internal combustion engine

InactiveCN105822448ACost effectiveReduce computational workloadElectrical controlFuel-injection pumpsRail pressureExternal combustion engine

Disclosed is a method of operating an internal combustion engine 110, wherein the internal combustion engine comprises a fuel rail 170 in fluid communication with a fuel pump 180 and with a fuel injector 160. The method comprises the steps of: operating the fuel injector to perform fuel injection and sampling a signal representative of a fuel pressure within the fuel rail during the fuel injection; using the pressure signal as an input of a first integral transform yielding as its output a value of a first function having as variables a fuel rail pressure drop caused by the fuel injection and a timing parameter indicative of an instant when the fuel injection started; using the pressure signal as an input of a second integral transform yielding as its output a value of a second function having as variables the fuel rail pressure drop caused by the fuel injection and the timing parameter indicative of the instant when the fuel injection started; using the value of the first function and the value of the second function to calculate a value of the fuel rail pressure drop caused by the fuel injection and a value of the timing parameter; and calculating s value of a fuel quantity injected by the fuel injection as a function of the value of the fuel rail pressure drop.

Owner:GM GLOBAL TECH OPERATIONS LLC

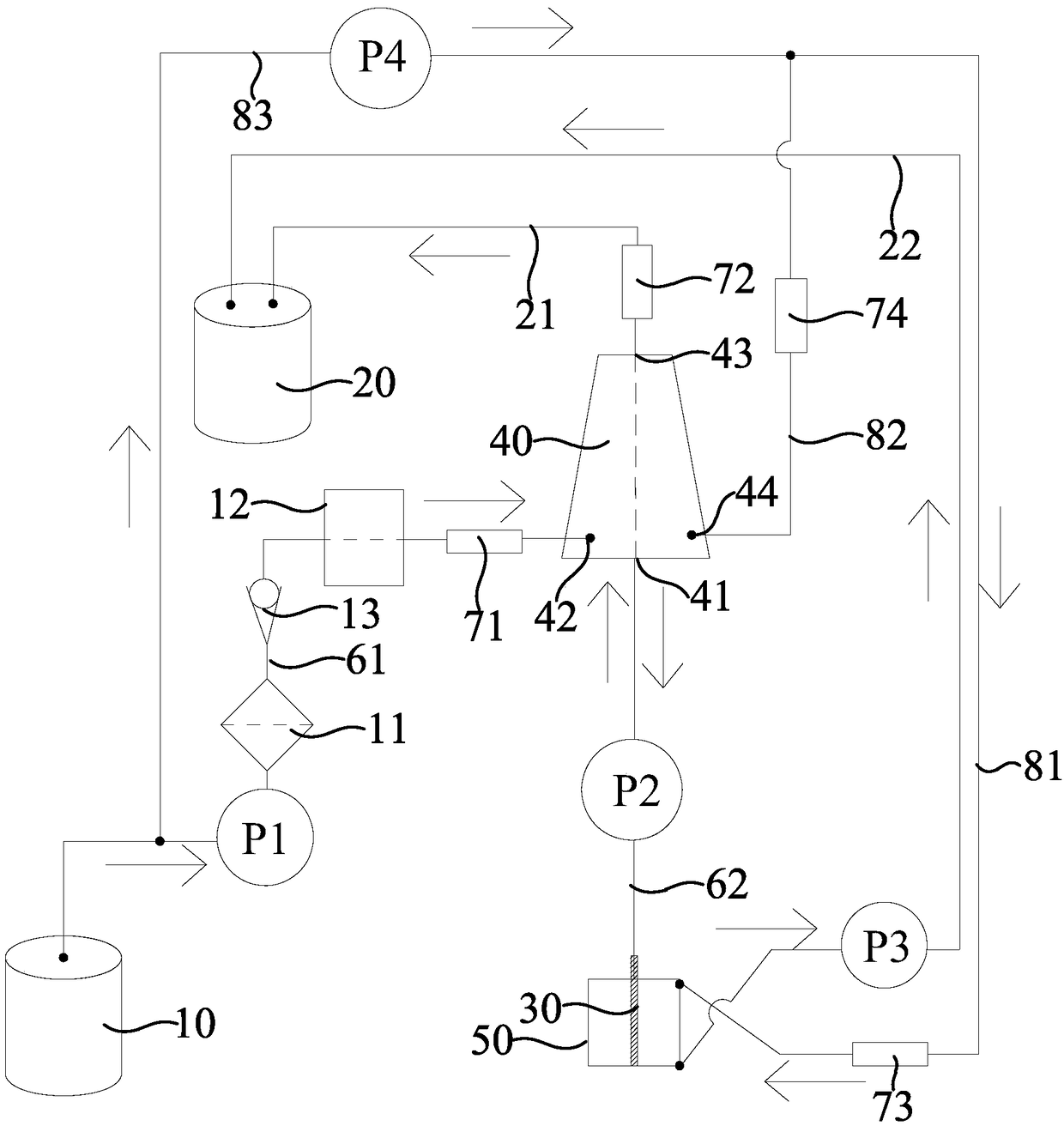

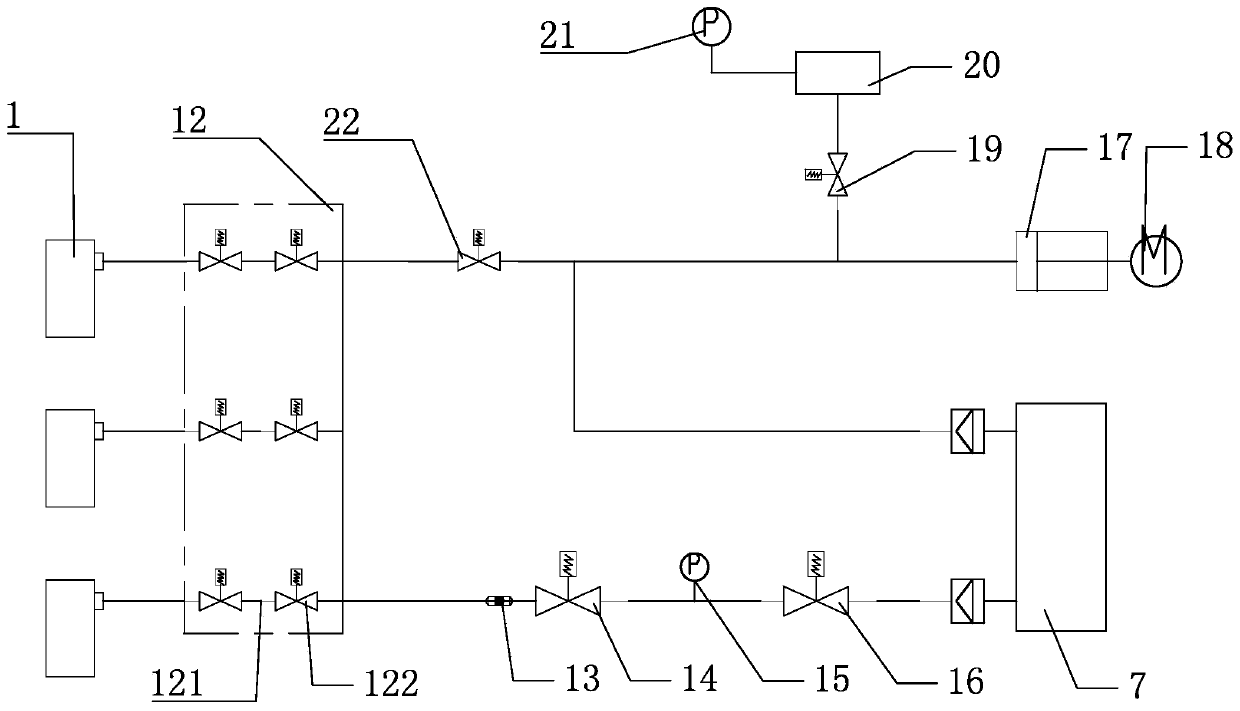

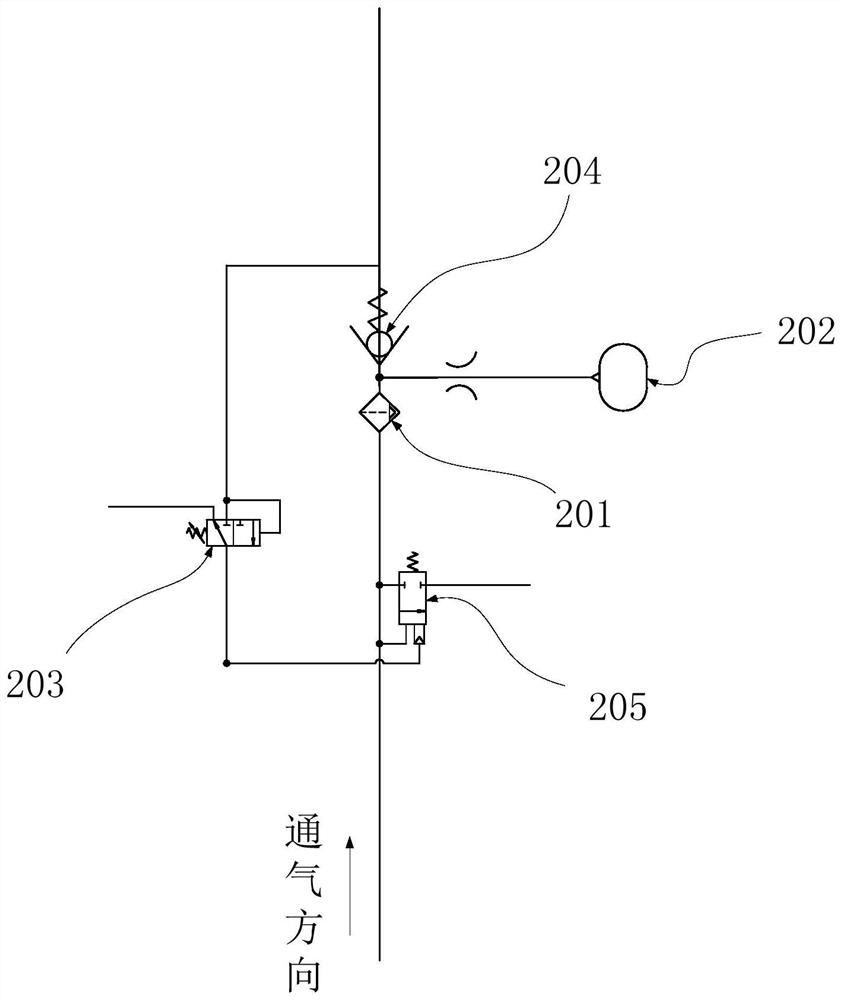

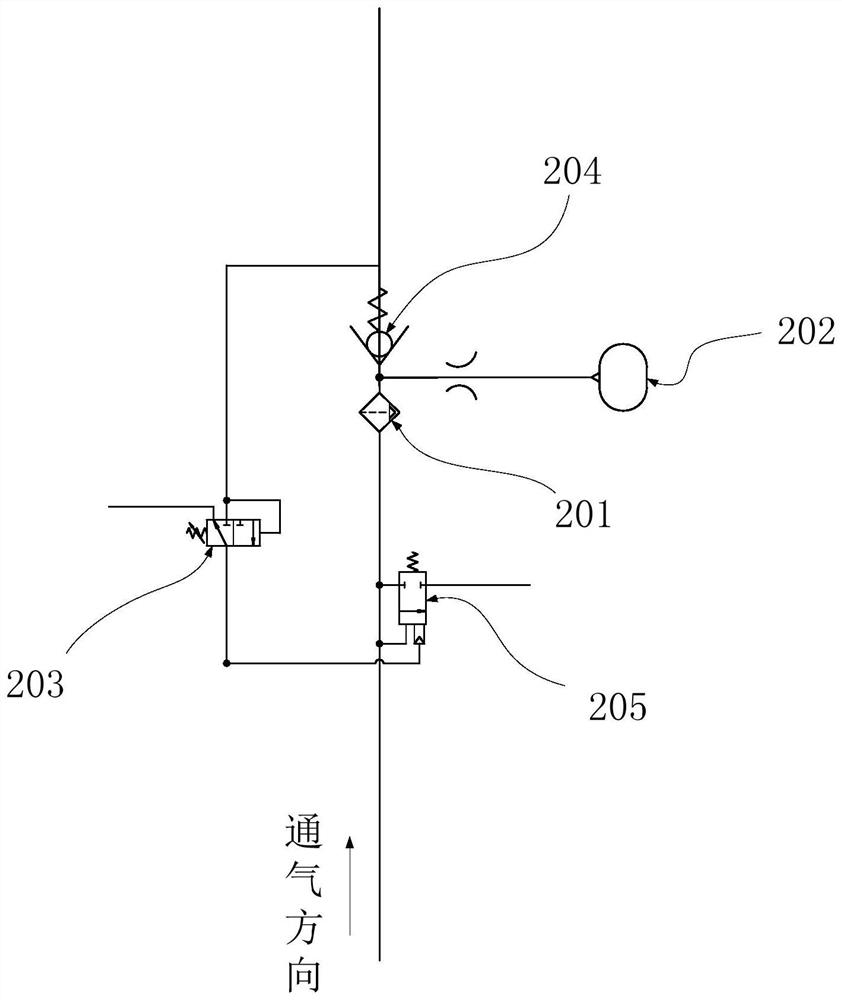

Particle analyzer as well as liquid path system and waste liquid discharging method thereof

PendingCN109444028AGuaranteed stabilityImprove stabilityIndividual particle analysisWaste managementPath system

The invention discloses a particle analyzer as well as a liquid path system and a waste liquid discharging method thereof. The liquid path system of the particle analyzer comprises a sheath liquid supply module used for supplying sheath liquid, a waste liquid receiving module used for receiving waste liquid, a sample supply module provided with a sampling needle and used for collecting and supplying samples, a flowing chamber used for flowing of the sheath liquid carrying samples, and a washing module, wherein the flowing chamber is provided with a sample inlet, a sheath liquid inlet and a waste liquid outlet; the sample inlet is communicated with the sampling needle; the sheath liquid inlet is communicated with the sheath liquid supply module; the waste liquid outlet is communicated withthe waste liquid receiving module through a first waste liquid pipe; the washing module is communicated with the sheath liquid feeding module through a first washing pipe so as to wash the outer wallof the sampling needle; the washing module is communicated with the waste liquid receiving module through a second waste liquid pipe so as to discharge the waste liquid of the washing module out of the waste liquid receiving module. The particle analyzer using the liquid path system is high in signal detection stability.

Owner:常州必达科生物科技有限公司

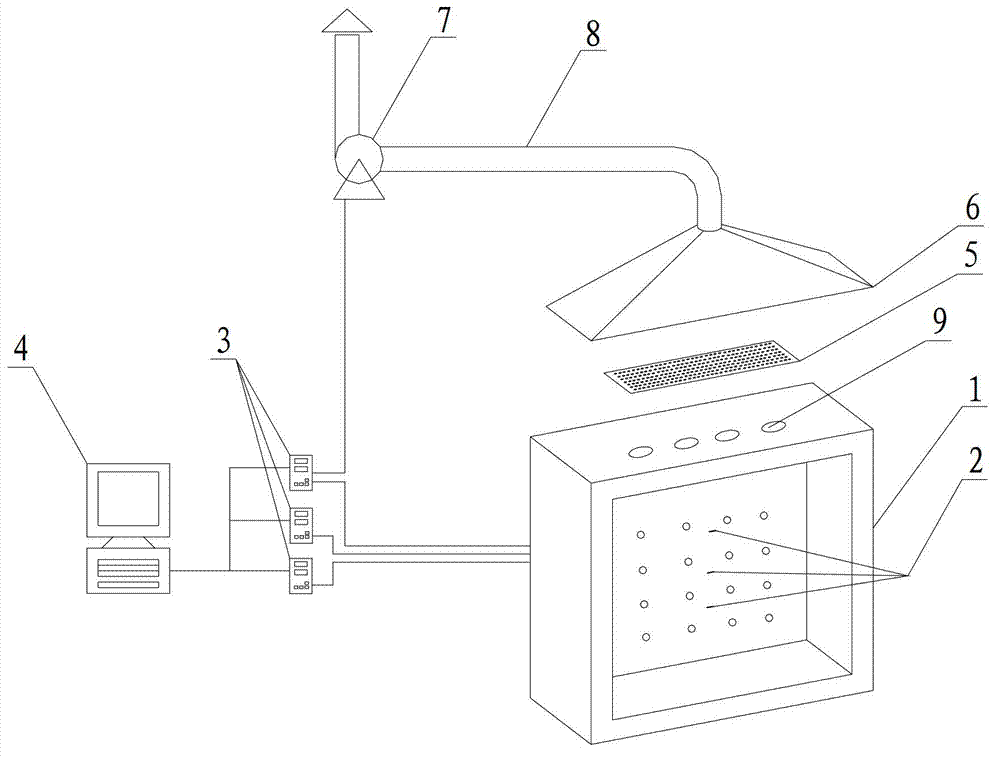

Method and device for controlling pressure in fire-resistance rating test furnace

ActiveCN102853667APressure effectReduce the immediate effects of stressFurnace typesControl devices for furnacesProportion integration differentiationEngineering

The invention discloses a method and a device for controlling the pressure in a fire-resistance rating test furnace. The device comprises the fire-resistance rating test furnace, pressure sensors, PID (proportion integration differentiation) controllers, a computer, porous smoke-discharge flow stabilization nets, a smoke collecting hood, a smoke discharge fan and a smoke discharge pipeline. According to the method, when fuel in the fire-resistance rating test furnace begins to burn, the pressure sensors in the furnace and the computer are used for sending actual in-furnace pressure data and set target pressure data to the PID controllers respectively, the PID controller is used for making comparison and analysis on the data and then sending a control instruction to the smoke discharge fan so that the rotation speed of the fan is regulated, and under the action of the smoke discharge fan, the smoke passes the test furnace, flows out of smoke discharge holes arranged at the top of the test surface, then passes the porous smoke-discharge flow stabilization nets into the smoke collecting hood and is discharged by the smoke discharge fan to a smoke treatment system. The method and the device adopt the computer and the PID controllers to control the pressure in the test furnace by changing the rotation speed of the smoke discharge fan, so that the pressure distribution in the test furnace can be controlled uniformly and stably.

Owner:广州市建筑材料工业研究所有限公司

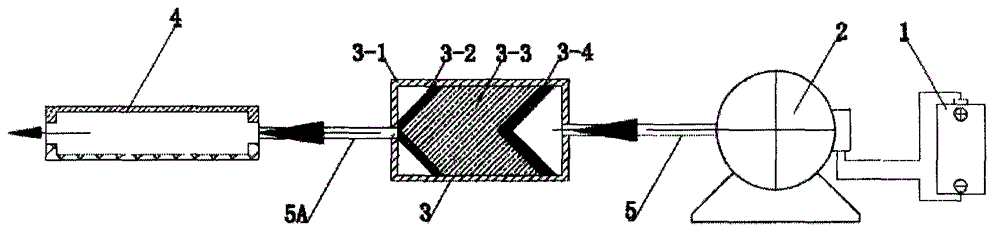

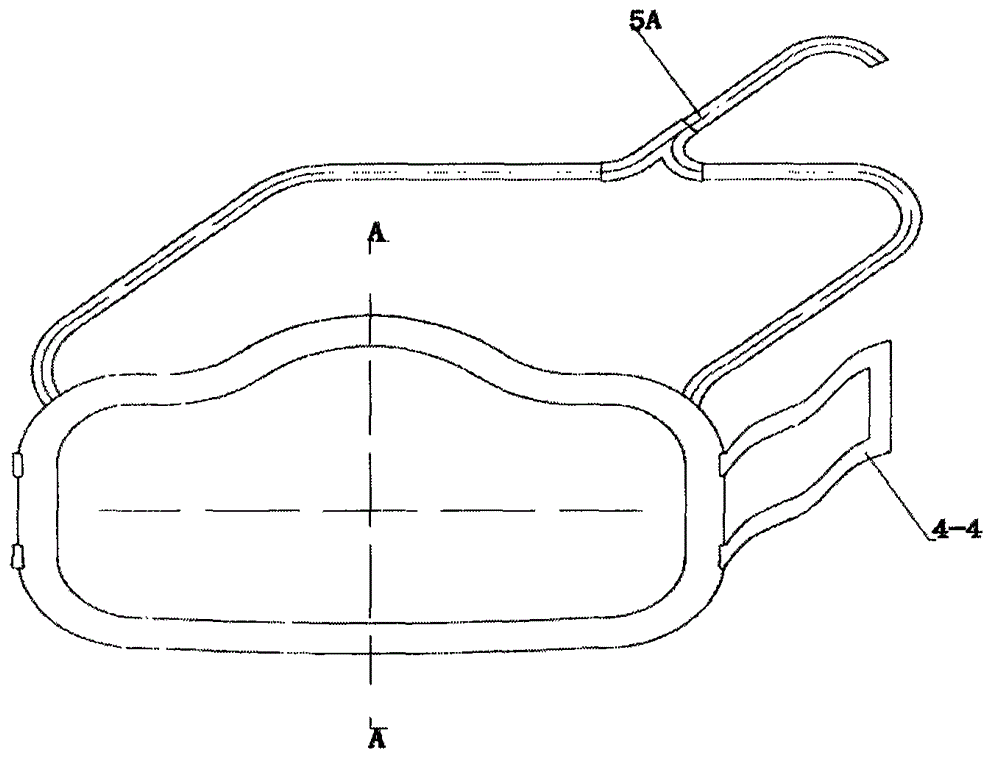

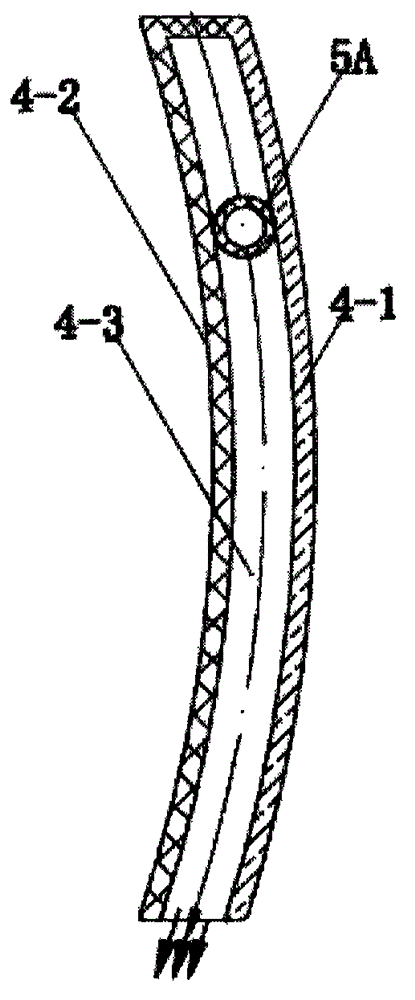

An air curtain protection mouth mask

InactiveCN105595465APressure effectReduce use costProtective garmentSpecial outerwear garmentsRespiratorAir filter

An air curtain protection mouth mask comprises a lithium ion battery (1), an air pump (2), an air filter (3), an air flow curtain face mask (4), a front end air conveying pipe (5) and a rear end air conveying pipe (5A). The air pump (2) is connected with the air filter (3) via the front end air conveying pipe (5), and the air filter (3) is connected with the air flow curtain face mask (4) via the rear end air conveying pipe (5A). An air flow curtain face mask outer side sealing isolation layer (4-1) is made of nylon taffeta fabric and an air flow curtain face mask inner side breathable isolation layer (4-2) is made of pure cotton spunlace cloth; a cavity air duct (4-3) is between the air flow curtain face mask outer side sealing isolation layer (4-1) and the air flow curtain face mask inner side breathable isolation layer (4-2). Clean air filtered by the air filter (3) exchanges with exhaled air in the cavity air duct (4-3). The air flow curtain face mask can reduce carbon dioxide reinhalation during breathing of people.

