Patents

Literature

297 results about "Rice product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Milling by-products. The main by-products of rice are rice husk or hull, rice bran, and brewer’s rice. Rice husks or hullsare generated during the first stage of rice milling, when rough rice or paddy rice is husked. Rice bran is generated when brown rice moves through the whiteners and polishers.

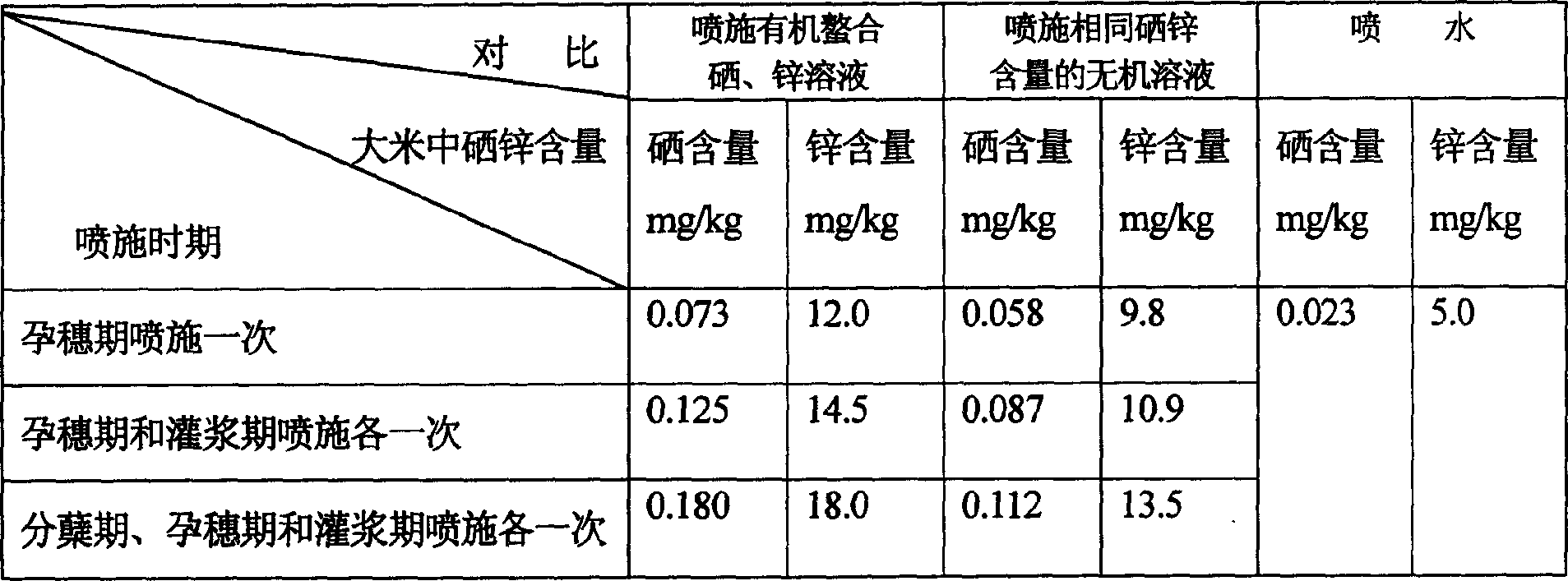

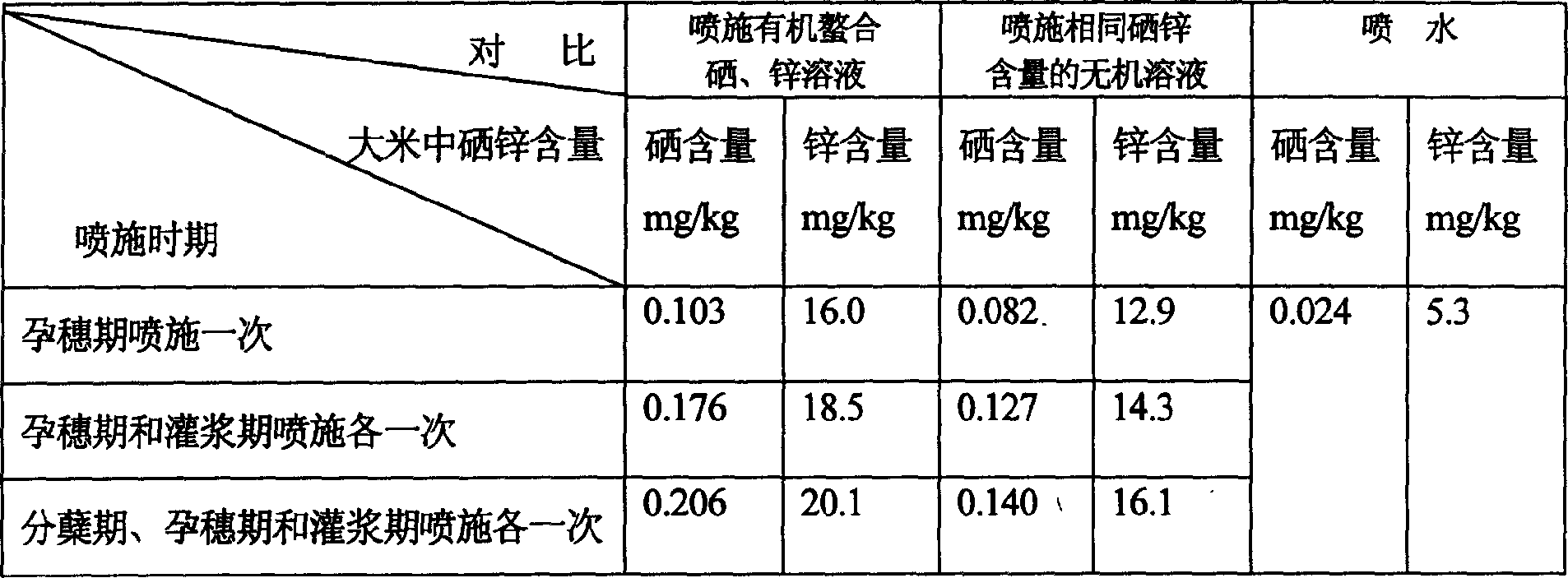

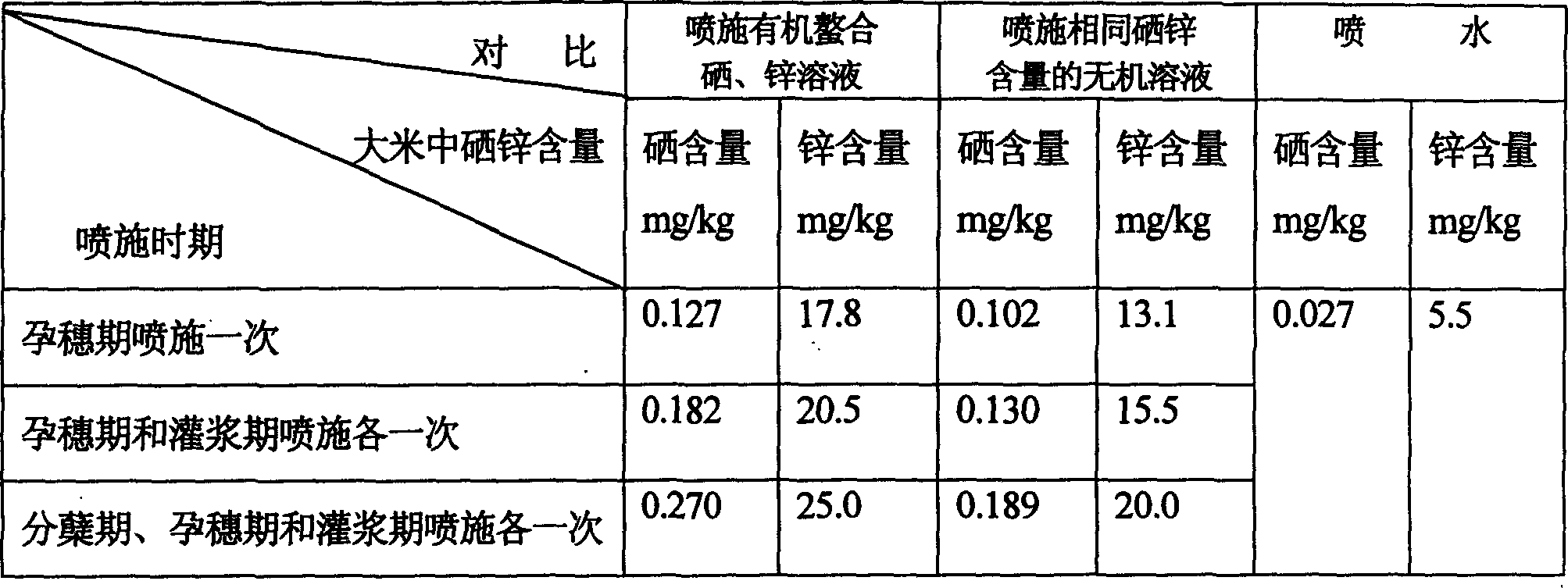

Nutritious rice with rich organic selenium and zinc and its production process

The nutritious rice with rich organic selenium and zinc is produced through diluting organic selenium and zinc chelating agent solution containing selenium in 3.56-7.12 g / kg and zinc in 45.30-67-94 g / kg in the amount of 200 g / mu with water in 150-300 times, spraying the diluted solution to rice leaf in the tillering period, booting period and grain filling period of rice for rice to absorb and convert, and other steps. The nutritious rice has selenium and zinc content of 0.070-0.270 ppm and 12-25 mg ppm separately, 2-10 times and 2-5 times higher than common rice product separately. The nutritious rice of the present invention may be used in producing public food for human body to replenish selenium and zinc.

Owner:吴敦虎 +2

Preparation method and product of germinated wheat rich in gamma-aminobutyric acid

InactiveCN103393013AControl Germination EnvironmentHigh nutritional valueFood preparationNutritive valuesTemperature control

The invention discloses a preparation method and product of germinated wheat rich in gamma-aminobutyric acid, and the method is used for solving the problems of bad existing effect and unstable yield since GABA is enriched by utilizing tea and rice products according to an existing method for preparing gamma-aminobutyric acid based on a biological concentration method. The method comprises the following steps of: raw material selection, pretreatment, imbibition, temperature control training and germination termination. Wheat seeds are dramatically taken as raw materials, the improvement of GAD enzyme activity in wheat seeds is effectively promoted by controlling germination conditions, a cultivated substrate and the pH value, and meanwhile the GAD activity is ensured by controlling the pH value, the activity of GABA aminopherase is inhibited, and the content of gamma-aminobutyric acid in germinated wheat is greatly improved, so that the nutritive value of wheat is greatly improved. Experimental results show that the content of GABA in the prepared germinated wheat is 31.08 mg per 100 g at most, and achieves domestic and international leading level of similar methods.

