Patents

Literature

373 results about "Expeller pressing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Expeller pressing (also called oil pressing) is a mechanical method for extracting oil from raw materials. The raw materials are squeezed under high pressure in a single step. When used for the extraction of food oils, typical raw materials are nuts, seeds and algae, which are supplied to the press in a continuous feed. As the raw material is pressed, friction causes it to heat. In the case of harder nuts (which require higher pressures) the material can exceed temperatures of 120 °F (49 °C).

Juice Containing Pouch and Press for Extracting Juice from the Pouch

InactiveUS20140314918A1Minimal clean-upReady-for-oven doughsDispensing apparatusFruit juiceEngineering

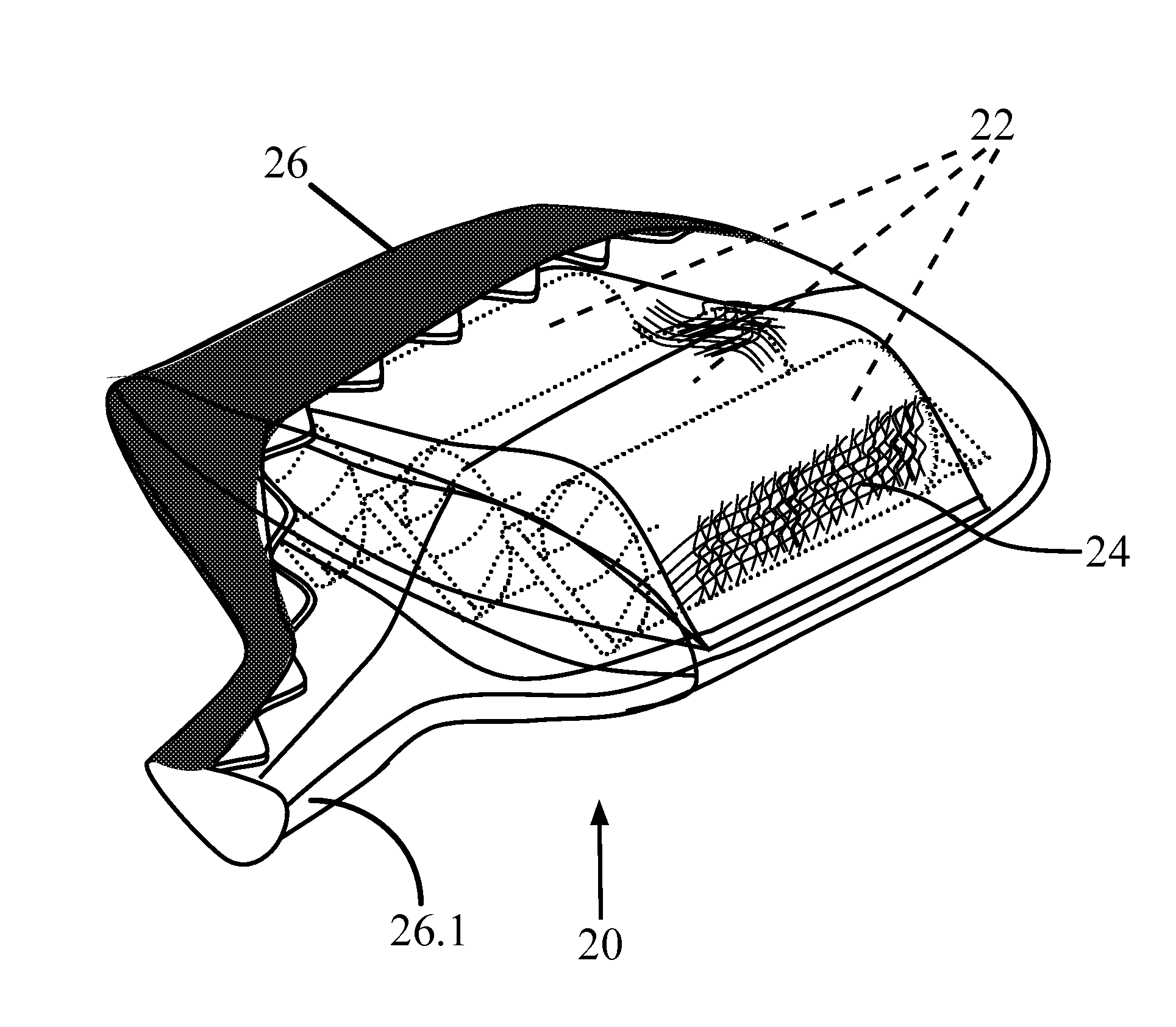

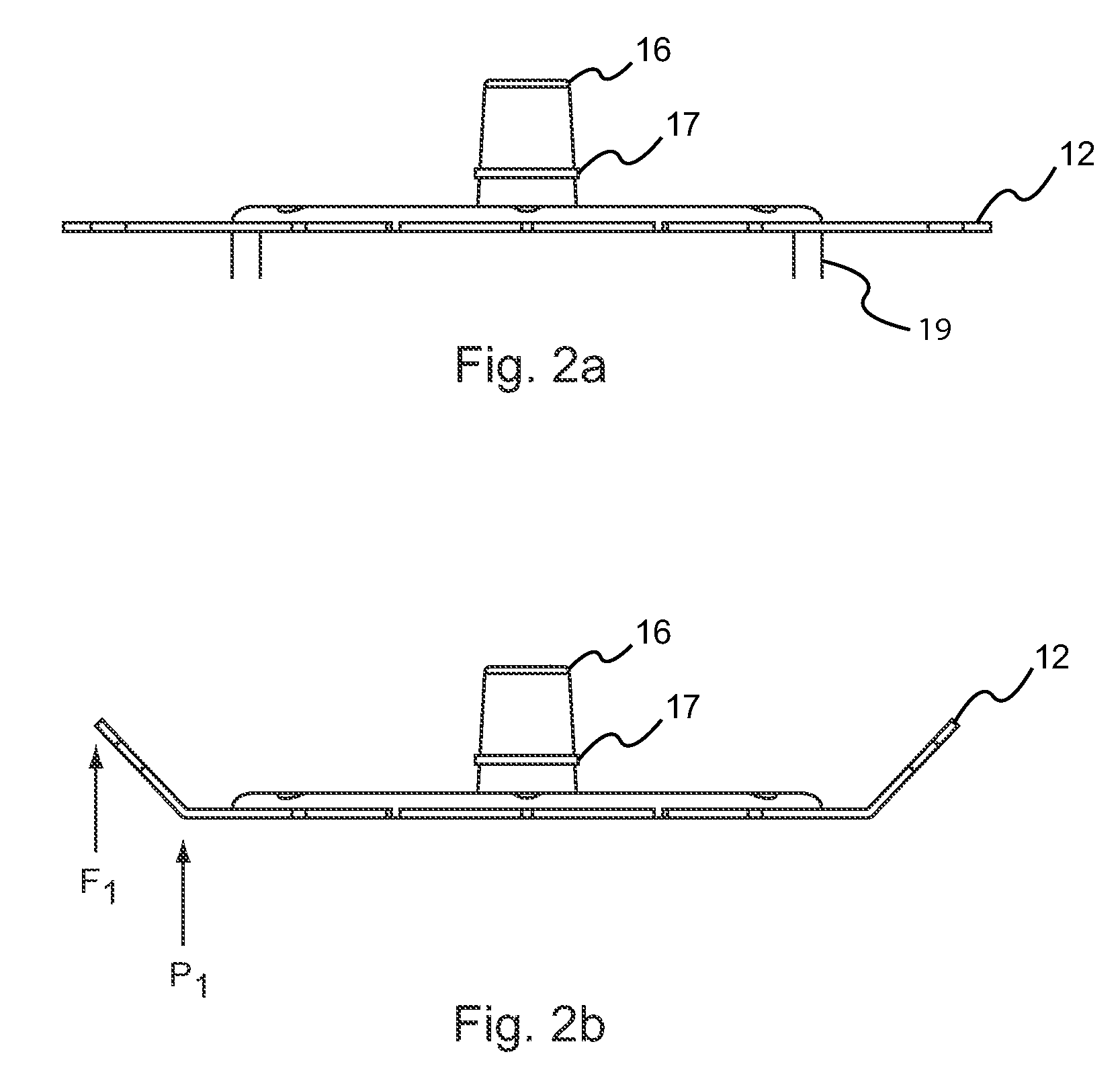

A multi-layer pouch assembly consisting of one or multiple inner sealed pouches that contain the ground produce or other product, and a surrounding mesh pouch or bag, acting as a filter for the juice contained in the inner pouches. The outer mesh or gauze pouch which completely envelops or surrounds the inner produce containing pouches has a volume at least equal to the total volume of the inner pouches, to allow for the pressing and expansion of the ground produce when the inner bags are burst by a press platen. Another alternative embodiment employs a third outermost sealable plastic pouch that is capable of holding the gauze bag or pouch, which holds the produce-containing pouches. This outer pouch can be sealed and serves as the package and container for storage in refrigerators or suitable storage facilities.

Owner:FRESH PRESS LLC

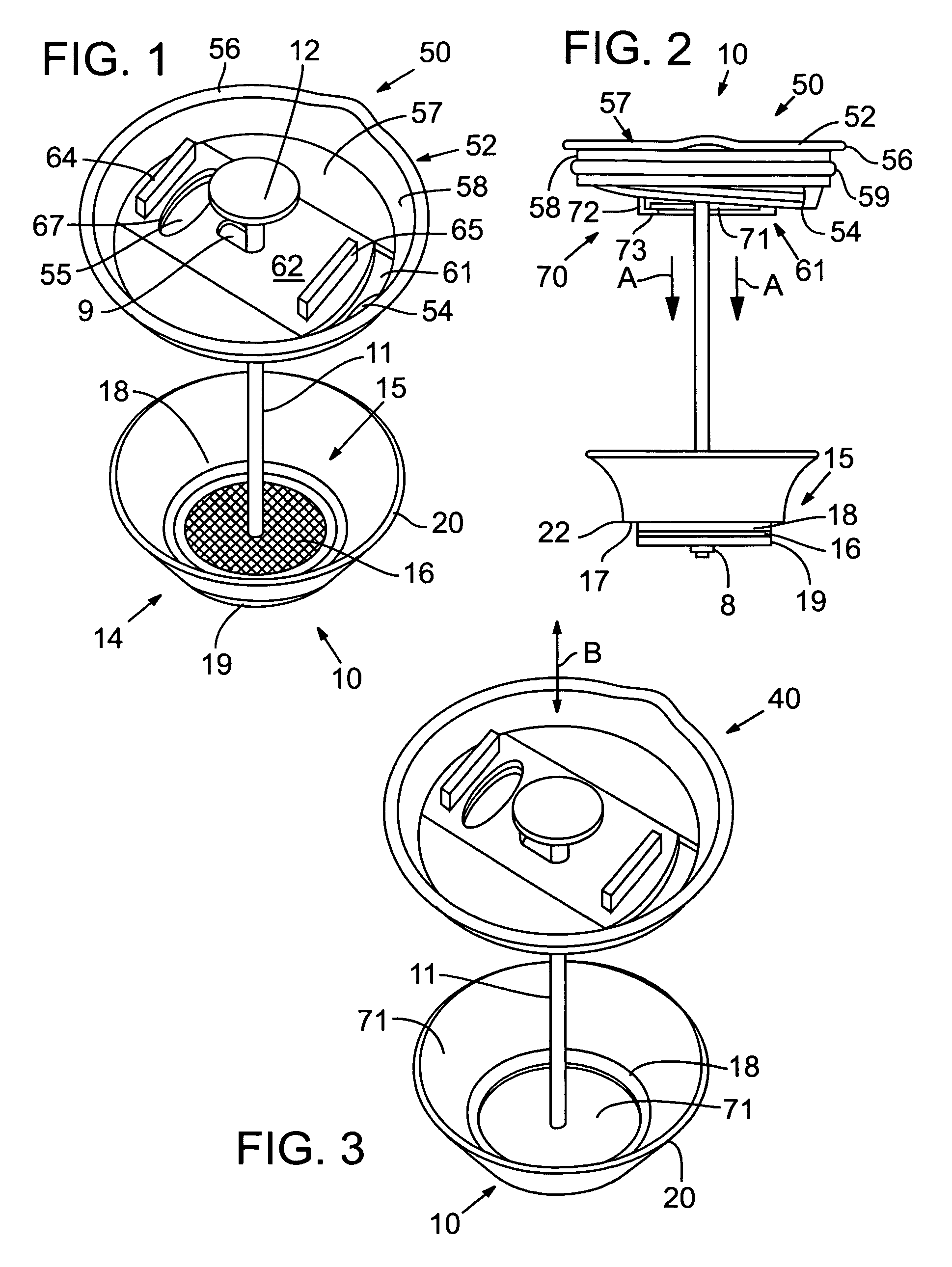

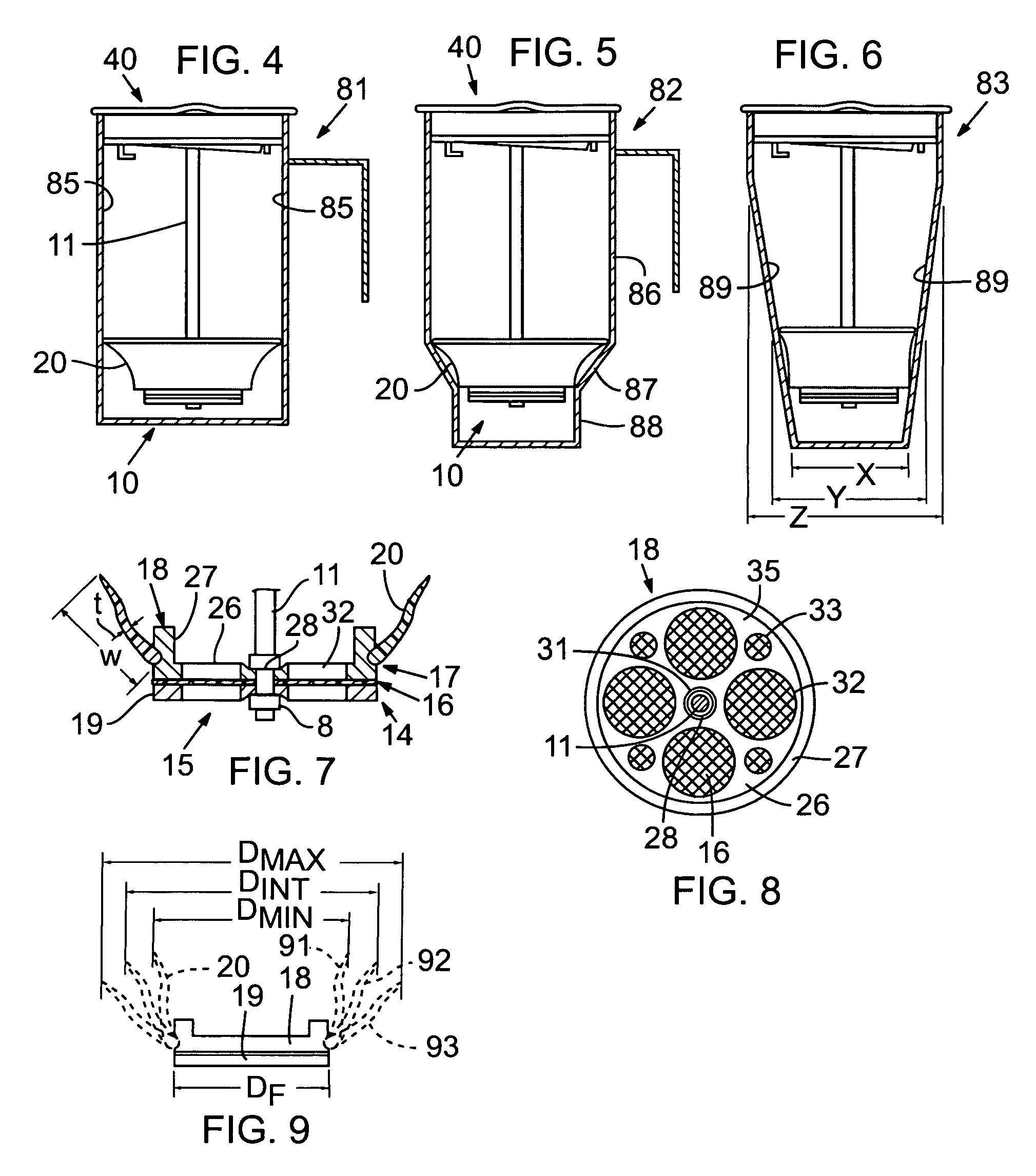

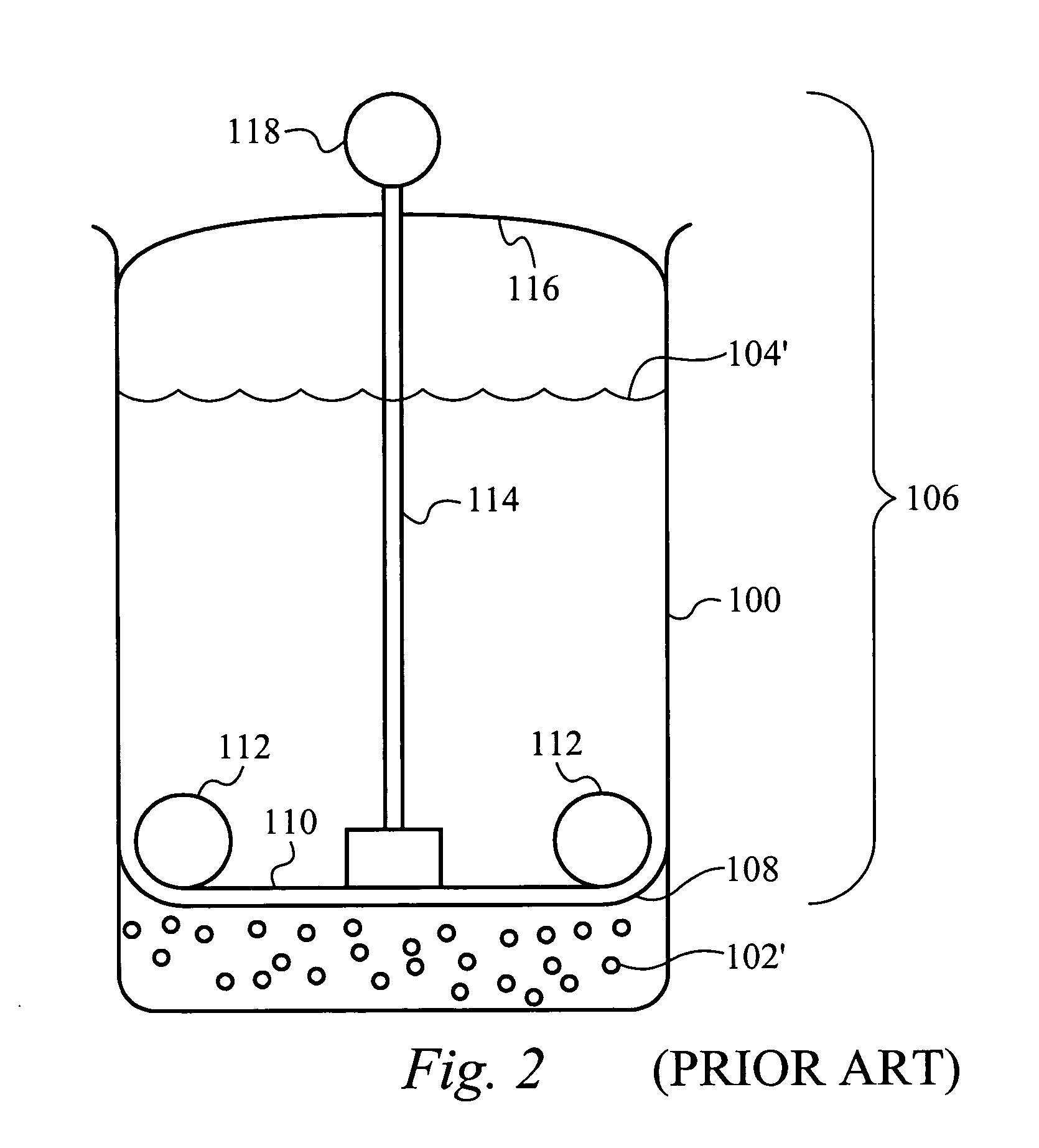

Plunger and lid apparatus for a beverage press and a beverage press having same

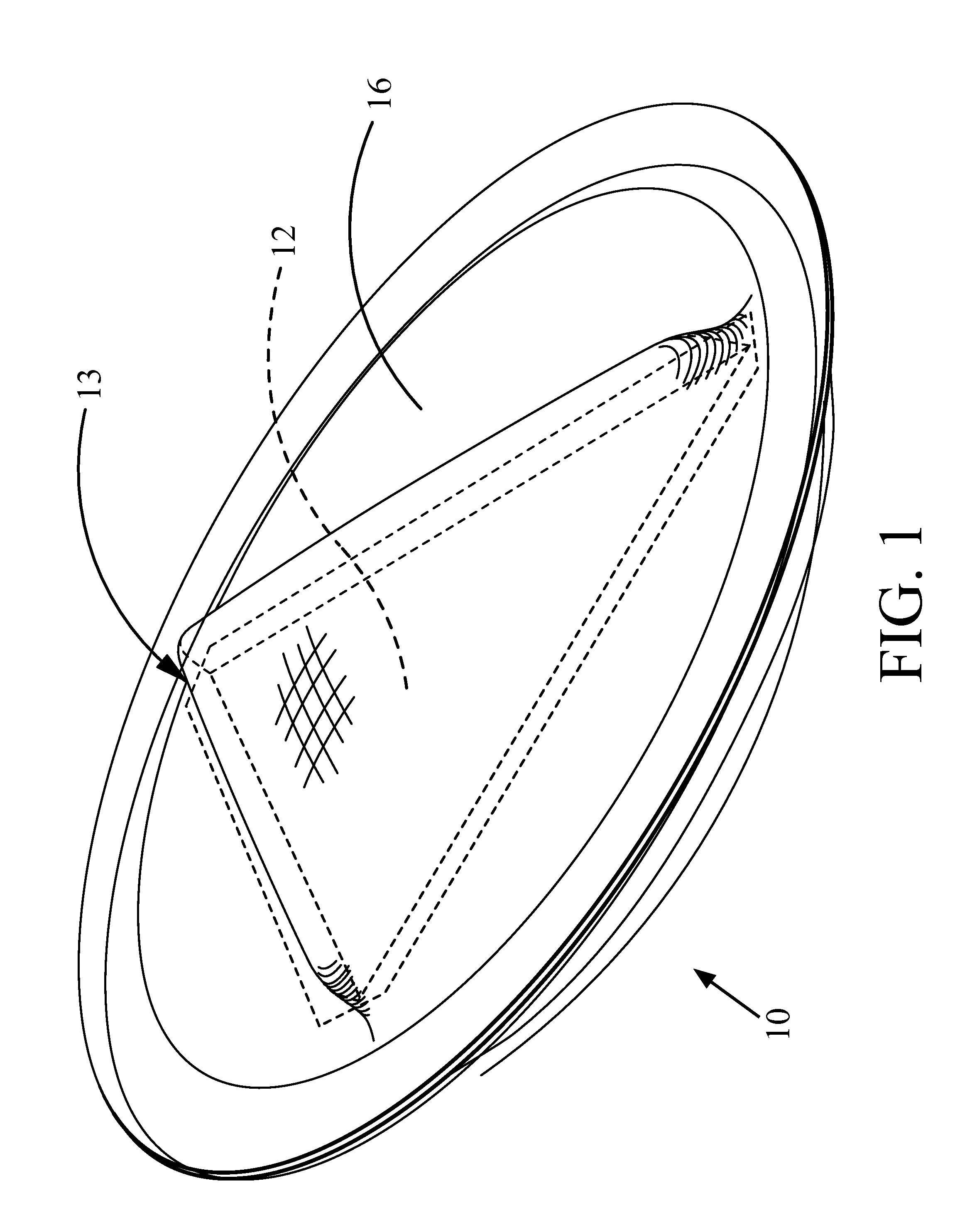

A plunger device for use with a beverage press having a screen for filtering fines from an infused beverage. A flexible seal is provided that is compressible to function properly in different sized containers. The seal may be made of a material such as rubber or rubberized plastics or the like and may have a width that is greater than its thickness. Various seal embodiments including ascending, descending and non-circular embodiments are disclosed. Brew control and multiple access openings are also disclosed.

