Patents

Literature

75results about How to "Improve gas production performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gasification device for classified gasification of moving bed, method for gasifying coal and applications thereof

ActiveCN101982528AIncrease supplyHigh yieldFixed-bed gasificationGranular/pulverulent flues gasificationThermodynamicsChilled water

The invention provides a gasification device for the classified gasification of a moving bed, and a method for classified gasifying of coal and applications thereof. The device comprises a compression shell, a coal filling hopper, a coal distributor, a stirrer, axially symmetrical water clamping sleeves, a slag chilling chamber, a circulatory chilled water inlet, a circulatory chilled water outlet, and a slag seal hopper, wherein, the top and the bottom of the compression shell are respectively provided with a first opening and a second opening, the upper lateral side of the compression shellis provided with a first coal gas outlet, and the same horizontal level at lower part of the compression shell is evenly provided with at least two gasification agent nozzles; the coal filling hopperis arranged on the first opening at the top of the compression shell; the coal distributor is arranged at the upper part in the compression shell; an axially symmetrical water clamping sleeve is arranged in the inner side below the first coal gas outlet of the compression shell, and the inner part of the axially symmetrical water clamping sleeve forms a gasification chamber; the slag chilling chamber is arranged below the second opening at the bottom of the compression shell; and the slag seal hopper is arranged below the slag chilling chamber. The invention is characterized in that at least two fine coal and gasification agent burners are evenly arranged at the lower part of the compression shell of the gasification device and the same horizontal level of the at least two gasification agent nozzles in a staggering manner.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

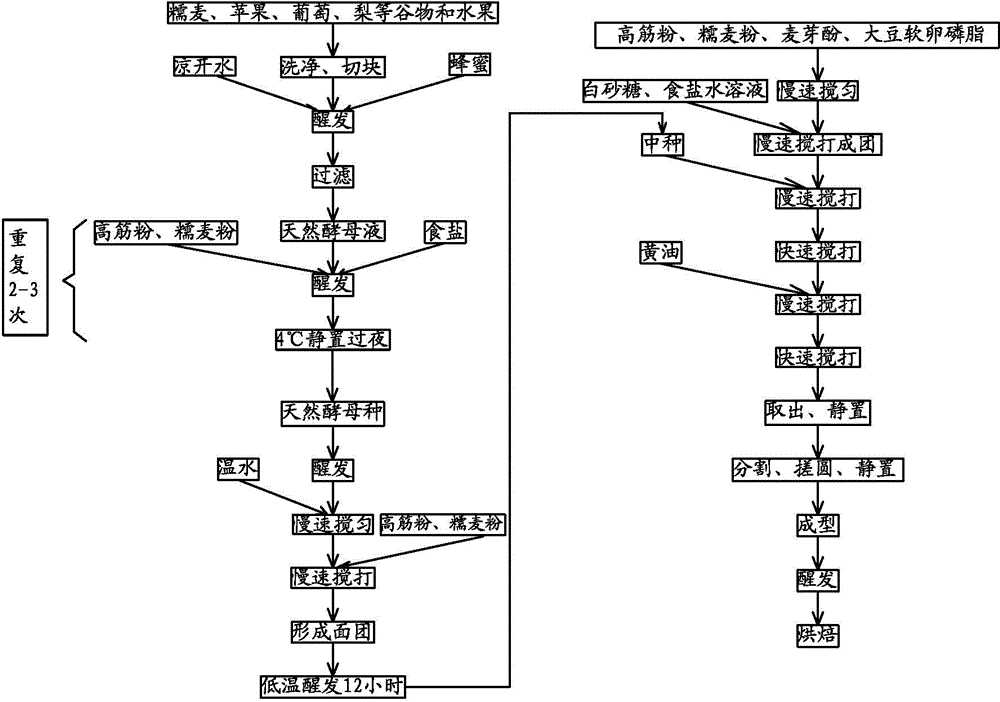

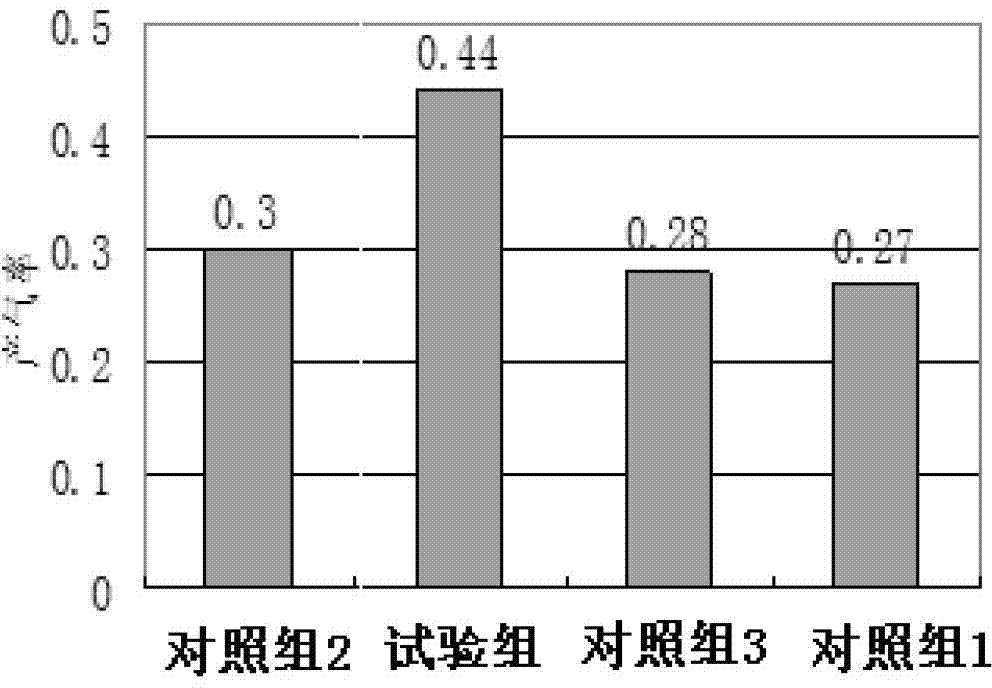

Natural yeast bread and manufacturing method thereof

InactiveCN104782702AAppropriate tasteUniform structureDough treatmentPre-baking dough treatmentNutritive valuesWarm water

The invention relates to a manufacturing method of natural yeast bread. The method includes the steps that a, natural yeast liquid raw materials selected from fruits and cereals at least including glutinous barley are fermented to obtain natural yeast liquid; b, high-gluten flour and glutinous barley flour are mixed to obtain mixed flour, the mixed flour and the natural yeast liquid are mixed to obtain a mixture, and the mixture is fermented to obtain primary natural yeast; c, after the primary natural yeast is fermented, the primary natural yeast, warm water, high-gluten flour and glutinous barley flour are stirred into mixed dough, and the mixed dough is fermented at low temperature to obtain sponge dough; d, high-gluten flour, glutinous barley flour, malt flour, soya bean lecithin and a water solution are stirred and then added into the sponge dough to form bread dough through stirring; e, the bread dough is fermented; f, a conventional method is used for baking to obtain the bread. The invention further discloses natural yeast bread manufactured by adopting the method. The high water absorption rate and the high aerogenesis capacity of the glutinous barley flour, the capacity of promoting yeast aerogenesis of the malt flour and the emulsifying capacity of the soya bean lecithin are used, and low-temperature secondary fermentation is combined to obtain the soft and healthy bread moderate in mouthfeel and high in nutritive value.

Owner:福建安麦高新生物技术有限公司

Method for ferment preparation of sludge gas with vegetable castoff as raw material

InactiveCN101153289APromote degradationSimple processWaste based fuelSludge processingWater bathsSludge

A firedamp preparation method with wasted vegetable as the raw material is provided, which belongs to the energy technical field. The invention the following steps that: at first pretreatment is made on the wasted vegetable as the raw material to adjust the carbon / hydrogen ratio to be 20:1-30:1, then inoculation with the inoculumis carried out, followed by mixing, to obtain the fermented raw material, then water and carbon powder are added for fermentation, with the original pH of fermentation liquid adjusted to be 6.5-7.5, then put into a sealed fermentation device, and immersed in a thermostatic water bath, to carry out the perfect mixing liner wet aerogenous fermentation, to produce the firedamp after 1-2 days, fermentation is carried out for 20-60 days, and the gas is collected with drainage method. The invention accomplishes sufficiently the utilization of wasted vegetable for resourcesiation, reduction and innocuity, and transforms the vegetable harming the environment into biological resources, which produces firedamp as the clean burnable energy and excellent organic fertilizer through anaerobic fermentation.

Owner:SHANGHAI JIAO TONG UNIV

Cold-region methane accelerator and preparation method thereof

InactiveCN102732566AImprove the nutritional environmentGrow fastWaste based fuelFermentationProduction rateSorbent

The invention discloses a cold-region methane accelerator and a preparation method of the cold-region methane accelerator and relates to a methane accelerator and a preparation method of the methane accelerator. The invention aims at solving the technical problems that the existing methane accelerators can not improve gas production rate at low temperature and are difficult to obtain. The cold-region methane accelerator provided by the invention comprises ferrum, cobalt, nickel, organic matters, an adsorbent and a filler. The preparation method comprises the following steps that: (1) ferrous sulfate, cobalt chloride, nickel chloride, the organic matters, the adsorbent and the filler are weighed; (2) distilled water is added to the weighed ferrous sulfate, cobalt chloride and nickel chloride to prepare saturated solution; the adsorbent is added; a crusher is used for crushing after drying to obtain powder; and (3) the organic matters and the filler are added to the powder and the mixture is evenly mixed to obtain the cold-region methane accelerator. The methane accelerator and the preparation method are applicable to the methane field.

Owner:黑龙江省农业科学院农村能源研究所

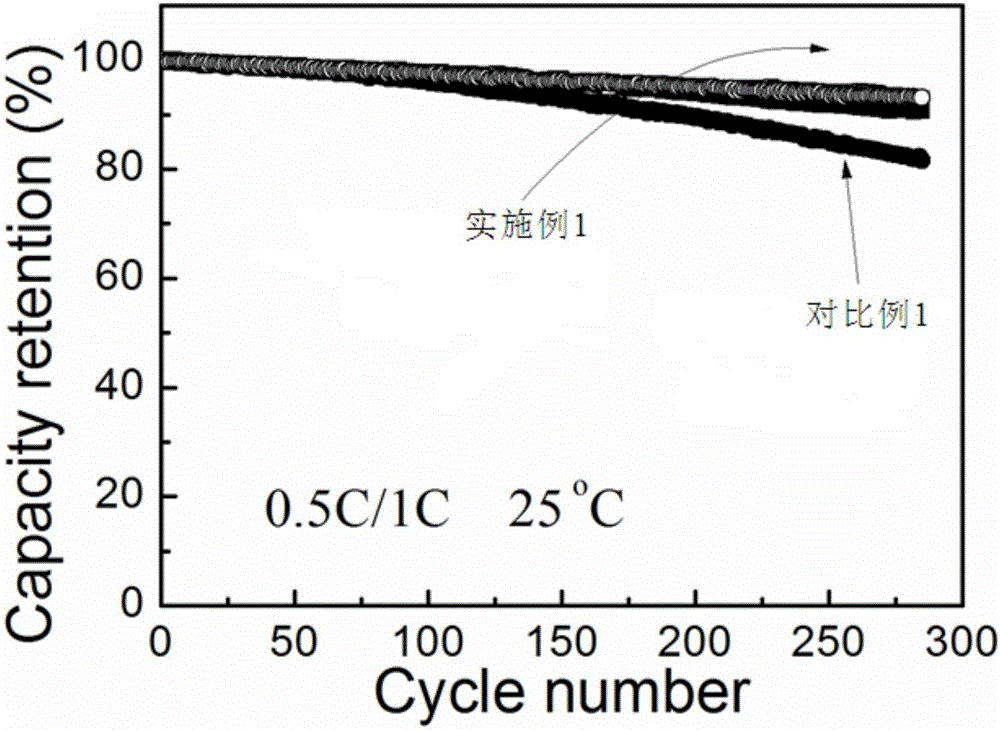

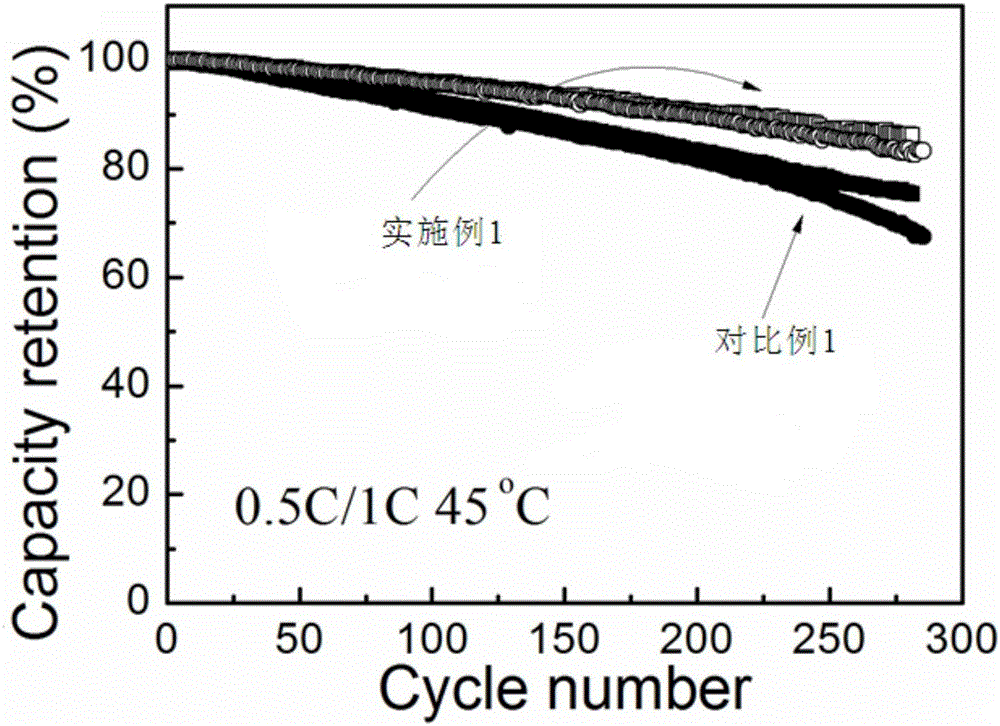

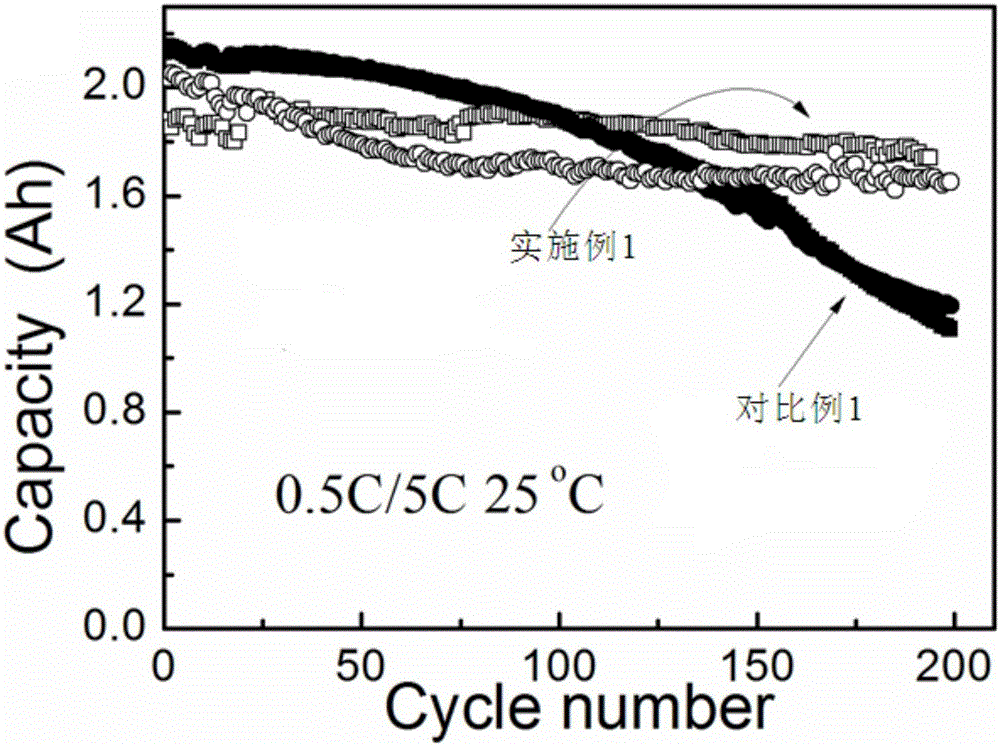

Gel polymer electrolyte power battery

ActiveCN106654353AImprove protectionImprove gas production performanceSecondary cellsPolymer electrolytesLithium

The invention belongs to the technical field of a power battery, and particularly relates to a gel polymer electrolyte power battery. The gel polymer electrolyte power battery comprises a negative electrode, a positive electrode, a gel polymer electrolyte and a diaphragm, wherein a negative electrode active material layer comprises graphite and a composite material dispersed in gaps of the graphite; a positive electrode active material layer comprises at least one kind of NCA, NCM and a lithium-rich manganese material; the gel polymer electrolyte comprises a liquid electrolyte, a polymer monomer and an initiator; and the polymer monomer is selected from at least one kind of TPGDA and PETEA. Compared with the prior art, the gel polymer electrolyte power battery with high energy density, excellent electrochemical performance and high safety can be obtained through synergistic interaction based on reasonable and creative matching and interaction of the positive electrode material, the negative electrode material and the gel polymer electrolyte; and particularly, the gel polymer electrolyte can well protect the positive electrode material, thereby improving the electrochemical performance and the safety of the battery.