Owner:SICHUAN AGRI UNIV

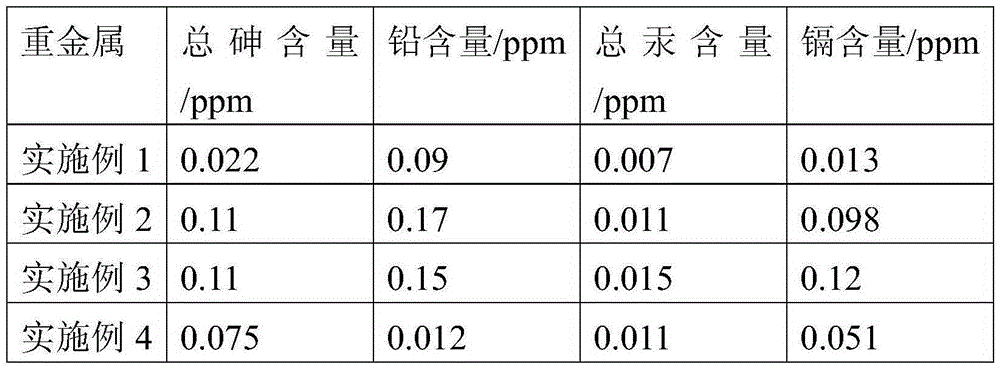

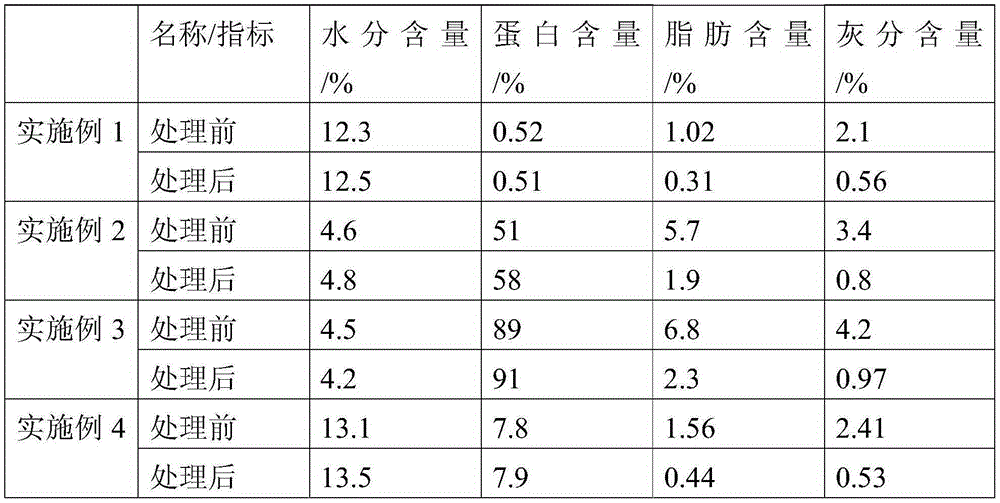

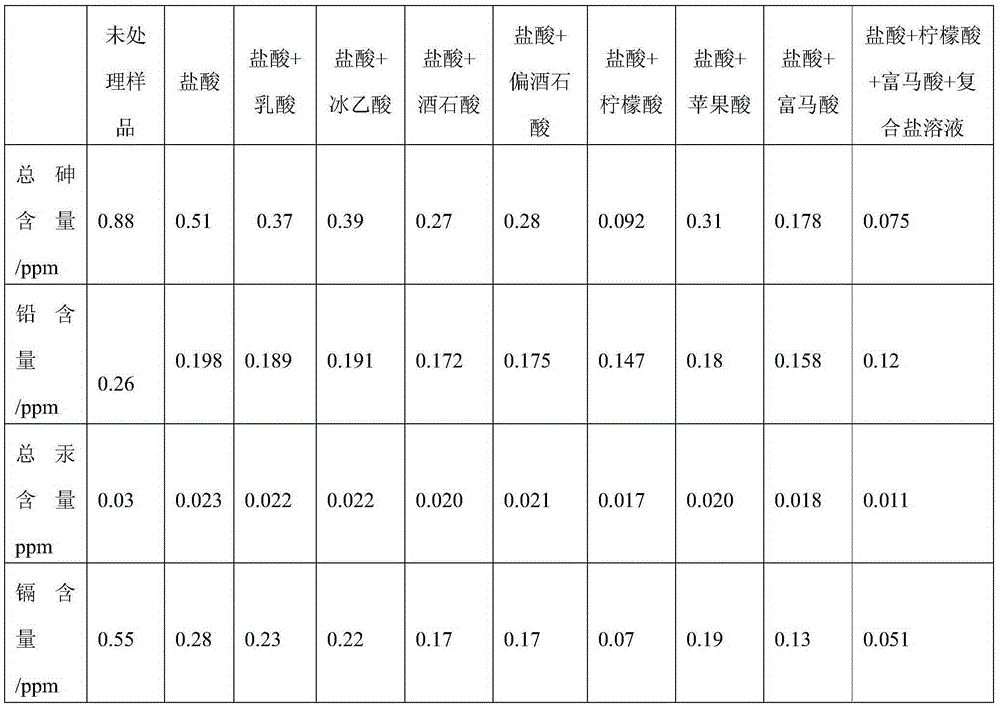

Preparation method of rice products with low content of heavy metal

ActiveCN105410598AImprove plasticityImprove water holding capacityFood scienceRice proteinRotational flow

The invention discloses a preparation method of rice products with a low content of heavy metal. The method comprises the following steps of performing pulp mixing, performing enzymolysis, performing complexing, performing washing separation and performing drying treatment on rice flour or rice protein flour, so that the rice flour or the rice protein flour with a low content of metal is finally prepared. According to the method disclosed by the invention, an enzyme method and a chemical method are used, so that the heavy metal in the rice flour or the rice protein flour is dissociated out in a complexing manner; then solid-liquid separation is performed by a physical method of the stepwise gradient separation of rotational flow, so that the purpose of reducing the content of the heavy metal in the rice flour or the rice protein flour is realized, and a deeply processed product, namely the rice flour or the rice protein flour, with high quality and high added value is prepared. The method is simple to operate and low in cost.

Owner:JIANGNAN UNIV

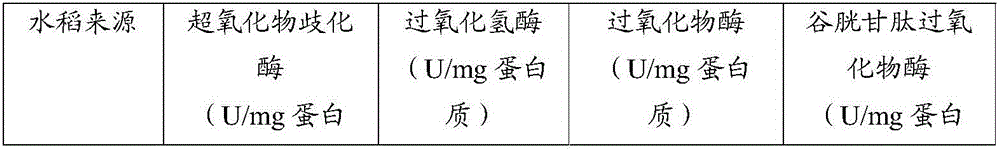

Method and fertilizer for planting high-SOD-content rice

ActiveCN105961104AEasy to synthesizeHigh active contentFertilising methodsNitrogenous fertilisersPaddy fieldRice grain

The invention belongs to the technical field of agricultural plantation, and specifically discloses a method for planting high-SOD-content rice, and also discloses a fertilizer for planting high-SOD-content rice. The method for planting high-SOD-content rice uses a silicon calcium magnesium fertilizer as a base fertilizer of a paddy field, and comprises: spraying a rice tillering stage fertilizer rice tillering stage, spraying a rice flower promoting stage fertilizer in a rice flower promoting stage, spraying a rice flower maintaining stage fertilizer in a rice flower maintaining stage, spraying a rice heading and flowering stage fertilizer in a rice heading and flowering stage, and spraying a rice filling stage fertilizer in a rice filling stage. The method for planting high-SOD-content rice promotes synthesis of four kinds of enzymes of SOD, CAT, POD, and GSH-Px in a rice growth process through applying different fertilizers according to growth characteristics of each growing period of rice, and the enzymes move and transfer into rice grains, and finally, rice products in high-content-SOD and other four enzymes are obtained.

Owner:河南达沃斯巅峰农业科技有限公司

Method for reducing heavy metal content of rice and products thereof

InactiveCN103652514ADifferent degrees of removalImprove securityFood ingredientsFood dryingNational standardHeavy metals

The invention relates to a method for reducing the heavy metal content of rice and products thereof. The method comprises the steps of soaking in alkaline liquid, separation, reaction, washing, drying and the like; the process realizes different degrees of removal effects on aflatoxin and heavy metals such as cadmium, arsenic, lead and mercury, and can effectively reduce the heavy metal content of rice and rice products such as rice noodles, starch, rice protein powder and the like prepared from rice; the method provided by the invention is simple in product, low in production cost and easy to implement; the heavy metal index of the produced product conforms to the requirements of national standard.

Owner:无锡市善源生物科技有限公司

Fermented rice cake and preparation method thereof

The invention relates to a rice product, in particular to a fermented rice cake and a preparation method thereof. The inventor takes more than ten years to study and experiment, and provides a proportion of raw materials of the fermented rice cake, particularly a ratio of rice to water so as to provide a process basis for the preparation of the fermented rice cake. The inventor also provides a preparation method for the fermented rice cake. In the method, the technical key points for grinding rice milk are improved, and the fermented rice milk is heated in a constant-temperature heating mode to shorten the fermentation time of the rice milk, so that the prepared fermented rice cake does not have sour taste, and the technical problem which cannot be solved by persons in the field for a long time is solved.

Owner:陈忠良

Konjak synthetic rice with targeting effect and preparation method thereof

The present invention discloses potential targeting konjak artificial rice and a making method. The potential targeting konjak artificial rice is made from raw materials of coarse cereals raw meals, vegetables and fruits raw meals, rice bran and konjak powders after expansion, grinding, stirring, extruding granulation, air drying or freezing dry, and particles polishing. The artificial rice made through the present invention has the advantages of high fiber, low heat and rich nutrition. The finished rice product has the characteristics of smooth and bright color, diversified colors, good cohesiveness and qualitative sense close to natural rice. The finished product has the advantages of soft taste and unease aging performance, which can be directly eaten and can be processed for eating according to the characteristics of the rice. The artificial rice of the present invention is provided with certain healthy and dietary therapy effects, which takes certain efficacy on the hypertension,the obesity, the diabetes mellitus and the beriberi. The present invention is especially suitable for the demands of various special food populations of militaries, field operators, etc. And the present invention can be applied for people for the long time consumption, who defend or operate at hard supplied places such as plateaus, deserts, islands, fields, etc.

Owner:贵州中山魔芋农业发展有限公司

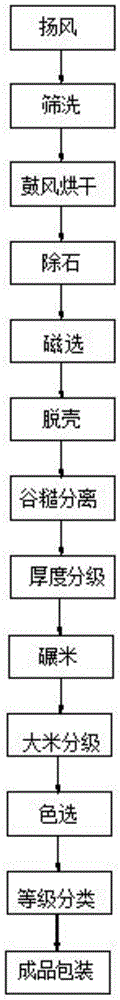

Rice screening method

InactiveCN104668021AGreat tasteImprove cleanlinessCleaning using liquidsGrain treatmentsAdditive ingredientScreening method

The invention discloses a rice screening method. According to the method, thirteen processes, namely blowing, screening and washing, blasting and drying, stone removal, magnetic separation, decldding, husked rice separation, thickness classification, rice milling, rice classification, colour selection, grade separation and finished product package, are adopted for finishing ice processing. According to the rice screening method, all process of a traditional process are optimized, all the steps are simplified, and the quality is ensured; especially a screening and washing process is added, so that dust and other water-soluble impurities can be removed by virtue of screening and washing, so that the rice is relatively clean, the prepared rice and rice chaff are relatively high in cleanliness and the rice product is high in quality and clean; a traditional polishing process is omitted, and a membrane which is rich in microelements at the outer surface of rice is reserved, so that losses of rice nutritional ingredients are prevented and the rice is relatively nutritional; the rice screening method is clear and reasonable in step, high in whole rice rate and high in production efficiency, and the prepared rice is high in nutritional ingredients, good in taste, high in quality and clean.

Owner:ANHUI TIANLI GRAIN & OIL GRP

Glutinous rice product and preparation method thereof

The invention relates to the technical field of food processing, in particular to a glutinous rice product and a preparation method thereof. The glutinous rice product has an improved preparation recipe consisting of 80 to 120 parts of high-quality glutinous rice flour, 10 to 20 parts of corn modified starch, 300 to 400 parts of high maltose syrup, 50 to 70 parts of water and compound improving agents which are 5 to 10 percent of the weight of the glutinous rice flour, wherein wrappers account for 70 to 80 percent of the total weight, and the stuffing accounts for 30 to 20 percent of the total weight. The preparation method comprises the following steps of: preparing wrapper, preparing stuffing, filling stuffing automatically, shaping and processing by smoothening agent; then, carrying out ozone sterilization for 1h; and packing to obtain finished products. The invention is characterized in that through the recipe and the process optimization, the preparation process has high automation degree, and the prepared glutinous rice product has strong water preservation performance, high elasticity, good flavor and rich nutrition and is convenient to eat. The problem that the traditional glutinous rice product has short shelf life and can be easily hardened is solved, and the shelf life of the glutinous rice product can reach more than 6 months.

