Patents

Literature

210results about How to "Keep the original taste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of traditional Chinese medicine ultrafine formula particles

InactiveCN101822697AReduce dosageKeep it authenticPteridophyta/filicophyta medical ingredientsGranular deliveryDiseaseAdditive ingredient

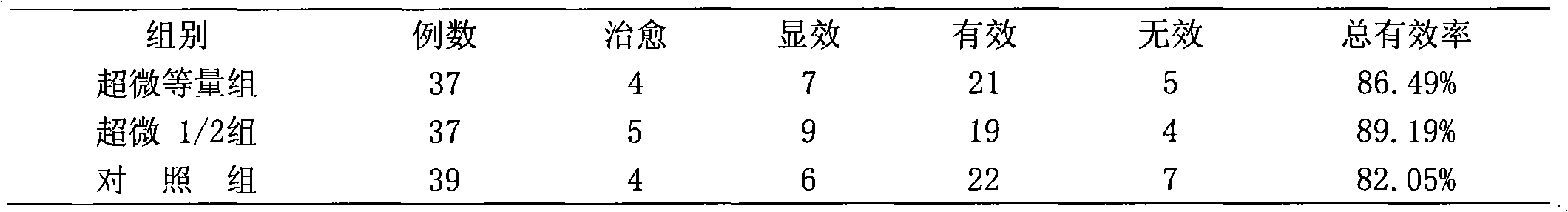

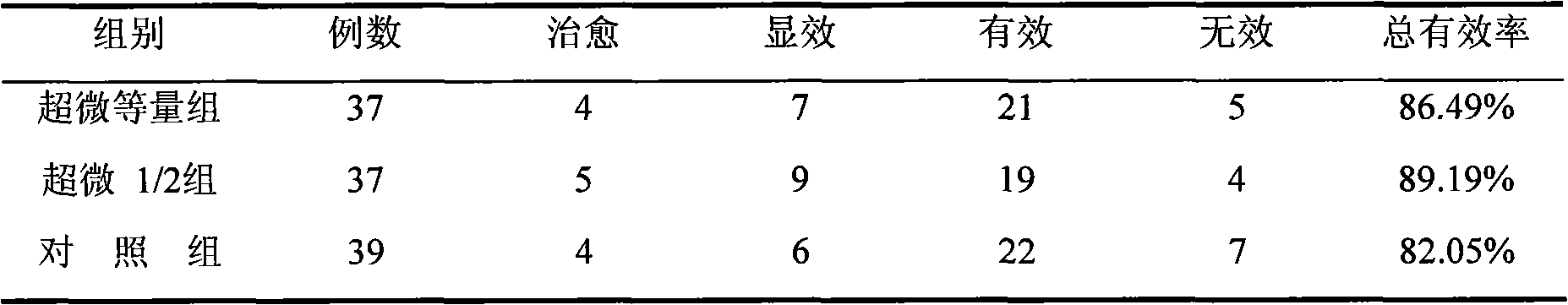

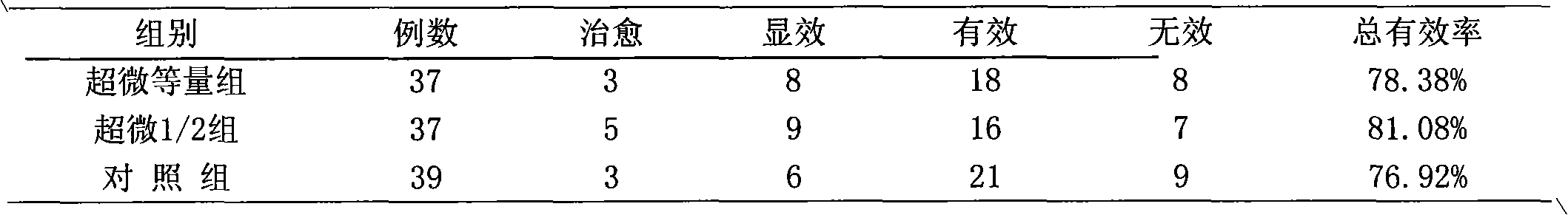

The invention discloses a preparation method of traditional Chinese medicine ultrafine formula particles. The preparation method comprises the following steps that: single Chinese medicinal material or traditional Chinese medicine decoction pieces are partially ultrafine-crushed into ultrafine powder, the other parts are coarse-crushed, extracted, concentrated, dried and crushed to obtain dry extract powder, the ultrafine powder and auxiliary materials are added to obtain mixture, and the obtained mixture is mixed uniformly, palletized, granulated and subpackaged. The traditional Chinese medicine ultrafine formula particles is characterized in that the characteristics of the traditional Chinese medicine ultrafine decoction pieces of saving medicine materials and being controllable in quality and convenient in administration. Compared with the traditional Chinese medicine formula particles, the preparation method better preserves the medicinal properties of the traditional Chinese medicines, has the advantages of little used amount of auxiliary materials, convenient identification, benefit to measuring the content of index ingredients, preserves the advantages that the traditional Chinese medicine decoction piece can be added and reduced according to the disease and the traditional decoction has unique curative effect, also overcomes the defects of troublesome decoction and inconvenient administration, and has advanced technique and controllable quality. The invention also discloses a processing method of the Chinese medicinal material, which extracts the raw medicinal materials partially, carries out ultrafining treatment partially and then carries out mixing. The method can obvious improve the utilization ratio and leachability of the Chinese medicinal materials.

Owner:湖南省中医药研究院

Technique for quick-frozen gingers

ActiveCN102696746AGuaranteed qualityKeep the original tasteFruits/vegetable preservation by heatingFruits/vegetable preservation by freezing/coolingIce waterRefrigeration temperature

A technique for quick-frozen gingers includes the processes of ginger selection, desulfurization, sterilization and quick-freezing. The process of ginger selection includes three steps, i.e. material selection, material trimming and winnowing; the process of desulfurization includes three steps, i.e. soaking for desulfurization, cleaning in clean water and sorting; the process of sterilization includes three steps, i.e. sterilization in medical solution, blanching for sterilization and cleaning in normal-temperature water; the process of quick-freezing includes three steps, i.e. cooling in ice water, quick-freezing and making of ice rinds; the gingers are quick-frozen under less than 25 DEG C below and within 15 minutes; in the steps of cooling in ice water and quick-freezing, water temperature is chosen according to the temperature of the quick-freezing tunnel of a fluidized quick-freezing machine, an ice water pond needs to be refrigerated if the temperature of the quick-freezing tunnel is higher than 30 DEG C below, the refrigeration temperature is controlled at 0 DEG C to 5 DEG C, and if the temperature of the quick-freezing tunnel is lower than 30 DEG C below, the ice water pond uses normal-temperature water; in the step of making of ice rinds, the gingers discharged out of the discharge outlet of the quick-freezing tunnel are directly put into a container containing ice water with temperature lower than 4 DEG C for 1 to 3 seconds; and after being packaged, the gingers are stored under the low-temperature condition of less than 18 DEG C below and transported to a point of consumption.