Owner:王翊臻

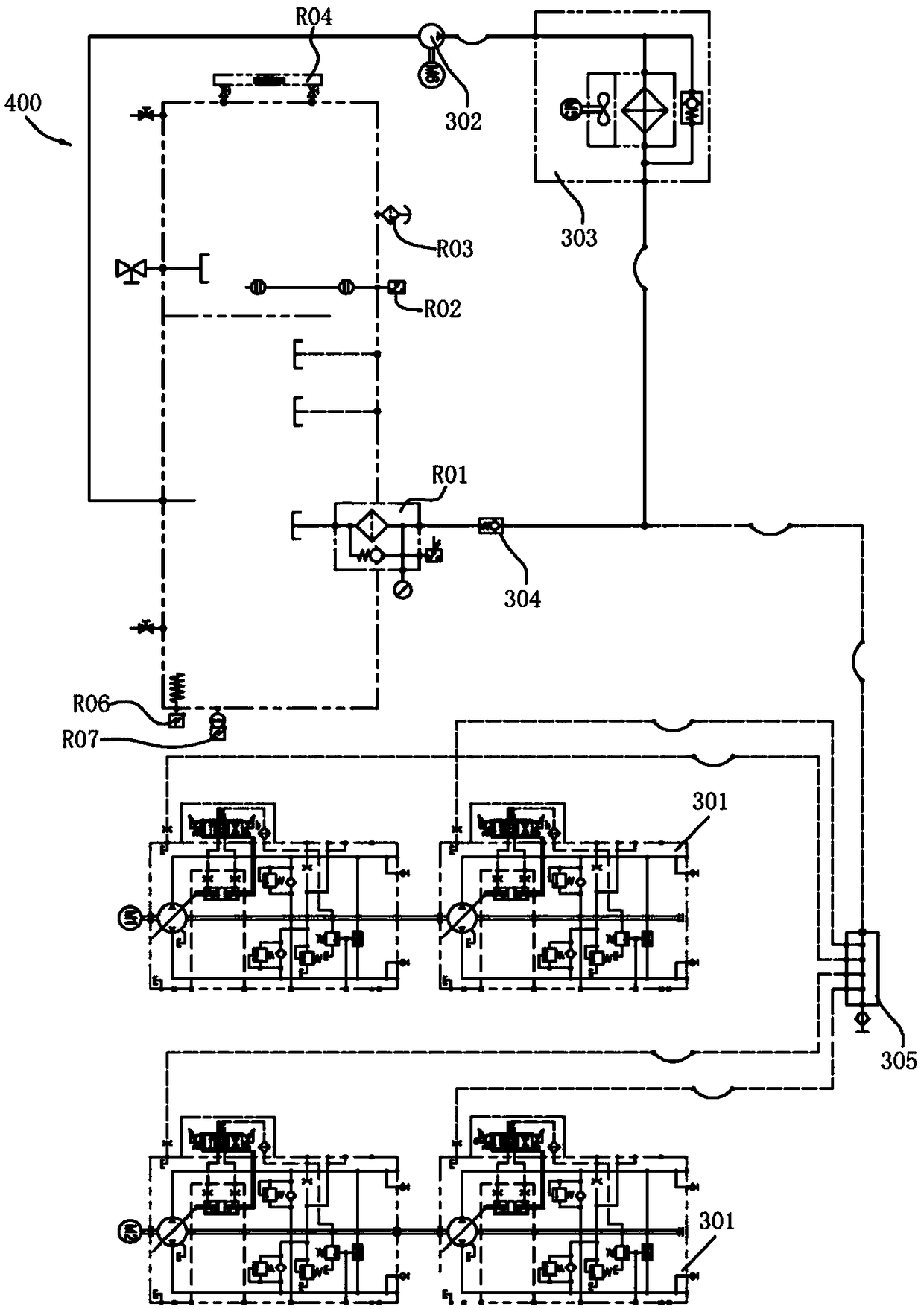

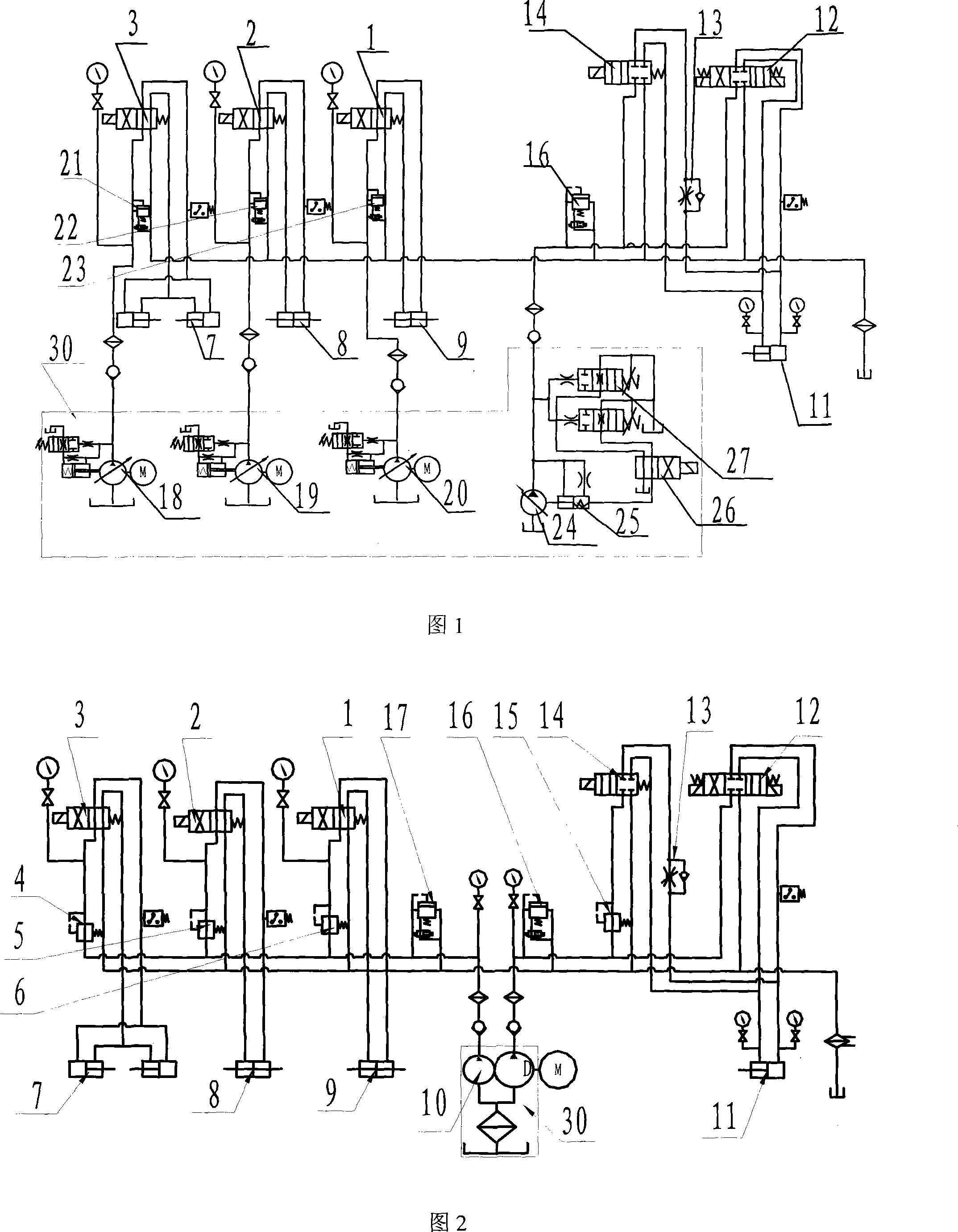

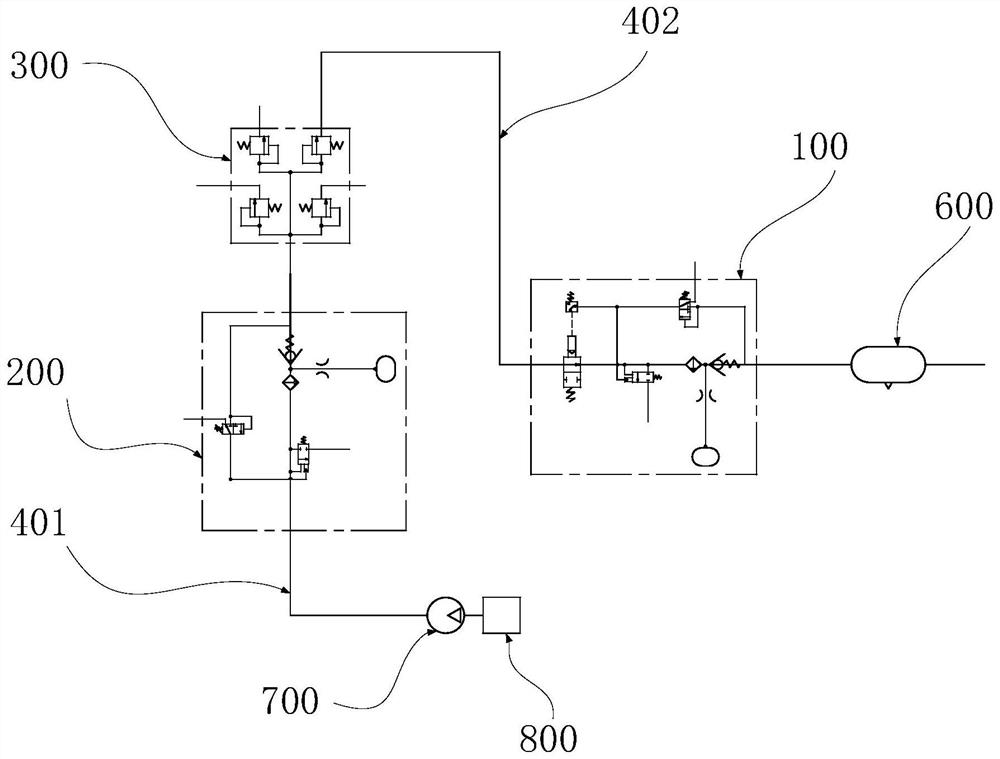

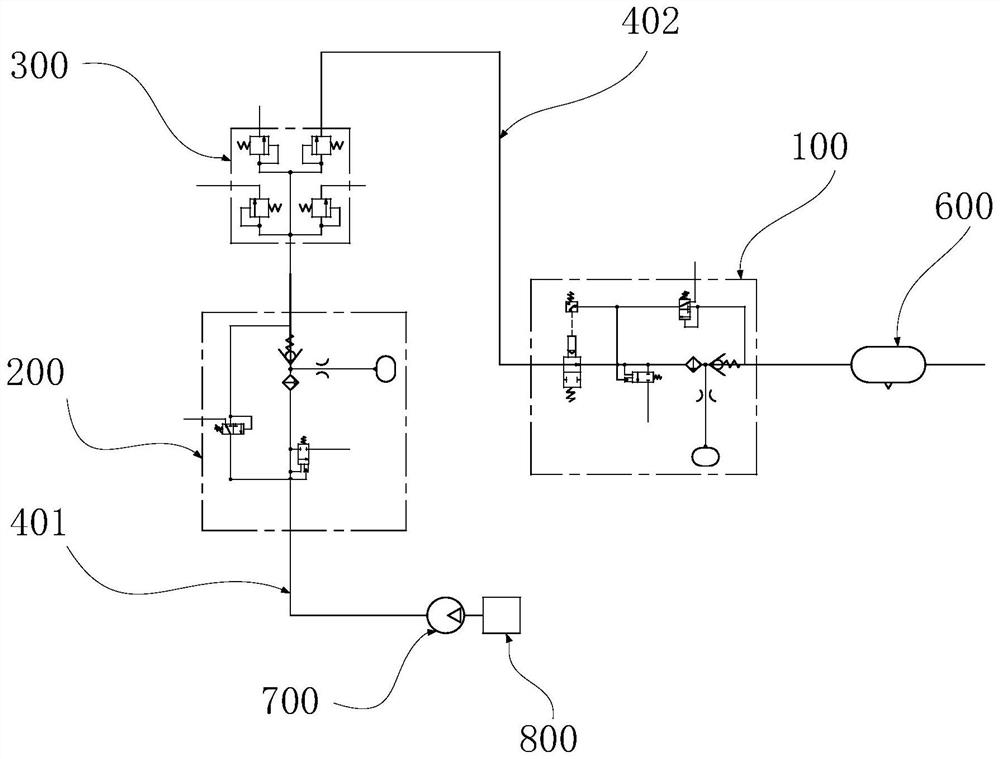

Hydraulic system of crane and working method

PendingCN109292630AGuaranteed to workPressure effectFluid-pressure actuator safetyServomotor componentsFuel tankHydraulic pump

The invention relates to a crane, and particularly relates to a hydraulic system of a crane for vessel operation and a working method. The hydraulic system of the crane comprises a fuel tank, a gyrating system for driving a gyrating platform, a brake system, a cooling system for decreasing the oil temperature, an oil supplementing system for supplementing oil, and an emergency gyrating system which is started in case of fault. According to the hydraulic system of the crane and the working method, the gyrating system is a closed hydraulic system, so that the energy utilization rate is high; theoil supplementing system is arranged and used for supplementing consumed hydraulic oil of the closed hydraulic system; a brake shuttle valve is arranged in the brake system; a normal brake system isconnected to a brake oil channel of a hydraulic emergency system, thus realizing a two-input and one-output brake system, and as a result, the safety is improved; the cooling system is arranged and used for cooling a hydraulic pump set, so that the probability of failure of the hydraulic pump set can be reduced; and the hydraulic emergency system is provided, so that the safety of the crane is improved.

Owner:SOUTH CHINA MARINE MACHINERY

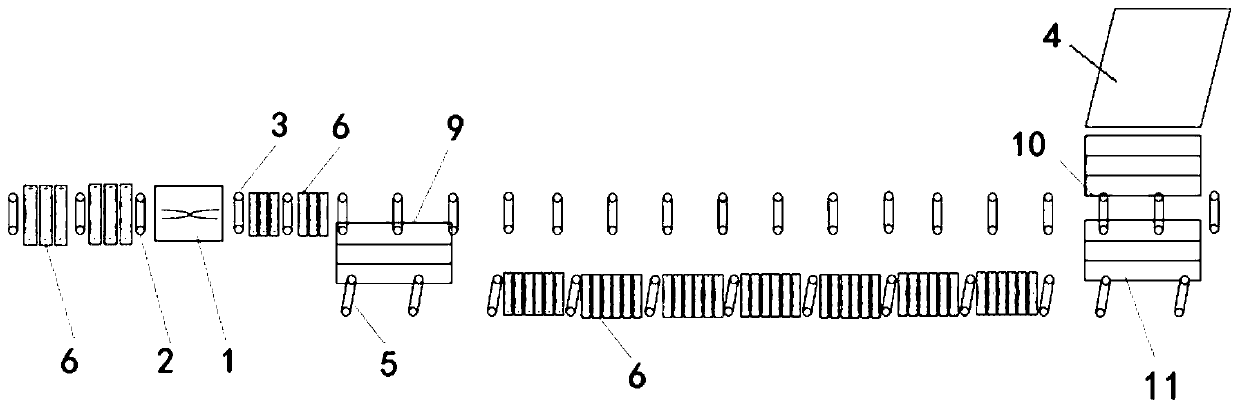

Hot rolled seamless steel pipe on-line cooling system and arrangement method of cooling device on hot rolled seamless steel pipe on-line cooling system

PendingCN111589885ARealize online regulationReduce waiting timeWork cooling devicesMetal rolling arrangementsProduction lineThermodynamics

The invention discloses a hot rolled seamless steel pipe on-line cooling system and an arrangement method of a cooling device on the hot rolled seamless steel pipe on-line cooling system. The main purpose is to improve the production efficiency and comprehensive performance of a hot rolled seamless steel pipe. According to the main technical scheme, the production line comprises a sizing front roller table and a sizing back roller table located before and after a sizing machine separately, a cooling roller table and a cooling device located between a cooling bed and the sizing machine; the cooling device is arranged at the sizing front roller table position; and / or the cooling device is arranged at the sizing back roller table position; and / or the cooling device is arranged at the coolingroller table position; the cooling device comprises a plurality of cooling sprinkler rings arranged along the conveying direction of the roller tables, water inlets are formed in the outer surfaces ofthe cooling sprinkler rings, the water inlets communicate with flow dividing water collecting pipes through water supply pipelines and regulating valve groups, the flow dividing water collecting pipes are arranged parallel to the cooling device, and the length of the water dividing collecting pipe is longer than the length of the cooling device; and water outlets are formed in the inner wall of the cooling sprinkler rings, ring partitions are arranged in the cooling sprinkler rings, and flow holes are formed in the ring partitions.

Owner:NORTHEASTERN UNIV

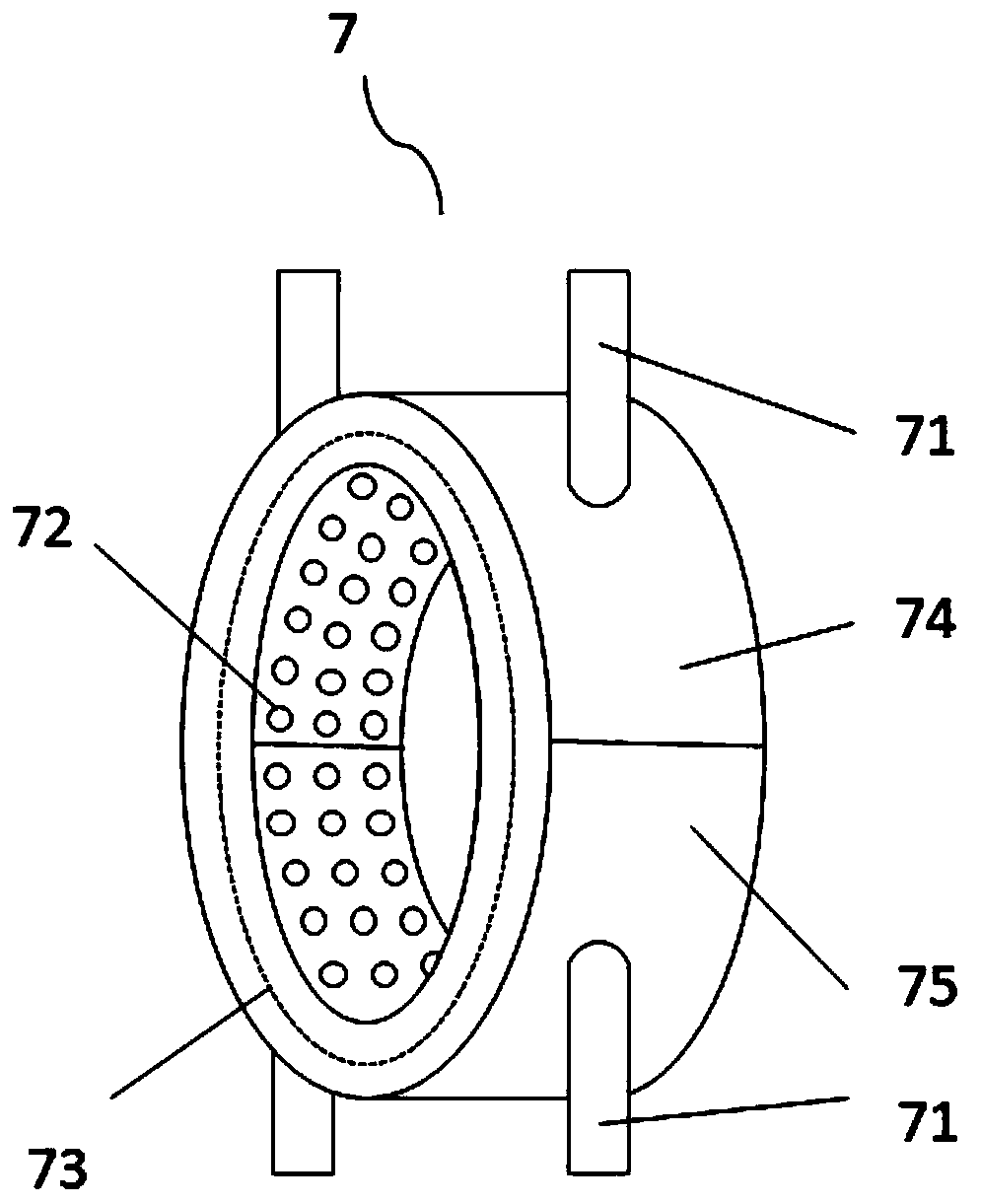

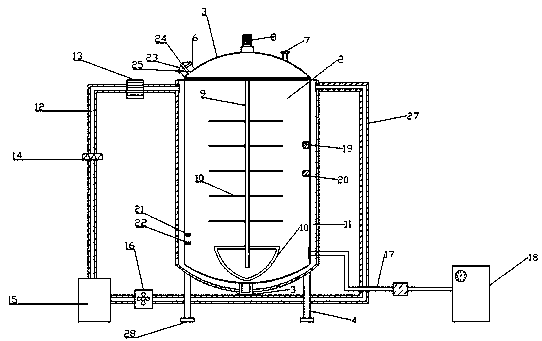

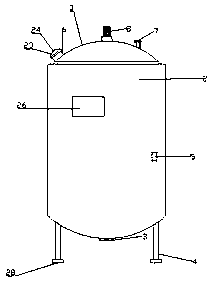

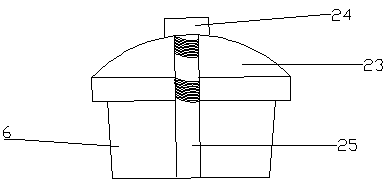

Microbial fermentation tank for production

InactiveCN109294904AReal-time monitoring of culture conditionsAvoid affecting monitoring dataBioreactor/fermenter combinationsBiological substance pretreatmentsWater bathsCoupling

The invention provides a microbial fermentation tank for production. The microbial fermentation tank for production comprises a tank body, a sealed tank cover, support legs and a controller, a stirring motor is arranged at the middle position of the sealed tank cover, the output shaft of the stirring motor is fixedly connected with a stirring shaft through a shaft coupling, one side of the stirring shaft extends into the tank body, the stirring shaft is fixedly provided with stirring paddles, a water bath constant-temperature room is arranged outside the tank body, one side of the upper end ofthe water bath constant-temperature room is connected with a water conveying tube, is sequentially connected with a water pump, a heater, a circulating water tank and a refrigerator through the waterconveying tube, and is connected to the other side of the upper end of the water bath constant-temperature room through the water conveying tube, one side of the lower end of the tank body is connected with an oxygen generator through a gas conveying tube, and a temperature sensor, a pressure sensor, a dissolved oxygen electrode and a pH electrode are arranged in the tank body. The microbial fermentation tank can effectively control the temperature, the pressure, the pH value and the dissolved oxygen content in the fermentation tank while stirring uniformly, and has a high practicability.

Owner:HEFEI KANGZHIHENG MACHINERY TECH CO LTD

Electromagnetic induction heating apparatus for corrugated paper and application method of electromagnetic induction heating apparatus

InactiveCN103938481APressure effectStable temperatureDryer sectionInduction heating apparatusControl systemEngineering

The invention discloses electromagnetic induction heating apparatus for corrugated paper and an application method of the electromagnetic induction heating apparatus, and belongs to the field of electrical heating technique. The electromagnetic induction heating apparatus comprises a heating system, and further comprises a control system, a pressure sensor, a radiator set, a water supplement pipe, a water return system, a water supply system and a water level sensor. The heating system is formed by a heating coil and a heating cylinder, the heating cylinder is wound by the heating coil, the top of the heating cylinder is communicated with one end of the radiator set through a pipeline, and the other end of the radiator set is sequentially communicated with the water return system, the water supply system and the bottom of the heating cylinder through pipelines. The heating system can be made in the mode that the size is small and the starting speed is high so that the heating system can be convenient to operate and easy to control, all the components can be adjusted and controlled through a control device, the temperature is stable in the operation process, the automation degree is high, performance of the corrugated paper processed in the mode is even, and the percent of pass is high.

