Patents

Literature

70results about How to "Change the processing method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

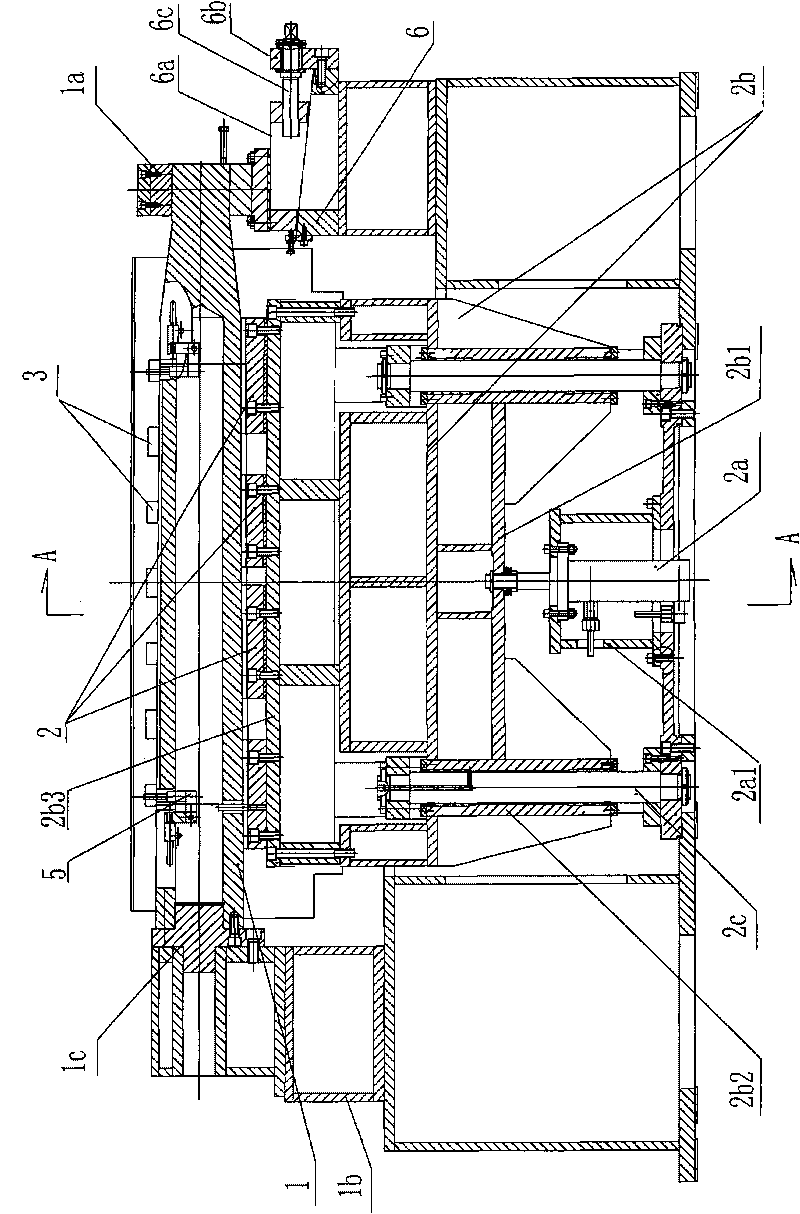

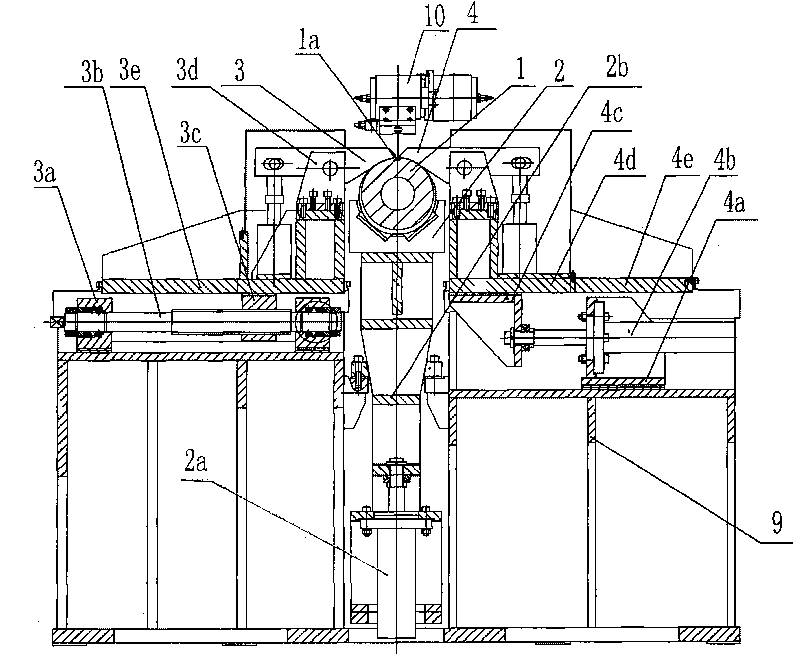

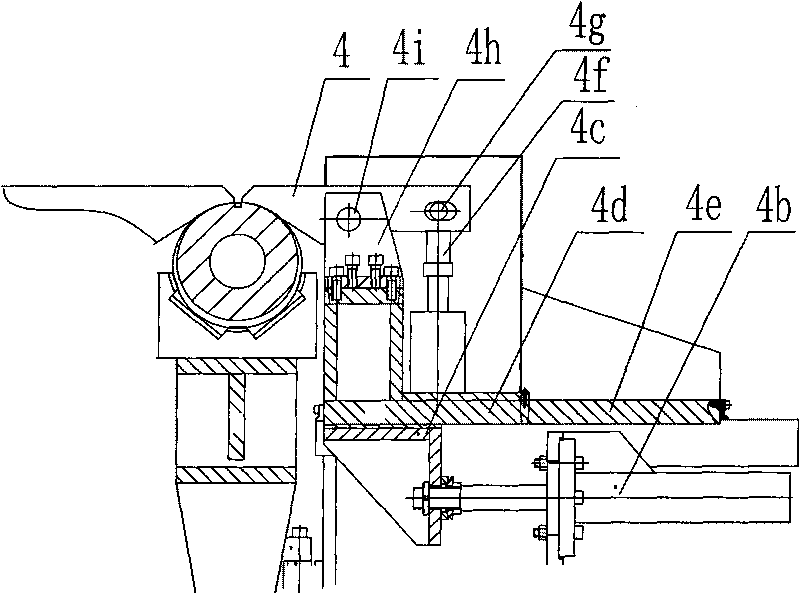

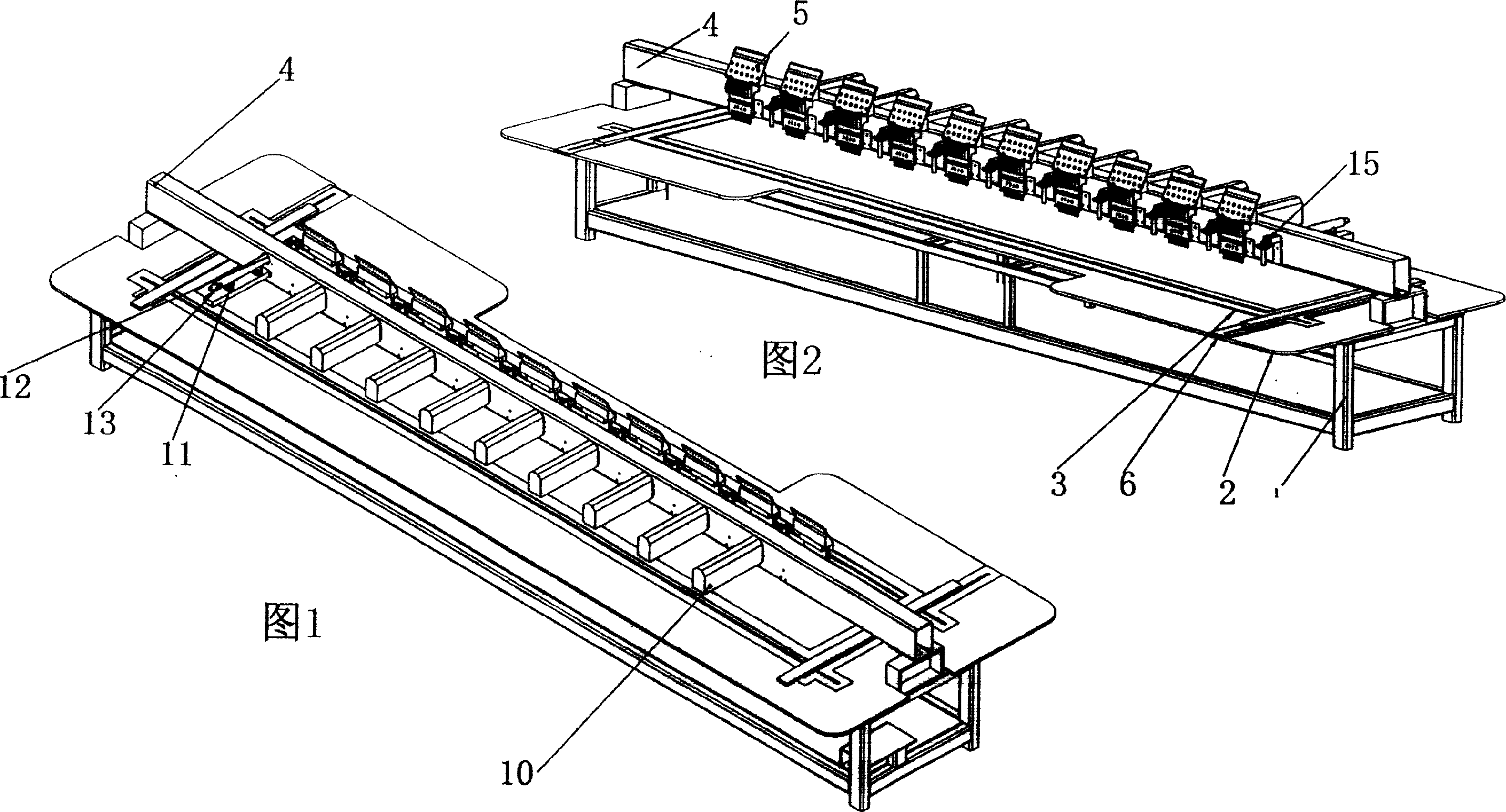

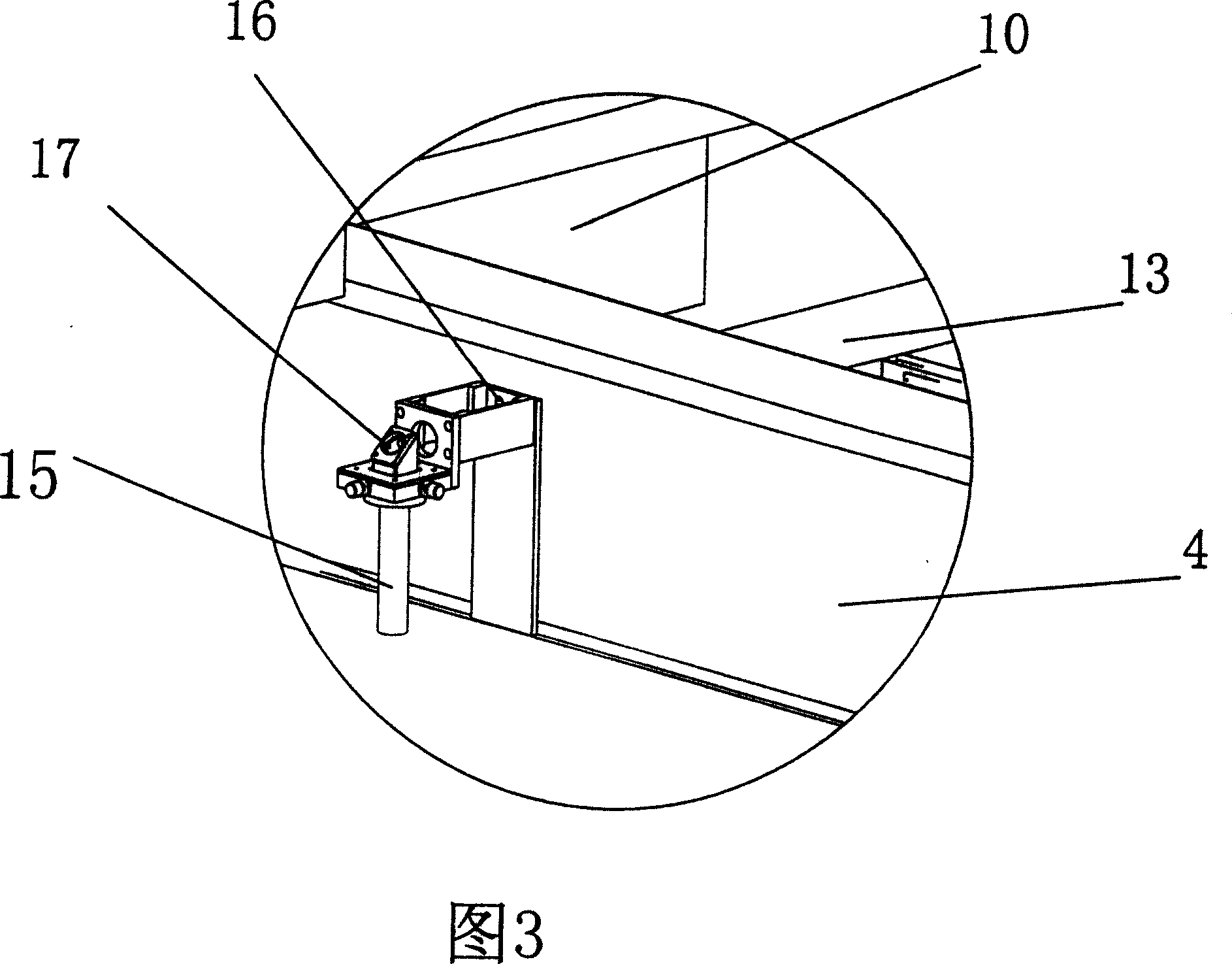

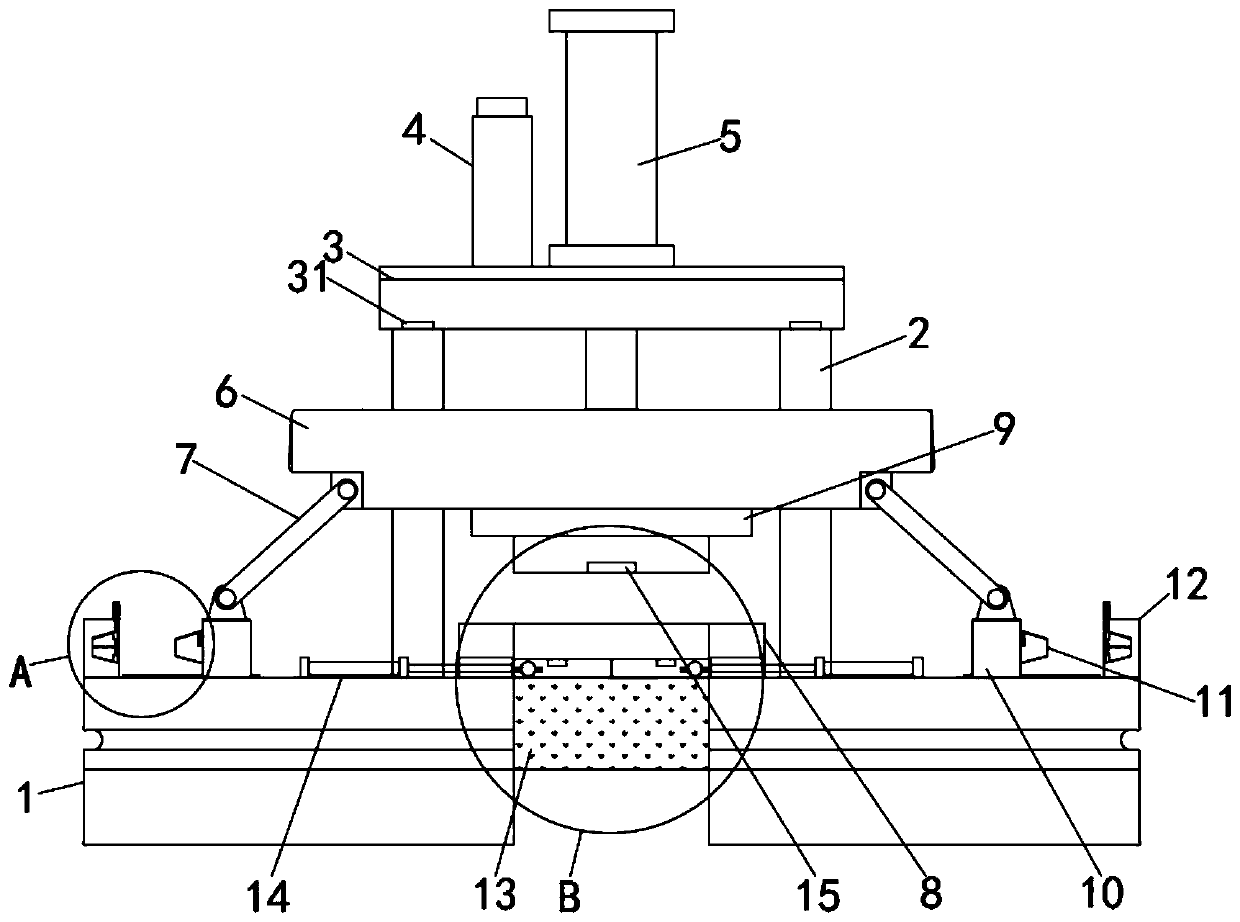

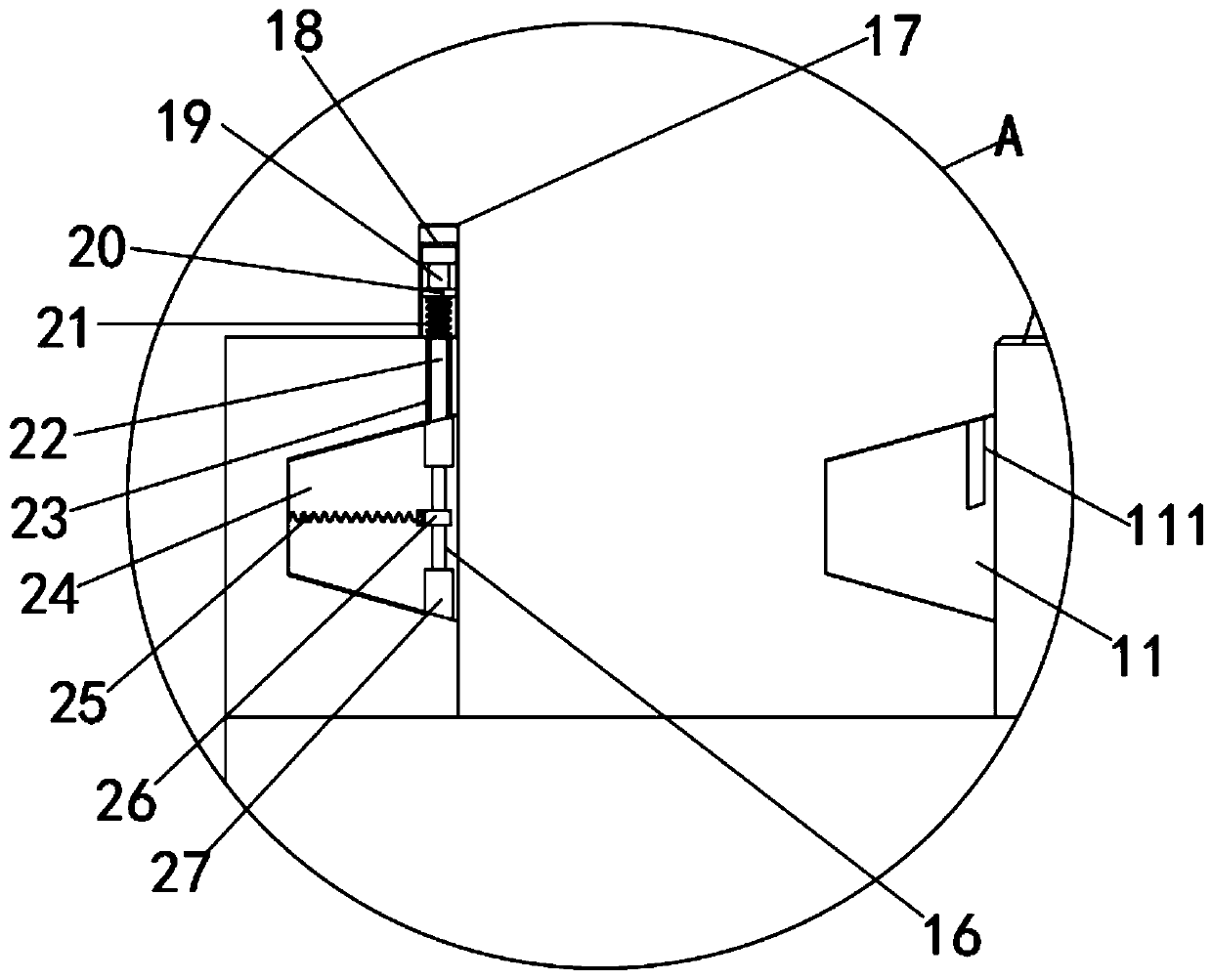

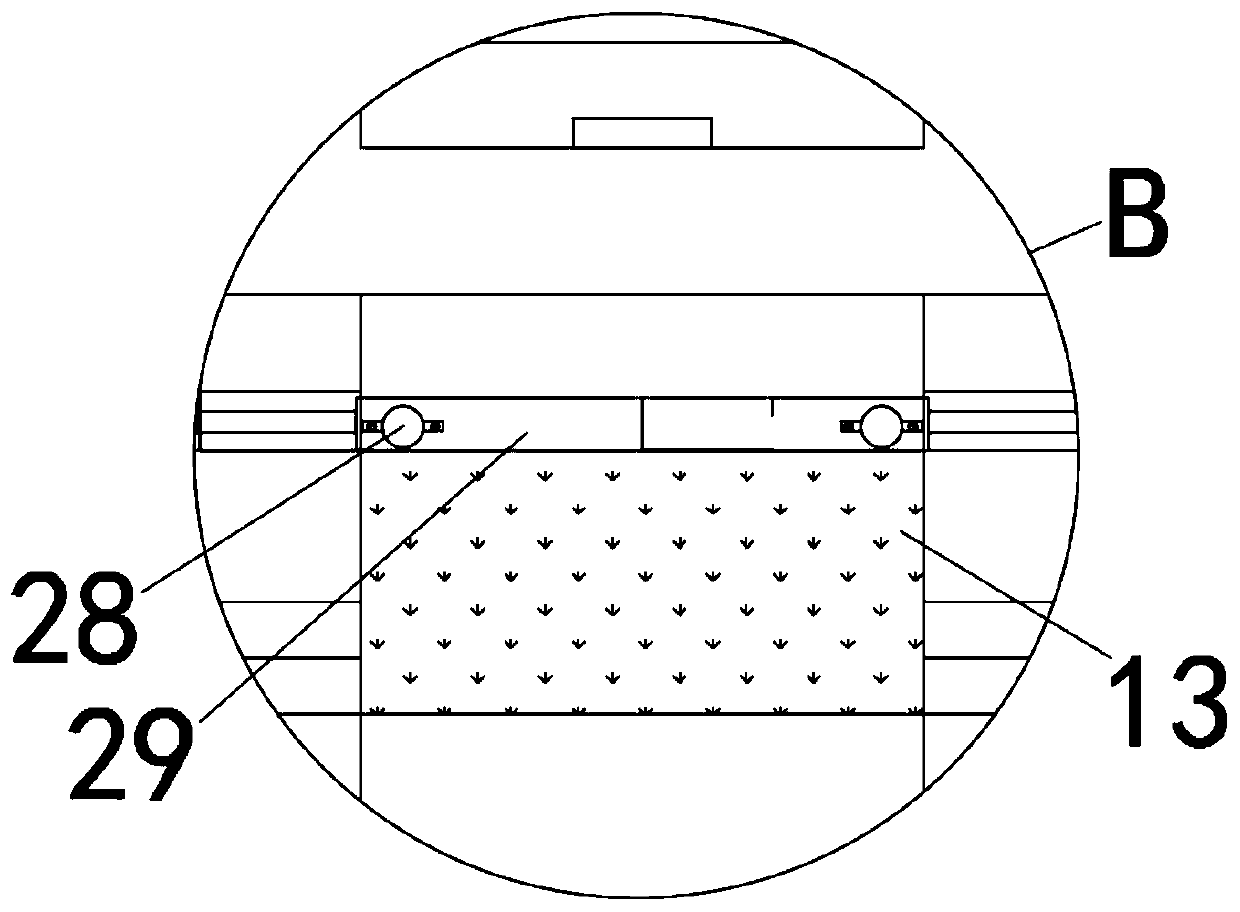

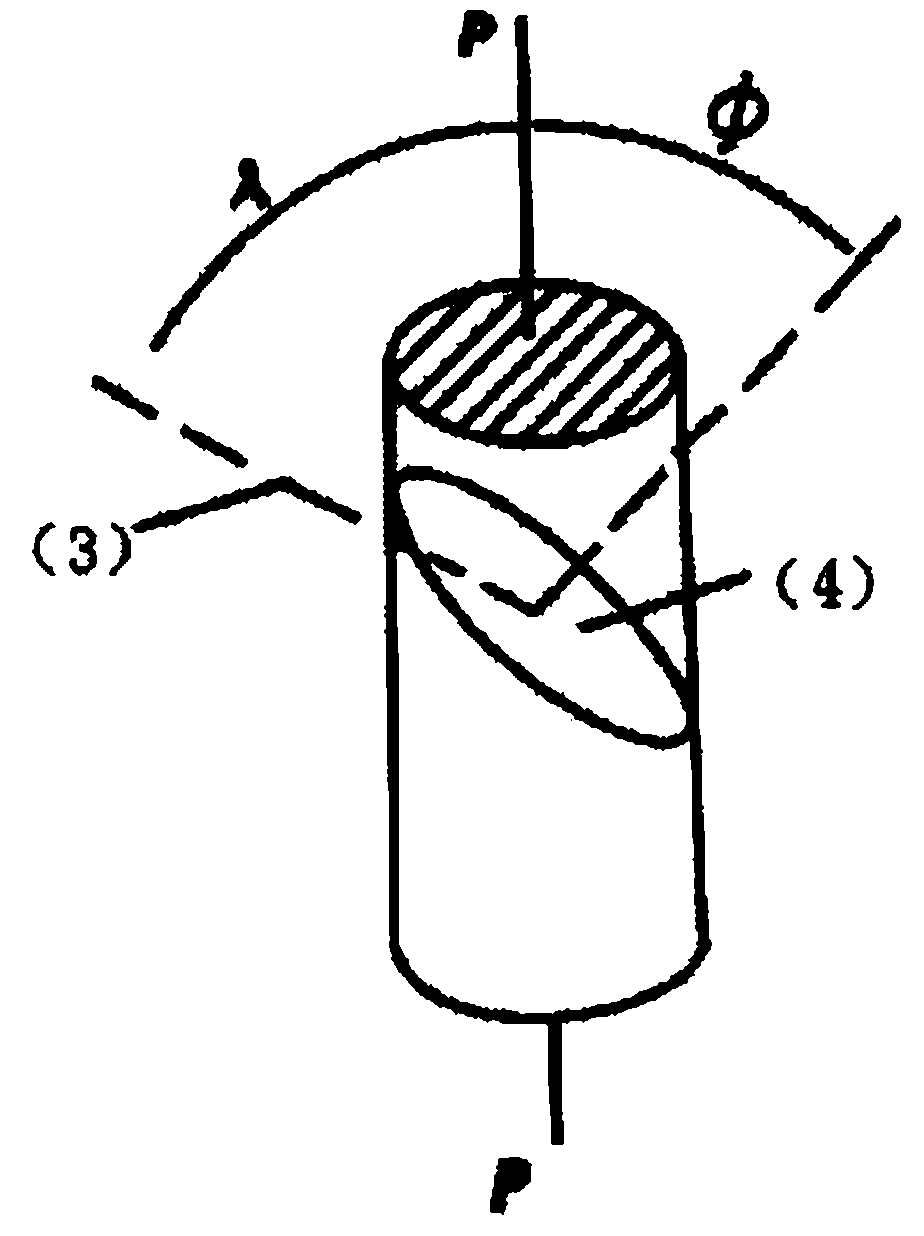

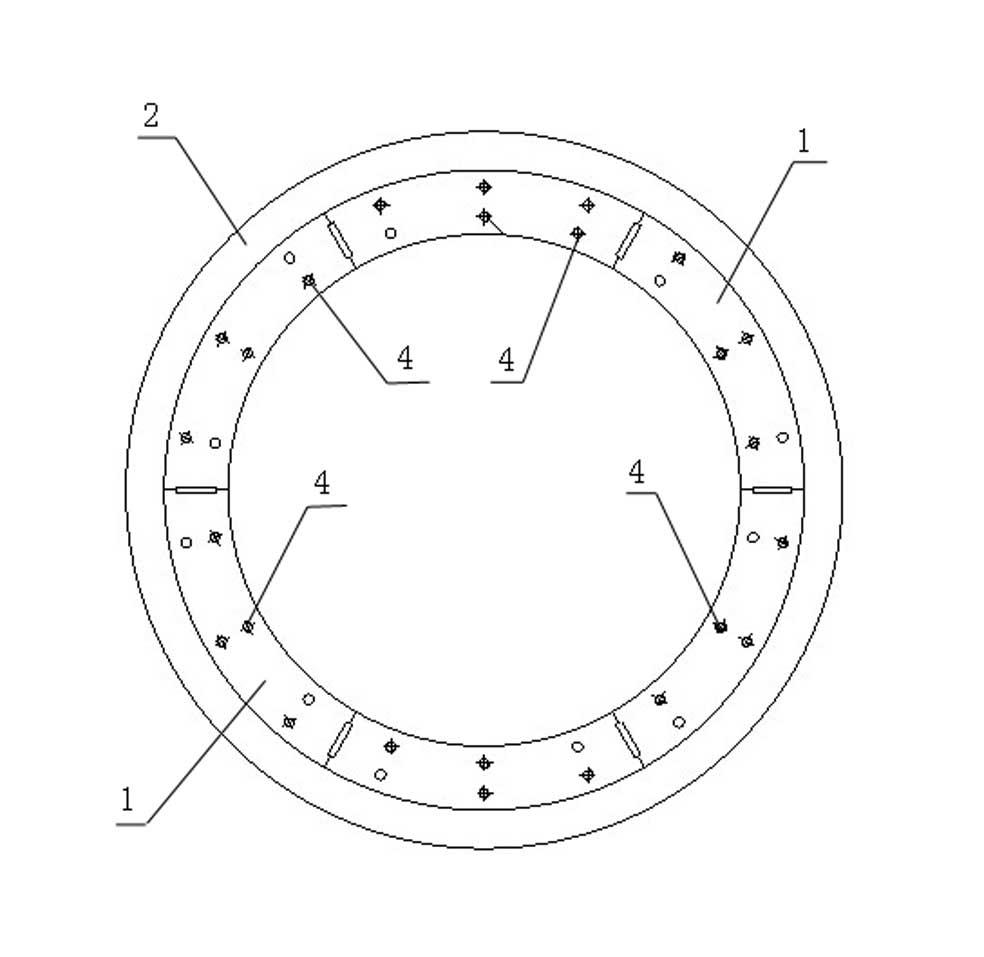

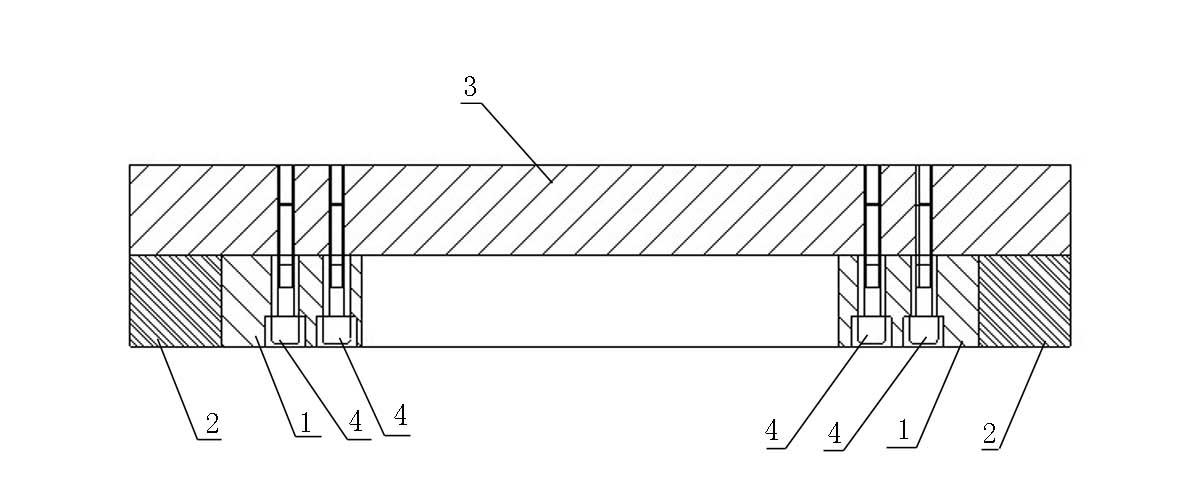

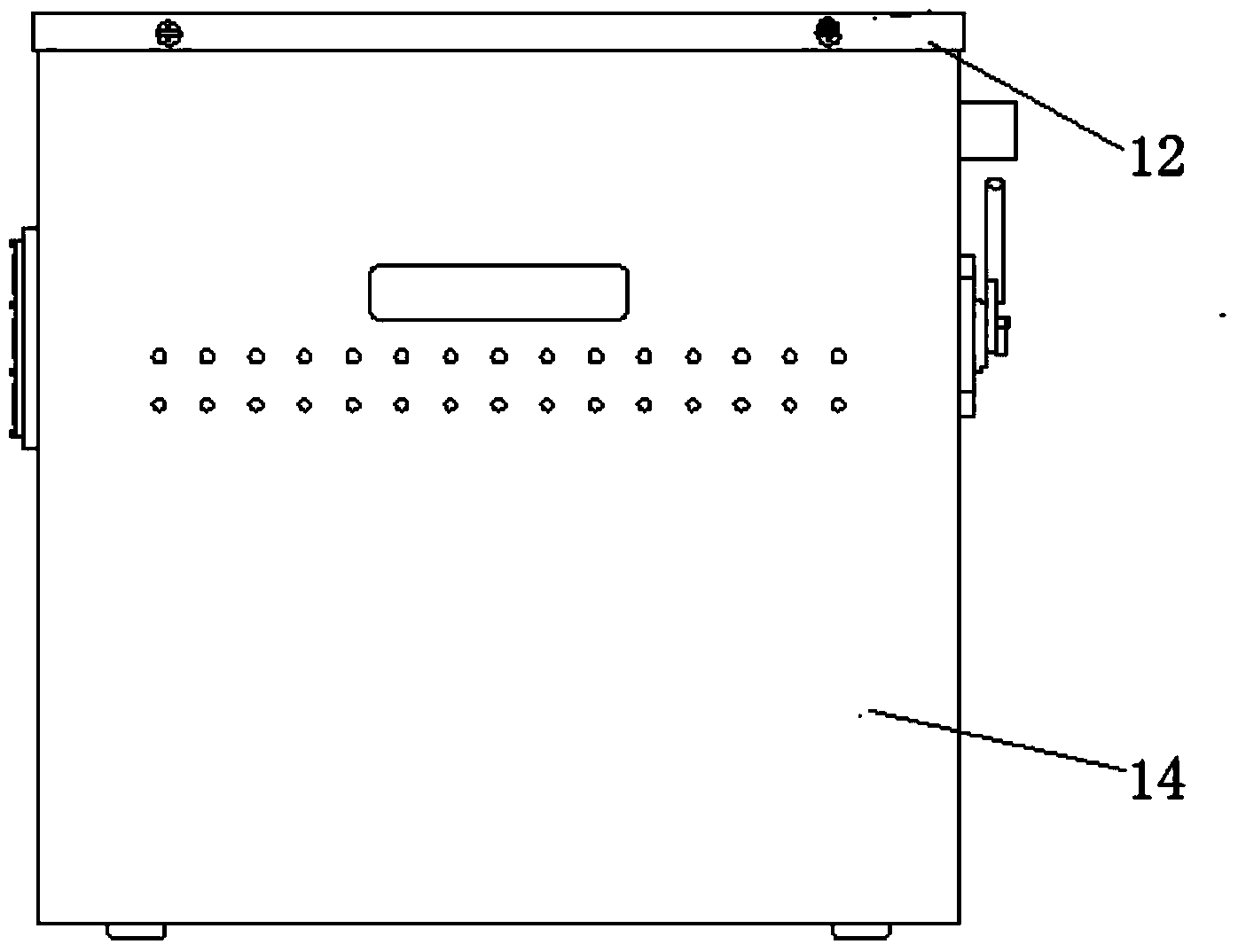

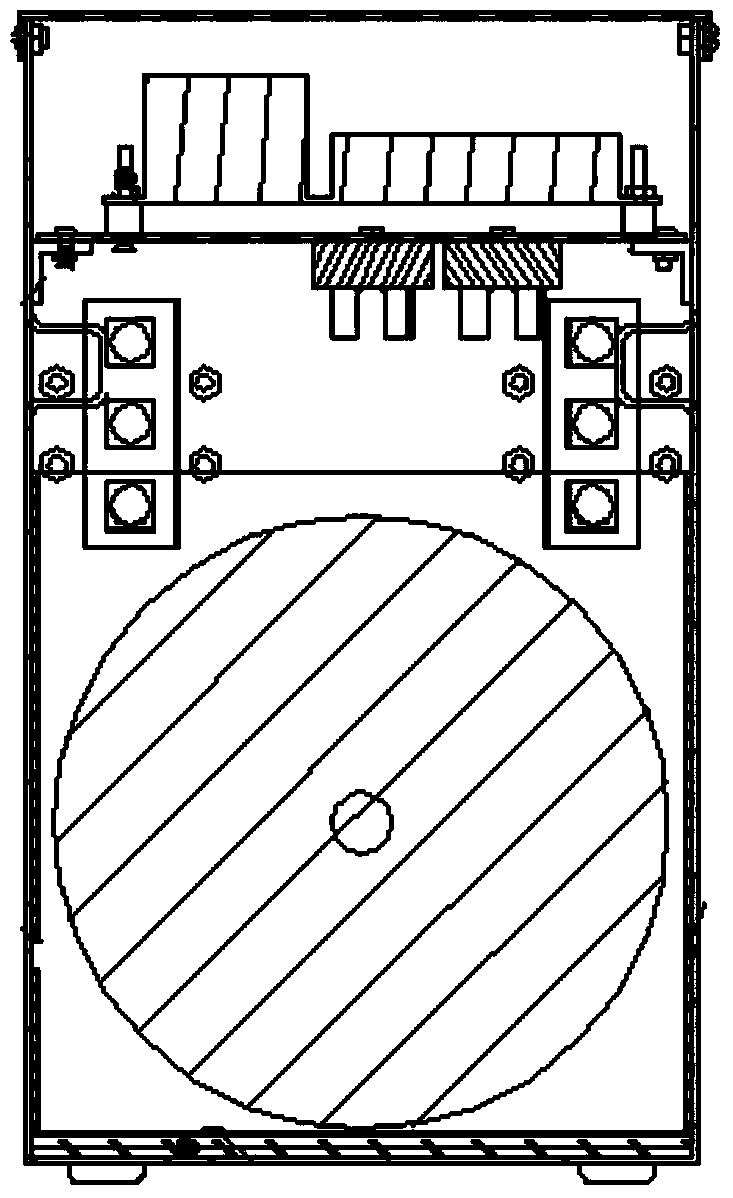

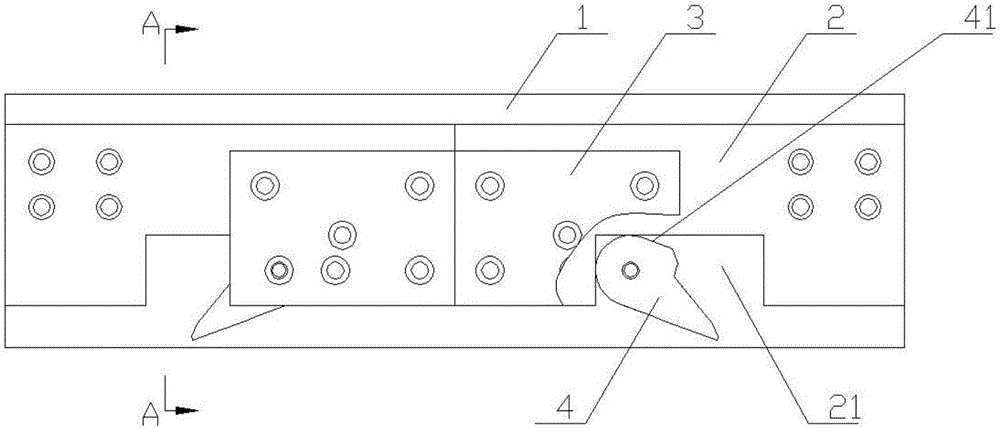

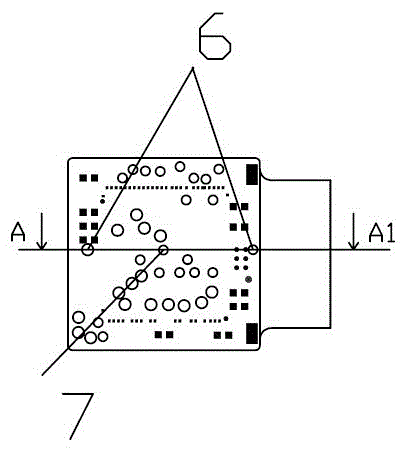

Longitudinal-seam laser welding positioning device for thin-wall circular tube

ActiveCN101758352APrecise positioningEffective positioningWelding/cutting auxillary devicesAuxillary welding devicesMechanical engineeringLaser

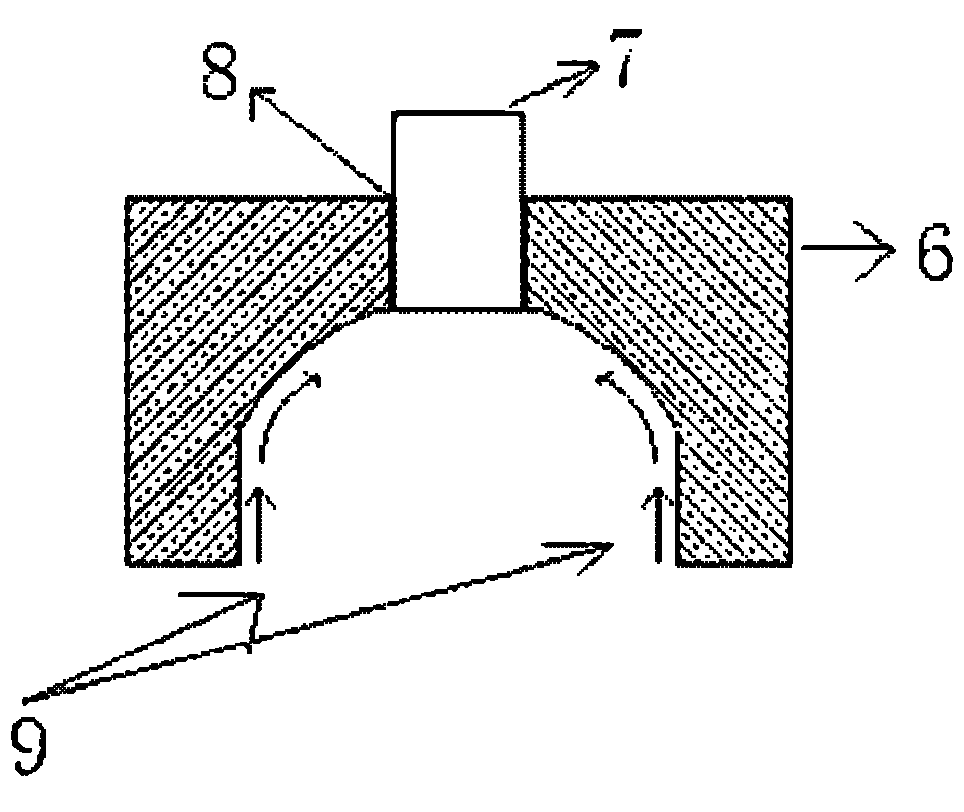

The invention provides a longitudinal seam laser welding positioning device for a thin-wall circular tube, comprising a support core shaft assembly of a molding sheet, an axial positioning mechanism, an opposite-seam positioning mechanism and an abutted-seam pressing mechanism, wherein the abutted-seam pressing mechanism comprises a lower