Owner:罗平县阳洋黄姜有限公司

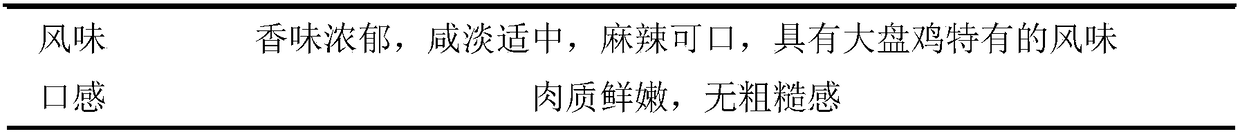

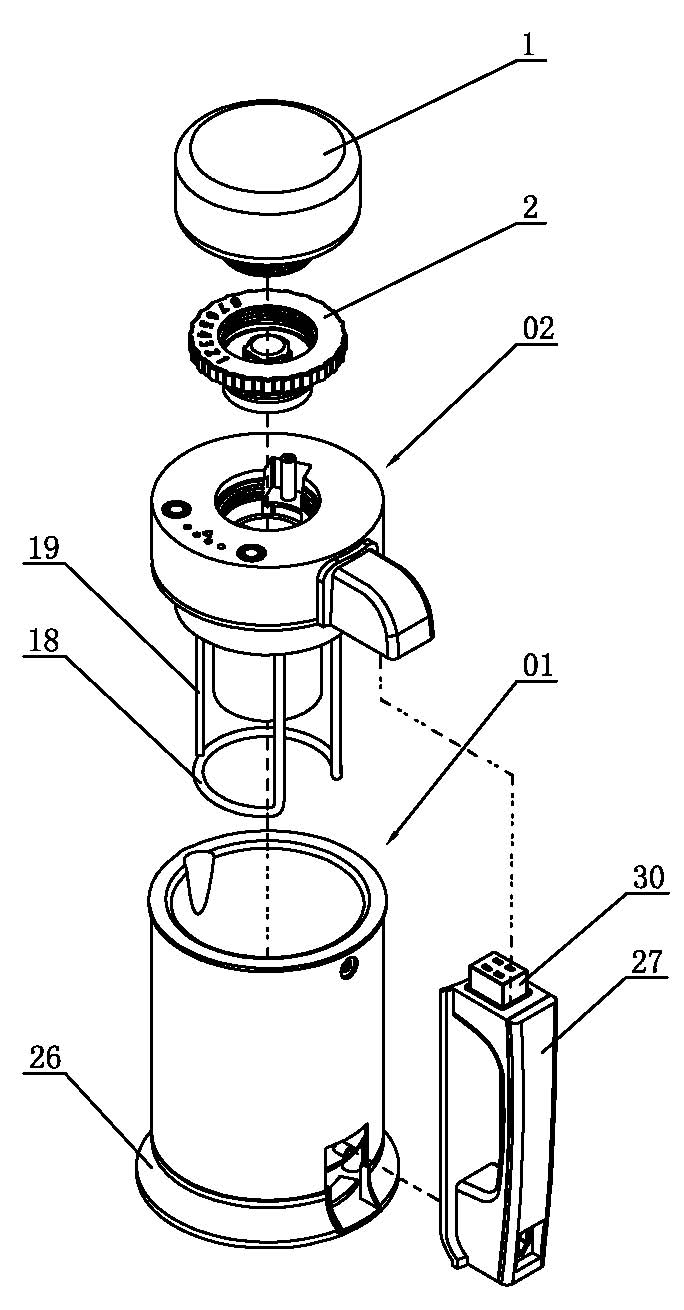

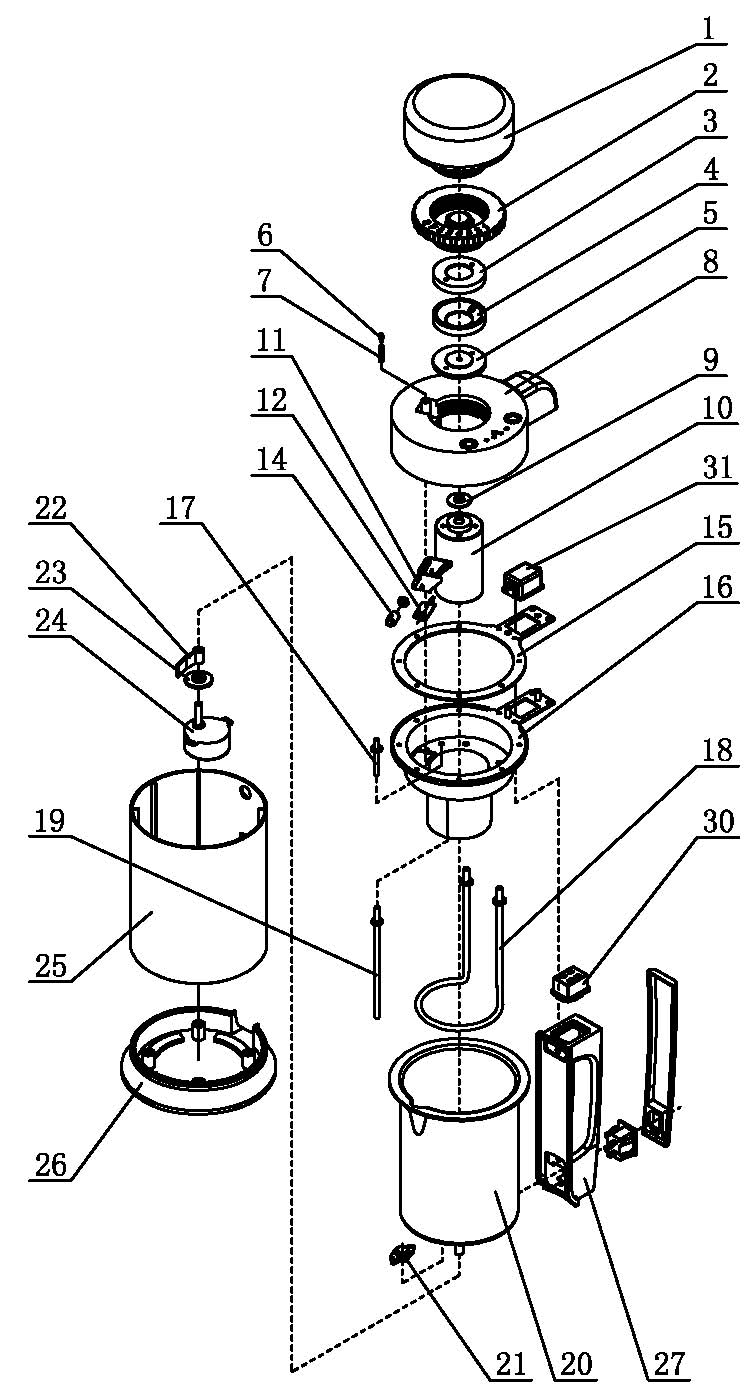

Household diet processing device and method for preparing soybean milk thereof

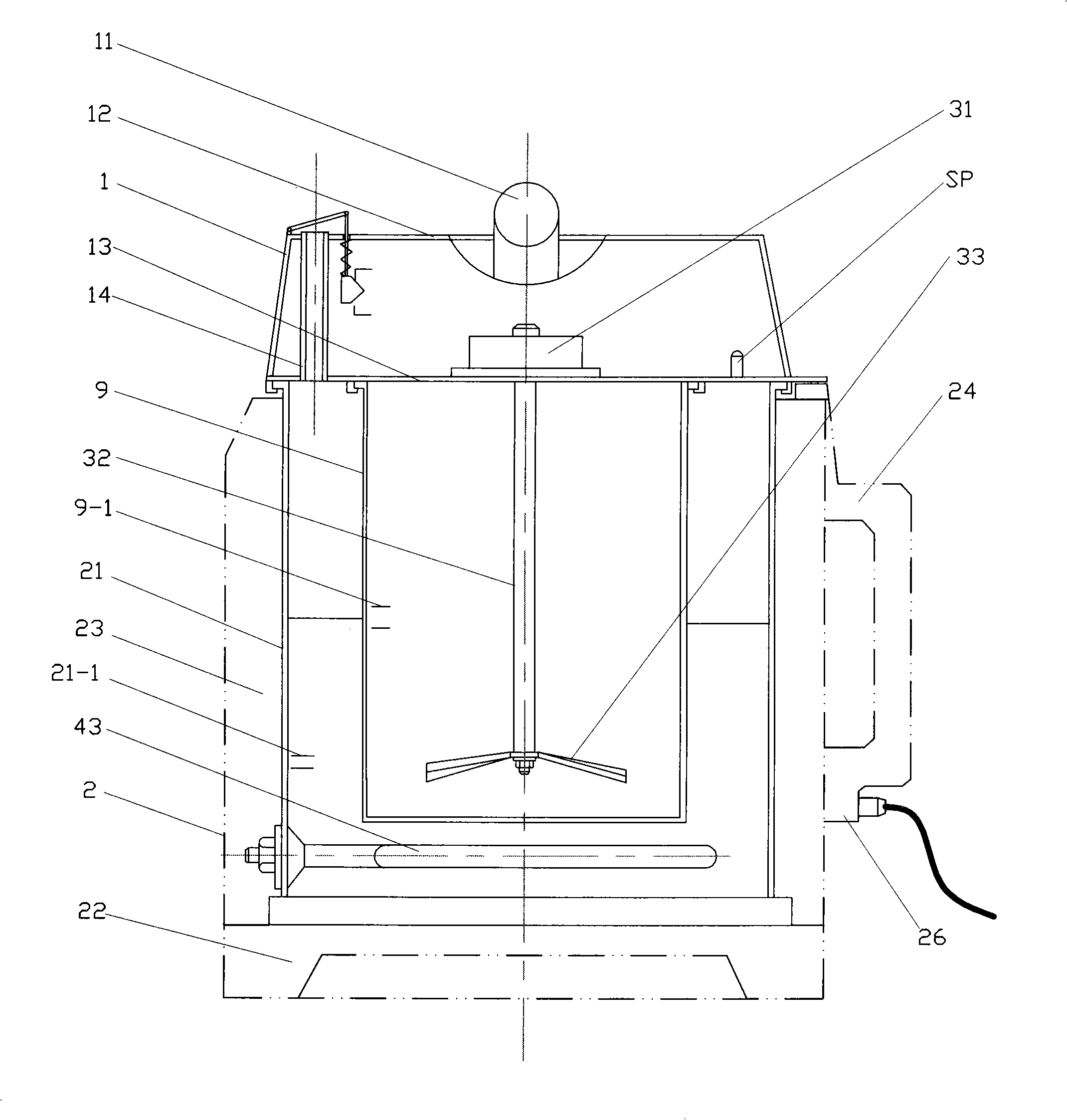

The invention relates to a home-use food processing device and a method for producing soybean milk. The home-use food processing device comprises a machine cover, a machine body, a food cup, a crushing motor, a crushing knife, an electrothermal tube, a circuit device and the like. The home-use food processing device is characterized in that the machine body comprises a water barrel, wherein the electrothermal tube is arranged in the water barrel; and when the device is used, the food cup is placed in the water barrel, and the electrothermal tube is isolated from the food cup by clear water. When heated, the electrothermal tube heats the clear water; then heat water heats the food cup and food materials in the food cup; and combined with food crushing, different processings can be carried out on different food materials. When the device is used to stew, steam or warm up the food by isolating water, water boiling temperature is the highest temperature, so as to ensure that nutrition loss is minimized, and burned pot and eschar are impossible to be produced, let alone stinks and carcinogen. The home-use food processing device can not only solve the problem of false boiling when the soybean milk is boiled, but also realize high efficiency and energy conservation. For example, the boiling of 1.2 liters of soybean milk consumes 0.2 kilowatt of electricity and takes 8 minutes.

Owner:方大同

Steamed beef with tea flavor and processing method thereof

The invention discloses a processing method of a steamed beef with tea flavor. The processing method comprises the steps of cleaning, soaking, condiment frying, kneading to enhance flavor, steaming with green tea, packaging and sterilizing, and when the beef is steamed, a Chinese medicinal herb bag and a condiment bag cover the beef, the lower part of the beef is filled up by green tea, and steamed spice is added in clean water. The beef processed by the processing method not only retains the original flavor of beef, but also contains concentrated tea flavor, is soft, silky, tasty, refreshing and delicious, leads a person to endless aftertastes, has a fresh and bright color, can promote appetite of people, and has a health protection function of replenishing Qi and blood.