Owner:ANHUI RESUDA ELECTRONICS TECH

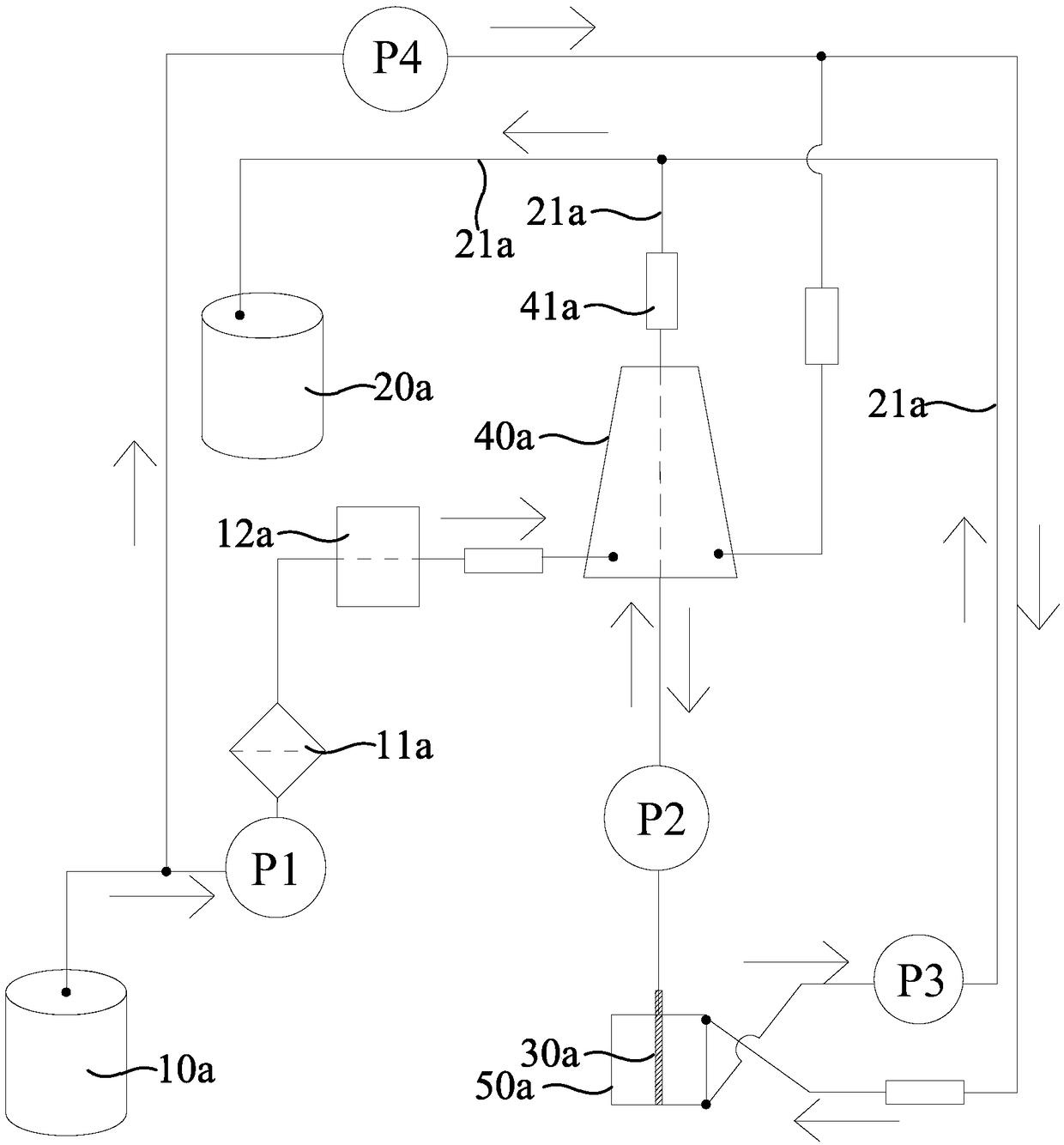

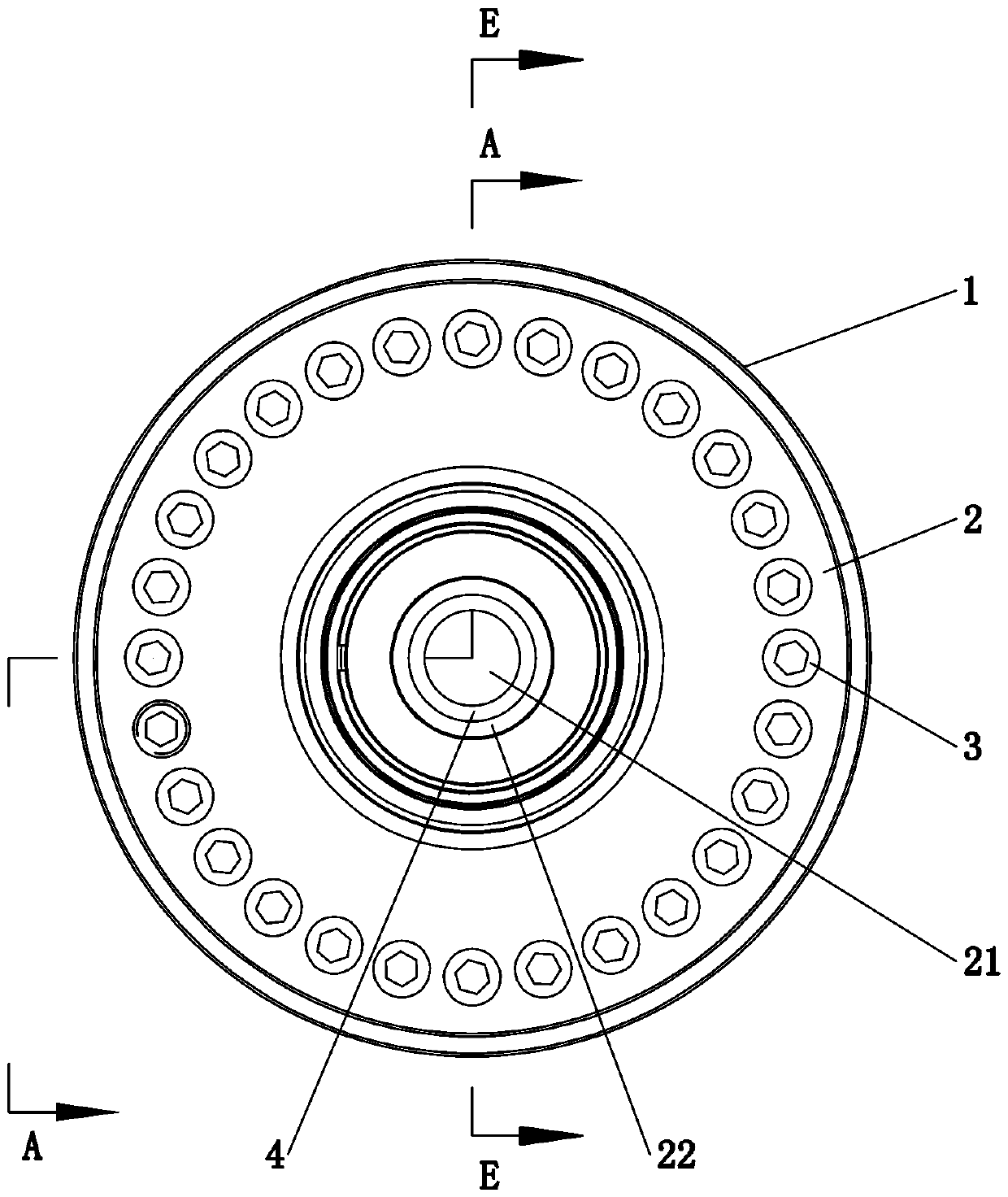

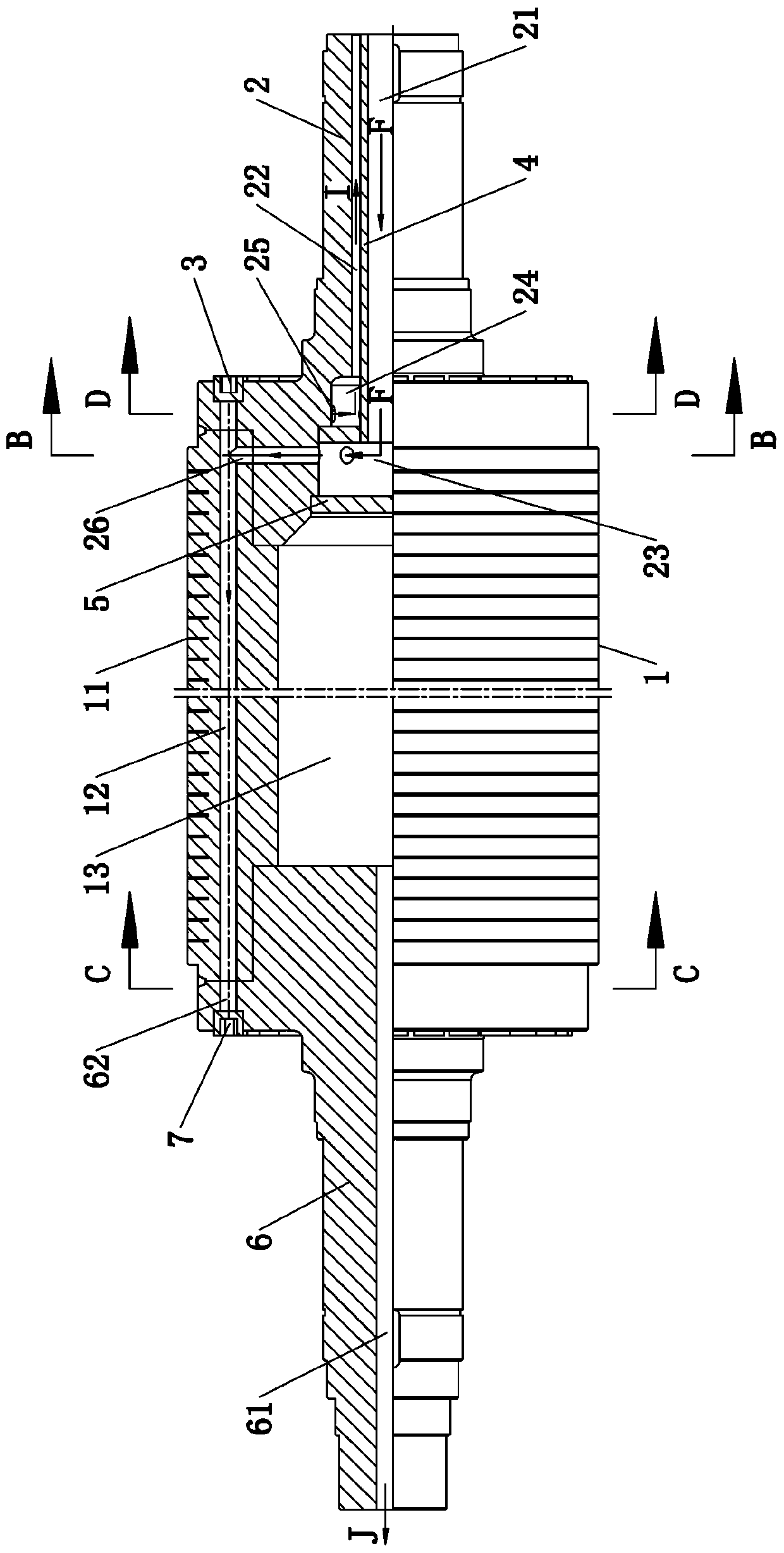

Friction welding machine constant voltage variable hydraulic control system

InactiveCN101168215AStable jobWork lessServomotorsNon-electric welding apparatusFriction weldingControl system

The invention discloses a hydraulic control system of a friction welder, comprising a two-position four-way directional control valve, a pressure reducing valve, an oil cylinder, a three-position four-way directional control valve, a speed control valve, an electromagnetic relief valve and a pump source device. The invention is characterized in that the pump source device is composed of three constant-voltage variable capacity pumps and a two-stage constant-voltage variable capacity pump, pressure oil which is needed to move a gripper oil cylinder, a rotary gripper oil cylinder and a clutch and braking oil cylinder is respectively provided by the three constant-voltage variable capacity pumps, and the pressure oil which is needed to move a push action cylinder is provided by the two-stage constant-voltage variable capacity pump. Because the pump source device of the invention employs the combination of the three constant-voltage variable capacity pumps and the two-stage constant-voltage variable capacity pump which replace a double fixed displacement pump to provide the oil pressure of the system, power consumption of the system is reduced, oil temperature is stabilized, finally stable operation of the system is ensured. According to measurement, with the employment of the hydraulic control system, the average power consumption of a circulating hydraulic system in a friction welding procedure of a C450-typed friction welder is decreased from 874 kilojoubles of the exiting technology to 436kilojoubles, and the average power consumption is reduced by 50%.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

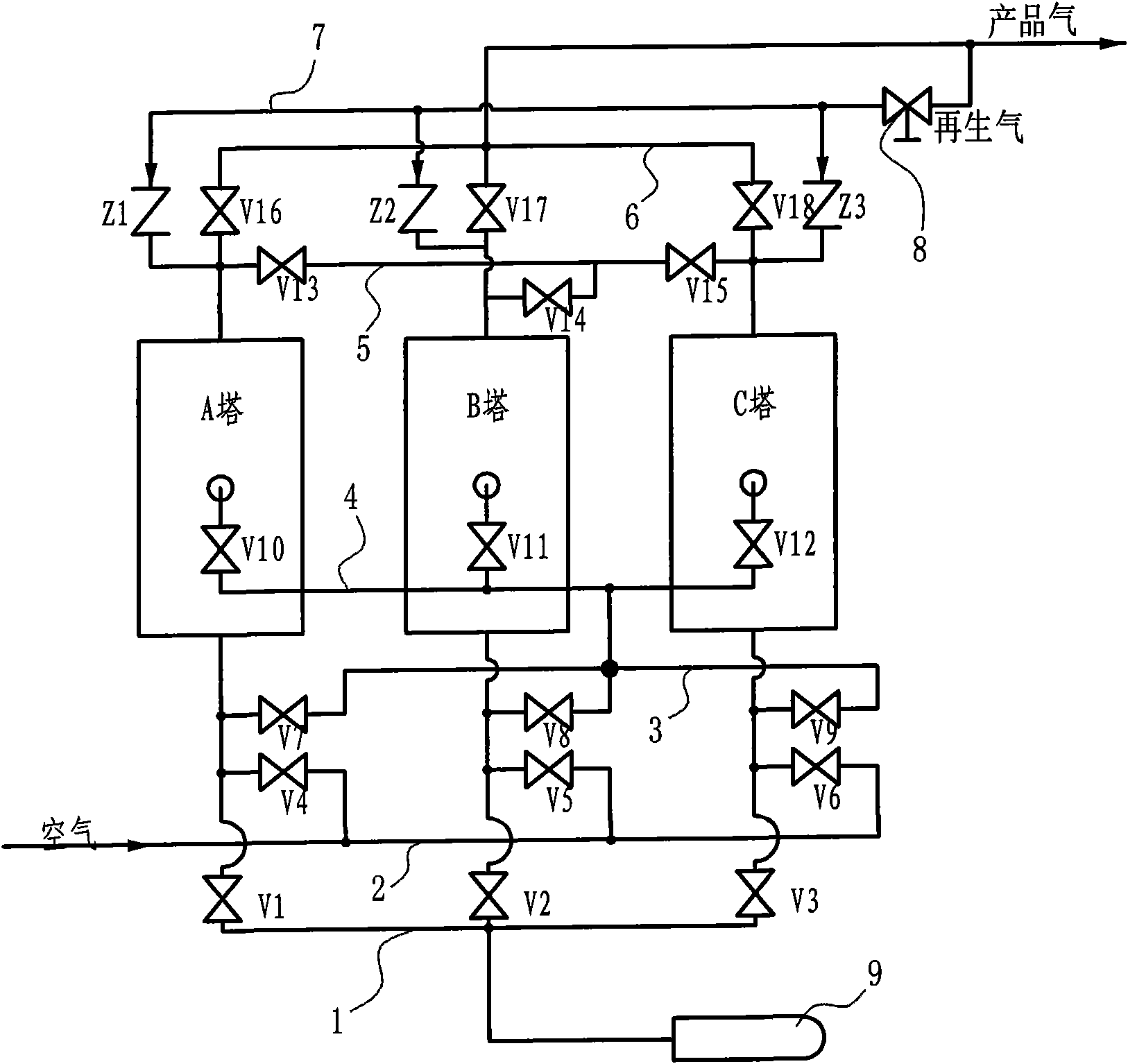

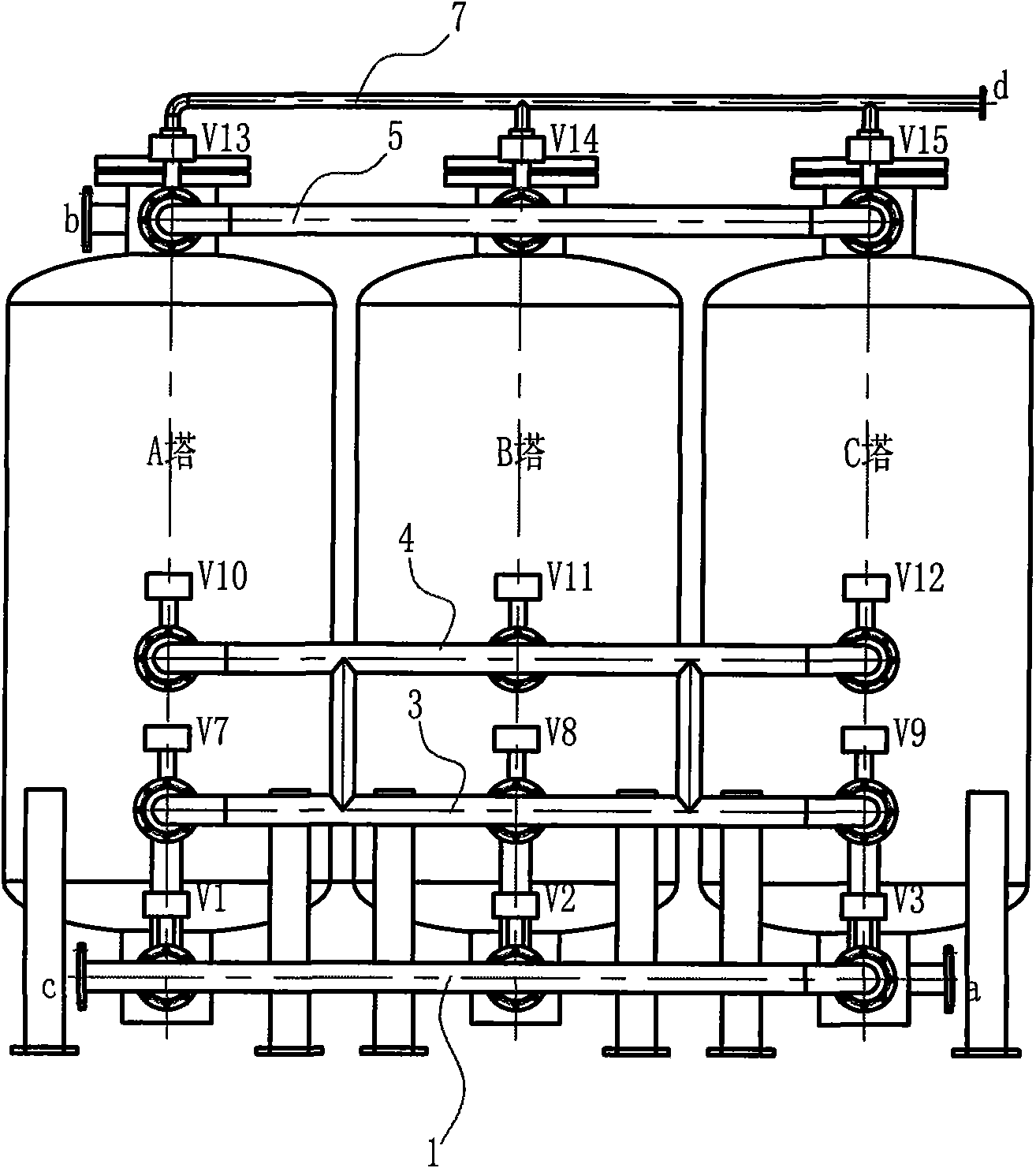

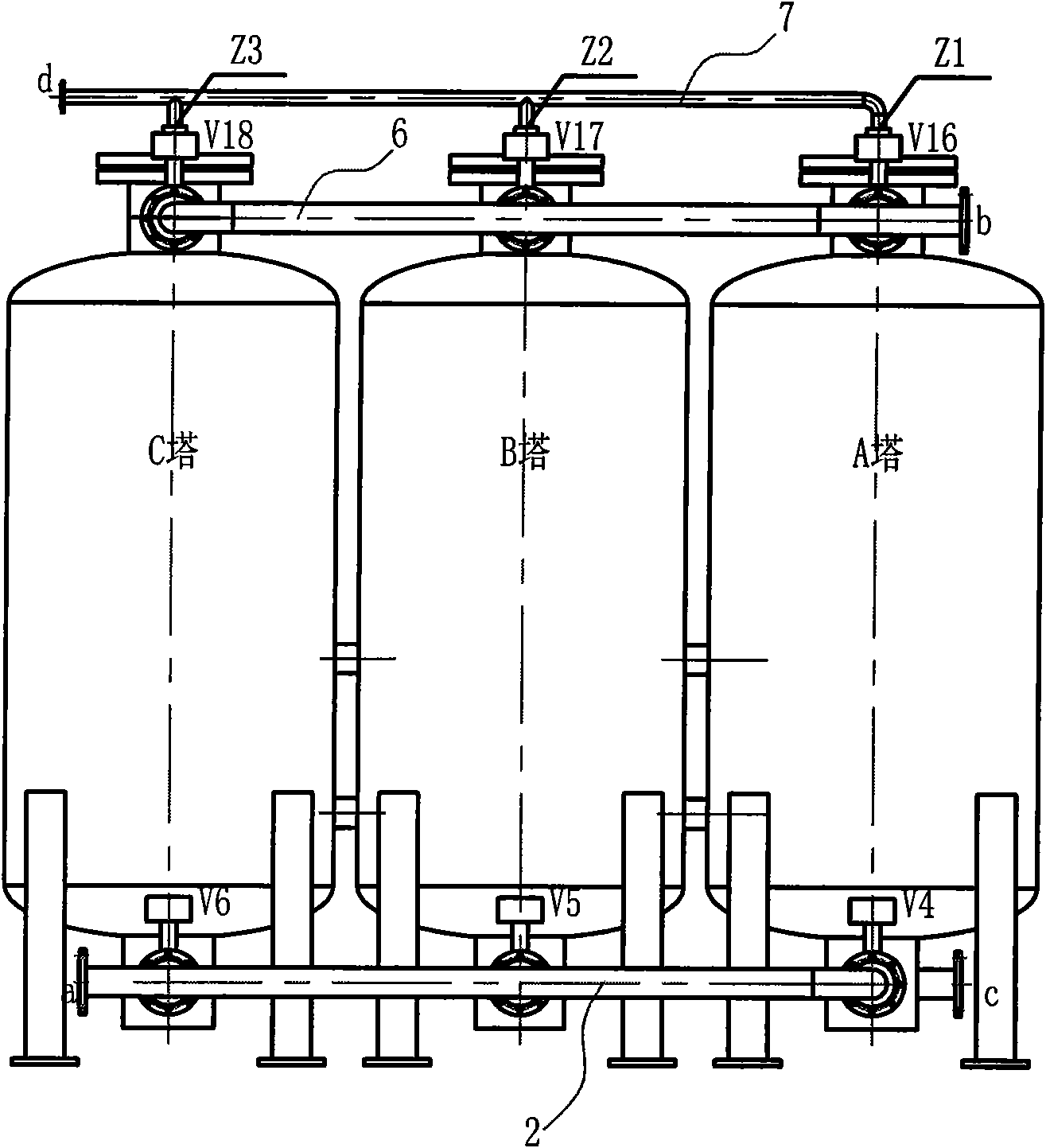

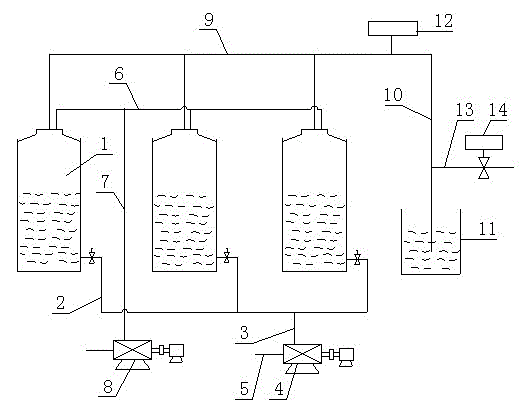

Nitrogen making machine with three-tower structure

ActiveCN101905874AImprove gas production performanceLow costNitrogen purification/separationNitrogenTower

The invention provides a nitrogen making machine with a three-tower structure, which has reasonable structure and high efficacy. The nitrogen making machine is provided with a tower A, a tower B and a tower C, wherein the bottom of the tower A is provided with a valve 1, a valve 4 and a valve 7 in parallel; the bottom of the tower B is provided with a valve 2, a valve 5 and a valve 8 in parallel,and the bottom of the tower C is provided with a valve 3, a valve 6 and a valve 9; the middle parts of the tower A, the tower B and the tower C are respectively externally connected with a valve 10, a valve 11 and a valve 12; the top of the tower A is provided with a valve 13 and a valve 16 in parallel, the top of the tower B is provided with a valve 14 and a valve 17 in parallel, and the top of the tower C is provided with a valve 15 he a valve 18 in parallel; the other ends of the valve 13, the valve 14 and the valve 15 are connected with a pipe 5, the other ends of the valve 16, the valve 17 and the valve 18 are connected with a pipe 6; the tops of the tower A, the tower B and the tower C are respectively connected with a check valve 1, a check valve 2 and a check valve 3 and the otherends of the check valve 1, the check valve 2 and the check valve 3 are connected with a pipe 7; and a pipe 2 is provided with an air inlet, and a pipe 3 and a pipe 4 are bypassed mutually. The invention is suitable for serving as oxygen manufacture equipment with larger flow requirement.