Owner:东莞市圣心食品有限公司

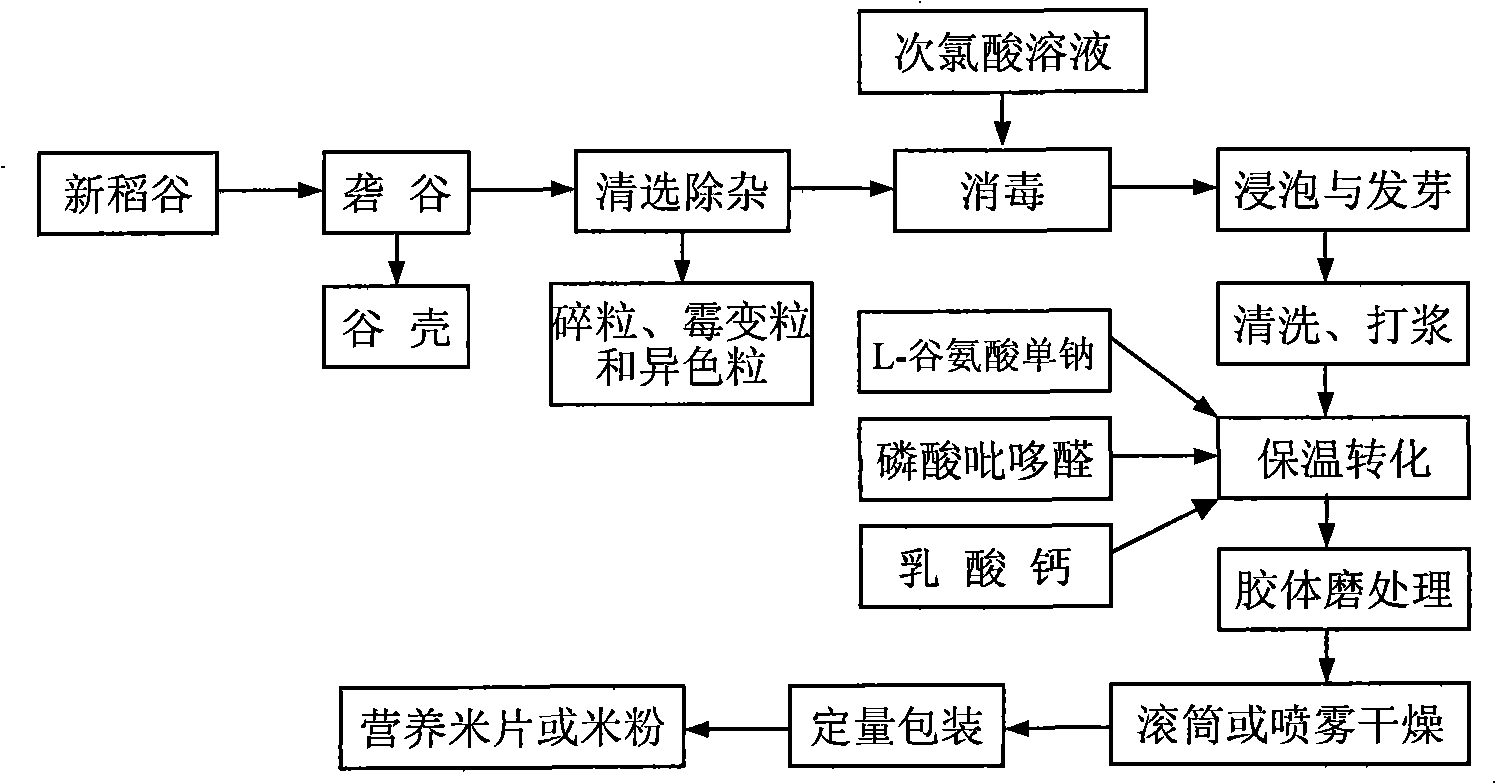

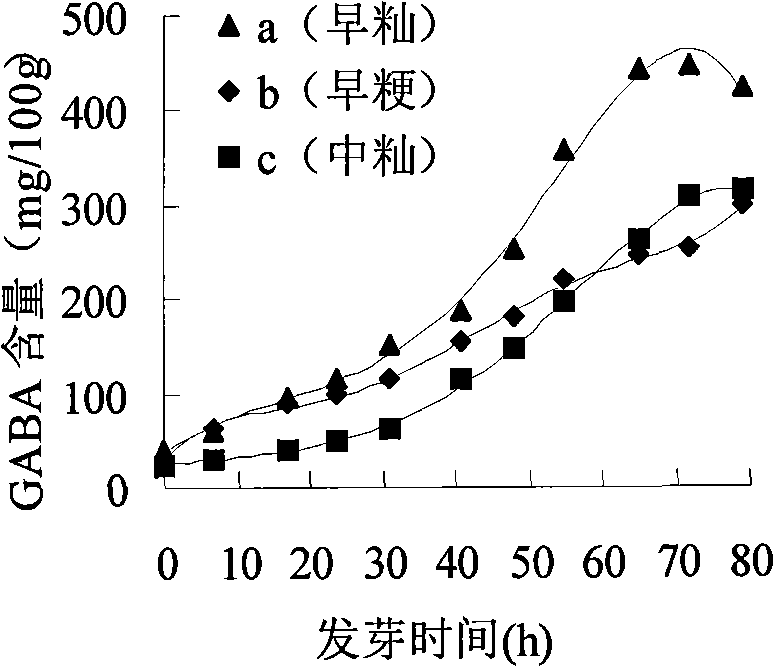

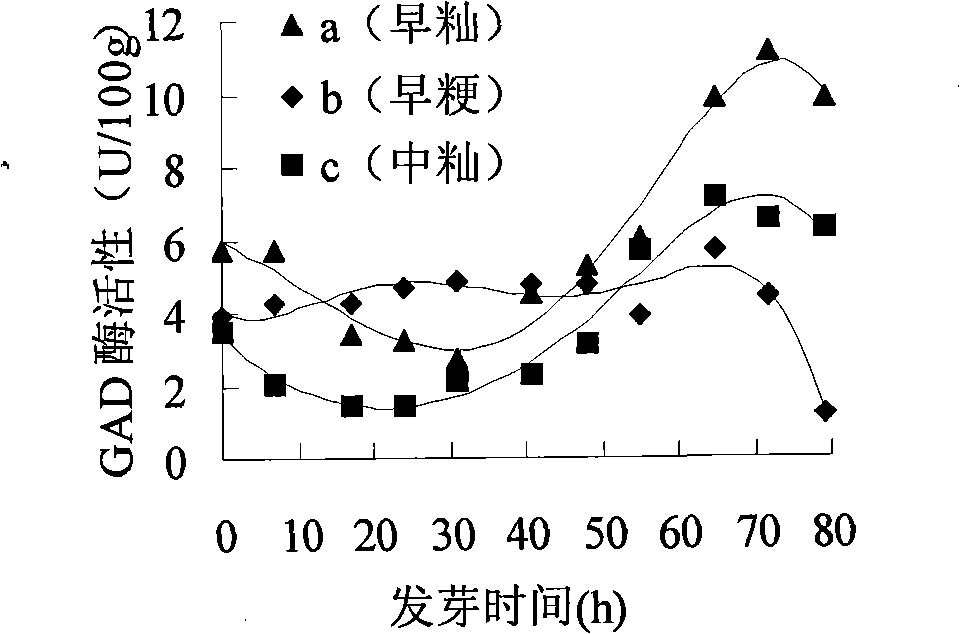

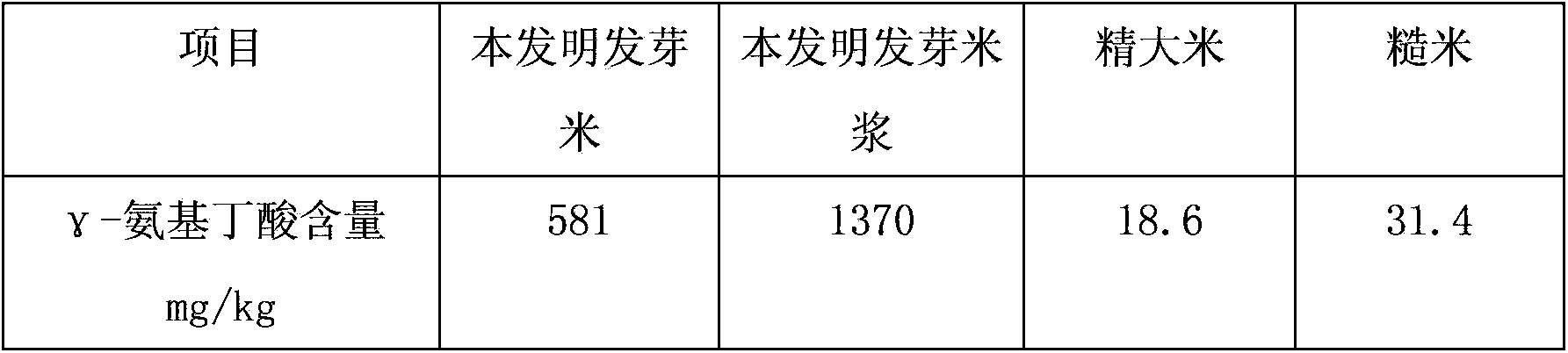

Rice product rich in gamma-aminobutyric acid and method for producing the same

The invention belongs to the technical field of rice deep processing, in particular to a production method of a functional rice product which has a special sweet flavor and is rich in Gamma-aminobutyric acid and a product thereof, the rice product is produced by virtue of the activities of high glutamate decarboxylase, amylase and protease in germinated brown rice of an indica type rice or a non glutinous rice. The invention takes the indica type rice or the non glutinous brown rice as a raw material which carries out the steps of cleaning, disinfection, soaking, germination, cleaning, beating into rice milk, heat insulation, transformation, drum drying or spray drying, and the like, to be produced into functional nutrition rice flake or rice powder which is rich in Gamma-aminobutyric acid. Compared with the prior art, the rice product makes full use of the activities of the glutamate decarboxylase, the amylase and the protease in the germinated brown rice; the produced rice product has the special sweet flavor; by calculating based on dry basis, the content of Gamma-aminobutyric acid is high (1,000-1,400mg / 100g), and the nutritional value and the digestibility are high. The rice product of the invention can be taken as the functional food for resisting fatigue and reducing blood lipid.

Owner:HUAZHONG AGRI UNIV

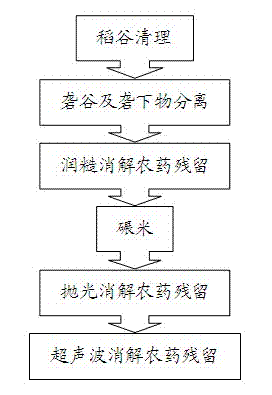

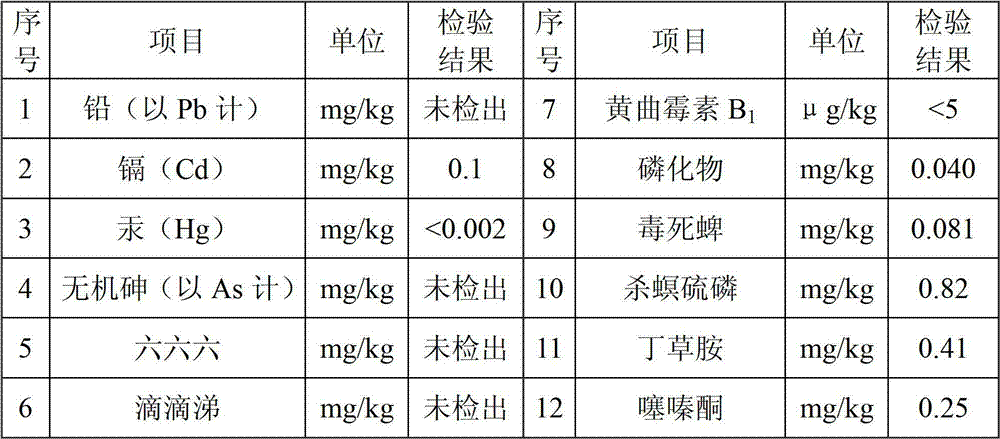

Paddy rice producing production technology for removing pesticide residue

ActiveCN102824934ASolve the problem of pesticide residuesChange qualityGrain huskingGrain polishingFlavorPesticide residue

The invention provides a paddy rice producing production technology for removing pesticide residue, and relates to the technical field of the processing and the producing of food, wherein the production technology comprises the following steps of: cleaning paddy, separating hull grains from hulled materials, removing the pesticide residue by means of coarseness humidifying, milling rice, removing the pesticide residue in a polishing way, and removing the pesticide residue by ultrasonic wave. The paddy rice producing production technology for removing the pesticide residue provided by the invention combines with the production of paddy rice producing, mainly aims at solving the problem that the paddy contains the pesticide residue, is scientific in technological process design, reasonable in technical method, and low in production cost, effectively and reliably removes the pesticide residue, can subsidiarily kill the toadstool in the paddy, can produce the paddy clearly, guarantees the quality safety of paddy-processed products, is free from secondary pollution of rice products in the process of processing and producing, can not change the original quality, nutrition and special flavor of the paddy, is particularly suitable for preparing the products which are higher in nutrition value and economic value such as germ-remaining rice, the clean rice and the like besides the common rice, and is further good for reducing the pesticide residue of byproducts prepared by comprehensive utilization.