Owner:南通市懋略科技有限公司

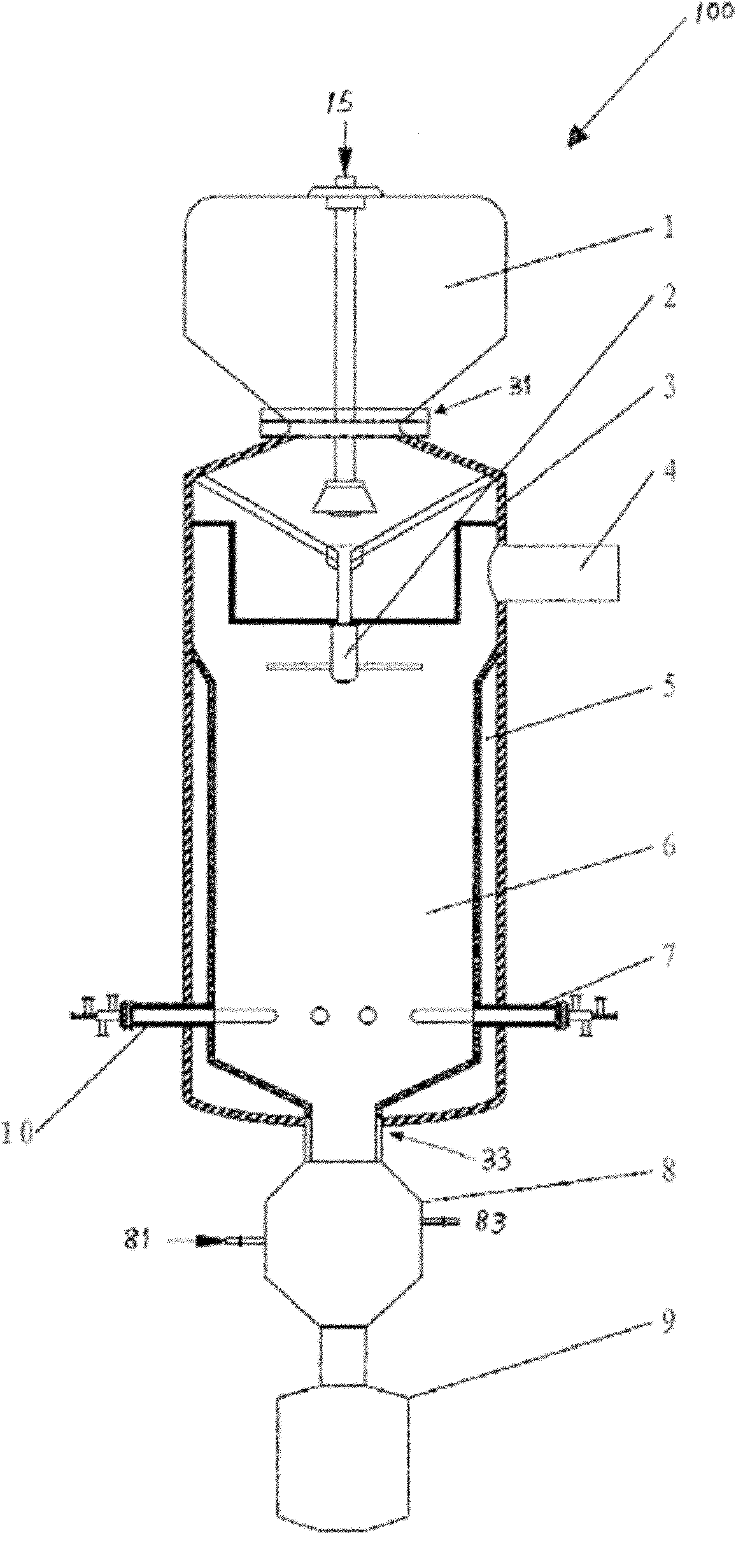

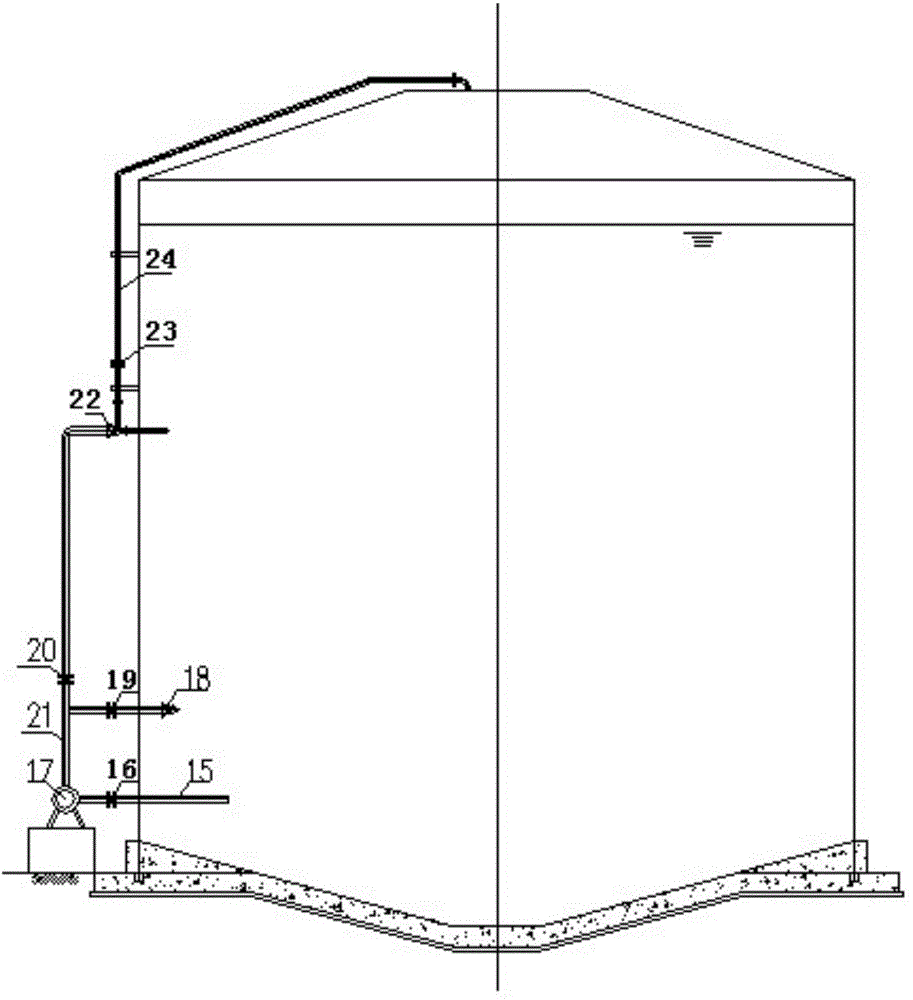

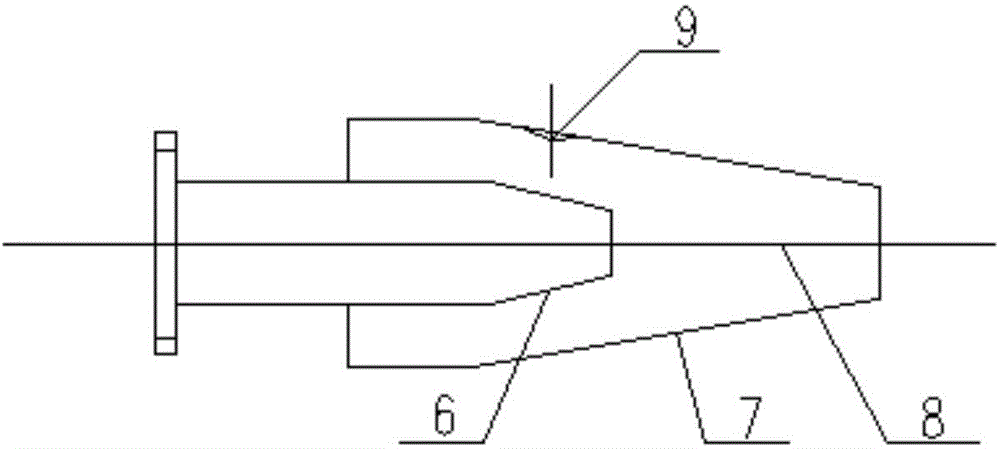

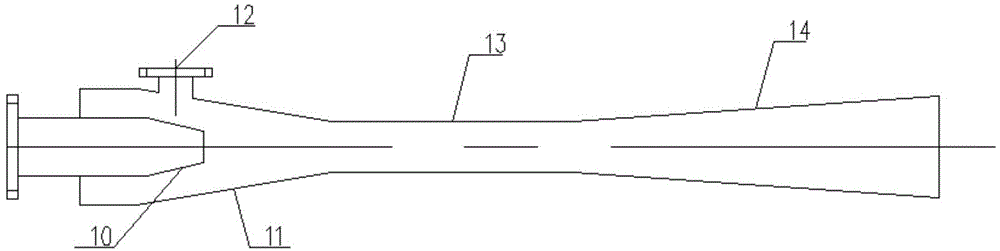

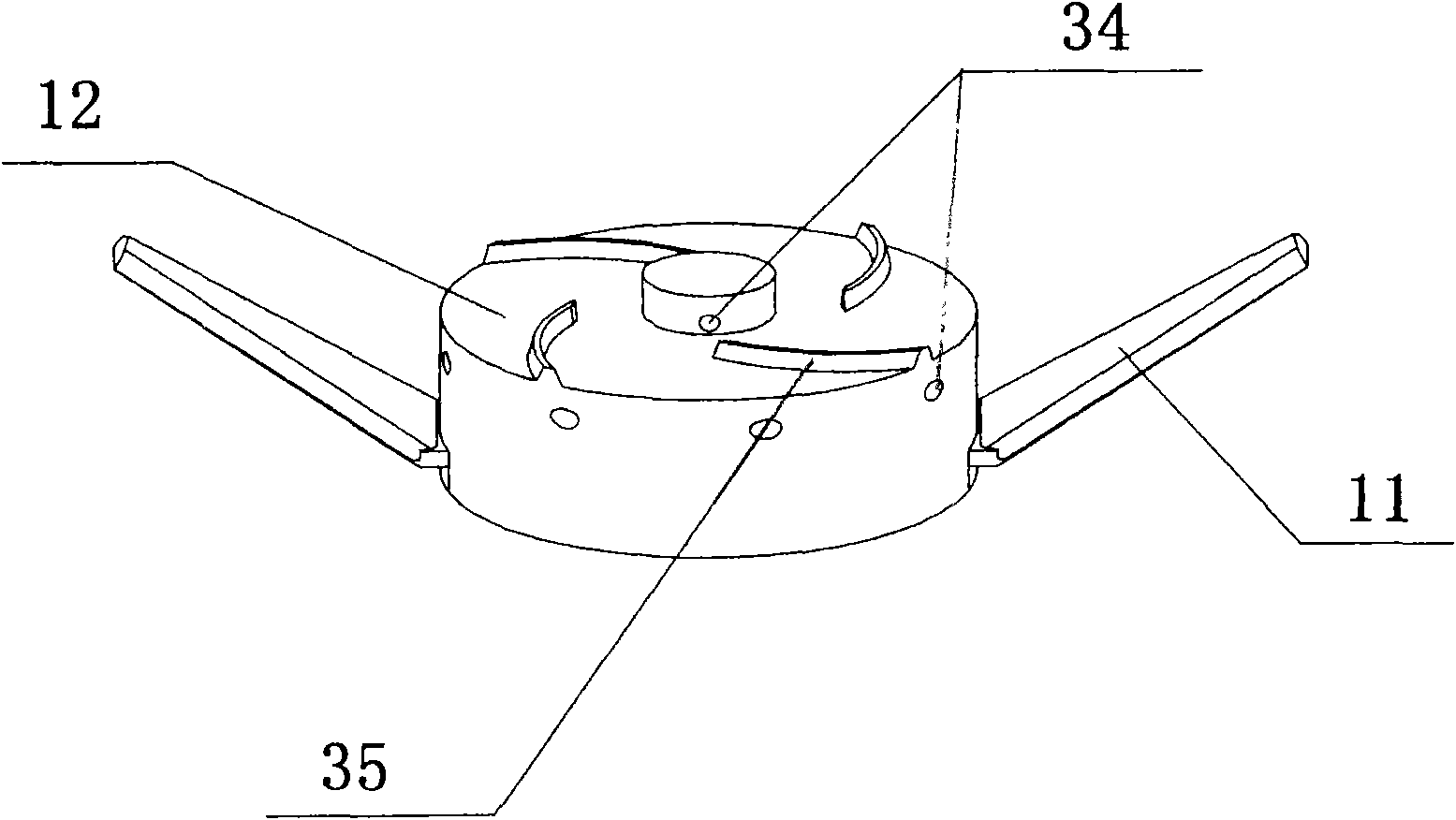

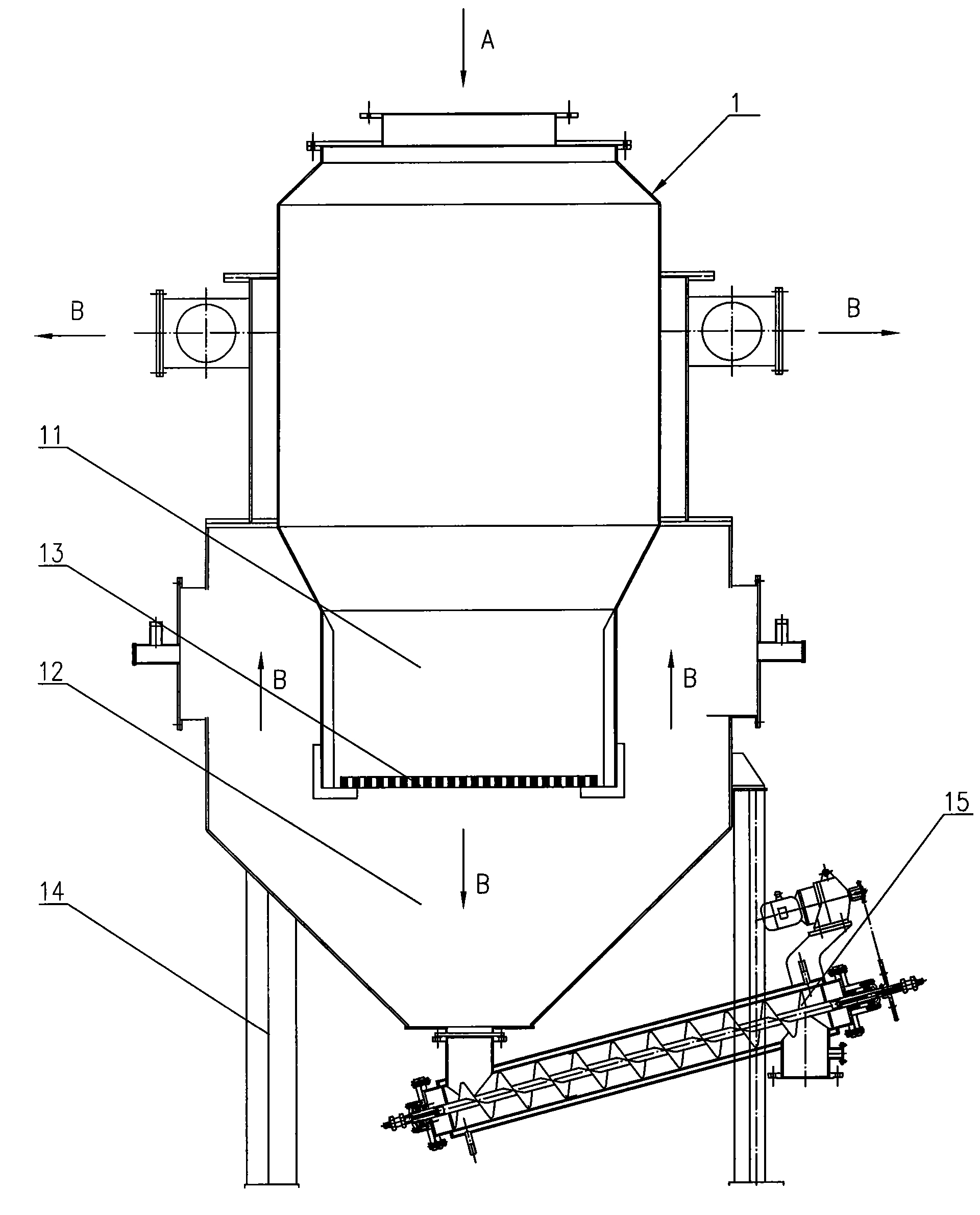

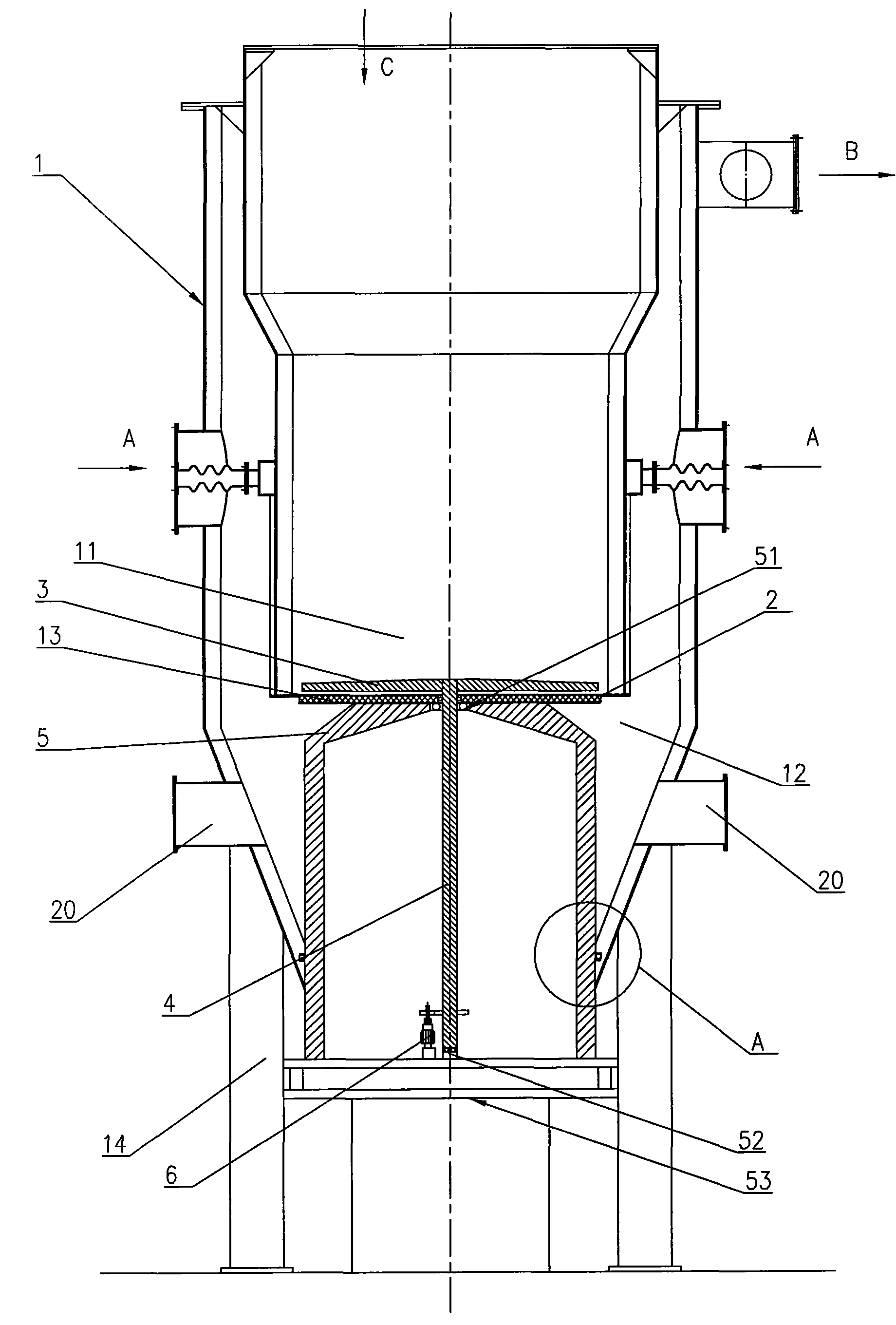

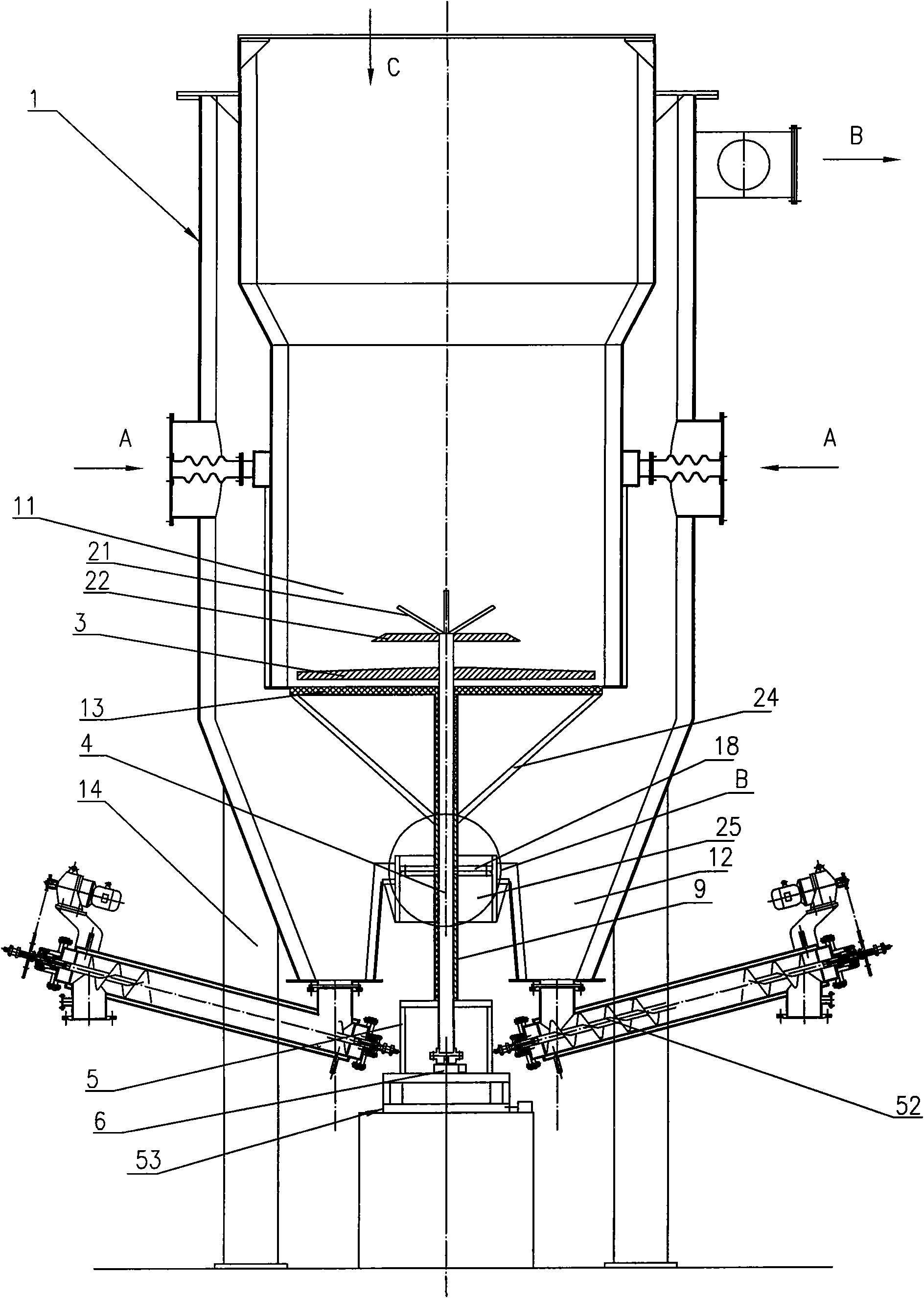

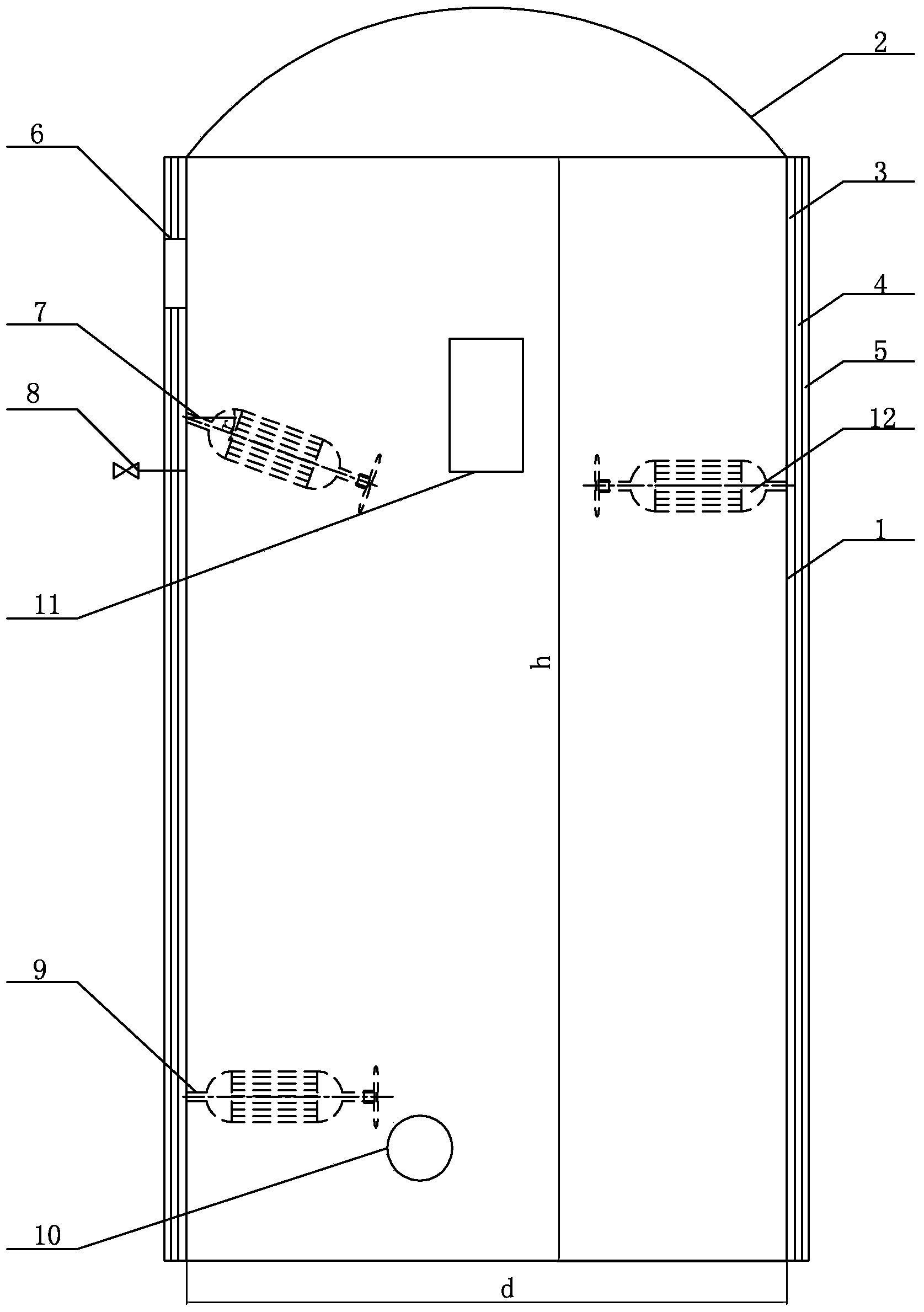

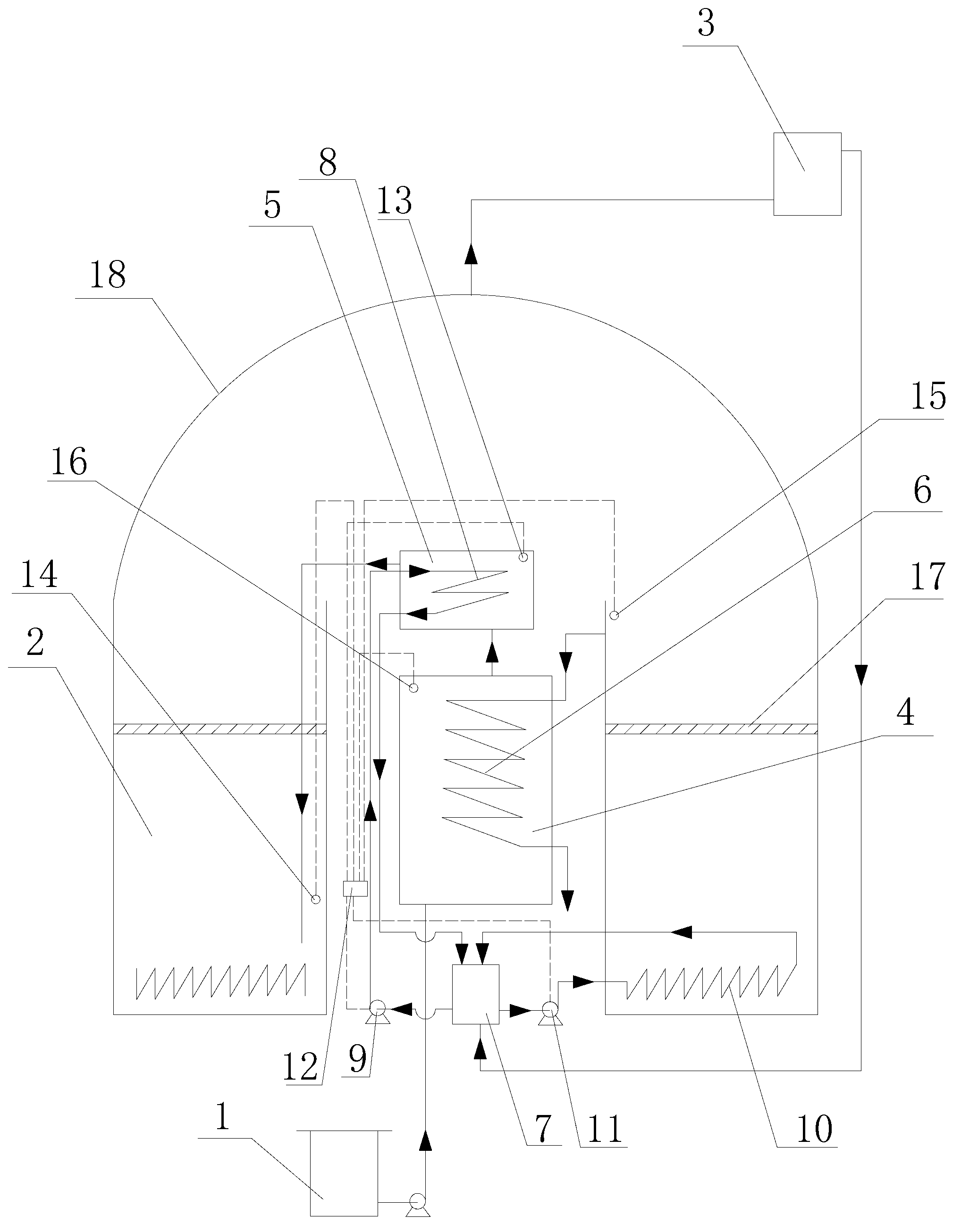

High-solid anaerobic fermentation tank and jet stirring device for same

ActiveCN104893964ALight structureEasy to installBioreactor/fermenter combinationsBiological substance pretreatmentsLiquid jetFermentation

The invention discloses a high-solid anaerobic fermentation tank and a jet stirring device for the same. The jet stirring device comprises a circulating crushing pump, a liquid-liquid jet stirrer and a gas-liquid jet stirrer. A feed inlet of the circulating crushing pump is connected with a suction pipe, a discharge outlet of the circulating crushing pump is connected with a supply pipe, a suction gate valve is arranged on the suction pipe, and the front end of the suction pipe is mounted on the inner lower portion of the anaerobic fermentation tank; the rear end of a liquid-liquid jet pipeline of the liquid-liquid jet stirrer is connected with the supply pipe of the circulating crushing pump, and a liquid-liquid jet device at the front end of the liquid-liquid jet pipeline is mounted on the inner lower portion of the anaerobic fermentation tank; a gas-liquid jet device at the front end of a gas-liquid jet pipeline of the gas-liquid jet stirrer is mounted on the inner upper portion of the anaerobic fermentation tank, the front end of a biogas pipeline connected to the upper end of the gas-liquid jet device is connected to the top of the anaerobic fermentation tank, and the biogas pipeline is communicated with the inside of the anaerobic fermentation tank. The high-solid anaerobic fermentation tank and the jet stirring device have the advantages that anaerobic fermentation mixing stirring effects can be realized by the jet stirring device, the jet stirring device has a scum crushing function, and accordingly the gas yield can be greatly increased by the jet stirring device; drainage pressures can be greatly lowered, accordingly, energy consumption can be saved, and the jet stirring device is suitable for the high-solid anaerobic fermentation tank.

Owner:北京中持绿色能源环境技术有限公司

Pretreatment method of promoting anaerobic fermentation of high-density sludge through alkaline-hydrolysis coupling ultrasonic processing

InactiveCN105330114AIncrease methane yieldHigh yieldWaste based fuelNature of treatment waterSolubilityPretreatment method

A disclosed pretreatment method of promoting anaerobic fermentation of high-density sludge through alkaline-hydrolysis coupling ultrasonic processing comprises preparing sludge with the solid concentration TS of 7%-9% from dewatered sludge, adding calcium oxide powder according to the concentration of 0.01 g / g-TS, and stirring uniformly; and then pouring into a trough type ultrasonic generator for ultrasonic processing, and controlling the ultrasonic frequency to be 20 KHz, the power density to be 0.15 KW / L and the processing time to be 30 min. The dissolvable COD concentration and the dissolvable polysaccharide concentration of the sludge subjected to the above processing process are both substantially increased compared with those