Owner:BENGBU FENGMU BEEF & MUTTON PRODS

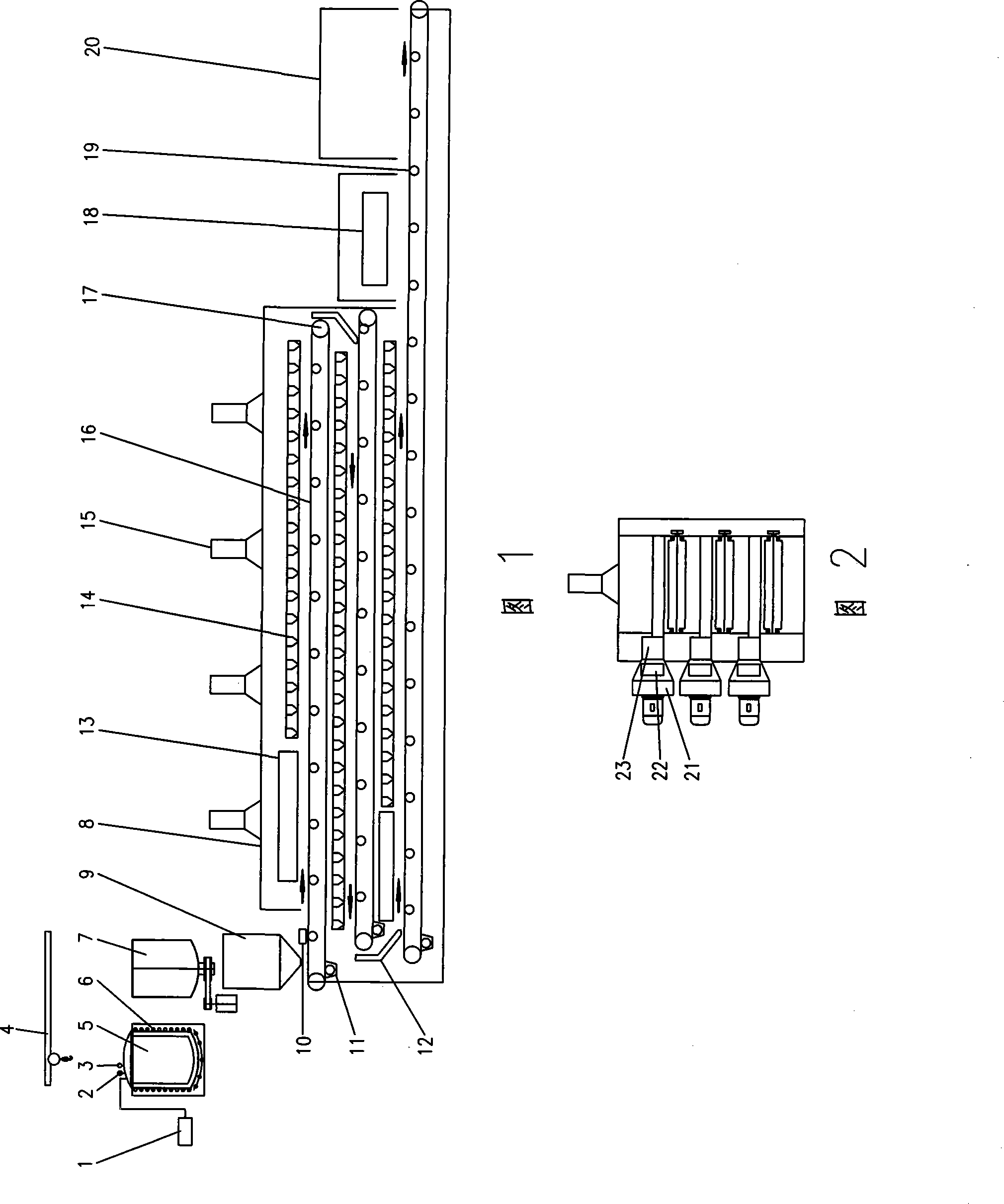

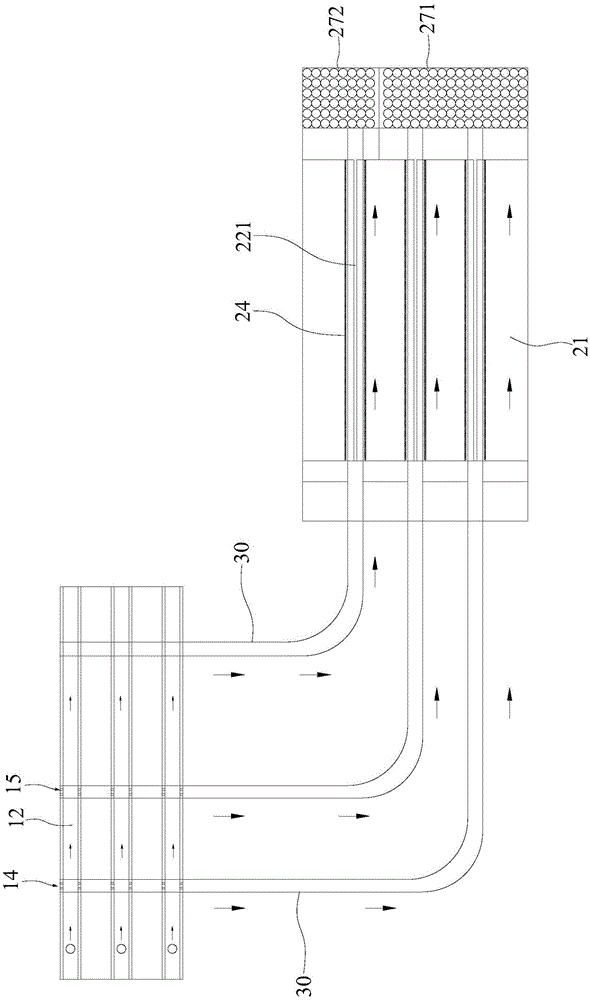

High-efficiency energy-saving automatic roasted seeds and nuts producing system

InactiveCN101238864AReduce energy consumptionShort energy consumptionFood preparationFood treatmentMaterial consumptionProcess engineering

The invention involves a high efficiency energy saving automatic system for producing roasted seeds and nuts, which includes cooking device, after being cooked by cooking device the product is lifted into dehydrator by lifting device, after dehydration the product is transferred into dryer through conveyor belt, entrance region of first layer conveyor belt in the dryer and last layer conveyor belt are equipped with infrared heater respectively, the top part of the dryer is equipped with humidity-discharging port, at least one layer of conveyor belt is installed in the dryer, the conveyor belt is driven by conveying roller and carrier roller belt, the upper part of the conveyor belt is installed with hot air injector, after being dried the product is cooled in cooler, after being cooled the product is separated in separator, at last the finished product is packed. The invention has merits of low energy consumption, low material consumption, high work efficiency, low producing cost and small occupation area.

Owner:邓元恺

Technique for producing fermented spareribs by using compound leavening agent

The invention belongs to the technical field of food processing and in particular relates to a technique for producing fermented spareribs by using a compound leavening agent. The technique comprises the following steps of: pretreatment of raw materials, pickling, predrying, frying, fermenting, baking, packaging, sterilizing and the like, wherein the compound leavening agent which takes microorganisms, such as lactobacillus plantarum, lactobacillus rhamnosus, Pediococcus pentosaceus and saccharomyces cerevisiae as strains is used for fermentation. The purpose of endowing spareribs with a basic fermentation flavor by using microbial fermentation is achieved; the nutritional value of the sparerib product is improved by fermentation; and the sparerib product do not need to be subjected to high-temperature and high-pressure sterilization by reducing the pH value of the sparerib product and combining the frying and baking processes, so that original taste and flavor of the sparerib product are ensured. The fermented sparerib product has the advantages of mellow flavor, high nutritional value, good safety, easiness in preservation, probiotic effect and the like; and due to development of the fermented spareribs, food which is unique in flavor, rich in nutritions and convenient to eat is provided for the society.

Owner:TENGQIAO FOOD CO LTD

Production technology of fresh zanthoxylum oil

ActiveCN101606676AHigh extraction rate of active ingredientsSimple processEdible oils/fatsFood preparationFruit juiceVegetable oil

The invention relates to a production technology of fresh zanthoxylum oil and aims at the defects of deficient and incomplete squeezing caused by an existing method that the fresh bunge prickly ash and edible vegetable oil after being mixed are squeezed, high residual oil content of waste residues and larger labor intensity. By the optimized procedures of material selection, pulverized manufacture of fruit juice, mixing, filtration, colloid removal, waxing, deposits and trace moisture thereof, the invention improves the production efficiency, shortens the production procedure, enhances the daily yield, lowers the rate of waste materials, lowers the cost, is timesaving and laborsaving, has better mouth feel, is more scientific and reasonable, improves the quality and the storage stability of a product, reflects the diversity of the product, increases the selectivity for consumers and enlarges the application range of production raw materials.

Owner:重庆市树上鲜食品(集团)有限公司

Steamed beef with tea flavor and processing method thereof

InactiveCN102763853AGood effect of removing fishy smellIncrease the fragranceFood preparationFood flavorGreen tea

The invention discloses a processing method of a steamed beef with tea flavor. The processing method comprises the steps of cleaning, soaking, condiment frying and salting, kneading, steaming with green tea, packaging and sterilizing, and when the beef is steamed, a condiment bag covers the beef, the lower part of the beef is filled up by green tea, and steamed spice is added in clean water. The beef processed by the processing method not only retains the original flavor of beef, but also contains concentrated tea flavor, is soft, silky, tasty, refreshing and delicious, leads a person to endless aftertastes, has a fresh and bright color, and can promote the appetite of people.

Owner:BENGBU FENGMU BEEF & MUTTON PRODS

Nourishing rice flour and method for processing the same

InactiveCN101467604AFormulation ScienceRich in nutrientsFood preparationAdditive ingredientInstant noodle

The invention discloses a kind of instant rice noodles and its production method, pertaining to pre-cooking noodles or instant noodles food. The major ingredient comprises rice flour, wheat flour, core powder and soybean flour while the minor ingredients comprise dry products such as vegetable, fungus, fruit and meat; the process comprises the following steps: firstly, performing smell-removing treatment for corn and soybean, evenly mixing rice flour, wheat flour and minor ingredients in the dough kneading machine with water to get raw meal; then, delivering the raw meal into the self-cooking dual-cylinder vermicelli machine to forming rice noodles. The product has numerous raw materials and abundant nutrients, achieves the nutrient balance, improves the reasonablity and effectivity of nutrients in food, and plays an important role in maintaining the human body nutrient balance, good health and long life of people.