Owner:DANYANG JIAHE RICE

Production process of parboiled rice

InactiveCN105558783AHigh nutritional valueHigh meal rateFood thermal treatmentNutritive valuesEconomic benefits

The invention relates to a production process of parboiled rice and belongs to the technical field of grain fine and profound processing. According to the production process, pollution-free, environment-friendly or organic rice is selected as the raw material, no additive is added, and a parboiled rice product is obtained through such processing technologies as cleaning and preliminary classification, soaking, steaming, drying, tempering and cooling, rice with huller and husked rice separation, rice milling, polishing, color sorting and packaging. The product is nutrient-enriched food and easy to store and eat and has the advantages of being high in nutritive value, high in rice cooking rate, high in oil extraction rate, long in storage life, short in cooling time and the like; economic benefits are remarkable, the formula is reasonable, the production process is simple, energy consumption is low, processing time is short, the process is safe and sanitary, investment is little, and on the basis of original common rice production equipment, only soaking and steaming equipment is added, and then the product can be produced on a large scale.

Owner:江苏奕帆农业科技有限公司

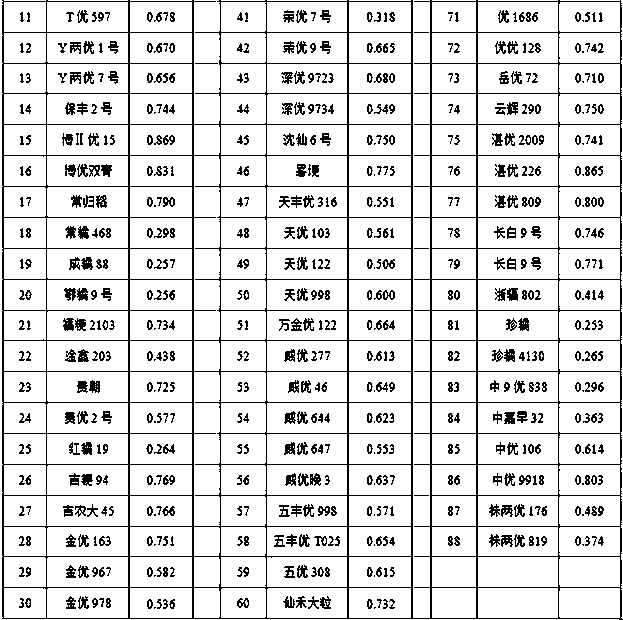

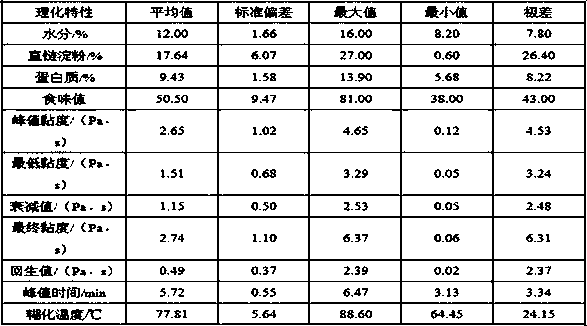

Method for rapidly screening raw material used to make rice product

ActiveCN107464020AImprove scienceImprove accuracyForecastingDesign optimisation/simulationRegression analysisMathematical model

The present invention discloses a method for rapidly screening a raw material used to make a rice product. The method comprises the following steps: (1) collecting a representative rice sample; (2) determining physical and chemical indicators of different varieties of rice raw materials; (3) processing the different varieties of rice raw materials into rice products; (4) for a feature of each variety of rice products, establishing a multi-level evaluation indicator factor set of quality of rice products, and obtaining a weight of each evaluation indicator by analytic hierarchy process; (5) determining a degree of membership of each evaluation factor and constructing a fuzzy evaluation matrix; (6) by adopting a fuzzy matrix compound operation, obtaining a fuzzy comprehensive evaluation value; (7) by regression analysis, obtaining a mathematical model between a comprehensive evaluation value of rice products and a characteristic of raw materials; and (8) by using the mathematical model, predicting suitability of the different varieties of rice raw materials for being processed into rice products. By adoption of the method disclosed by the present invention, the suitability of the different varieties of raw materials for being processed into rice products can be calculated quantitatively, so as to support scientific utilization of raw materials.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY +2