of sludge not subjected to pretreatment, the pH value is about 7.6, and the processed sludge can be directly poured for anaerobic reaction for fermentation and generating methane, and after the anaerobic fermentation reaction is performed for 25 d, the methane accumulated yield is improved by 55.1% compared with that of unprocessed sludge. The method is simple in operation, saves reagent usage amount and energy consumption, and does not influence subsequent processing and disposal, also the gas production performance of the sludge is improved and the anaerobic reaction period is shortened.

Owner:TIANJIN UNIV

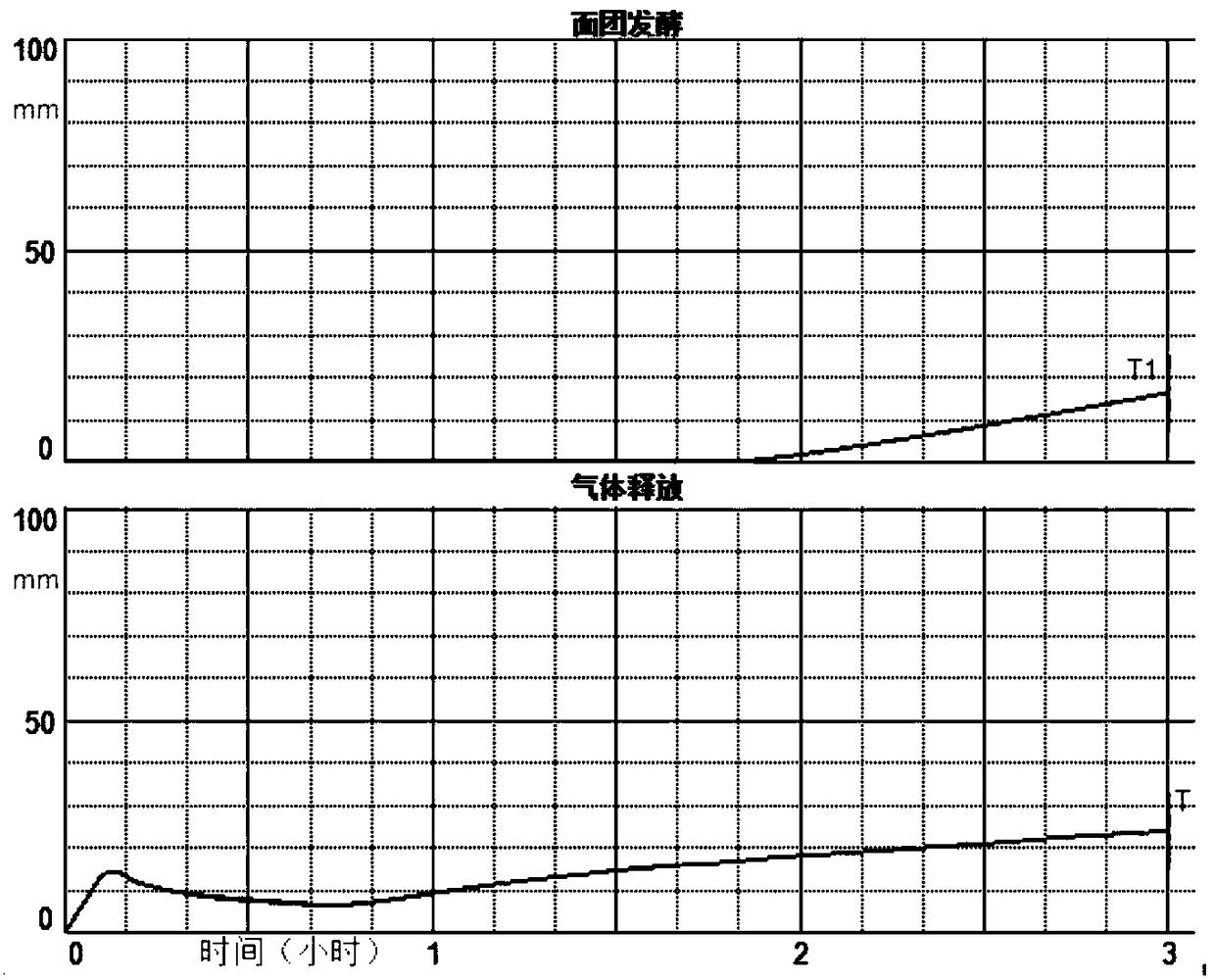

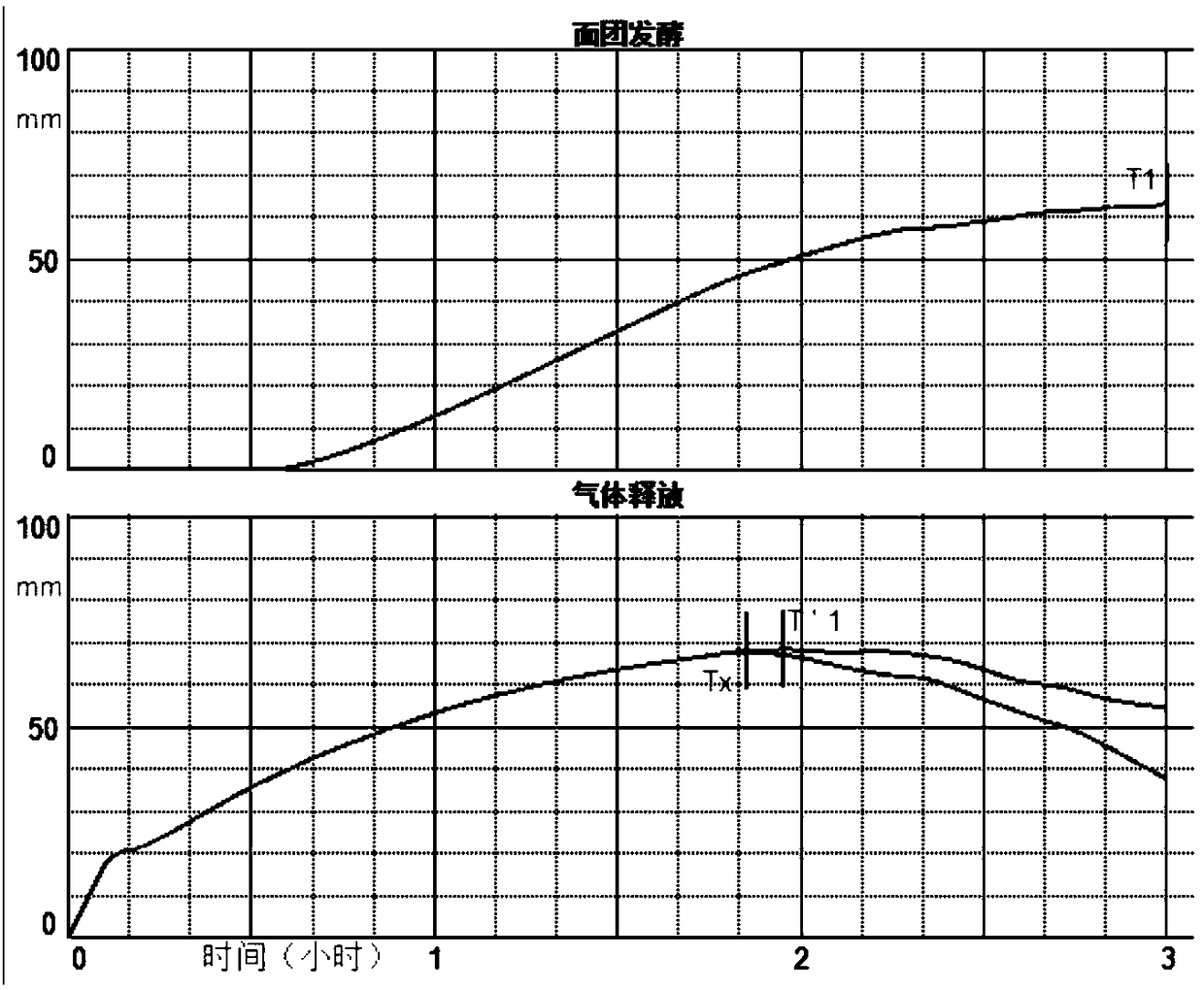

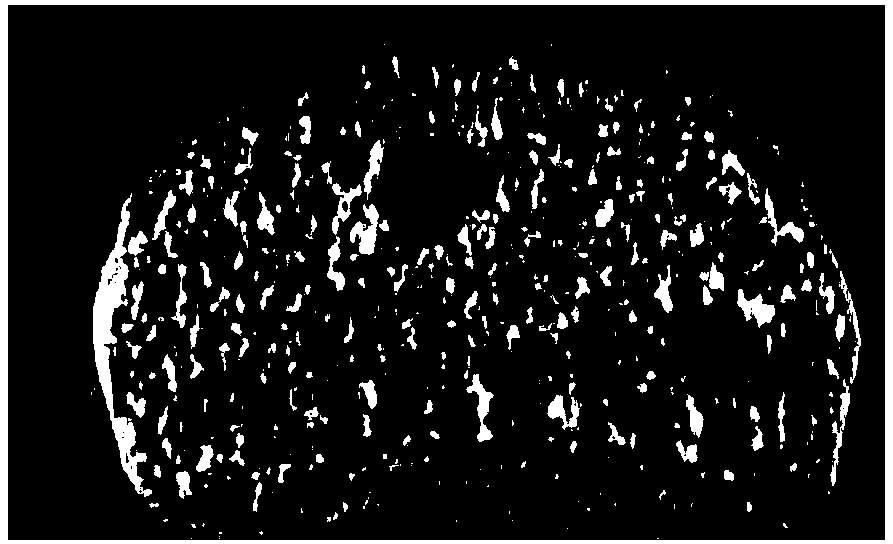

Frozen dough and preparation method thereof

InactiveCN108606022APromote enrichmentImprove gas production performanceReady-for-oven doughsDough treatmentSpecific volumeGluten

The invention discloses frozen dough. The frozen dough is mainly made from the following components of 150-160 parts of Levain, 90-100 parts of high gluten flour, 1.5-1.8 parts of frozen yeast, 30-35parts of water, 15-20 parts of eggs, 15-20 parts of margarin, 25-30 parts of white sugar, 2-3 parts of salt and 0.1-0.3 part of avenin. Bread made through performing unfreezing, fermenting and bakingon the frozen dough not only has fragrance of natural fermented bread, but also maintains the specific volume of original bread, is uniform, fine and smooth in internal structure, is elastic and is free from bubbling on surfaces. The invention further discloses a preparation method of the frozen dough.

Owner:广东省贸易职业技术学校

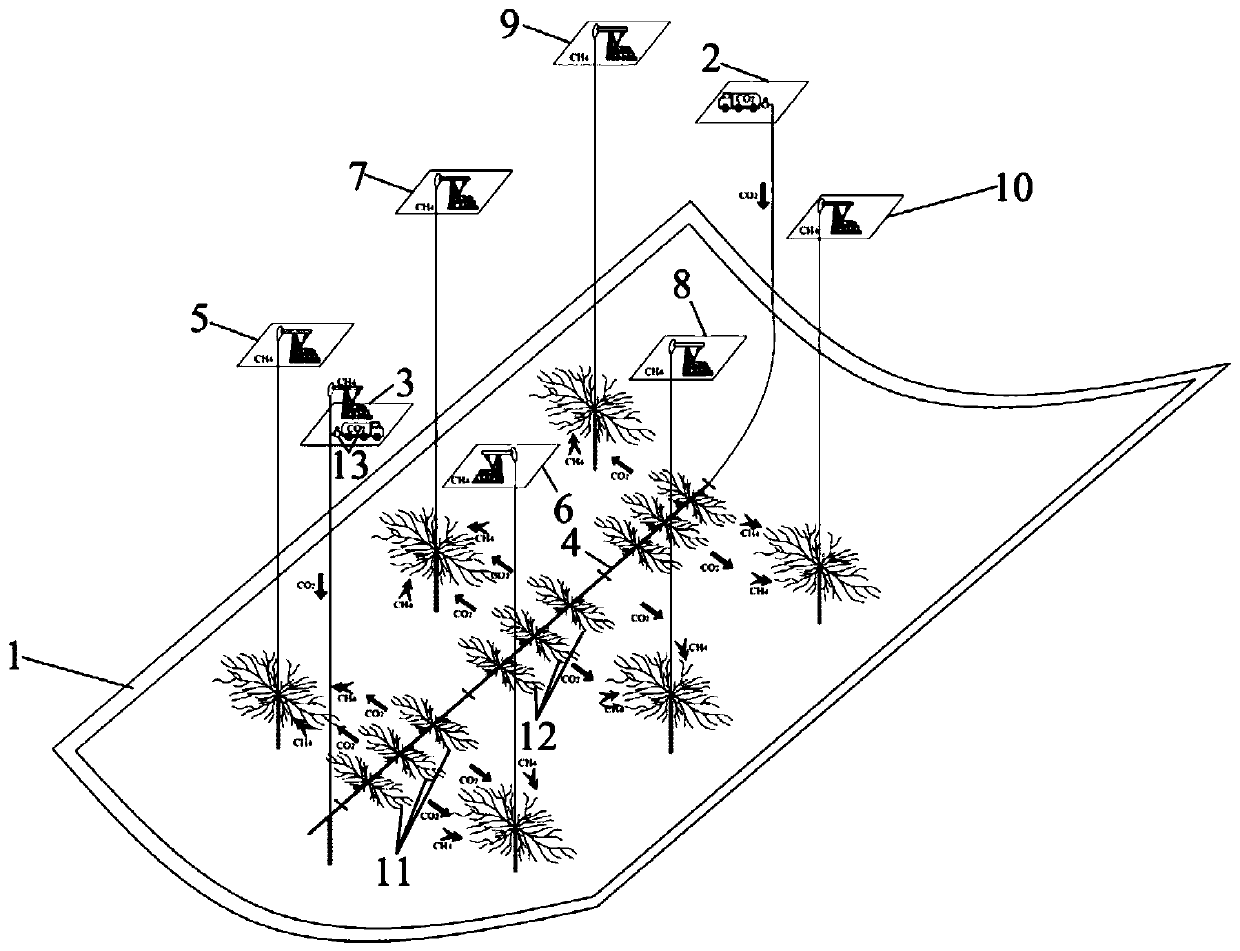

Displacement coalbed methane yield increase method under combined mining of coalbed methane by vertical wells and U-shaped butted well

ActiveCN110397428AImprove gas production performanceEnhanced resource recoveryFluid removalGas removalProduction rateSoil science

The invention provides a displacement coalbed methane yield increase method under combined mining of coalbed methane by vertical wells and a U-shaped butted well. The method comprises steps as follows: (a), the U-shaped butted well is constructed along the secondary syncline axis trace and a horizontal well section is subjected to well cementation; (b), 6-8 vertical wells are constructed on syncline two wings, and cased hole completion is performed; (c), clustering perforation and staged fracturing are carried out from the far end of the horizontal well section of the U-shaped butted well; (d), the vertical wells and the adjacent horizontal well section are subjected to synchronous fracturing; (e), the vertical wells and the U-shaped butted well are subjected to drainage gas recovery; (f),when the daily gas production rate of the U-shaped butted well is reduced to 1 / 6 of the stable gas production rate and the water yield is lower than 0.5 m<3> / d, liquid carbon dioxide is continuouslyinjected from the U-shaped butted well under stable pressure; (g), the vertical wells carry out continuous drainage gas recovery, and gas and water yield and composition are monitored for a long time.On the basis of the conditions of combined mining of coalbed methane by the vertical wells and the U-shaped butted well, efficient mining of coalbed methane is realized by the displacement effect ofcarbon dioxide for methane, and the recovery ratio of coalbed methane resource can be remarkably increased.