Owner:TIANJIN ZHONGYING HEALTH FOOD

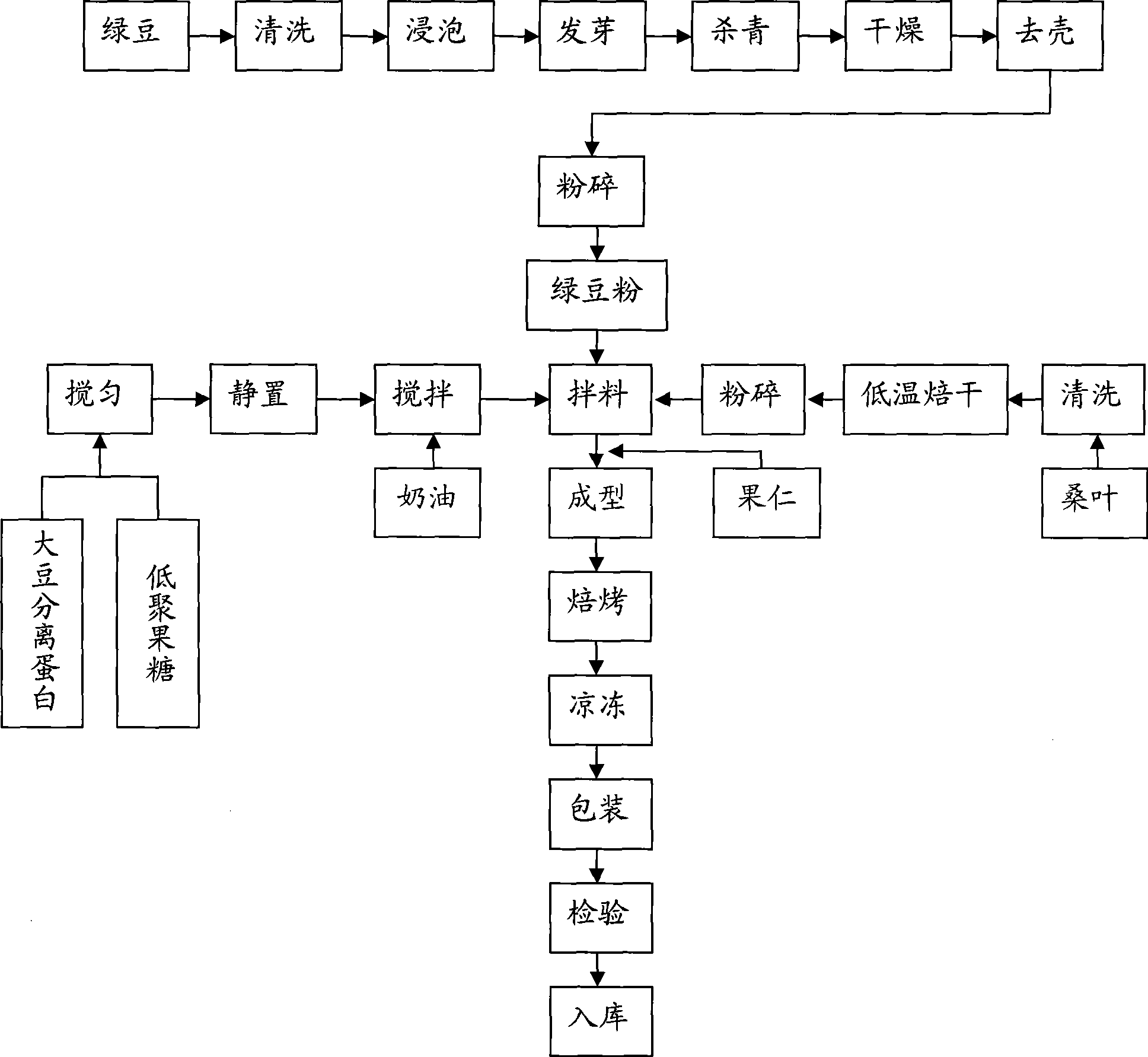

Chinese almond cake and production method thereof

The invention relates to an almond cake and a production method. The almond cake takes mung bean powder, soy protein isolate, fructo-oligosaccharides and mulberry leaf powder as raw material, can also use the nuts with a certain flavor and taste as the supporting material; and the improved almond cake raw material formula is more scientific, while the nutrition is more balanced. To produce the almond cake, firstly, first-grade mung beans are selected, soaked, germinated, blanched, dried, peeled and finely ground into mung bean powders; fresh mulberry leaves are picked, washed, dried at low temperature and crushed to get mulberry leaf dry powders which are then reserved; then the soy protein isolate and the fructo-oligosaccharides are added into a mixing barrel, stirred into uniform emulsion and kept static for 45 to 60 minutes; after butter is added into the uniform emulsion and stirred evenly, the green bean powders and the mulberry leaf powders are added into the mixture to generate the powder material; finally, the prepared powder material is placed in a cake mold, molded into a cake, put into an oven with the temperature less than 100 DEG C, baked for 35-60 minutes, cooled, sorted and packed.

Owner:JUXIANGYUAN HEALTH FOOD ZHONGSHAN

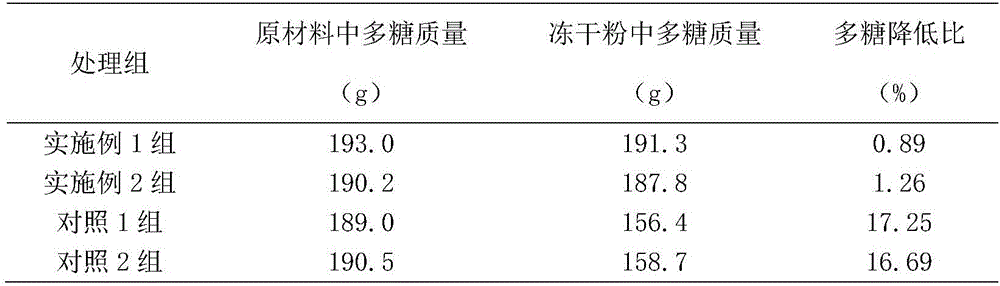

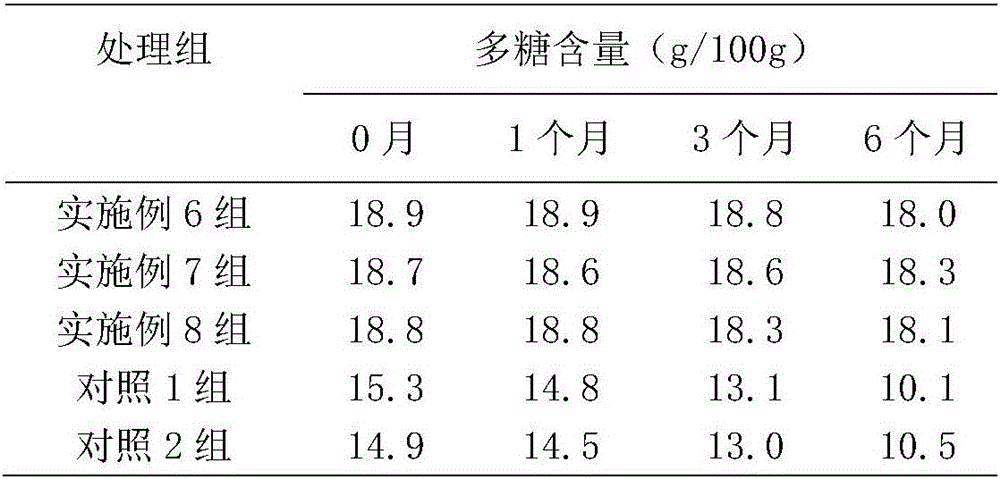

Process for preparing dendrobium officinale freeze-dried powder

ActiveCN106421414AEnriched active ingredientsKeep the original tastePowder deliveryPill deliveryFreeze-dryingSolvent

The invention discloses a process for preparing a dendrobium officinale freeze-dried powder. The process comprises the following steps: (1) preparing a raw material, namely, washing dendrobium officinale which meets standards with water, removing impurities, and bleaching with purified water; (2) dicing, namely, cutting the dendrobium officinale into segments of 2-4cm by using a machine; (3) crushing and pulping, namely, crushing and pulping by using pure water in a solid-liquid ratio of 1g:(80-120)ml, screening by using a net of 28-32 meshes, and collecting filtrate; (4) performing vacuum drying, namely, performing pre-freezing on the pulp at minus 18 DEG C to minus 20 DEG C over night, performing vacuum freeze-drying for 16-22 hours, and finally sublimating for 12-18 hours; (5) crushing, tidily crushing the freeze-dried powder obtained in the step (4), and screening granules by using a net of 70-90 meshes, thereby obtaining the dendrobium officinale freeze-dried powder. Compared with the prior art, the process disclosed by the invention is simple to operate, scientific and reasonable in step, free of solvent pollution or residue in the preparation process of the dendrobium officinale freeze-dried powder, low in preparation temperature, and capable of ensuring that bioactivity of functional substances of the dendrobium officinale is not lost.

Owner:NANJING XIYUAN BIOPHARML SCI & TECH

Corn cake and method for producing the same

InactiveCN101467540AFull of nutritionRich in nutrientsDough treatmentBakery productsAdditive ingredientCorn flour

The invention discloses a kind of corn cake with diversity of raw materials and rich nutrient, and its production method, pertaining to products acquired from cereal containing starch. The cake is made of the following raw materials: corn flour, millet flour, buckwheat flour, sorghum flour, soya bean flour, egg liquid and leaven. The minor cereals in raw materials are processed for removing smell, fermented by leaven and made into the flour paste; the flour paste is poured into a mold, baked in an oven and checked after refrigeration; qualified products are packaged and enter a warehouse. The minor cereal flour produced in the invention has good taste, strong elasticity, and remains primary taste; because of low processing temperature when removing smell, nutrients lose little; the invention improves the reasonableness and availability of nutrients in food, and plays an important role in people's good health and long life.

Owner:TIANJIN ZHONGYING HEALTH FOOD

Production method of zanthoxylum oil

InactiveCN103749742AKeep the original tasteRich in nutrientsEdible oils/fatsZanthoxylum leprieuriiVegetable oil

The invention discloses a production method of zanthoxylum oil. The method comprises the following steps: selecting dried zanthoxylum and vegetable oil; baking and sauting the vegetable oil for 10-60 minutes at 60-100 DEG C, adding the dried zanthoxylum accounting for 6-12wt% of the vegetable oil when cooling the vegetable oil to 50-80 DEG C and maintaining for 2-10 minutes so as to obtain mixed oil; adding the mixed oil obtained in the mixing and sauting manner into an oil presser, maintaining the temperature within 70-100 DEG C and performing initial squeezing so as to obtain the zanthoxylum oil; performing preliminary filtration on the initially-squeezed zanthoxylum oil by using a filter screen so as to filter a majority of impurities; introducing the zanthoxylum oil subjected to the preliminary filtration into a vacuum filter; performing filtration on zanthoxylum oil again under the condition that the oil temperature is maintained within 75 DEG C to 105 DEG C so as to improve the filtration efficiency; adding the zanthoxylum oil subjected to the vacuum filtration into a centrifugal oil filter and performing rotating precipitation and filtration again, thereby obtaining the zanthoxylum oil. The method is high in production efficiency, wide in raw material resource, low in cost and pure in zanthoxylum oil taste.

Owner:安顺市西秀区百岁陈德文牌食品加工厂

Bagged soaking coarse food grain tea and its producing process

The present invention belongs to beverage and especially bagged coarse food grain tea and its production process. During the production process, various kind of coarse food grain, including barley, corn, millet, buckwheat, kaoliang, etc is roasted in roaster at 100-500 deg.c for 30-90 min, crushed in crusher to size smaller than 3 mm, granulated and bagged. Different kinds of coarse food grain may be also combined. The bagged coarse food grain tea is delicious and fragrant and has rich nutrients.