Owner:HANGZHOU SHENGDA MECHANICAL & ELECTRICAL HI TECH CO LTD

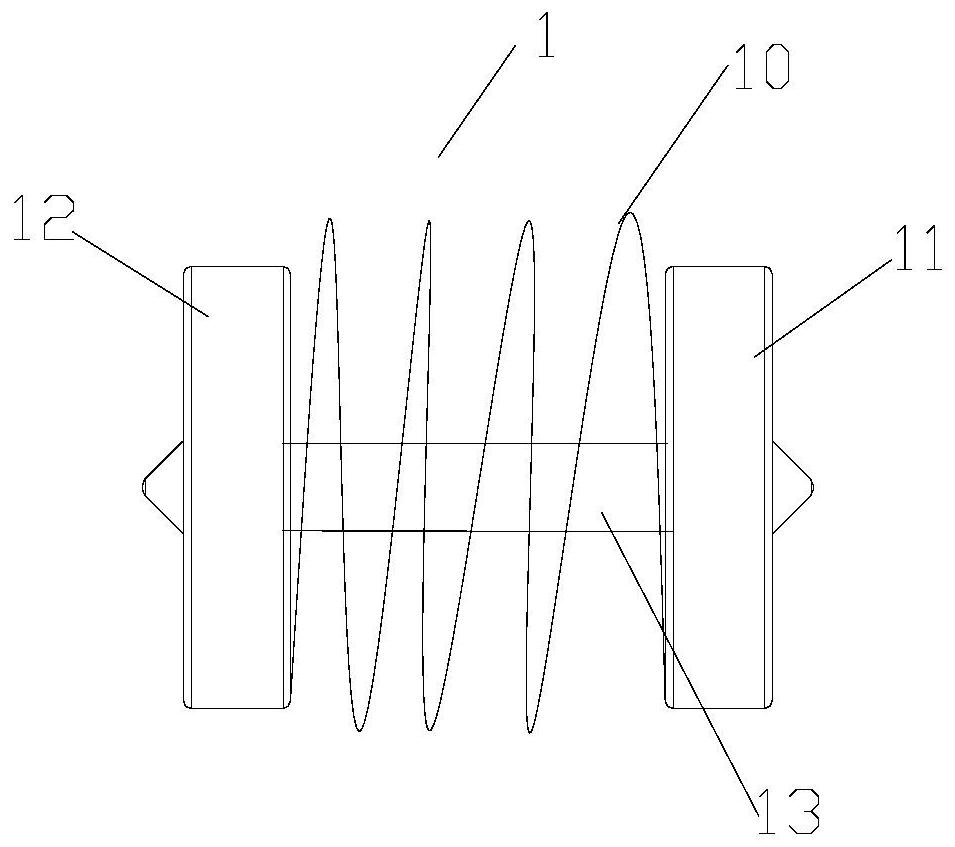

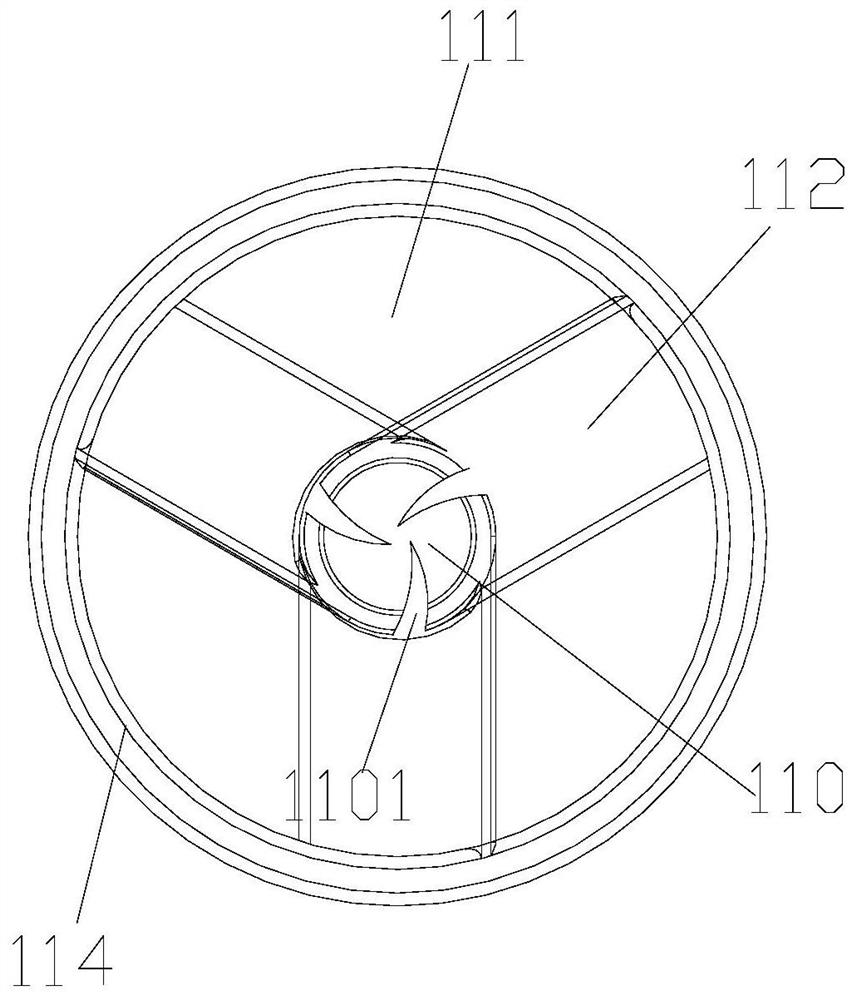

Condenser pipeline on-line cleaning system based on cleaning brush

The invention is applicable to the technical field of condenser cleaning. The invention discloses a condenser pipeline on-line cleaning system based on a cleaning brush. The condenser pipeline on-linecleaning system comprises a condenser and an on-line cleaning mechanism which is matched with a condenser pipeline and can move in the water flow direction; the cleaning mechanism comprises the cleaning brush, and impellers are arranged at the two ends of the cleaning brush respectively; a brush body is arranged between the two impellers; the brush body comprises bristles and a connecting body for fixing the bristles; the two ends of the connecting body are respectively connected with the centers of the two impellers; and the bristles exceed the outer diameters of the impellers. When in use,the condenser pipeline on-line cleaning system is placed in the condenser pipeline, and after the direction of water flow in the condenser pipeline is reversed, a cleaning mechanism in the condenser pipeline moves horizontally under the action of pressure of water and rotates under the action of an impeller structure, namely, the cleaning mechanism moves spirally and horizontally. On the one hand,resistance during moving is reduced, on the other hand, grooves on the inner wall of the condenser pipeline can be cleaned, the cleaning efficiency is improved, and the pressure of the condenser pipeline cannot be greatly affected.

Owner:深圳市纽乐节能设备工程有限公司

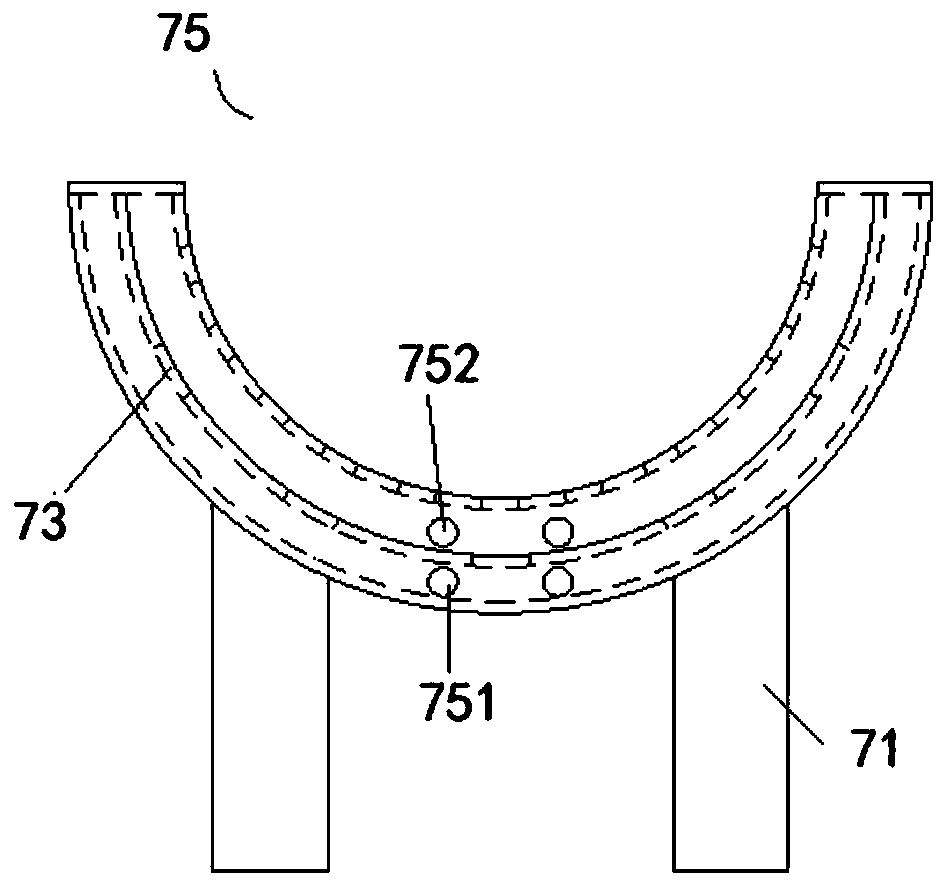

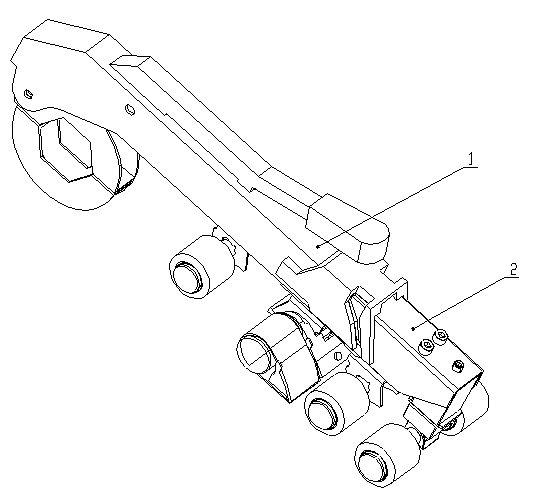

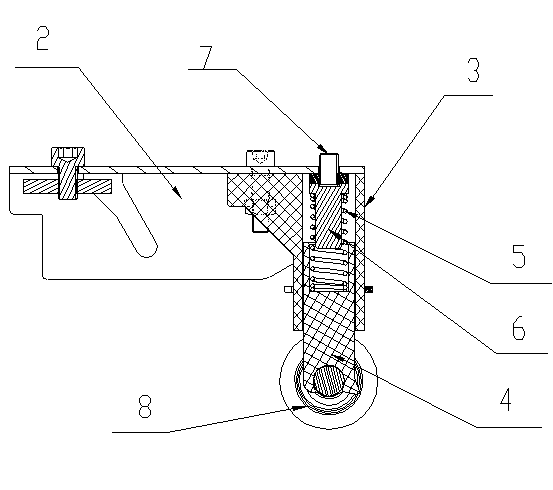

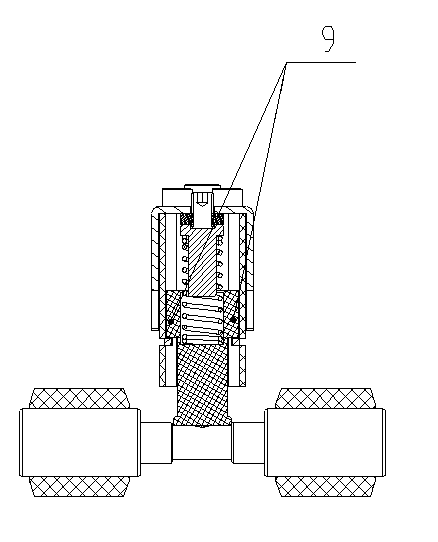

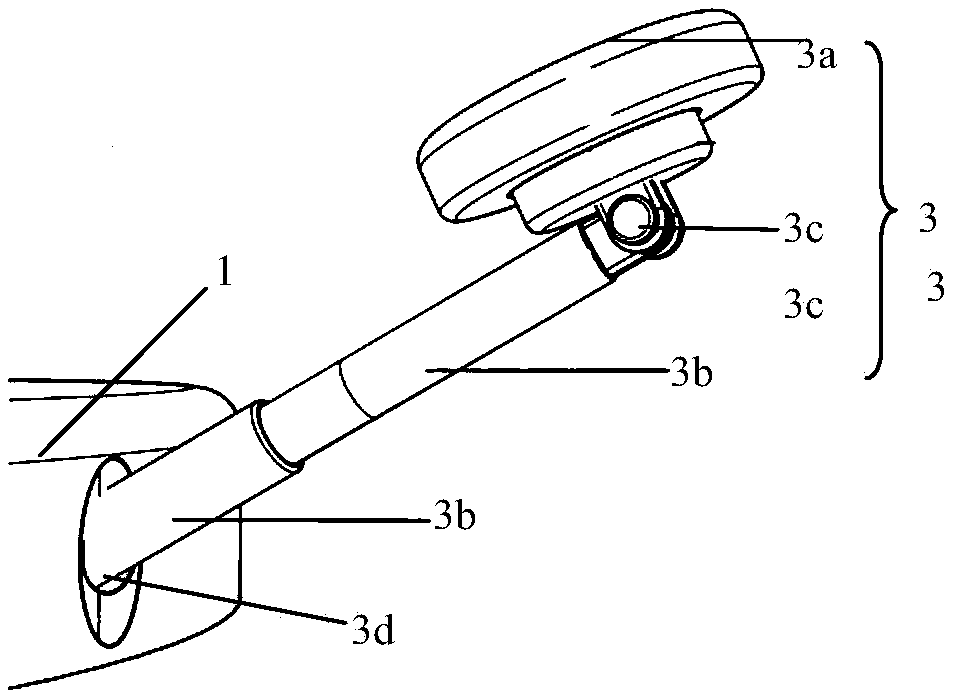

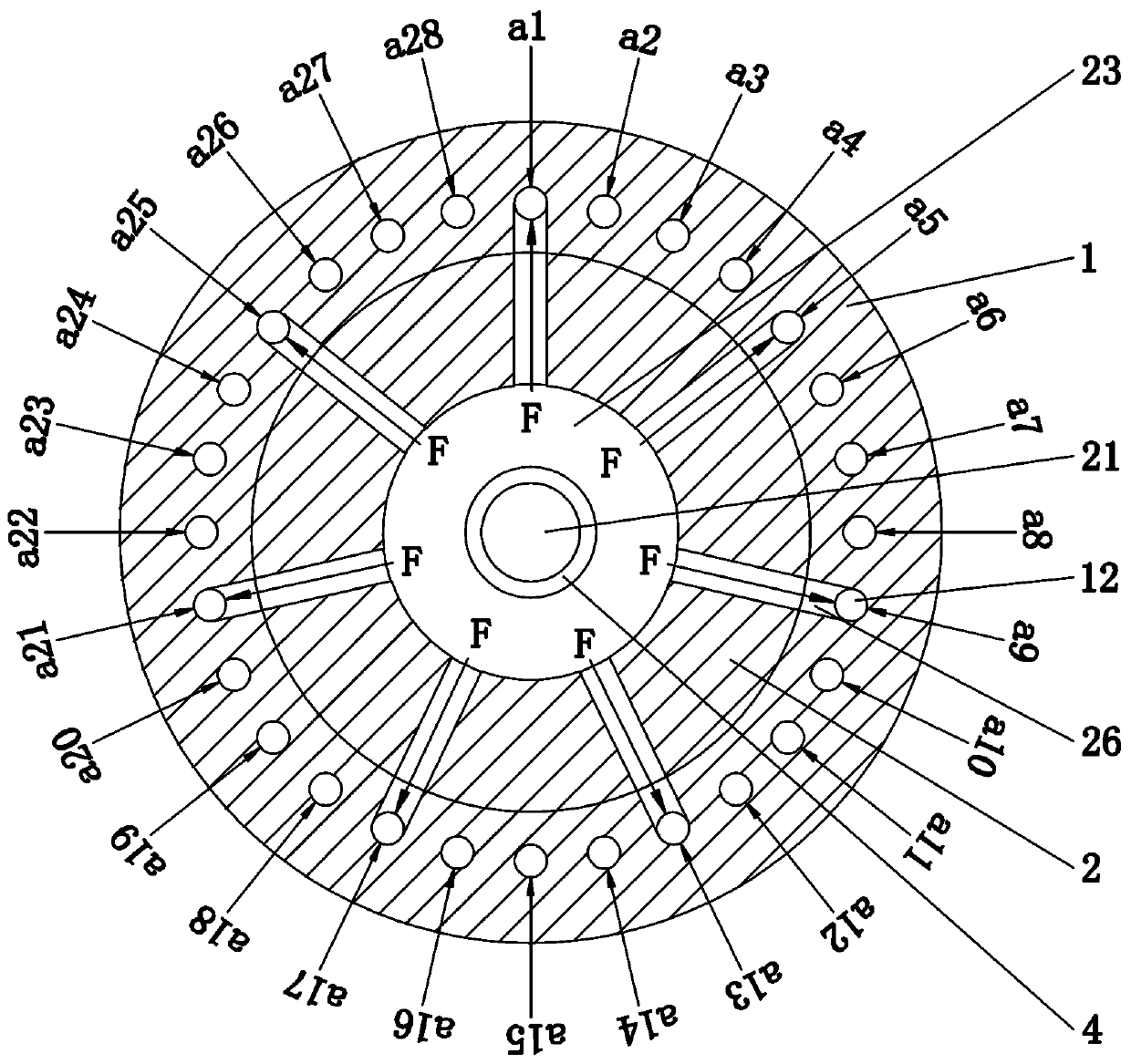

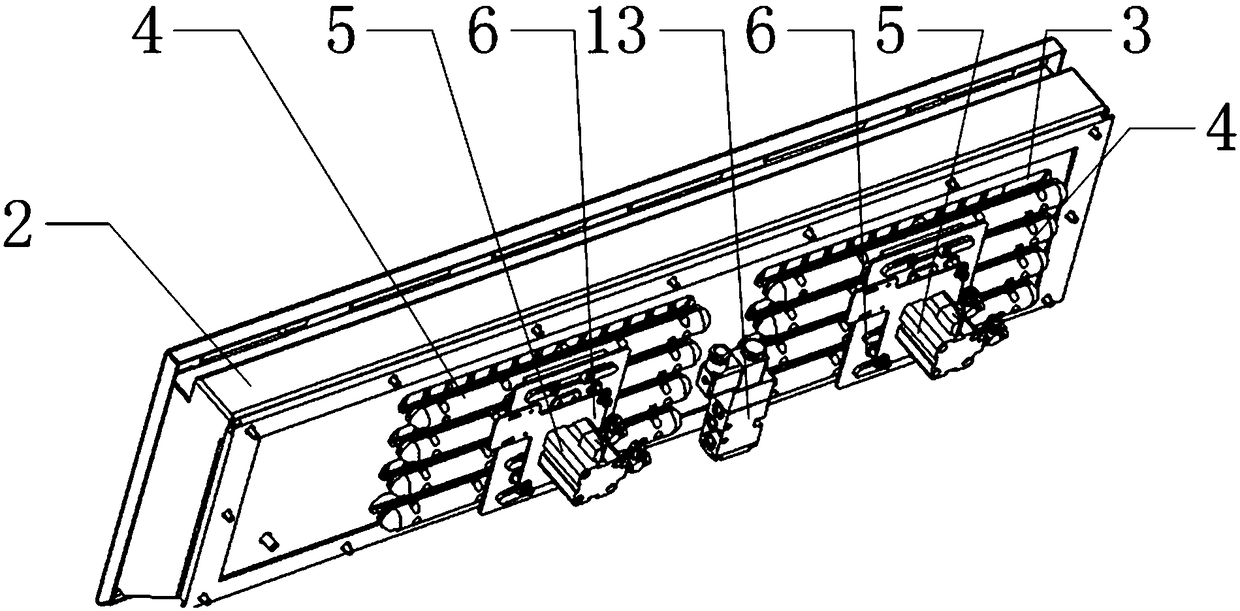

Compact-spinning cradle pressurizing device

InactiveCN102864530APressure effectSimple structureDrafting machinesEngineeringMechanical engineering

The invention relates to a compact-spinning cradle pressurizing device comprising a cradle (1) and a pressurizing device connected with the cradle. The compact-spinning cradle pressurizing device is characterized by comprising a connector (2) and a roller clamping jaw fixing base (3); wherein one end of the connector is connected with the cradle in a blocking manner; the roller clamping jaw fixing base is vertically fixed on the other end of the connector; a roller clamping jaw (4) is fixed in the roller clamping jaw fixing base; a spring (5) is inserted in a circular hole in the upper part of the roller clamping jaw; a locating pin shaft (6) is inserted on the upper part of the spring; and the upper part of the locating pin shaft is fixed on the connector by an adjusting nut (7). The compact-spinning cradle pressurizing device provided by the invention is simple in structure and convenient to assemble and disassemble, and is capable of independently pressurizing by using the spring, so that the yarn quality is ensured.

