Filter plate group of horizontal type spring squeezer

A press and filter plate technology, which is applied in the field of horizontal spring presses, can solve the problems of high pressure, low production efficiency, slow water filtration and drainage, etc., and achieve the effects of reducing pressure, improving production efficiency and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

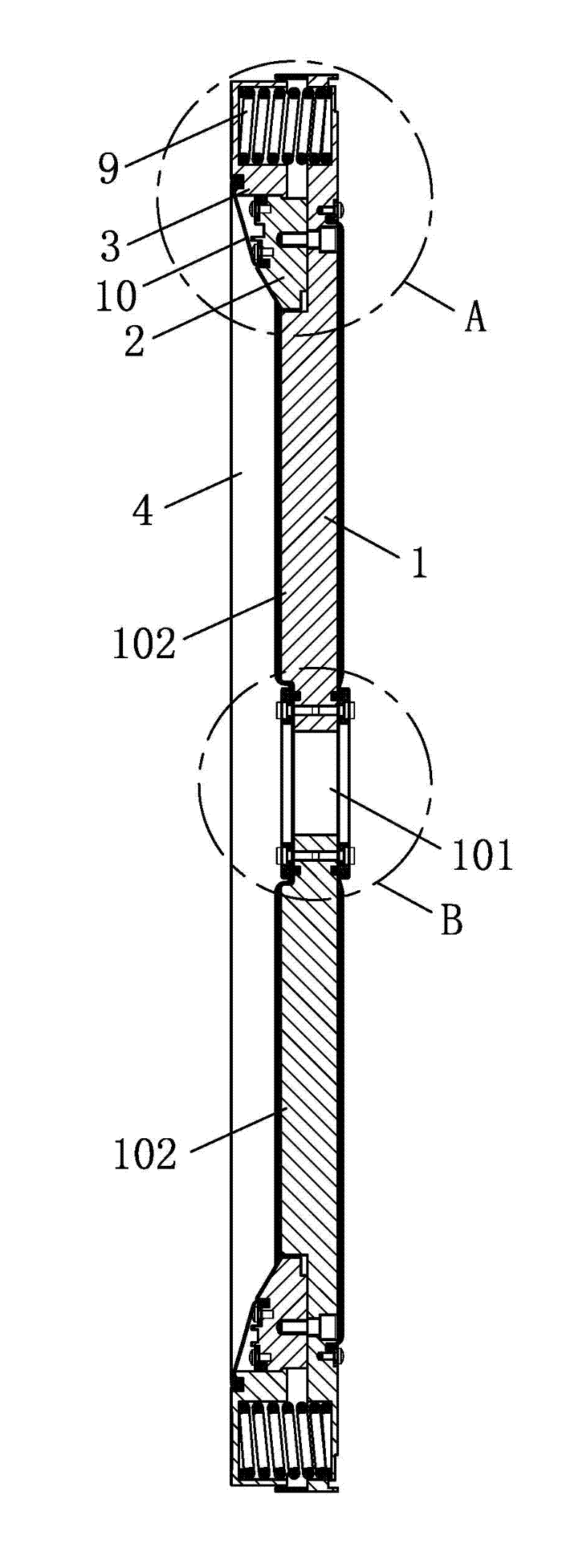

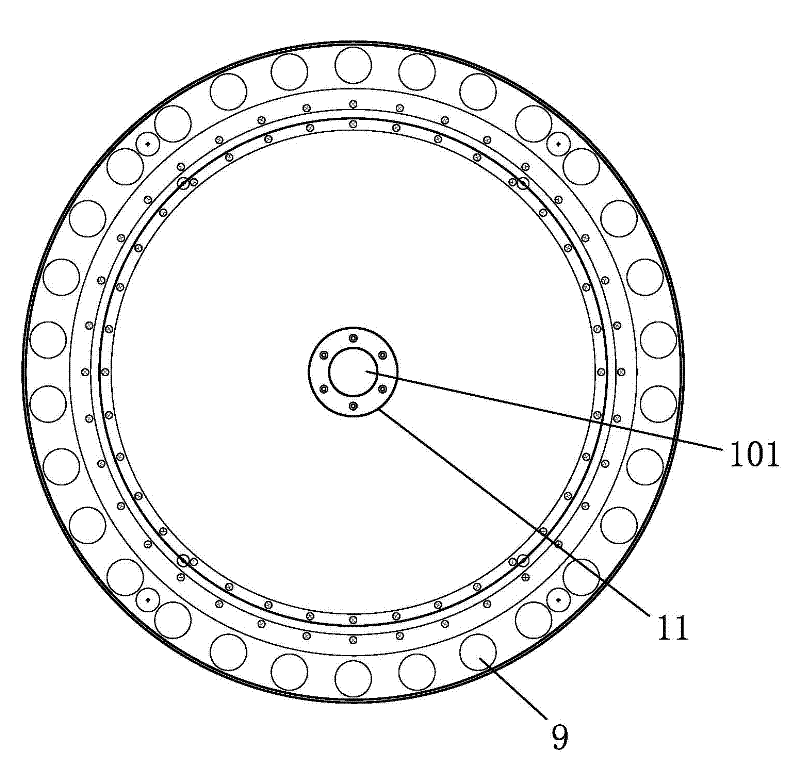

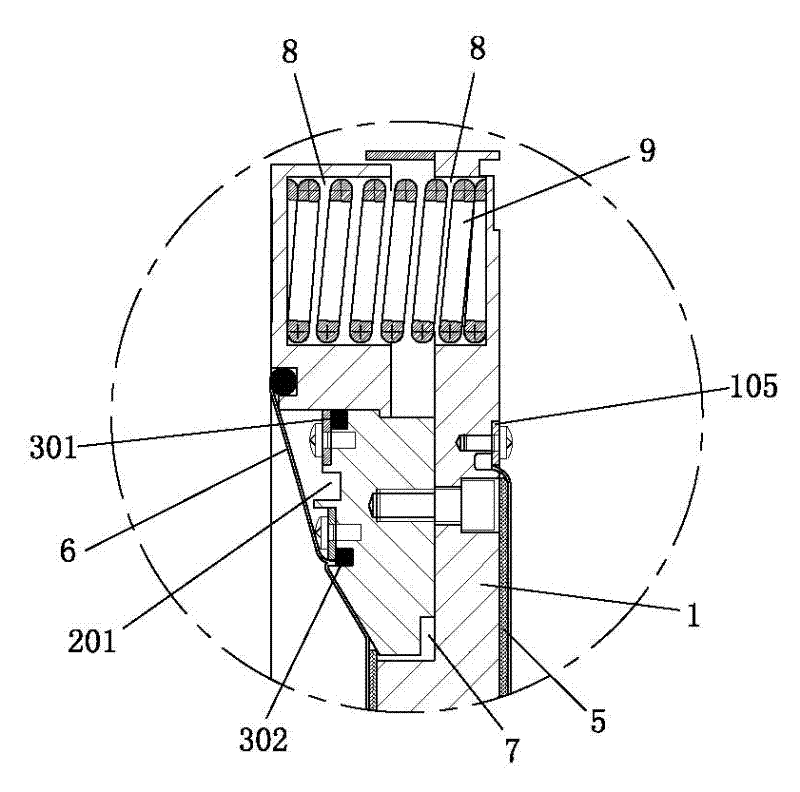

[0031] See Figure 1 to Figure 4 . A filter plate set for a horizontal spring press in this embodiment includes a filter plate 1, a main frame 2 and a sub frame 3; the filter plate 1 is a circular plate with a through hole 101 in its middle and a ring on its outer circumference. platform 102; the main frame 2 is an annular frame, which is set on the ring platform 102; the sub-frame 3 is an annular frame, which is set on the main frame 2; the gap between the main frame 2 and the sub-frame 3 is sealed by a bead 301; wherein, the bead 301 is locked on the front of the main frame 2 and close to the side of the sub-frame 3 by screws. The bead 301 can prevent the water detached from the material from penetrating into the spring groove 8 through the gap between the main frame 2 and the auxiliary frame 3, thereby preventing the spring 9 in the spring groove 8 from being corroded.

[0032] A material cavity 4 is arranged inside the main frame 2; the material cavity 4 is used to accom...

Embodiment 2

[0045] Embodiment 2 of the filter plate group of a horizontal spring press according to the present invention, the difference between this embodiment and Embodiment 1 is that the gap spacing of the annular gap 7 is 1 mm, and the pipe diameter of the drainage channel is 5 mm. The annular notch 7 provided in the embodiment can also make the water filtration and drainage speed of the present invention fast, which greatly reduces the pressure provided by the hydraulic device to the filter press device and improves the production efficiency; meanwhile, it also avoids the filter screen 5 somewhere A blockage causes water to accumulate there. Other structures and working principles of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

Embodiment 3

[0047]Embodiment 3 of the filter plate group of a horizontal spring press according to the present invention, the difference between this embodiment and Embodiment 1 is that the gap spacing of the annular gap 7 is 3 mm, and the pipe diameter of the drainage channel is 15 mm. The annular notch 7 provided in the embodiment can also make the water filtration and drainage speed of the present invention fast, greatly reduces the pressure provided by the hydraulic device to the filter press device, and improves the production efficiency; meanwhile, it also avoids the pressure of the filter screen 5 somewhere A blockage causes water to accumulate there. Other structures and working principles of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com