Owner:卢新秋

Nourishing rice flour product and method for processing the same

The invention discloses a nutrious rice noodle product and its production method, pertaining to noodles such as macaroni, flat bar-shaped noodles or noodles with other shapes. The product is mainly composed of rice flour, wheat flour, corn powder, soybean powder and gluten powder; the rice flour, wheat flour and processed corn powder and soybean powder are evenly mixed in a dough kneading machine, added with water and stirred evenly to get raw meal; the raw meal is delivered into an extruder to produce into strips after cooking, and cooled by water; the cooled dough strips are produced into rice noodle products with shapes of macaroni, shell, screw, osmanthus fragrans and so on by different molds of the forming machine, and cut into segments with equidistant length, then dried to get the products. The nutrious rice noodle has numerous raw materials and abundant nutrients, plays an important role in maintaining the human body nutrient balance, good health and long life of people, also increases a new variety to the rice product processing enterprise.

Owner:TIANJIN ZHONGYING HEALTH FOOD

Orange peel chewable tablet

InactiveCN102462761AEasy to carry and useIncrease the way of takingDigestive systemPill deliveryPeppermintsNutrient

The invention discloses an orange peel chewable tablet, which is characterized by being prepared from coarse orange peel powder serving as a main component, mannitol, cane sugar, xylitol, lactose aspartame, a peppermint essence, citric acid, malic acid, starch and cellulose serving as auxiliary materials, superfine silica gel powder serving as a flow aid and magnesium stearate serving as a lubricating agent. In a preparation method, the orange peel chewable tablet is prepared by adopting a dry tableting method or wet tableting method. In the invention, the chewable table is prepared by taking orange peel as a main component and is convenient to carry and use, and a taking way of the orange peel is increased; and the orange peel processed by performing freeze drying in vacuum has the advantages that: the original taste of the orange peel is kept, the nutrient components in the orange peel are protected to the maximum extent, and the bioavailability of the orange peel is increased.

Owner:DALIAN CHUANGDA TECH TRADE MARKET

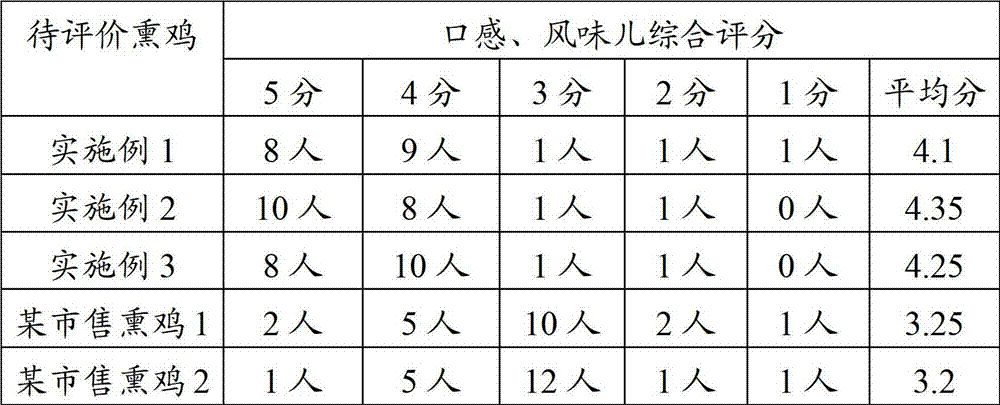

Preparing process of smoked chicken

The invention discloses a preparing process of a smoked chicken. The preparing process comprises the following steps of: firstly, carrying out rolling and pickling on a chicken in a seasoning solution with a specific formula; then, adopting a two-step drying manner including first low temperature drying and second high temperature drying; then, steaming and smoking; and finally, selectively coating sesame oil, and packaging in vacuum, sterilizing at a high temperature to prepare the finished-product smoked chicken. The preparing process adopts the seasoning solution with the specific formula to prepare so that the flavor of the smoked chicken is good; the two-step drying manner including first low temperature drying and second high temperature drying is used for drying so that water in the smoked chicken is more completely evaporated; and the water boiling is replaced by steaming so that the original taste and flavor of the chicken are kept, the nutrition is prevented from being lost, and the chicken is relatively tough; and furthermore, the preparing process is simple to operate and is sanitary and safe.

Owner:SHANDONG FENGXIANG

Meat substitute stuffing dessert and preparation method thereof

InactiveCN104206485AWell mixedAvoid churnBakery productsFood preparationNutritive valuesVegetarian diets

The invention provides a meat substitute stuffing dessert and a preparation method thereof. The meat substitute stuffing dessert comprises main materials and auxiliary materials, wherein the main materials comprise edible mushrooms, textured soybean protein, soybean protein isolate, starch, konjaku flour, edible oil and edible salt. The preparation method comprises the following steps: washing the edible mushrooms, soaking and dicing into small blocks; then stirring and blending the components of the edible mushrooms, the textured soybean protein, the soybean protein isolate, the konjaku flour and the like in a chopping mode, then encrusting, steam cooking, quickly freezing and packaging to obtain the meat substitute stuffing dessert. The preparation method of traditional dessert is changed, and the vegetable diet food materials of the edible mushrooms, the konjaku flour and the like are added to the dessert, so that the nutritional value of the dessert is improved, and the vegetable diet characteristic of the meat substitute stuffing dessert can also be used for preventing and curing a plenty of modern diseases.