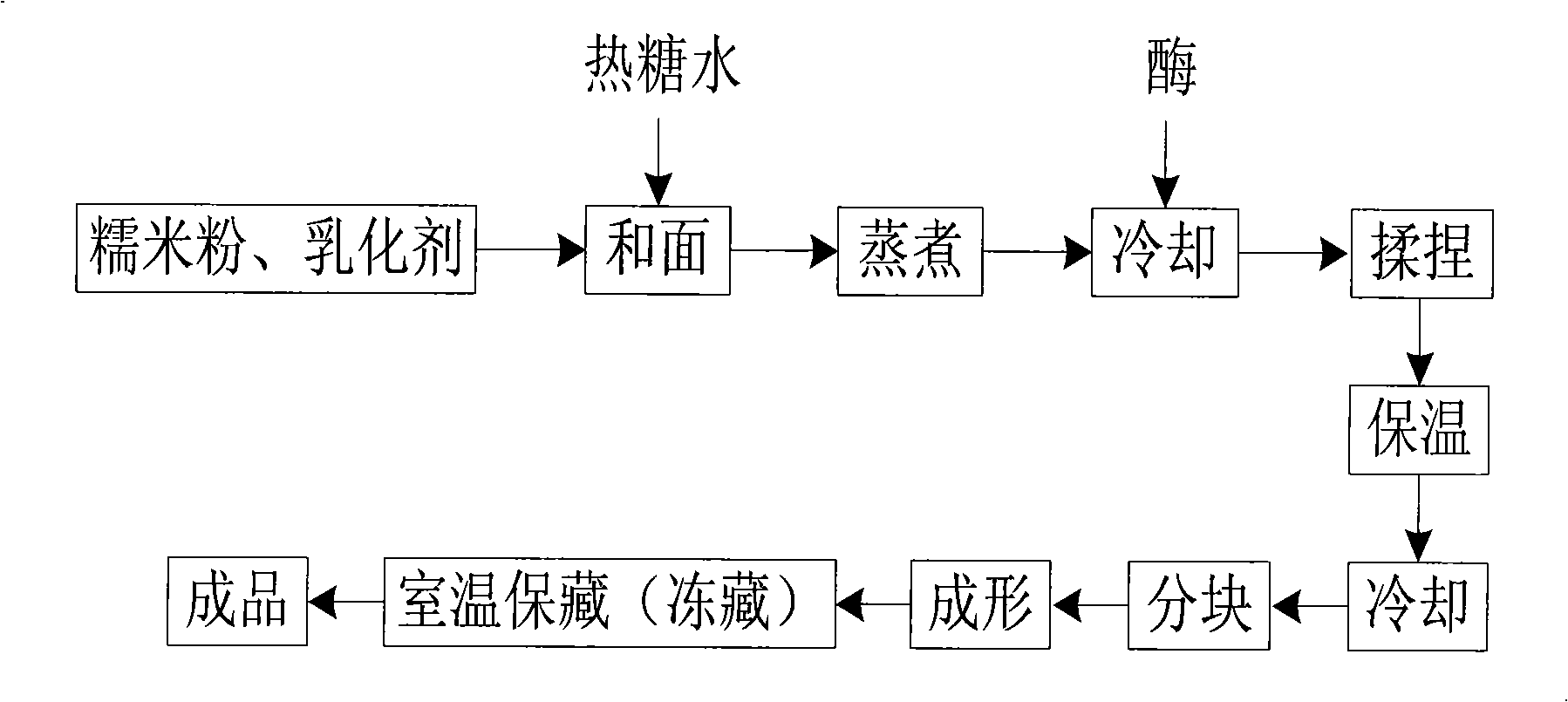

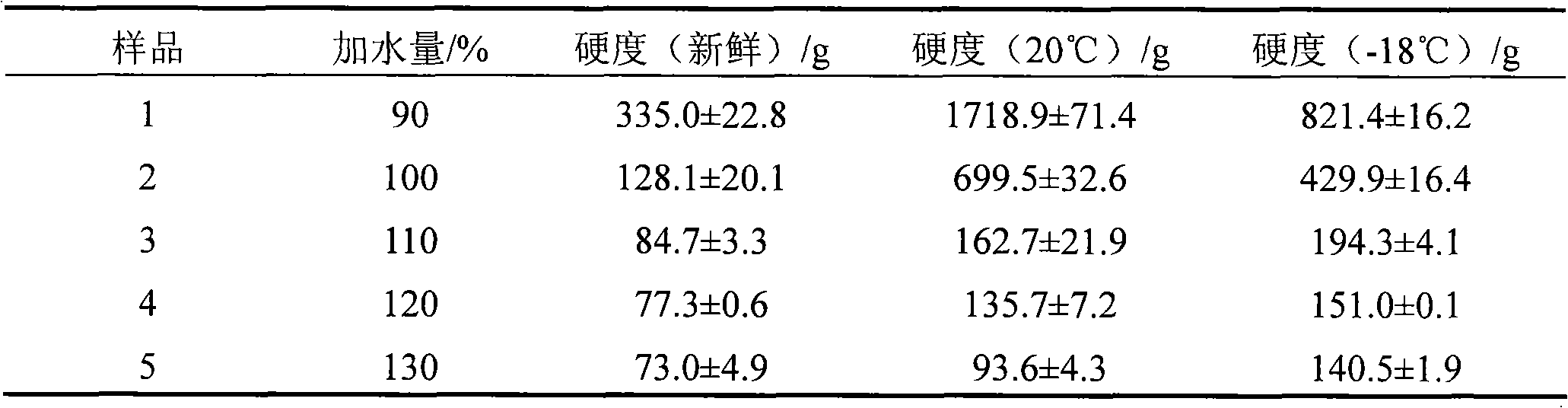

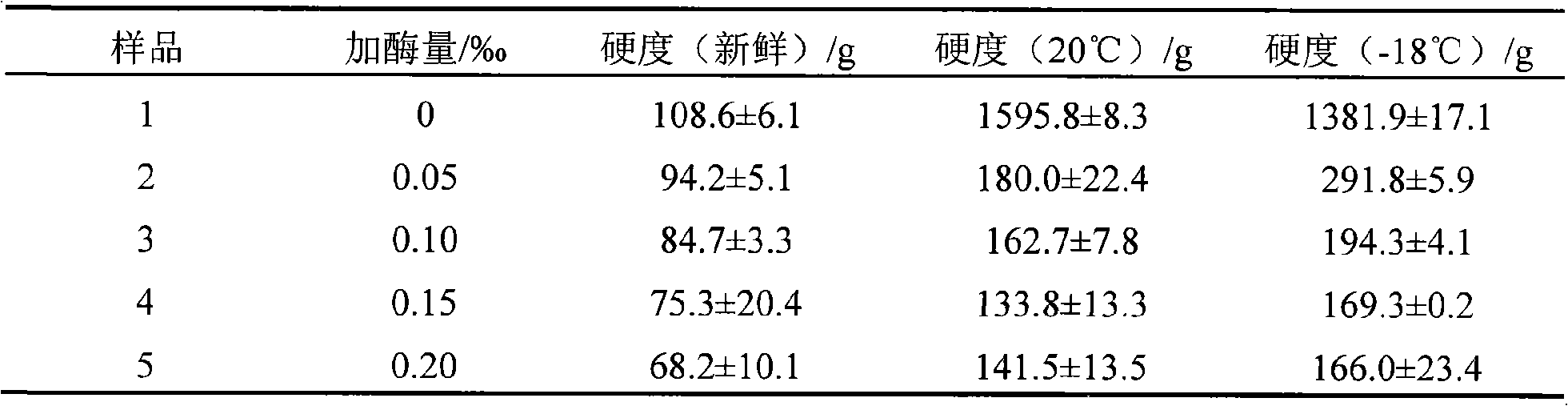

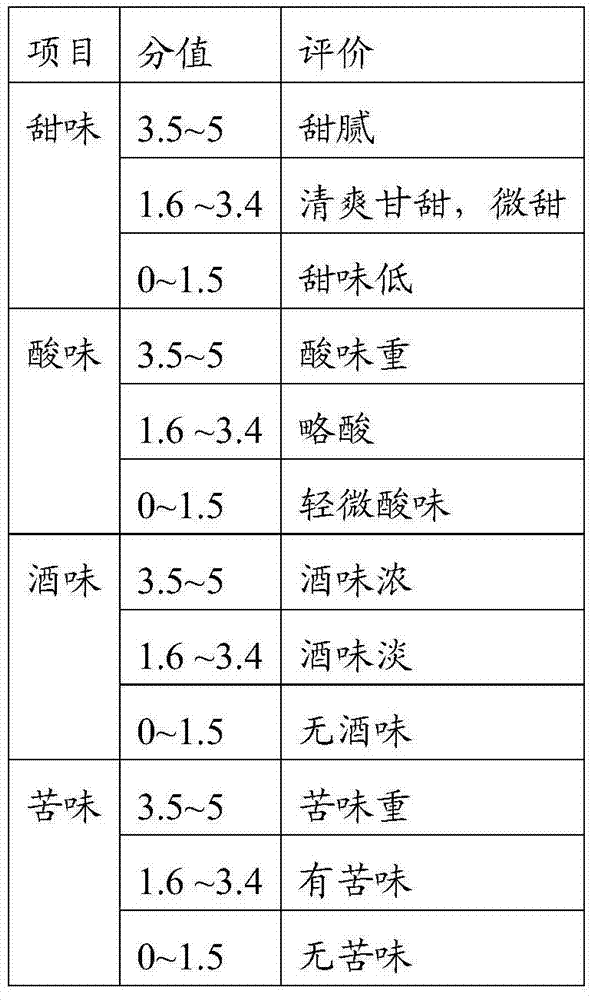

Antiaging method for rice product-mashu

InactiveCN101406311AExtended shelf lifeEasy to storeFood preservationBakery product preservationBiotechnologyFood additive

The invention provides an anti-aging method for deep-fried glutinous rice cake stuffed with bean paste, which belongs to the technical field of agro-product processing and food additive. The invention mainly relates to preparation of an anti-aging compound emulsifying agent and anti-aging application of the compound emulsifying agent and an enzyme agent to the deep-fried glutinous rice cake stuffed with bean paste. In the invention, glutinous rice flour is taken as a main raw material, certain amount of the compound emulsifying agent, the enzyme agent, sugar and water are added, and the product, namely deep-fried glutinous rice cake stuffed with bean paste is produced by stewing and forming processes. The compound emulsifying agent is mainly produced by an extrusion method. A plurality of powder emulsifying agents with good anti-aging effect is evenly distributed on the surface of starch particles. The compound emulsifying agent with good anti-aging effect is obtained by controlling extrusion parameters. The optimal adding amount of the compound emulsifying agent is between 0.2 and 3 percent. The enzyme agent mainly adopts maltose amylase with the adding amount of between 0.02 and 0.15g / kg. The adding amount of the water and the sugar is respectively 110 to 120 percent and 20 to 50 percent of the weight of the glutinous rice flour. Through adding the compound emulsifying agent and the enzyme agent, the deep-fried glutinous rice cake stuffed with bean paste has good anti-aging function, and ensures that the guarantee period is more than 60 months.

Owner:JIANGNAN UNIV

Preparation method and fermented glutinous rice prepared by method

InactiveCN103695243AObvious fermented glutinous rice aromaAvoid lostAlcoholic beverage preparationFermentationChemistry

The invention relates to the technical field of foods, and in particular relates to a preparation method and fermented glutinous rice prepared by the method. The method comprises the following steps: soaking 1 part by mass of sticky rice in water for 4 to 24 hours; draining off water from the sticky rice; steaming the sticky rice for 10 to 30 minutes so as to obtain steamed sticky rice; flushing the steamed sticky rice with pure water until the sticky rice is cooled to reach 30 DEG C to 35 DEG C; draining off water; mixing the sticky rice with 0.004 part by mass of sweet wine cube; performing first fermentation at 30 DEG C to 34 DEG C for 20 to 50 hours; adding a liquid; performing second fermentation at 30 DEG C to 34 DEG C for 5 to 20 hours; and refrigerating at 0 DEG C to 10 DEG C for 1 to 48 hours, thereby obtaining the fermented glutinous rice. According to the method, the fermented glutinous rice is fresh and sweet, so that the palatability of the fermented glutinous rice is enhanced; a cooking or blending process required by a traditional fermented glutinous rice product before the product is eaten is avoided, so that the loss of nutrition is avoided.

Owner:郑明星

Cadmium removing method for rice and products thereof

InactiveCN103621852AEfficient removalReduce contentFood preparationFood extractionChemistryRice flour

The invention relates to a cadmium removing method for rice and products thereof. The method comprises the following steps: soaking, reacting, washing and drying and the like. By the method, the cadmium content in rice and rice products such as rice flour, starch, rice noodle, rice albumen powder and the like can be effectively reduced, with the cadmium removing rate of more than 70%; the method has the characteristics of simple process, relatively low production cost, strong applicability and the like.

Owner:JIANGNAN UNIV

Rapid screening method of processing raw rice for rice products

InactiveUS20190041374A1Improve scientificityImprove accuracyForecastingDesign optimisation/simulationRational useBiotechnology

A rapid screening method of processing raw materials for rice products is disclosed. The invention establishes a membership function between the raw materials and the processing suitability of raw materials by adopting theories in fuzzy mathematics. In combination with the analytic hierarchy process to obtain the weight of each evaluation index, the invention then establishes a two-level evaluation model for evaluating the quality of the rice products to improve the scientificity and accuracy of rice products' quality evaluation. On the basis of the above, a mathematical model between the characteristics of raw materials and the comprehensive evaluation values of the quality of rice products is constructed through regression analyses, which can quantitatively calculate the suitability of different varieties of raw materials in the processing of rice products and can provide support for reasonable use of the raw materials.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Method for identifying rice DNA identities and application thereof

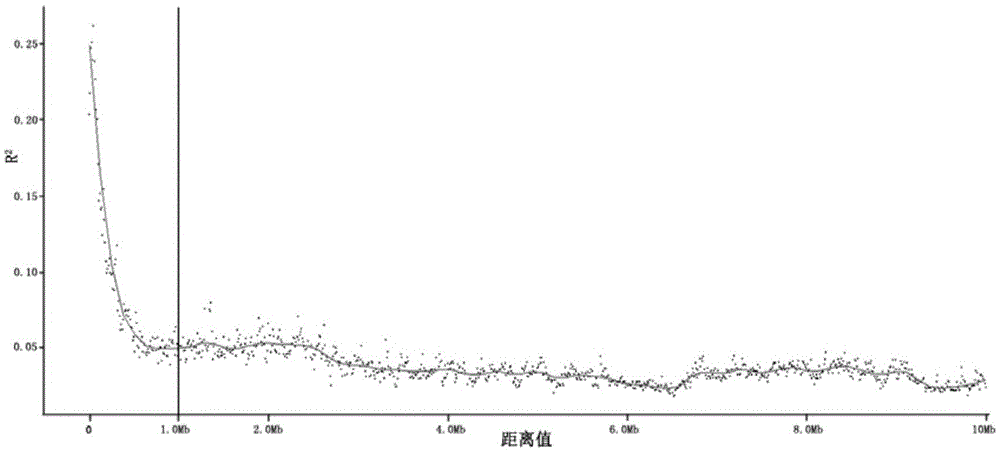

InactiveCN105550537AReduce volatilityEasy to useSequence analysisSpecial data processing applicationsGenetic diversityGenotype

The invention provides a method for identifying rice DNA identities, comprising following steps: obtaining standard gene fingerprint data of rice through detecting the genotypes of the genetic diversity molecular markers of the whole genome of the rice, identifying the DNA identities of the rice, or further, identifying the DNA identities of the rice through feature gene fingerprint data. According to the method provided by the invention, the DNA identities of the rice can be identified rapidly and accurately; and the method is applicable for new rice product identification, seed supervision and management or variety right protection.

Owner:CHINA NAT SEED GRP

Production method of fresh keeping wet rice sticks

The invention discloses a production method of fresh keeping wet rice sticks, and belongs to the technical field of depth processing of rice products. The production method of fresh keeping wet rice sticks is realized through synchronous re-steaming and sterilization of wet rice sticks by using a high pressure technology. The method adopting early indica rice starch as a raw material mainly comprises the following steps: immersing the early indica rice starch at room temperature for 3-4h, draining the immersed rice starch, crushing the drained rice starch, sieving the crushed rice starch by a 60 mesh sieve, adjusting the water content of the rice starch to 40-55%, carrying out extrusion molding, carrying out standing ageing on the extrusion molded rice starch at room temperature for 4h, ageing the obtained rice starch at 4DEG C for 2h, carrying out vacuum packaging, and carrying out ultrahigh pressure treatment at 50-60DEG C under 150-250Mpa for 10-20min to obtain the fresh keeping wet rice sticks with the advantages of short production period, good mouthfeel and flavor and long shelf life. The production method prolongs the storage life of the fresh keeping wet rice sticks, improves the chewiness and mouthfeel of the fresh keeping wet rice sticks, and shortens the production time of the fresh keeping wet rice sticks.

Owner:NANCHANG UNIV

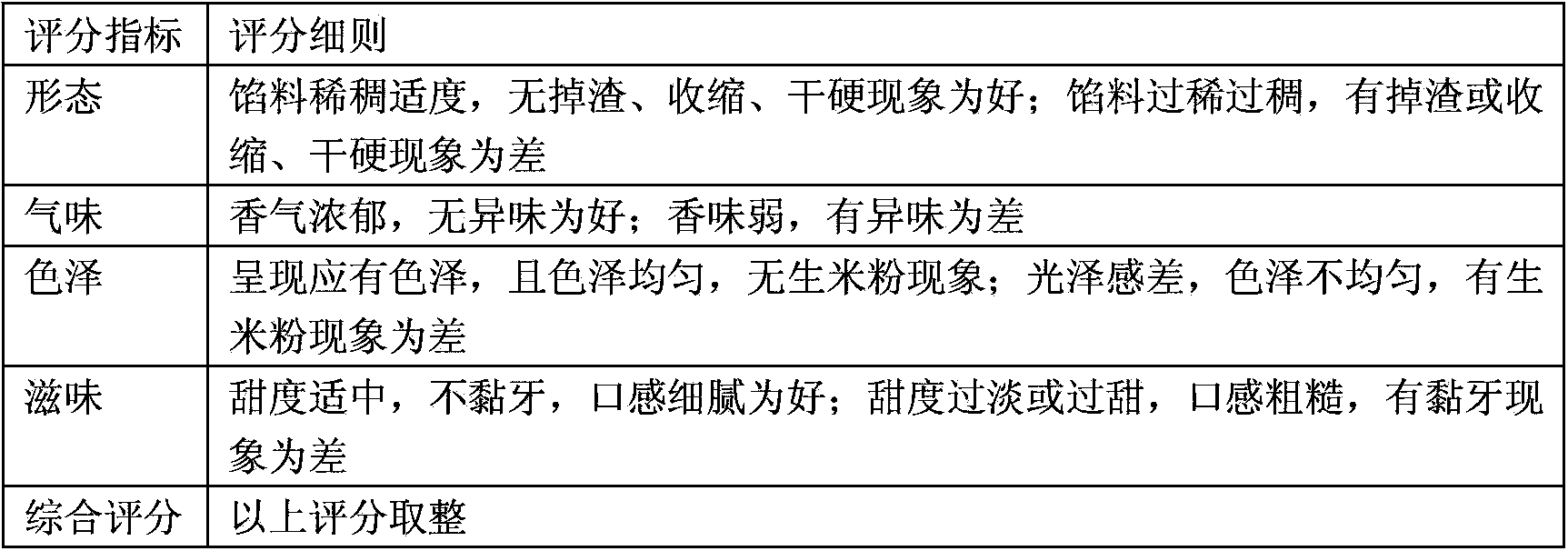

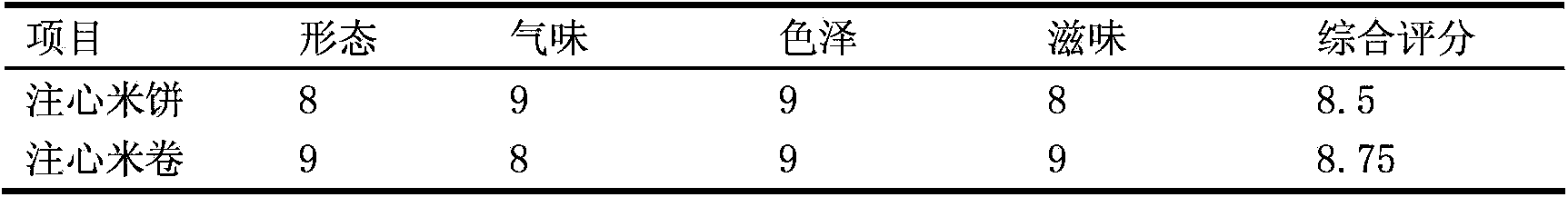

Production method of rice products rich in gamma-aminobutyric acid and products

ActiveCN103445090AMeet the requirements of healthy nutritionPromote formationFood shapingFood preparationGamma-Aminobutyric acidSprouting