Owner:PACIFIC CORNETTA

Coffee infusion press for stackable cups

InactiveUS20050139091A1Enhance and speed processEasy to installJuice extractionBeverage vesselsMechanical engineeringEngineering

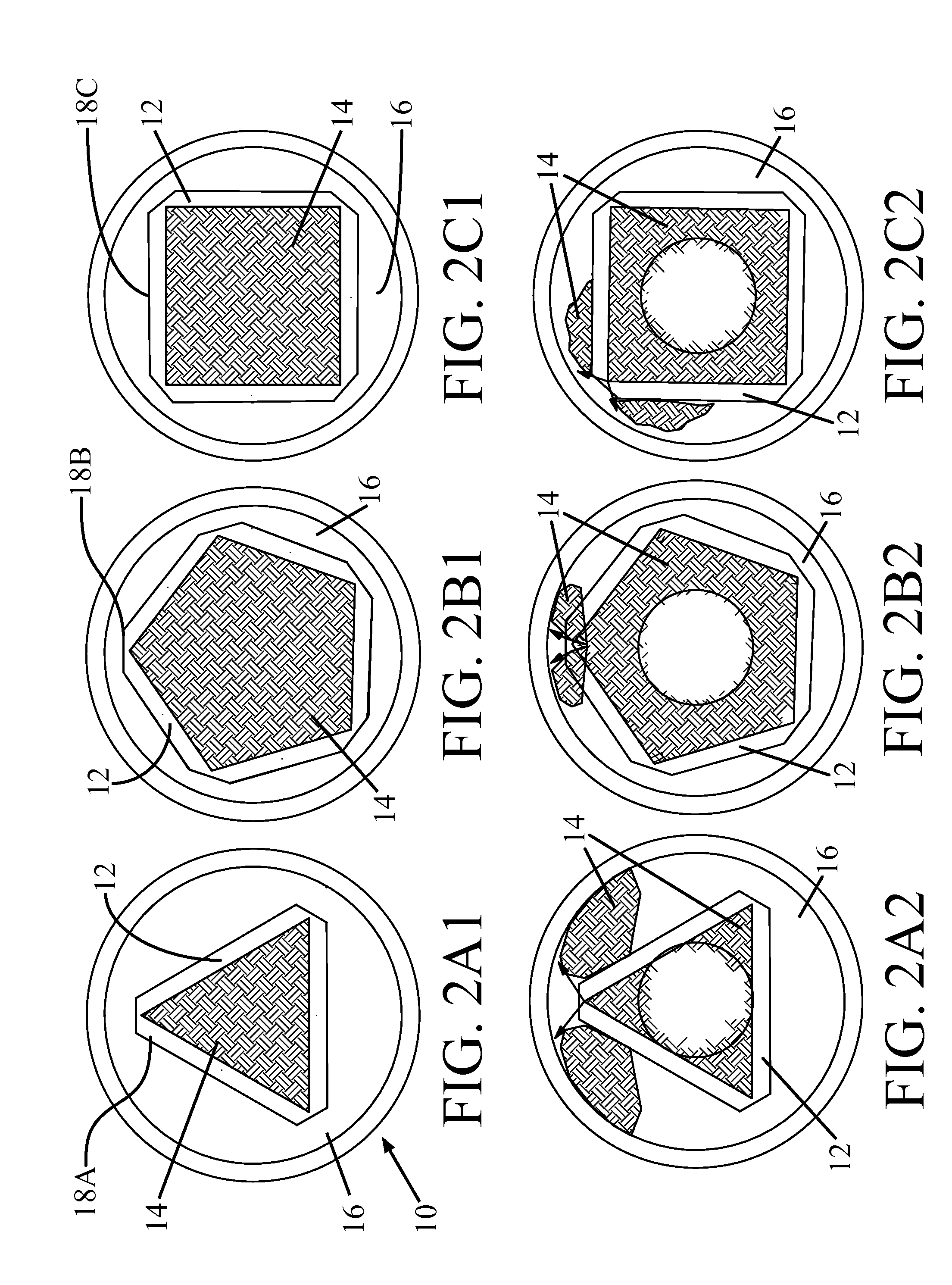

A press assembly is adapted to be used with a disposable stackable cup. According to the preferred embodiment, the press includes a filter. A resilient radially compressible support forms a seal is formed between the filter and the interior of the cup. A detachable rod is mounted to the support. The support is sized to accommodate all radii of the cup. As the user presses down the rod, the press assembly is pushed downward to the bottom of the vessel. The seal maintains continual and firm pressure on the inside surface of the vessel so that the pressurized liquid passes through the filter and the infuision substance is trapped.

Owner:HAVERSTOCK THOMAS B

Multi-purpose culinary implement

InactiveUS20050252387A1Low costReduce spacingJuice extractionProtein composition from eggsEngineeringIngested food

A food preparation apparatus is provided, the apparatus comprises: a main frame having a central opening for receiving a food preparation implement and having opposing ends; and at least one interchangeable food preparation implement designed to be inserted within the central opening and locked onto the main frame during usage and being removable for cleaning and storage during non-use, the food preparation implement is selected from a group consisting of mandolins, graters, cutting devices, potato fry cutters, slicers, corers, peelers, pressing devices, food mashers, food presses and mixtures thereof.

Owner:CORNFIELD RANDALL

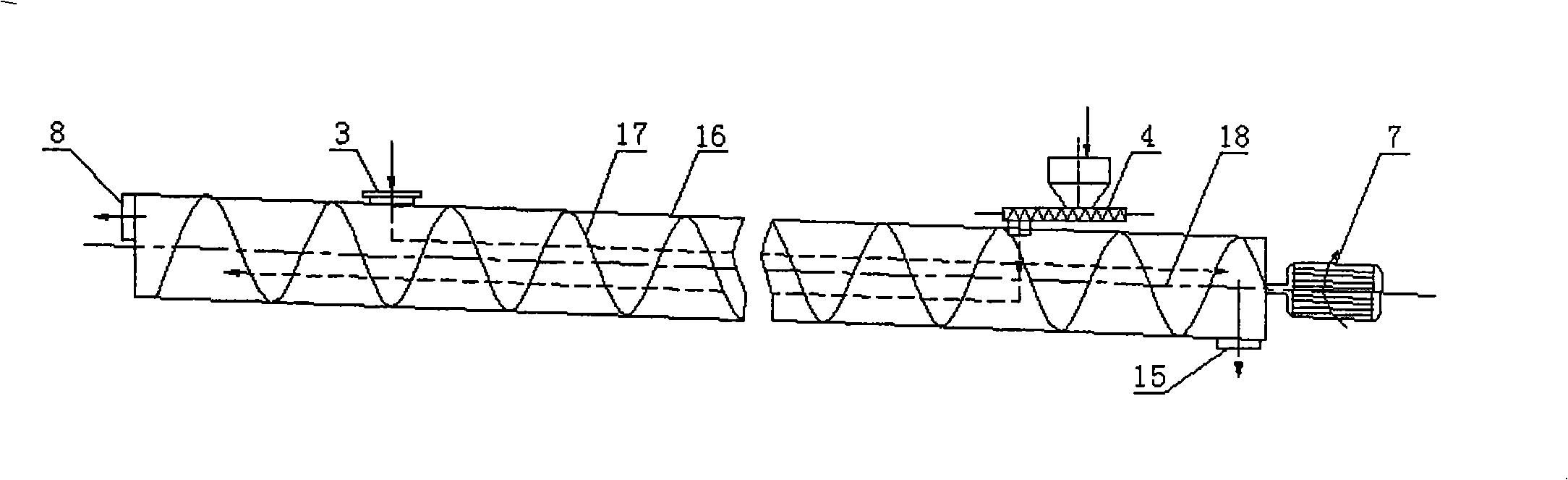

Preparation method for tea oil by double helix low-temperature squeezing

InactiveCN102757858AAvoid heatingAvoid processing powerFatty-oils/fats refiningFatty-oils/fats productionChemical treatmentFiltration

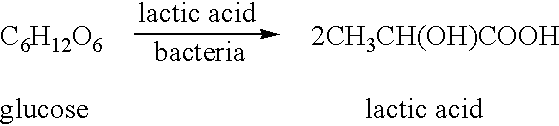

The invention relates to a preparation method for tea oil by double helix low-temperature squeezing, which comprises the following steps: a) drying at low temperature; drying screened tea seeds by a flat dryer and an induced fan, wherein the drying temperature is 45-55 degree C, the drying time is 55-65 minutes, and the moisture content of dried tea seed is 6-10%; b) husking for separation; c) squeezing at low temperature; d) making squeezed oil stand for filtration; e) performing winterization treatment; and f) obtaining the finished product. Through low-temperature drying, squeezing by a double helix squeezer as well as the filtration technology by standing, the preparation method disclosed by the invention can avoid overheating and excessive chemical treatment to the oil, avoid residues of harmful substances generated during high-temperature processing, and avoid residues of acid, alkali and heavy metals due to addition of chemical addition agents; in addition, the technology disclosed by the invention can retain the pure natural quality of the tea-seed oil, and as much as possible retains physiological characteristic substances in the tea oil, such as vitamin E, gamma-linolenic acid and other beneficial components.

Owner:ANHUI YIHONG BIOTECH

Method and equipment for preparing tea seed oil from tea seeds and extracting tea polyphenol from byproduct tea seed cake

InactiveCN102028042AEasy feedingEfficient separationSugar derivativesSteroidsAcetic acidCamellia oleifera

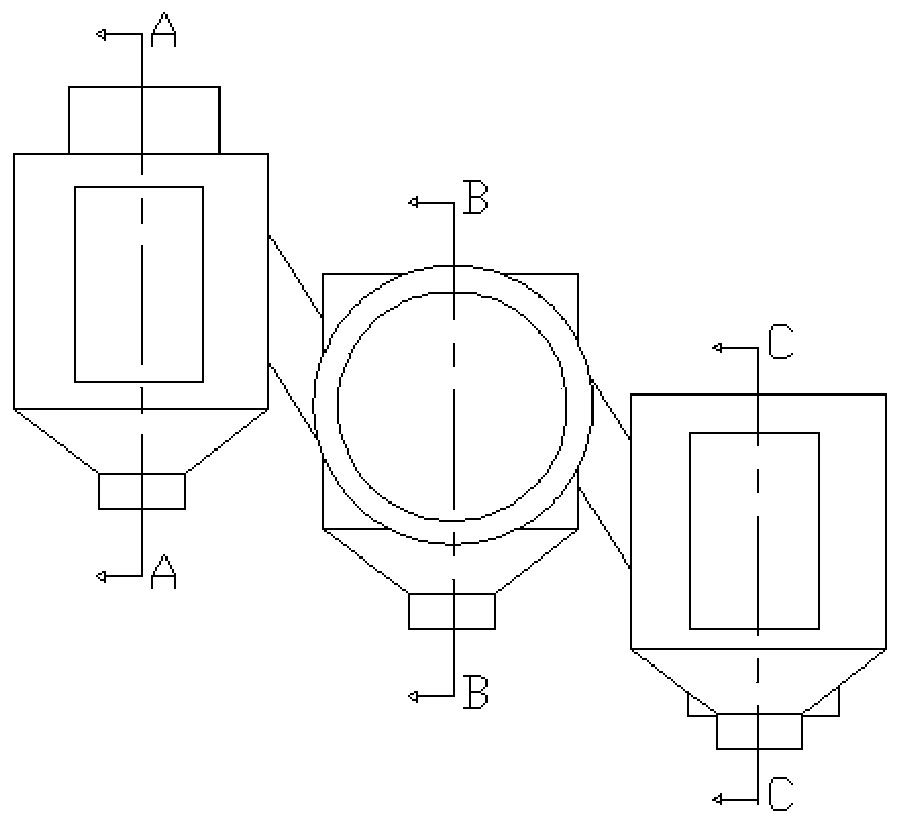

The invention discloses a method and equipment for preparing tea seed oil from tea seeds and extracting tea polyphenol from a byproduct tea seed cake. The method comprises the following steps of: screening; drying; husking, crushing, separating and grinding the tea seeds to obtain tea seed powder; cooking tea seed powder; wrapping a cake; squeezing a tea cake into tea seed oil and the byproduct tea seed cake; and extracting tea polyphenol and saponin from the byproduct tea seed cake. The method is characterized in that: petroleum ether or No.6 solvent oil is used for soaking the tea seed cakeso as to obtain a tea seed oil product; and a degreased tea seed cake is extracted by using solution of methanol or ethanol, concentrated solution is extracted by using ethyl acetate, extract liquor is evaporated and the solvent is recycled so as to obtain a tea polyphenol product. A piece of special equipment comprises a drier, a husking machine, a cooking machine, a squeezer and a tea seed cakegrinder. Good separation of kernels from shells is achieved by a special husking machine and the cooking degree of the tea seed powder can be controlled well by a special cooking machine. A special tea seed cake grinder is used, so that grinding efficiency is higher and the service life of the equipment is prolonged.

Owner:FUJIAN YOUXI COUNTY SIN LONG EDIBLE OIL

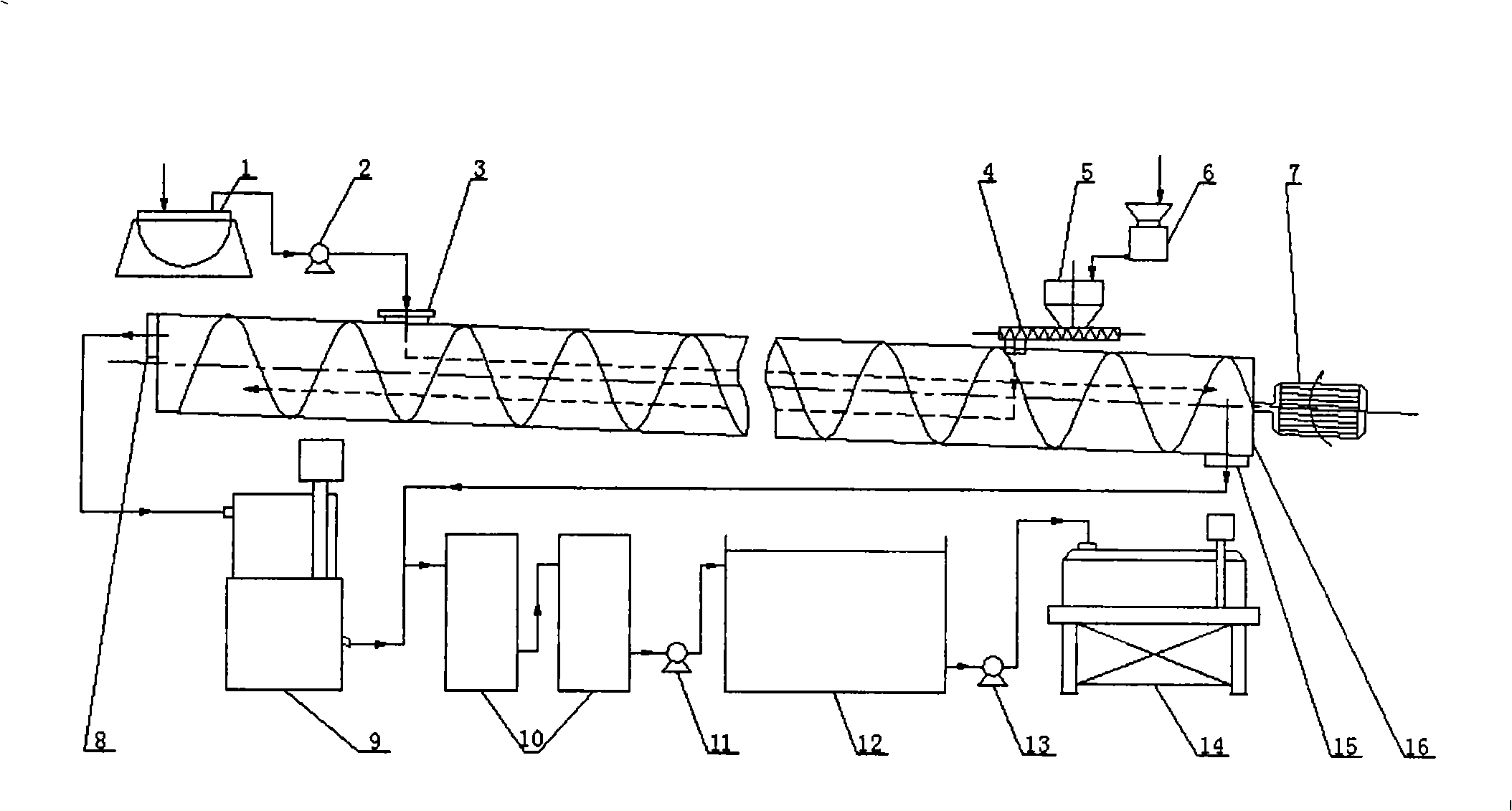

Lixiviation apparatus for zanthoxylum oil and digestion method

InactiveCN101341966AImprove extraction efficiencyShort runtimeEdible oils/fatsFood preparationVegetable oilZanthoxylum bungeanum

The invention discloses an extracting device and an extracting method for zanthoxylum oil and is characterized in that an oil joint (3) at the left upper end of a low temperature refluxing extracting device (16) is connected with a plant oil heater by a first oil transportation pump(2); the right upper end is connected with a spiral propeller (4); a slag outlet (8) at the left side of the low temperature refluxing extracting device is connected with a squeezer (9); the oil outlet of the squeezer after being jointed with the oil outlet (15) of the low temperature refluxing extracting device is connected with a filter (10); the filter is connected with a clarifying pool (12) by a second oil transportation pump(11); the clarifying pool is connected with a filling machine (14)by a third oil transportation pump(13). The materials are added according to a mass ratio that the ratio of plant oil to zanthoxylum is 2:0.5 to 1. The plant oil is added into a heater (1) to pre-heat to be 80 to 90 DEG C; the zanthoxylum is added into a cracker (6) for being crashed to 20 to 40 meshes; the materials are respectively and continuously fed into the low temperature refluxing extracting device (16) at the two ends; the temperature in the low temperature refluxing extracting device (16) is maintained between 80 to 90 DEG C. The left side of the low temperature refluxing extracting device (16) is for fueling and discharges the slag; the right side is for feeding and discharges the oil to obtain the fished product of the zanthoxylum oil.