supporting plate positioned below the support core shaft and a driving mechanism thereof as well as a left claw, a right claw and a driving mechanism, wherein the left claw and the right claw are arranged at the left side and the right side of the support core shaft; the opposite-seam positioning mechanism comprises an axial opposite-seam slot arranged on the support core shaft; the axial positioning mechanism comprises a positioning block at one end of the support core shaft and a stop block at the other end of the support core shaft, wherein the stop block is driven by using a screw rod; the driving mechanism of the lower support plate comprises a driving cylinder, a lower support plate sliding seat, a driving cylinder and vertical guide rails positioned at the front and the back of the driving cylinder, wherein the output end of the driving cylinder is connected to the lower part of a lower beam of the lower support plate sliding seat, and sliding seat guide sleeves are arranged at the front and the back of the lower support plate sliding seat and play a leading role by matching with the two vertical guide rails; the lower support plate is arranged on an upper beam of the lower support plate sliding seat; and the left claw is driven by using a screw rod, and the right claw is driven by adopting an abutted-seam cylinder.

Owner:WUHAN FARLEYLASERLAB CUTTING SYST ENG

Seasoning formula of seasoning tilapia filets and production process of filets

InactiveCN101991143AOvercoming Perishability and DeteriorationOvercome the difficulty of not being easy to preserveFood preparationMeat/fish preservation by dryingMonosodium glutamateVegetable oil

The invention provides a seasoning formula of seasoning tilapia filets and a production process of the filets. The ingredients of the formula comprise common salt, distilled spirit, ginger, monosodium glutamate, five-spice powder, white granulated sugar and vegetable oil. The production process comprises the following steps of: preprocessing fresh tilapias; de-odorizing the fresh tilapias after removing scales, viscera and heads; and performing drying, seasoning, vacuum package and sterilization to obtain a finished product of yellow-white flaky fish slices, which has loose meat quality, is chewy, has delicious taste and strong fragrance, and has appropriate degree of saltiness. The product has a special production process, a unique flavor, an appropriate mouthfeel, is difficult to deteriorate, has long storage time, is convenient to transport and easy to deposit, can be produced by conditioned factories and has considerable benefits.

Owner:郑元平

Processing technology of half-dry seasoning tilapia fillet

