Nitrogen making machine with three-tower structure

A nitrogen generator and working tower technology, applied in the direction of nitrogen purification/separation, can solve the problems of low use efficiency of molecular sieve, large gas production capacity of nitrogen generator, low gas production efficiency, etc., to achieve stable overall purity and improve production efficiency. , The effect of stable air supply pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

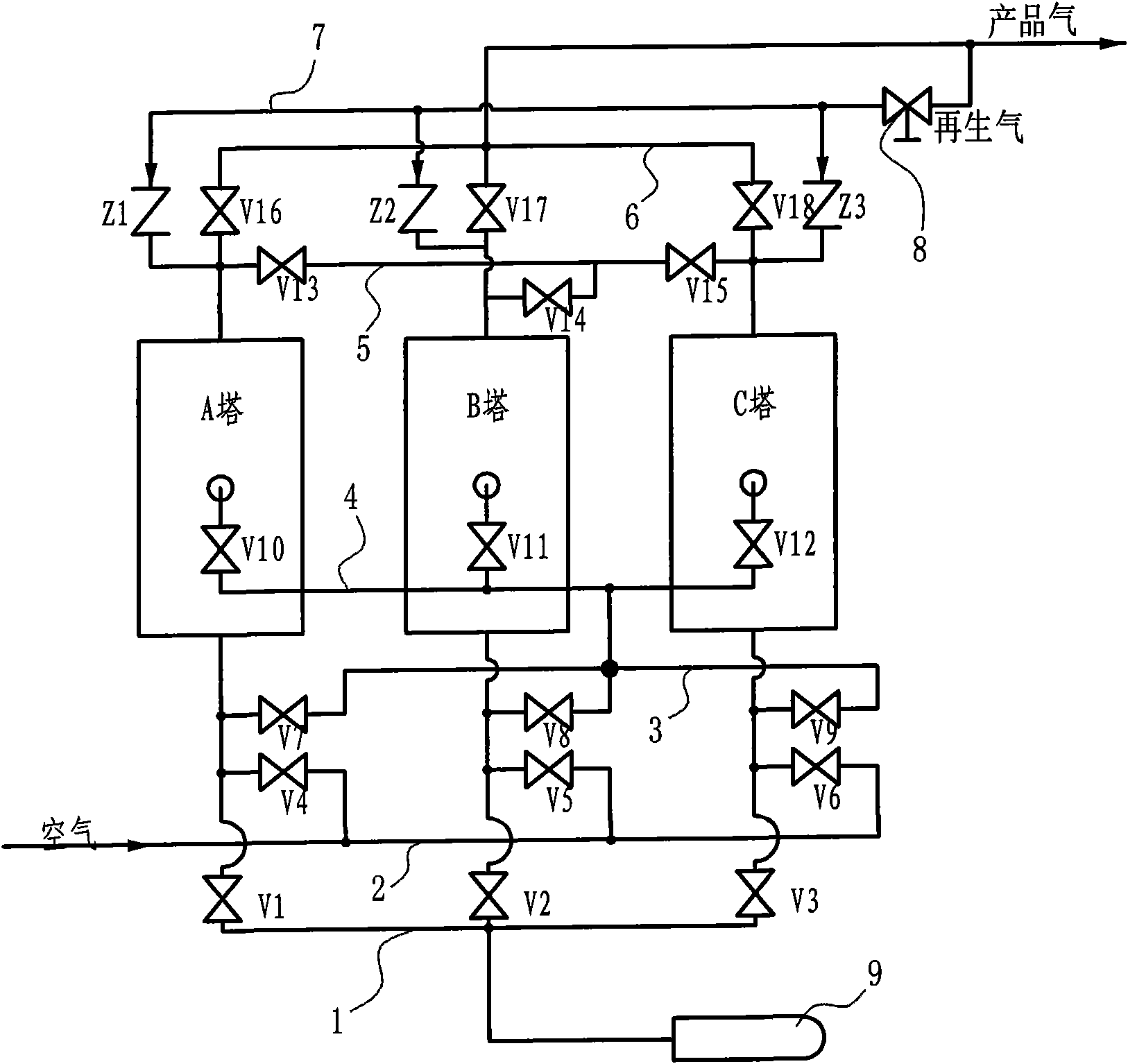

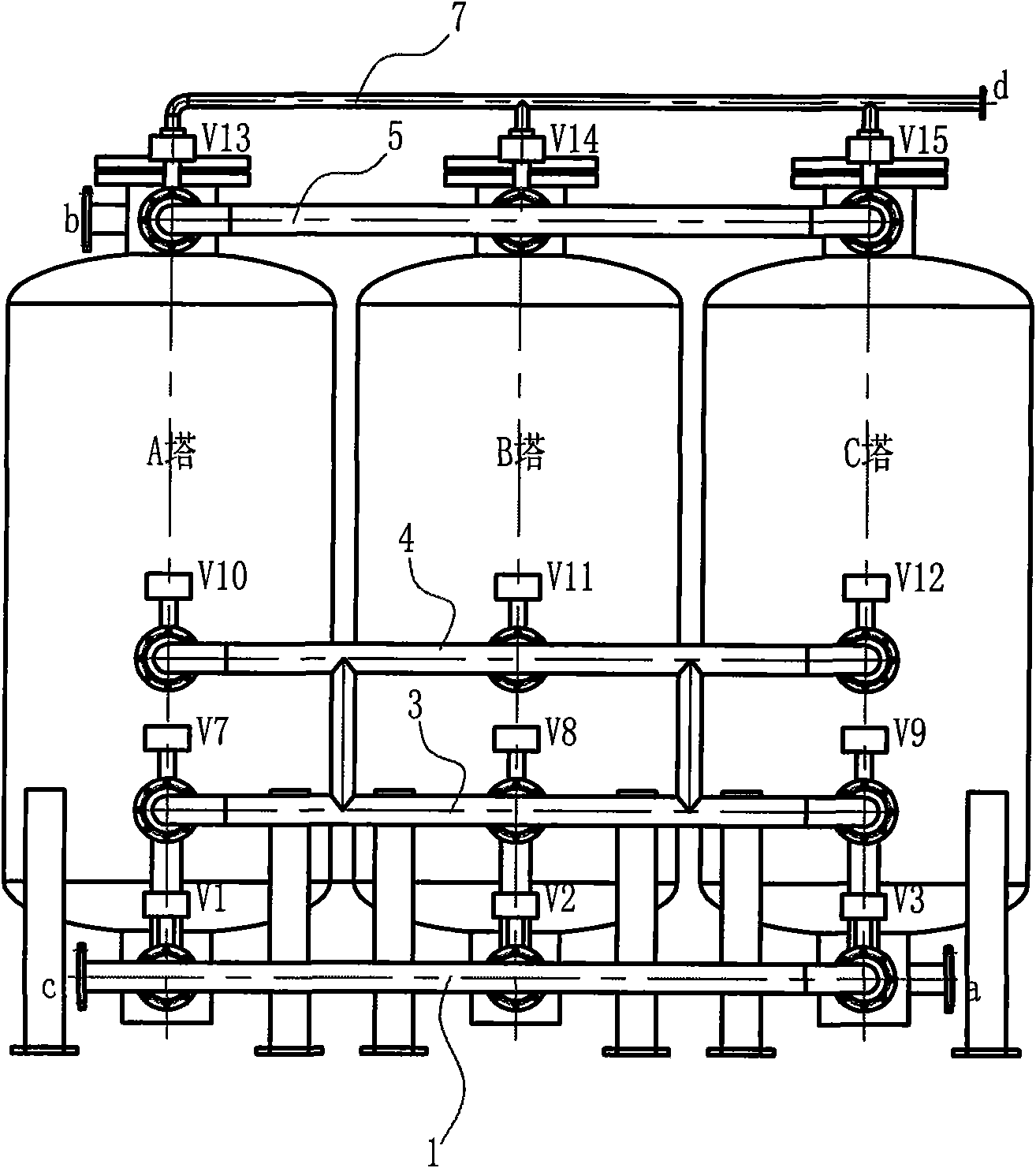