Owner:SICHUAN UNIV

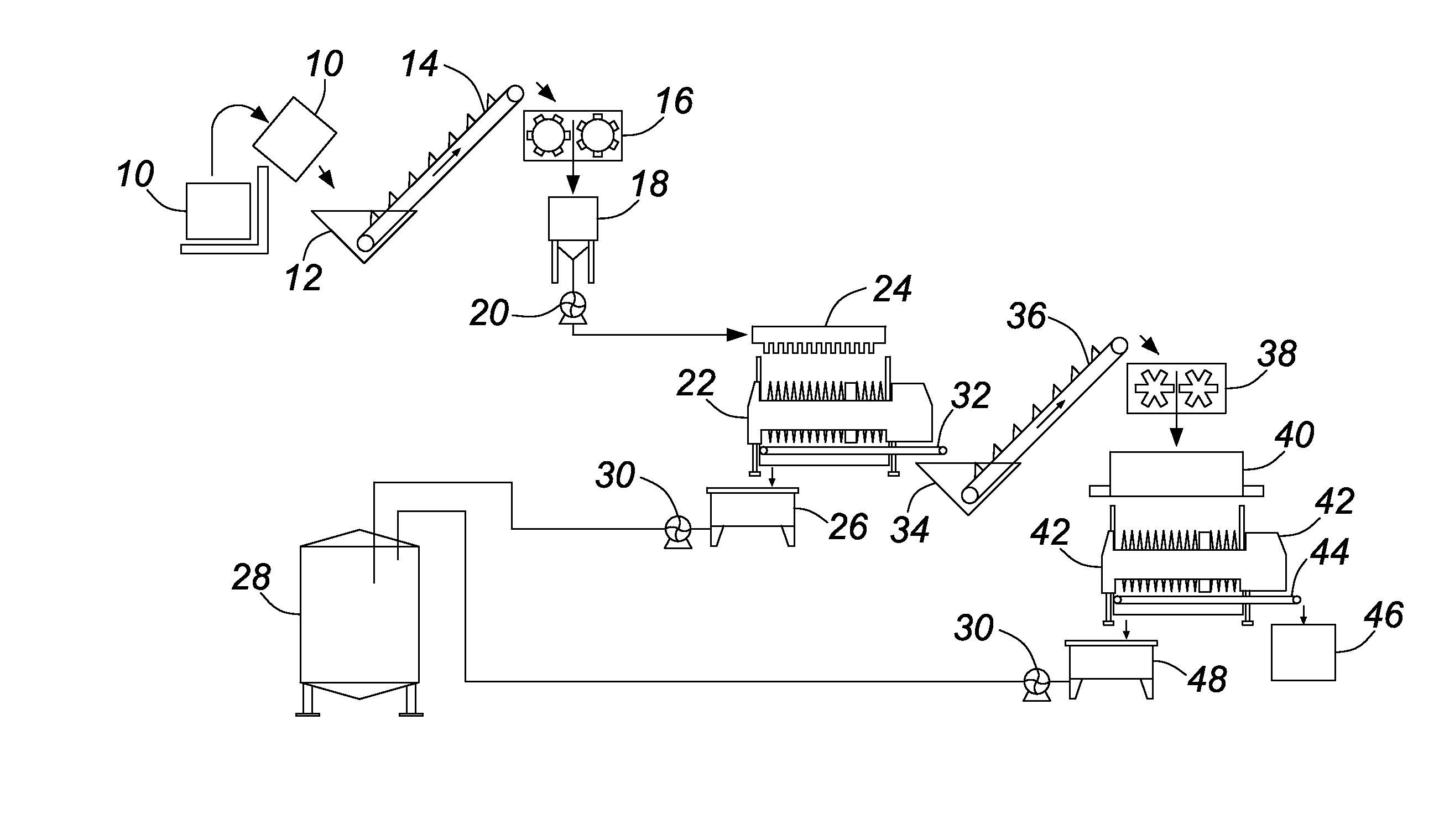

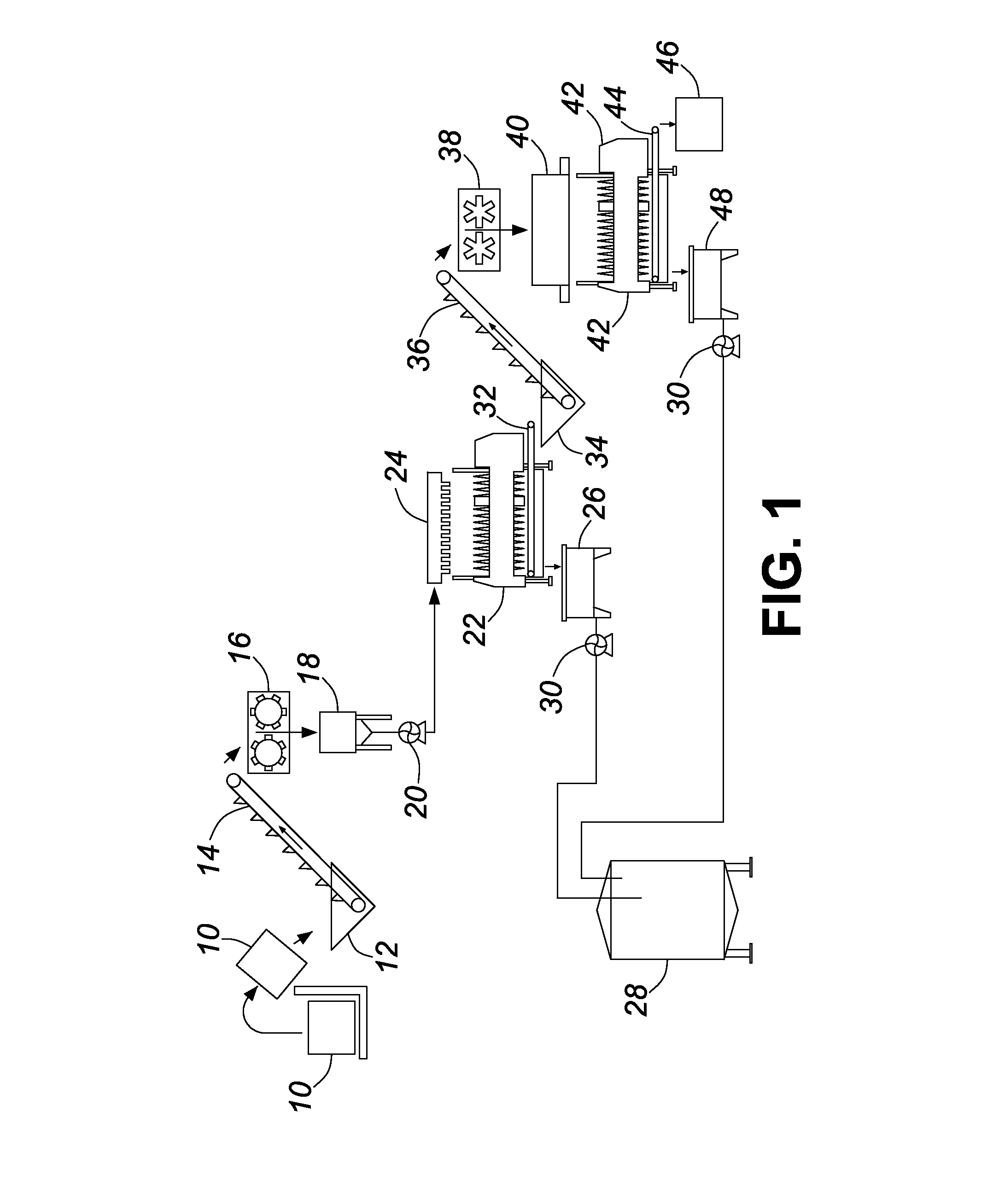

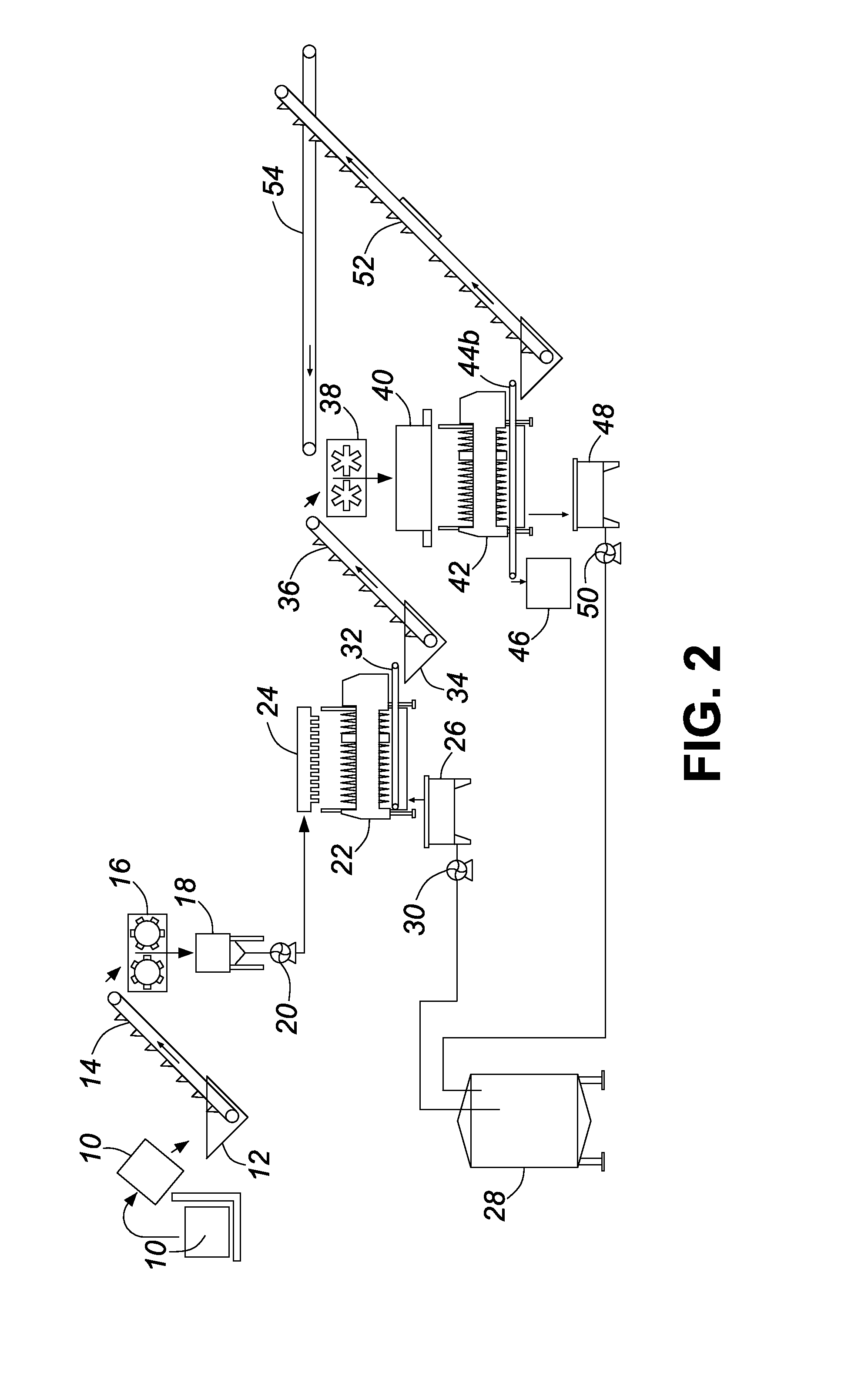

Method and Apparatus for Pressing Fruit

InactiveUS20140224137A1For quick ejectionQuickly and easily loadedJuice extractionEggs preservationThin layerEngineering

A method and apparatus for extracting juice from a previously de-juiced fruit mass which as been pressed within a primary press, the previously de-juiced fruit mass being discharged from the primary press and then being broken-up and mixed externally of the primary press, and then pressed again preferably by using a secondary thin layer repressing press which permits the repressed press cake to be quickly and easily loaded and emptied.

Owner:WETTLAUFER DALE +2

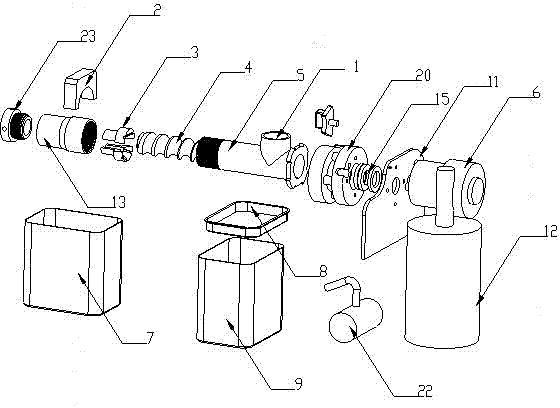

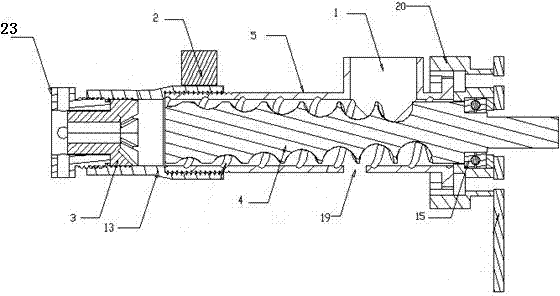

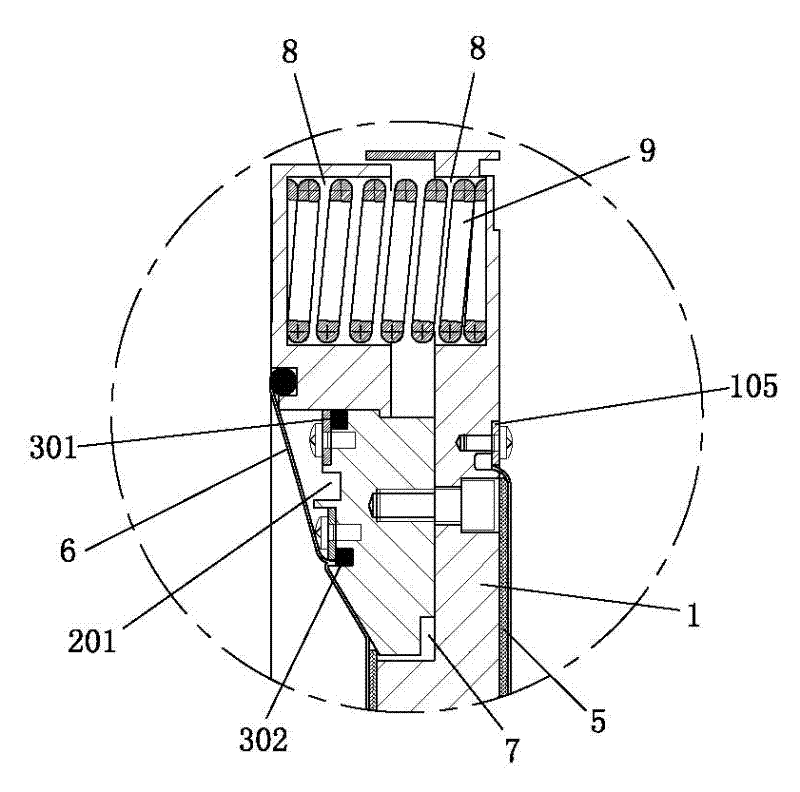

Household two-level pressing low temperature oil press

InactiveCN102774029AAchieving secondary pressingImprove oil yieldPressesReduction driveElectric machine

The invention relates to a household two-level pressing low temperature oil press. The oil press comprises an oil press base, a pressing mechanism and a driving mechanism, the pressing mechanism is installed on the oil press base, the driving mechanism is used for providing motive power for the pressing mechanism, the pressing mechanism includes a barrel, a pressing head, a pressing shaft and a pressing head casing, the barrel is provided with a feed port and an oil outlet, one end of the barrel is connected with the oil press base, the pressing head casing is connected with the other end of the barrel, one end of the pressing shaft is provided with screw threads and sleeved in a chamber formed by the barrel and the pressing head casing, the other end of the pressing shaft extends out of the barrel to serve as a rotating bar to be connected with the driving mechanism, the pressing head is installed in the pressing head casing, pressing space is formed by one side of the pressing head and one corresponding end of the pressing shaft, one or a plurality of material passing holes is / are arranged on the pressing head, one side surface of the pressing head where the pressing head is in a cut grafting with the pressing shaft is provided with a groove, one or a plurality of oil guide grooves which is / are communicated with the material passing holes is / are mounted on the wall surface of the groove, a heater is arranged on the pressing head casing or the barrel, and the driving mechanism and the heater are connected with a power supply. The driving mechanism includes a motor and a speed reducer which are disposed on the oil press base, and the speed reducer is in a transmission connection with a rotating shaft of the motor and the rotating bar of the pressing shaft. By means of the household two-level pressing low temperature oil press, the low temperature cold pressing can be achieved, the oil yield is high, the produced oil quality is good, and the oil press is easy to clean.

Owner:唐华

Enzyme-rich sprouted food products with limited pH drop and methods of making same

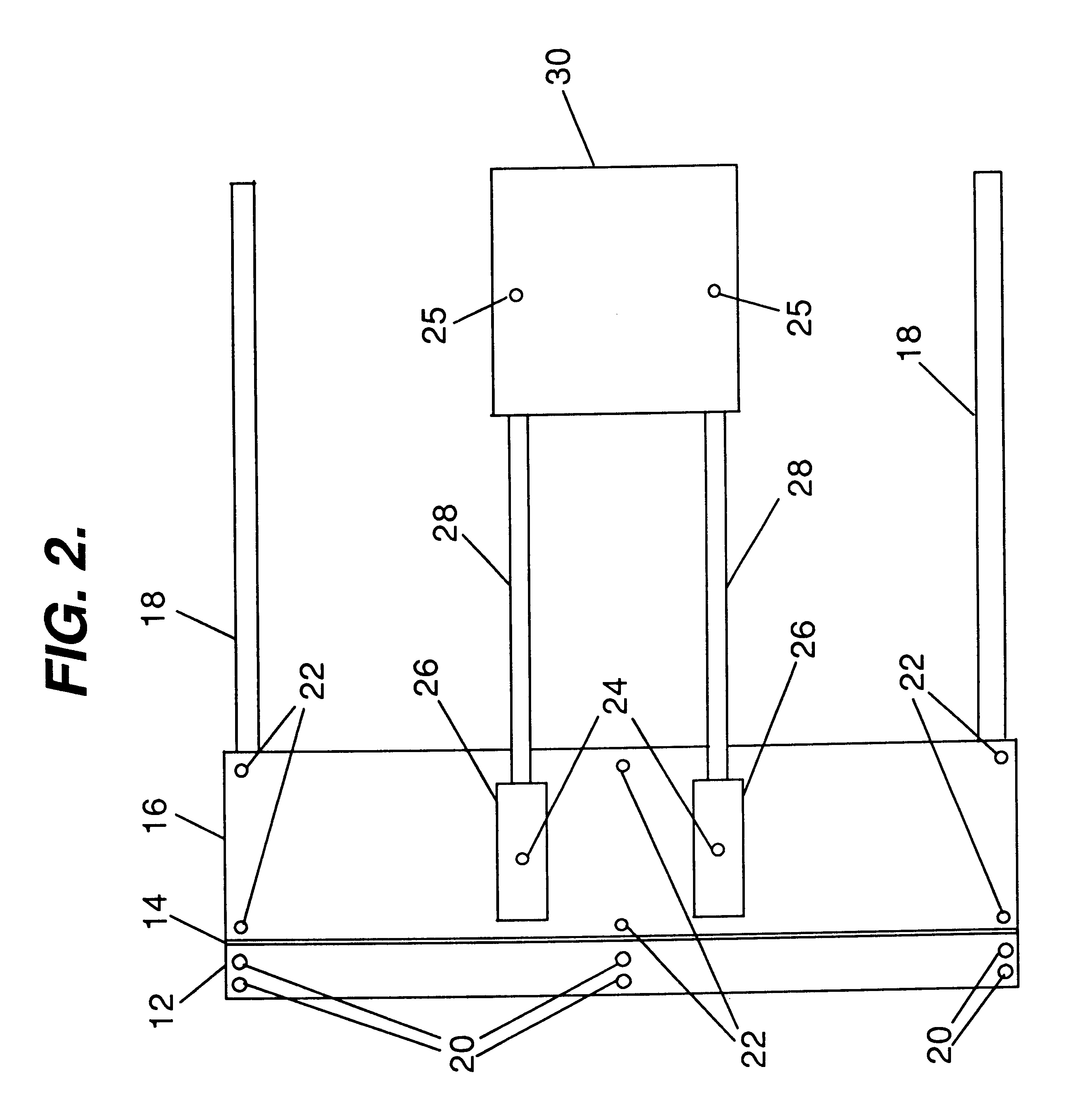

A class of food products whose nutrients have not been damaged by heat during the preparation process. These products are prepared with methods to limit souring thus permitting these food products to be prepared at a temperature low enough to minimize damage to vital nutrients (especially enzymes) without the objectionable excessive sourness and bitterness of similar products prepared without such methods. The result is a new class of delicious and nutrient rich health food products with many health benefits. Also disclosed is a Wet Grain Press for quickly and easily compressing very wet sprouts.

Owner:HARVEST FESTIVAL LTD THE

Tangerine oil and preparation method and application thereof

ActiveCN101768516AGood anti-inflammatory effect on skinImprove securityCosmetic preparationsAntipyreticMass ratioSolvent

The invention relates to a tangerine oil, which is prepared according to the steps as follows: (1) adding tangerine peels and water with the mass ratio of 5:0.9-1.1 into a screw extrusion press, pressing and filtering the pressed liquid with an 80-120 meshed screen to obtain filtrate; (2) adding salt accounting for 5-7% of the mass of the filtrate in the filtrate in step (1), mixing evenly, standing for 20-28h, pouring out the tangerine oil at the upper layer, placing in a refrigerating chamber with the temperature of 5-7 DEG C for 7-9 days, separating the upper layer once again to obtain the tangerine oil crude product; and (3) distilling the tangerine oil under reduced pressure at the temperature of 70-90 DEG C and vacuum degree of 40-60 Pa, purifying to obtain the tangerine oil. The invention has the beneficial effects that the prepared tangerine oil is transparent and colorless, has good anti-inflammatory effect on skin, can be used as a solvent for cosmetics and has improved security on human body.

Owner:ZHEJIANG UNIV OF TECH

Method for producing wood pulp sponge

The invention discloses a method for producing wood pulp sponge. The method is as follows: using wood pulp as the main raw material, soaking, squeezing, yellowing, gluing, mixing, foam forming and washing with water to obtain the biodegradable wood cellulose sponge product, wherein (a) soaking process: adding sodium hydroxide and wood pulp into a dip vat in a mixing manner to prepare wood pulp; (b) squeezing process: placing the soaked wood pulp into a presser to obtain compressed alkali cellulose blocks; (c) yellowing process: smashing the alkali cellulose blocks after standing into particles or small lumps of alkali cellulose using a mill, and introducing an excess ratio of carbon disulfide gas for yellowing reaction; (d) gluing process: putting xanthate and additional wood pulp, bamboo pulp and water into a kneader for mixing to prepare a gluing material; (e) mixing process: mixing the gluing material with sodium sulfate crystals and toner ribbon to prepare a heat foaming sponge mixture; (f) foam forming process: preparing sponge blocks using the sponge mixture.

Owner:NINGBO NECO SPONGE TECHONOLOGY CO LTD

Application of black soldier fly larvae as oil-crop insect

InactiveCN101880593ARelieve stressHigh nutritional valueBiofuelsFatty-oils/fats productionChemical industryBiodiesel

The invention belongs to the fields of foods or bioenergy and develops a new oil source, i.e. black soldier fly larvae as an oil-crop insect. Oil can be obtained by using a compression method (larvae is fed into a screw-type press while hot to press oil out) after black soldier fly adult and larvae are dried by hot wind or microwave. The oil can be used as raw oil for eating, chemical industry and biodiesel. The oil content of the black soldier fly larvae is 30-35 percent, through analyzing the nutritious components of the oil, and oil extracted from the black soldier fly larvae contains various unsaturated fatty acids needed by human bodies, thereby being high-quality health oil. The black soldier fly larvae has short growth period which is only 20-30 days and very small floor area, can be cultured under the condition of high density, reaches the oil production per mu of 4t / mu.year, can be carried out in an industrial factory building without occupying land area, contains no toxin, is safe and reliable, and has simple extraction process.

Owner:SUN YAT SEN UNIV

Puffing expression method for producing oil with low oil-containing oil-bearing material

InactiveCN101245284AImprove product qualityAvoid excessive denaturationFatty-oils/fats productionPress cakeImpurity

The invention relates to a method for extracting oil by swelling and pressing low oil content oil seeds and is characterized by comprising the following steps: 1) clearing: impurities are removed from the oil seeds; 2) quality-adjusting: the temperatures and water contents are adjusted for the oil seeds; 3) the oil seeds are pressed and swelled; 4) enzyme killing and drying are carried out for the pressed and swelled oil seeds; 5) most of the oil is pressed from the dried oil seeds; the oil seeds can be crushed and then the quality adjusting can be done after the clearing of the step 1); after the step 2) of quality-adjusting, the bloom rolling can be done to the oil seeds and then the pressing and swelling can be done. The method adds the procedures of pressing and swelling before the traditional one time pressing and obtains pure physical pressed oil with high quality and pressed cakes which can be directly used for feed processing, which increases the processing amount of a press and reduces the power consumption and wearing. The method is mainly used for producing small-scale pressed oil and pressed cakes with good qualities and raw materials of low oil content oil seeds such as soybeans and rice bran.