InactiveCN102100372AOvercoming Perishability and DeteriorationOvercome the difficulty of not being easy to preserveFood preparationMeat/fish preservation by dryingMonosodium glutamateVegetable oil

The invention provides a processing technology of a half-dry seasoning tilapia fillet, which comprises the steps: preprocessing fresh tilapia; removing scales, internal organs and head and removing fishy smell; and carrying out microwave drying, seasoning and vacuum packaging and sterilizing to make the ready tilapia fillet, wherein the seasoning comprises salt, white spirit, monosodium glutamate, hot pepper, five spice powder, vegetable oil and the like. The ready tilapia finished product prepared by the method is a yellow and white fish fillet which has loose meat, delicious taste and strong fragrance, is hard and achieves the best taste between salty and tasteless. In addition, the product has unique flavor, suitable taste and long shelf life, has small possibility of deteriorating, and is convenient to transport and store, thereby being produced by qualified processing factories and having considerable benefits.

Owner:郑元平 +1

Processing technology of vegetable and coarse cereal formula rice

ActiveCN103190690AIncrease appetiteChange the processing methodFood shapingFood preparationVitamin CCooking Practices

The invention provides a processing technology of vegetable and coarse cereal formulation rice. The processing technology specifically comprises the following steps of: smashing raw materials, mixing, extruding, forming in a cutting way, cooling, drying by microwaves, cooling, classifying in a sieving way and packaging. Vegetables, grains, coarse cereals and the like are mixed according to a certain proportion to prepare the rice product, the formed rice product has the appearance of rice after being treated by a plurality of working procedures, and therefore, the formula rice can be cooked according to the cooking method of the common rice when being eaten. The appearance of the formula rice is the same as that of the common rice when the formula rice is eaten, and the content of nutrient elements, i.e. vitamin C, carotene, dietary fiber, calcium and ferrum, further increases, so that the consequences of nutrition intake unbalance, malnutrition, body immunity decline and the like since children avoid certain food and have the partiality for a particular kind of food can be solved. The extrusion forming process of the materials in an extruder is a short-time, high-temperature and high-shear fusion and gelatinization process, so that the mixing uniformity, the gelatinization degree and the expression of the final product can be guaranteed after the materials are sufficiently smashed, and the product quality can be improved.