Owner:江阴市华方新技术科研有限公司

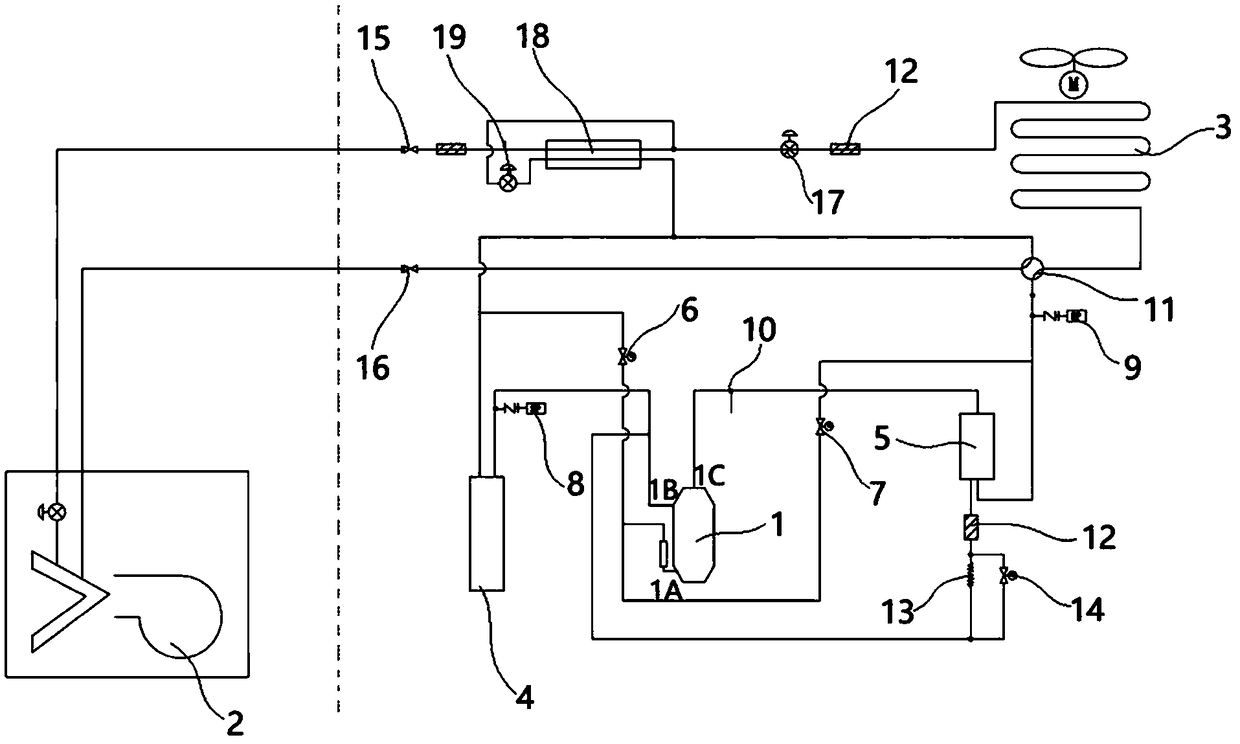

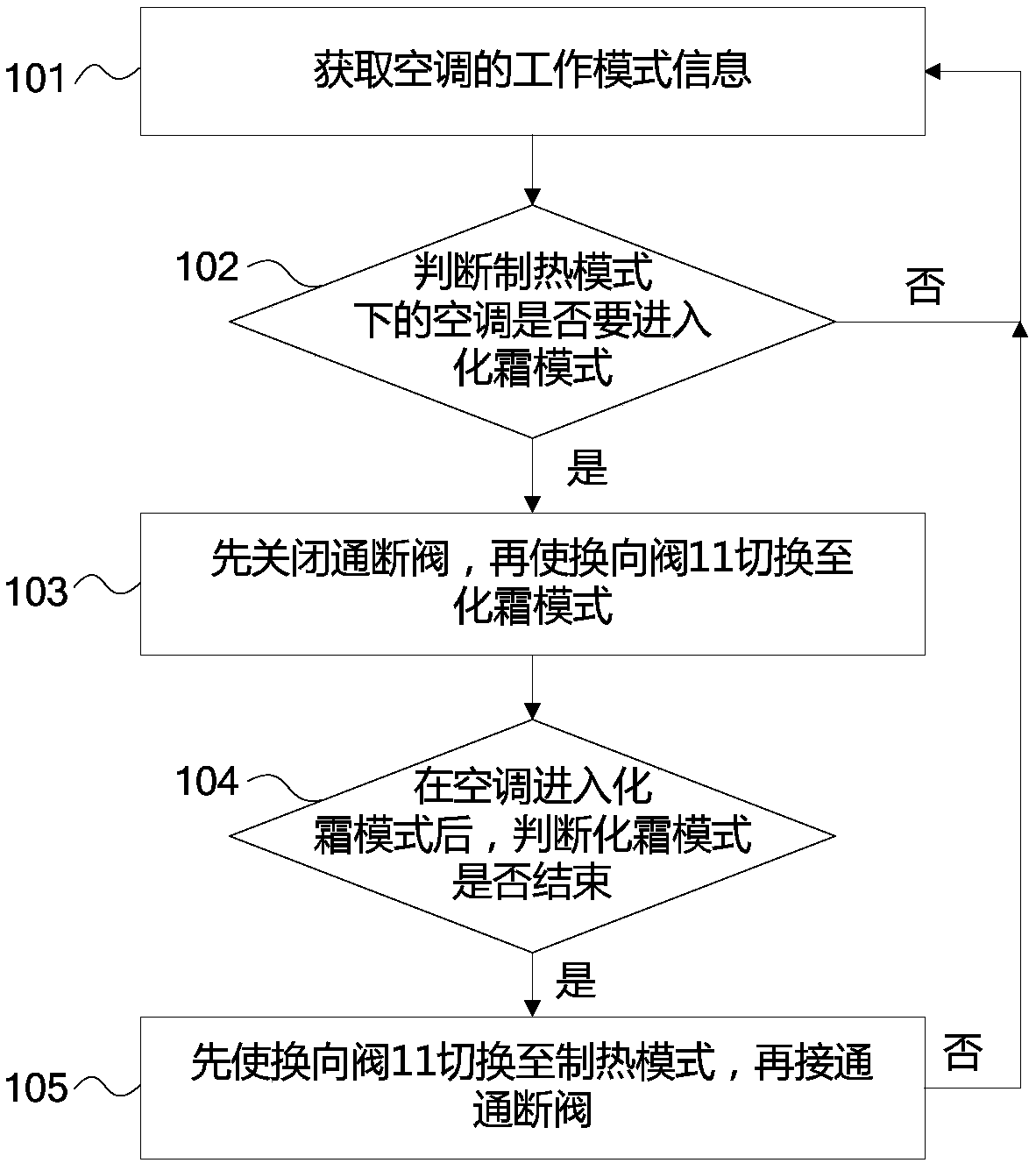

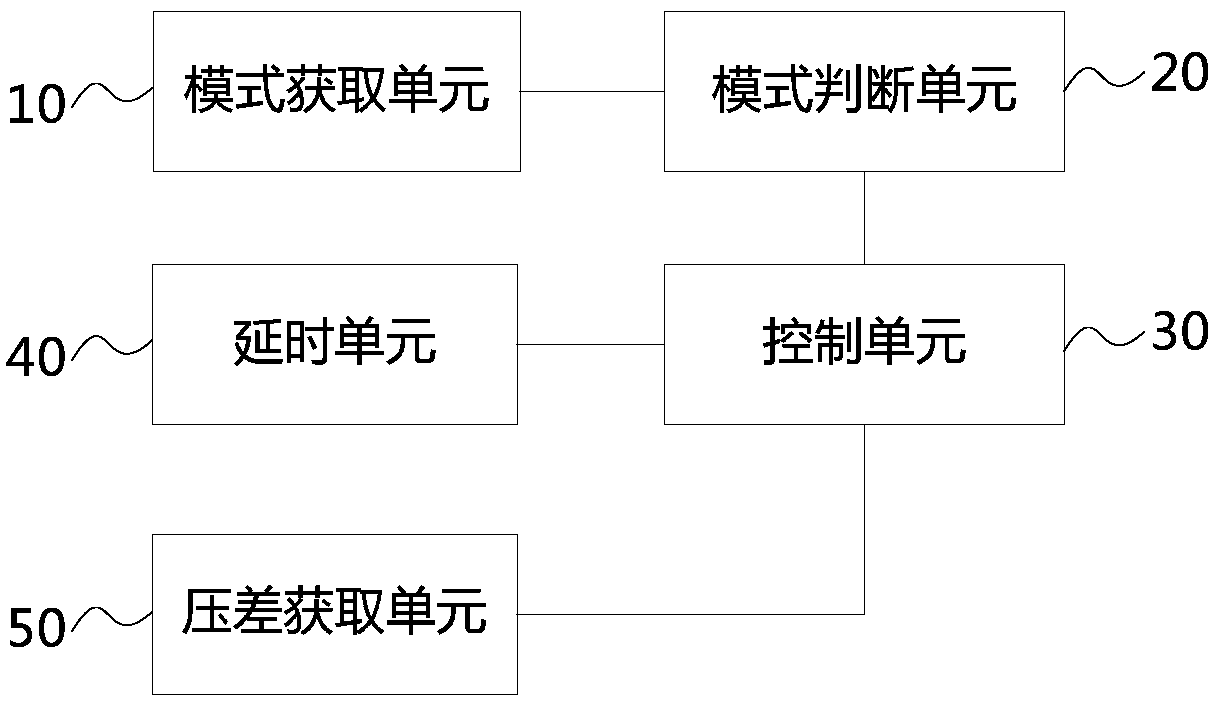

Air conditioner control method and system based on volume switching and air conditioning equipment

ActiveCN109163426AGuaranteed uptimePressure effectMechanical apparatusSpace heating and ventilation safety systemsDifferential pressureAir conditioning

The invention relates to an air conditioner control method and system based on volume switching and air conditioning equipment. The control method comprises the following steps that working mode information of an air conditioner is acquired; whether the air conditioner in the heating mode needs to enter a defrosting mode is judged, if the air conditioner in the heating mode needs to enter the defrosting mode, firstly, an on-off valve arranged between a volume switching port (1A) of a compressor (1) and a reversing valve (11) is switched off, and then the reversing valve (11) is used for switching to the defrosting mode; after the air conditioner enters the defrosting mode, whether the defrosting mode is finished is judged; and if the defrosting mode is finished, firstly, the reversing valve (11) is used for switching to the heating mode, and then the on-off valve is switched on. According to the control method, the influence on pressure of the volume switching port in the defrosting process can be avoided, pre-closed high-pressure air can enable the volume switching port to reach the volume switching pressure condition required by the normal heating mode in a short time, so that the compressor is guaranteed to operate normally during switching of the working modes and get free of influence of system differential pressure fluctuation, and the operation reliability of the systemis improved.