Owner:中机康元粮油装备(北京)有限公司

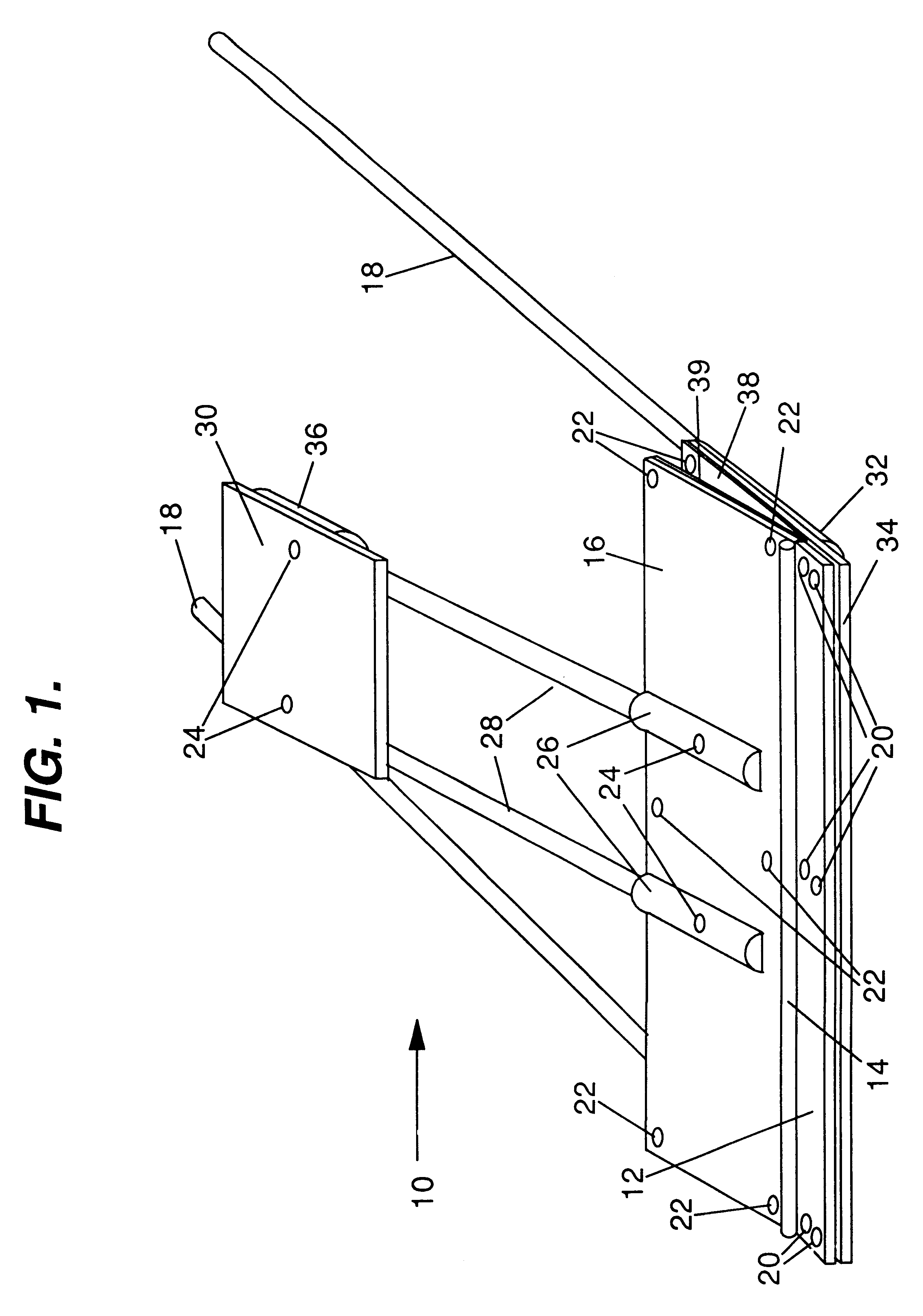

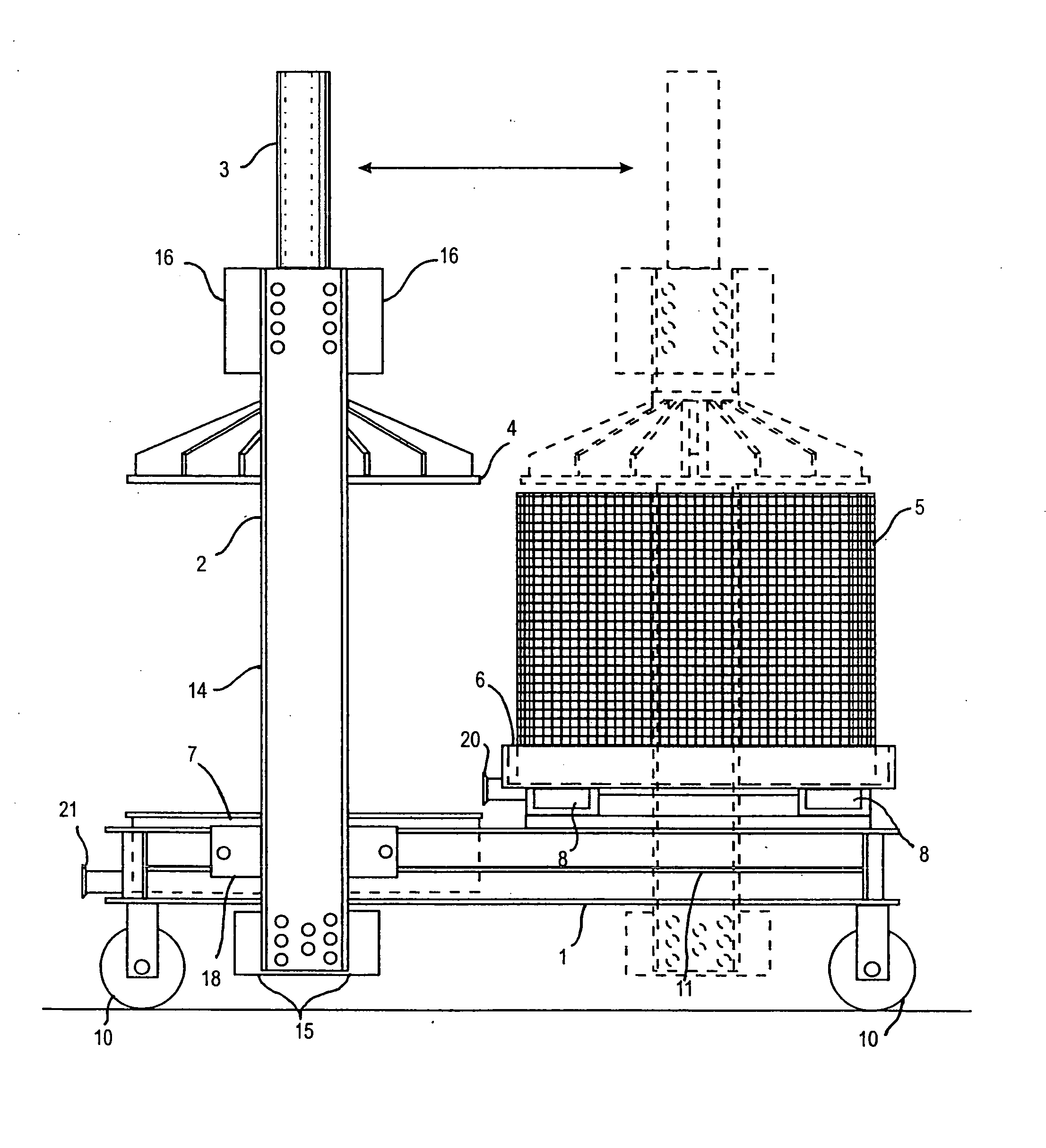

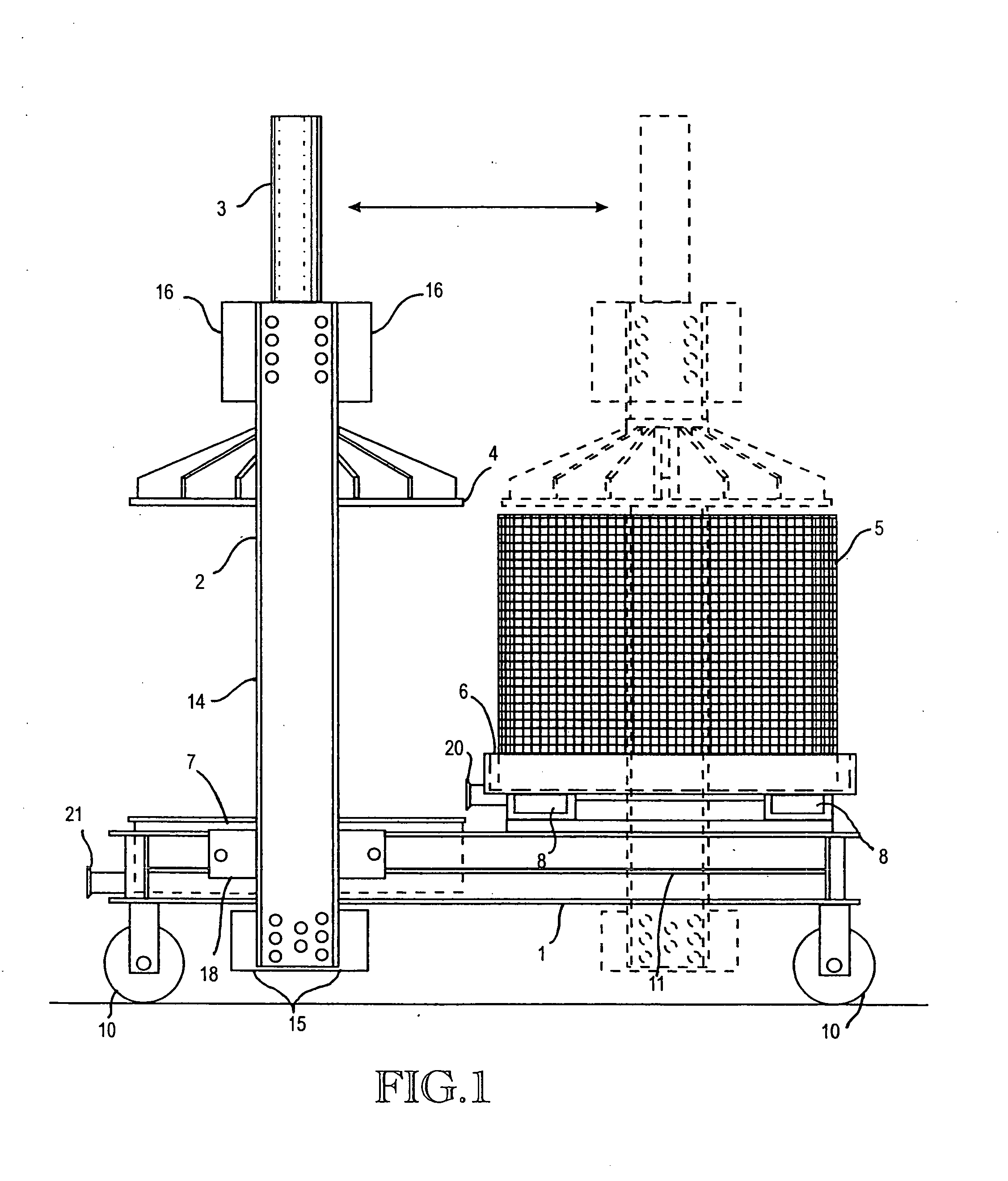

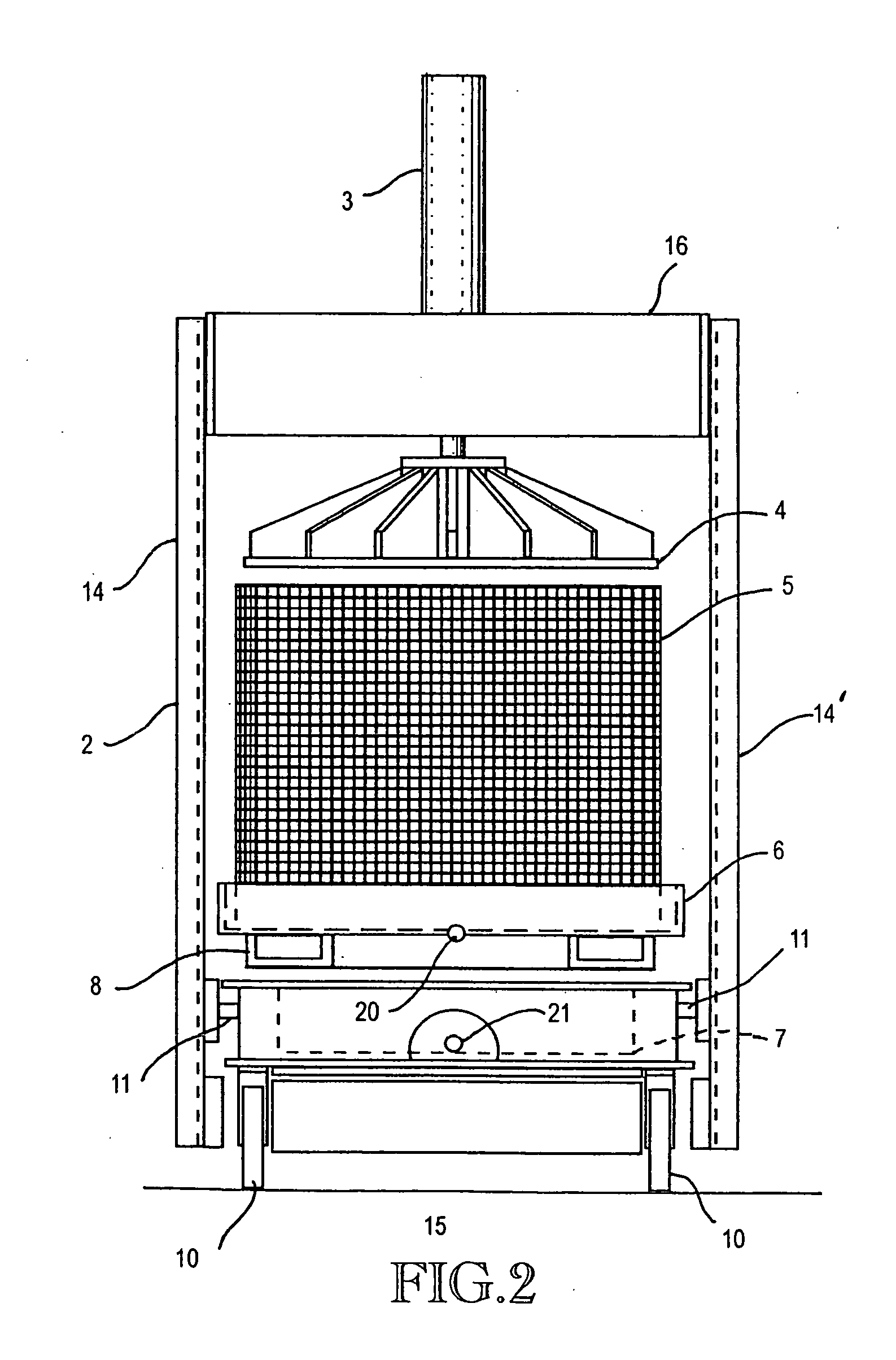

Horizontally positionable vertical wine press

InactiveUS20050139093A1Minimize possibility for overflowImprove efficiencyWine preparationRoasters/grillsSludgeEngineering

A juice press as used in the production of wine for removing liquids from solids, having a horizontally positionable press frame that allows a vertical press mechanism to be rolled to a first position for interference-free loading of a press basket with material to be pressed, and then rolled to a second operating position located over the press basket. The press basket has a liquid channeling plate having an arrangement of holes and channels that creates a perimeter seal along a circumference at the bottom of a loaded press basket. The liquid channeling plate traps naturally occurring sludge along the circumference bottom and allows for efficient evacuation of extracted juice from the bottom of the basket as the press mechanism is operated. In one embodiment, the press frame is configured with a hydraulic press basket lift that raises and holds the press basket after a press operation is completed and allows the press mechanism to be used to eject a disk of compressed solids from the bottom of the raised press basket.