Owner:重庆好媳妇食品有限公司

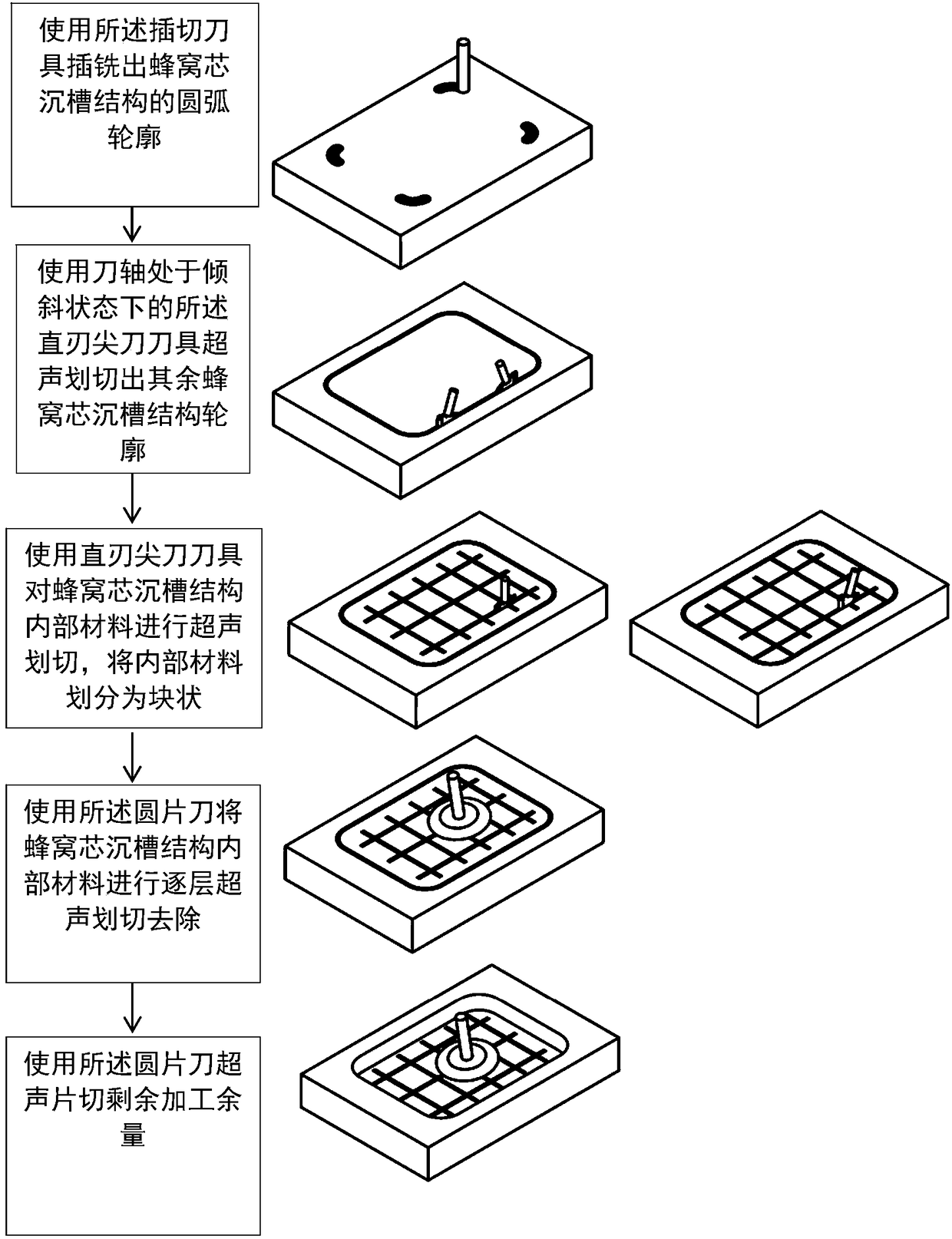

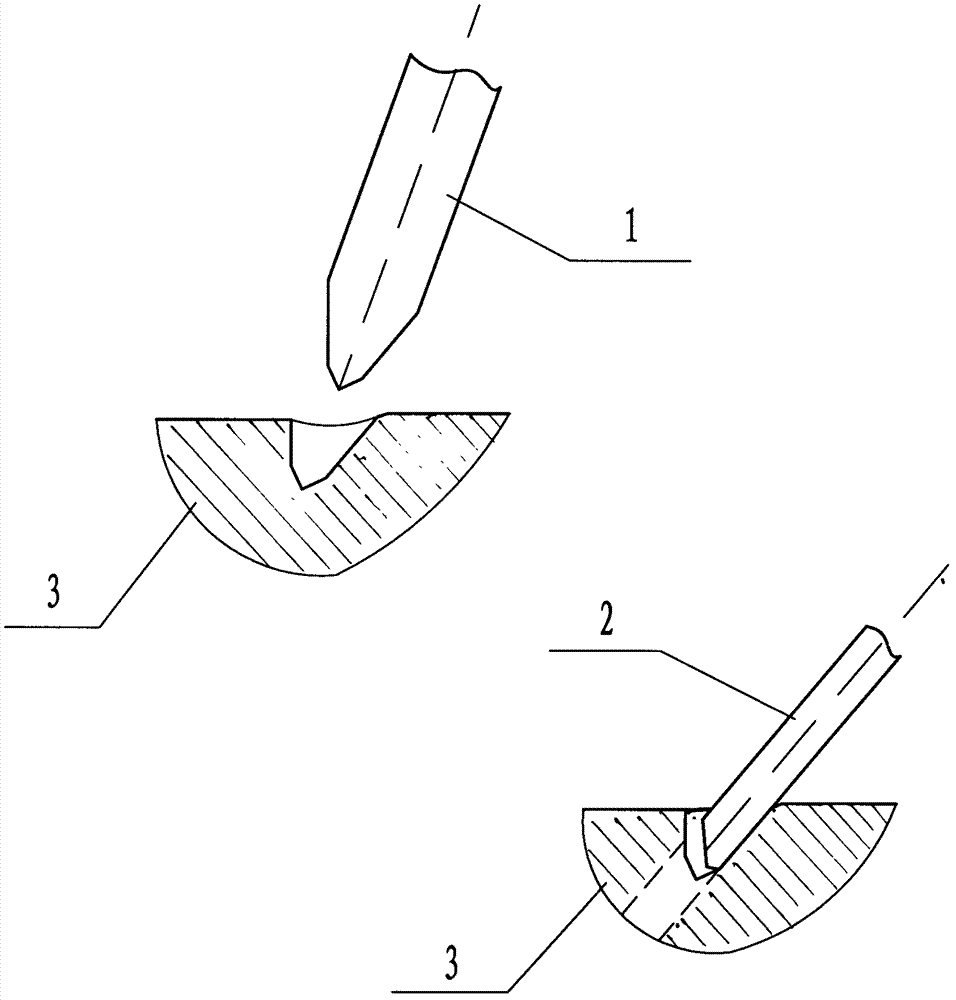

Ultrasonic cutting method for honeycomb core settling tank structure

The invention discloses an ultrasonic cutting method for a honeycomb core settling tank structure. The ultrasonic cutting method includes the following steps of S1, contour forming processing, S2, block dividing processing, S3, honeycomb core settling tank structure internal material removing processing, and S4, honeycomb core settling tank structure bottom face finish processing. Ultrasonic cutting is adopted, a traditional honeycomb core cutting mode is changed, processing defects caused by traditional cutting are avoided, and processing quality and processing efficiency of the honeycomb core settling tank structure are improved.

Owner:DALIAN UNIV OF TECH

Production process for preparing high-activity compound dietary fibers by extracting from Gracilaria

The invention discloses a production method for preparing high-activity compound dietary fibers by extracting from Gracilaria. The production process comprises the following steps of: (1) alkali treatment: cleaning a dry Gracilaria product by using tap water and then soaking the dry Gracilaria product by using alkali liquor at high temperature; (2) bleaching: bleaching by using sodium hypochlorite; (3) acidification: acidifying the frond by using hydrochloric acid after the frond is bleached; (4) colloid extraction: placing the frond in an extraction kettle after acidifying and adding distilled water for extracting colloid; then filtering by using nylon cloth to obtain filter liquor and filter residues and cooling the filter liquor to obtain the colloid; freezing, dewatering, drying and pulverizing the colloid into powdered soluble dietary fibers; (5) activation: activating the filter residues by using cellulase and then dewatering, drying and pulverizing the activated filter residues into powdered insoluble dietary fibers; and (6) mixing: mixing the soluble dietary fibers and the insoluble dietary fibers by a certain proportion to obtain the Gracilaria high-activity compound dietary fibers. In the invention, both the soluble dietary fibers and the insoluble dietary fibers of the Gracilaria are utilized, thereby solving the recycling problem of the Gracilaria filter residues and improving the utilizing value of the Gracilaria.