Owner:井冈山井祥菌草生态科技股份有限公司

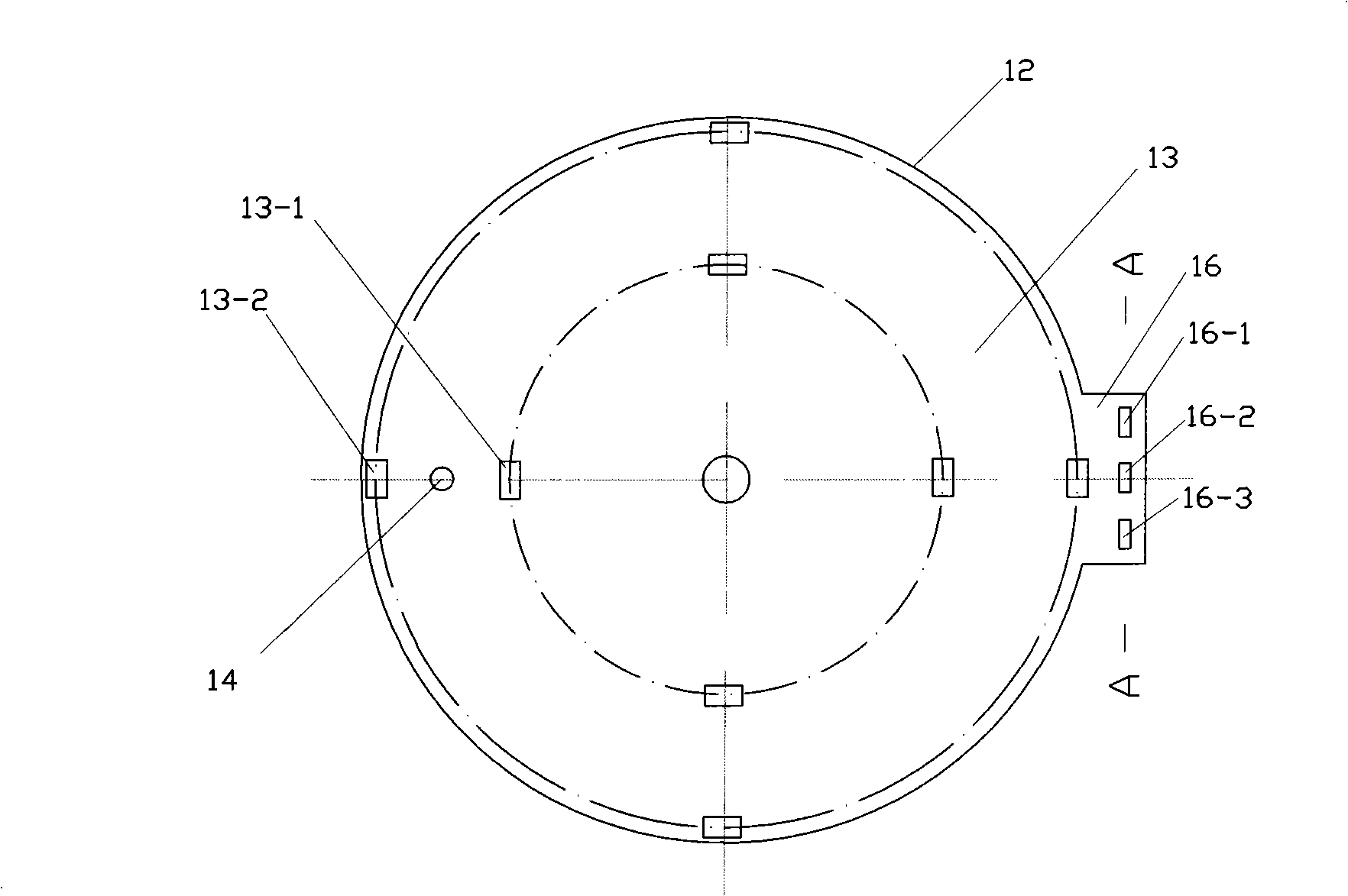

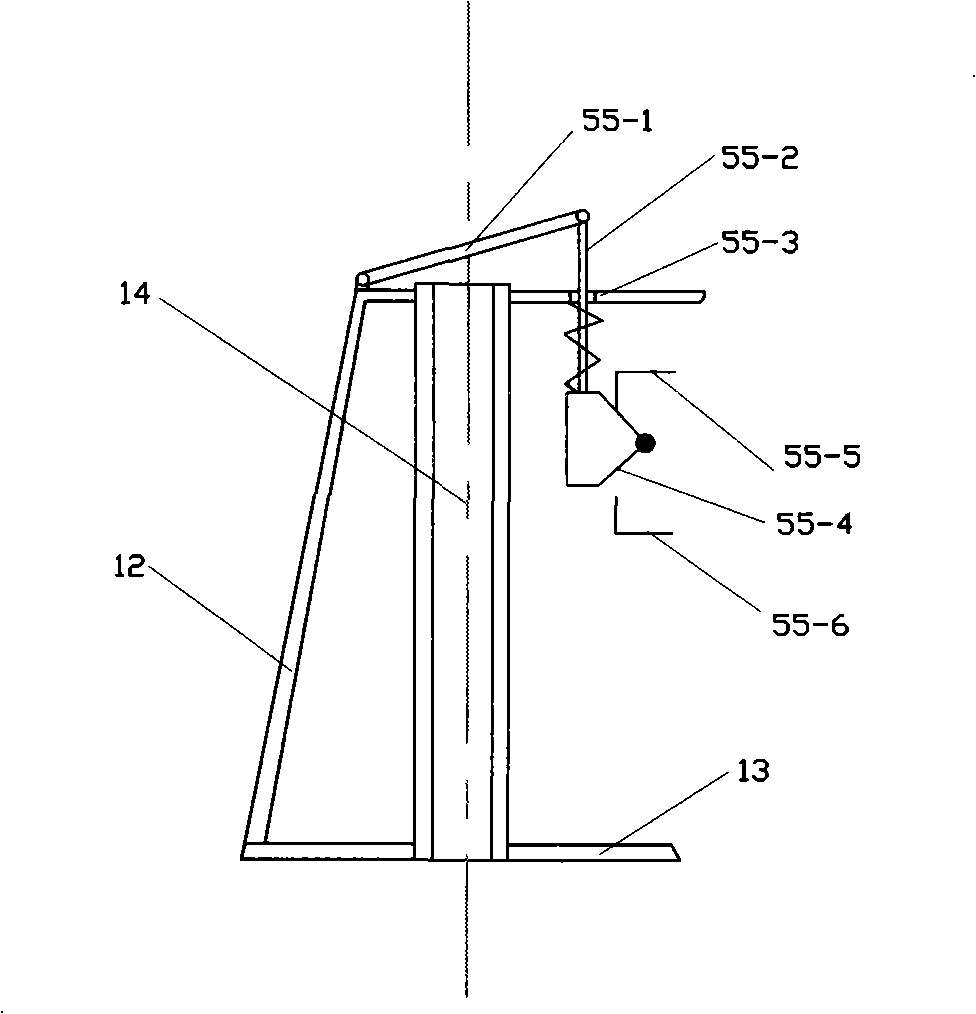

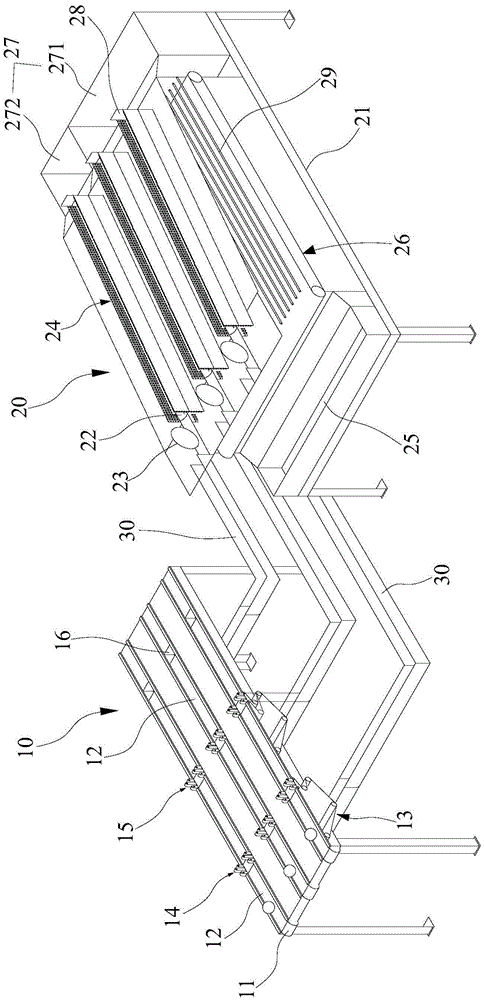

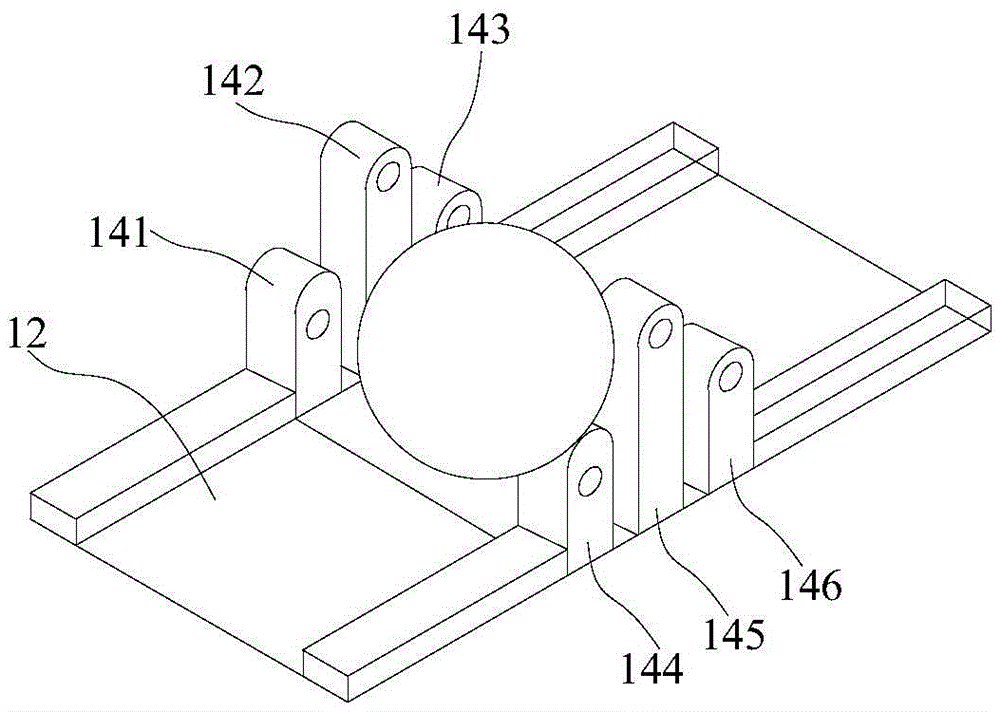

Continuous litchi classifying and peeling machine

ActiveCN105124723AKeep the form intactKeep the original tasteVegetable peelingGradingControl systemLychee fruit

The invention relates to the technical field of food processing equipment, and provides a continuous litchi classifying and peeling machine. The continuous litchi classifying and peeling machine comprises a classifying and screening device, a peeling device, track devices and a control system, wherein the classifying and screening device comprises a first work table, one or more classifying tracks, one or more level sensors, and transporting structures, wherein opening passages are also formed in the forefront in the advancement directions of litchis on the classifying tracks; the peeling structure comprises a second work table, at least two peeling tracks, cutting knives and tearing knives, wherein a litchi peel collecting tank is arranged at one ends of the at least two peeling tracks, a first transmission device which is used for transmitting litchi peel into the litchi peel collecting tank is arranged under the tearing knives, and a litchi collecting tank is formed in the other ends of the at least two peeling tracks; each transporting structure communicates to the corresponding peeling track through a corresponding track device, and the opening passages also communicate to the corresponding peeling track through the track devices. According to the continuous litchi classifying and peeling machine disclosed by the invention, the peeling efficiency is greatly improved, the operation is convenient, realization of automation is facilitated, and industrialized production is convenient.

Owner:SHENZHEN POLYTECHNIC

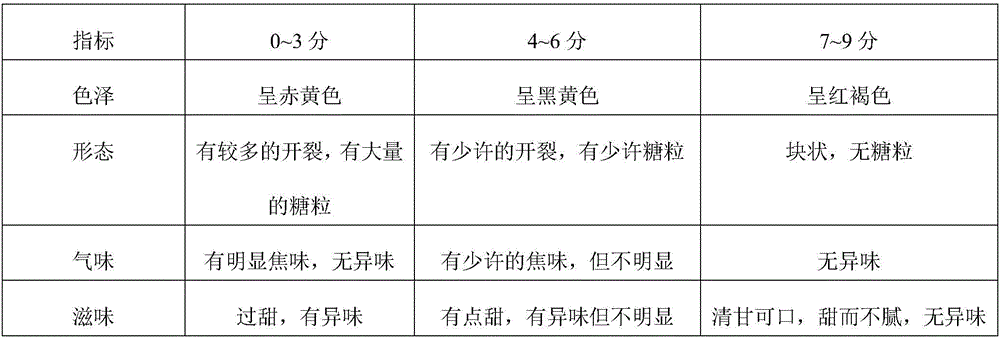

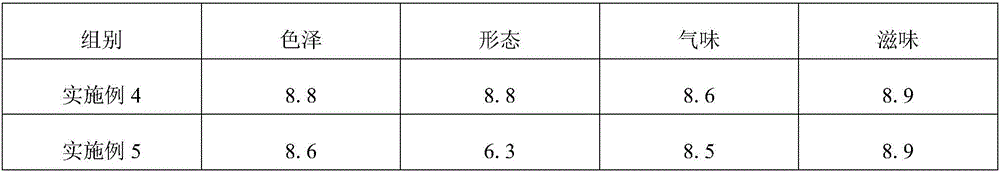

Preparation method of ancient-process brown sugar

The invention belongs to the field of food processing, and in particular, relates to a preparation method of ancient-process brown sugar, wherein the preparation method includes four steps of juice extraction, high vacuum evaporation processing, viscosity reduction processing, and high-vacuum low-temperature sugar boiling; the preparation method has the advantages of short sugar preparation time, high production efficiency, and low manufacturing cost, and is suitable for industrialized production and application; the ancient-process brown sugar obtained by the preparation method retains the original juice and flavor of sugarcane, and has the advantages of high nutritional value, low water content, difficult moisture regaining, and high stability, and facilitates preservation; the ancient-process brown sugar is pure, sweet and delicious, is sweet but not greasy, and also has the efficacies of dispersing cold and warming stomach, promoting blood circulation to remove blood stasis, tonifying spleen and warming stomach, nourishing qi and blood and the like.