Owner:GREE ELECTRIC APPLIANCES INC

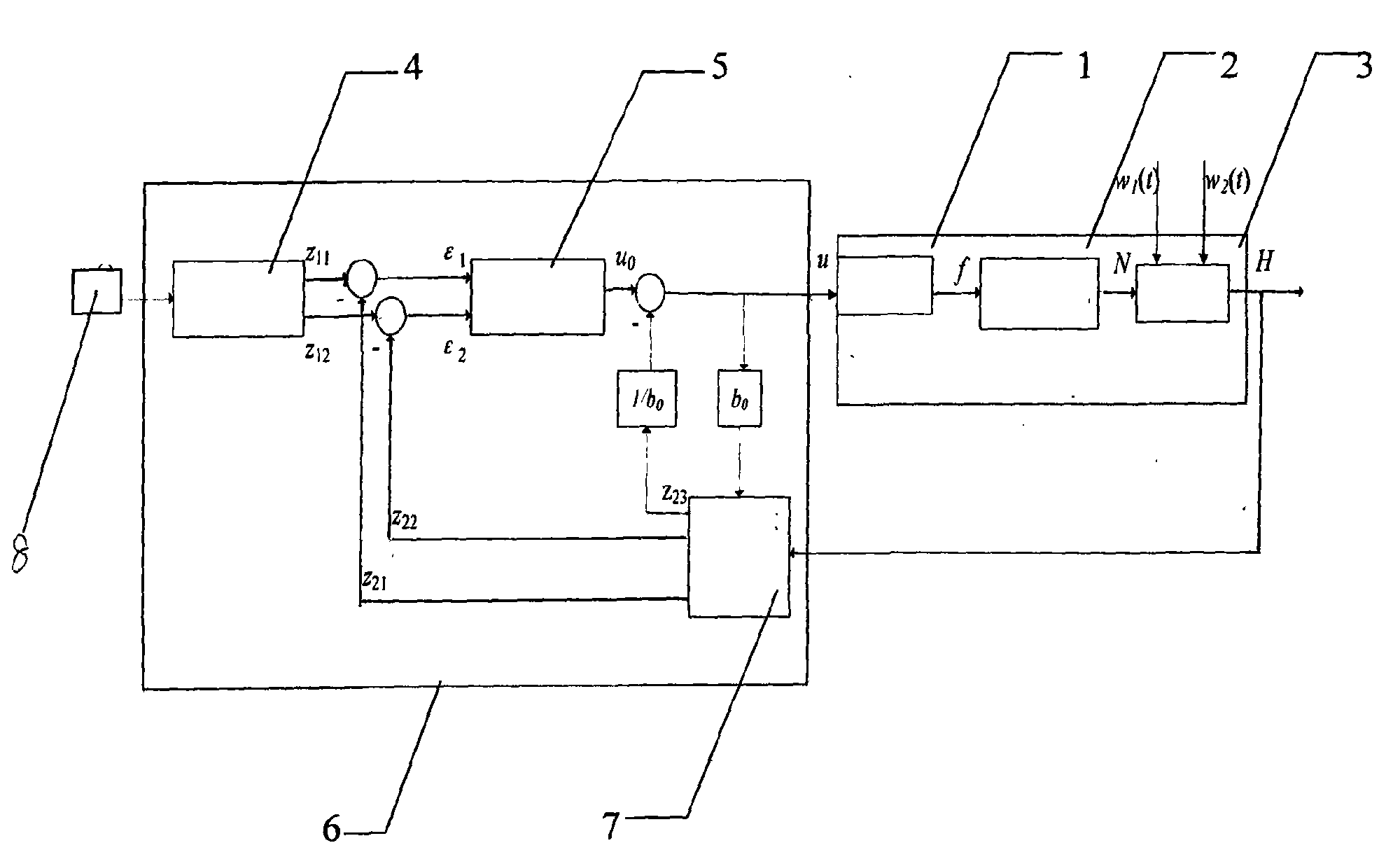

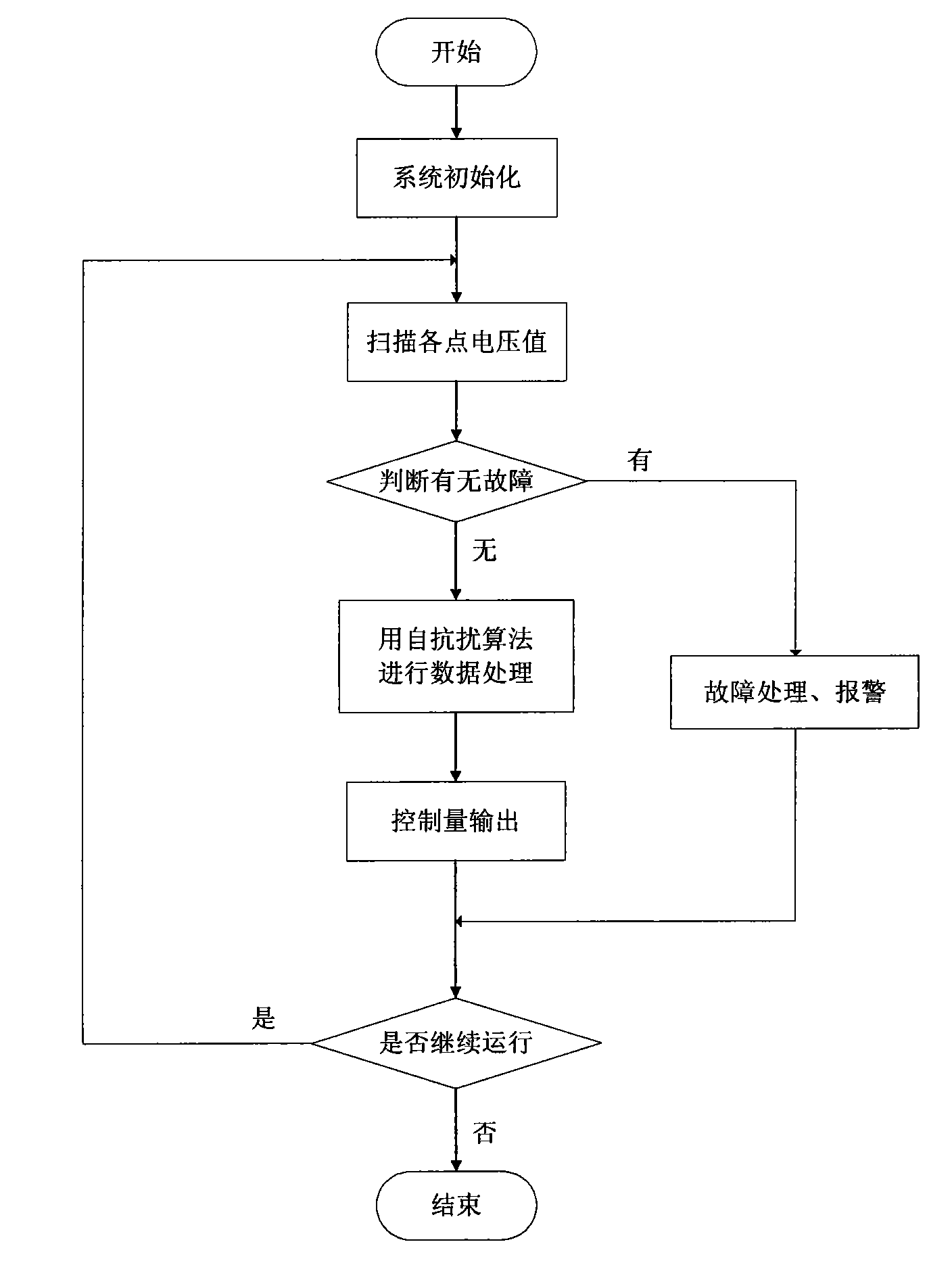

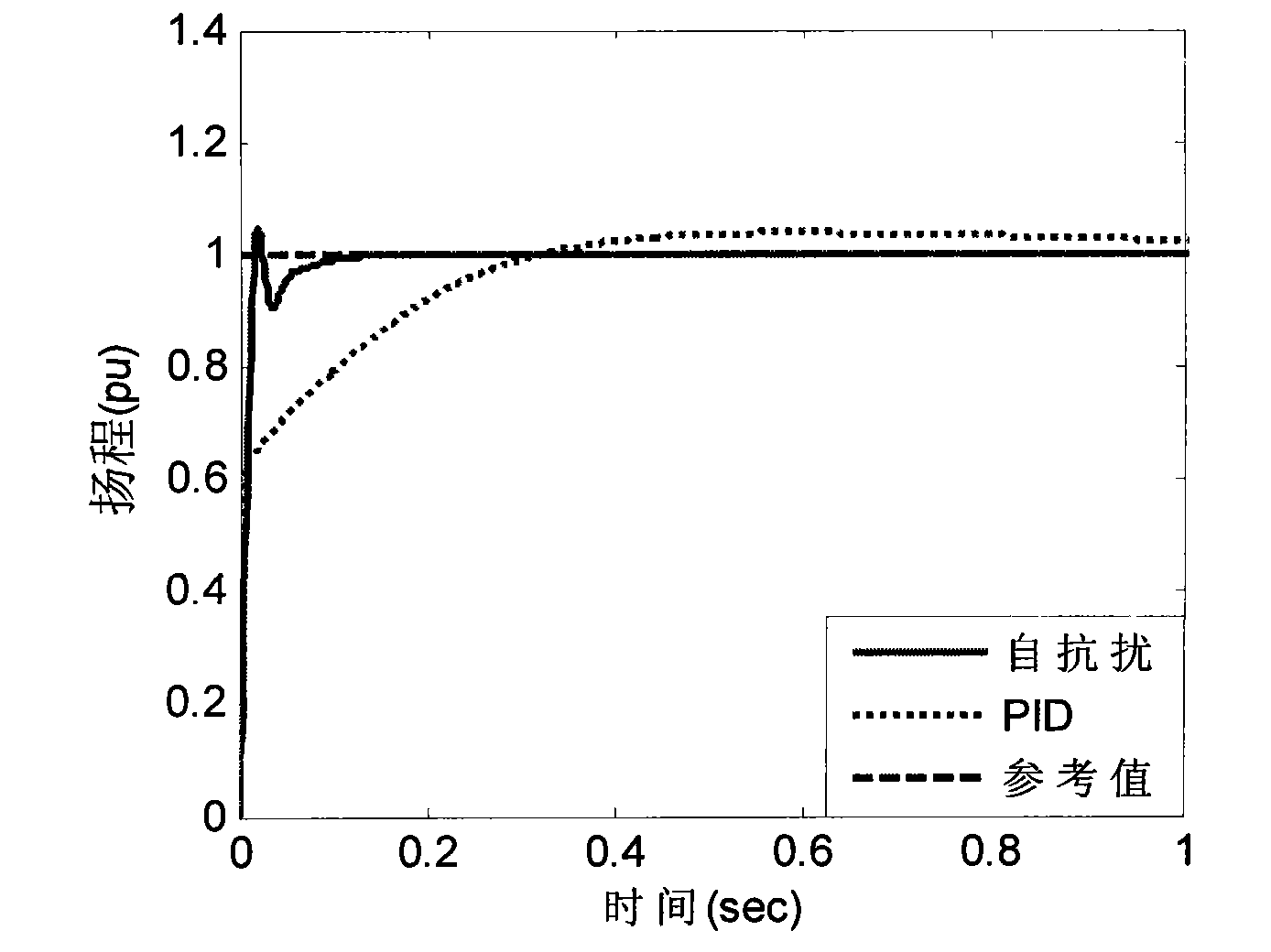

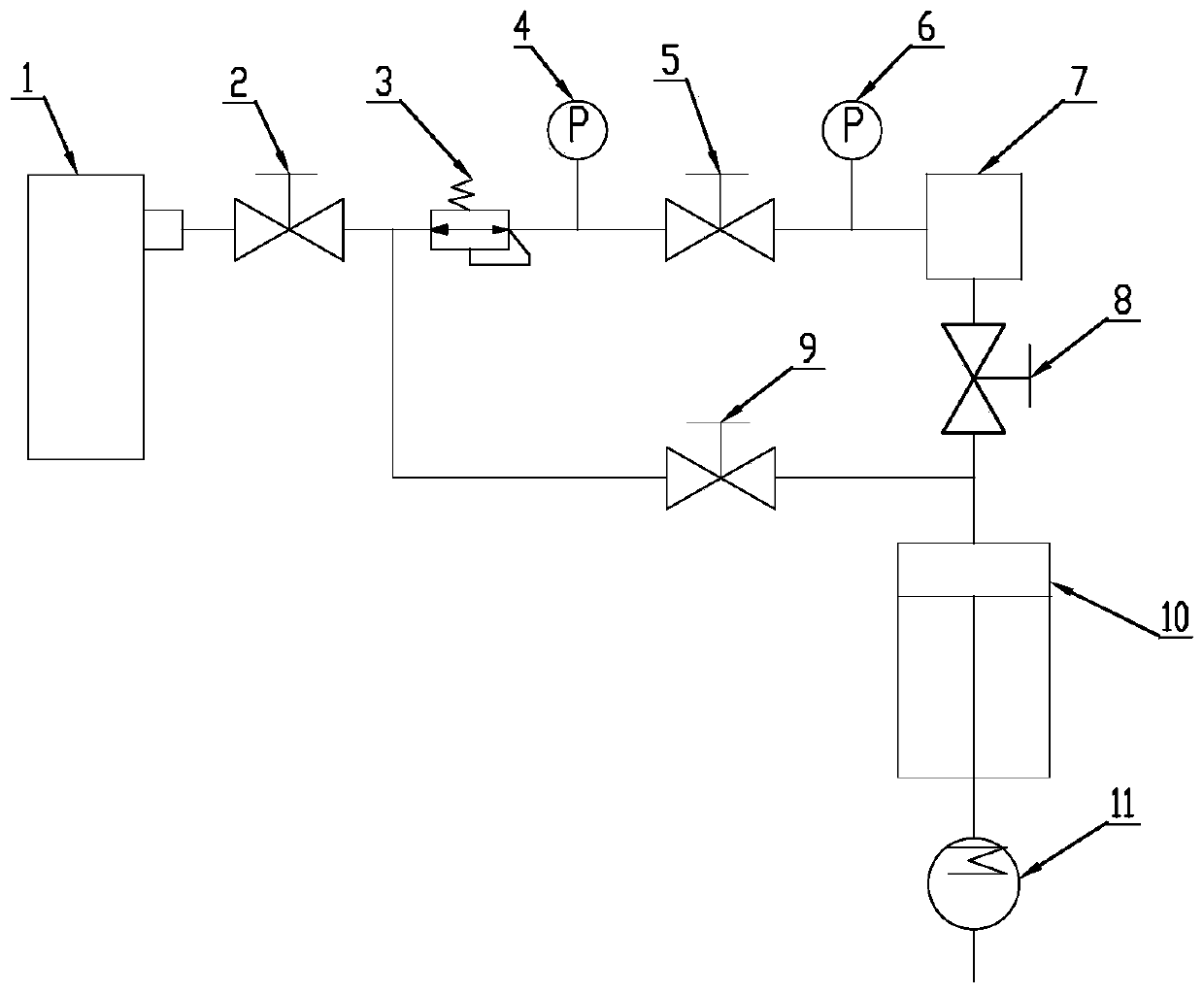

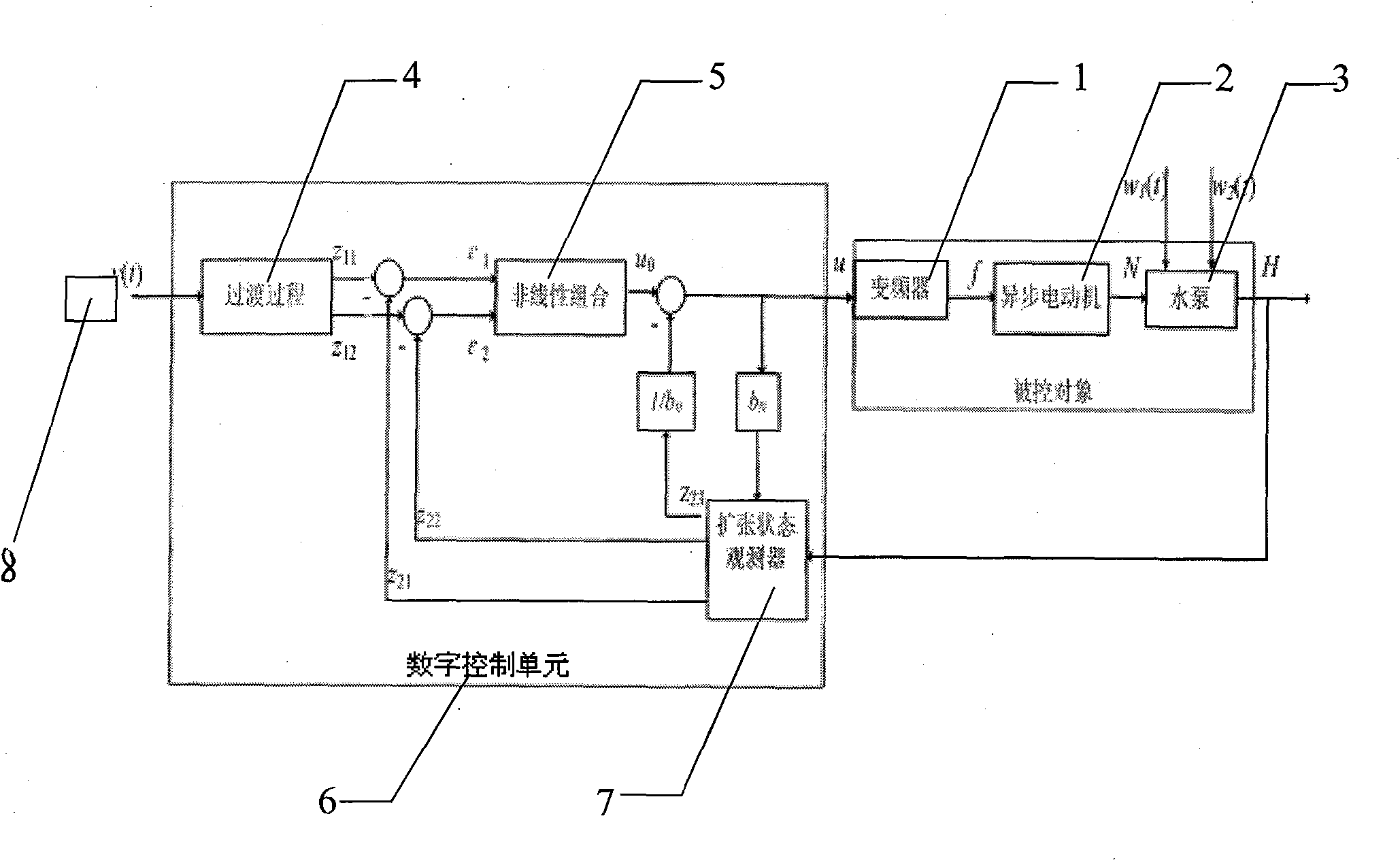

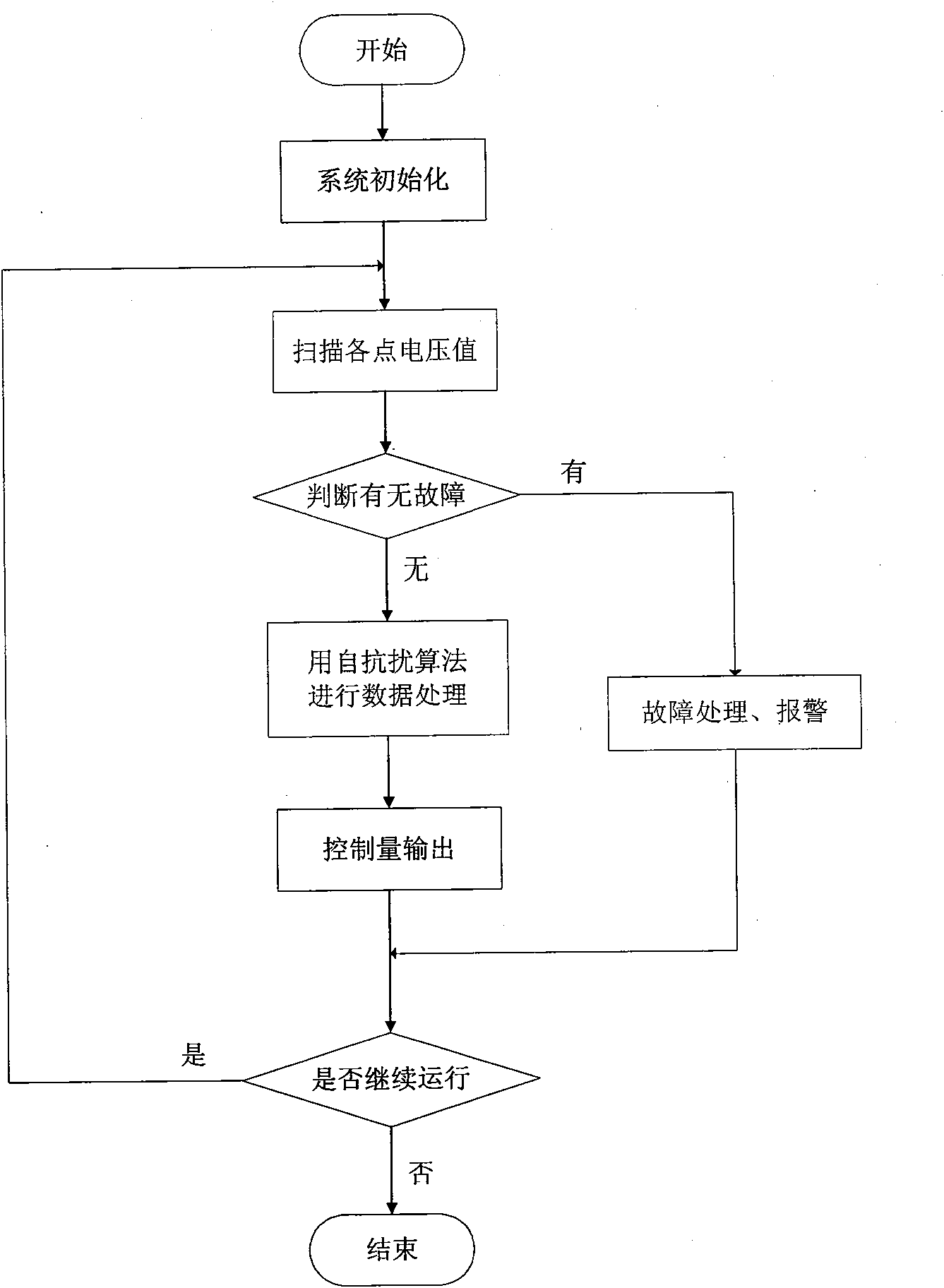

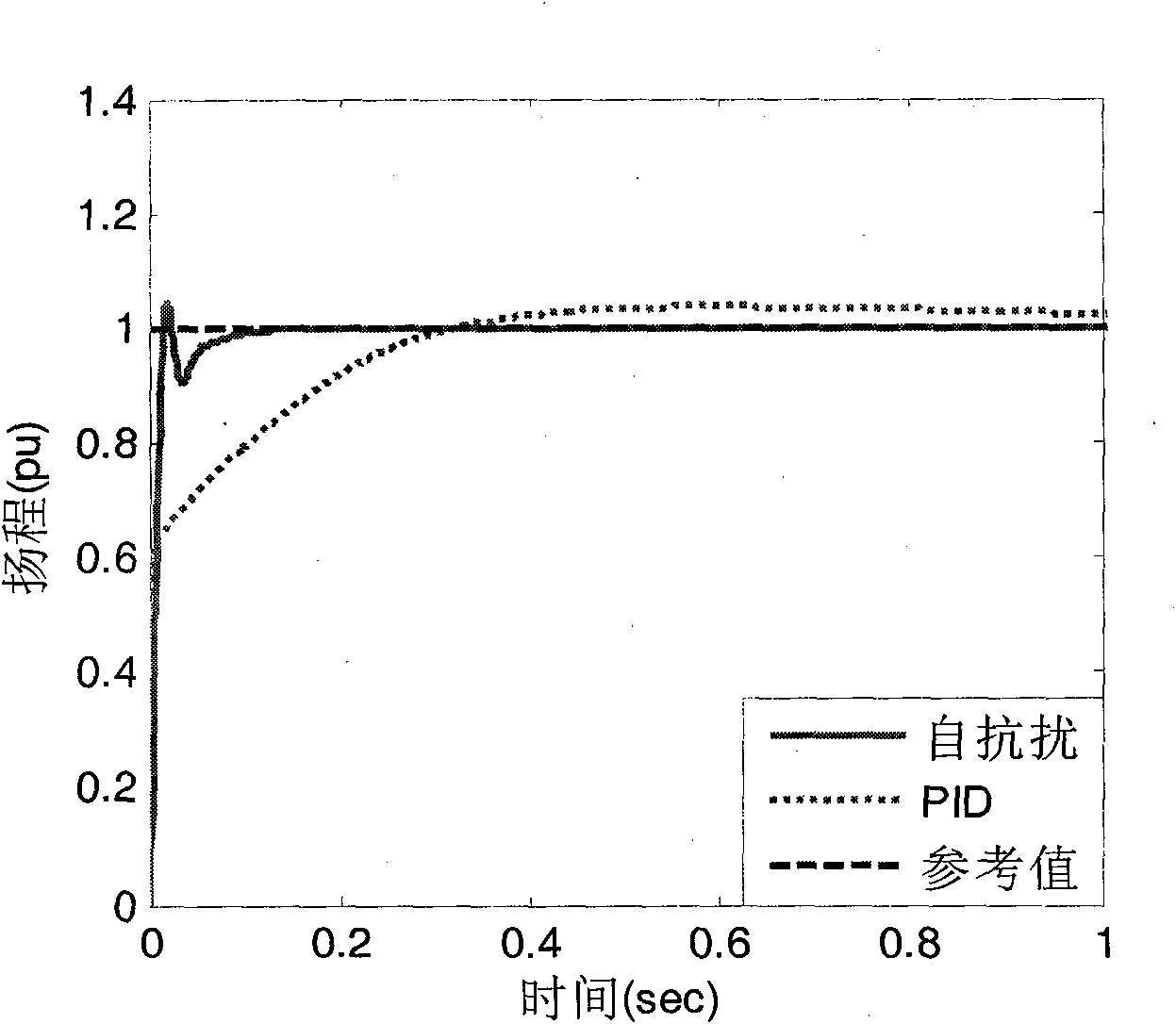

Network pressure superposition water supply system based on optimal auto disturbance rejection control

ActiveCN101654920AImprove control effectQuick responseFluid pressure control using electric meansWater supply tanksAutomatic controlWater supply network

The invention relates to a secondary water supply system and the automatic control field, in particular to a network pressure superposition water supply system based on optimal auto disturbance rejection control. The system comprises a transducer, an asynchronous motor, a water pump, a pressure sensor and a digital control unit based on auto disturbance rejection algorithm; wherein the digital control unit based on auto disturbance rejection algorithm receives the pressure value input by a pressure sensor and outputs the pressure value to the transducer in the form of analog voltage signal after A / D conversion and processing of internal auto disturbance rejection program; the output terminal of the transducer is connected with the input terminal of the asynchronous motor, the asynchronousmotor adjusts speed according to the voltage and frequency signal given by the transducer, thus regulating the exit pressure of the water pump. The invention has the beneficial effects that: the control problem of the existing network pressure superposition water supply system is solved, thus improving performances of response speed, anti-interference ability, robustness and the like of the systemand improving safety of water supply and comfort of user water.

Owner:TIANJIN GANQUAN GROUP

On-line sampling system for sulfur hexafluoride gas

InactiveCN110779777APressure effectGuaranteed pressureWithdrawing sample devicesElectric machineryEnvironmental geology

The invention relates to the technical field of on-line monitoring equipment of electrical equipment gas, particularly to an online sampling system of sulfur hexafluoride gas. The online sampling system comprises a channel selection module including one or more groups of gas circuit branches; the channel selection module is connected with an air inlet pipeline; a pressure reduction device, a sampling electromagnetic valve, a detector pressure detection device and a detection electromagnetic valve are sequentially arranged on the air inlet pipeline; the air inlet pipeline is connected with a detector inlet; a detector outlet is connected with a sampling cylinder through a gas outlet pipeline; and the sampling cylinder connected with an electric push rod connected with a sampling motor. Theair outlet pipeline is connected with a buffer pipeline; the buffer pipeline is connected with a buffer tank; and a buffer pipeline is connected with a buffer electromagnetic valve. The air outlet pipeline is connected with a backflushing pipeline; a backflushing electromagnetic valve is arranged on the backflushing pipeline; the backflushing pipeline is connected with the channel selection module; and the channel selection module, the pressure reduction device, the sampling electromagnetic valve, the detector pressure detection device, the detection electromagnetic valve, a detector, the sampling motor, the buffer electromagnetic valve and the backflushing electromagnetic valve are all connected with a control system through electric signals. The online sampling system has advantages of optimized structure, rapidness, and high efficiency; and the detection precision is improved and various demands are satisfied.

Owner:ELECTRIC POWER RES INST OF STATE GRID ANHUI ELECTRIC POWER +1

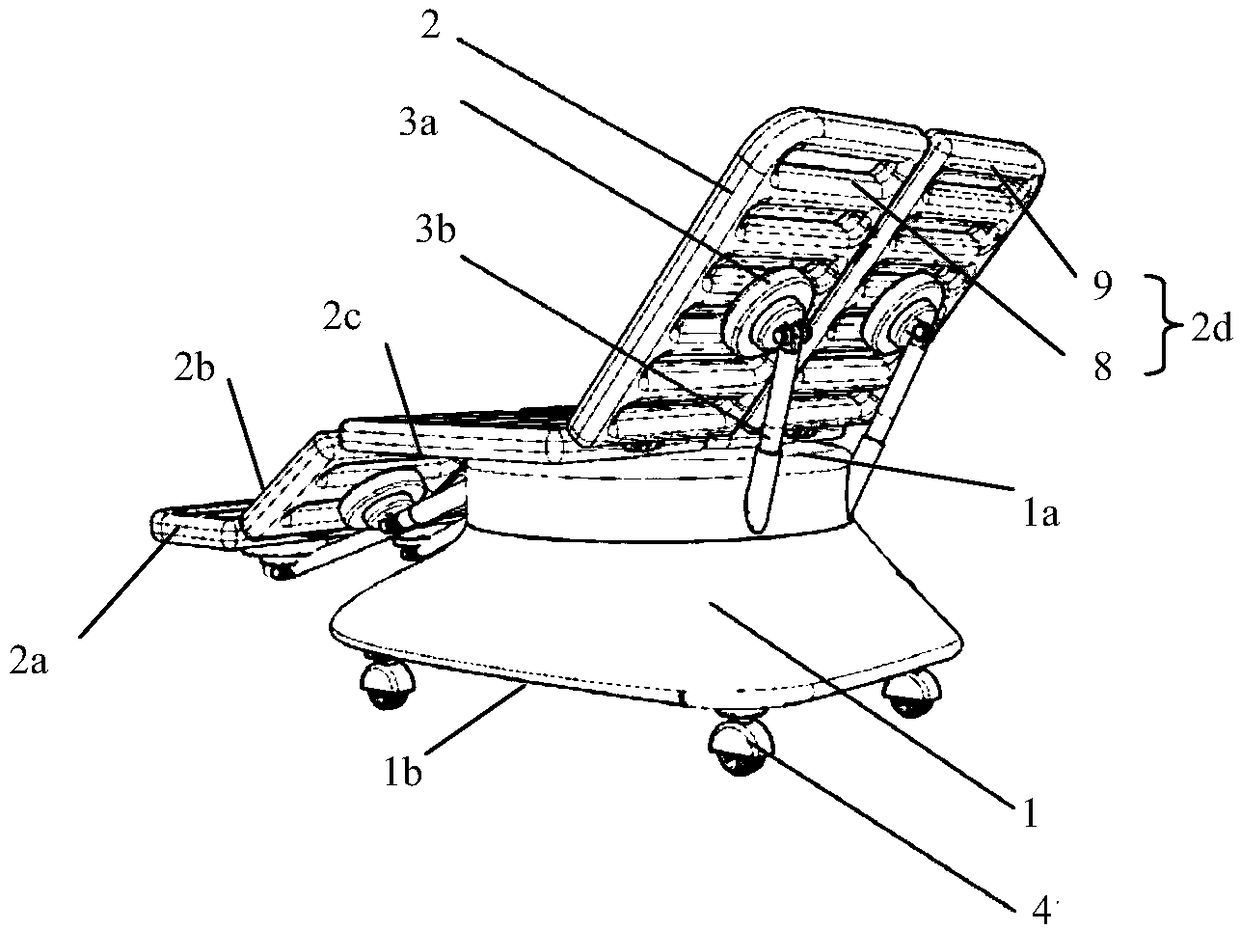

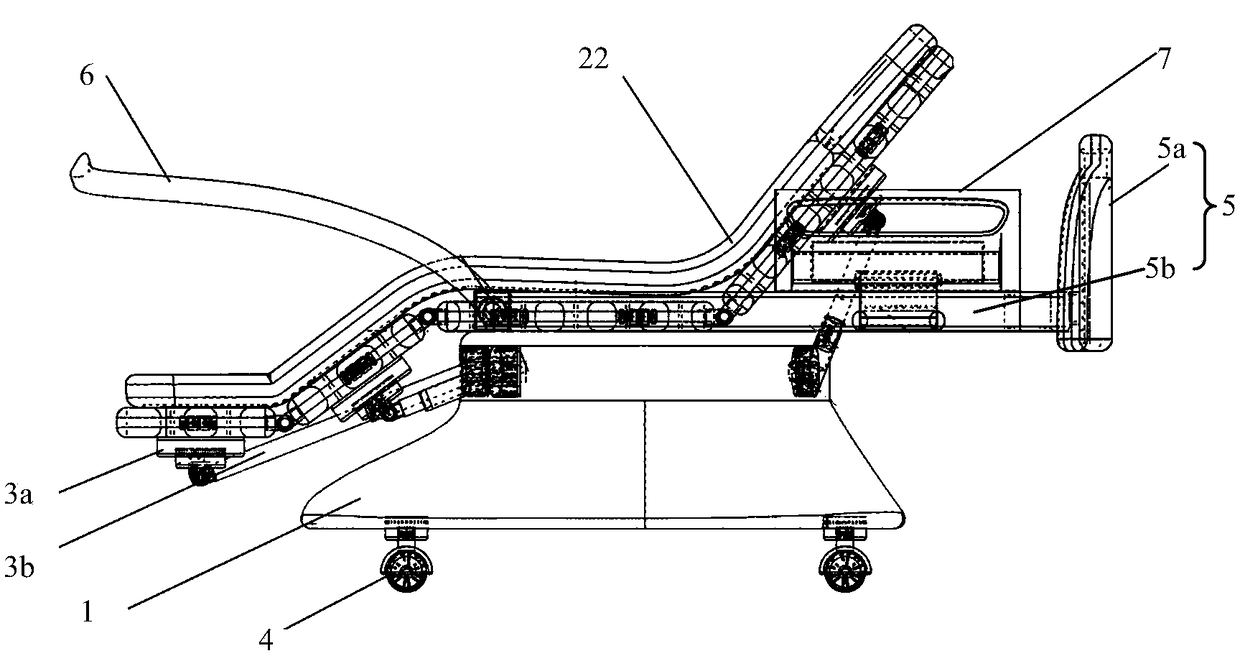

Hydraulic nursing bed

ActiveCN109044671APressure effectComfort experienceNursing bedsDiagnostic recording/measuringEngineeringBed boards

The invention relates to a hydraulic nursing bed. The hydraulic nursing bed at least comprises a bed board disposed on a bed body, the bed board at least includes a first bed plate, a second bed plate, a third bed plate and a fourth bed plate which are movably connected to one another, and the fourth bed plate can rotate around the third bed plate on the basis of a first external force, so that afirst included angle is formed between the fourth bed plate and a first fixing surface; the second bed plate can rotate around the third bed plate on the basis of a second external force, so that a second included angle is formed between the second bed plate and the first fixing surface; a first form of the bed board is defined under the case of increasing the first included angle and the second included angle, and a second form of the bed board is defined under the case of increasing the first included angle and decreasing the second included angle; when the bed board is switched from the first form to the second form, at least the posture of the human body can be changed and / or the human body is prevented from tilting forward. According to the hydraulic nursing bed, a forward tilting trend can be predicted in time when a user tilts forward due to fatigue, and correspondingly the risk of falling due to excessive forward tilting of the user is effectively avoided.