Owner:AMERICAN BASKET PRESS

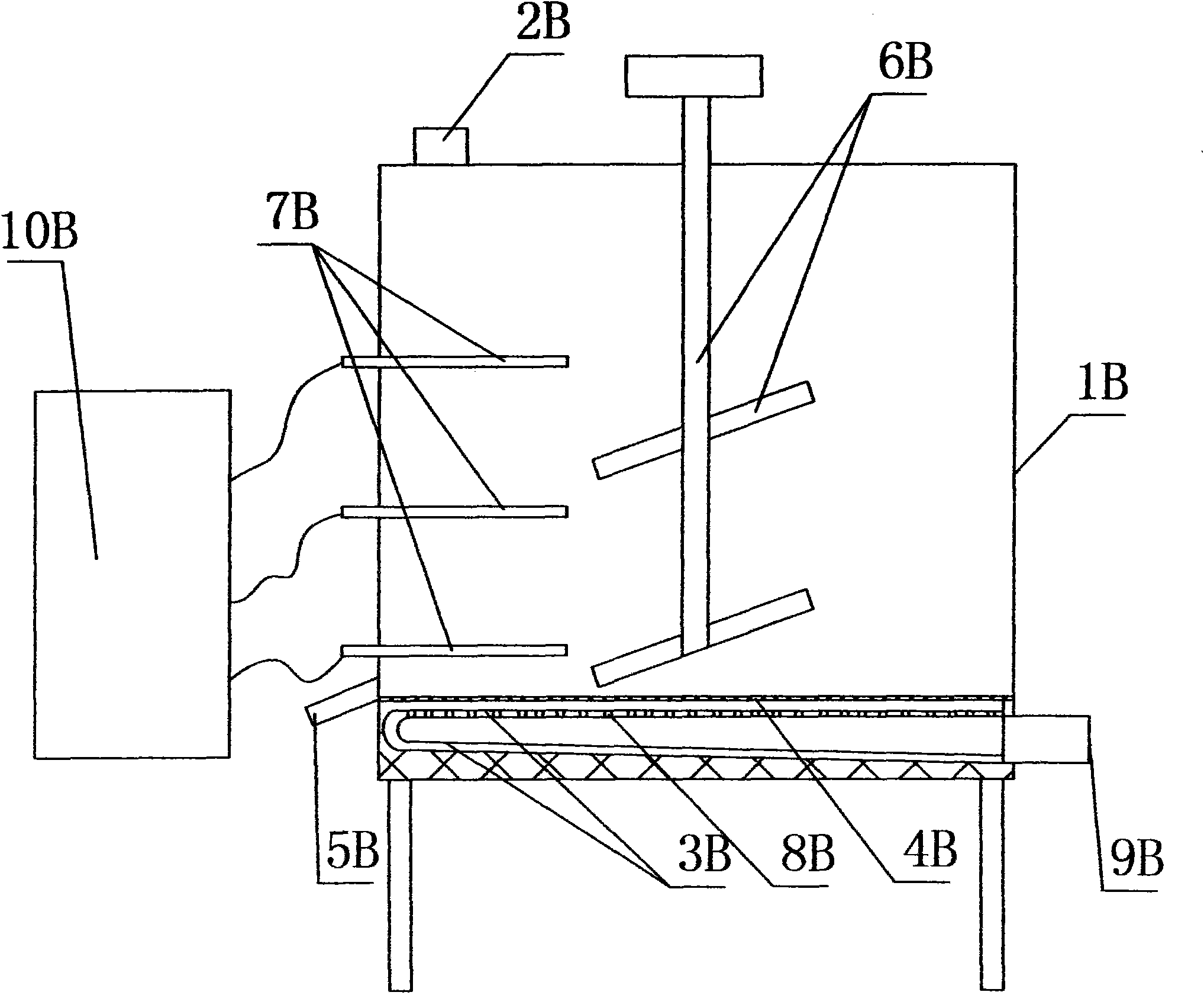

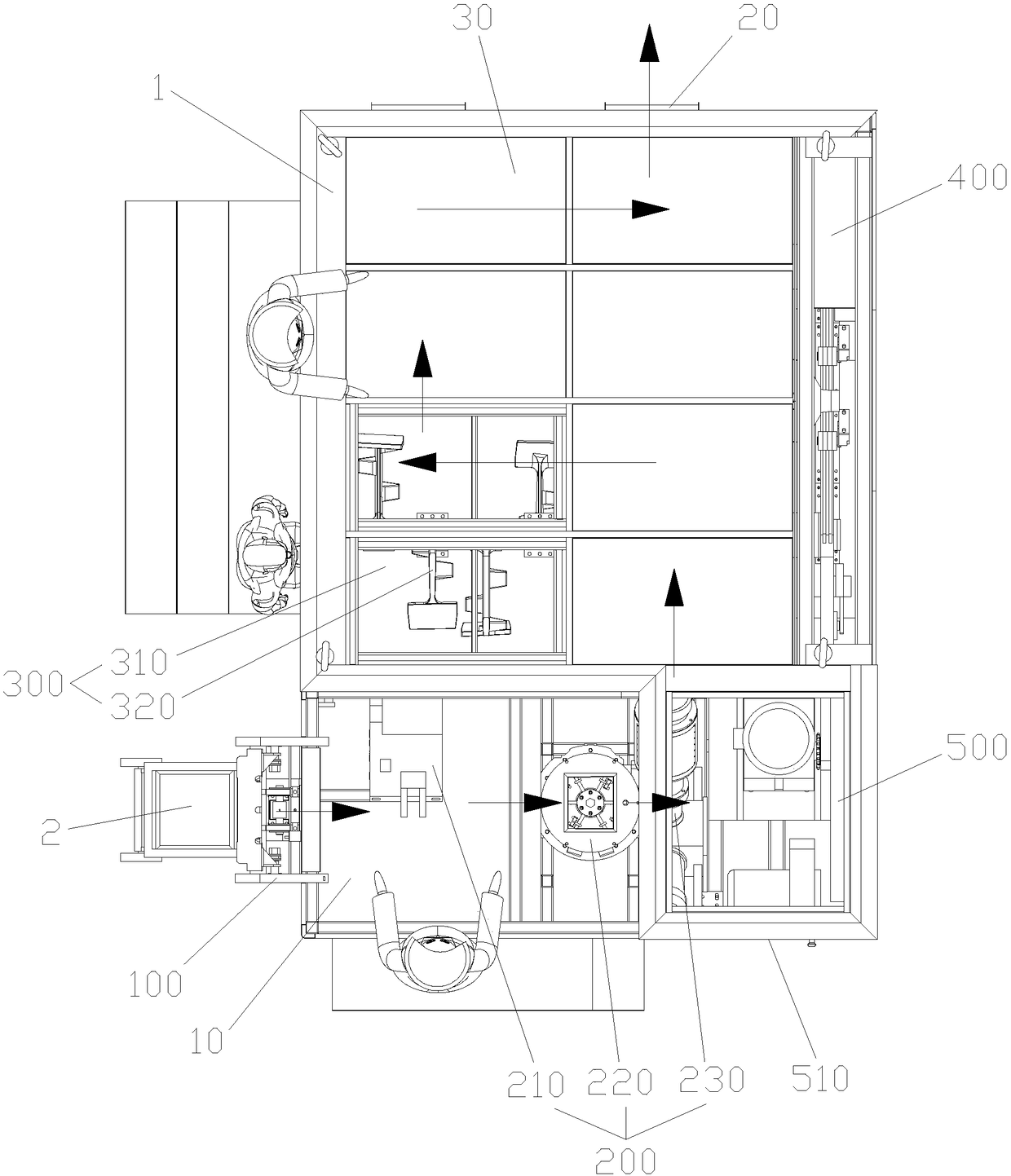

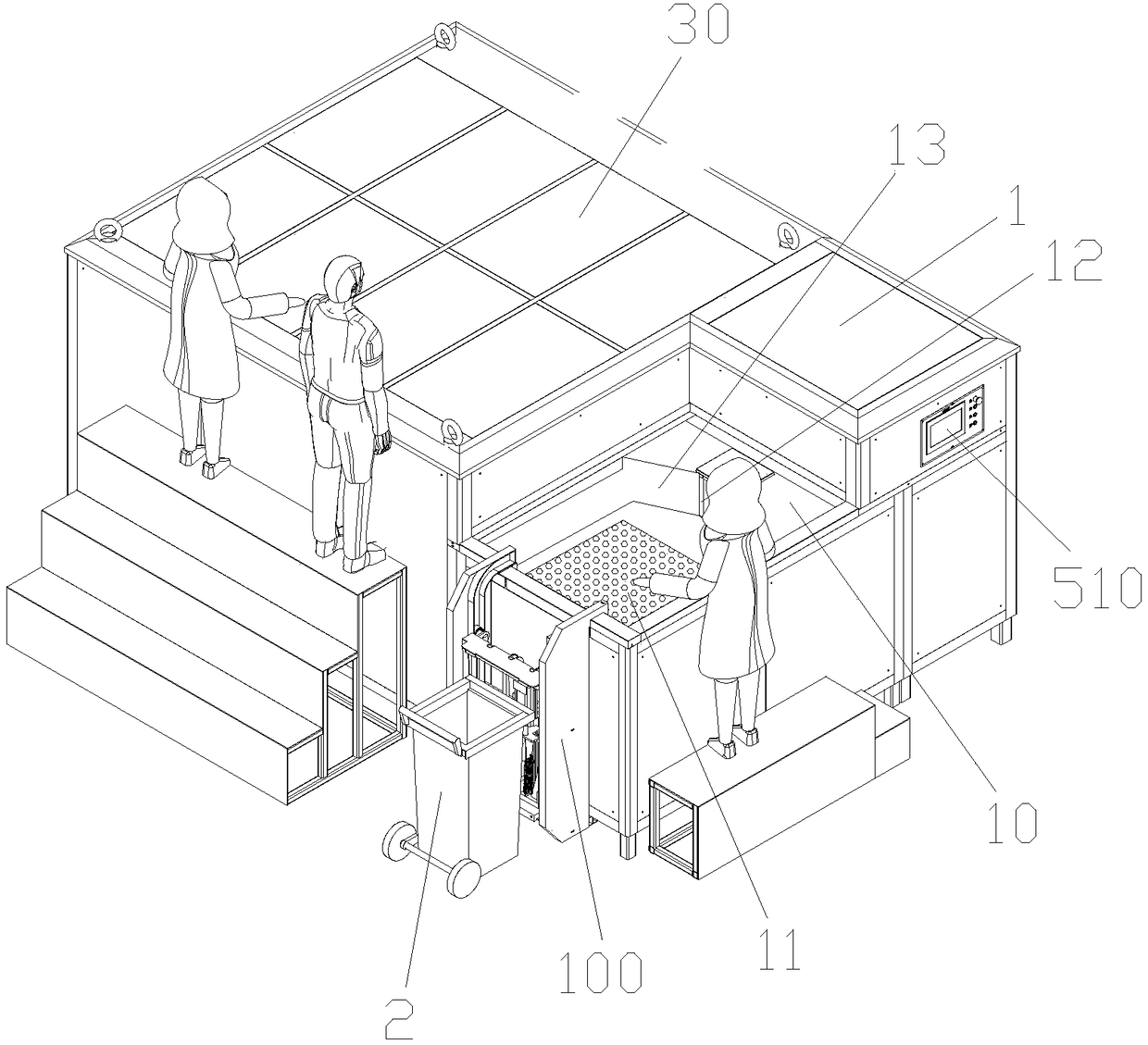

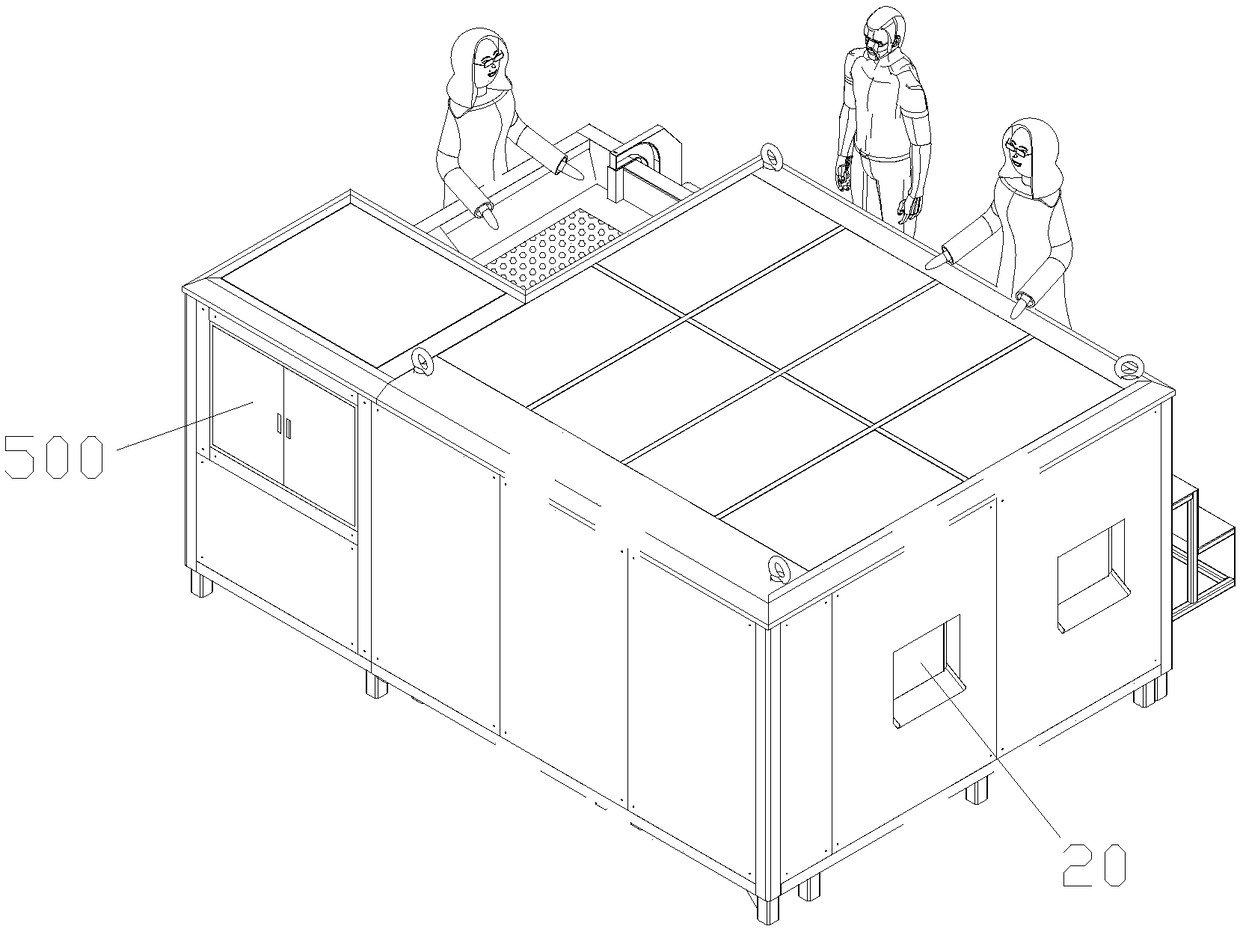

Intelligentized organic waste integrated processing device and process

ActiveCN108326010ACompact structureReduce volumeBio-organic fraction processingSolid waste disposalTreatment targetsMan machine

The invention relates to an intelligentized organic waste integrated processing device and process. The device includes an outer shell and an elevator. The interior of the outer shell is integrally provided with a preprocessing device, a stirring fermenting device and a deodorizing device. The outer shell is provided with a sorting operation platform; the elevator is arranged on the outer side ofthe outer shell and is located by the side of the sorting operation platform; the bottom of the sorting operation platform is provided with a filter screen plate, and the side part of the sorting operation platform is provided with an organic waste outlet. The preprocessing device includes an oil-water separator, a crusher and a squeezer. The stirring fermenting device includes at least one fermentation chamber, and a discharge port of the squeezer is led to the fermentation chamber; the interior of the outer shell is also provided with a control device; the control device is electrically connected with the elevator, the oil-water separator, the crusher, the squeezer, the stirring and fermenting device and the deodorizing device, and is also electrically connected with a man-machine operation interface. The intelligent organic waste integrated processing device and process can realize the harmless, decrement and resourceful treatment targets of organic waste.

Owner:福建省劲牛重工发展有限公司

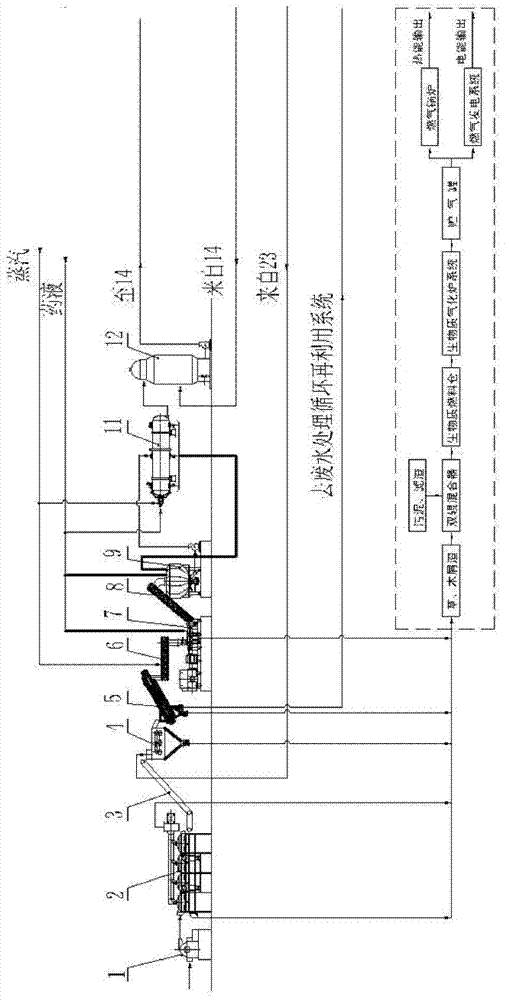

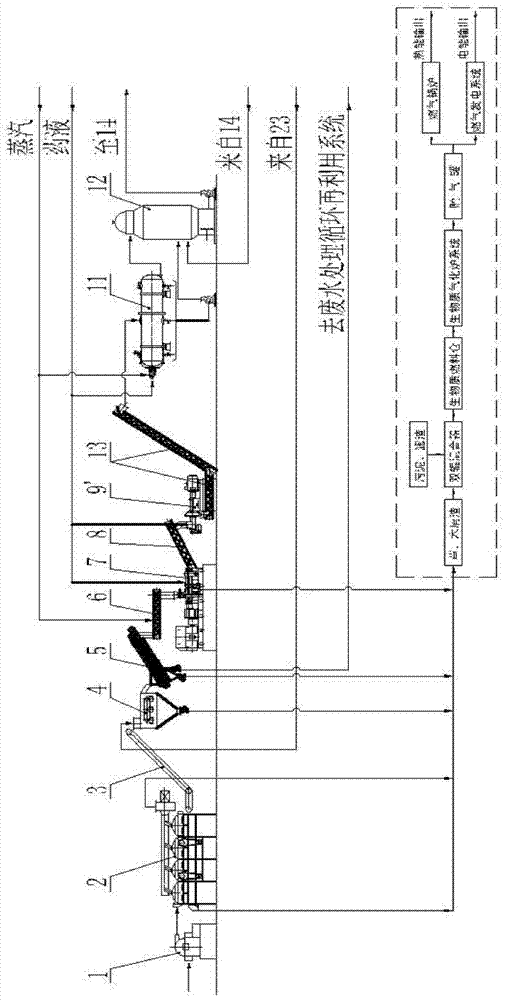

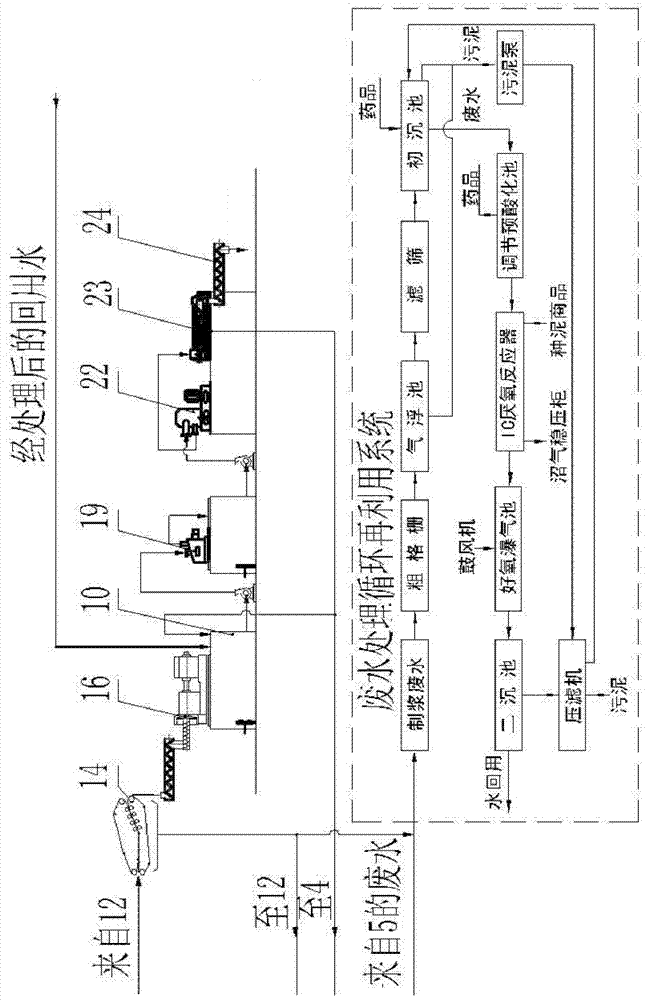

High-yield environment-friendly papermaking and pulping process method and system

ActiveCN102817262AReduce adverse effectsImprove wettabilityPretreatment with water/steamPretreatment with alkaline reacting compoundsBlack liquorPlant fibre

The invention provides a high-yield environment-friendly papermaking and pulping process method which includes a raw material pre-processing section, a physical threading immersion processing section, an immersing, steaming and bleaching integrated pulping section and a thickening and dewatering processing section. A high-yield environment-friendly papermaking and pulping system for achieving the pulping process method sequentially comprises a stock cutter, a hammer thread screening deduster, a washing deduster, a dewatering conveying device, a steaming spiral conveyor, a squeezing cracking and thread squeezing impregnator, a disperse impregnating device, a high-concentration cooking and bleaching pulping all-in-one machine, a pulp bin, a concentration dewaterer, a high-concentration stuff grinder, a screening purifier and a concentration presser according to the process route, wherein a pump pipe is connected onto the high-concentration cooking and bleaching pulping all-in-one machine, a discharging pipe of the high-concentration cooking and bleaching pulping all-in-one machine is connected to the pulp bin, a pulp bin pump pipe is connected with the concentration dewaterer, the output end of the concentration dewaterer is connected onto the high-concentration stuff grinder, and the output end of the high-concentration stuff grinder is sequentially connected with the screening purifier and the concentration presser. The high-yield environment-friendly papermaking and pulping process method and system fundamentally solve problems of high pollution and energy consumption, shortage of papermaking raw materials and the like existing in the papermaking industry, and achieve the technical purposes of efficient bleaching, high yield, no black liquor and low energy consumption by using abundant plant fibers in the nature.

Owner:丹东东方轻工机械有限公司

Steaming-free yellow wine brewing method

InactiveCN1468951AImprove qualityHigh nutritional valueAlcoholic beverage preparationBiotechnologyAcetic acid

The steaming-free yellow wine brewing process uses the materials including rice as main material, yellow wine yeast, yellow wheat yeast, quick yeast, citric acid, glacial acetic acid and water. The technological process includes the following steps: soaking rice in water for 1.5-3 hr and rinsing; fermenting via adding all the materials into one fermenting pot, stirring and fermenting for 15-35 days; squeezing the fermented rice in a plate-frame filter or bag-type filter to separate out rice and obtain yellow wine liquid; and sterilizing and packing the transparent yellow wine in sealed pot.

Owner:陈佩仁

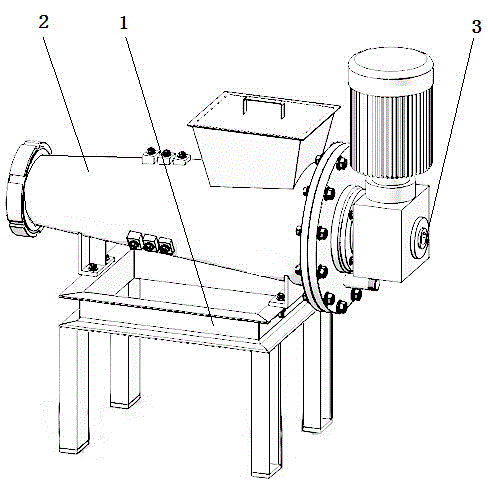

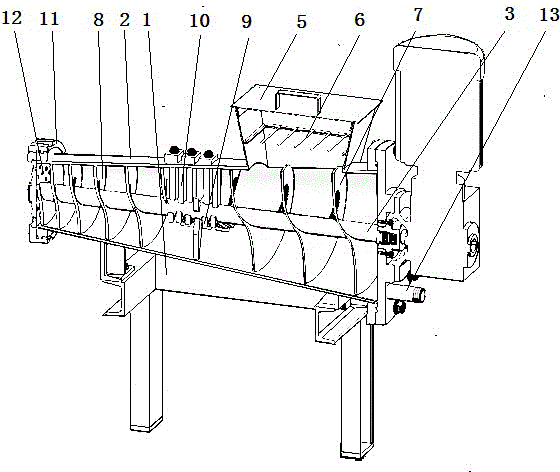

Crushing press used in kitchen

ActiveCN104437771ANovel structureEasy to useSolid waste disposalGrain treatmentsHelical bladeExpeller pressing

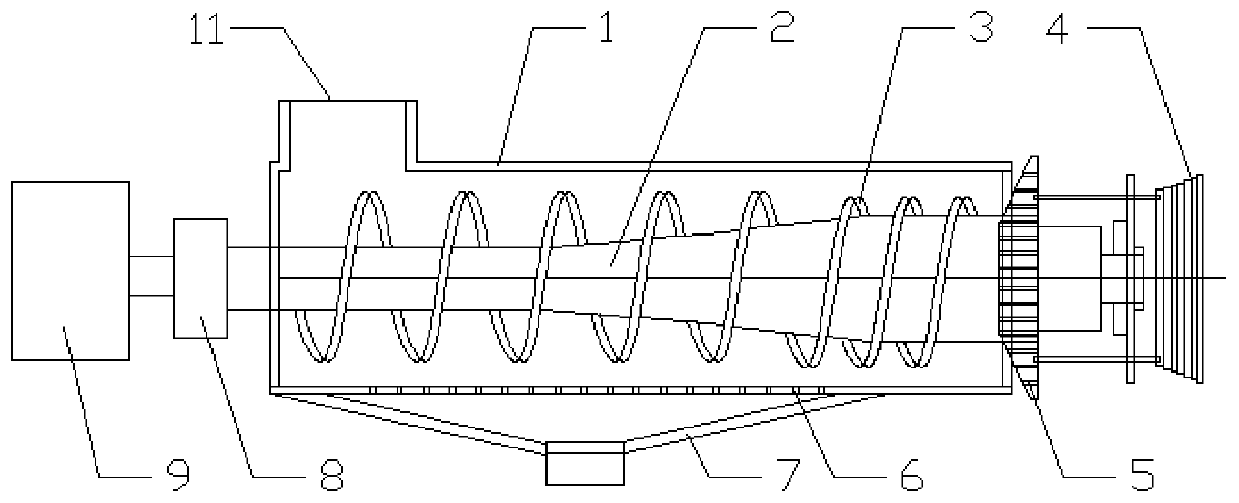

The invention discloses a crushing press used in a kitchen. The crushing press comprises a rack, a barrel, a transmission shaft and a power source, wherein a screw blade knife is arranged on the transmission shaft. The crushing press is characterized in that an intercepting grid is horizontally arranged on a feeding hopper at the upper end of the barrel; the barrel is in a conical shape; the diameter of the barrel is gradually reduced from the feeding end to the discharge end; a liquid outlet is formed in the bottom of the large-diameter end of the barrel, liquid of pressed and crushed materials flows to the liquid outlet through the gradient of the barrel, and is discharged through the liquid outlet, and thus the target of automatically discharging liquid is achieved; the screw blade knife on the transmission shaft is a screw blade with a conical gradual changing pitch; and the outer diameter conicity of the screw blade is the same as that of a taper clearance in the inner wall of the barrel, so that leftovers are crushed and pressed out under the variable pitch action of the screw blade knife. The crushing press has the advantages of being novel in structure, convenient to use, free of blockage, high in crushing and pressing efficiency, reliable in performance, fast to install and the like.