Owner:广东橘香斋大健康产业股份有限公司

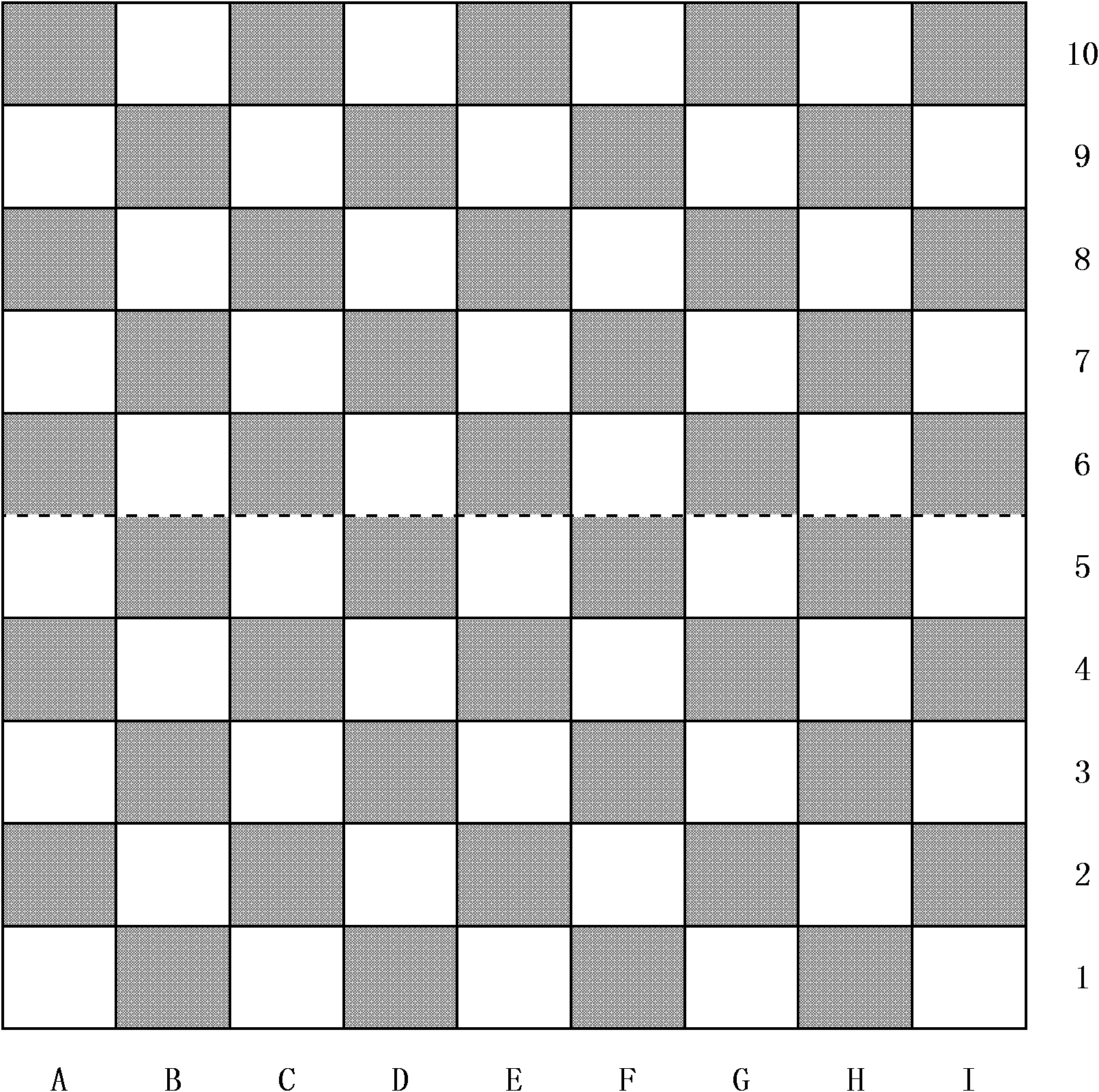

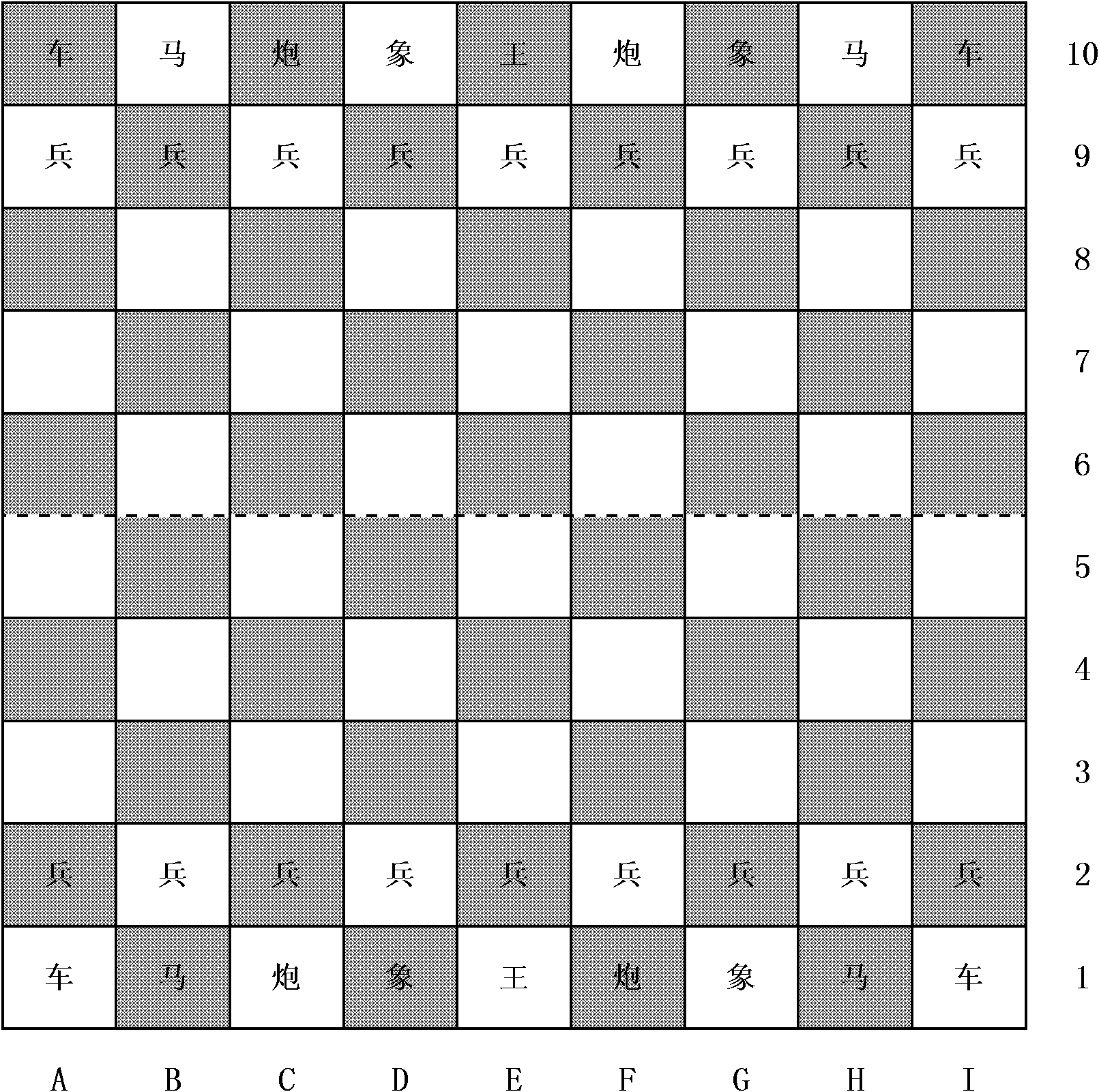

World chess

The invention discloses a world chess. Chessboard space of Chinese chess is adopted, chess foothold is changed into check from point, and one virtual line at the middle of the chessboard is used for substituting the original great 'the border of two opposing powers', the linear chessboard of Chinese chess is improved to be internationally universal check chessboard, 'cannon' of the Chinese chess is introduced in, and the moving rule thereof is changed into playing rule applicable to international chess, the advantages of the two chesses are combined, thus being changeable and interesting; besides, the invention can realize 'one chess with dual purposes', the chessboard thereof can be taken as the changed chessboard of Chinese chess, the chess pieces can substitute all the chess pieces of Chinese chess, thus being used as Chinese chess compatibly, so that people who like Chinese chess can have fun when playing Chinese chess in check, and meanwhile check type chessboard is more consistent with aesthetic standard and playing habit of westerner, thus being beneficial to international popularization of Chinese chess. The invention is easy to popularize and is applicable to both national use and international use.

Owner:曾进

Steamed lotus-flavored beef and making method thereof

InactiveCN102763852AGood effect of removing fishy smellIncrease the fragranceFood preparationFresh waterFood flavor

The invention provides a making method of steamed lotus-flavored beef. The making method includes cleaning, soaking, rubbing, steaming with lotus leaves, packaging and sterilizing. During steaming, beef is covered with condiments and cushioned with the lotus leaves, and steaming spices are added in fresh water. The steamed lotus-flavored beef retains natural flavor of beef, has strong flavor of the lotus leaves, is soft, smooth and cool in taste and delicious, has lasting aftertaste and fresh color, and is appetizing.