Owner:CHINA UNIV OF MINING & TECH

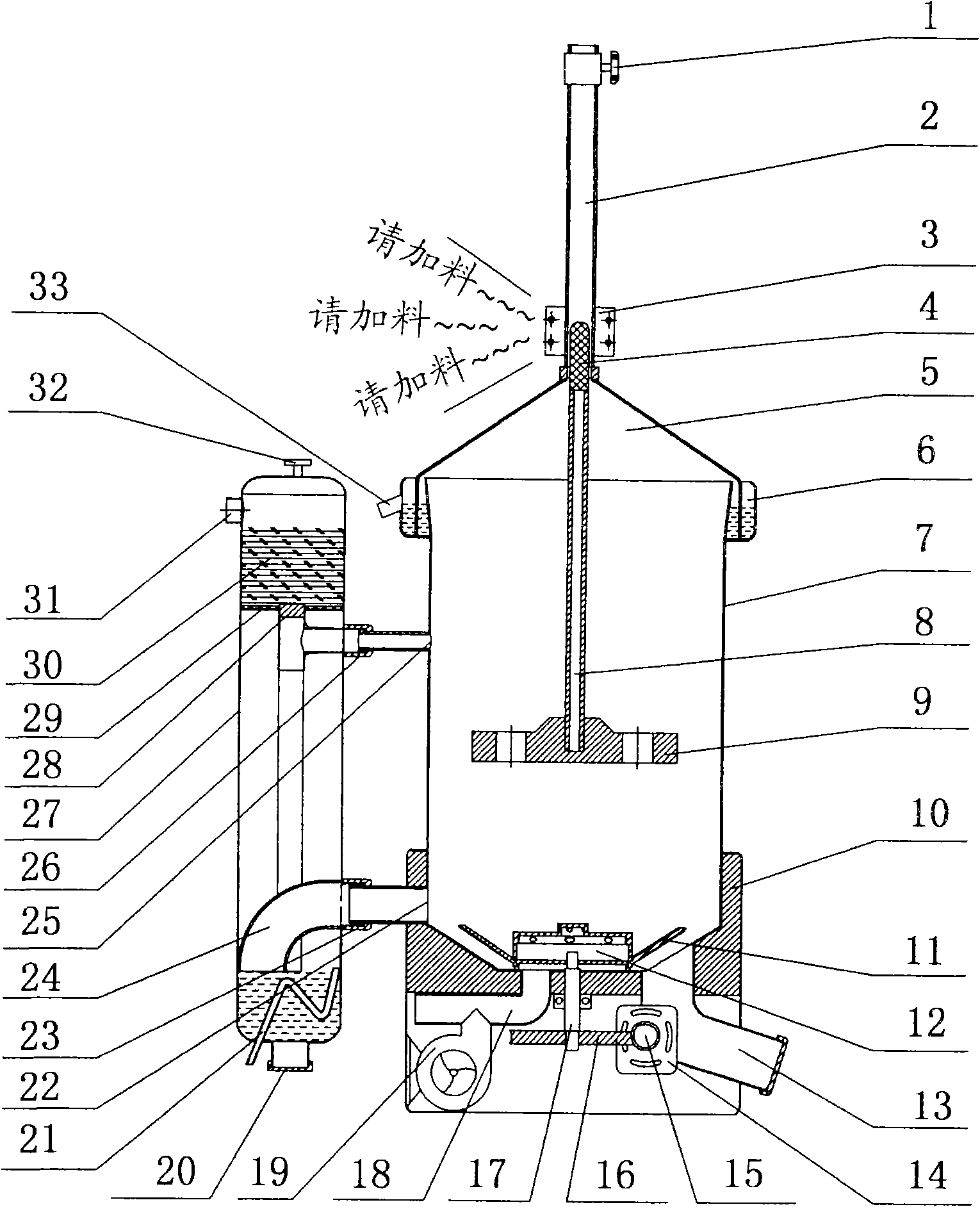

Intelligent straw gasification furnace

InactiveCN101644448AEasy to useLow failure rateDomestic stoves or rangesLighting and heating apparatusHearthOxygen

The invention relates to an intelligent straw gasification furnace, in particular to an updraft-type household gasification furnace for converting agricultural waste into combustible gas by a limiting-oxygen combustion pyrolytic reaction. A stripping detection alarm and dehumidifying furnace cover system is arranged to increase the density of fuel in the furnace, improve the gas-generating effect,automatically give feeding alarm without stripping material and shutting down, and has no requirements on straw moisture; a porous gas-guiding device is arranged to obtain gas which occupies 80 percent of the total amount and does not contain tar and moisture; the intelligent straw gasification furnace is also provided with an external dredging purifier for convenient dismounting, dredging or replacement; and an automatic anti-blowoff intake system is arranged to ensure full uniform combustion, avoid deflected and suspended combustion in a hearth, and timely crack coke about to form, surely and continuously generate gas and achieve continuous combustion effect. Aiming to overcome the defects that the prior gasification furnace adopting a common steel plate to manufacture the hearth is easy to oxidize and strip to cause perforation in a long-term high-temperature combustion environment, the invention adopts a fireproof casting material to manufacture the hearth and prolongs the servicelife of the gasification furnace.

Owner:沈桀

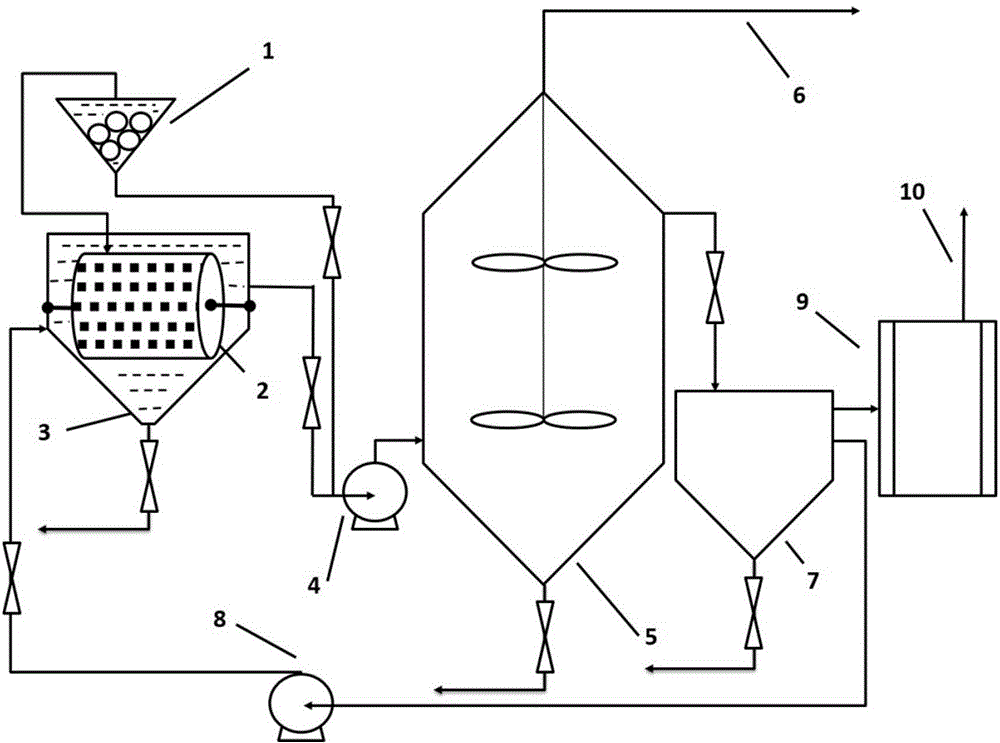

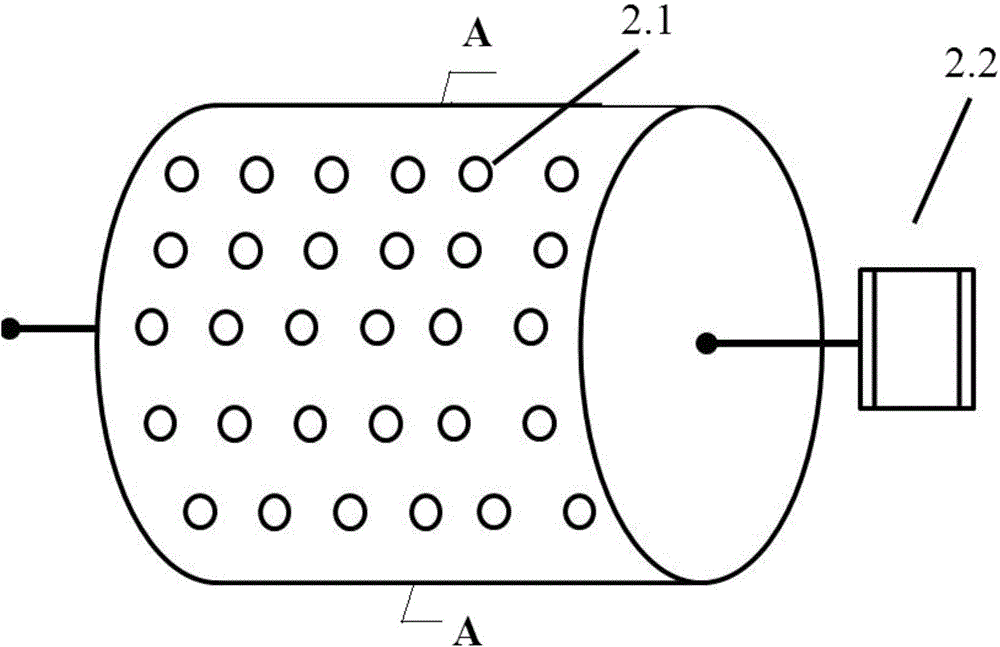

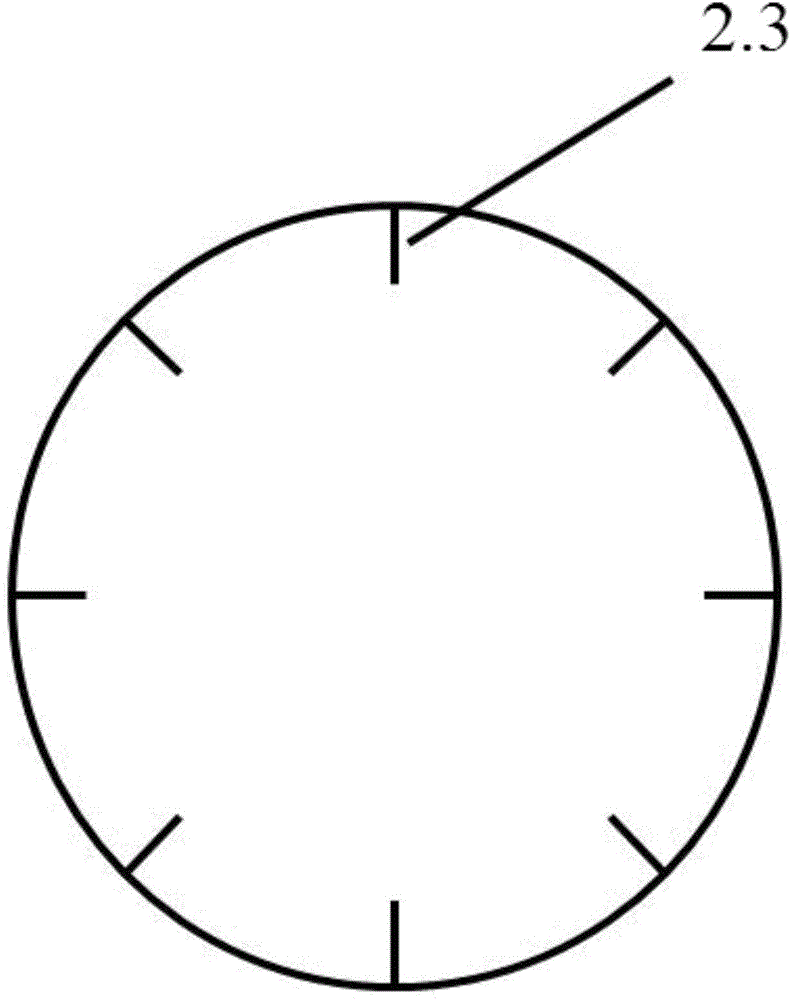

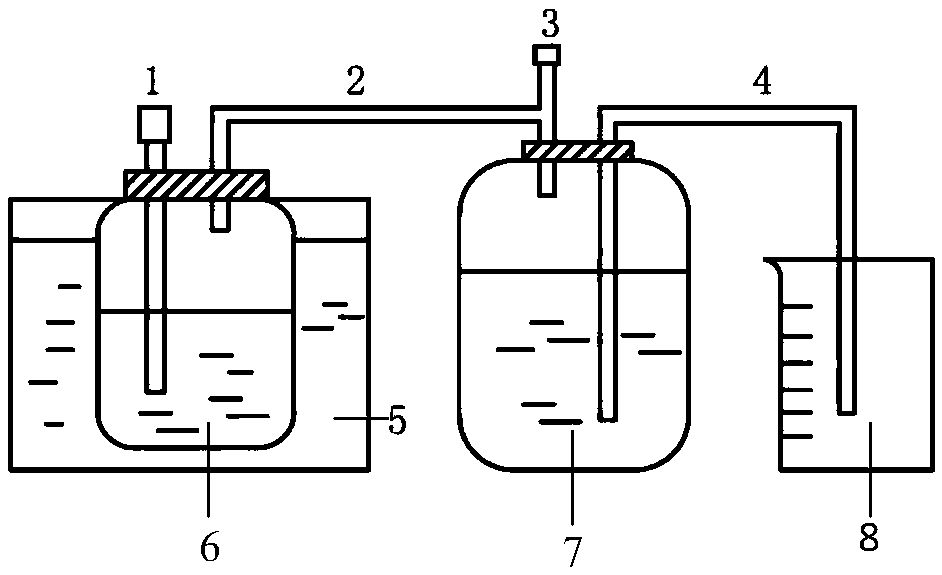

Device and method for preparing biological gas and liquid organic fertilizer from fruit and vegetable wastes of collecting and distributing center

ActiveCN104651219AFully hydrolyzedPrevent compactionBio-organic fraction processingBiological substance pretreatmentsFiberHydrolysate

The invention discloses a device and a method for preparing a biological gas and a liquid organic fertilizer from fruit and vegetable wastes of a collecting and distributing center. The method comprises the following steps: squeezing and crushing the fruit and vegetable wastes collected by a collecting and distributing center to obtain a crushed solid raw material and a liquid, and directly feeding the liquid into an anaerobic fermentation reactor for fermentation; feeding the crushed solid raw material into a rotatable hollowed-out cylindrical hydrolyzing device arranged in a hydrolyzing and desilting basin for hydrolyzing and desilting, thereby obtaining a hydrolysate; and then feeding the hydrolysate into the anaerobic fermentation reactor for fermentation to generate methane, and sterilizing the digestive fluid left after fermentation at a high temperature to obtain a liquid fertilizer. According to the method, the fermentation period is shortened, the fermentation efficiency of the raw material is improved, the problems of difficult sorting of small impurities, huge influence on the anaerobic fermentation process, difficult degradation of high-fiber content wastes and the like are overcome, the impurities are prevented from entering the anaerobic fermentation reactor, and the fruit and vegetable waste processing capability and the gas producing capability are improved; meanwhile, the high-quality liquid organic fertilizer is produced, the cost is reduced and the efficiency is improved.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

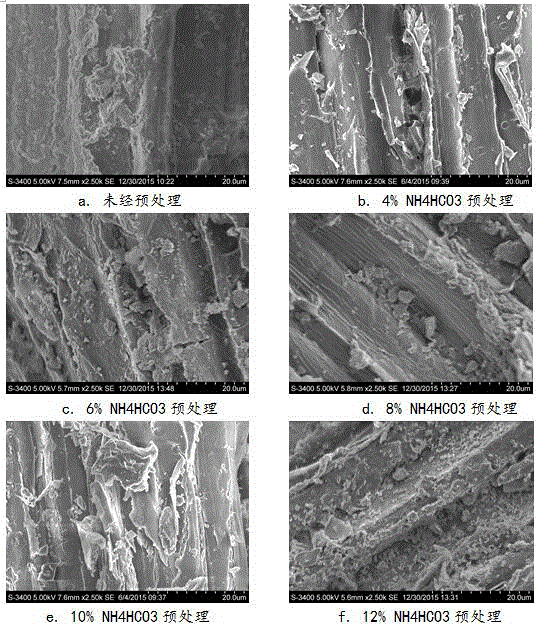

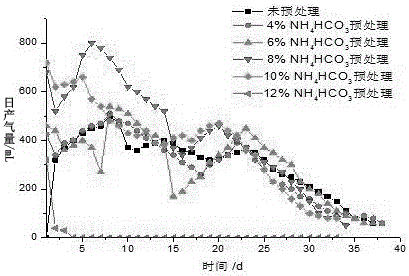

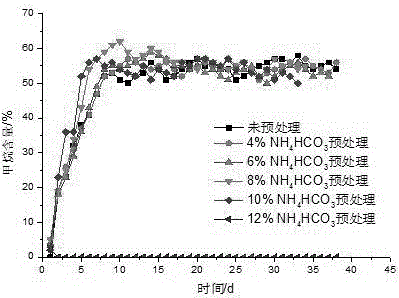

Method for pretreating maize straws by utilizing NH4HCO3, and anaerobic fermentation method of maize straws

InactiveCN106119295AIncrease contact areaAnaerobic digestion time extensionWaste based fuelFermentationRoom temperatureFermentation

The invention aims at providing a method for pretreating maize straws by utilizing NH4HCO3, and an anaerobic fermentation method of maize straws. The method for pretreating maize straws by utilizing NH4HCO3 comprises the following steps: crushing maize straws and sieving with a 40-mesh sieve, adding 4%-10% ( by mass concentration) NH4HCO3 solution, evenly mixing, then performing microaerobic treatment for days at room temperature, then taking out the treated maize straws and adding water and evenly stirring, standing, filtering and drying for later use; and then performing anaerobic fermentation gas production to the obtained maize straws. The gas production of the maize straws pretreated by utilizing the method is increased by 30.6% compared with no treatment, and the removal rate of COD during the anaerobic fermentation of the pretreated maize straws is also obviously promoted.

Owner:HENAN AGRICULTURAL UNIVERSITY

Biomass gasifier

InactiveCN101654629AImprove work efficiencyAvoid leakageCombined combustion mitigationFixed-bed gasificationBiomassEngineering

The invention discloses a biomass gasifier, comprising a gasifier body, a grate, an ash chamber, a support for supporting the gasifier and an ash discharging mechanism, wherein, the grate is arrangedin the gasifier body; the ash chamber is positioned below the gasifier body; the grate is in a flat structure with no hole in the middle; an ash discharging hole is arranged at the edge part at whichthe inner walls of the grate is connected with the gasifier body; an ash poking mechanism used for poking the ash residue on the grate into the ash discharging hole is additionally arranged on the grate; and the ash poking mechanism is connected with an ash poking drive mechanism which is arranged in a shield positioned below of the grate. By adopting the ash poking drive mechanism to drive the ash poking mechanism, the invention can realize the purpose of continuous ash discharge of ash residue on the grate, is beneficial for successfully carrying out the chemical reaction of biomass raw materials to improve the work efficiency of the gasifier, the middle part of the gasifier is in a flat structure with no hole, thereby avoiding the defect of materials leakage of the existing grate; and the shield arranged the ash chamber below the grate is used for protecting the ash poking drive mechanism.

Owner:广州市宇联机电有限公司

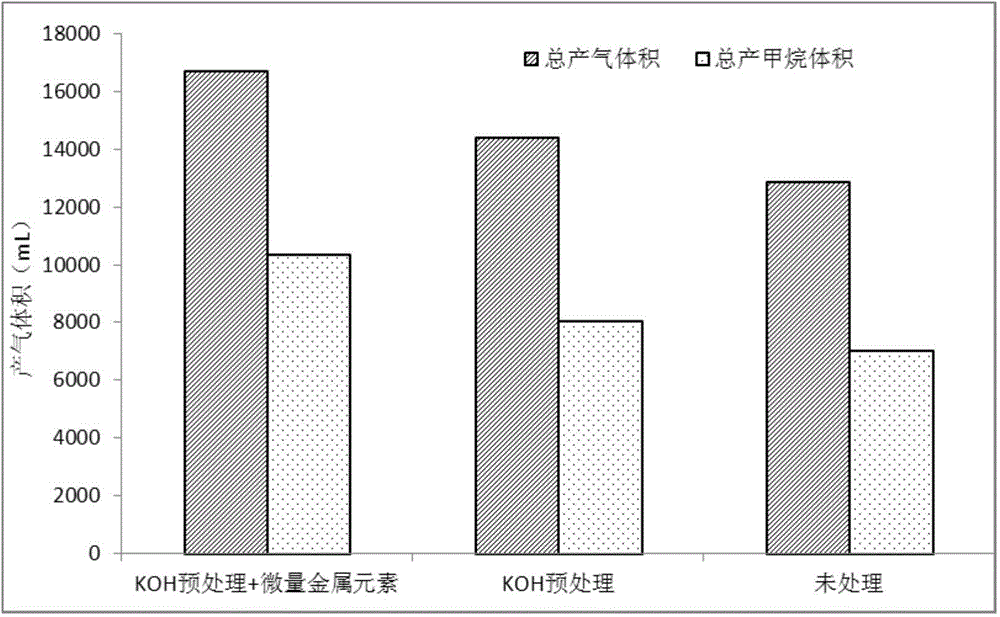

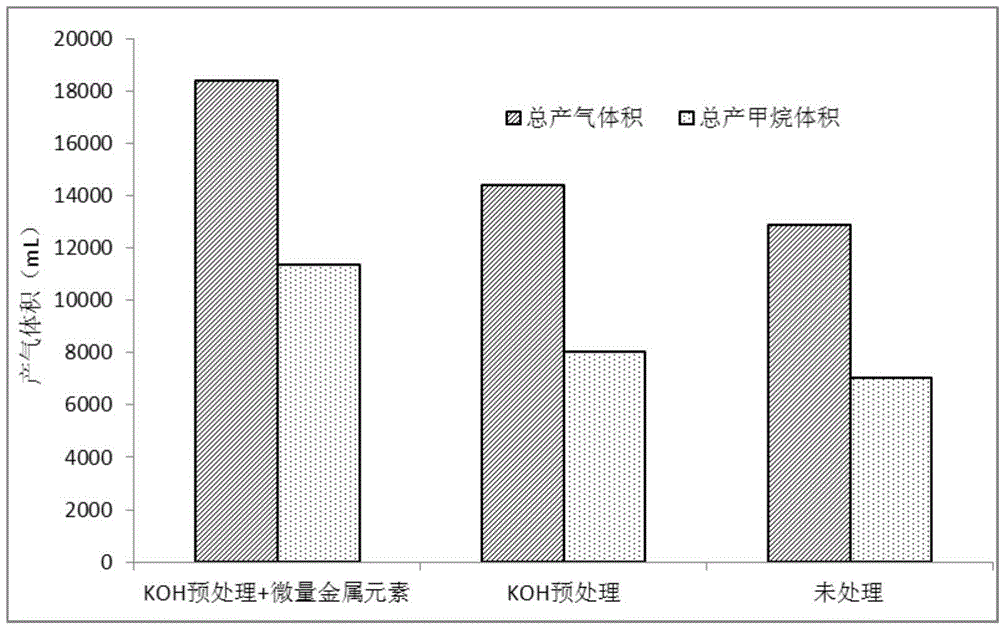

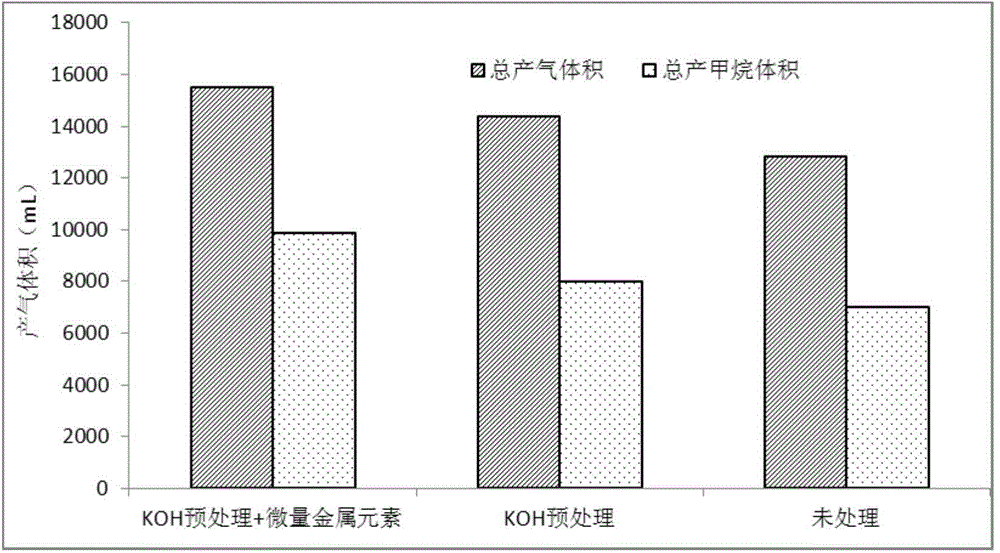

Method for improving methane yield of corn straw anaerobic digestion by combined pretreatment of alkali and salt