Owner:SHANDONG SHUANGLUN

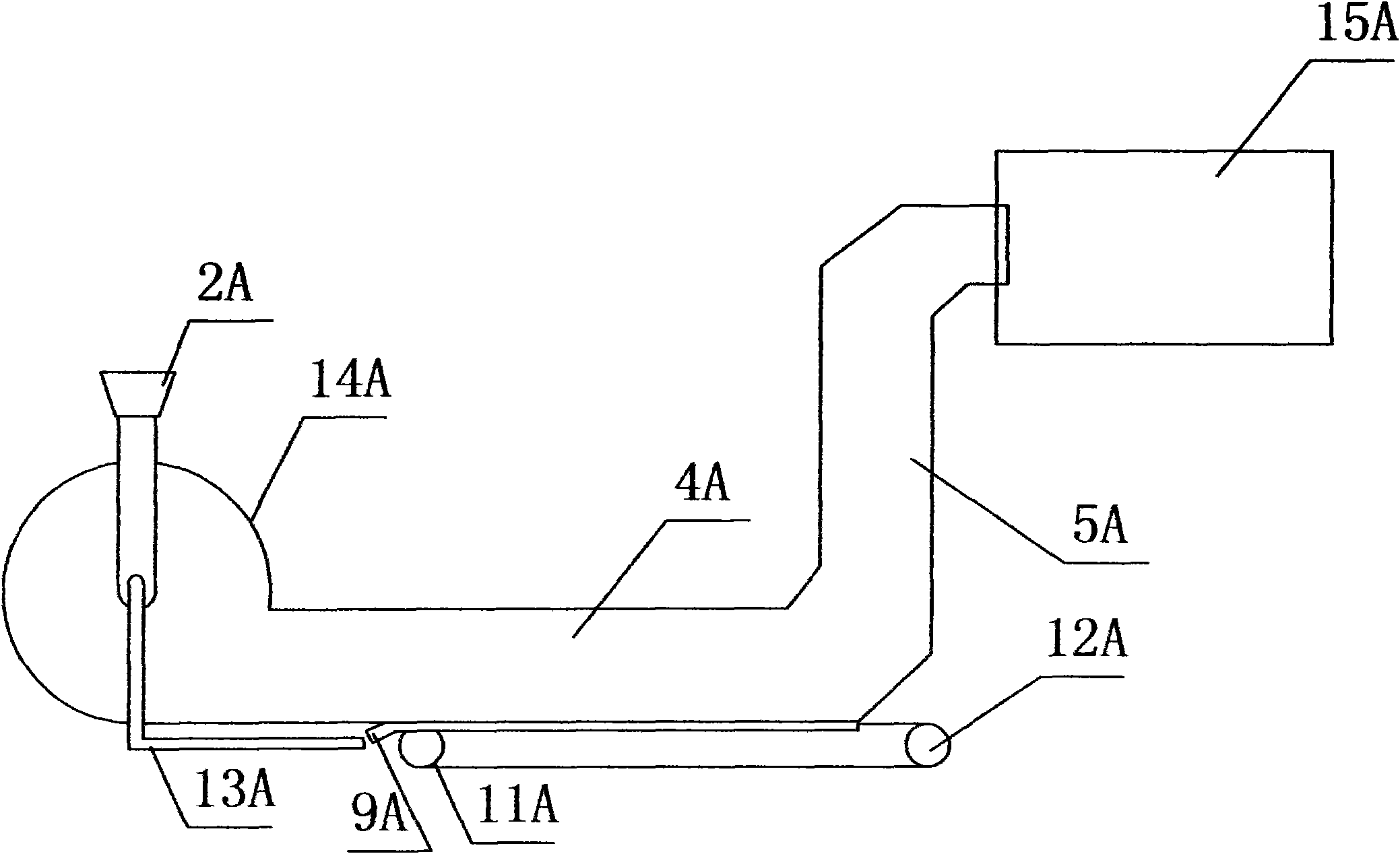

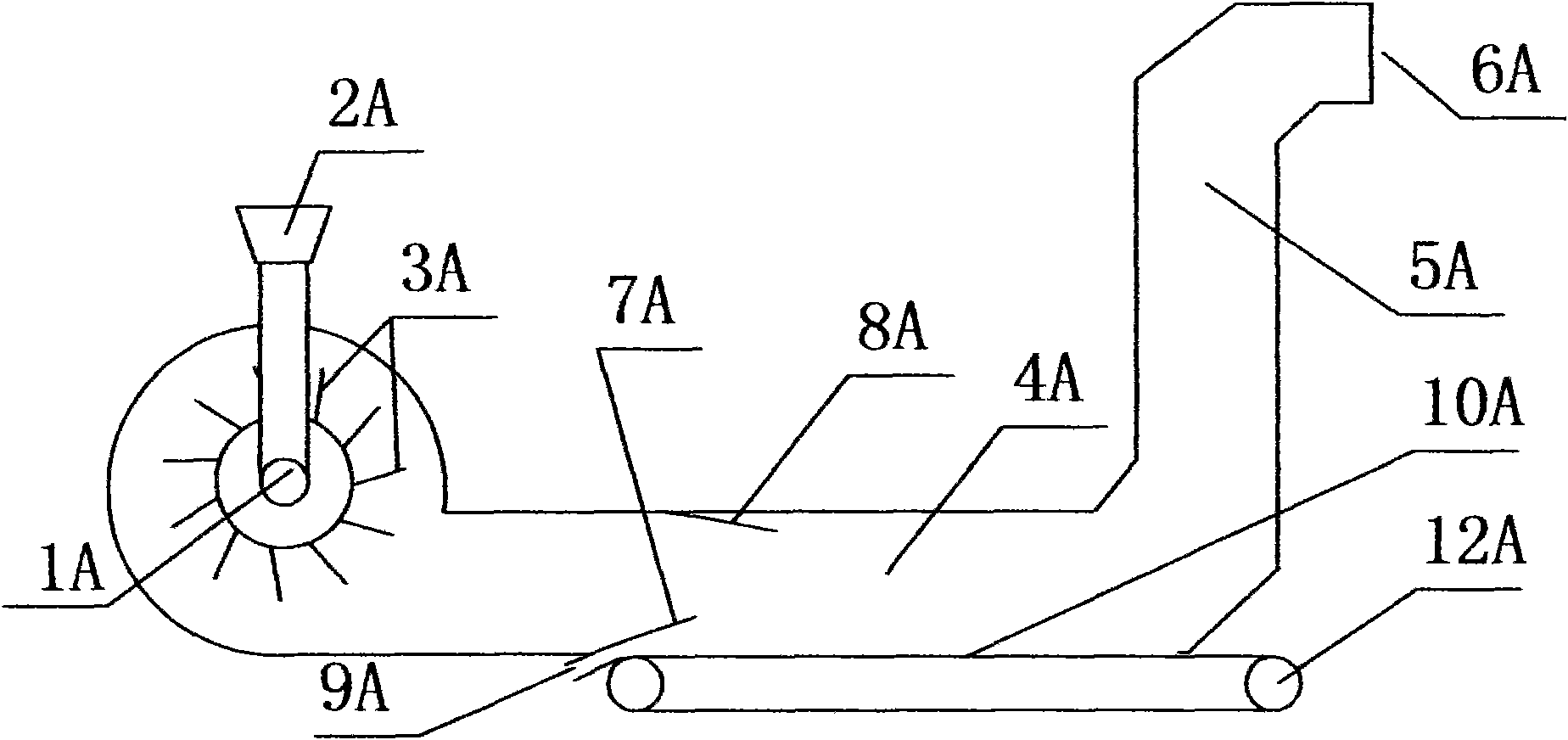

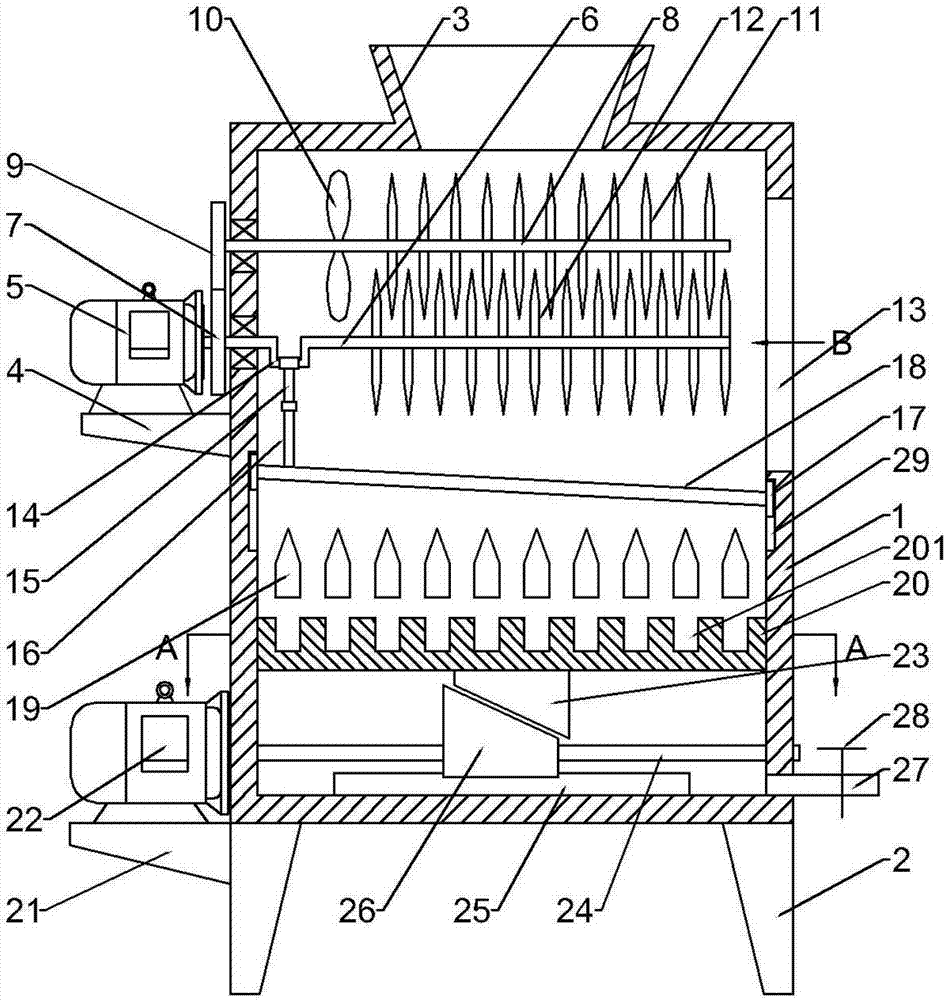

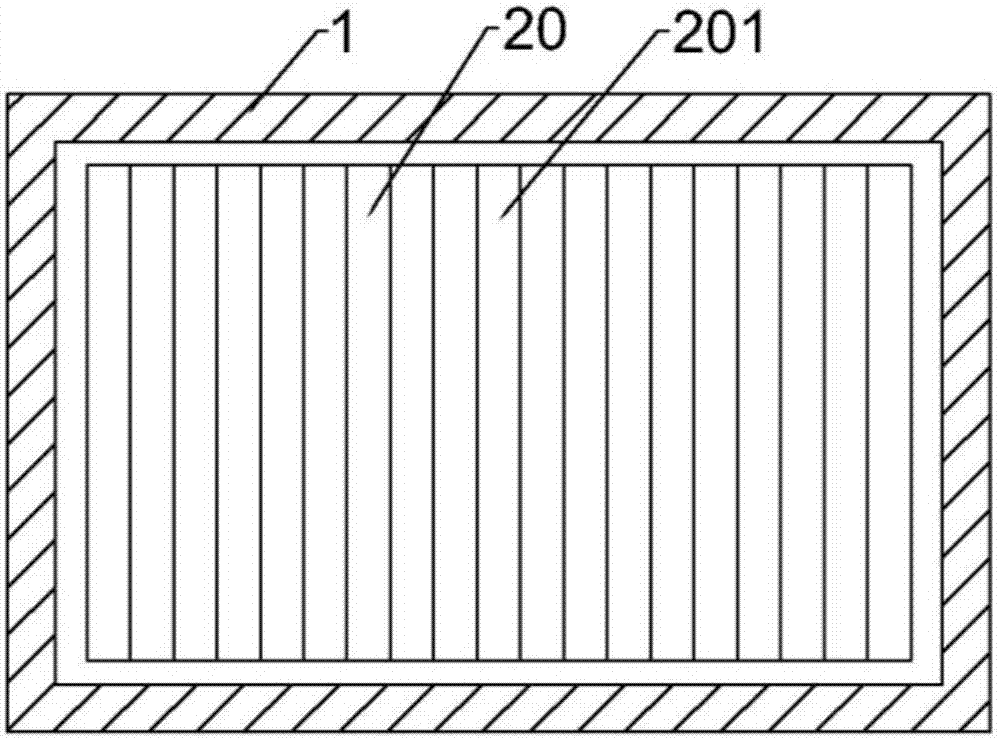

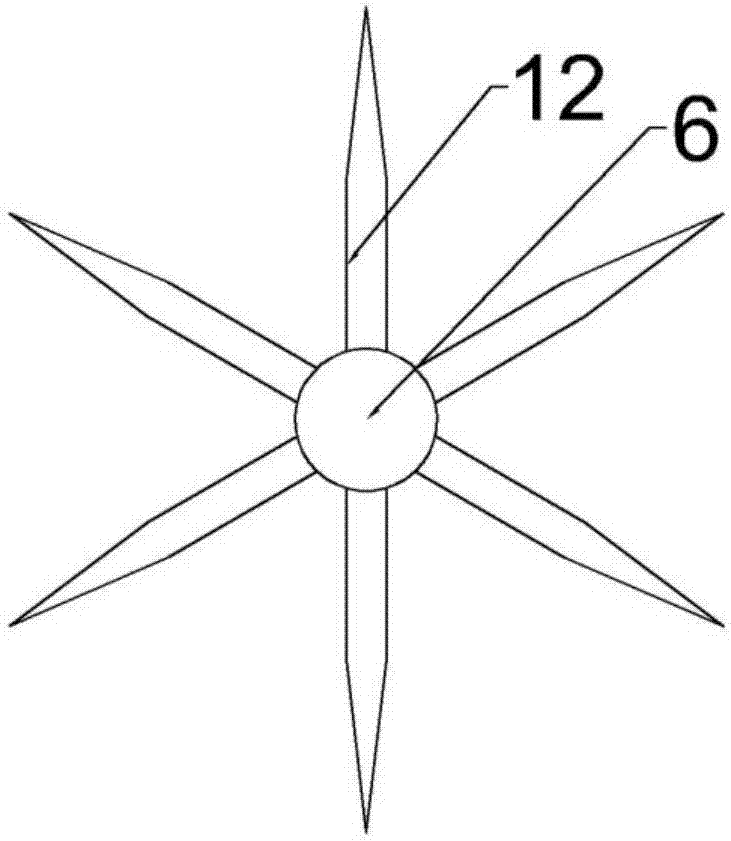

Shelling and cold-pressing integrated device used for production of camellia oil

InactiveCN107287023ASimple processIncrease productivityFatty-oils/fats productionAgricultural engineeringExpeller pressing

The invention discloses a shelling and cold-pressing integrated device used for production of camellia oil. The device includes a shell body of which the cross section is rectangular in shape. A feeding hopper is fixedly connected to the top of the shell body. A first motor base is fixedly connected to the upper part of the left side of the shell body and is fixedly connected to the shell body through bolts. A first motor is fixedly connected to the upper part of the first motor base. A lower rotary shaft is rotatably connected to the upper part of interior of the shell body. The left end of the lower rotary shaft is fixedly connected to an output end of the first motor. A driving gear is fixedly connected to the left side of the lower rotary shaft. Compared with the prior art, the device has simple structure and is practical and convenient to use in production of camellia oil. During the production of camellia oil, shelling, screening and cold-pressing processes are carried out in one-step, so that the process of pressing the camellia oil is simplified. The device is free of complex steps of the shelling, screening and cold-pressing, which are carried out independently, in a conventional pressing process, so that the device is simplified, is improved in production efficiency and is valuable to promote.

Owner:临泉县生产力促进中心

Preparation method of cold-pressed peony seed oil with high oil yield

InactiveCN105602700AIncreased oil rateFatty-oils/fats productionUltrasonic assistedExpeller pressing

The invention relates to a preparation method of cold-pressed peony seed oil with a high oil yield. Peony seeds which are dried in the sun and selected elaborately are heated to 50-60 DEG C, kept at the temperature for 10-12 min and instantly sent to a husking machine in a refrigerator for husking, husk and kernel separation is performed through winnowing by a vibration screen in the refrigerator after husking, kernels which go bad are sorted out through a mildewed seed screening device, grinding and sieving are performed after sorting, the kernels are conveyed out of the refrigerator and heated, an enzyme solution is sprayed, the heating temperature does not exceed 40 DEG C, the kernels are put into a presser to be pressed after being dried and conditioned, the primary pressing temperature and the pressing chamber temperature are both 58 plus or minus 2 DEG C, coarse oil and oil cakes are obtained, the oil cakes are subjected to ultrasonic aided oil extraction, and coarse oil obtained twice is combined. According to the cold-pressing method, the oil yield is remarkably improved and reaches 32%-36% through shock cooling and shock heating type temperature treatment, enzyme treatment and ultrasonic secondary pressing.

