Method and equipment for preparing tea seed oil from tea seeds and extracting tea polyphenol from byproduct tea seed cake

A technology of tea seed cake and camellia seed, which is applied in the field of tea seed oil, by-products and its extracts from camellia seed, can solve the problems of strong water absorption, darkened color, stickiness, etc., and achieve convenient discharging and feeding Material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

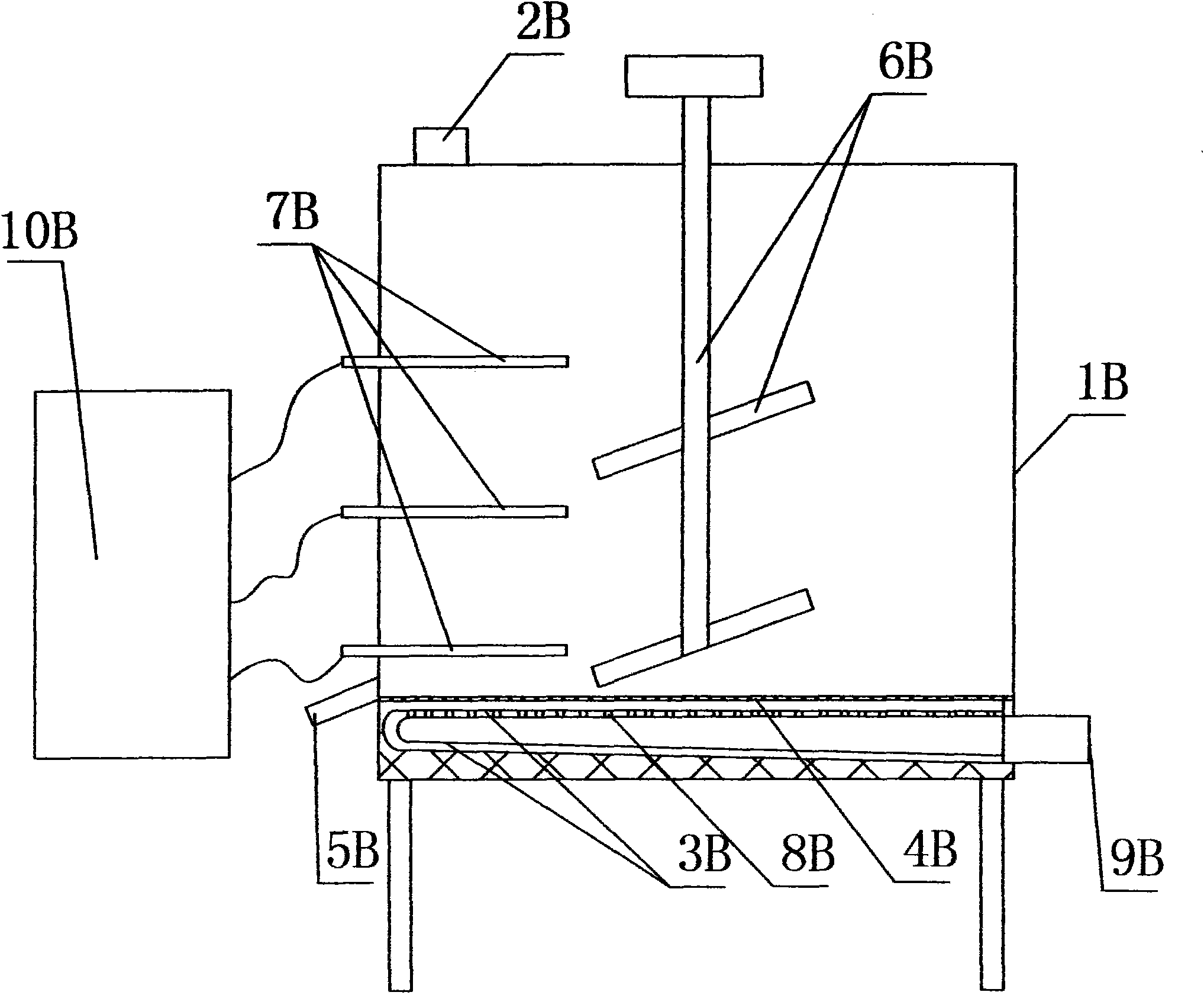

[0051] (1) special equipment used in the method for extracting tea polyphenols and saponin from camellia oleifera seed oil and by-product tea seed cake of the present invention, including dryer, sheller, cooking machine and press machine and The structural features of the tea seed cake pulverizer are as follows:

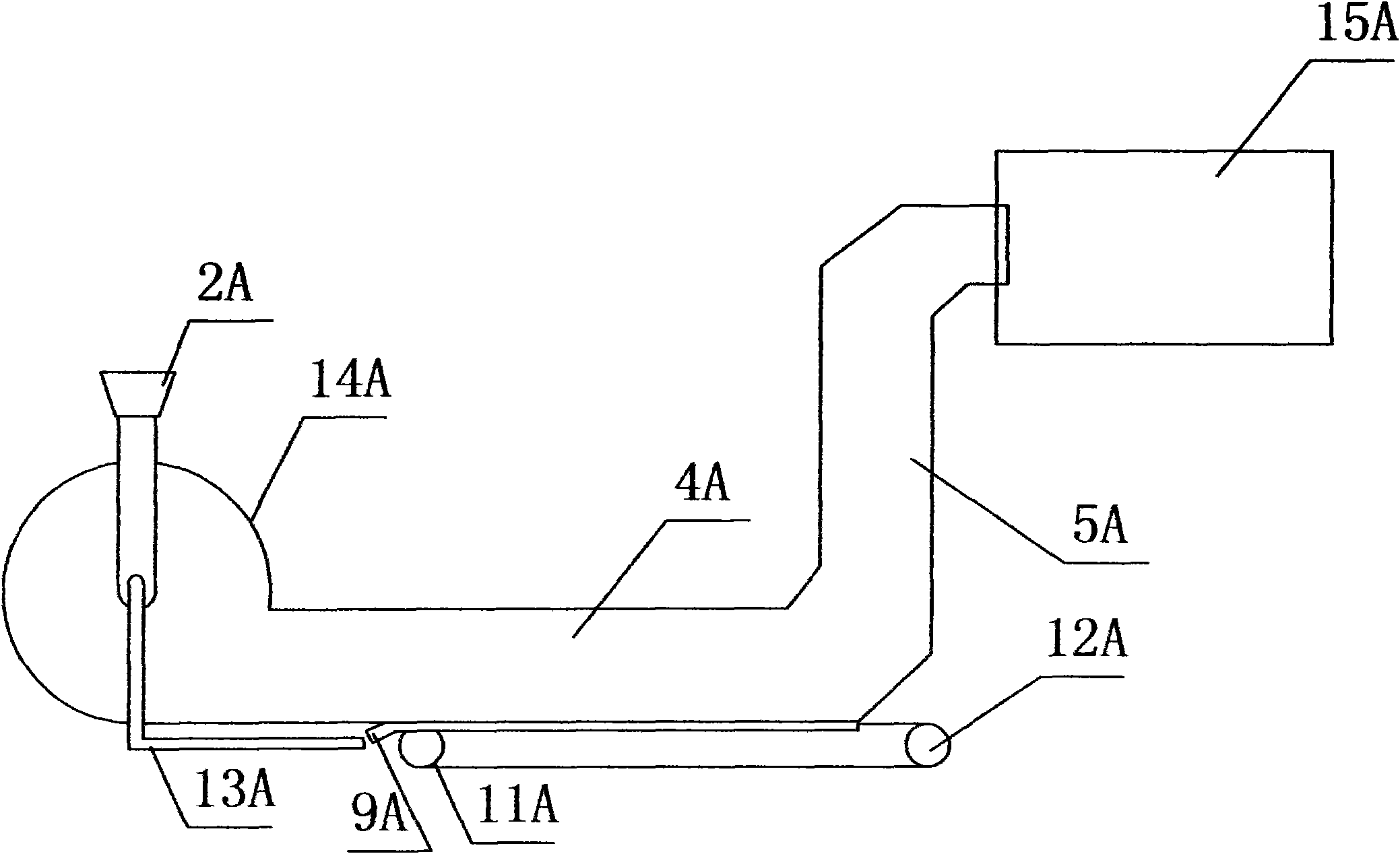

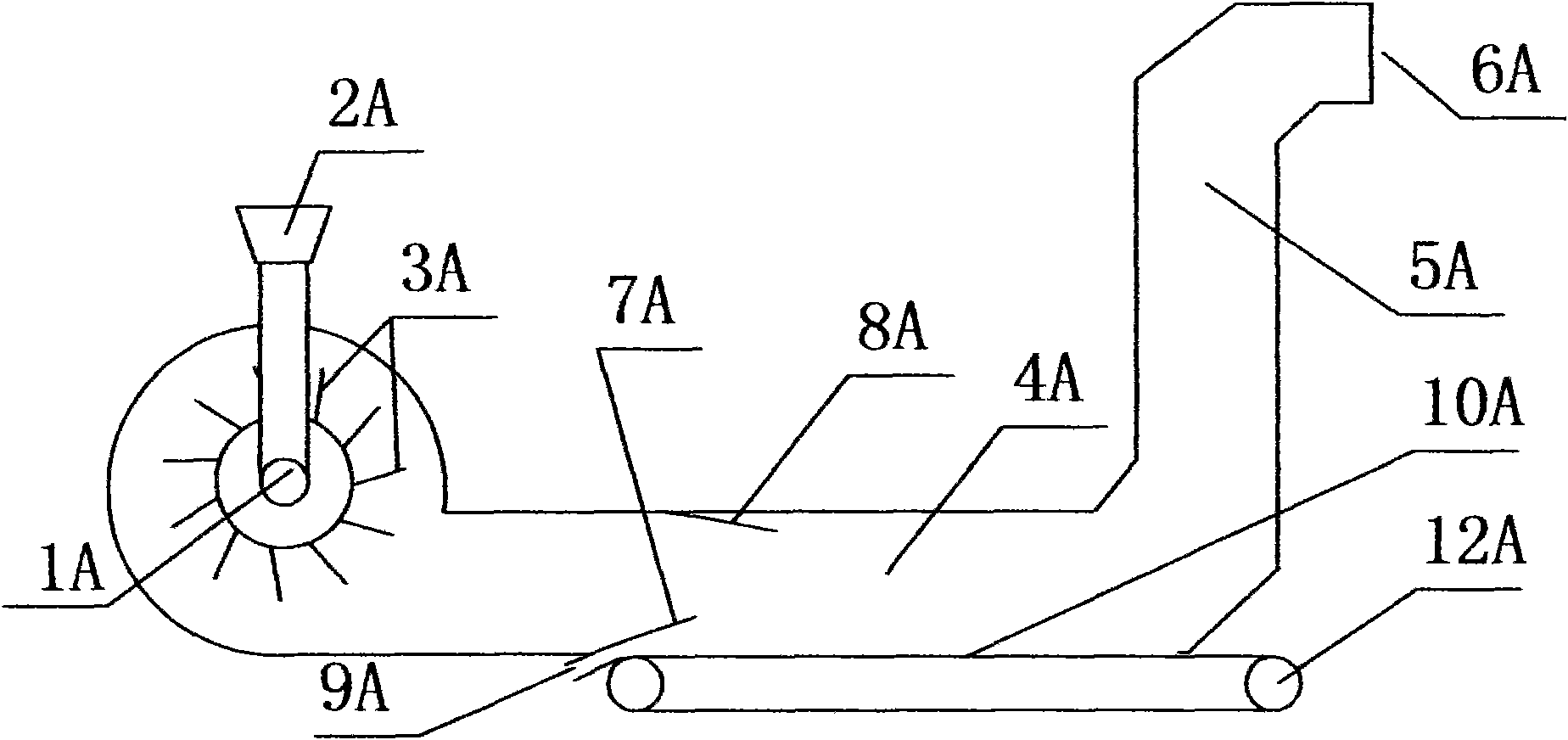

[0052] 1) if Figure 1A , Figure 2A As shown, the peeling machine of the present invention includes a power system, a transmission mechanism and an electrical control part. The power system can use a motor as the power system, and of course other powers can also be used as the power system. The transmission mechanism is a prior art. The characteristic of the invention is to improve the structure of the existing blower fan, transform the air inlet of the fan into a feed inlet 1A, and connect a feed hopper 2A outside the feed inlet, so as to facilitate feeding, and change the blade of the blower fan into a shelling impeller 3A , the shelling impeller not only has the...

Embodiment 2

[0060] (2) The method for extracting tea polyphenols and saponin from camellia oleifera seed oil and by-product tea seed cake of the present invention includes the following steps: 1) screening; 2) drying; 3) shelling, crushing, separation, and pulverization 4) Steaming of Camellia oleifera seed powder; 5) Packing cake; 6) Pressing tea cake into tea seed oil and by-product tea seed cake; 7) Extracting tea polyphenols and soap from by-product tea seed cake The products such as plain, concrete steps comprise tea seed cake pulverization, and above-mentioned steps 1)-6) are conventional technology of prior art, it is characterized in that:

[0061] Weigh 200g of tea seed cake, crush it to 40 mesh, put it in a Soxhlet extractor, add 600mL of petroleum ether, reflux and extract in a water bath at 70°C for 4 hours, and recover the solvent from the petroleum ether extract under reduced pressure to obtain the extracted crude oil. oil, wash and extract the crude oil twice with 20 mL of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com