ActiveCN104593432AAnaerobic fermentation cycle shortenedLow investment costWaste based fuelFermentationActivated sludgeDry weight

The invention discloses a method for improving methane yield of corn straw anaerobic digestion by combined pretreatment of alkali and salt, and belongs to the technical field of anaerobic fermentation of agricultural organic solid wastes. The method comprises the following steps: crushing the corn straw, and carrying out pretreatment the corn straw by employing potassium hydroxide and metal salts as pretreatment agents, wherein the metal salts comprise ferrous chloride, cobalt chloride and nickel chloride; adding water, so that the total mass of the water and the water contained in the corn straw is six times of dry weight of the corn straw; fully stirring, and sealing by a sealing film; carrying out sealed storage at a room temperature for 3 days, and then carrying out anaerobic fermentation, wherein activated sludge is needed in the anaerobic fermentation process; adding activated sludge which is 12g TS relative to 52g of TS corn straw, and adding water to reach 80% of total volume of a reaction device; filling nitrogen, and sealing by virtue of a rubber stopper; and fixing the reactor in a table concentrator, and keeping the constant temperature of the table concentrator at 35+ / -2 DEG C. According to the method, the anaerobic fermentation cycle can be shortened; the total gas production volume and the total methane production volume are greatly improved; and the removal rate of substances is significantly improved.

Owner:BEIJING UNIV OF CHEM TECH

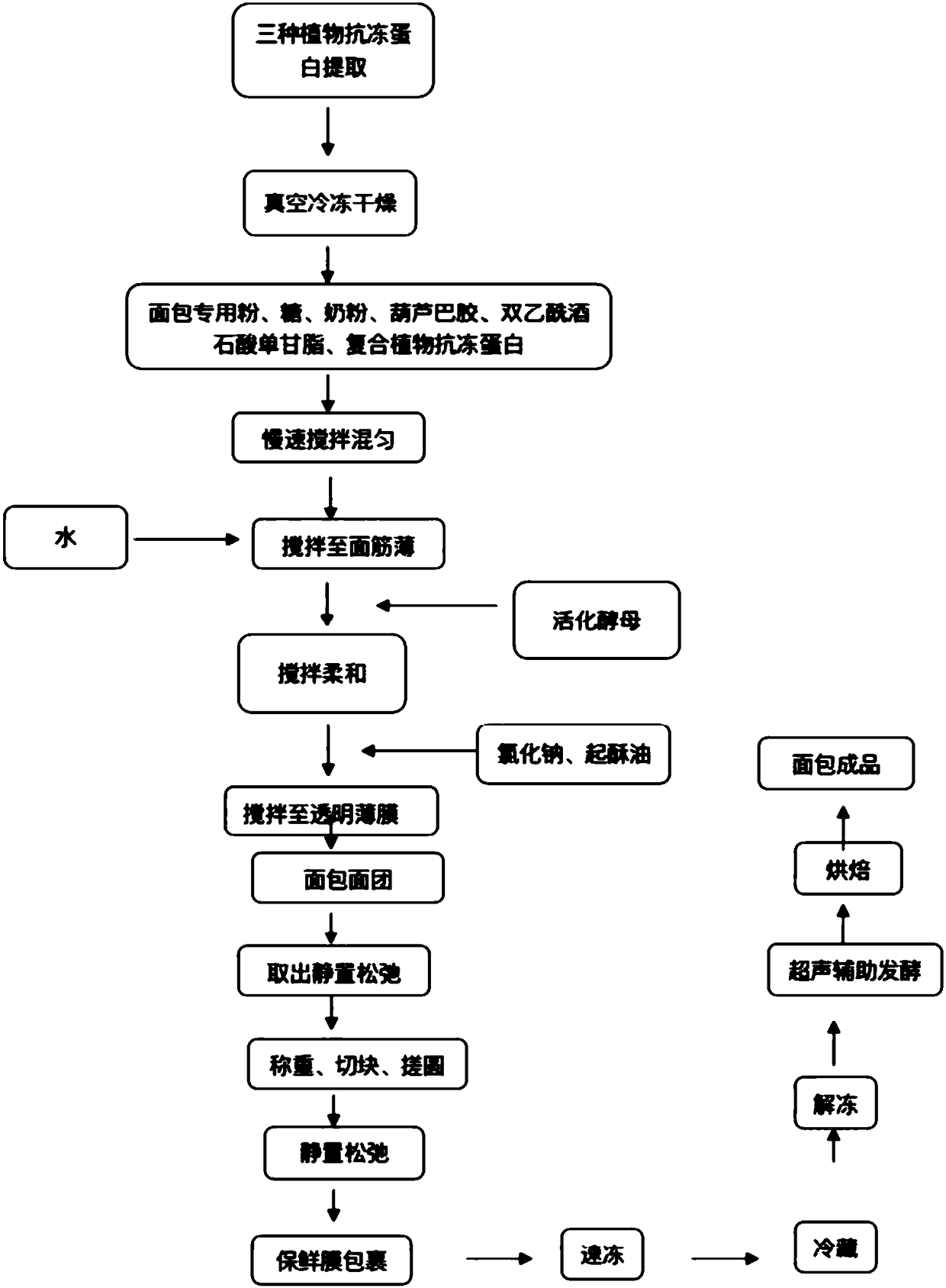

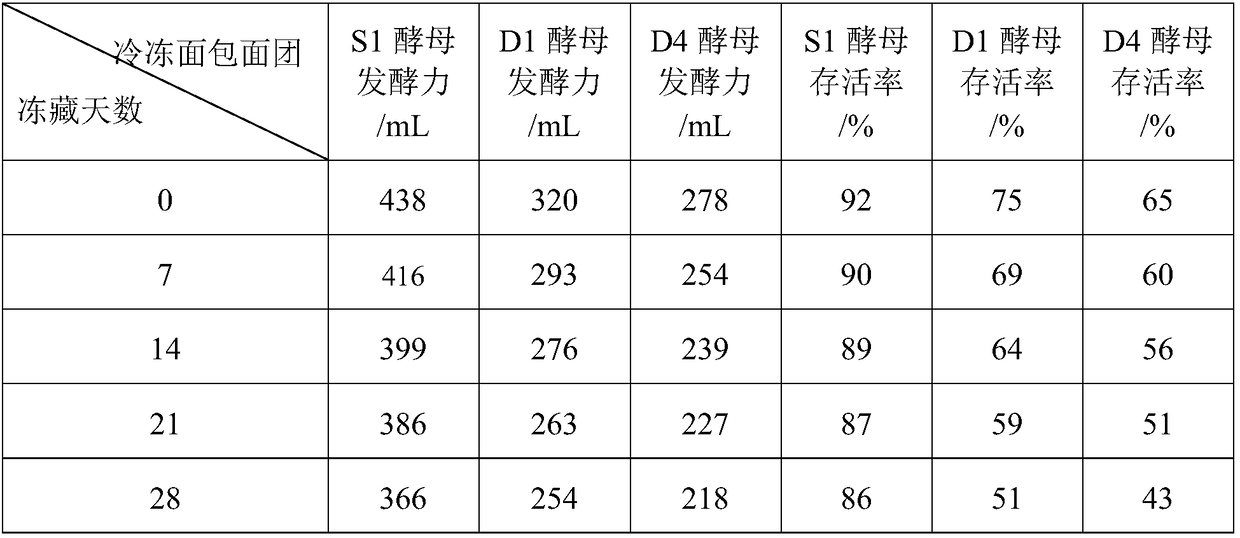

Frozen bread dough containing compound plant antifreeze protein, preparing method thereof and method for preparing bread through optimized process

The invention discloses frozen bread dough containing compound plant antifreeze proteins, a preparing method thereof and a method for preparing bread through an optimized process. The frozen bread dough is prepared from, 40-50 wt% of bread special flour, 9-12 wt% of sugar, 0.5-1.5 wt% of yeast, 0.4-0.8 wt% of sodium chloride, 1.5-3 wt% of milk powder, 5-11 wt% of shortening, 0.05-0.15 wt% of fenugreek gum, 0.05-0.30 wt% of monoglycerides tartartaric acid diacetate, 20-30 wt% of water, 0.25-1.5 wt% of carrot antifreeze protein powder, 0.5-3 wt% of Tangut rhodiola rosea leaf antifreeze protein powder and 0.5-3 wt% of polygonum viviparum leaf antifreeze protein powder. The bread produced after the bread antifreeze dough is unfrozen, leavened and baked has the advantages of being large in specific volume, crispy, soft and delicious, and extremely excellent in sensory quality.

Owner:WUHAN POLYTECHNIC UNIVERSITY

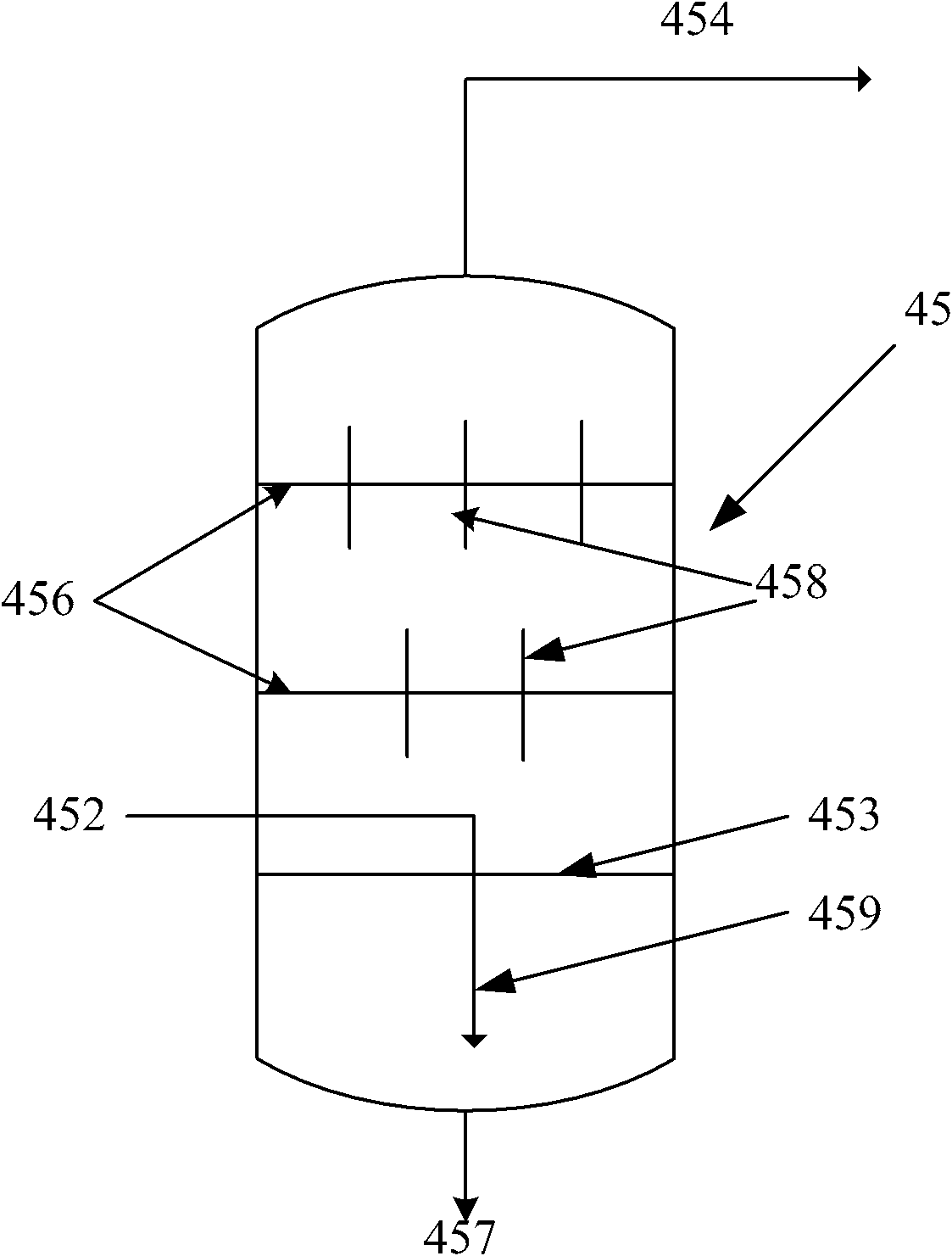

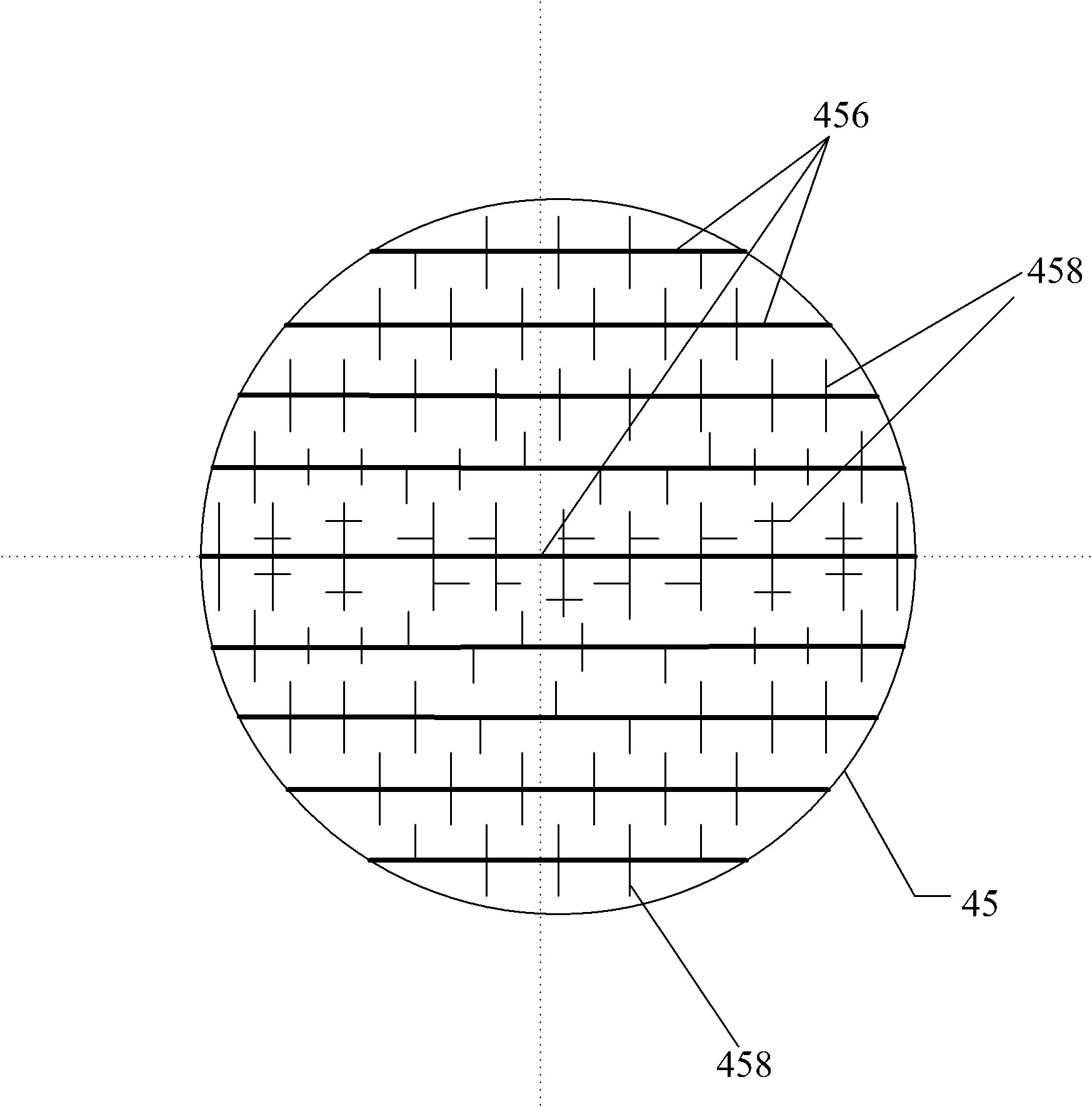

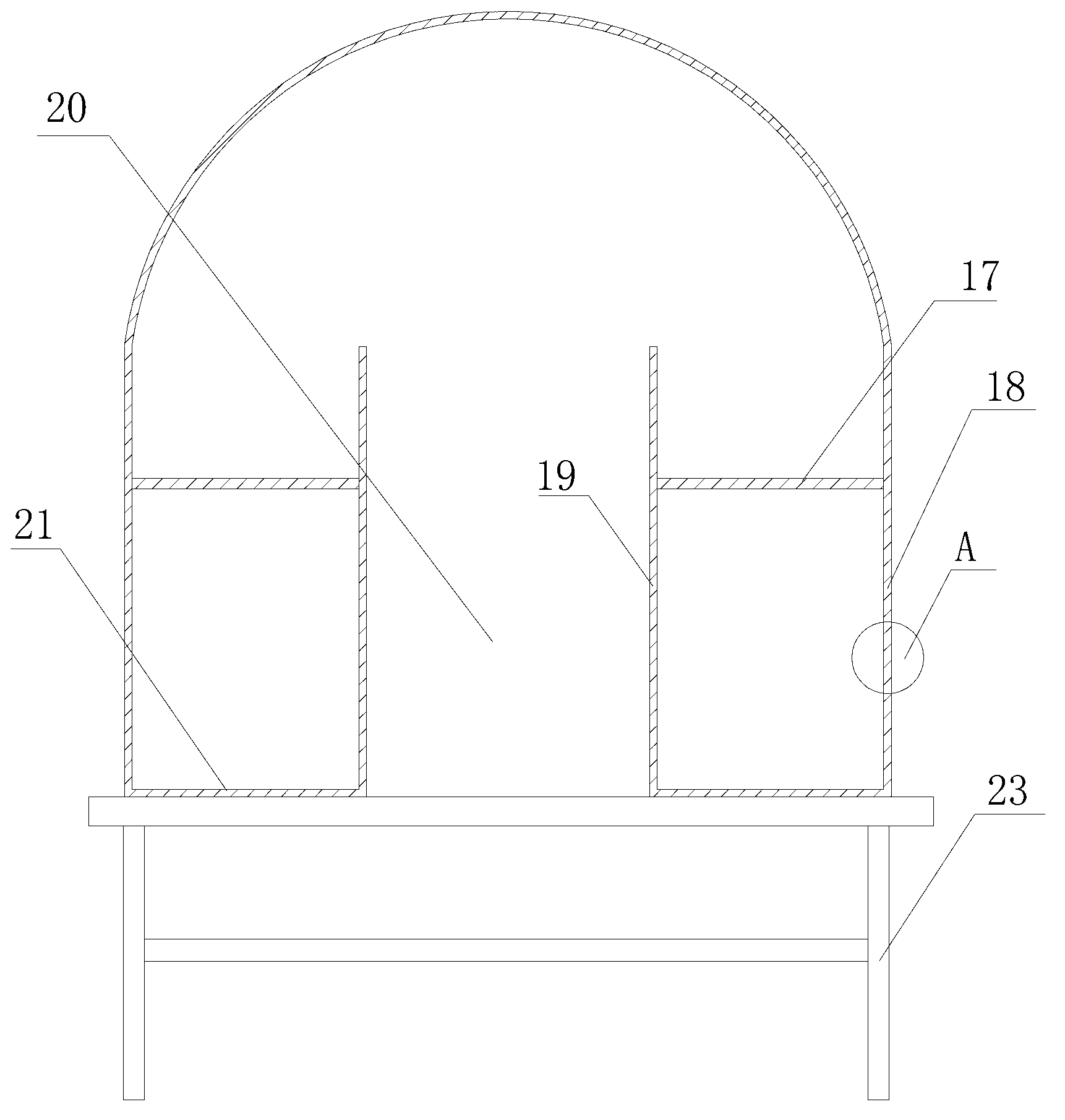

Fermentation reactor integrating functions of stirring and crusting breaking and stirring crust-breaking method

ActiveCN103396942AImprove gas production efficiencyImprove gas production performanceBioreactor/fermenter combinationsBiological substance pretreatmentsChemistryProduction rate

The invention relates to a fermentation reactor integrating functions of stirring and crusting breaking and a stirring crust-breaking method, and the problems in the prior art are solved that an anaerobic reactor is low in gas production rate and low in gas productivity during fermentation. The fermentation reactor comprises a digester, a heat tracing band, a heat-insulation layer and a protective layer; the fermentation reactor also comprises a digester upper cover, a first stirrer with a frequency converter, a charge level indicator, a second stirrer with a frequency converter and a third stirrer with a frequency converter; the digester upper cover is buckled on the digester; the protective layer, the outer side wall of the digester is successively sleeved by the heat-insulation layer and the heat tracing band from outside to inside; the inner side wall of the digester is provided with a feed inlet; and the first stirrer with the frequency converter and the third stirrer with the frequency converter are disposed on the digester; the second stirrer with the frequency converter is disposed on the bottom inner wall of the digester. The fermentation reactor integrating the functions of stirring and crusting breaking is applied to the field of full-mixing anaerobic fermentation.