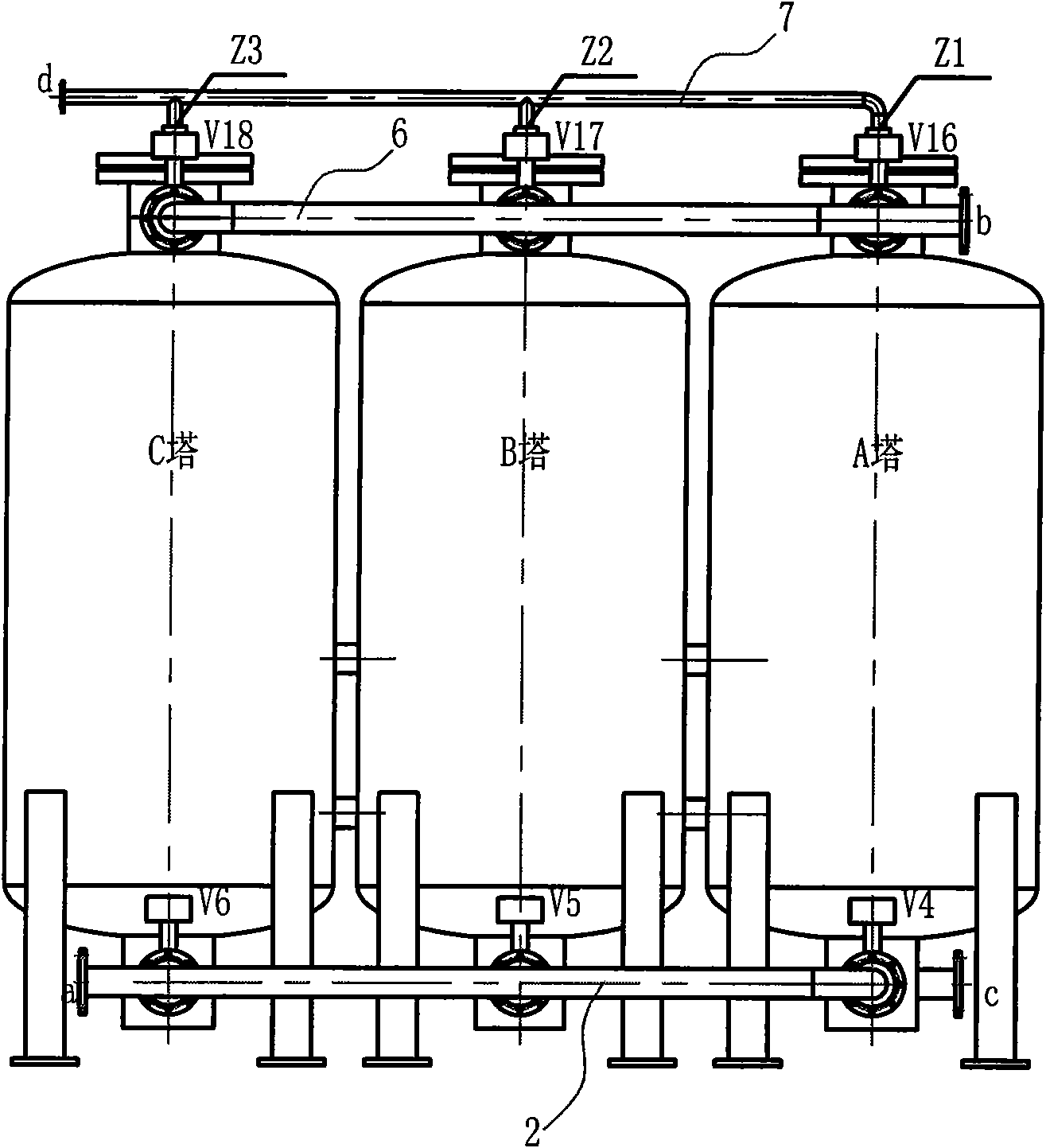

[0024] The three-tower structure nitrogen generator has a working tower with a built-in molecular sieve. The working towers are tower A, tower B and tower C. The bottom of tower A is connected in parallel with valve one V1, valve four V4 and valve seven V7. The bottom of tower B is connected in parallel. Valve 2 V2, valve 5 V5, and valve 8 V8 are connected in parallel through connecting pipes. The bottom of tower C is connected in parallel with valve 3 V3, valve 6 V6 and valve 9 V9 through connecting pipes. The other ends of valve 1, valve 2 and valve 3 are connected to pipe 1. The other ends of valve four, valve five and valve six are connected with pipe two and two, and the other ends of valve seven, valve eight and valve nine are connected with pipe three and three; the middle parts of tower A, tower B and tower C are respectively connected to the outside through connecting pipes There are valve 10 V10, valve 11 V11, valve 12 V12, the other end of valve 10, valve 11, and val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com