Owner:HEFEI UNIV OF TECH

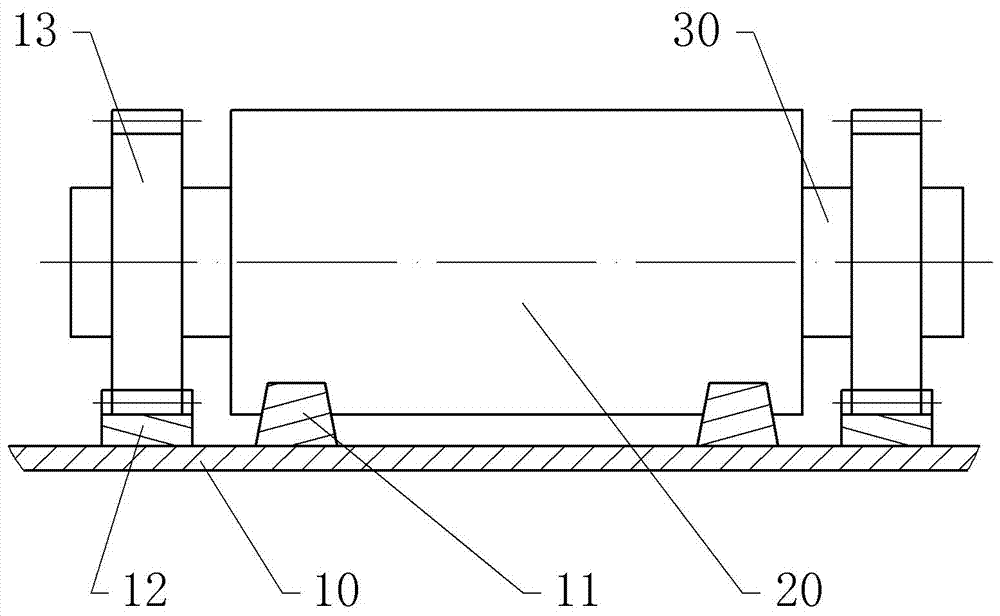

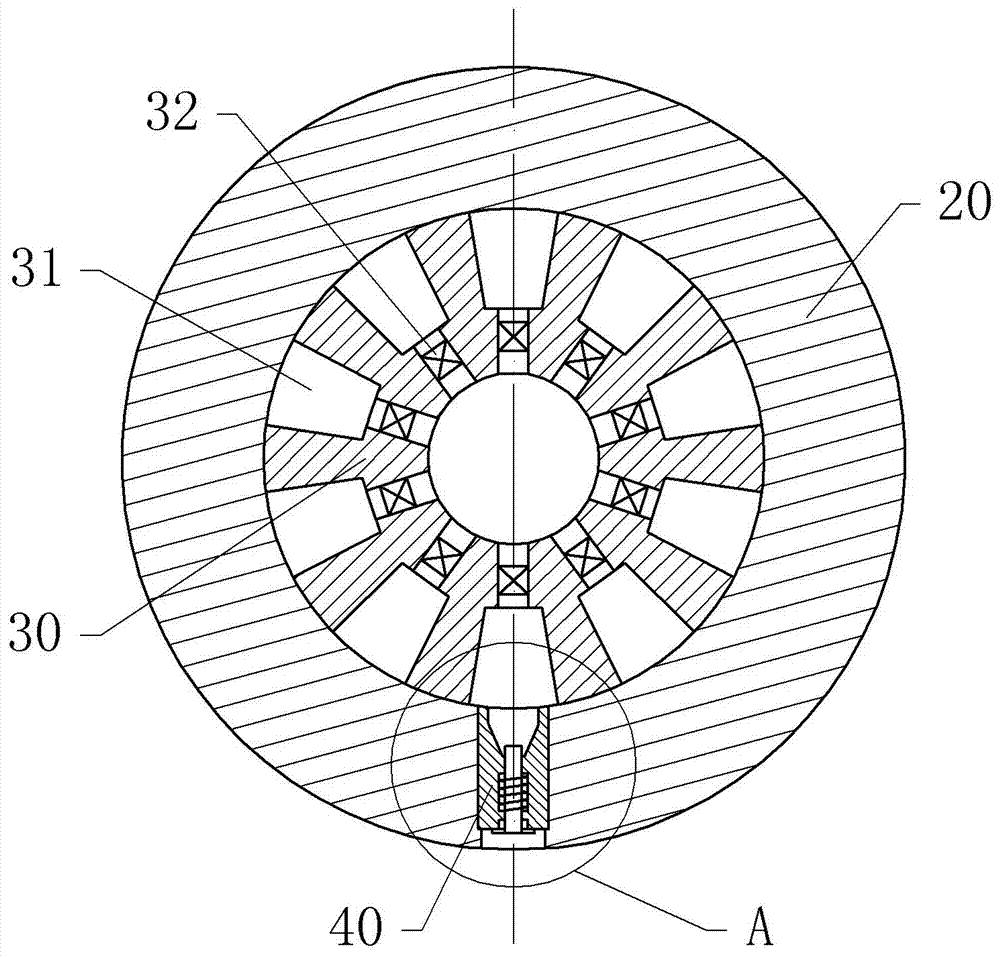

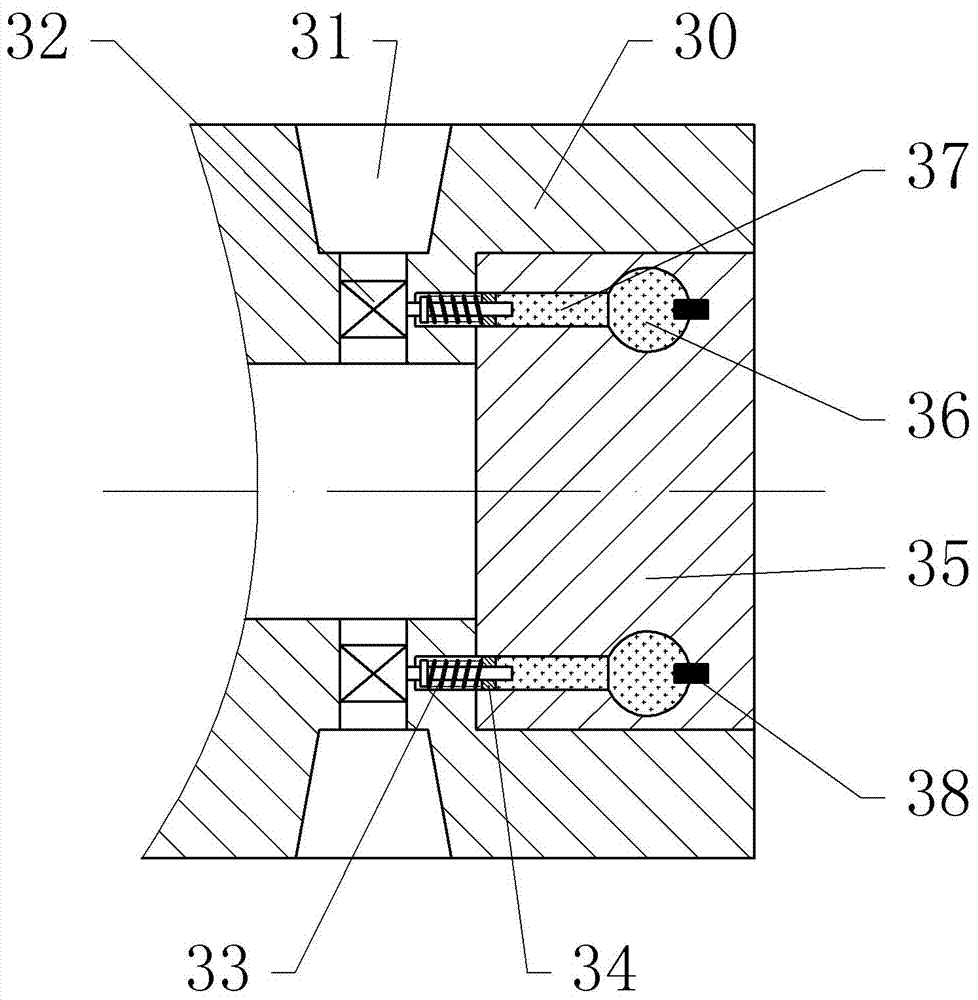

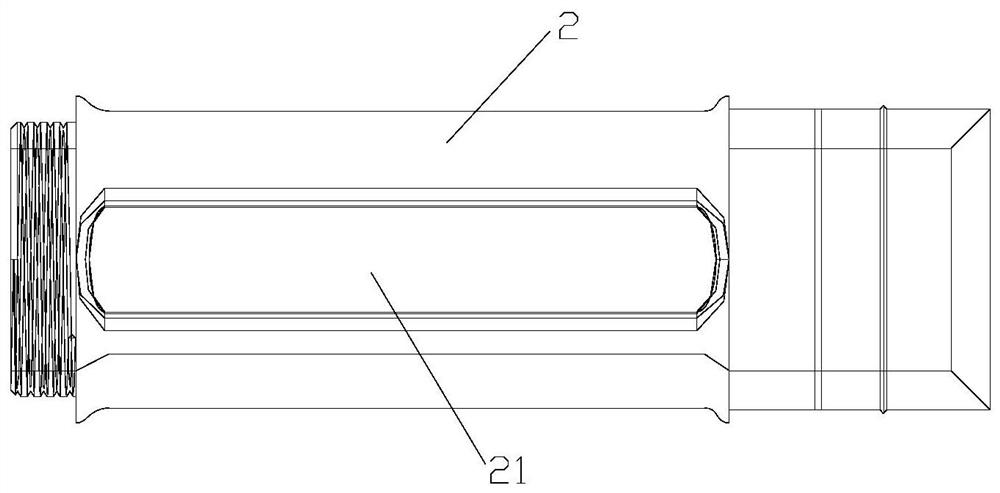

Inner peripheral heating corrugated roller

The invention relates to an inner peripheral heating corrugated roller. The inner peripheral heating corrugated roller comprises a corrugated roller body, a plurality of groups of steam channels are arranged in the corrugated roller body, each group of steam channels is annularly and uniformly distributed around the center of the corrugated roller body and close to the outer wall surface of the corrugated roller body; each group of steam channel comprises more than four pipelines, the pipes point along the axis direction of the corrugated roller body, and the pipelines are sequentially in communication; and one end of the corrugated roller body is provided with a steam inlet channel and a steam return channel, and the two ends of each steam channel are in communication with the steam inletchannel and the steam return channel correspondingly. According to the inner peripheral heating corrugated roller, the steam channels are distributed on the wall of the corrugated roller body, due tothe fact that the steam channels are close to the outer wall surface of the corrugated roller body, the heating speed is high, and the heat loss is reduced.

Owner:佛山市界龙机械有限公司

Die cutting device

ActiveCN107399104AAdjust the incision lengthEasy to operateBag making operationsPaper-makingInlet channelEngineering

The invention discloses a die-cutting device, which relates to the fields of printing and packaging; it includes a frame, a die-cutting cylinder, a rolling knife and an adjustment mechanism. The frame is provided with a guide rail and a rack parallel to the guide rail, and the die-cutting cylinder is slidably connected. On the track, the die-cutting cylinder is provided with a mounting hole along the radial direction of the die-cutting cylinder and through the side wall of the die-cutting cylinder. The rolling knife and the adjustment mechanism are installed in the mounting hole, and the air control shaft connected to the frame is also included. , the die-cutting cylinder is set outside the air control shaft, and the air control shaft is provided with an air inlet and a number of air chambers arranged radially along the air control shaft. One end of the air chamber is connected to the air inlet, and the air chamber is connected to the air inlet. There is a pressure reducing valve; the end of the air control shaft is fixed with a transmission gear that meshes with the rack; the adjustment mechanism includes a cylinder, a thimble located in the cylinder and a spring sleeved outside the thimble; one end of the cylinder can be Connected with the air chamber, the thimble can slide along the inner cavity of the cylinder body, and one end of the thimble is fixed with the rolling knife. The device can change the length of the cut on the packaging material.

Owner:瑞安市振华印刷机械加工有限公司

Network pressure superposition water supply system based on optimal auto disturbance rejection control

ActiveCN101654920BBroaden your optionsEasy to tuneFluid pressure control using electric meansWater supply tanksFrequency changerAutomatic control

The invention relates to a secondary water supply system and the automatic control field, in particular to a network pressure superposition water supply system based on optimal auto disturbance rejection control. The system comprises a transducer, an asynchronous motor, a water pump, a pressure sensor and a digital control unit based on auto disturbance rejection algorithm; wherein the digital control unit based on auto disturbance rejection algorithm receives the pressure value input by a pressure sensor and outputs the pressure value to the transducer in the form of analog voltage signal after A / D conversion and processing of internal auto disturbance rejection program; the output terminal of the transducer is connected with the input terminal of the asynchronous motor, the asynchronousmotor adjusts speed according to the voltage and frequency signal given by the transducer, thus regulating the exit pressure of the water pump. The invention has the beneficial effects that: the control problem of the existing network pressure superposition water supply system is solved, thus improving performances of response speed, anti-interference ability, robustness and the like of the system and improving safety of water supply and comfort of user water.

Owner:TIANJIN GANQUAN GROUP

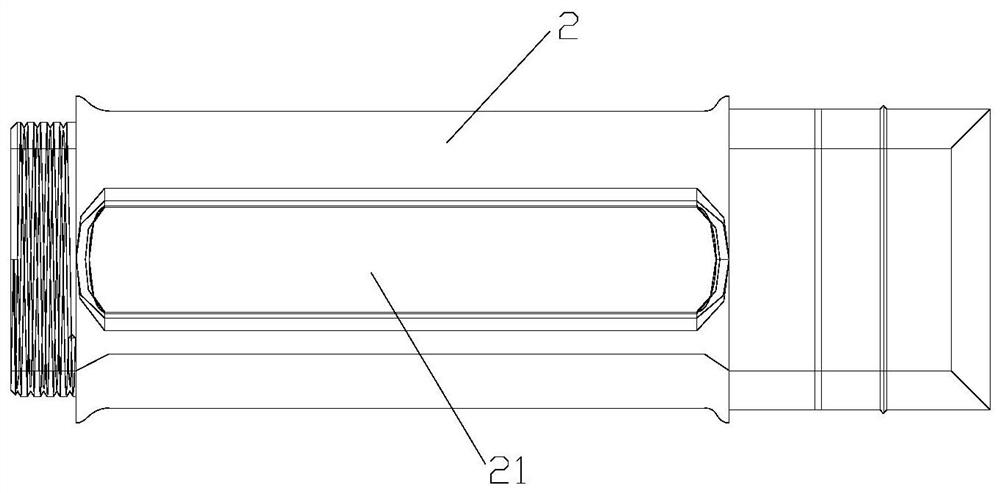

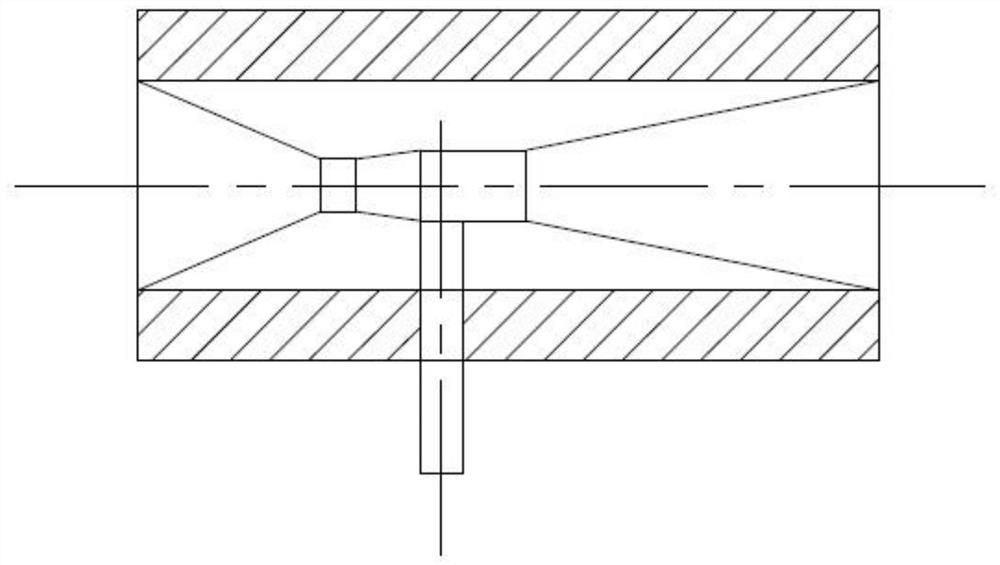

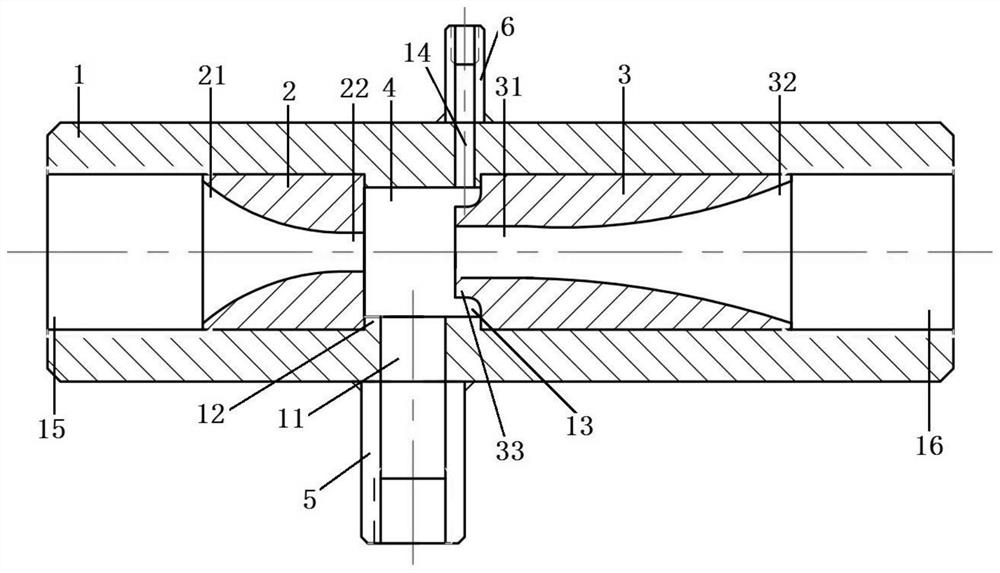

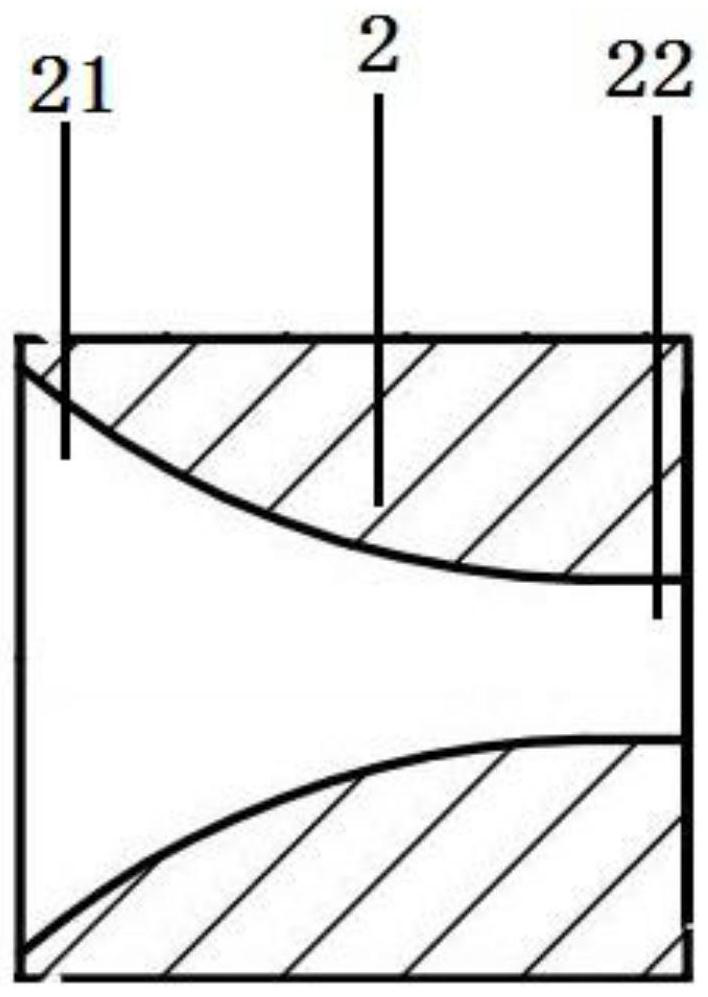

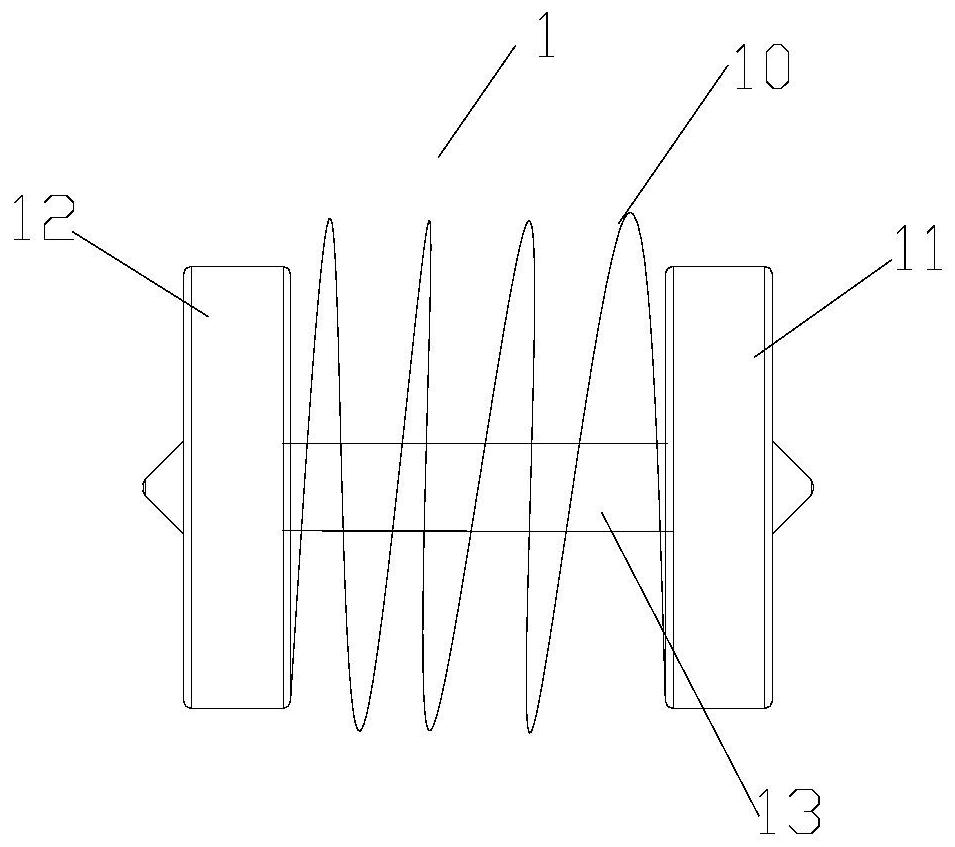

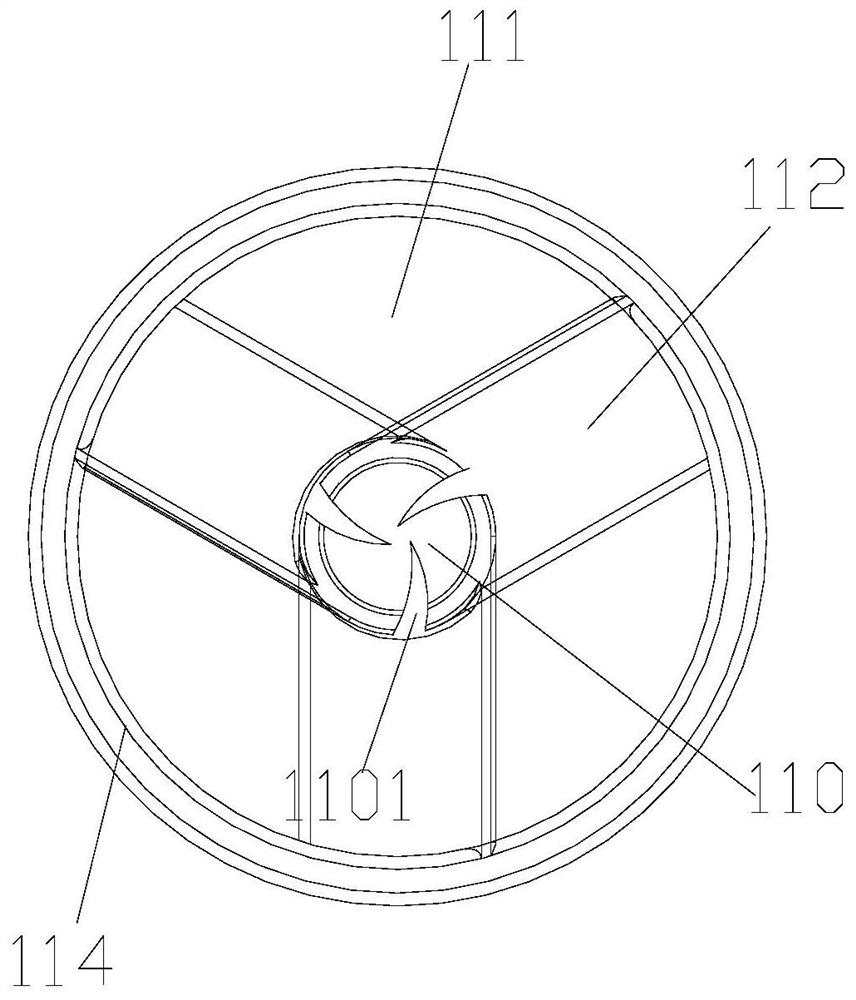

Venturi type multiphase fluid mixer and multiphase fluid mixing method

PendingCN113069949ALess quantityReduce flow rateFlow mixersTransportation and packagingEngineeringMechanical engineering

The invention discloses a venturi type multiphase fluid mixer and a material mixing method. The venturi type multiphase fluid mixer comprises a sleeve (1), an upstream reducing pipe (2), a downstream increasing pipe (3), a multiphase fluid mixing cavity (4) and a feeding pipe (5); the gauge pressure at the multiphase fluid mixing cavity (4) is from -0.01 MPa to + 0.01 MPa; the multiphase fluid mixing comprises gas-liquid mixing, gas-liquid-solid mixing, liquid-liquid mixing and liquid-liquid-solid mixing; and the cross sectional area of the multiphase fluid mixing cavity (4) is larger than that of the throat part. The hydrostatic pressure at the multiphase fluid mixing cavity (4) is from micro-negative pressure to micro-positive pressure and is easy to control, so that the pressure at the throat part is not influenced by downstream equipment or pipelines and is stable, the second material is introduced into the multiphase fluid mixing cavity (4) by adopting positive pressure supply equipment, and the positive pressure of the positive pressure supply equipment can be stably controlled, and thus the amount of the second material introduced into the multiphase fluid mixing cavity (4) can be stably controlled.

Owner:SHENZHEN REVELATION TECH CO LTD

Condenser pipeline online cleaning device

PendingCN112066784APressure effectReduce resistanceFlush cleaningRotary device cleaningBristleWater flow

The condenser belongs to the technical field of condensers, and discloses a condenser pipeline online cleaning device. The condenser pipeline online cleaning device comprises a cleaning mechanism capable of periodically moving back and forth on a condenser pipeline, and the cleaning mechanism comprises a cleaning brush. Impellers are correspondingly arranged at the two ends of the cleaning brush,a brush body is arranged between the two impellers, the brush body comprises bristles and a connecting body for fixing the bristles, the two ends of the connecting body are correspondingly connected with the centers of the two impellers, and the bristles exceed the outer diameters of the impellers. The condenser pipeline online cleaning device is placed in the condenser pipeline when being used, and after the direction of water flow in the condenser pipeline is reversed, the cleaning mechanism in the condenser pipeline moves horizontally under the action of pressure of water and rotates underthe action of an impeller structure, namely, the cleaning mechanism moves spirally and horizontally. On the one hand, resistance during moving is reduced, on the other hand, grooves in the inner wallof the condenser pipeline can be cleaned, the cleaning efficiency is improved, and the pressure of the condenser pipeline cannot be greatly affected.

