Kitchen waste processing system and method

A kitchen waste and treatment system technology, applied in the removal of solid waste and other directions, can solve the problems of low degree of resource utilization, weak anaerobic digestion capacity, poor economy, etc., to improve economic and ecological benefits, Wide application prospects and market space, ensuring the effect of anaerobic fermentation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

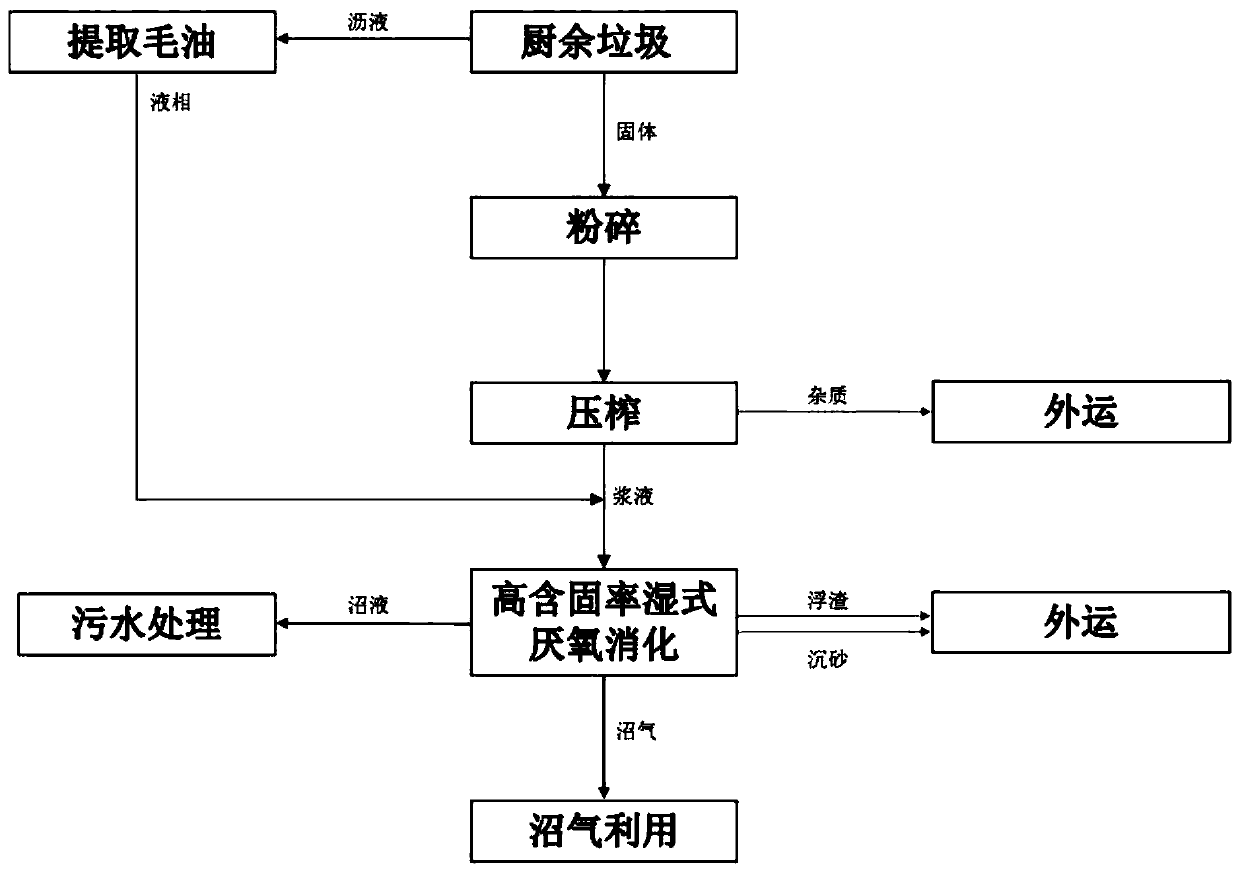

Method used

Image

Examples

Embodiment 1

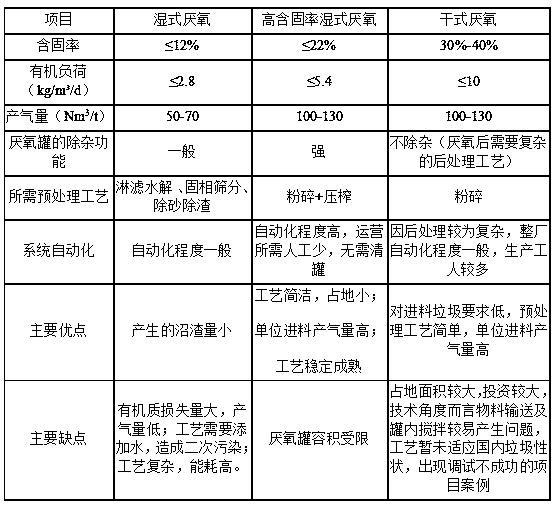

[0083] Example 1: Food waste treatment plant in Jiangjin District, Chongqing

[0084] Experimental project: Food waste treatment project in Jiangjin District, Chongqing

[0085] Treatment scale: 200t / d food waste + 20t / d sludge

[0086] Production year April 2017

[0087] Operation Status Continuous operation for nearly 3 years (no production stop to clear tanks)

[0088] Solid content in the tank ≤18%

[0089] Organic loading ≤3.5 OTSV kg / (m3·d)

[0090] Gas production 100-130m³ / t

[0091] Oil extraction 8-10t / d

Embodiment 2

[0092] Embodiment 2: German Garmisch organic waste treatment plant

[0093] Project Name Garmisch Organic Waste Treatment Plant, Germany

[0094] Processing scale 50t / d kitchen waste + dining waste

[0095] Production year 2014

[0096] Operation status 4 years of continuous operation (no production stop to clear tanks)

[0097] Solid content in the tank ≤22%

[0098] Organic loading ≤5.4 OTSV kg / (m3·d)

[0099] Gas production 130-150m³ / t

Embodiment 3

[0100] Example 3: German Rothmuehle Kitchen Waste Treatment Plant

[0101] Project Name Kitchen Waste Treatment Plant in Rothmuehle, Germany

[0102] Processing scale 80t / d kitchen waste

[0103] Production year 2014

[0104] Operation status 4 years of continuous operation (no production stop to clear tanks)

[0105] Solid content in the tank ≤22%

[0106] Organic loading ≤5.4 OTSV kg / (m3·d)

[0107] Biogas output 130-150m³ / t

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com