Gasification device for classified gasification of moving bed, method for gasifying coal and applications thereof

A gasification device and moving bed technology, applied in the field of gasification, can solve the problems of reduced lump coal yield, high price, limited source of raw coal, etc., and achieve the effect of improving gas production capacity and increasing production volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] Specific embodiments of the present invention are provided below. It should be understood by those skilled in the art that the examples herein are for illustrative purposes only and should not be construed as limiting the scope of the invention defined by the claims in any way.

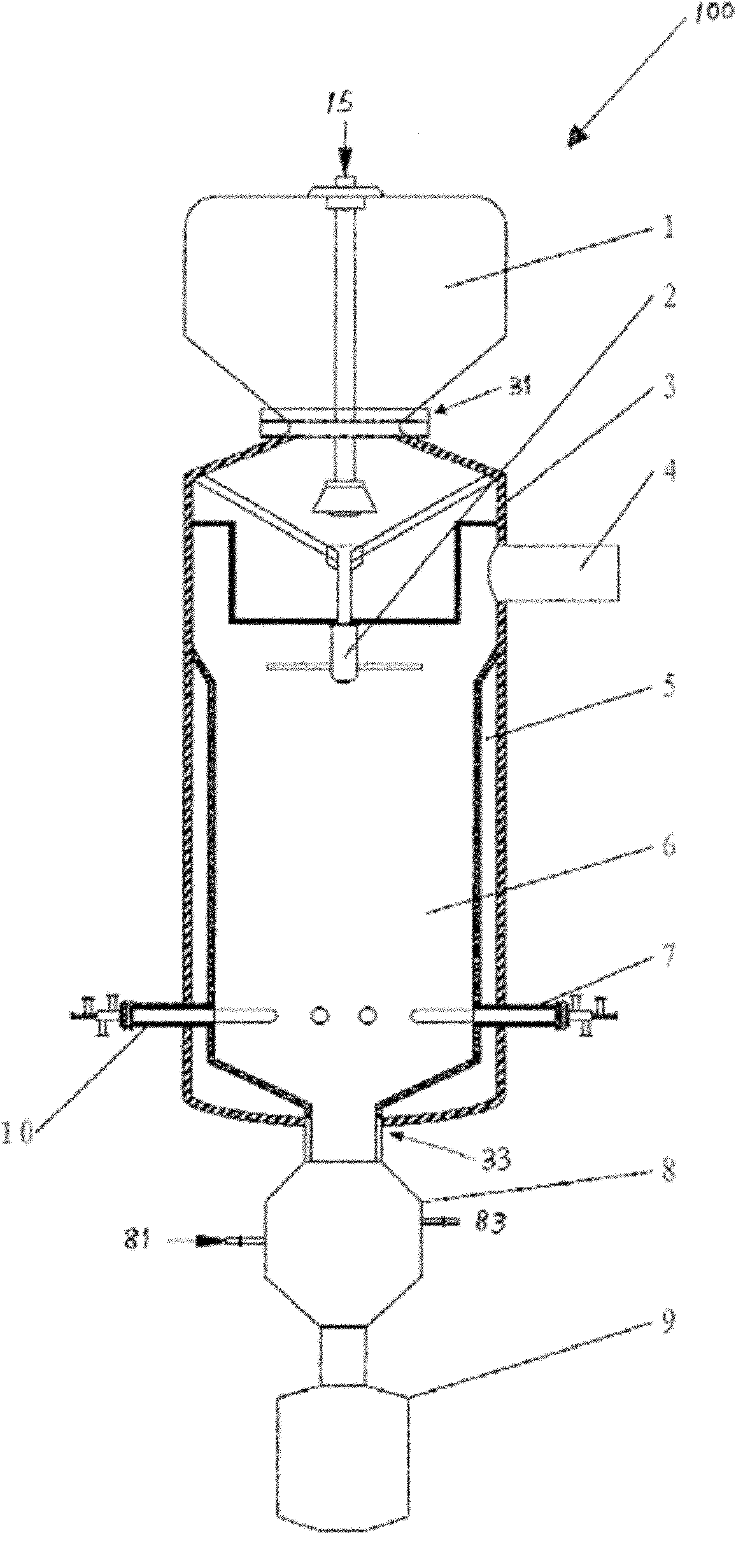

[0067] An embodiment of the present invention provides a graded gasification moving bed gasification device, including: a graded gasification moving bed gasification device 100, including:

[0068] The pressure shell 3 has a first opening 31 at the top of the pressure shell, a second opening 33 at the bottom of the pressure shell, and a first gas outlet 4 is arranged on the upper side of the pressure shell, and the moving bed gas in the staged gasification At least two gasification agent nozzles 10 are evenly arranged on the same horizontal plane of the lower part of the pressure housing 3 of the gasification device 100;

[0069] The coal hopper 1 is arranged above the first opening 31 on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com