Owner:深圳市纽乐节能设备工程有限公司

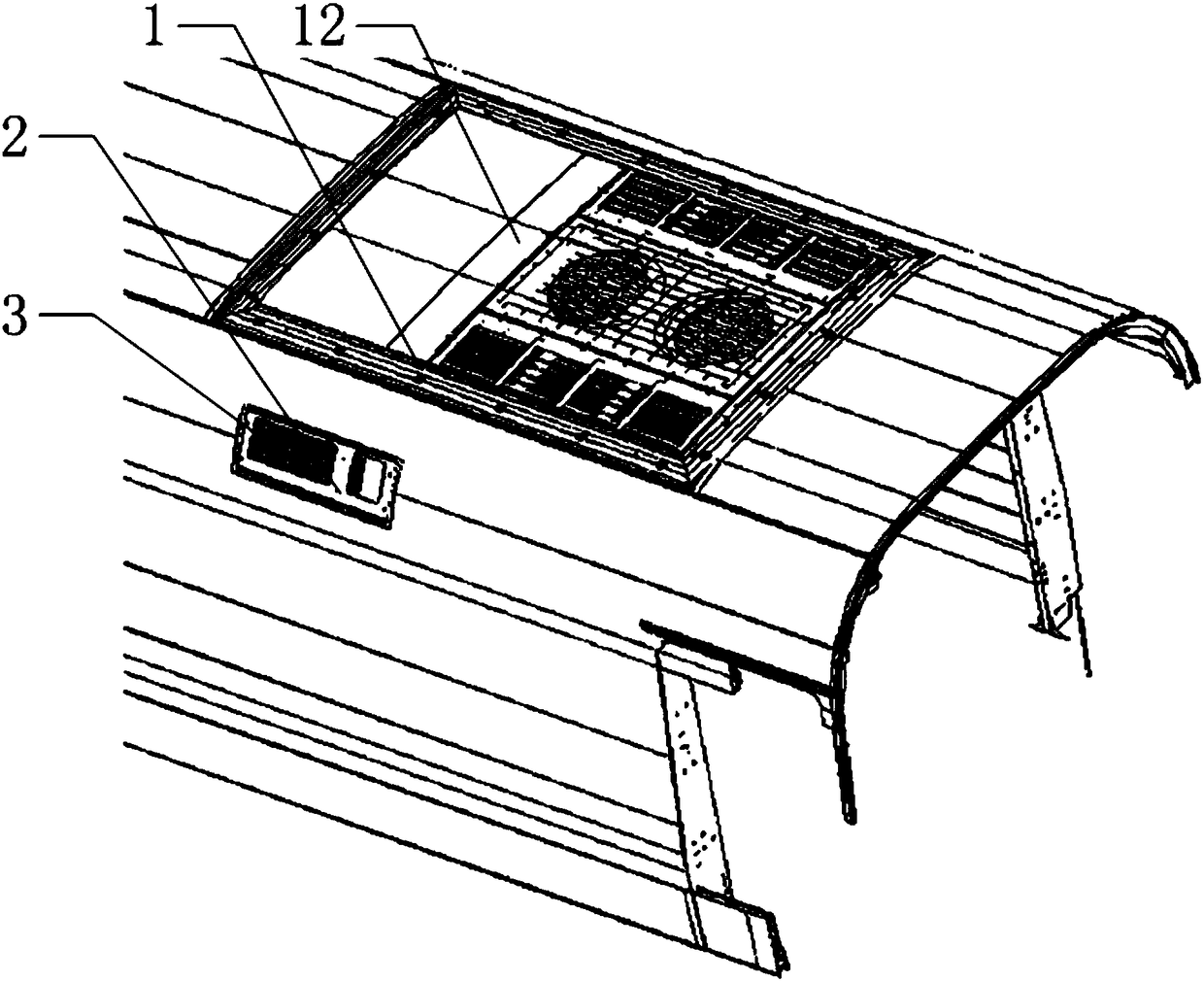

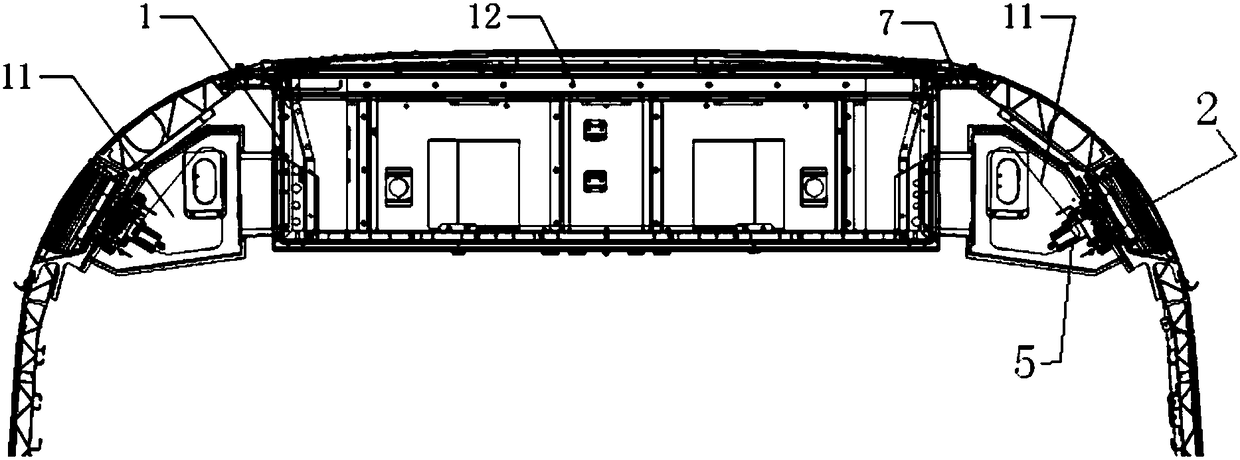

Rail train and air-conditioning unit complete equipment thereof

The invention discloses air-conditioning unit complete equipment of a rail train. The air-conditioning unit complete equipment is of an integrated structure and comprises a body, a mounting seat, a grating air opening and a mixed air box; an air-conditioning unit is mounted in an air-conditioning unit mounting opening in the top of the rail train through the mounting seat in embedded and sunken modes, the mounting seat and the body are provided with a sealing component therebetween and connected through connecting pieces, and the top surface of the air-conditioning unit is lower than or flushwith the top of a train body; grating type pressure wave protection devices are arranged on the two sides of the air-conditioning unit. The structure is good in manufacturability, work efficiency canbe conveniently improved, leakage points are reduced, system reliability is guaranteed, and meanwhile the mounting strength and rigidity requirements are met and airtightness is guaranteed. When pressure fluctuation occurs outside the rail train, a controller can quickly respond to drive the sealing component to seal a vent opening, pressure in the train is prevented from being affected by pressure fluctuation outside the train, and thus comfort is improved, resistance is reduced and airtightness is enhanced. The invention further discloses the rail train comprising the air-conditioning unit.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

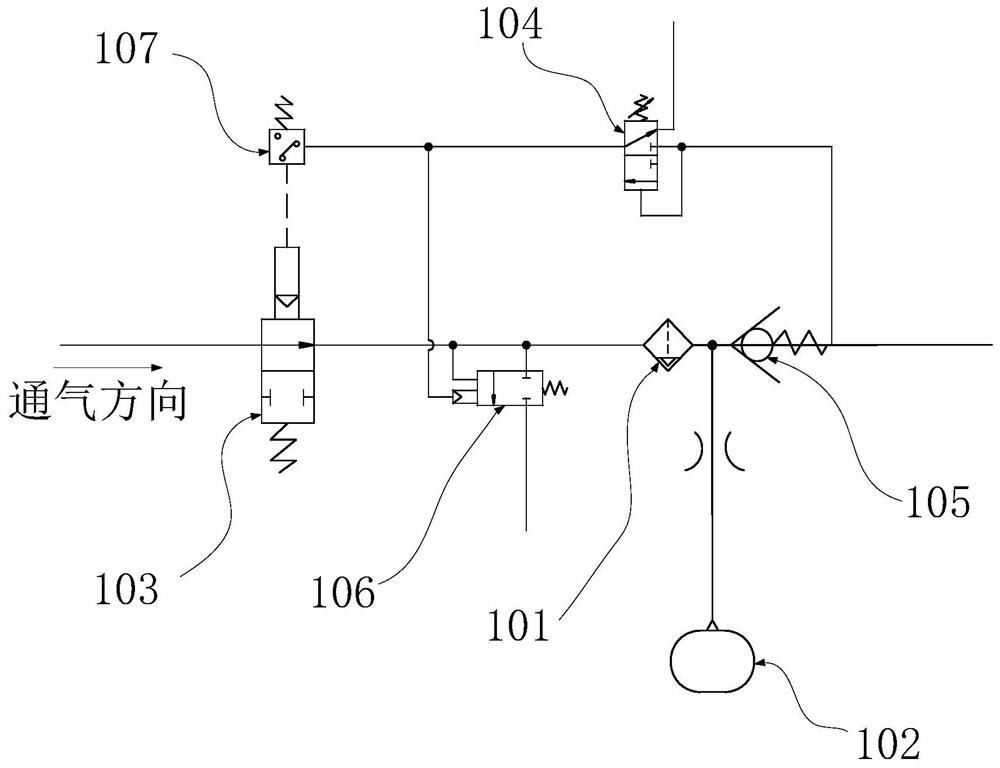

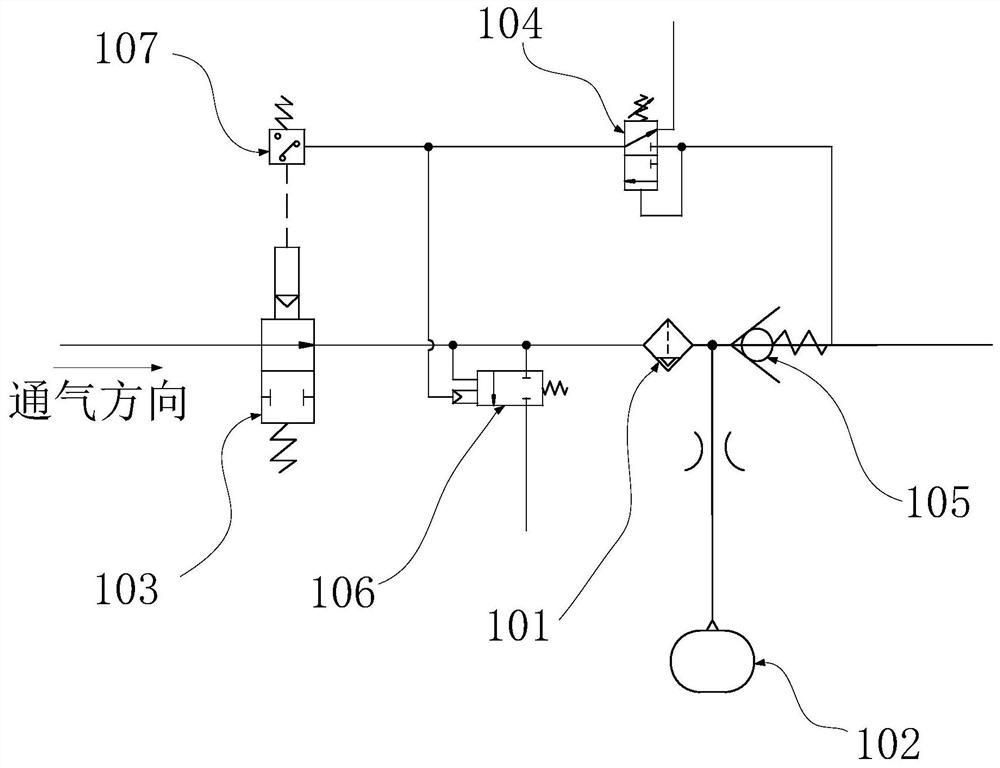

Auxiliary gas circuit drying device and braking system

ActiveCN111661024ADoes not affect pressurePressure effectAir treatment devicesMolecular sieveExhaust valve

The invention discloses an auxiliary gas circuit drying device and a braking system, and relates to the technical field of gas circuit drying devices. The auxiliary gas circuit drying device comprisesa first molecular sieve, a first regeneration cylinder, a first exhaust valve and a control valve. The first regeneration cylinder and the first exhaust valve are connected with the first molecular sieve, the control valve and the first molecular sieve are both installed on a gas circuit, the control valve is arranged on one side of an air inlet of the first molecular sieve, and the control valveis switched into a closed state when the pressure of the gas circuit exceeds a first threshold value. The auxiliary gas circuit drying device is applied to an auxiliary gas circuit of the braking system, can further dry the auxiliary gas circuit and does not influence pressure of a main gas circuit.

Owner:SANY AUTOMOBILE HOISTING MACHINERY

Method for replenishing hydrochloric acid for acid washing on rolled steel production line

ActiveCN102534639BExtend your lifeAvoid air pressure imbalanceWork treatment devicesMetal rolling arrangementsProduction lineAcid washing

The invention discloses a method for replenishing hydrochloric acid for acid washing on a rolled steel production line, which is characterized in that the upper ends of a plurality of hydrochloric acid containers are communicated through pipelines and connected to a water solution of an acid mist collecting tank through a collecting pipeline; the collecting pipeline is provided with a pressure sensor for detecting the air pressure in the collecting pipeline, and a by-pass pipe for replenishing air, so that one end of the by-pass pipe far from the collecting pipeline is communicated with the atmosphere; the by-pass pipe is provided with an electric ball valve; and the pressure sensor is utilized to control the electric ball valve, so that the air pressure in the hydrochloric acid containers can be kept normal in the fresh acid replenishment process and the acid washing hydrochloric acid production supply process. The method has the advantages of low implementation cost, practical and reliable effect and the like, and is convenient and simple to implement; and since the hydrochloric acid is recycled, the loss is lowered, and thus, the invention has favorable economic benefit and environmental benefit if being used for a long time.

Owner:CHONGQING IRON & STEEL CO LTD

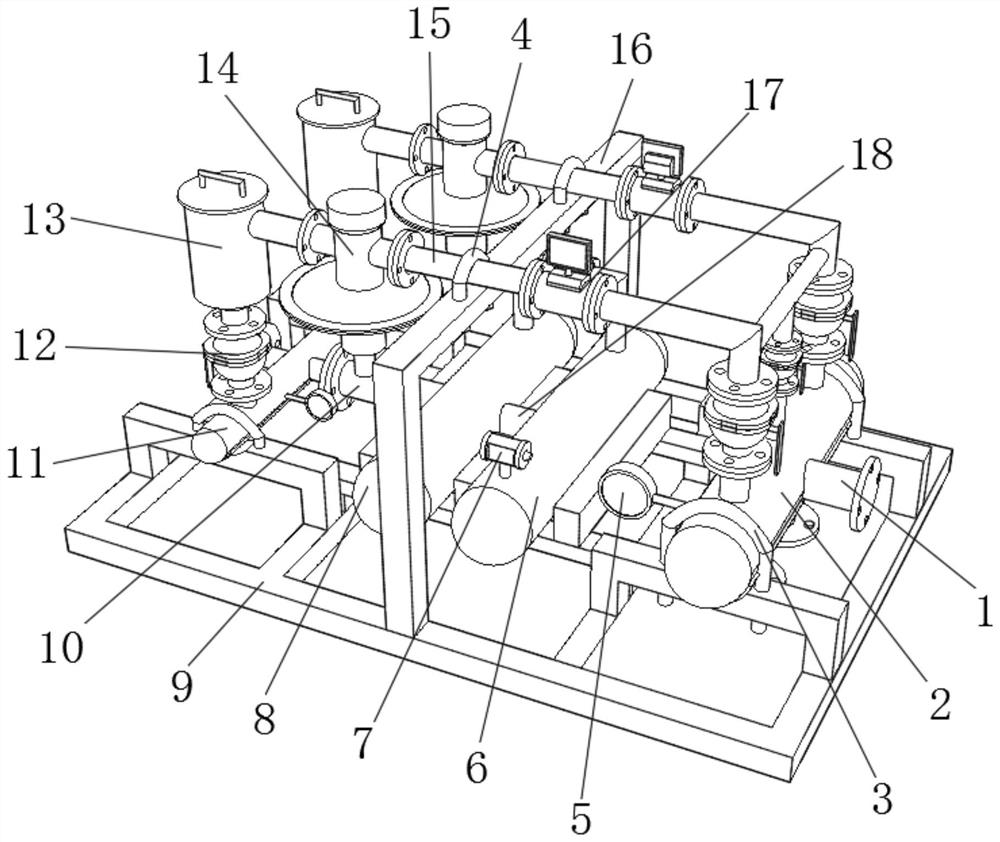

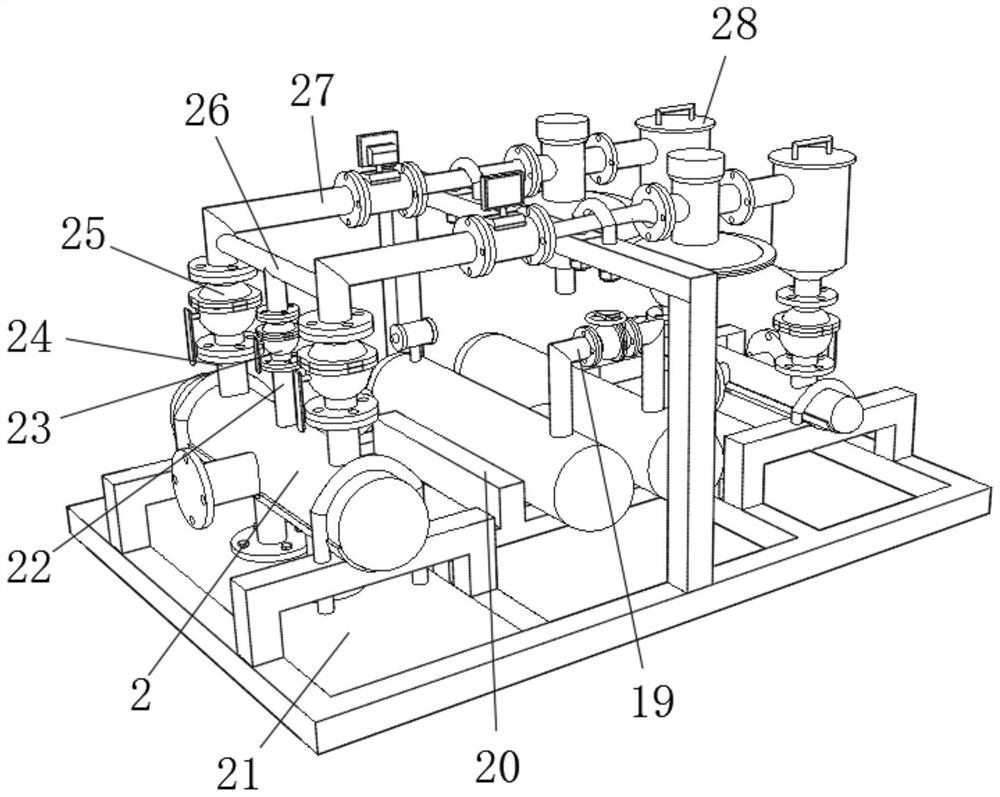

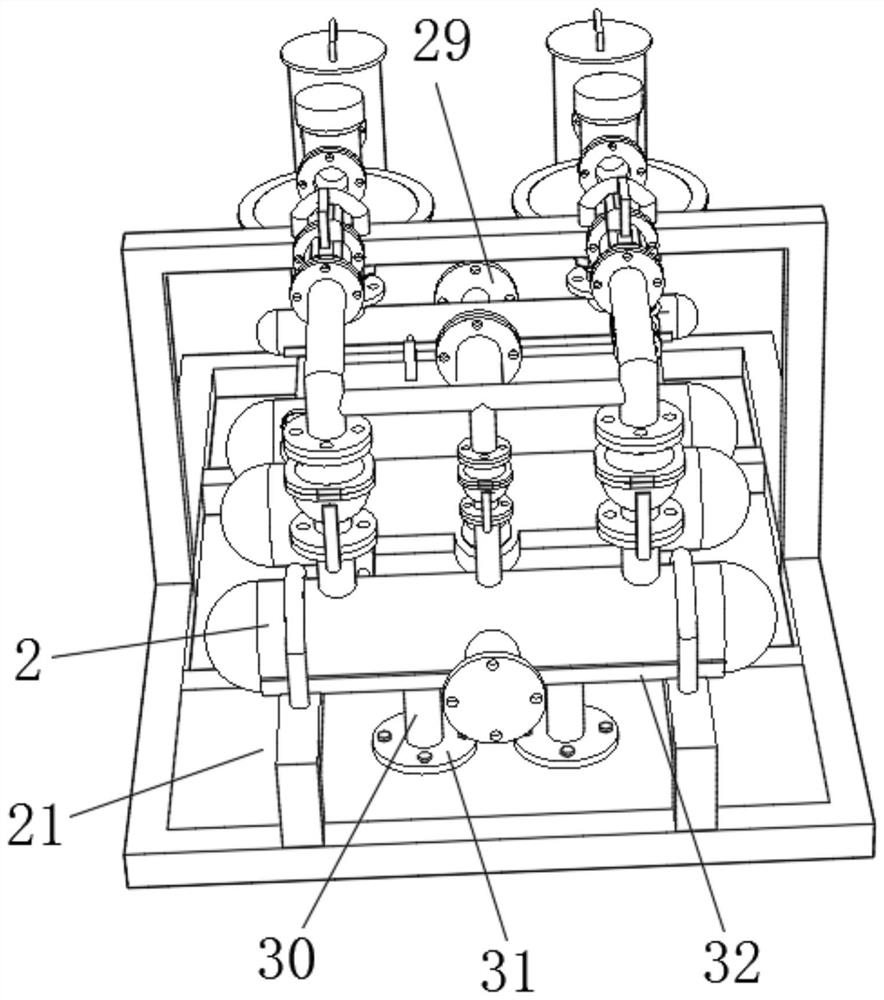

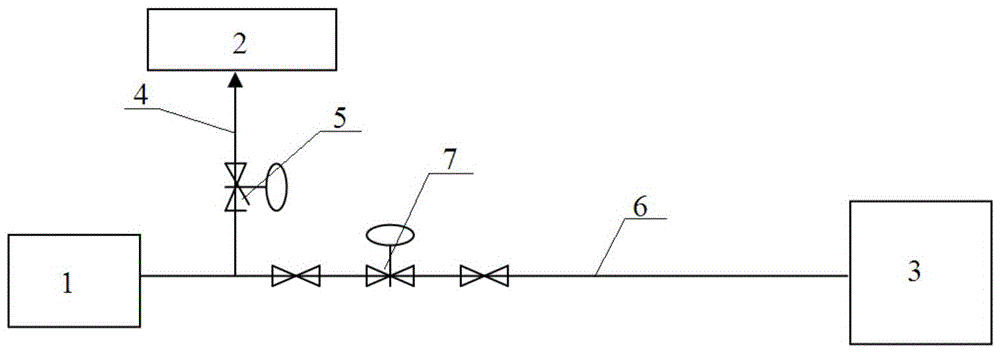

A regional gas pressure regulating skid with safety warning function

ActiveCN112013276BGas stabilizationEasy to usePipeline systemsPhysical medicine and rehabilitationEngineering

Owner:WUXI NOBETTER FLUID EQUIP TECH CO LTD

Method for using hydrogen and carbon monoxide to separate cold box tail gas as reformer fuel

The invention relates to a method using hydrogen and carbon monoxide separation cold box tail gas as a converter fuel. Partial cold box tail gas is connected to a torch through a discharge pipeline, and combusts, and the residual cold ox tail gas is connected to a converter through a tail gas reuse pipeline, and is used as a converter fuel; and the discharge pipeline is provided with a regulating valve for regulating the flow amount and the pressure of the cold box tail gas entering the torch and combusting, and the tail gas reuse pipeline is provided with a regulating valve for regulating the flow amount and the pressure of the cold box tail gas entering the converter and combusting. The method concretely comprises the following steps: starting the converter to make the converter normally run; regulating the regulating valve on the discharge pipeline to regulate the pressure of the cold box tail gas entering the torch and combusting to 0.6-1bar; regulating the regulating valve on the tail gas reuse pipeline to regulate the pressure of the cold box tail gas entering the converter and combusting to 0.4-0.8bar; and controlling the flow amount of the cold box tail gas entering the converter and combusting to 30-120nm<3> / h. Compared with the prior art, the method has the advantages of cost saving, large economy value, environmental protection and cleanness.

Owner:SHANGHAI HUALIN IND GASES

Auxiliary gas path drying device and braking system

ActiveCN111661024BPressure effectDoes not affect pressureAir treatment devicesMolecular sieveExhaust valve

Owner:SANY AUTOMOBILE HOISTING MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com