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE

Anaerobic reaction system for sewage and anaerobic treatment method for sewage

InactiveCN103011400AImprove environmental conditionsIncrease speedBioreactor/fermenter combinationsBiological substance pretreatmentsAutomatic controlAnaerobic reactor

The invention discloses an anaerobic reaction system for sewage and an anaerobic treatment method for sewage. The anaerobic reaction system comprises a sewage collection pool, an anaerobic reactor and a biogas storage tank which are sequentially connected, wherein a heat recoverer and a heat exchanger are sequentially connected between the sewage collection pool and the anaerobic reactor, a heat exchange tube is arranged in the heat recoverer, the water outlet of the anaerobic reactor is connected with the water inlet of the heat exchange tube, and the water outlet of the heat exchange tube is connected with the next water treatment procedure. The anaerobic reaction system further comprises a heating device, wherein the heating device comprises a boiler, a circulating heat dissipation tube and a temperature control device used for automatically controlling the heating temperature of sewage in the heat exchanger and the anaerobic reactor. The anaerobic reaction system for sewage and the anaerobic treatment method for sewage disclosed by the invention have the advantages that the process flow is simple, the biogas yield is high, the energy consumption is low, and moreover, the anaerobic reaction system for sewage is low in construction cost.

Owner:湘潭秋水环境技术有限公司

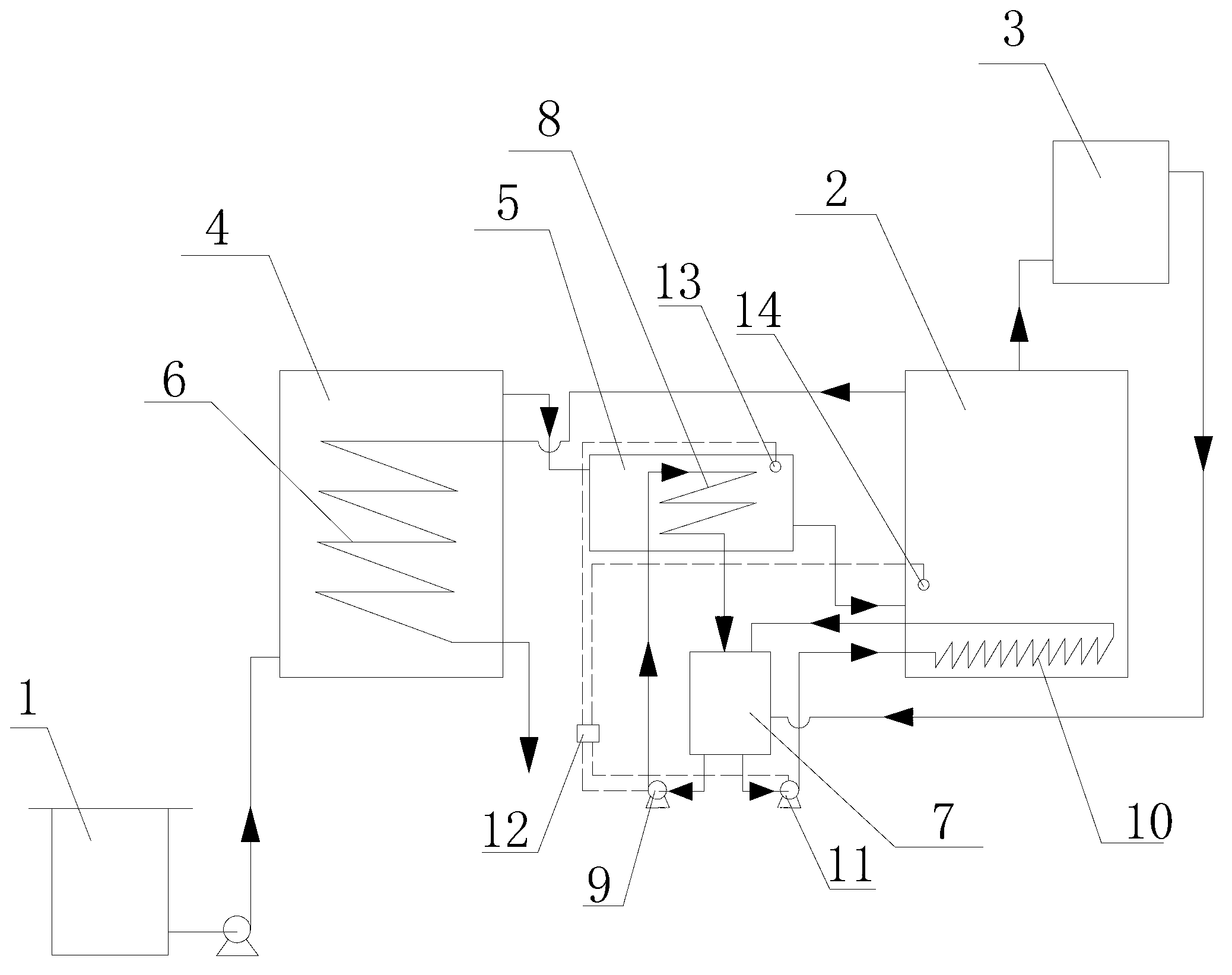

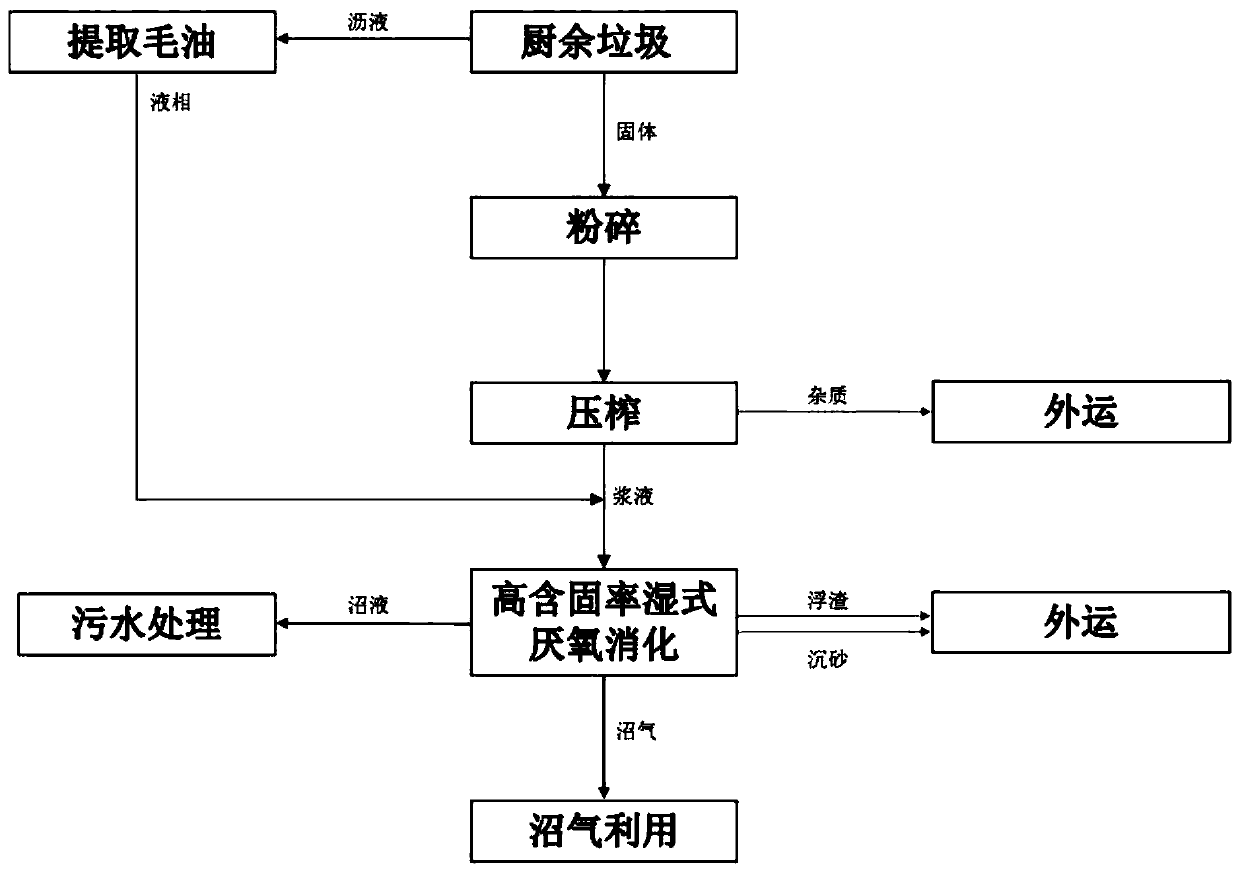

Kitchen waste processing system and method

PendingCN111054735ASimplified processing stepsImprove gas production performanceSolid waste disposalWaste processingSlurry

The invention discloses a kitchen waste processing system and method. The kitchen waste processing method comprises the following steps: a kitchen waste receiving and transporting trolley pours kitchen waste into a kitchen waste receiving hopper; solid-phase waste in the receiving hopper is conveying to a smashing unit through a screw conveyor; the smashed solid-phase waste in a closed pipeline isconveyed to a first-stage presser via a valve plunger pump; the solid-phase substance obtained through first-stage pressing is conveyed to a second-stage presser for second-stage pressing through theclosed pipeline; the solid-phase impurities obtained through second-stage pressing and separating are discharged externally in the closed pipeline, and after centralized collection, the solid-phase impurities are externally transported for treatment; slurry and receiving hopper leachate obtained through two stages of pressing are conveyed to a wet type anaerobic digestion tank with high solid content; and organic slurry generates methane, biogas slurry and biogas residue under the action of anaerobic digestion. The kitchen waste processing method improves the capacity of wet type anaerobic digestion in a break-through manner, overturns the pretreatment concept in the existing kitchen waste processing method, obtains an unexpected technical effect, and greatly increases the economic benefit and the ecological benefit.

Owner:菲德克(天津)环保科技有限公司

Resource utilization method of sludge biogas residue

InactiveCN110342780AAchieve reductionImprove decomposition efficiencySludge treatment by pyrolysisByproduct vaporizationResource utilizationNovel treatment method

The invention discloses a resource utilization method of sludge biogas residue. The resource utilization method comprises the steps that a flocculating agent is added to raw sludge from a sewage plantfor dehydration to obtain dehydrated sludge; the obtained dehydrated sludge is subjected to anaerobic digestion treatment to obtain digested sludge and generate biogas; the obtained digested sludge is dried, and obtained solid sludge biogas residue is subjected to low-temperature pyrolysis to obtain pyrolytic carbon; and the sludge biogas residue pyrolytic carbon is added to the dehydrated sludgefor anaerobic digestion treatment. According to the resource utilization method of the sludge biogas residue, the dehydrated sludge is subjected to anaerobic digestion treatment, so that centralizedtreatment of municipal sludge is facilitated, reduction of the sludge is realized, problems of existing anaerobic digestion sludge treatment are solved, and a new method is created; and by optimizingan anaerobic digestion treatment process of a sewage treatment plant, a novel treatment method for sludge treatment stabilization and reduction is provided, the effect of anaerobic digestion treatmentof the sludge is improved, the degree of stability of heavy metal pollutants is improved, "pollution control by pollution" cyclic utilization of resources is achieved, and the sludge production rateis reduced.

Owner:SHANGHAI UNIV

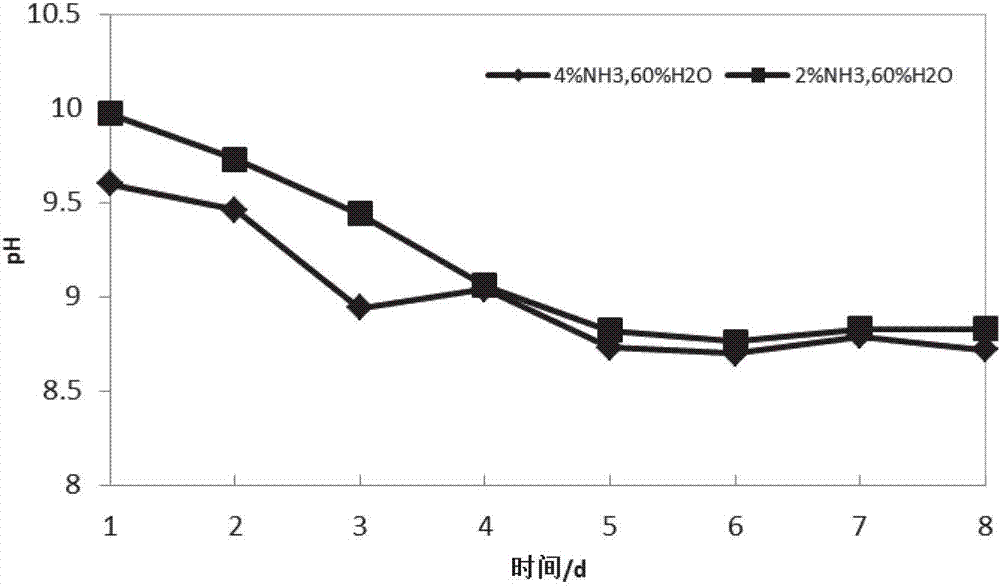

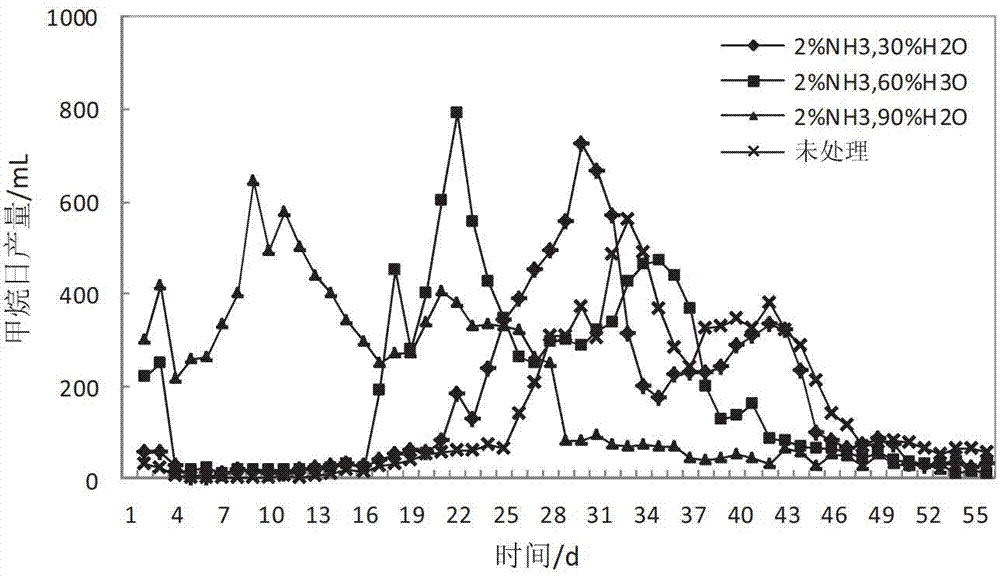

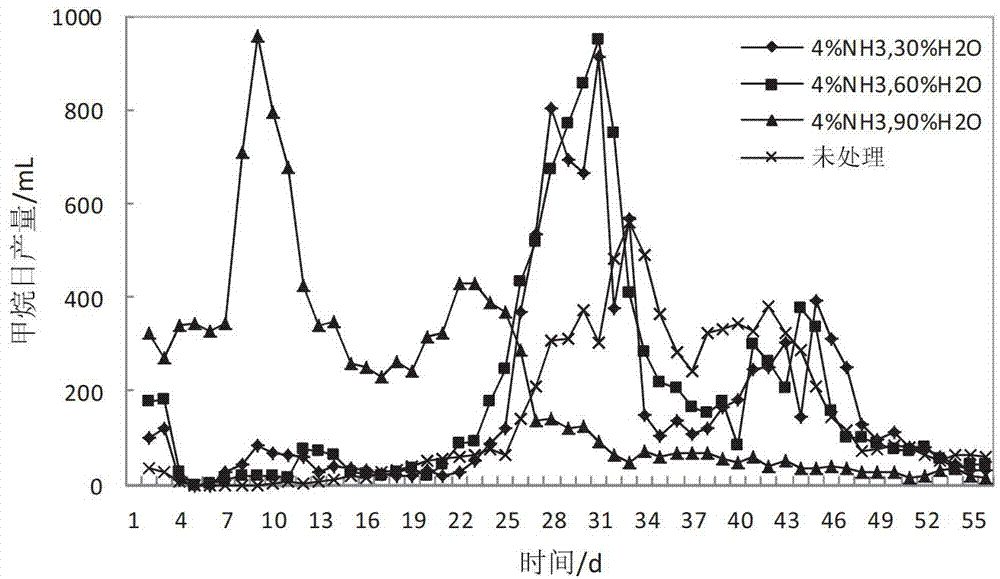

Method for improving straw methane yield through pure ammonia wet process soaking normal temperature pretreatment

ActiveCN102827879AReduce preprocessing timeEasy to produceWaste based fuelFermentationMethane yieldPre treatment

The invention discloses a method for improving the straw methane yield through straw pretreatment. According to the method, ammonia water and water are mixed and are uniformly sprayed onto straws placed in a sealed bag so that the straws are in a wet soaking state, and the pretreatment is carried out for 90 hours to 110 hours under the normal temperature condition. The pretreatment effect is improved through regulating different moisture contents in the wet type soaking state, and in addition, the methane content in the methane is obviously improved in the anaerobic fermentation process. Results show that the straws pretreated under the condition of 60 to 90 percent of moisture content at the normal temperature can fast enter the methane production peak period, and in addition, the anaerobic fermentation period is effectively shortened. When the pure ammonia concentration is 2 to 6 percent, when the moisture content is 60 to 90 percent, T80 is shortened by 23.23 to 50.1 percent, 9.30 to 50.1 percent and 9.30 to 25.5 percent through being compared with that of 43 days without the treatment. When the result is applied to the practical engineering, the engineering scale can be reduced by one time, and the investment cost is greatly reduced. Meanwhile, through being compared with that of straws which are not pretreated, the unit VS methane yield is respectively improved by 5.09 to 14.63 times, 1 to 16.1 times and 1.6 to 10.15 times.

Owner:BEIJING UNIV OF CHEM TECH

Low-temperature straw biogas fermentation promoter and preparation method thereof

InactiveCN104031942ASimple ingredientsIncrease costWaste based fuelFermentationBiotechnologyPulp and paper industry

The invention discloses a low-temperature straw biogas fermentation promoter and a preparation method thereof, and relates to the technical field of agricultural production. The promoter is prepared from the following raw materials in parts by weight: 10 parts of FeCl2.4H2O, 2-4 parts of NiCl2.6H2O, 1-2 parts of CoCl2.6H2O, 44-67 parts of wheat bran and 20-40 parts of cellulose in dissolving and even mixing manners. The low-temperature straw biogas fermentation promoter has the advantages of being simple in ingredient, low in cost, easy to prepare, flexible to use, easy to regulate and control and the like, low-temperature inhibition is relieved by adding the promoter, and efficient gas production of the straw biogas is achieved.

Owner:HUAIYIN TEACHERS COLLEGE

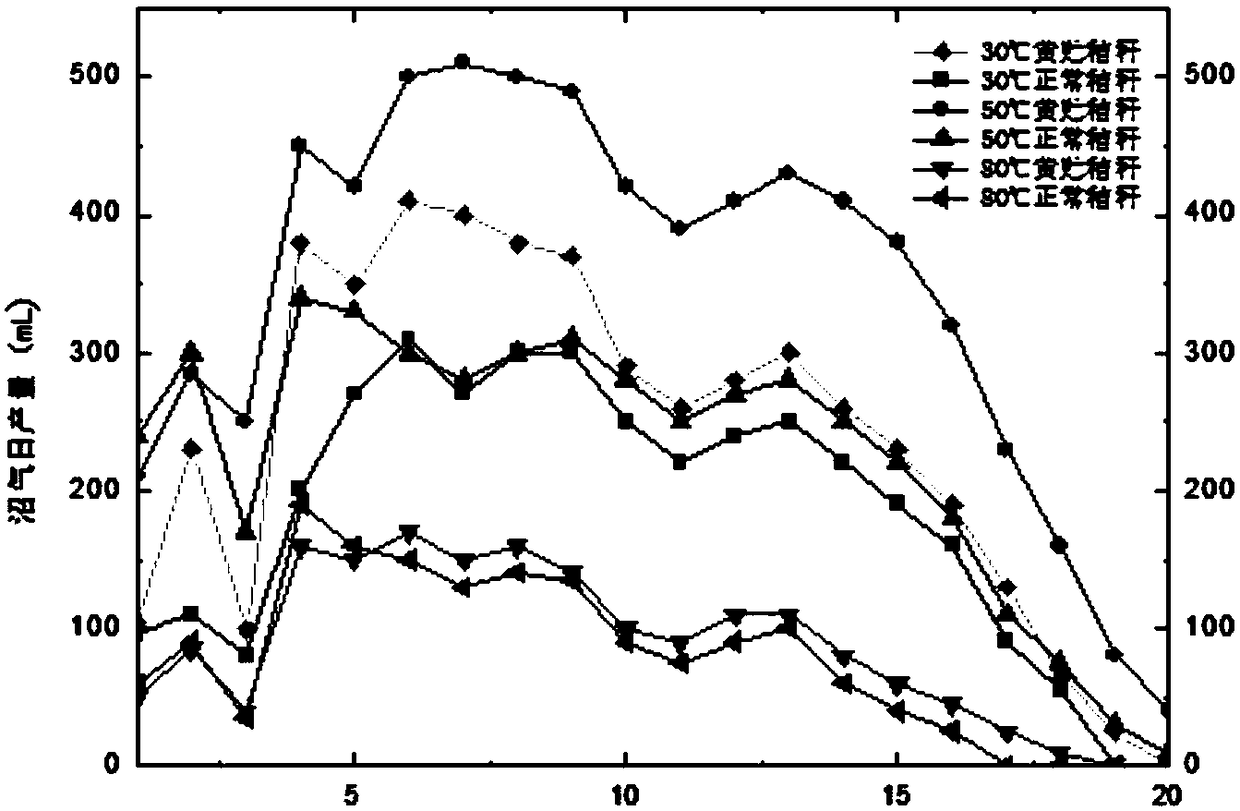

Crop straw pretreatment method for straw biogas engineering in cold regions

InactiveCN109321606AEffective contactReduce crystallinityWaste based fuelFermentationBiotechnologyPretreatment method

The invention relates to a crop straw pretreatment method for straw biogas engineering in cold regions, and belongs to the technical field of pretreatment of raw materials of biogas engineering, whichsolves the problems of long straw pretreatment time and low enzymolysis efficiency. The crop straw pretreatment method specifically comprises the following steps of step 1, crushing crop straw, putting into a sealed container, adding water into the sealed container to enable the crushed straw to maintain a certain water content, pressing the crushed straw, sealing the container, and storing for aperiod of time at a certain temperature, so as to obtain straw subjected to yellow corn silage; step 2, uniformly spraying pretreatment liquid of sodium hydrogen sulfite with a certain mass concentration to the straw subjected to yellow corn silage obtained in step 1, soaking for a certain period of time at a certain temperature, so as to complete pretreatment. The crop straw pretreatment methodhas the advantages that the structure of lignin in the straw is changed by the sodium hydrogen sulfite, and the lignin is dissolved out, hemicellulose is effectively degraded and dissolved out under acid conditions, the effective contact between a cellulase system and cellulose is increased, the enzymolysis efficiency is improved, and the pretreatment time is shortened.