Owner:HUAQIAO UNIVERSITY

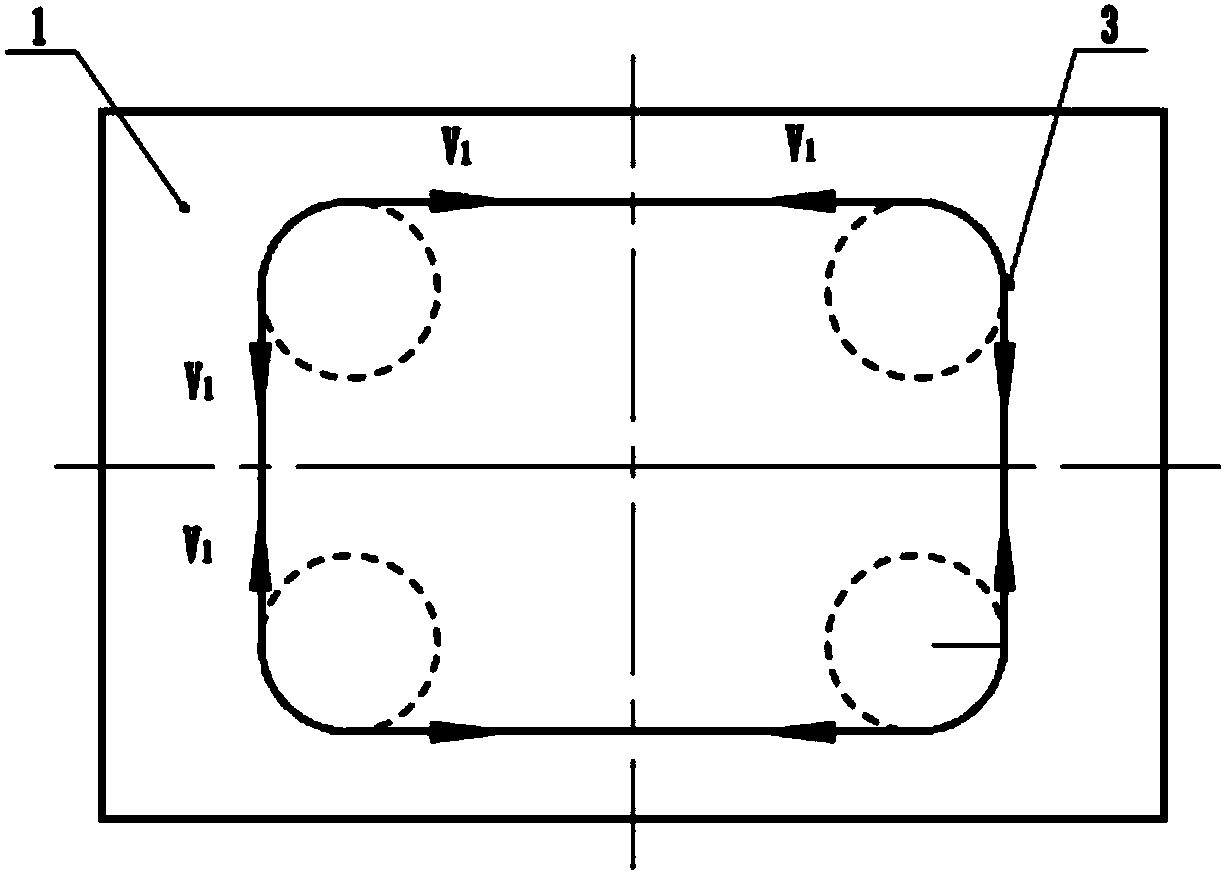

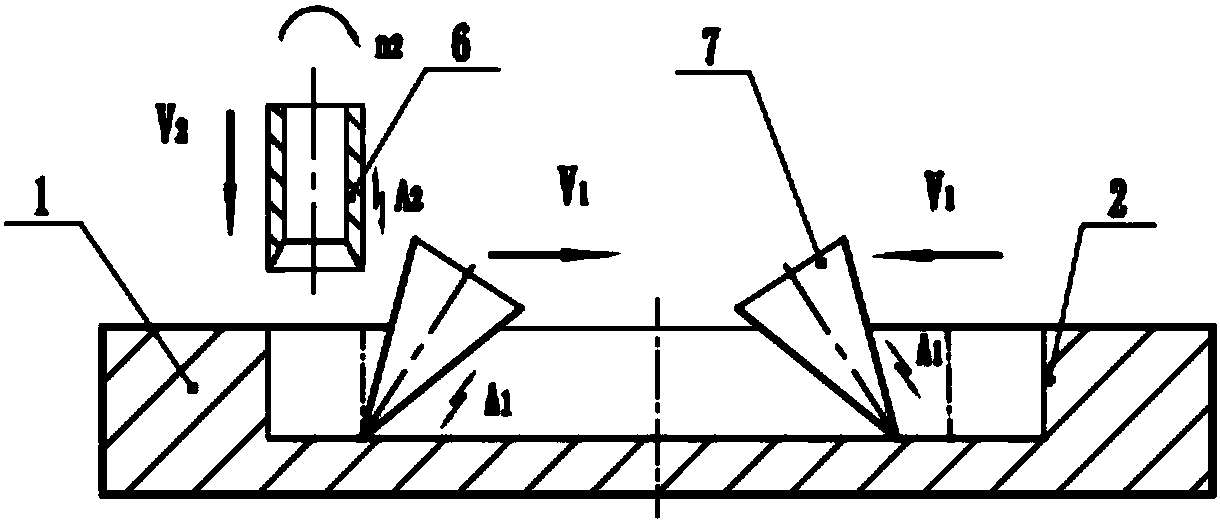

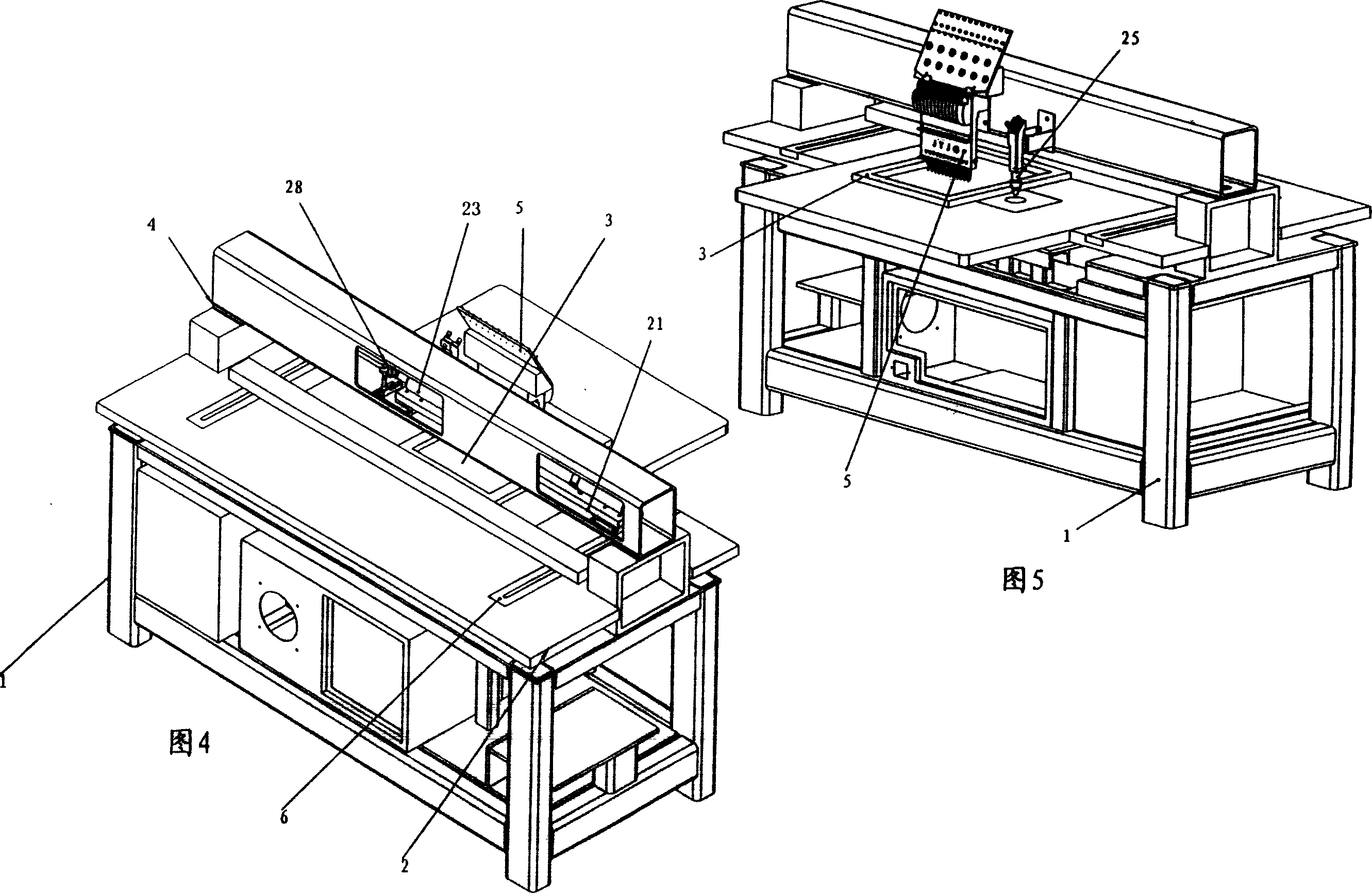

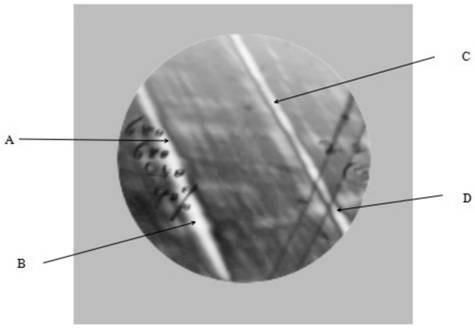

Laser embroidery integrated machine and processing method

InactiveCN101012611AMatureRealize automatic alignmentWorkpiece carriersAutomatic machinesEngineeringLaser cutting

The invention discloses an integrative machine with laser embroidery and the manufacturing method. The integrative machine comprises support rack; working plate on the support rack; embroidery frame on the working plate, which can moves in two dimension; connecting beam on the support rack; single embroidery equipment or multiple embroidery equipments on the beam; laser tube, laser path and laser cutting head connected on the beam. The laser cutting head is corresponding to the embroidery equipment and it is set at the side of embroidery equipment. The invention is the subliming machine under the lack of laser cutting machine in embroidery area. It not only continues the superiority of laser machine to the conventional embroidery process but also compensates the lack. It is another jump in efficiency and effect from hand to mechanism and to the laser. The integrative machine with laser embroidery changes the conventional process method of embroidery machine thoroughly.