Owner:BENGBU FENGMU BEEF & MUTTON PRODS

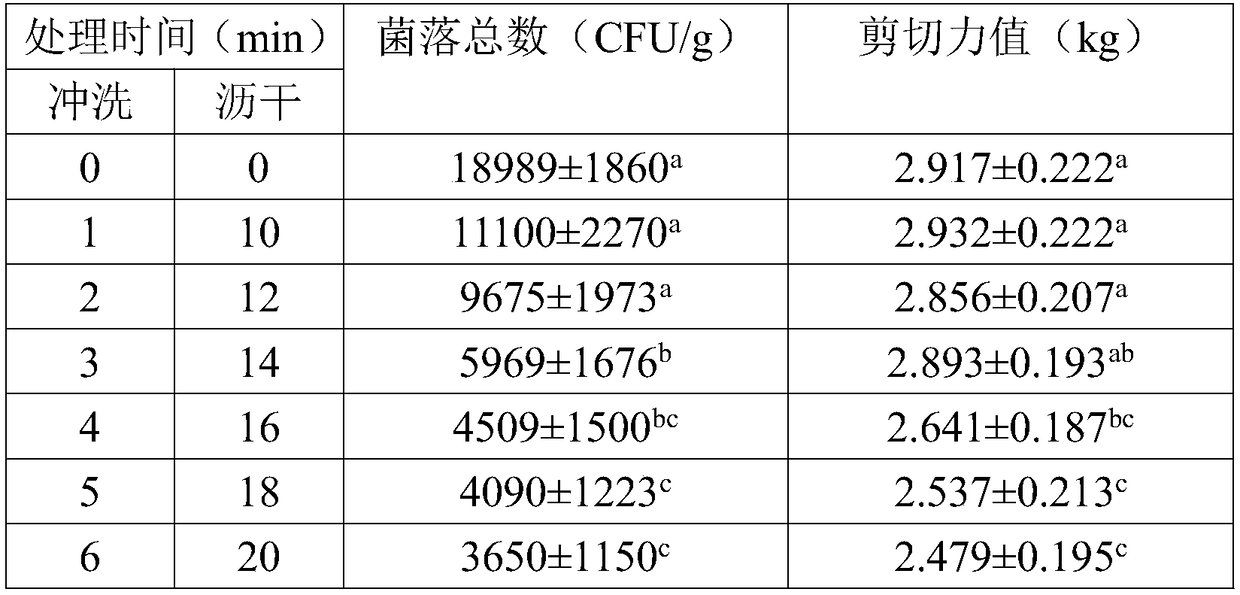

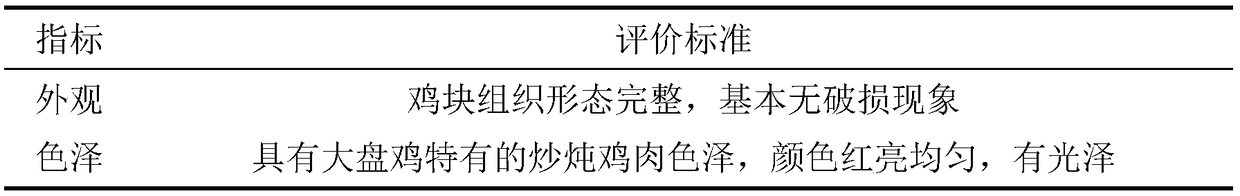

Standardized processing method of instant chicken dish

InactiveCN108651874AImprove the taste of meatKeep the traditional flavorFood thermal treatmentFood ingredient as flavour affecting agentFlavorPre treatment

The invention provides a standardized processing method for an instant chicken dish, and belongs to the technical field of food processing. The standardized processing method includes the following operating steps: pretreatment, flavoring powder preparation, pickling agent preparation, rolling-kneading type pickling and vacuum packaging. Chicken is used as the main ingredient, and is subjected torolling-kneading type pickling combined with the flavouring powder and the pickling agent, vacuum packaging and high-pressure sterilization. The invention adopts the sterilization technology with slightly acidic electrolytic water from the source of raw materials to ensure the safety of the raw materials, and ingeniously uses the vacuum packaging sterilization technology and high-temperature and high-pressure steam sterilization technology, so that the standardized processing method is convenient, safe and highly-efficient, capable of improving the meat texture and mouthfeel, retaining the original flavor of chicken without needing the traditional stir-frying and stewing processes and retaining the original active ingredients and nutritional value of the raw materials by blending with theflavorings. The instant chicken dish is fine and smooth in meat texture and unique in flavor.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

Making method of ready-to-eat dumplings with water retention layers

InactiveCN105495307AAchieving the purpose of hard-to-eat dumplingsExtended shelf lifeFood ingredientsReady to eatProtein materials

The invention belongs to the technical field of food processing, and provides a making method of ready-to-eat dumplings with water retention layers. The ready-to-eat dumplings are particularly suitable for being eaten at stations or in travel and suitable for white-collar workers and field staff. The method comprises the following steps of dough blending, filling preparing, water retention layer material adding, making, bagging, vacuum packing and back pressure sterilization, wherein water retention layer materials are put on the inner surface of each dumpling and / or the outer surface of each dumpling filling, and the water retention layer materials are formed by mixing the soybean isolated protein material with glycerin or by mixing chitosan polysaccharide materials and the glycerin. Finished dumpling products are cooked dumplings, the products can be stored at normal temperature and eaten after bags are opened. The made ready-to-eat dumplings can be eaten after the bags are opened or eaten after being heated. Due to the fact that the water retention layer materials are put inside dumpling wrappers, the dumpling filling can maintain rich water content for a long time, the dumplings are delicious and succulent, and the ready-to-eat dumplings are ready-to-eat products which have great market development potential.

Owner:JILIN UNIV

Wolfberry fruit paste and production method thereof

The invention provides a production method of wolfberry fruit paste. The production method comprises the following steps: step A, mixing wolfberry fruits with water, then crushing, wherein the mass ratio of the water to the wolfberry fruits is (1.8-2.5) to 1, and then collecting liquid for later use; and step B, heating the liquid until the liquid is boiled, then boiling the liquid at 150-250 DEG C for 2.5-3.5 hours, stopping heating and airing for 1.5-2.5 hours, boiling the liquid at 150-250 DEG C for 1-2.5 hours, stopping heating and airing for 7-9 hours, and finally, continually boiling at 80-120 DEG C for 18-23 minutes to form the paste. The production method of the wolfberry fruit paste is simple to operate and convenient for production; and the prepared wolfberry fruit paste is convenient to use, and has very wide application so that the probability of obtaining nutrients from the wolfberry fruit paste by people is increased. Furthermore, the invention further relates to the wolfberry fruit paste prepared by the production method.

Owner:YINCHUAN HUIHUIXIANG FOOD CO LTD

Process for preparing okra seed oil

InactiveCN104450165AKeep the original tasteMellow fragranceFatty-oils/fats productionEngineeringChemical residue

The invention discloses a process for preparing okra seed oil. The method comprises: sequentially performing seed sorting, washing, seed frying, seed breaking and precise squeezing treatment, wherein in a seed frying process, the final pan temperature of the okra seeds is ensured to 95-120 DEG C; in a seed breaking process, the fried okra seeds are broken in a double-roller grinding manner, and the seed breaking rate is controlled to 50-60%; in a precise squeezing process, a horizontal oil press is adopted, and the thickness of a final oil discharge cake is guaranteed to 1-1.5cm; the process for preparing okra seed oil designed in the invention has the advantages of physical pressing and chemical leaching, no chemical agent is used, thus no chemical residue is generated, the original taste and flavor of okra are kept, the fragrance is mellow, the abundant nutritional ingredients of the okra are not broken, and meanwhile the oil yield is greatly improved.

Owner:DAFENG FENGHUA XIANNONG AGRI

Fermented beef jerky product and manufacturing method thereof

InactiveCN106071913ASolve the shortcomings of hard textureTextured hard imperfections to avoidFood sciencePutrefying bacteriaNitrite

The invention discloses a fermented beef jerky product and a manufacturing method thereof. The fermented beef jerky product is prepared from 10 kg of tendon beef, 50 g of salt, 50 g of white sugar, 10 g of glucose, 50 g of ground black pepper, 10 g of ajinomoto, 50 g of fresh ginger, 50 g of onion, 50 g of light soy sauce, 0.02 g of nitrite and 20 g of papain. The manufacturing method comprises the steps of raw beef trimming, leavening agent preparation and activation, raw beef curing, raw beef fermentation, fermented beef jerky drying, fermented beef jerky maturing, fermented beef jerky aseptic packaging and storage and the like. The fermented beef jerky product has the advantages that the traditional beef jerky quality, taste and flavor are improved, the color is more bright, original color and taste are kept, the beef jerky normal temperature preservation time is prolonged, nutritional ingredients can be easily absorbed by people in the fermentation process, putrefying bacteria are effectively retrained from growing, and production and processing are not limited by seasonality.

Owner:额敏县新大同创生物工程有限责任公司

Preparation method of pickled rutabaga

InactiveCN103300322AKeep the original tasteStrong sauceFood preparationTraditional Chinese medicineAdditive ingredient

The invention discloses a preparation method of pickled rutabaga. In a preparation process, rutabaga, chayote and white radish are sterilized by using an ozone water solution, so that the quality guarantee period can be effectively prolonged; a vacuum freeze-drying process is adopted, so that the original taste and flavor of the rutabaga, the chayote and the white radish can be well kept and the nutrition of the rutabaga, the chayote and the white radish cannot be destroyed; traditional Chinese medicine liquid can be uniformly permeated into all parts of the rutabaga, the chayote and the white radish, so that the nutrition content of the rutabaga, the chayote and the white radish is increased; the pickled rutabaga is fresh, tender, tasty and rich in flavor, keeps the natural nutrition ingredients of the rutabaga, the chayote and the white radish, is convenient to store and eat, and meets the demands of different crowds.

Owner:吴东

Method for boiling grains or beans and automatic boiling machine suitable for same

InactiveCN102090548AReduce exposure timeReduce the degree of oxidationBeverage vesselsFood preparationControl circuitThermal water

The invention provides a method for boiling grains or beans. The method comprises the following steps of: adding water into a container for heating, and putting the grains or beans into a grinding device; when the water is heated to hot water with the temperature between 68 DEG C and 90 DEG C, starting the grinding device to grind the grains or beans into powder particles with a selected finenessdegree; putting the powder particles into the container; continually heating and stirring; after heating to 94-99 DEG C, stopping heating; when the temperature of the mixture falls by 1-3 DEG C, reheating; and heating repeatedly 12-16 times to form a boiled pasty mixture. The method has the advantages of simple procedure, great reduction in the loss of nutrients, obtaining of optimal mouthfeel and high nutrition value. The invention also provides an automatic boiling machine suitable for the method. The machine comprises a kettle body, a control circuit, a temperature sensor, a heating pipe and a handpiece, wherein the handpiece is detachably connected with the kettle body; a handpiece cover is provided with a shifting device and a storage tank; and a handpiece lower cover is provided with a movable opening and closing door and a driving mechanism. The machine is convenient to operate and is simple and quick.

Owner:GUANGDONG LUBY ELECTRONICS

Chicken flavor material and preparation method thereof

The invention discloses a chicken flavor material and a preparation method of the chicken flavor material. The chicken flavor material comprises the components of chicken, a chicken bone, an egg, chicken fat, water, protease, compound flavor protease, glucose, white sugar, xylose, vitamin B1, L-cysteine, methionine, salt, aginomoto, corn starch and maltodextrin. The prepared chicken flavor material keeps the original taste and flavor of the natural chicken to the highest extent, the delicate mellow flavor is greatly improved, the taste is real, the aftertaste lasts long, the chicken flavor material is excellent in heat stability, only 10% of the chicken flavor material is denatured after being sterilized at the temperature of 121 DEG C, and the technological requirements in thermal treatment in the food industry are met.

Owner:HUNAN JIAPIN JIAWEI BIOTECHNOLOGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com