Owner:黑龙江省科学院科技孵化中心 +1

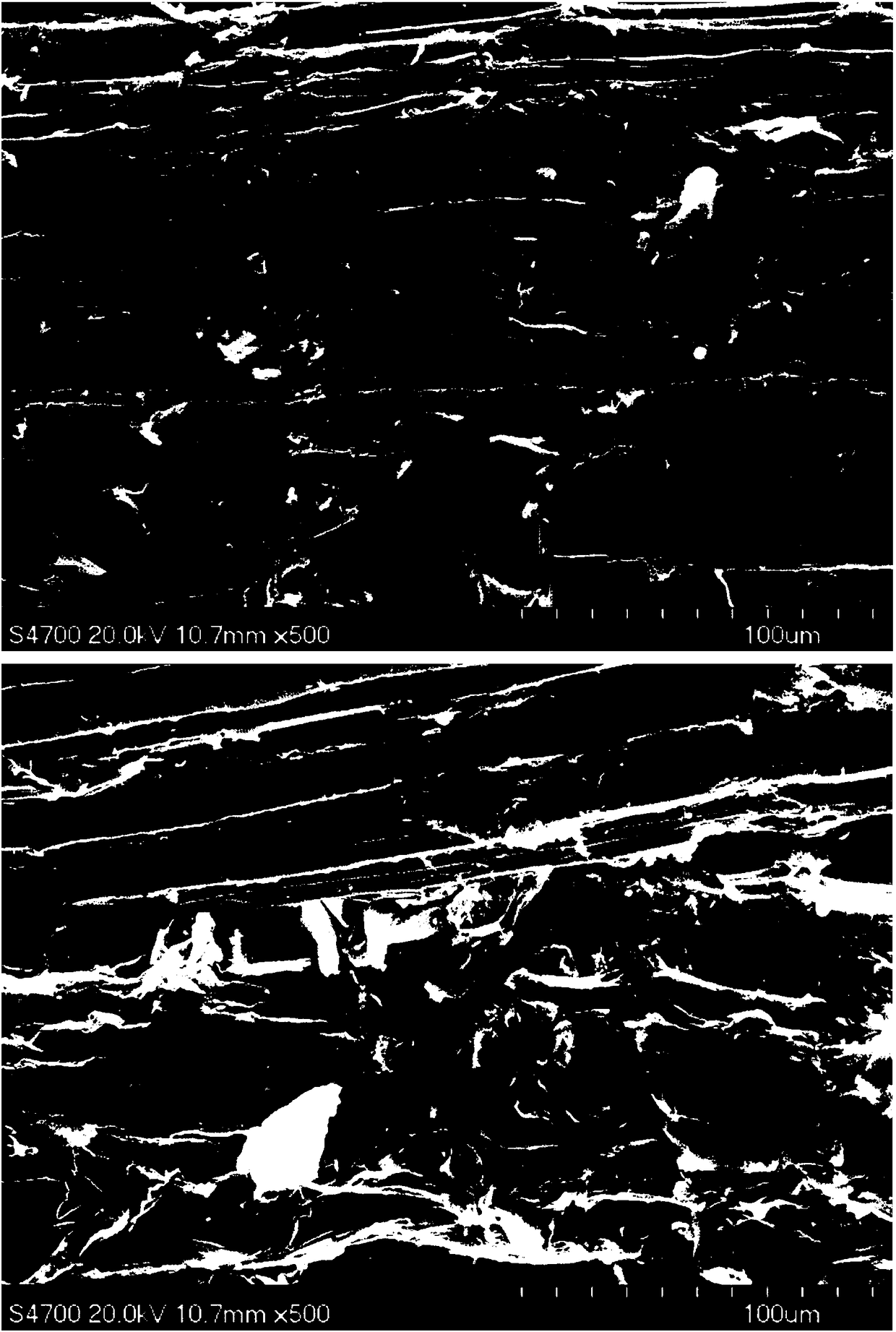

Method for improving anaerobic fermentation gas production performance by repeated freezing/thawing and potassium hydroxide compounded modification of corn stalks

ActiveCN108486165AGood modification effectAnaerobic fermentation cycle shortenedWaste based fuelFermentationMethane yieldPotassium hydroxide

Belonging to the field of renewable energy sources, the invention relates to a method for improving the anaerobic fermentation gas production performance by repeated freezing / thawing and potassium hydroxide compounded modification of corn stalks. The method includes the steps of: loading corn stalks into a self-sealing bag, then adding tap water with different solid-liquid ratios (1:5-1:15) and KOH alkaline reagents of different concentrations (2%-6%), and then putting the self-sealing bag into a cabinet freezer at a temperature ranging from -22DEG C to -41DEG C for freezing, and conducting thawing in a 21DEG C thermotank, specifically, after every 12h of freezing, taking the self-sealing bag out for thawing for 12h, and conducting cyclic freezing / thawing for 2-7d; and subjecting the pretreated materials to intermediate temperature anaerobic fermentation. Compared with the prior art, the method provided by the invention has the following beneficial effects that: (1) the pretreatment effect is obviously enhanced; (2) the anaerobic fermentation cycle T80 is obviously shortened (28.1%-40.6%); and (3) the biogas yield and the methane yield are significantly increased (30.1%-45.9%, 40.7%-54.9%).

Owner:BEIJING UNIV OF CHEM TECH

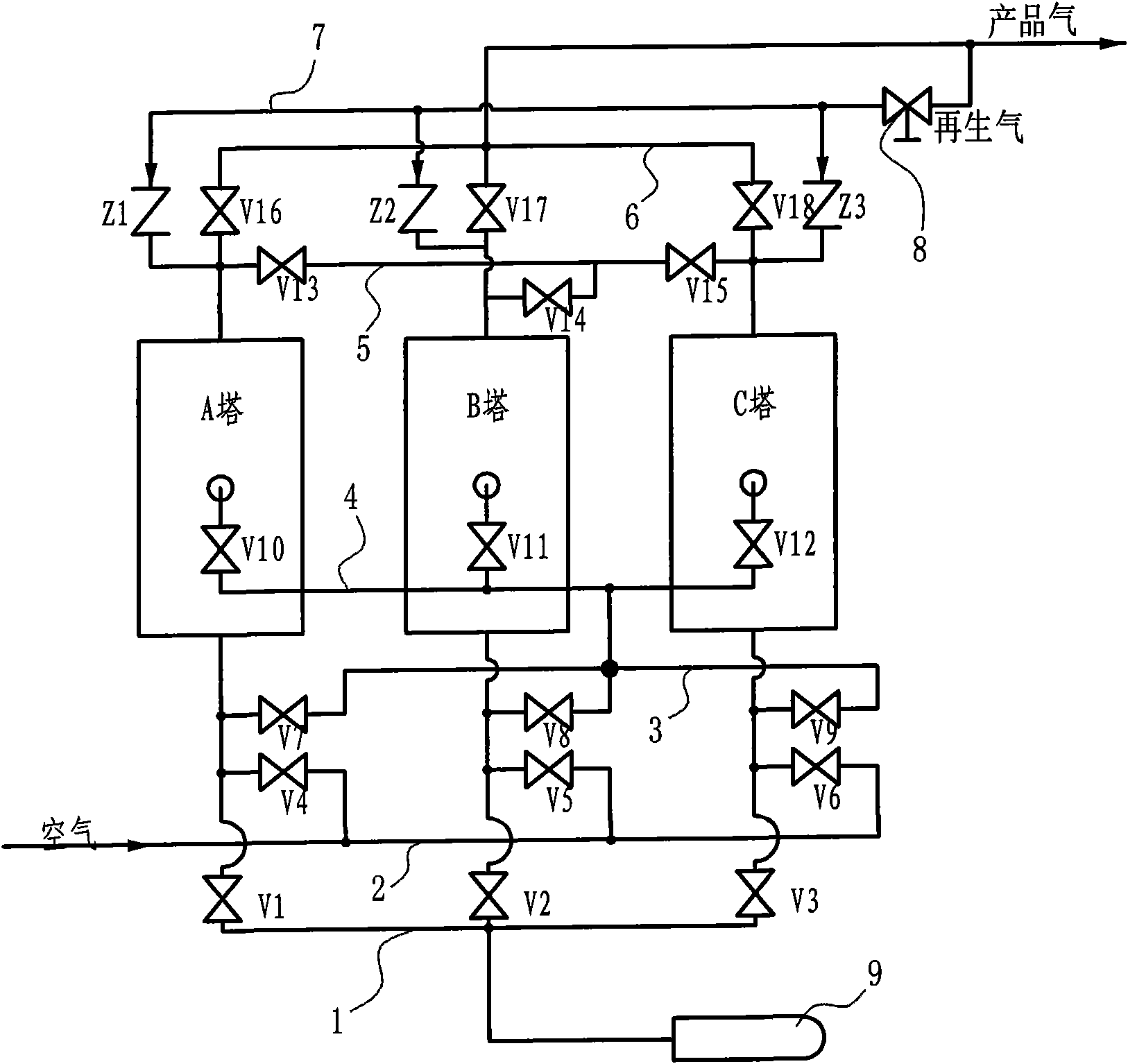

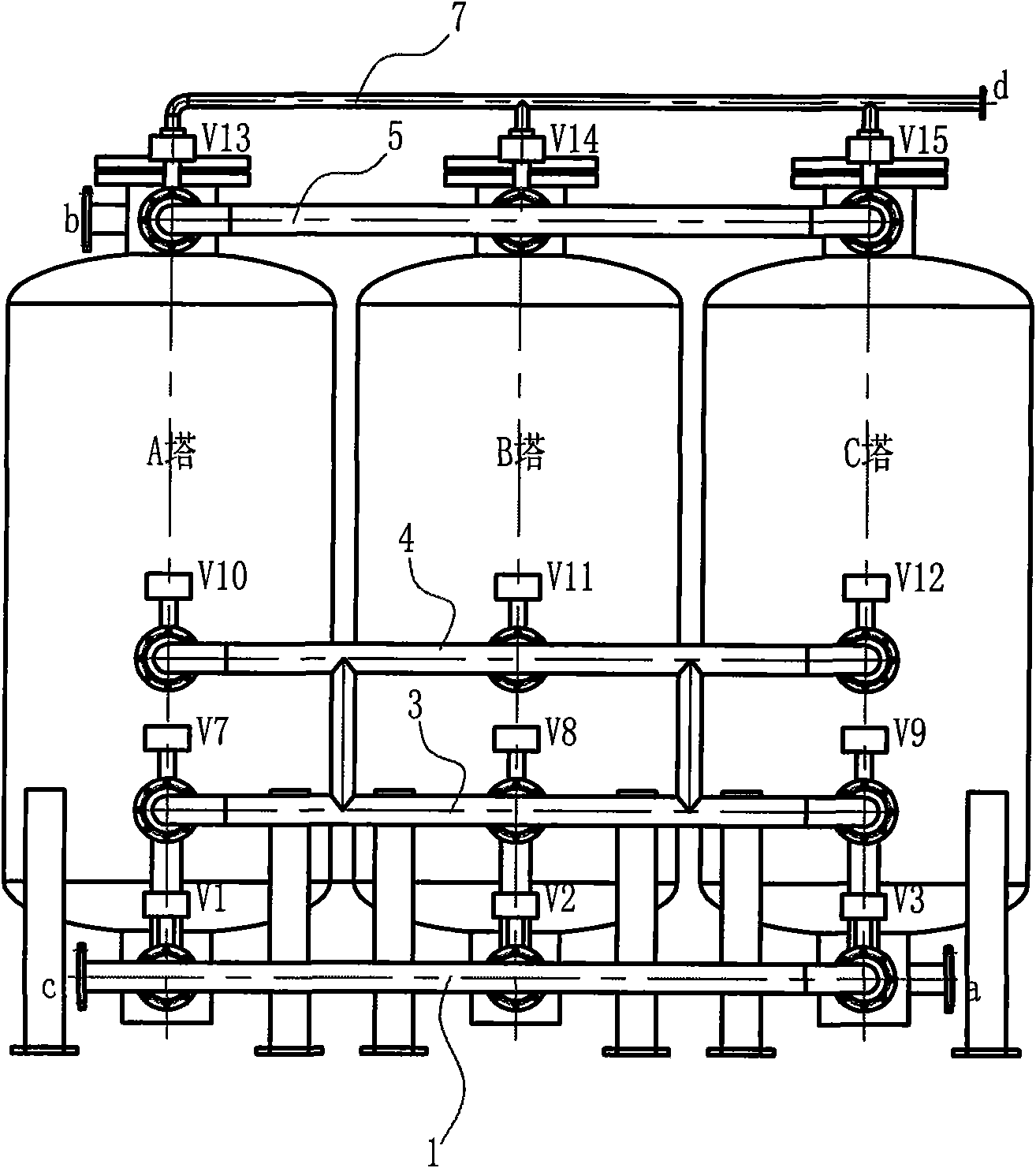

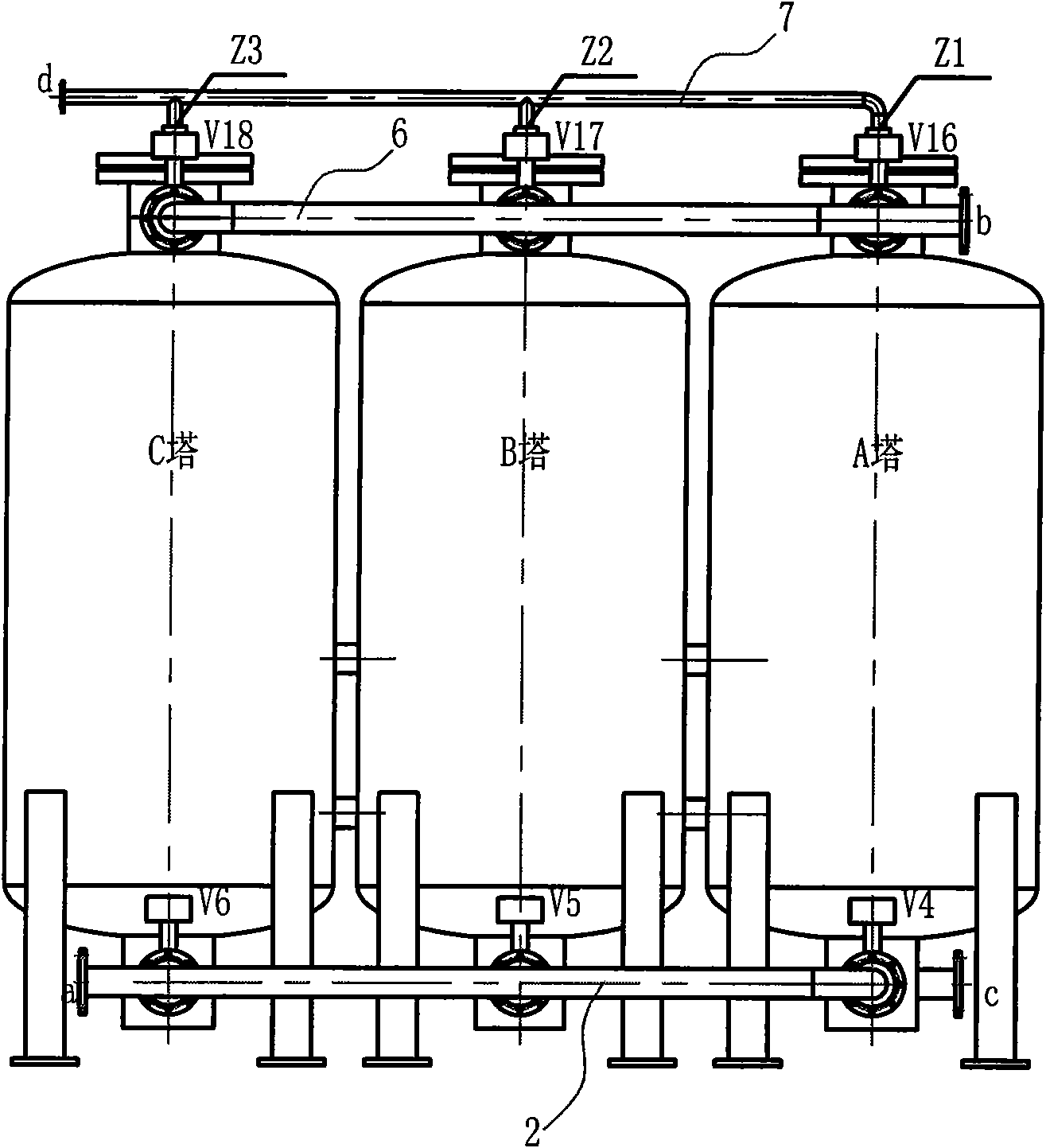

Nitrogen making machine with three-tower structure

ActiveCN101905874AImprove gas production performanceLow costNitrogen purification/separationNitrogenTower

The invention provides a nitrogen making machine with a three-tower structure, which has reasonable structure and high efficacy. The nitrogen making machine is provided with a tower A, a tower B and a tower C, wherein the bottom of the tower A is provided with a valve 1, a valve 4 and a valve 7 in parallel; the bottom of the tower B is provided with a valve 2, a valve 5 and a valve 8 in parallel,and the bottom of the tower C is provided with a valve 3, a valve 6 and a valve 9; the middle parts of the tower A, the tower B and the tower C are respectively externally connected with a valve 10, a valve 11 and a valve 12; the top of the tower A is provided with a valve 13 and a valve 16 in parallel, the top of the tower B is provided with a valve 14 and a valve 17 in parallel, and the top of the tower C is provided with a valve 15 he a valve 18 in parallel; the other ends of the valve 13, the valve 14 and the valve 15 are connected with a pipe 5, the other ends of the valve 16, the valve 17 and the valve 18 are connected with a pipe 6; the tops of the tower A, the tower B and the tower C are respectively connected with a check valve 1, a check valve 2 and a check valve 3 and the otherends of the check valve 1, the check valve 2 and the check valve 3 are connected with a pipe 7; and a pipe 2 is provided with an air inlet, and a pipe 3 and a pipe 4 are bypassed mutually. The invention is suitable for serving as oxygen manufacture equipment with larger flow requirement.