Owner:江苏国色天香油用牡丹科技发展有限公司

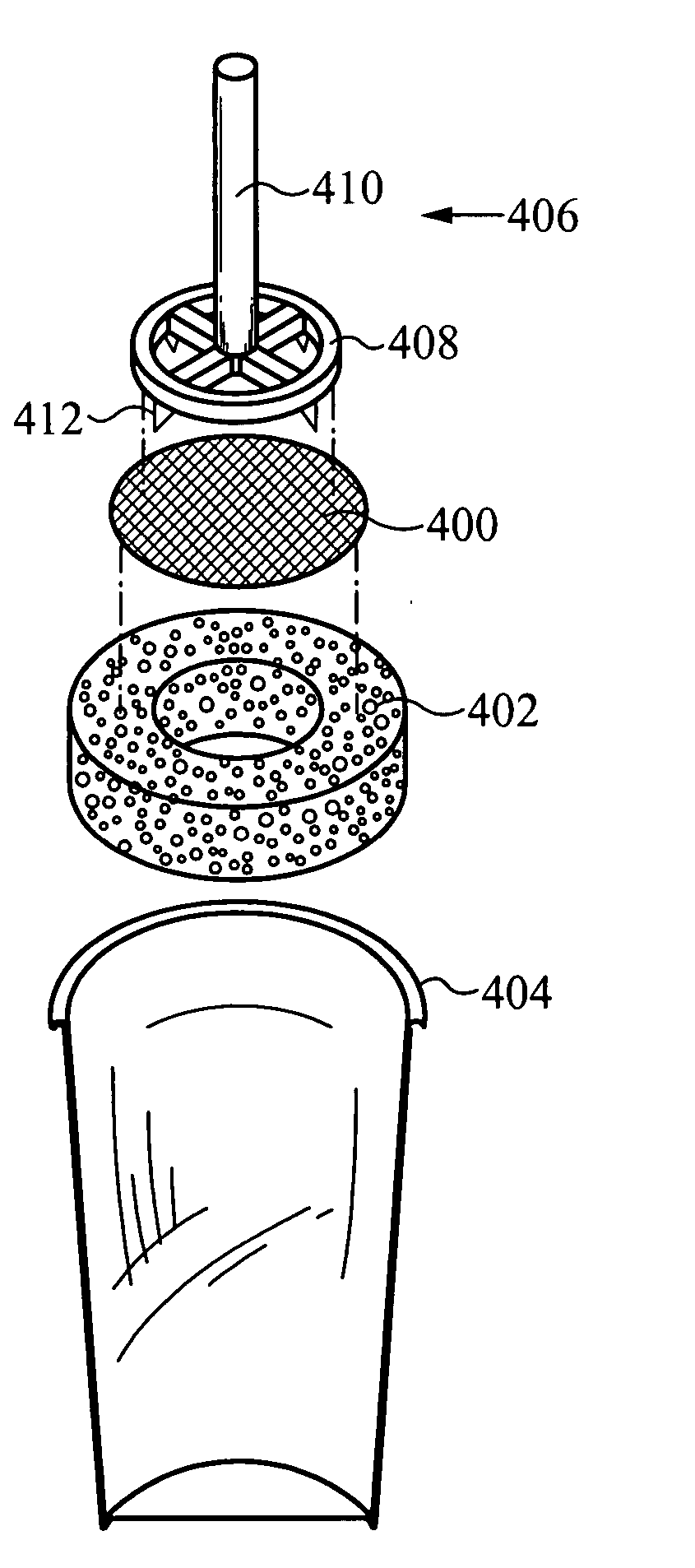

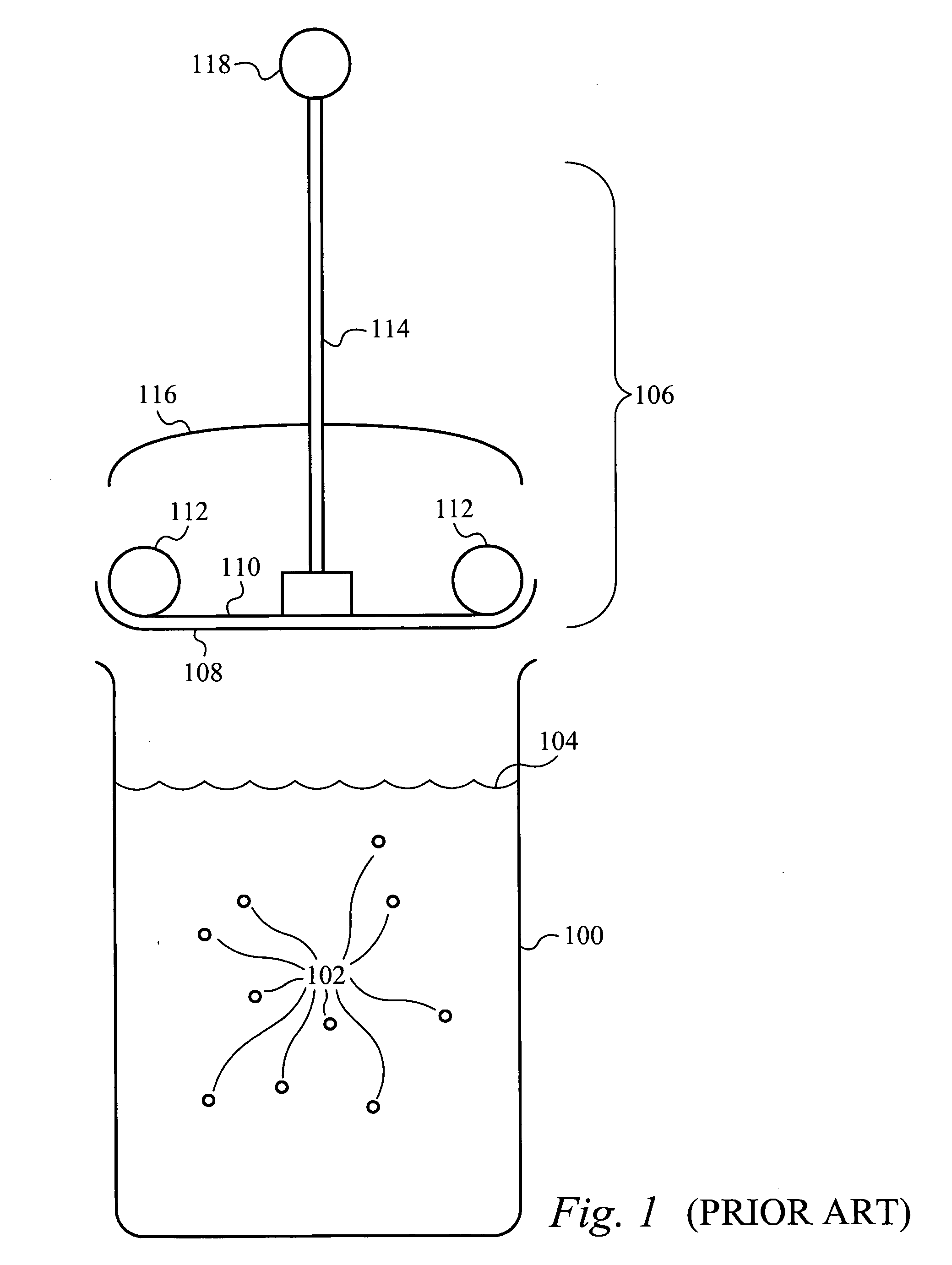

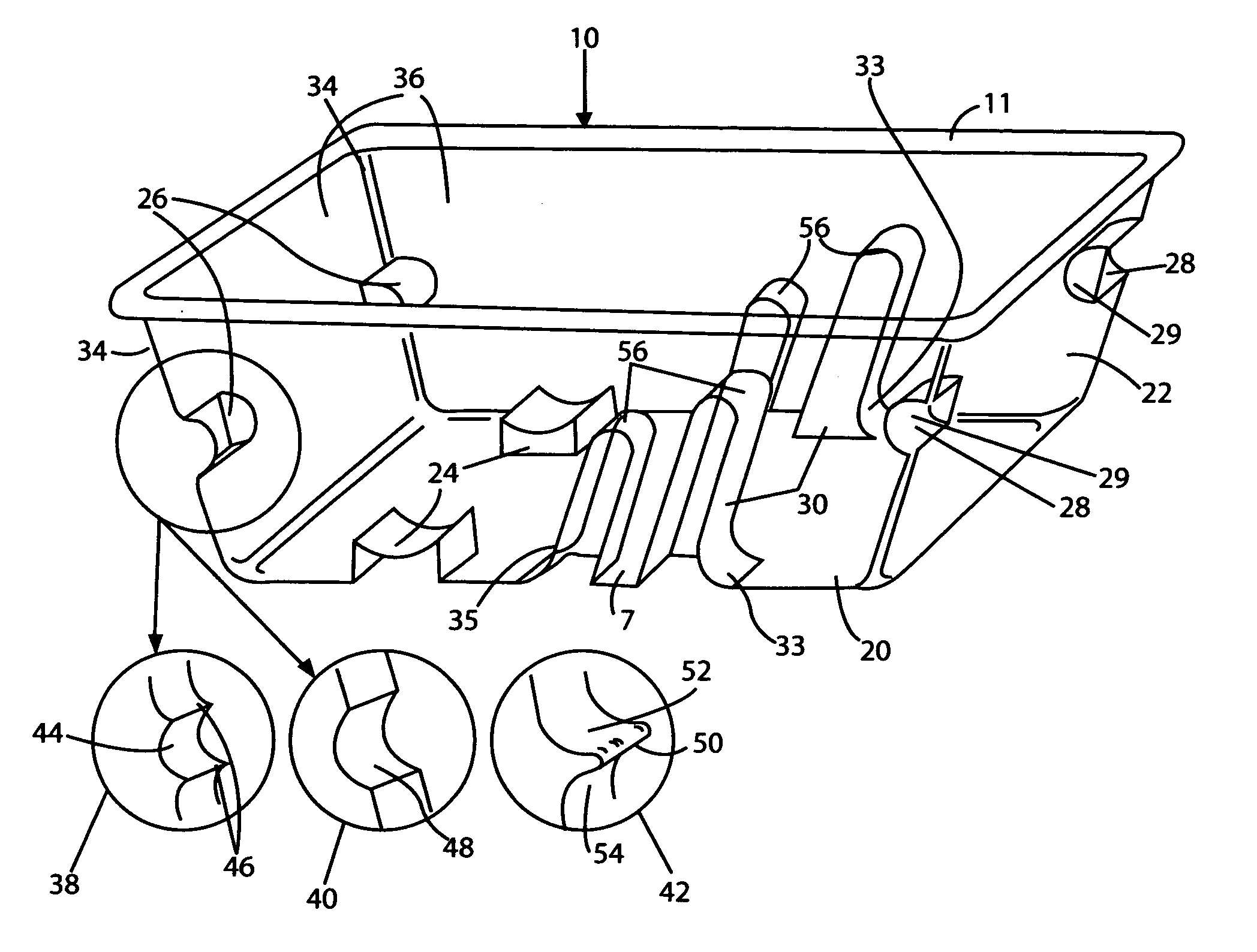

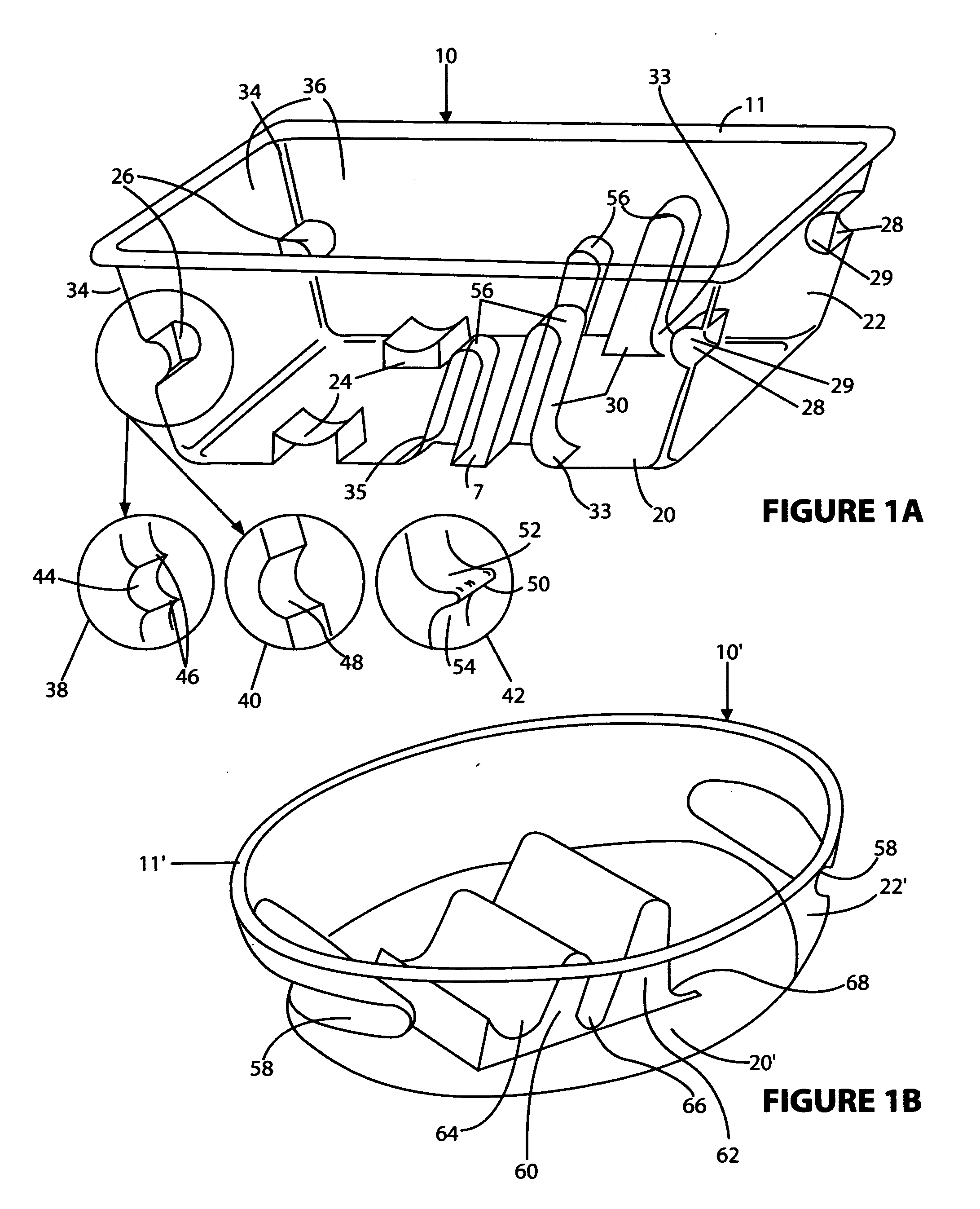

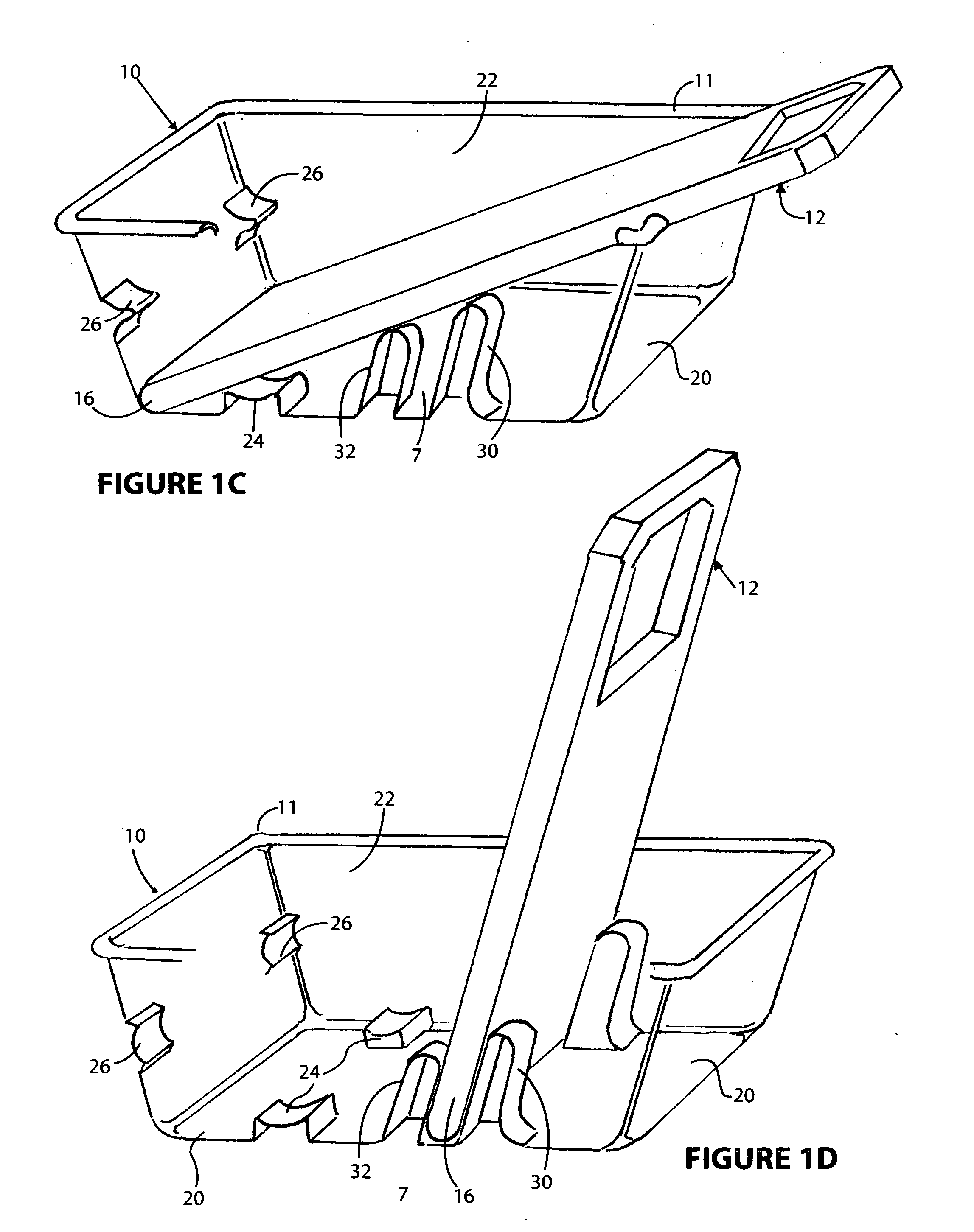

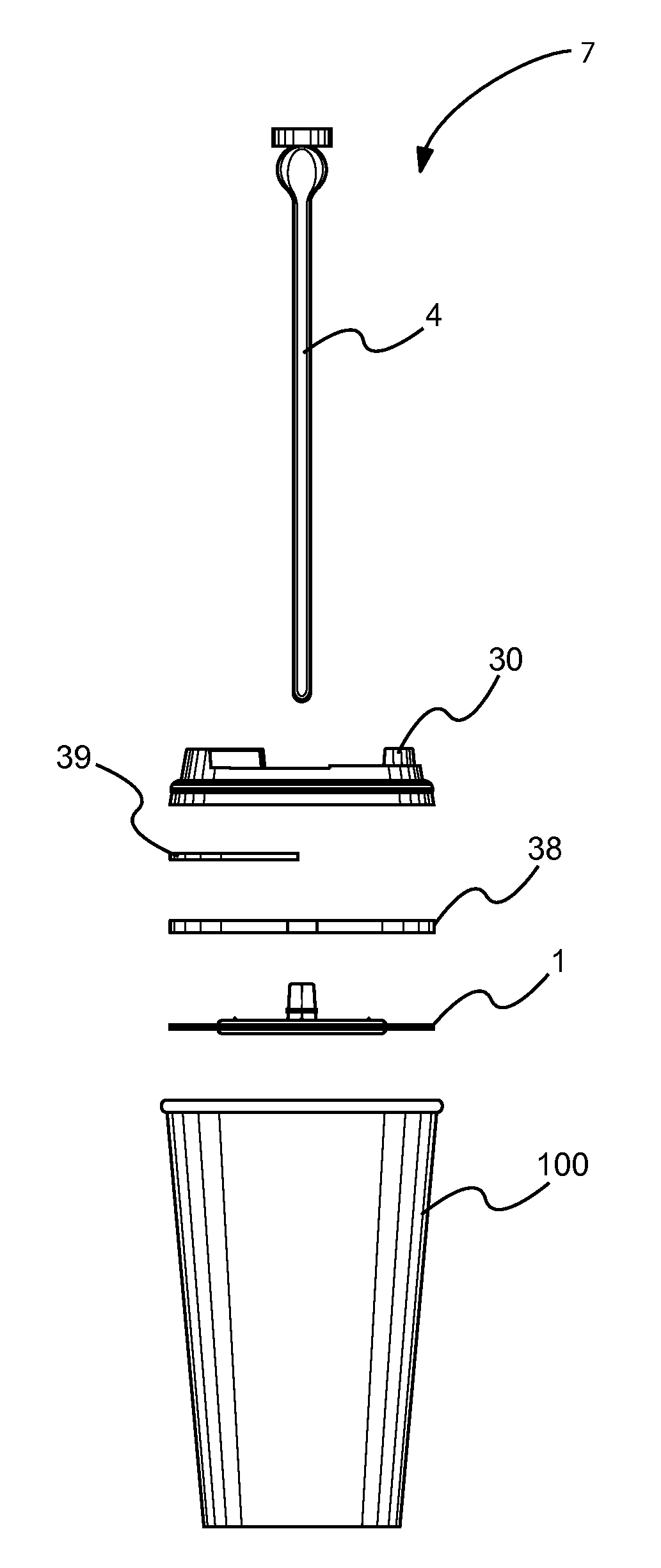

Disposable beverage press

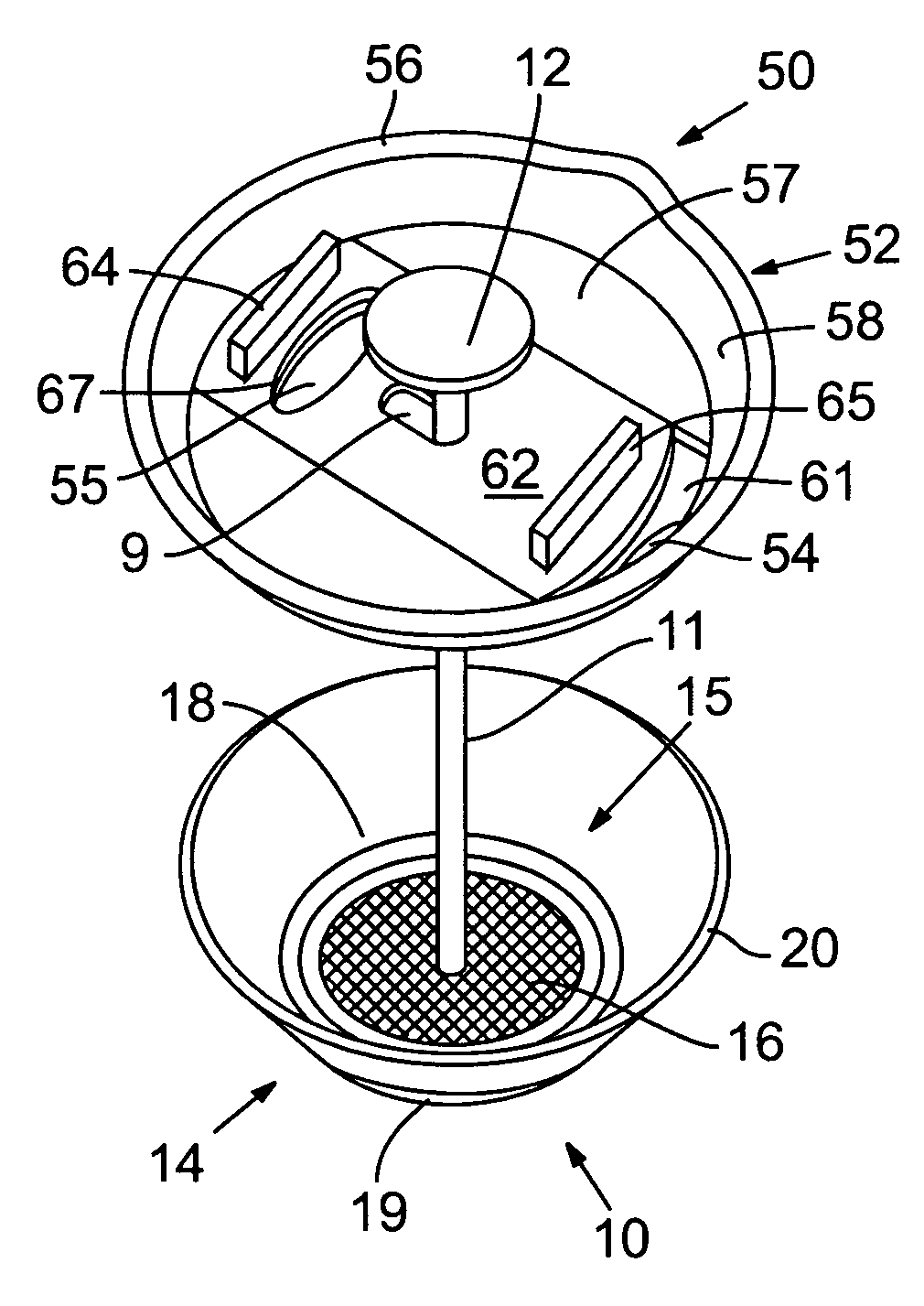

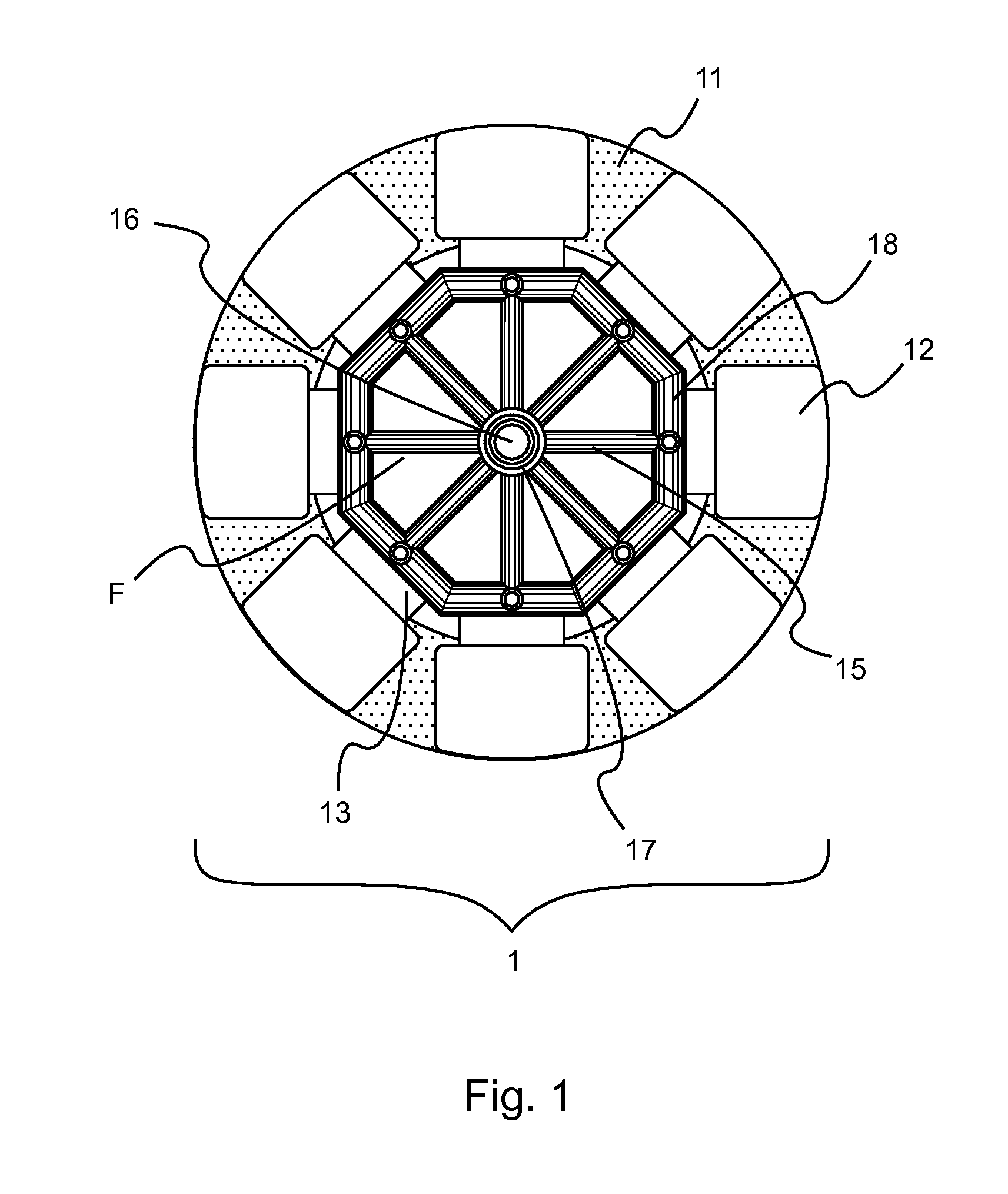

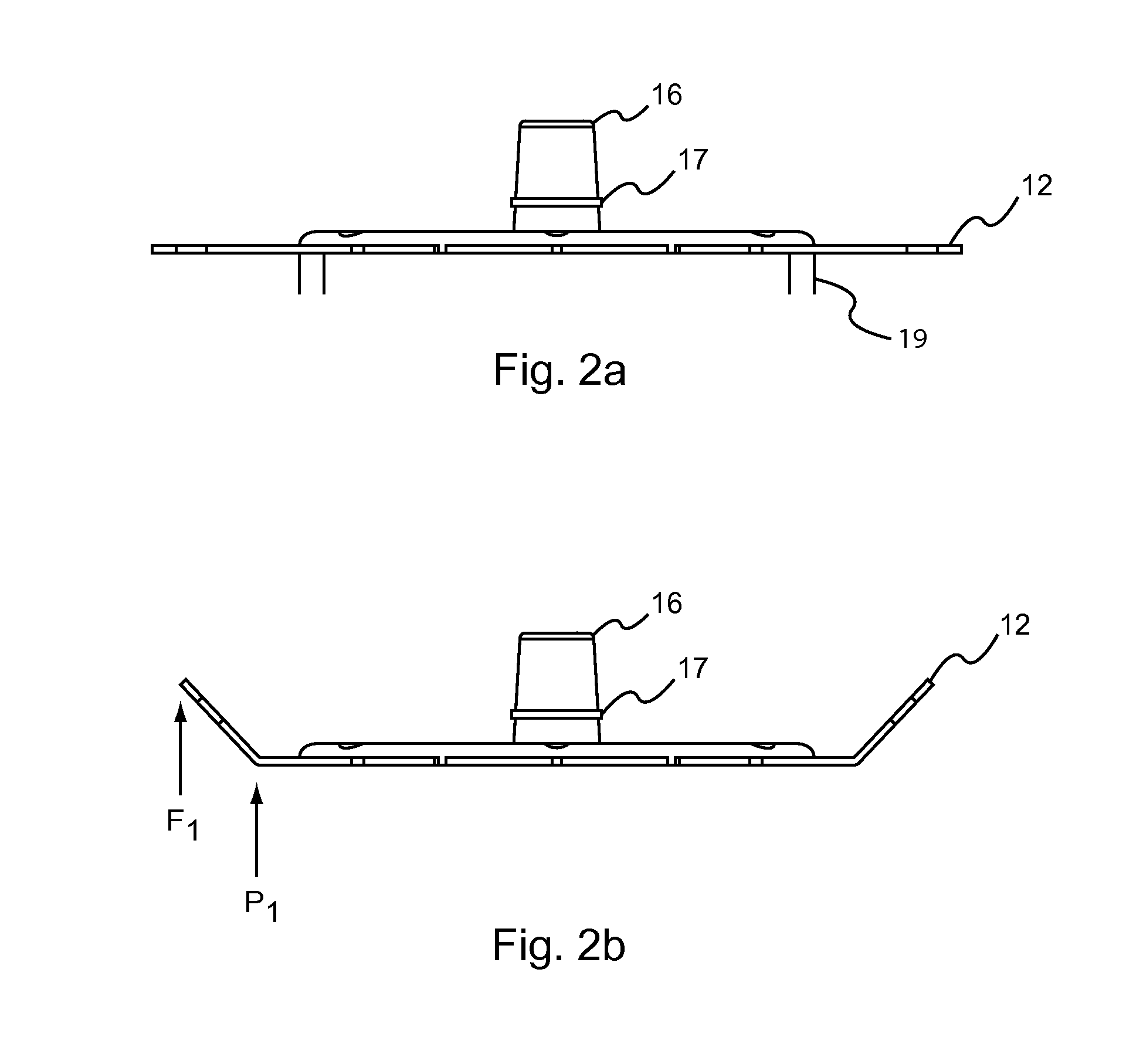

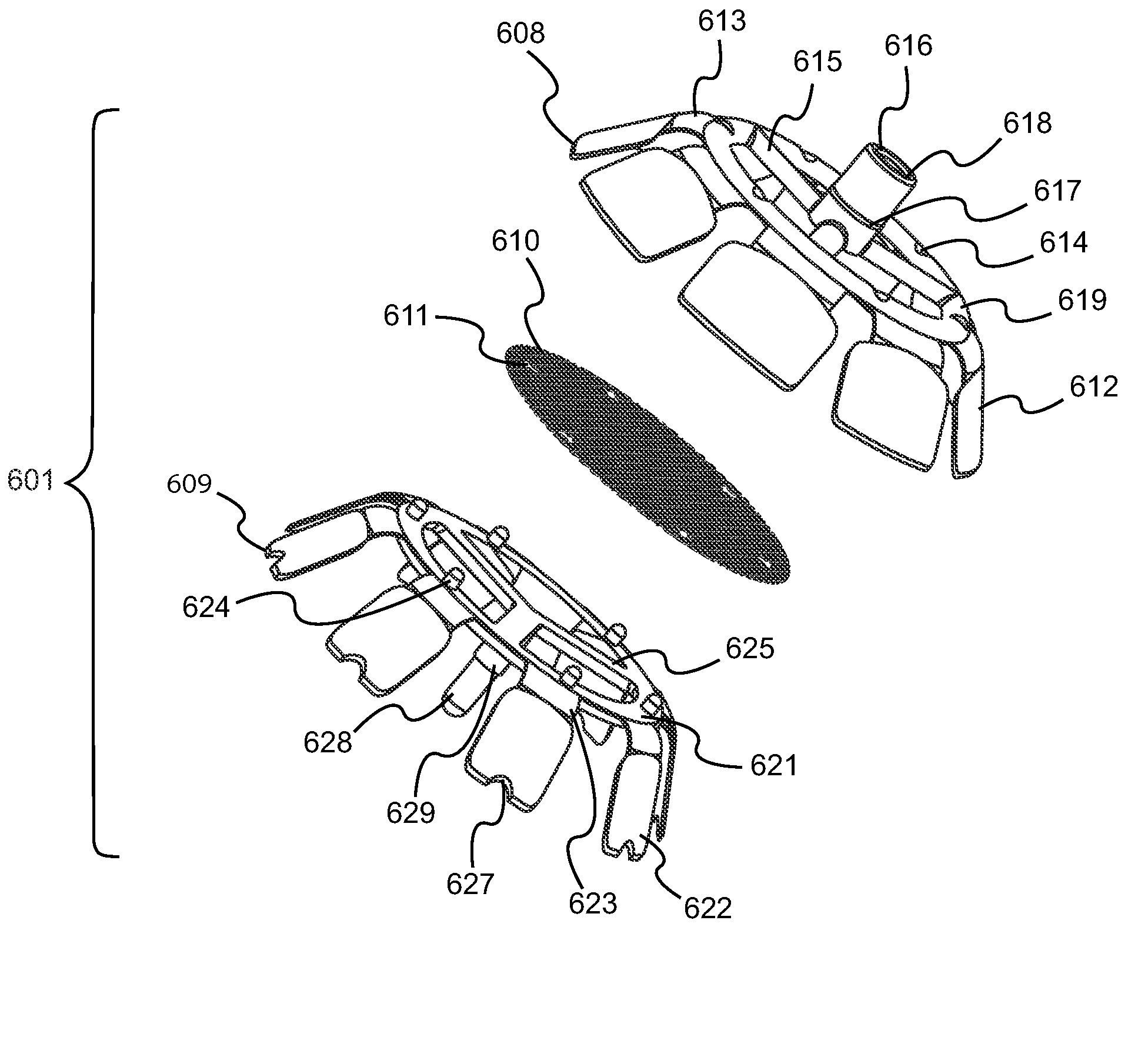

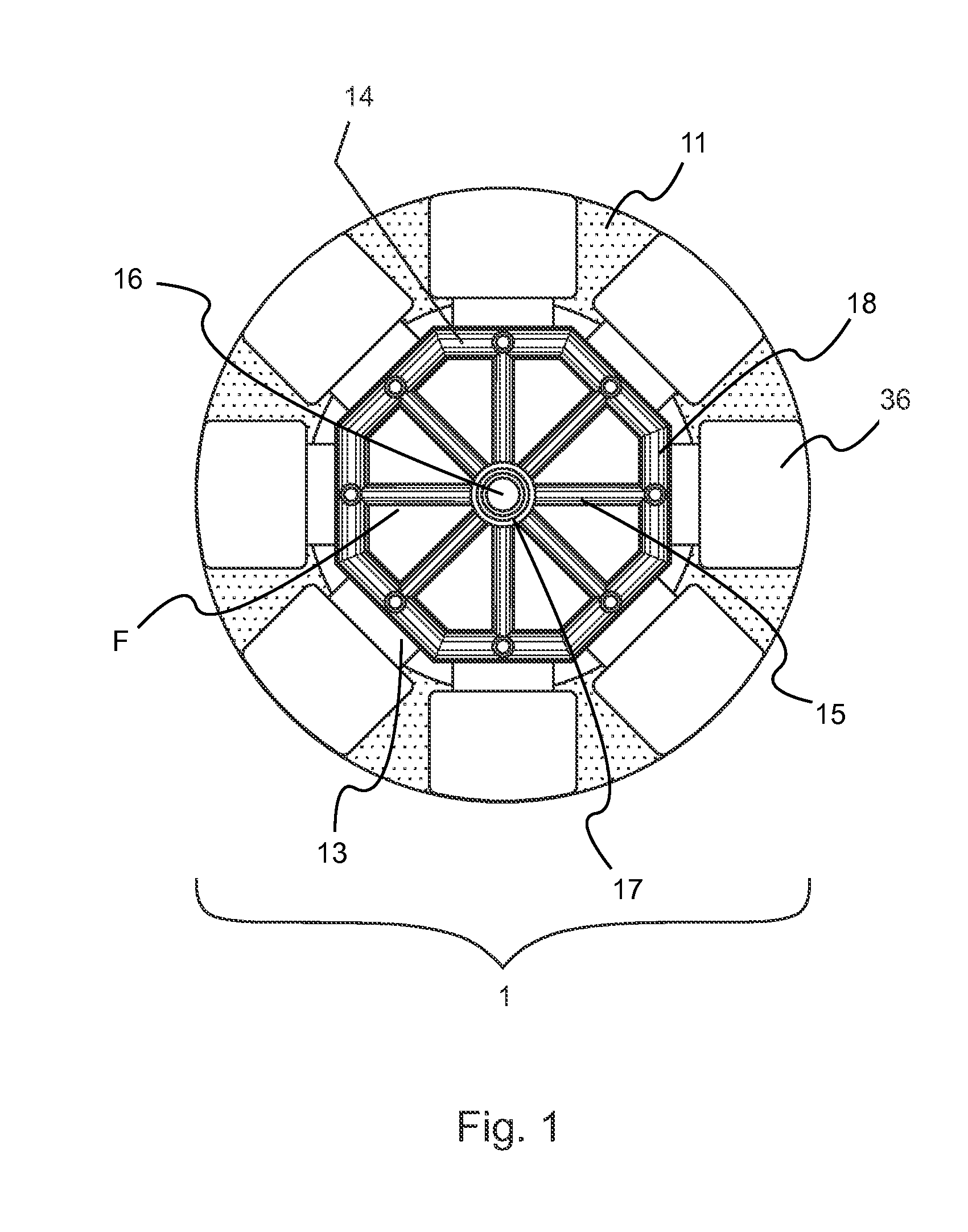

Apparatuses, systems and methods for providing a pressed beverage using a press and lid system. In one aspect, a beverage material is pressed to the bottom of a beverage container by means of a press ring including a filter. The walls of the beverage container exert a force on the press ring, folding flaps (perimeter portions) that are attached to the press ring by means of a flexible attachment member. Any beverage material or other debris that is not collected by the filter in the press ring is collected by a filter in the lid. Other variations and features consistent with the present invention exist.

Owner:R W WILSON

Disposable beverage press

Apparatuses, systems and methods for providing a pressed beverage using a press and lid system. In one aspect, a beverage material is pressed to the bottom of a beverage container by means of a press ring including a filter. The walls of the beverage container exert a force on the press ring, folding flaps (perimeter portions) that are attached to the press ring by means of a flexible attachment member. Any beverage material or other debris that is not collected by the filter in the press ring is collected by a filter in the lid. Other variations and features consistent with the present invention exist.

Owner:R W WILSON

Application of housefly maggots as oil material insects

InactiveCN101880591ARelieve stressHigh nutritional valueBiofuelsFatty-oils/fats productionChemical industryBiodiesel

The invention belongs to the food field or the field of bio-energy and develops a new oil material source-oil material insect housefly maggots. Grease can be obtained by carrying out hot air or microwave drying on aged housefly maggots and then using the press method (sending the housefly maggots into a screw press when the housefly maggots are still hot and pressing out the grease) for pressing. The grease can be used as a raw material oil for food, chemical industry and biodiesel. The oil content of the housefly maggots is 13-17%, and the grease extracted therefrom contains a variety of unsaturated fatty acids required by a human body through the analysis of nutritional ingredients, thereby being a high-quality healthy oil material; the growth cycle is short which is only 4-5 days, the occupied area is very small, the cultivation can be carried out under the high-density condition, the annual oil production per mu can achieve about 20t / mu year, and the cultivation can be carried out in an industrial plant without occupying the cultivated land area; and the grease is non-toxic, safe and reliable, and the extraction process is simple.

Owner:SUN YAT SEN UNIV

Production method of zanthoxylum oil

InactiveCN103749742AKeep the original tasteRich in nutrientsEdible oils/fatsZanthoxylum leprieuriiVegetable oil

The invention discloses a production method of zanthoxylum oil. The method comprises the following steps: selecting dried zanthoxylum and vegetable oil; baking and sauting the vegetable oil for 10-60 minutes at 60-100 DEG C, adding the dried zanthoxylum accounting for 6-12wt% of the vegetable oil when cooling the vegetable oil to 50-80 DEG C and maintaining for 2-10 minutes so as to obtain mixed oil; adding the mixed oil obtained in the mixing and sauting manner into an oil presser, maintaining the temperature within 70-100 DEG C and performing initial squeezing so as to obtain the zanthoxylum oil; performing preliminary filtration on the initially-squeezed zanthoxylum oil by using a filter screen so as to filter a majority of impurities; introducing the zanthoxylum oil subjected to the preliminary filtration into a vacuum filter; performing filtration on zanthoxylum oil again under the condition that the oil temperature is maintained within 75 DEG C to 105 DEG C so as to improve the filtration efficiency; adding the zanthoxylum oil subjected to the vacuum filtration into a centrifugal oil filter and performing rotating precipitation and filtration again, thereby obtaining the zanthoxylum oil. The method is high in production efficiency, wide in raw material resource, low in cost and pure in zanthoxylum oil taste.

Owner:安顺市西秀区百岁陈德文牌食品加工厂

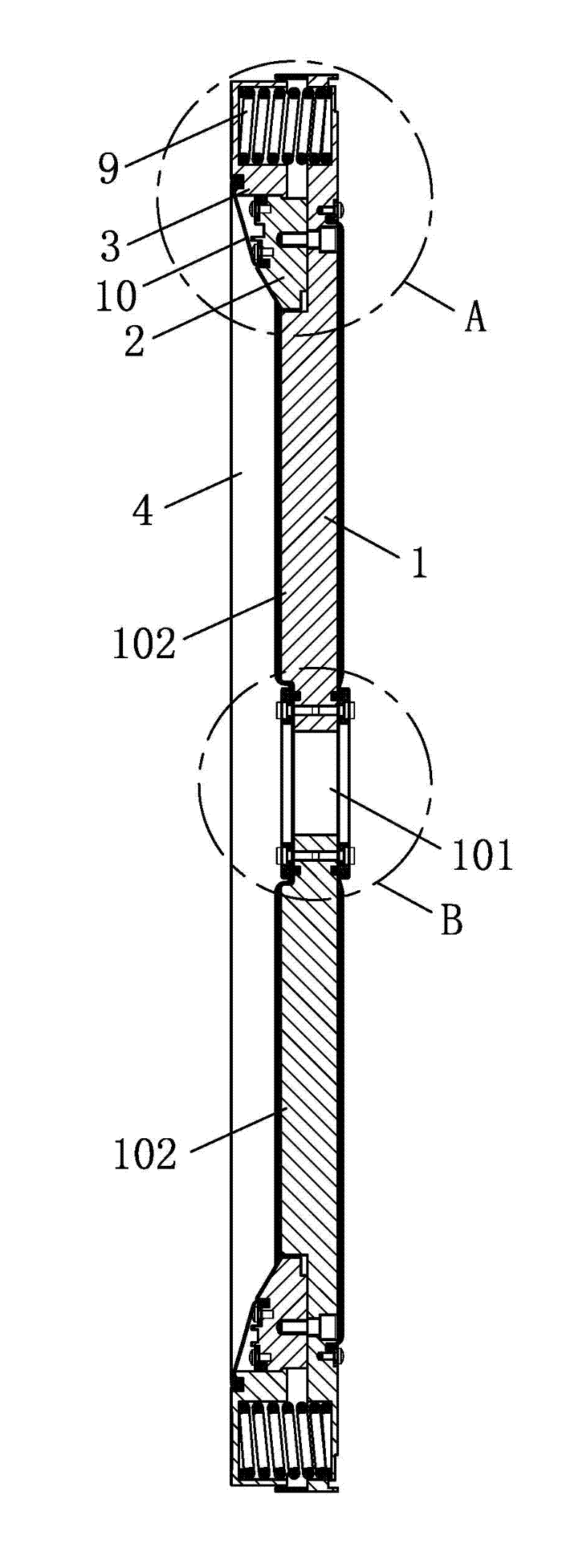

Preparation method of walnut oil and spiral oil extracting device thereof

InactiveCN109777605AEasy to shellImprove oil yieldFatty-oils/fats productionPressesMicrowaveSpiral blade

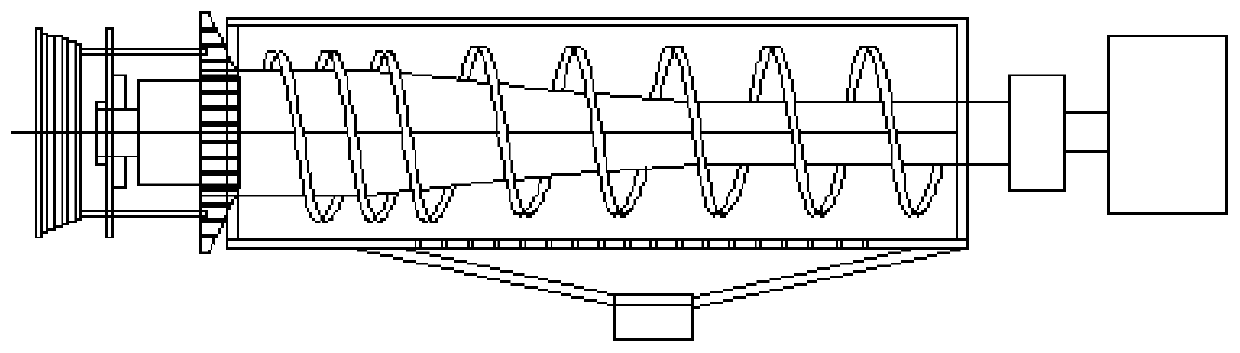

The invention discloses a preparation method of walnut oil and a spiral oil extracting device. The preparation method comprises the following steps of placing selected walnuts into a wok for stir-frying, obtaining the mature walnuts, and cooling for prepare use; breaking shells, and separating the shells and walnut kernels; conducting liquid nitrogen freezing treatment on the walnut kernels, and conducting microwave thawing treatment to remove skin; sending the peeled walnut kernels to a crusher for crushing, crushing to a coarse grain shape, and obtaining a pressing raw material; conducting low temperature pressing after putting the pressing raw material in a presser to obtain the walnut oil and an oil residue; filtering the walnut oil to obtain initial filtering oil; placing the initialfiltering oil under vacuum, filling nitrogen, and standing; filtering the initial filtering oil after standing through a refined filtering device to obtain a finished product. Through the above treatment process, the method improves the oil yield and ensures the quality and taste of the walnut oil. The spiral oil extracting device improves the oil yield of the pressed walnuts by setting multi-stage pressing screws and gradually decreasing spacing between spiral blades on each pressing screw.

Owner:北京同仁堂安徽中药材有限公司

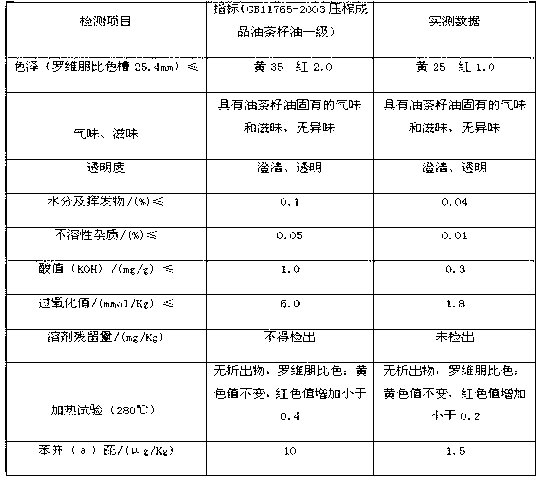

Refining process of original sweet tea seed oil via low-temperature physical membrane method

ActiveCN103215124ARetained tocopherolRetained sterolsFatty-oils/fats refiningIndustrial waste waterSterol