The invention belongs to the technical field of food processing, and particularly relates to a production method of rice products rich in gamma-aminobutyric acid and the products. The production method comprises the following steps of: (1) cleaning and disinfecting raw materials; (2) preparing sprouting rice: (3) obtaining the dried sprouting rice by adopting a high temperature and humidity and staged drying method; (4) adding auxiliary materials to the dried sprouting rice serving as the raw material, and grinding so as to obtain rice pulp rich in gamma-aminobutyric acid; (5) adding auxiliary materials to the rice pulp as the raw material so as to prepare stuffing rich in gamma-aminobutyric acid; (6) puffing the obtained sprouting rice, and bonding by using syrup so as to form rod-shaped or spherical or massive food rich in gamma-aminobutyric acid; (7) adding auxiliary materials to the rice pulp as the raw material so as to prepare rice milk rich in gamma-aminobutyric acid; (8) adding auxiliary materials to the rice pulp as the raw material so as to prepare buccal tablets rich in gamma-aminobutyric acid. The invention also discloses a preparation method of the products.

Owner:HUAZHONG AGRI UNIV

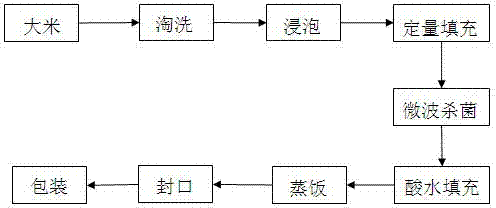

Method for producing microwave-based instant rice

The invention provides a method for producing microwave-based instant rice, belonging to the field of food processing. The method is characterized by taking high-quality northeastern round shaped rice as a raw material and adopting a technology combining microwave sterilization and acid water filling to prepare the instant rice. The method specifically comprises the following steps of: rinsing the high-quality round shaped rice, soaking the rinsed rice, quantitatively filling and sterilizing the rice with microwaves, filling acid water, cooking the rice, sealing and cooling the cooked rice, and then packaging the rice, thus obtaining an instant rice product. The microwave-based instant rice produced by the method provided by the invention has a simple preparation process, maintains the original taste, quality and nutrition of the rice, has relatively low cost, is convenient to eat, only needs to be heated with microwaves for a few minutes, and has long shelf life. Therefore, the instant rice is worthy to be popularized and applied.

Owner:JIANGNAN UNIV

Process for preparing fermented bean curd powder

InactiveCN102058068AReduce inhibitionRaise the fermentation temperatureFood preparationFreeze-dryingAdditive ingredient

The invention relates to a process for preparing fermented bean curd powder. The process comprises the following steps of: vaccinating equivalent 0.1-0.3 percent pure racemomucor M.H.C-7CCTCCM 201026 subjected to enlargement culture and rhizopus oligosporus CGMCC 3.4392 and fermenting to form a mould billet; adding salt and Chinese rice wine, uniformly mixing and then vaccinating 0.2 percent activated Angel high-temperature-resistant active dry yeast; sealing for fermenting; pulverizing to form a viscous fluid and precooling; drying into freeze-drying powder in vacuum; and bottling and sealing to obtain the fermented bean curd powder. Ingredients can be added to the freeze-drying powder to be prepared into various seasoners which have the fermented bean curd flavor and different applications, and the freeze-drying powder can be widely applied to seasoners of potato chips, flour products, rice products, roasted meat products, and the like and can be also used as an ingredient of instant noodle seasoning bags. The fermented bean curd powder has the advantages of scientific process design and short process period, is particularly suitable for annual production and is obviously different from fermented bean curd products of other forms. The process can be used for realizing industrial continuous production and has the advantages of controllable process, stable quality and wide application and provides a feasible method for developing novel seasoners.

Owner:CHANGSHA TANTANXIANG FLAVORING FOOD +1

Processing technology of vegetable and coarse cereal formula rice

ActiveCN103190690AIncrease appetiteChange the processing methodFood shapingFood preparationVitamin CCooking Practices

The invention provides a processing technology of vegetable and coarse cereal formulation rice. The processing technology specifically comprises the following steps of: smashing raw materials, mixing, extruding, forming in a cutting way, cooling, drying by microwaves, cooling, classifying in a sieving way and packaging. Vegetables, grains, coarse cereals and the like are mixed according to a certain proportion to prepare the rice product, the formed rice product has the appearance of rice after being treated by a plurality of working procedures, and therefore, the formula rice can be cooked according to the cooking method of the common rice when being eaten. The appearance of the formula rice is the same as that of the common rice when the formula rice is eaten, and the content of nutrient elements, i.e. vitamin C, carotene, dietary fiber, calcium and ferrum, further increases, so that the consequences of nutrition intake unbalance, malnutrition, body immunity decline and the like since children avoid certain food and have the partiality for a particular kind of food can be solved. The extrusion forming process of the materials in an extruder is a short-time, high-temperature and high-shear fusion and gelatinization process, so that the mixing uniformity, the gelatinization degree and the expression of the final product can be guaranteed after the materials are sufficiently smashed, and the product quality can be improved.