Owner:HANGZHOU SHENGDA MECHANICAL & ELECTRICAL HI TECH CO LTD

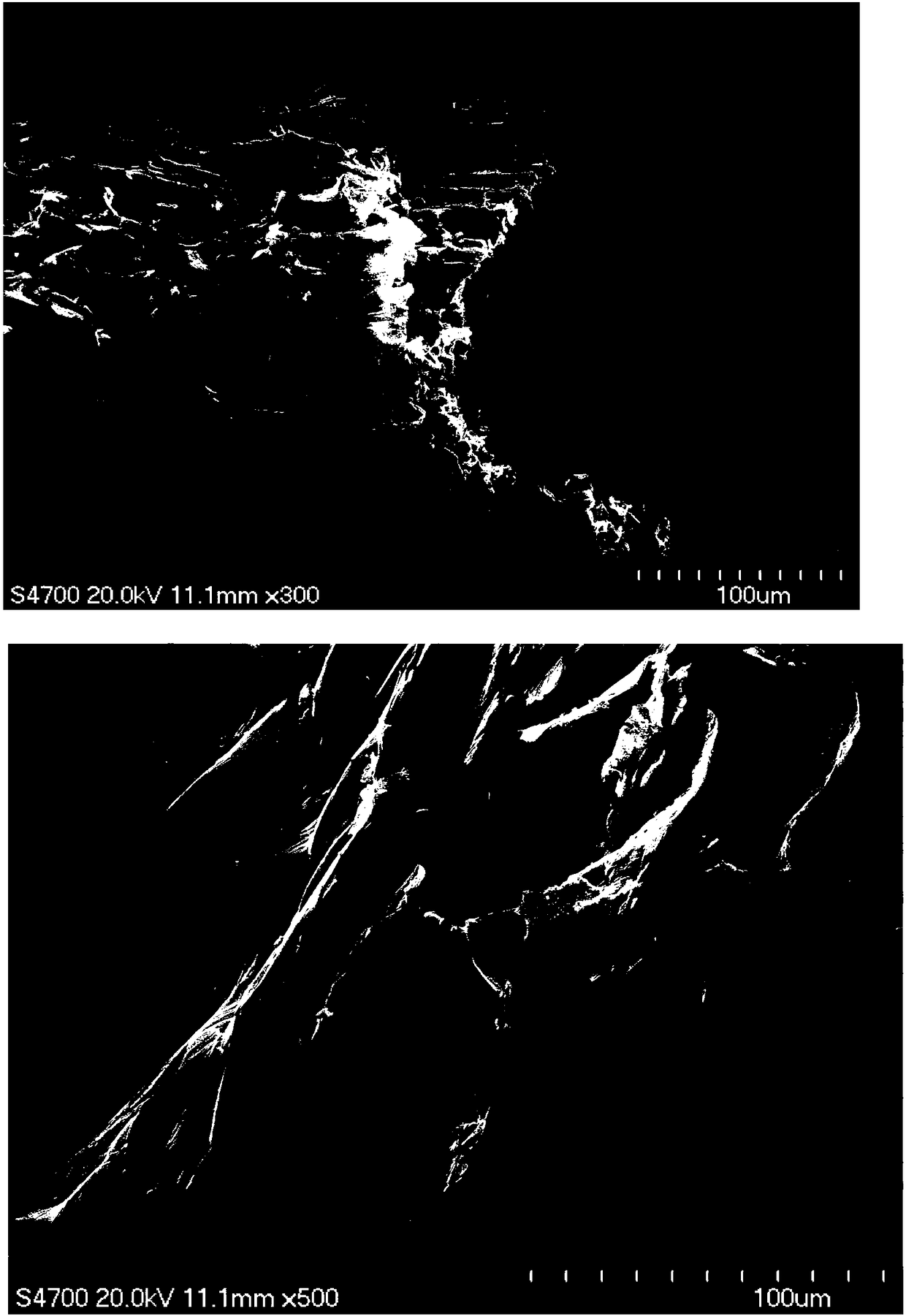

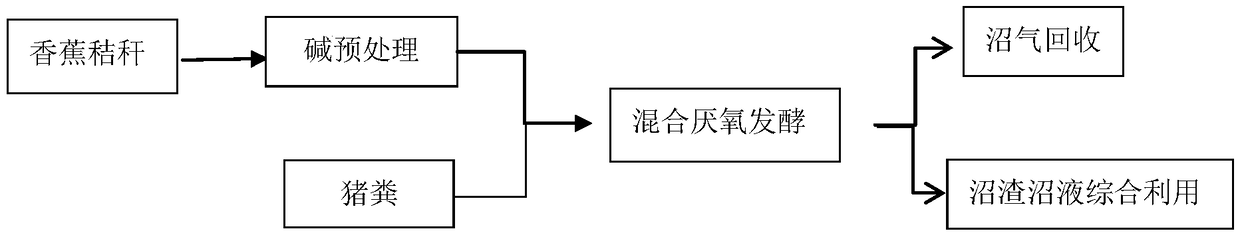

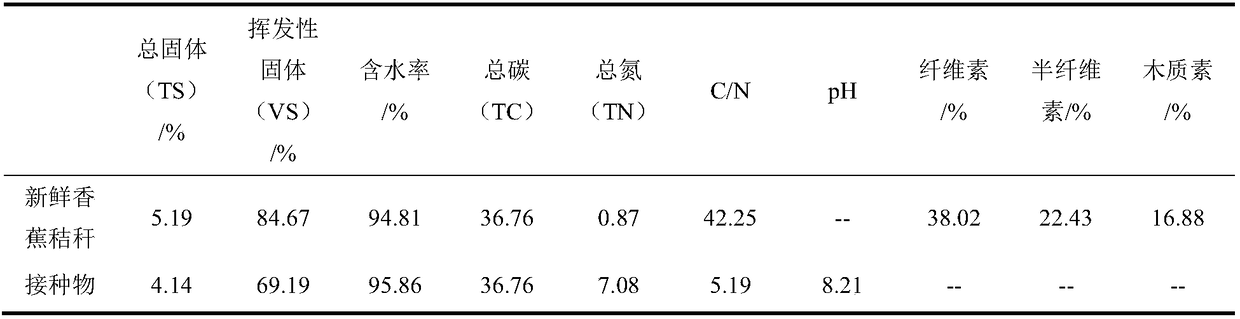

Method for promoting anaerobic fermentation to produce biogas by alkali-pretreated banana straw cooperating with pig manure

ActiveCN108795993AHigh utilization rate of raw materialsImprove gas production effectWaste based fuelFermentationBiogasStart up time

The invention discloses a method for promoting anaerobic fermentation to produce biogas by alkali-pretreated banana straw cooperating with pig manure. The banana straw is subjected to alkali pretreatment, and then the banana straw after alkali pretreatment is mixed with the pig manure for anaerobic fermentation. The alkali pretreatment can greatly improve the raw material utilization rate and thegas production effect of the banana straw, shortens the start-up time of anaerobic fermentation, and makes the fermentation system more stable; then the banana straw after alkali pretreatment is mixedwith the pig manure for anaerobic fermentation, the total gas production amount can be further improved and the level of resource utilization of waste is improved. The problems of difficult degradation of cellulose, more inhibiting factors, unstable system and low gas production efficiency when the banana straw and the pig manure are treated separately are solved.

Owner:GUANGXI UNIV

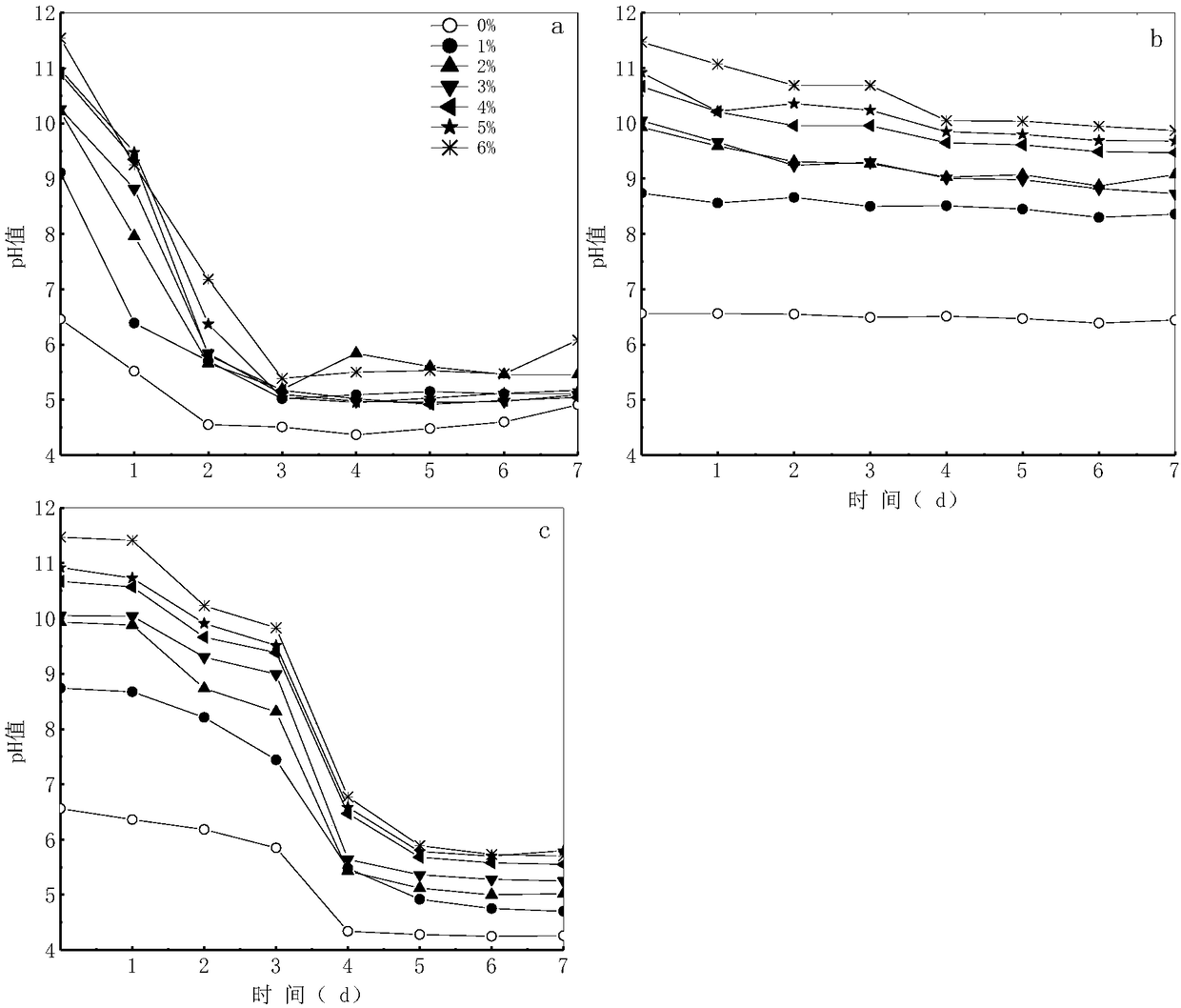

Method for improving anaerobic digestion gas-production performance of maize straws through directional acidification pretreatment

ActiveCN104593430AHigh activityPromote degradationWaste based fuelFermentationMethanationResource utilization

The invention discloses a method for improving the anaerobic digestion gas-production performance of maize straws through directional acidification pretreatment, and belongs to the field of efficient resource utilization of maize straws. The method comprises the following steps: carrying out pretreatment on maize straws by using sodium hydroxide; acidifying the maize straws, and adding activated sludge into the pretreated maize straws, wherein relatively, 10-50 g of TS activated sludge is added into 52 g of TS maize straws; adding tap water until the tap water accounts for 80% of the total volume of a reaction container, mixing the obtained object, filling nitrogen into the reaction container, and hermetically fixing the container in a shaking table, wherein the temperature of the shaking table is kept at 40+ / -2 DEG C; measuring the pH value by using a pH meter every time, and when the pH value is less than 5.5, stopping acidifying; and after methanation startup is completed, by taking an acidified discharged material as a raw material, carrying out feeding and discharging once a day, wherein a fed material and the discharged material are same in volume, and the HRT (hydraulic retention time) is 40 days. According to the invention, the separation of an acidification stage and a methanation stage in biological sciences is realized, and the effects of acidification bacteria groups and methane-producing bacteria groups in respective stage are enhanced, thereby facilitating the stable and efficient operation of an acidification phase and a methane-producing phase, and greatly improving the biodegradability and gas production performance of maize straws.

Owner:BEIJING UNIV OF CHEM TECH

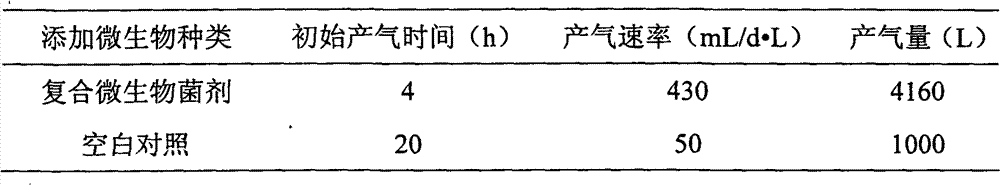

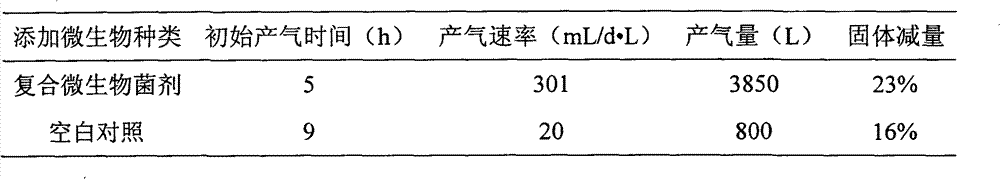

Complex bacterial preparation and application thereof

Owner:江苏加德绿色能源有限公司

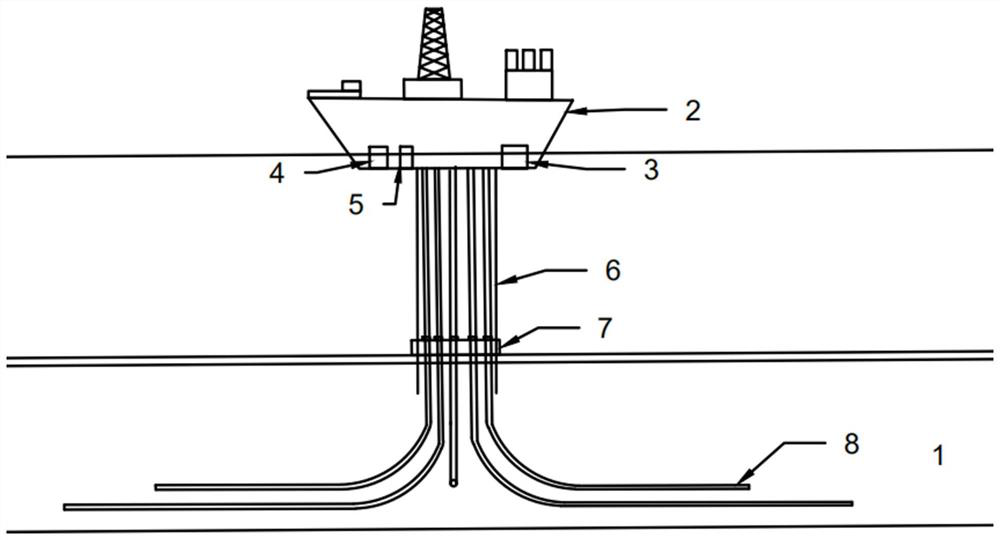

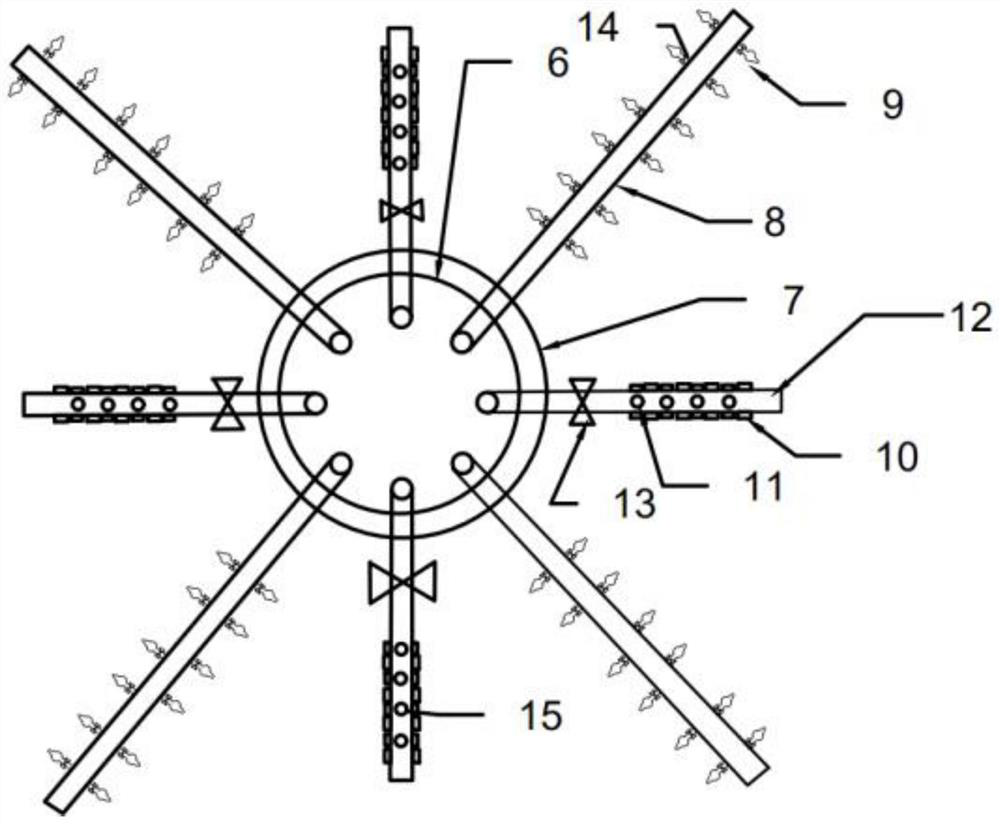

Natural gas hydrate exploitation system and method based on CO2 fracturing

PendingCN114718521AEfficient developmentEfficient miningSurveyMining devicesCo2 storageFracturing fluid

The invention belongs to the field of natural gas hydrate exploitation, and provides a natural gas hydrate exploitation system and method based on CO2 fracturing, the system comprises a fracturing system, a gas production system, a data monitoring system and a main well, and fracturing wells and depressurization wells in the main well are alternately arranged in a star shape along the axis of the main well. The method comprises the steps that firstly, free gas in a reservoir is released, after the reservoir is stabilized, supercritical CO2 fluid is injected, heat is provided for the reservoir, CO2 hydrate is generated while hydrate decomposition is promoted, and the strength of the stratum is enhanced. And when the gas production rate is reduced again, the supercritical CO2 fluid is injected for the second time to carry out secondary fracturing and reservoir strengthening on the reservoir. The fracturing mode is carried out in the mode that fracturing fluid nozzles are spirally arranged on a fracturing well, and multi-angle transformation of the hydrate reservoir is achieved. The depressurization wells and the fracturing wells are separately arranged in a star-shaped arrangement mode, pressure regulation and control are facilitated, the mining range is effectively enlarged, the stability of gas production and the safety of the whole system are guaranteed, and the mining efficiency and the CO2 storage amount are improved through cooperation of multiple wells.

Owner:DALIAN UNIV OF TECH

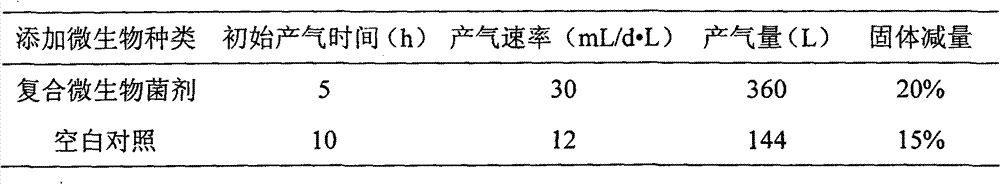

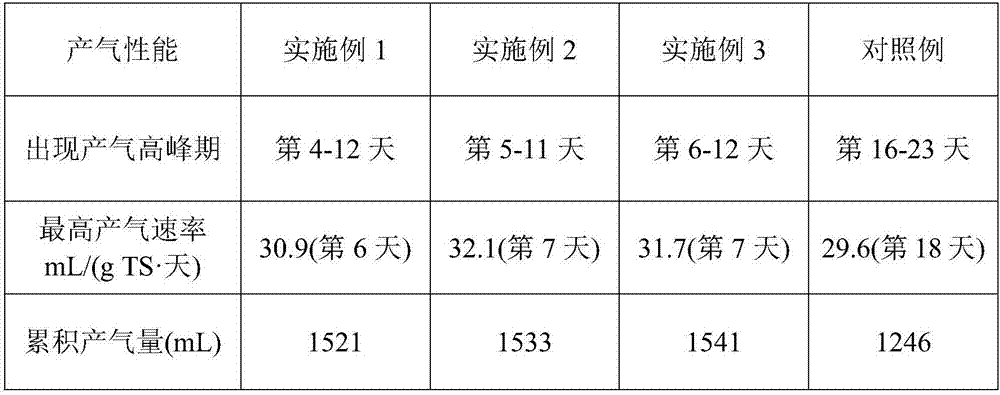

Method for promoting anaerobic fermentation of needle mushroom feet for producing biogas by adopting activated carbon

InactiveCN107338273ASolve wasteImprove gas production performanceWaste based fuelFermentationActivated carbonProduction rate

The invention provides a method for promoting anaerobic fermentation of needle mushroom feet for producing biogas by adopting activated carbon. The method comprises the following steps: (1) taking the waste feet of fresh needle mushroom, grinding the waste feet, adding 1% of sodium hydroxide into the grinded mushroom feet, and then carrying out composting; and (2) after composting is completed, adding activated carbon into the product obtained in step (1), wherein the mass ratio of activated carbon to the needle mushroom feet is 1: (5-10), after sufficient mixing, adding an inoculum into the mixture, carrying out anaerobic fermentation for producing biogas, wherein the temperature of anaerobic fermentation is 35-55 DEG C, the fermentation pH is 6.5-7.5, and the total solid content in the anaerobic fermentation liquid is 5-8 %. According to the method provided by the invention, anaerobic fermentation is carried out on the needle mushroom feet, the activated carbon additive is added into the fermented material, so that the gas production rate of the needle mushroom feet through anaerobic fermentation is greatly improved, the gas production peak is 10-13 days earlier than that obtained not adopting the additive, and the accumulated biogas yield of anaerobic fermentation is also greatly improved.

Owner:BIOGAS SCI RES INST MIN OF AGRI

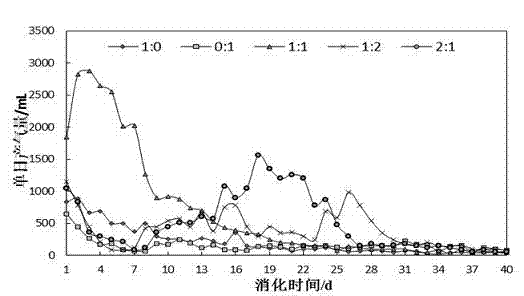

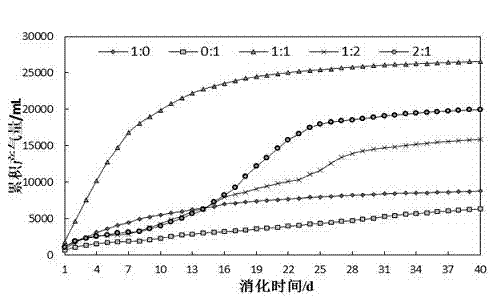

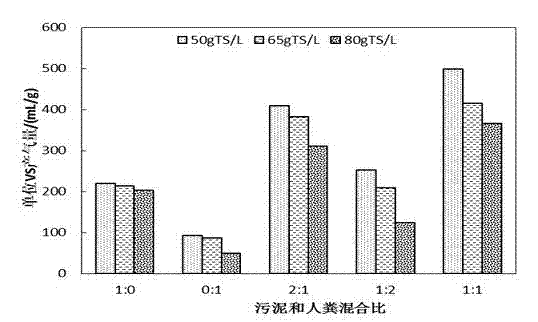

Method for improving performance of methane produced by anaerobic reaction on manure

InactiveCN102964044AImprove gas production performanceHigh biotransformation rateWaste based fuelBiological sludge treatmentCentrifugationPhysical chemistry

The invention discloses a method for improving performance of methane produced by anaerobic reaction on manure, and the method comprises the following steps of: mixing manure with sludge after centrifugation or sedimentation in total solid weight ratio of (1-2):(2-1), placing a mixed material into an anaerobic digestion reactor, adding inoculated sludge, and reacting under the low temperature, middle temperature or high temperature condition. The method disclosed by the invention has the advantages that the process is simple, the operability is strong, two or more than two organic solid wastes can be treated at the same time, and the unit volatile solid gas yield is improved by 4.7-6.8 times compared with that of separate manure.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com