The invention discloses a refining process of original sweet tea seed oil via a low-temperature physical membrane method. The refining process disclosed by the invention comprises the following steps of: (1) squeezing and filtering, namely physically squeezing cleaned and husked dry oil tea seeds in a squeezer, treating acquired slag-containing oil via an oil purifying tank, and subsequently pumping the oil into a plate-frame type filter or a leaf filter via a pump for filtering to acquire filtered crude oil with original sweet flavor of the tea seed oil; (2) degumming, namely pumping the filtered crude oil into a degumming tank via the pump, adding a flocculating agent in a certain proportion to the degumming tank, fully stirring the crude oil and the agent for a period of time, and subsequently separating and degumming the oil via a disc type centrifugal machine; (3) dewaxing, namely adding a crystal-promoting filter aid in a certain proportion into the degummed crude oil for winterization crystallization, growing crystal for a period of time, and subsequently separating the oil via a flat microporous membrane filter to acquire dewaxed crude oil; and (4) deacidifying and decoloring, namely pumping the dewaxed crude oil into a spiral turbulence promoter and then into a compound nanofiltration membrane device via a booster pump, and circularly deacidifying and decoloring neutral oil via an oil storage tank equipped with an ultrasonic device to acquire the high grade edible tea seed oil, wherein in the compound nanofiltration membrane device, free fatty acid and pigments pass through a filtering membrane. The tea seed oil prepared by the process disclosed by the invention keeps the original natural fragrance and effectively retains specific active nutrition ingredients, such as tocopherol, squalene and sterol, of the tea seed oil; and simultaneously, the refining method is low in cost and no industrial wastewater is generated.

Owner:HUNAN BOBANG AGRI & FORESTRY TECH CO LTD

Preserved beancurd white blank automatic production method

ActiveCN101326984AWhite texture denseControl concentrationCheese manufactureFood preparationPhysical hard workWorking environment

The invention relates to a tofu automatic production method which comprises the following steps: soybean is ground into paste after being screened, cleaned and soaked; after siruping, a screw extruder is used to separate paste residue and eliminate bean dregs; the obtained soya-bean milk is coagulated by an automatic rotary coagulating machine; after twice of effort, a vacuum pump is used to continuously extract bellow slurry water by sections; the bean curd obtained after the yellow slurry water is extracted is pressed by an automatic pressing machine, to obtained the shaped tofu. The production method of the invention has the advantages of quantitatively controlling all process parameters, such as the soya-bean milk, coagulator, spicing, pressing, etc., realizing standardized and automated operation as well as quantitative control, replacing manual operation of workers with automatic machines and equipments, reducing poor batches, improving product quality, ensuring product sanitation and stabilizing product quality, relieving employees from traditional heavy physical labor by implementing the automatic production method, reducing labor intensity, improving labor efficiency, and creating good working environment for the employees.

Owner:北京王致和食品有限公司

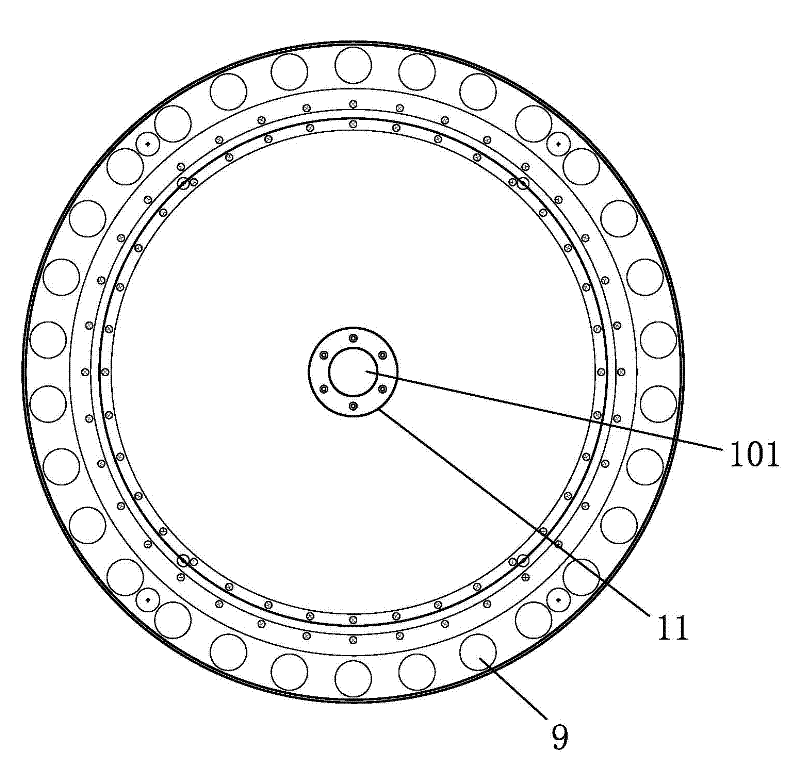

Filter plate group of horizontal type spring squeezer

ActiveCN102652888ARelieve pressurePrevent sprayingFiltration separationFiltrationStructural engineering

The invention provides a filter plate group of a horizontal type spring squeezer. The filter plate group comprises a filter plate, a main frame and a subframe, wherein the filter plate is a circular plate, the middle part of the filter plate is provided with a through hole, and the outer periphery is provided with an annular table; the main frame is an annular frame and is sleeved on the annular table; the subframe is an annular frame and is sleeved on the main frame; a gap between the main frame and the subframe is sealed by a third stressing strip; the main frame is internally provided with a material cavity; inner and outer surfaces of the filter plate are respectively provided with a filter screen, and the surface of each filter screen is provided with drainage lines for water diversion; two sides of the material cavity are provided with filter cloths, the filter cloths are connected with the filter plate and the inner and outer surfaces of the main frame and the subframe; an inner ring of the surface (in contact with the filer plate) of the main frame is provided with an annular gap for draining water, and the inner side of the annular gap is connected with a water draining channel. Therefore, the annular gap and the water draining channel improve the speed of water filtration and water drainage of the filter plate group provided by the invention, the pressure provided to a filter pressing device by a hydraulic device is greatly reduced, the filter screens are prevented from being blocked somewhere and causing water accumulation, and materials are prevented from being sprayed out from the edge of the filter plate, and thus the production efficiency can be greatly improved.

Owner:FOSHAN JINKAIDI FILTRATION EQUIP CO LTD

Processing method of purple potato clear juice with high anthocyanin content

The invention relates to a processing method of purple potato clear juice with a high anthocyanin content. The processing method comprises the following steps: (1), processing raw materials: crushing raw materials, and adding the crushed raw materials with water to form potato pulp; (2), stewing the potato pulp: heating the purple potato pulp to be 70-80 DEG C, and carrying out heat preservation for 30-60 min; (3), carrying out pulp enzymolysis: cooling the pulp to be 50-55 DEG C, and adding amylase and potato pulp enzymes for enzymolysis for 1-2 h; (4), squeezing: after pulp enzymolysis, squeezing the pulp with a squeezer to obtain purple potato raw juice; (5), carrying out raw juice enzymolysis: heating the purple potato raw juice, cooling, and adding pectinase and amylase for enzymolysis for 1-2 h; (6), carrying out ultrafiltration; (7), concentrating. The processing method is characterized in that citric acid is added so as to regulate the pH value to be 3.0 when the raw materials are crushed, so that anthocyanin components in purple potatoes can be effectively protected, and nutritional ingredients in purple potatoes can be retained; the potato pulp is heated to be 70-80 DEG C for low temperature gelatinization, therefore gelatinization is ensured while the loss of anthocyanin is avoided, and through potato pulp enzymolysis and raw juice enzymolysis, starch in purple potatoes is fully converted into sugar, the utilization ratio of the raw materials is increased, and the purple potato concentrated clear juice which is rich in nutrition and stable in quality is further obtained through processing.

Owner:SHANDONG LULING FRUIT JUICE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com