Owner:重庆好媳妇食品有限公司

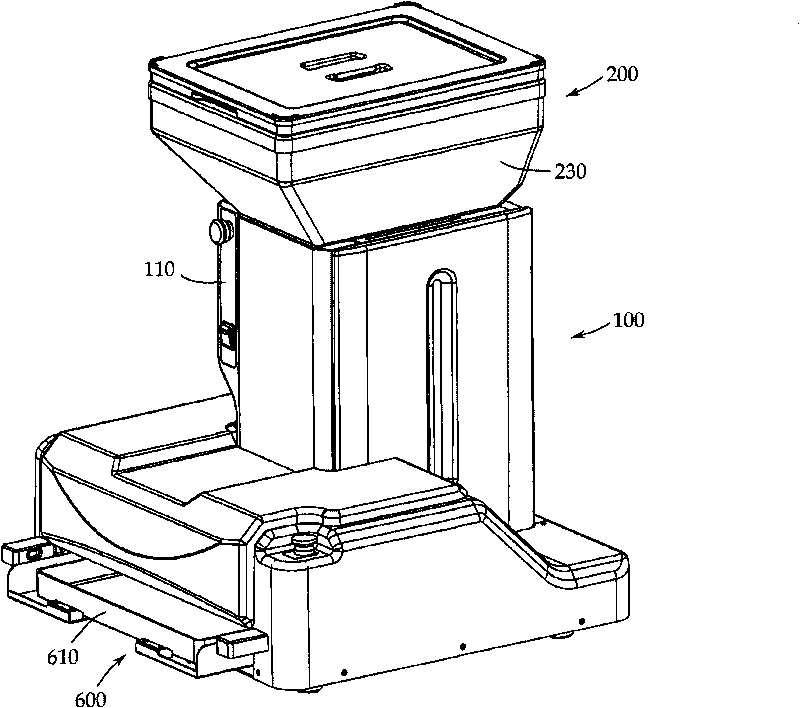

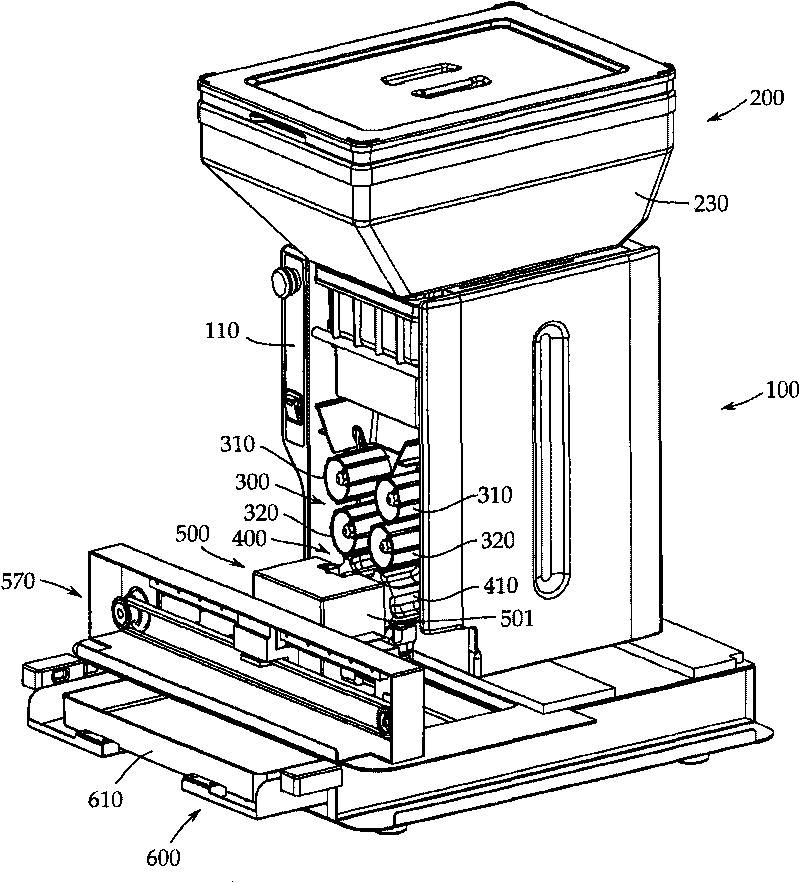

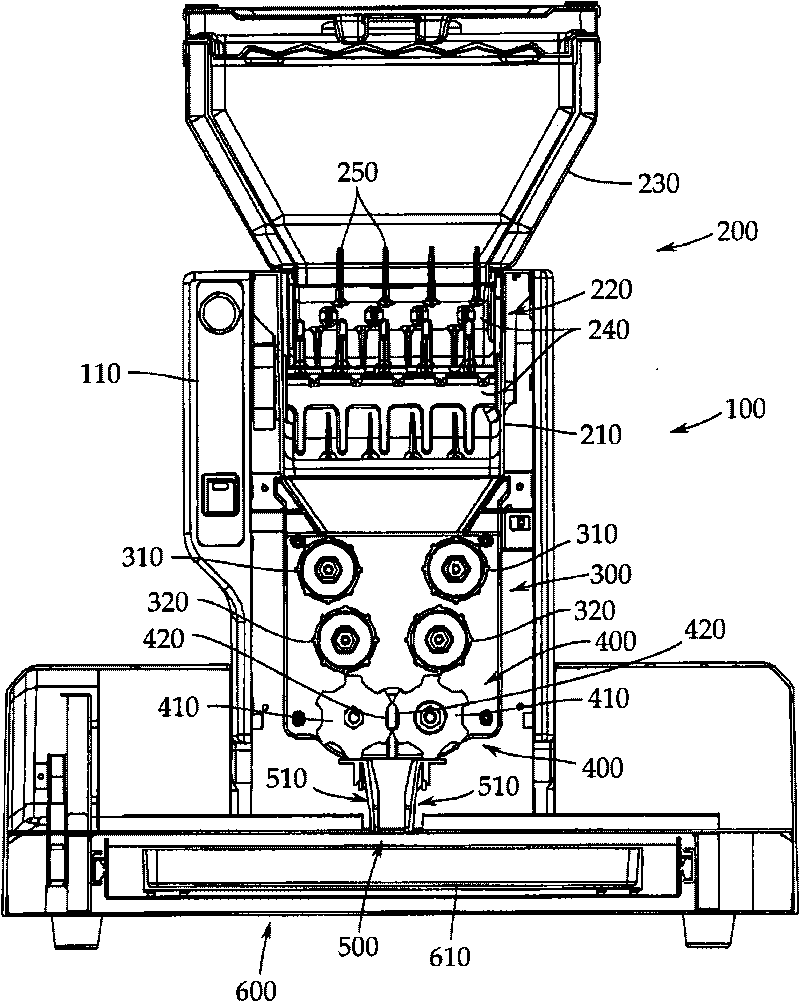

Apparatus for molding cooked rice

Owner:AUDIO-TECHNICA

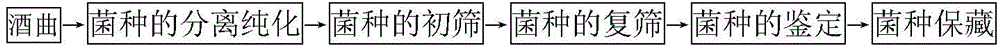

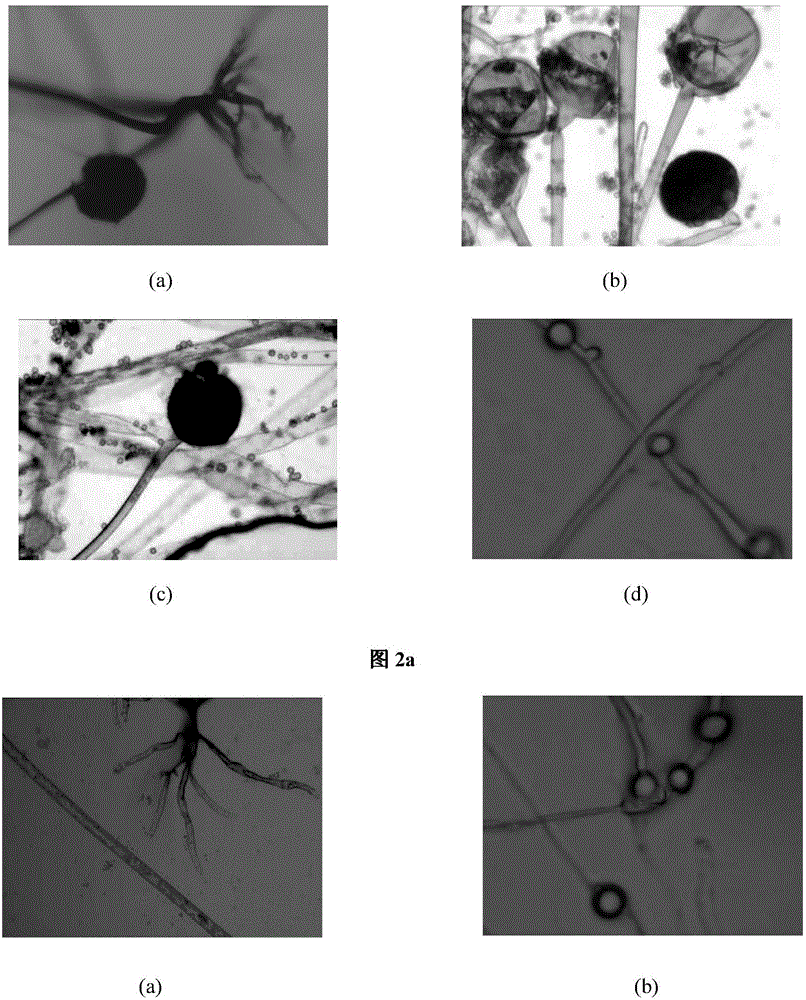

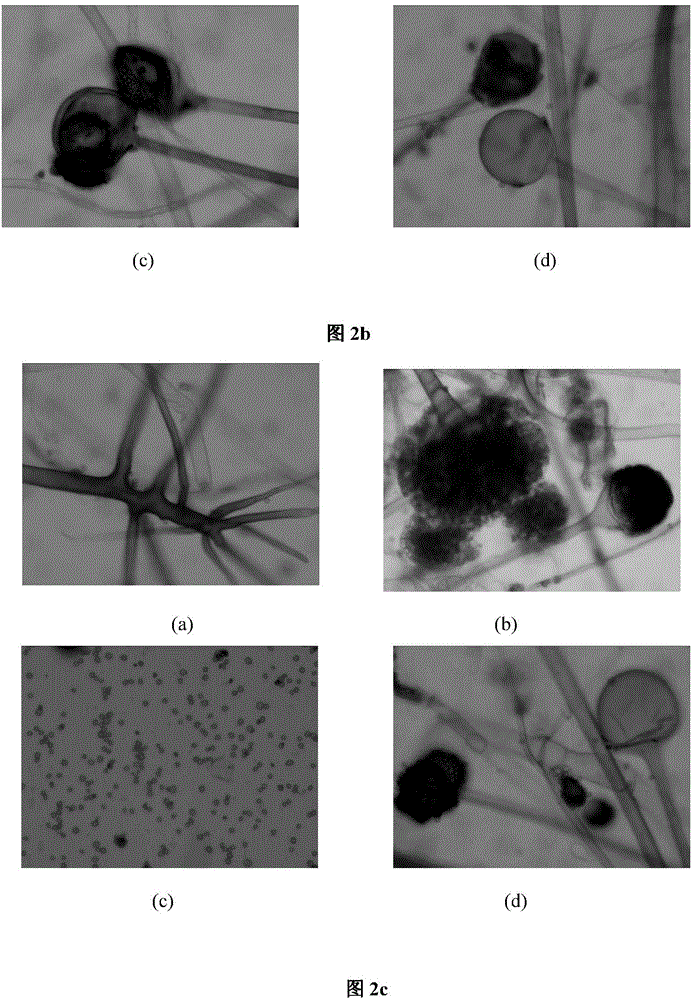

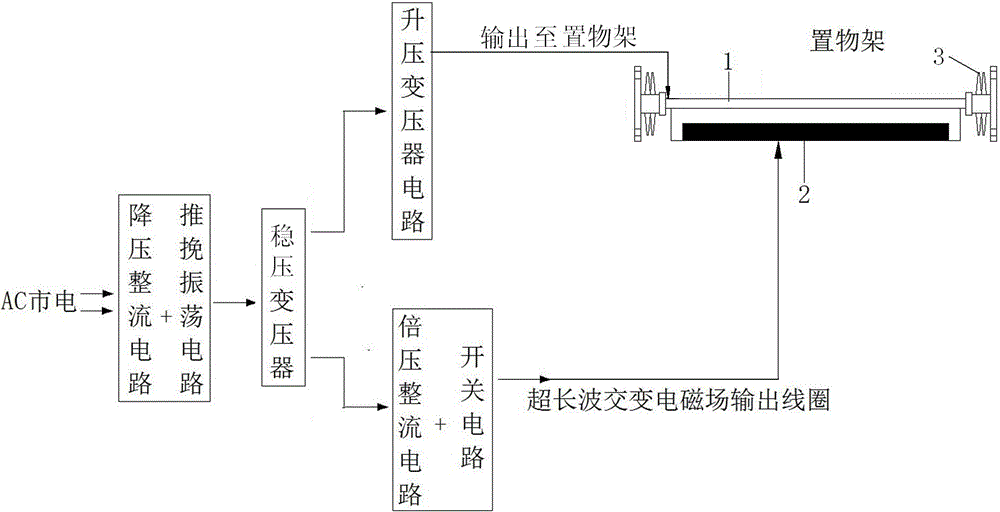

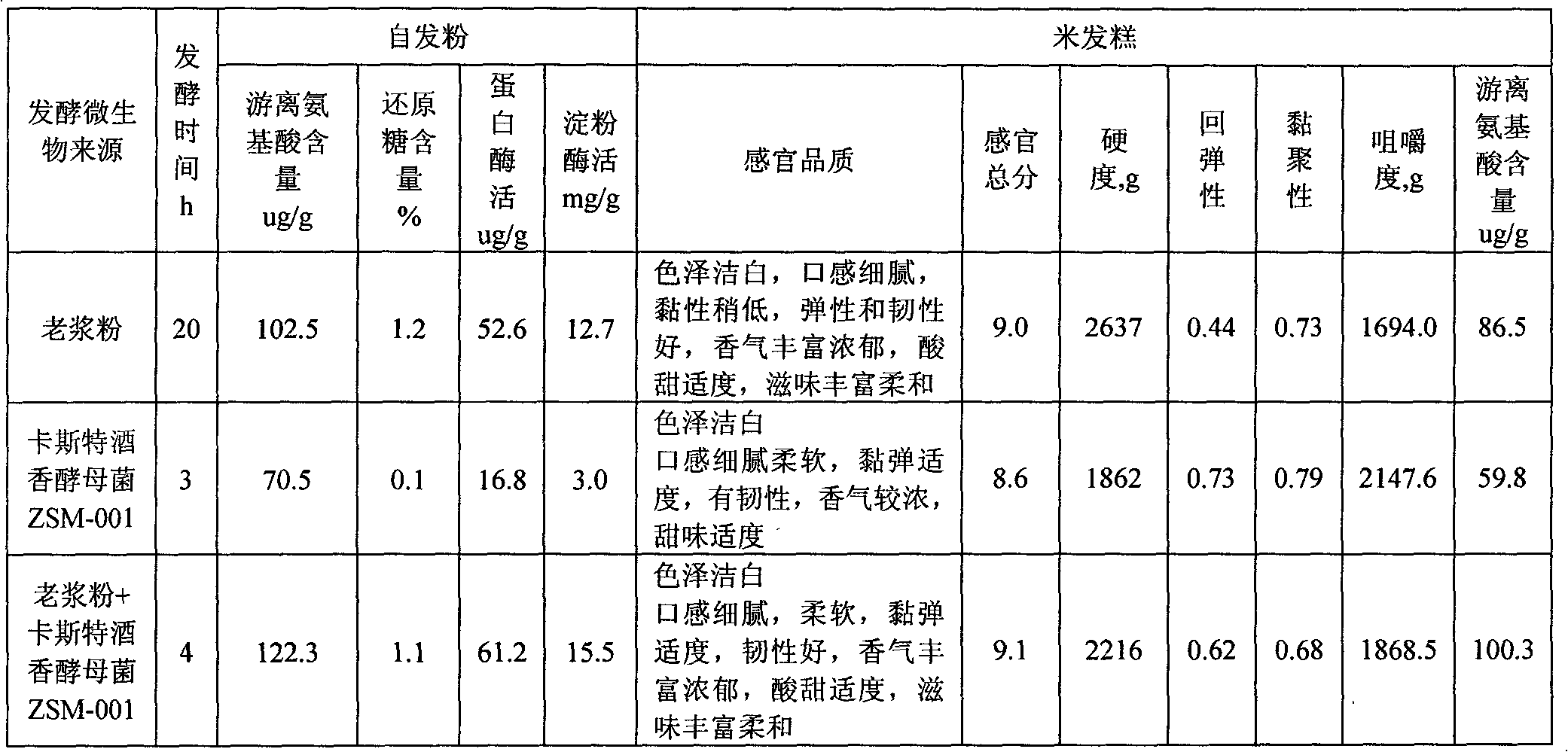

Rhizopus for food fermentation and application

The invention belongs to the field of food fermentation, and in particular relates to rhizopus for food fermentation and application. Rhizopus oryzae zsm-003, zsm-004 and rhizopus zsm-005 suitable for rice product and sweet rice wine fermentation are separated from sweet rice wine. A microorganism complex bacterium agent for food fermentation is developed, which comprises rhizopus oryzae zsm-003, zsm-004 and brettanomyces custersii ZSM-001. Strain survival rate of the complex fermenting agent reaches more than 35%, and the produced sweet rice wine is relatively rich in sugar composition, intense in flavor, good in taste, and relatively high in contents of delicious amino acid and essential amino acid. Furthermore, the invention discloses a preparation method and application of the complex fermenting agent.

