High-efficiency energy-saving automatic roasted seeds and nuts producing system

A production system, high-efficiency and energy-saving technology, applied in food processing, application, food preparation, etc., can solve the problems of uneven moisture content of products, long cooling time, and easy damage to the film of products, to eliminate residual bacteria, improve production efficiency, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

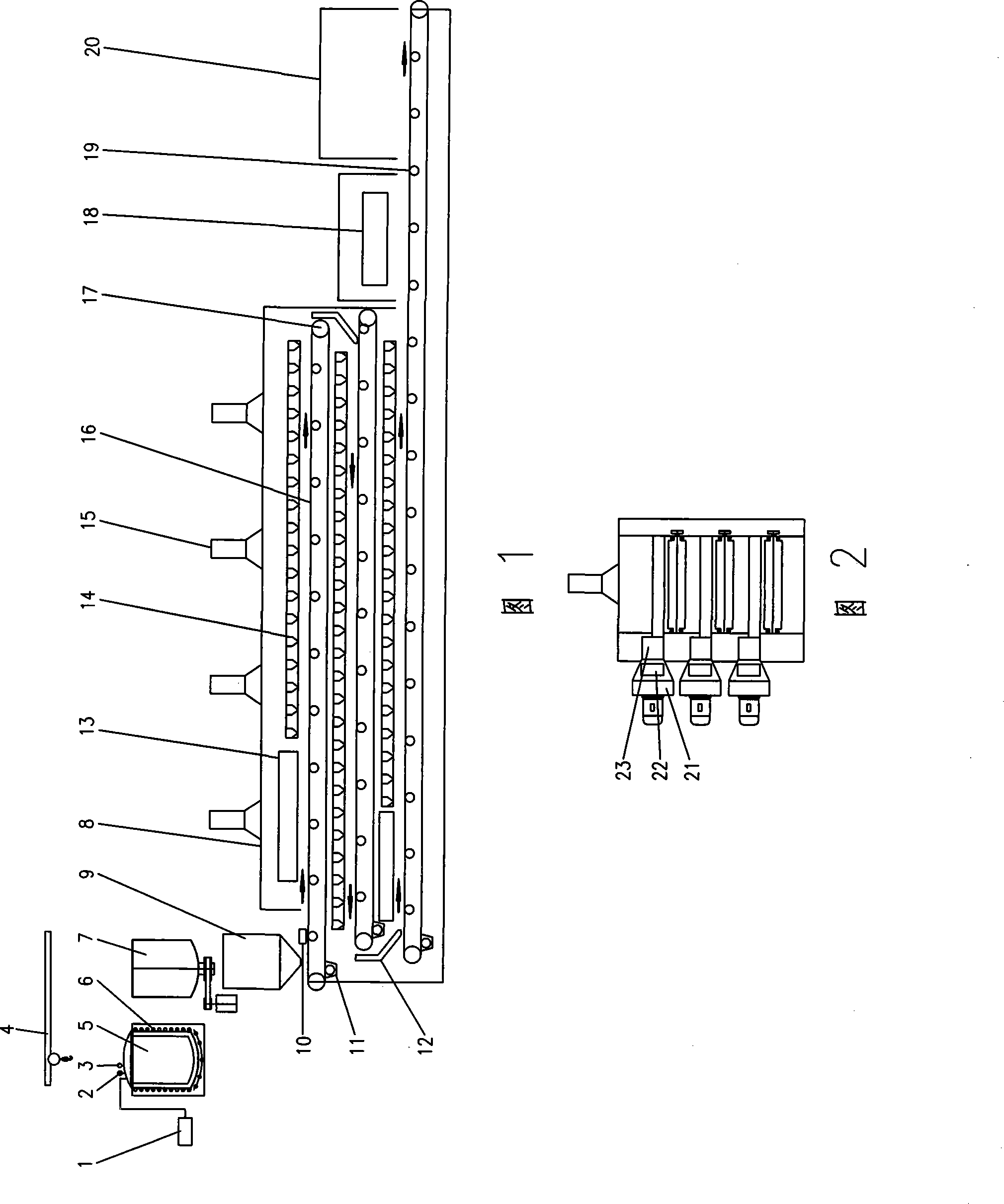

[0017] Referring to Figure 1 and Figure 2, a high-efficiency energy-saving automatic roasted seeds and nuts production system includes a cooking device, which includes a cooking container 5 and a heater 6 for heating the cooking container 5, and is equipped with a pump 1 and a pressure gauge 2 and temperature gauge 3 to monitor the temperature and pressure of the product in the cooking container 5. After the product is cooked by the cooking device, it enters the dehydrator 7 through the hoisting device 4, and a feed bin 9 is installed below the dehydrator 7. The product from The outlet below the dehydrator 7 enters the silo 9, and the product is transported from the outlet below the silo 9 to the conveyor belt 16 of the dryer 8; the dryer 8 is equipped with three layers of conveyor belts 16, and each layer of conveyor belt 16 are all supported and drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com