Owner:HUAZHONG AGRI UNIV

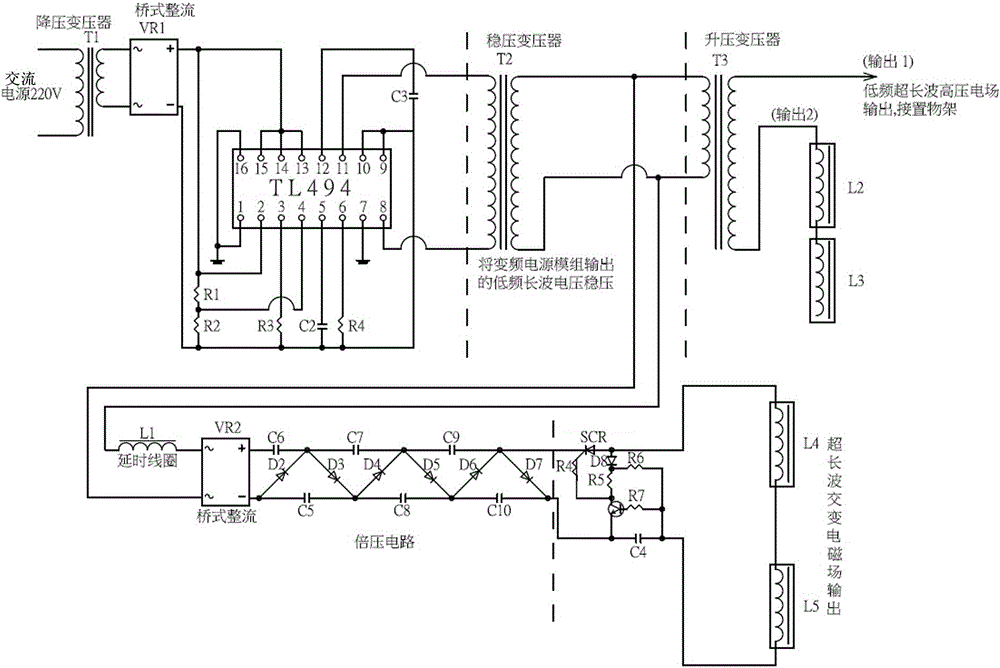

Super-long wave low-frequency high-voltage alternating electric field based food treating device for

The invention relates to a super-long wave low-frequency high-voltage alternating electric field based food treating device. The food treating device is suitable for the freezing, preserving and unfreezing of the food including meat products, fish products, rice products, etc., reduction of food frying temperature, meat and wine maturation and storage of wine products. The super-long wave low-frequency high-voltage alternating electric field based food treating device is characterized by comprising a super-long wave low-frequency high-voltage alternating electric field electronic circuit, a super-long wave low-frequency high-voltage alternating electromagnetic output coil and an accommodating container, wherein the super-long wave low-frequency high-voltage alternating electric field electronic circuit comprises a voltage-reducing rectifying circuit, a push-pull oscillating circuit, a voltage stabilizing transformer, a boosting transformer circuit, a voltage doubling rectifying circuit, a switch circuit and the super-long wave low-frequency high-voltage alternating electromagnetic output coil.

Owner:黄于展

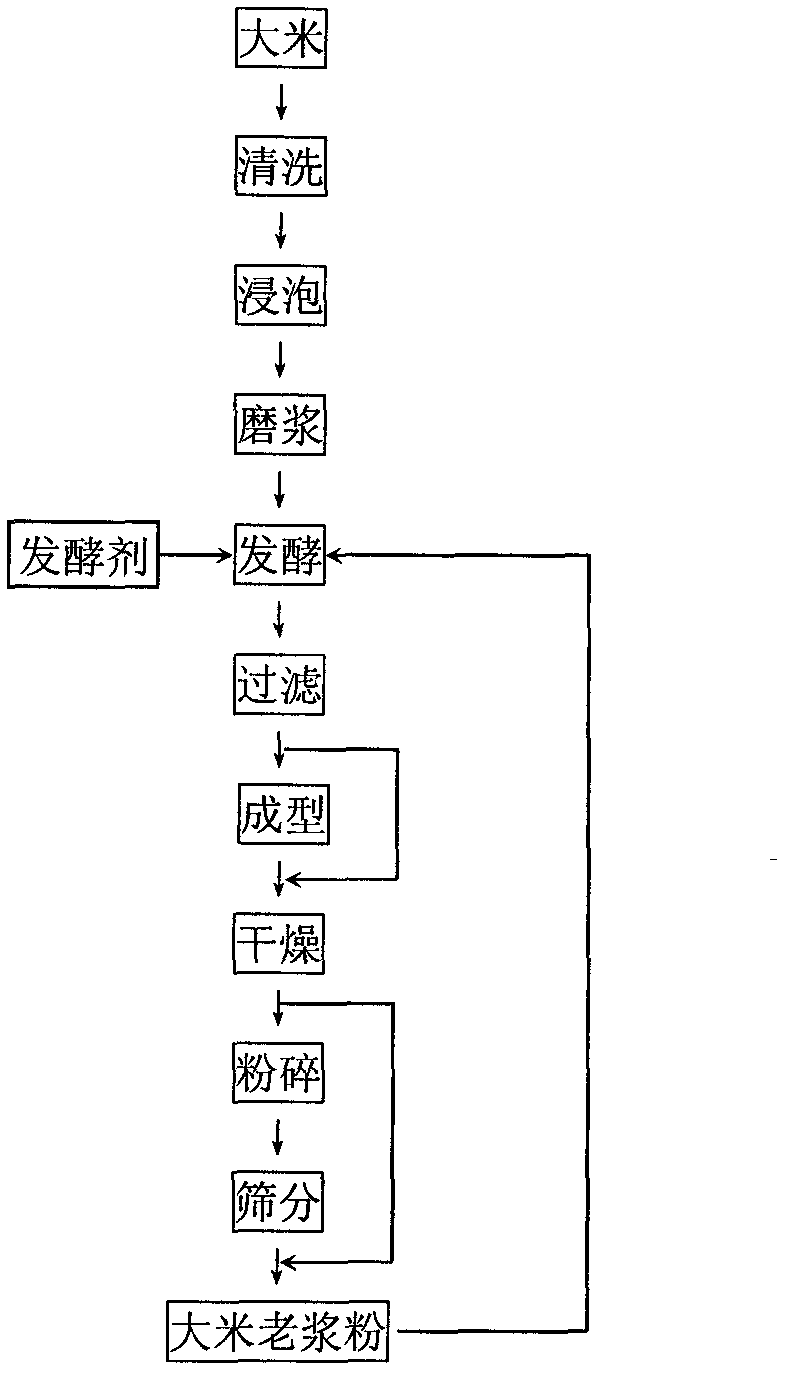

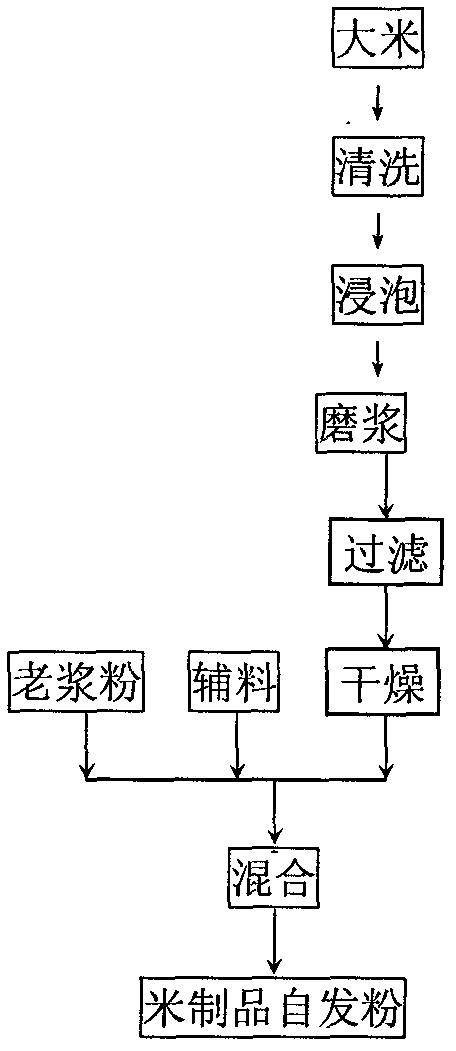

Rice product self-rising flour, producing method thereof and application thereof

The invention belongs to the technical field of foodstuff processing, and concretely relates to rice old slurry powder, rice product self-rising flour, a producing method thereof and an application thereof. The rice product self-rising flour provided by the invention comprises main material powder, the old slurry powder, fermenting bacteria agents and accessories, wherein the old slurry powder is produced by using a traditional fermentation process; the fermenting bacteria agents comprise Custer wine yeast, active dry yeast or plant Lactobacillus; the accessories comprise a sweetener, a sour agent, an enzyme preparation, flour, red bean powder, mung bean powder, calcium carbonate and starch powder; raw materials of the main material powder are selected from one of rice, broken rice, corn, millet, black rice and red rice, or combinations thereof; and the starch powder is selected from potato powder, sweet potato powder or yam powder. The invention further discloses a producing technology of the self-rising flour. Rice steamed sponge cakes, glutinous rice cakes and other products produced by the self-rising flour of the invention have advantages of soft flavor and high quality.

Owner:黄冈东坡粮油集团有限公司

Method for preparing rice steamed bread

InactiveCN103190565AIncrease profitSimple internal structureFood preparationNutritive valuesNetwork structure

The invention discloses a method for preparing rice steamed bread. The method comprises the steps of (1) kneading dough, (2) stewing, (3) molding, (4) fermenting; (5) steaming; and (6) cooling in production of the rice steamed bread. By providing the method for producing the rice steamed bread including a process of directly adding a certain amount of gluten powder and sodium alga acid into the gelatinized rice or rice to change the properties that the rice product does not have a gluten network structure, and has high viscosity and hardness, the rice steamed bread prepared by the preparation method has the structure similar to that of the common wheat bread, but has higher nutritive value than that of the common wheat bread.

Owner:ZHONGKAI UNIV OF AGRI & ENG

Pregelatinized and re-pelleted composite brown rice

InactiveCN102652548ANutrition, Green and Environmental ProtectionNutritional diversityFood preparationCorn flourSemen

The invention discloses pregelatinized and re-pelleted composite brown rice which is prepared from the following raw materials in parts by weight: 10-120 parts of coarse rice powder, 8-15 parts of corn starch, 5-10 parts of black soya bean powder, 3-8 parts of purslane lyophilized powder, 3-5 parts of semen sesami nigrum powder, 3-5 parts of lotus leaf powder, 3-5 parts of lotus seed powder, 3-5 parts of Lycium barbarum L powder, 3-5 parts of buckwheat powder and 3-5 parts of lily root flour. The pregelatinized and re-pelleted composite brown rice is prepared by adopting double-screw extruding re-pelleting technology and processes such as gelatinization, extruding and re-pelleting on the raw materials which are rich in nutrition, the nutrition rice has the same shape as the common rice, a rice product with the same steaming performance and method as the common rice can be achieved, the process is green, environment-friendly, flexible in operation, efficient in production and low in fault rate, and the prepared composite brown rice has more complete nutrition and finer taste than the common brown rice.

Owner:ANHUI LV ZHEN FANG AGRI SCI & TECH

Novel process for processing instant food and method thereof

The invention provides a novel process for processing instant food and a method thereof, relating to technology of flour products, starch products and rice products, such as instant cold noodles, instant sheet jelly and gluten, instant cold jelly, instant noodles, instant mungbean noodles, instant rice noodles and the like. Various instant foods processed according to the method of cooking, forced cooling, oil impregnating (oil frying or oil spraying) and evenly stirring, cooling, quantitative packaging and sterilizing treatment can be eaten for a long time within the shelf life; in particular, the emergence of the instant cold noodles, the instant sheet jelly and gluten and the instant cold jelly increases the variety of the instant foods. The instant foods processed by the method overcome the defects of deep-fry and dry package of the traditional instant foods, taste of original foods and higher manufacture cost, and not only maintain the taste basically the same as foods which are freshly made, but also can be eaten more conveniently and rapidly with and without boiling water; and the food is particularly suitable for being eaten when people travel, adventure and construct outdoors. The method can be an innovation on the traditional instant food processing method.

Owner:张昆华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com