Owner:WUHAN GOLDEN LASER

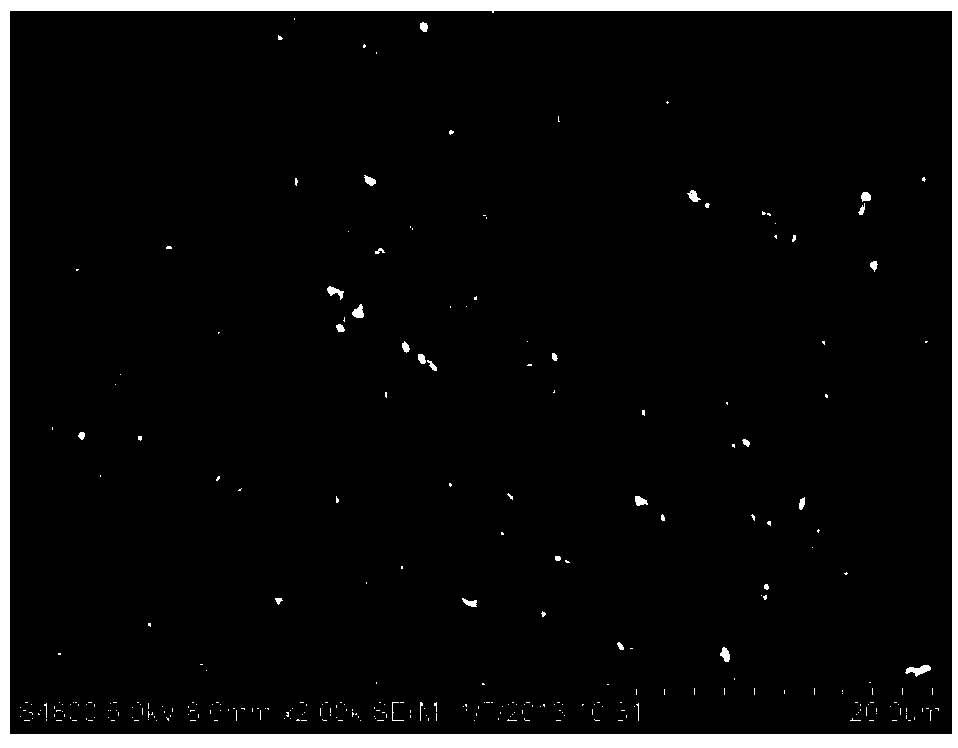

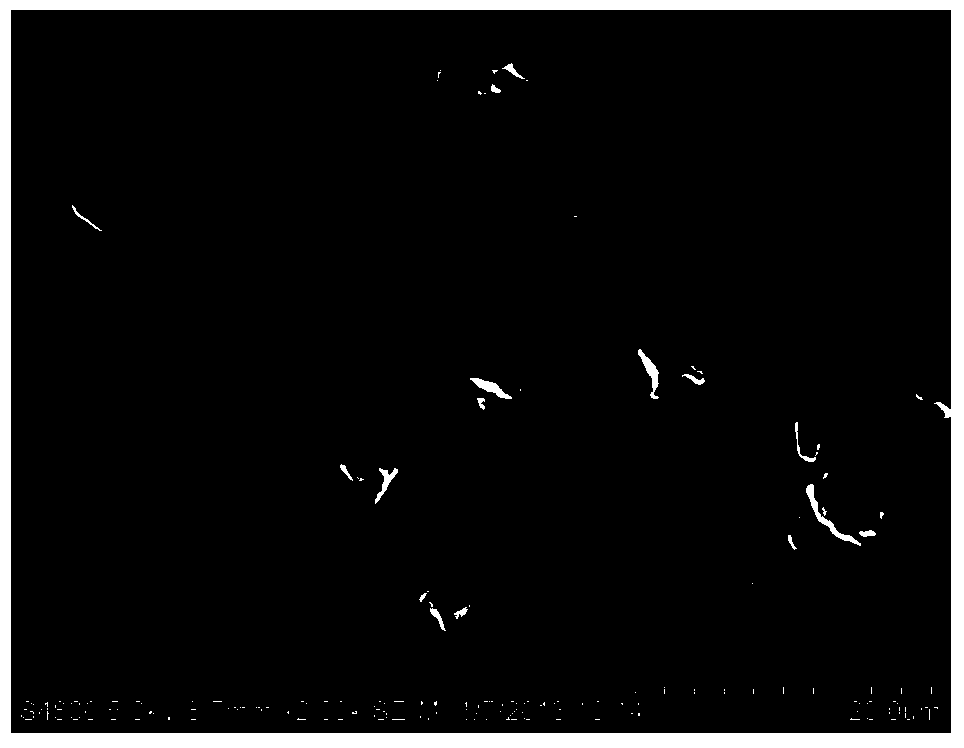

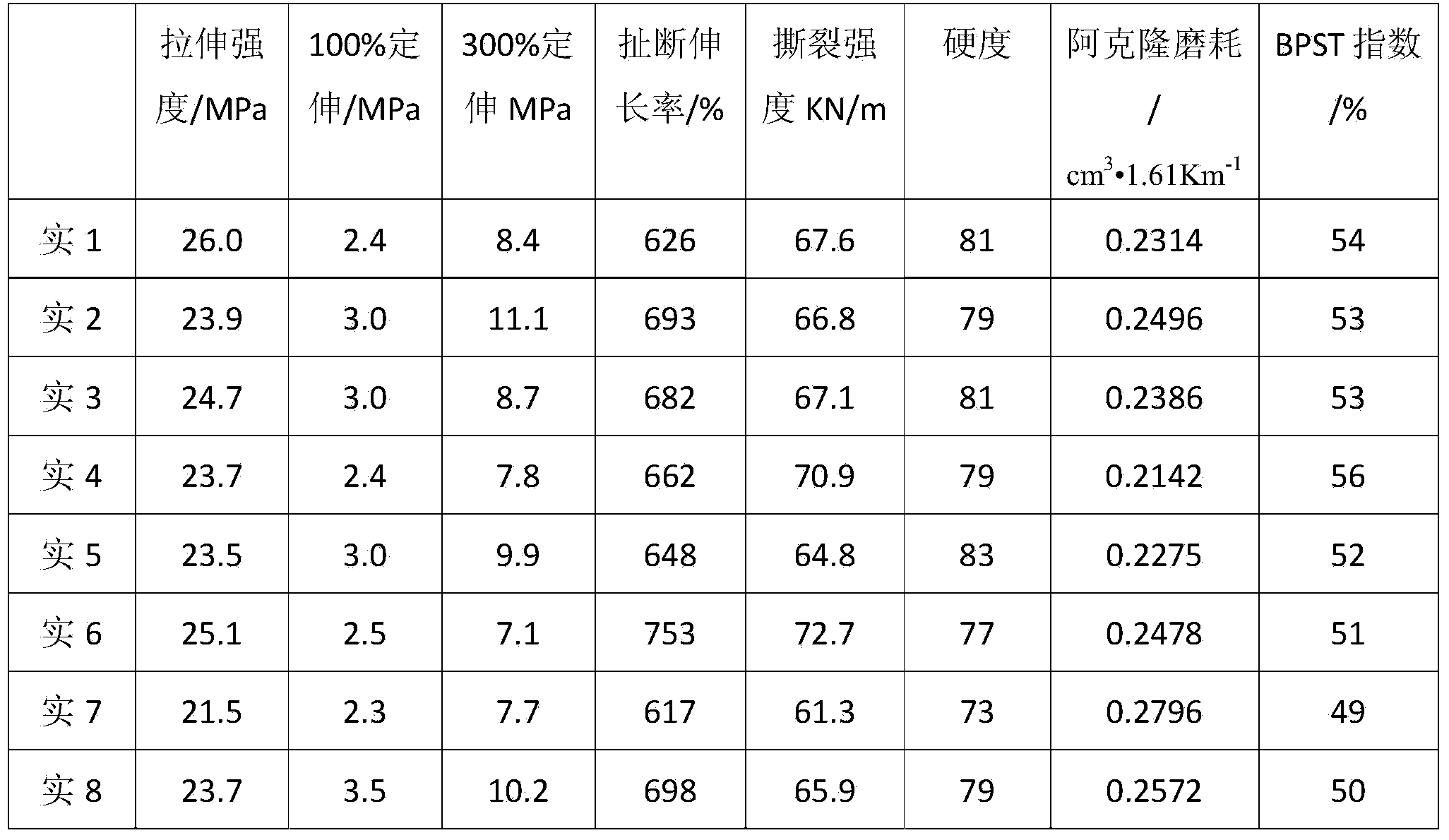

Preparation method of starch modified white carbon black/rubber composite filler

The invention relates to a preparation method of a starch modified white carbon black / rubber composite material, which comprises the following step: by using traditional rubber processing equipment, uniformly dispersing a previously gelatinized starch paste into a white carbon black / rubber composite material to obtain a starch modified white carbon black / rubber composite material. The introduced starch macromolecular chains and silicon hydroxyl groups on the surface of white carbon black interact with each other, so that the dispersion of the filler in the rubber matrix is reinforced, thereby improving the slip resistance and abrasion resistance of the white carbon black / rubber composite material and reducing the rolling resistance of the white carbon black / rubber composite material. According to the invention, the method is simple and easy to implement, does not change the traditional rubber processing mode, is short in production cycle, low in raw material cost, friendly to environment and suitable for preparation of various vulcanized rubber products, and has wide application prospects.

Owner:BEIJING UNIV OF CHEM TECH

Productive technology for extracting diet fiber from-sargassum

A process for extracting edible fibres from sargassum includes such steps as washing, cutting, immersing, extracting by sodium carbonate, filter, neutralizing, filtrate, adding calcium chloride to obtain gel, bleaching with sodium hypochlorite, activating, dewatering, baking, pulverizing to obtain soluble edible fibres, treating the filtered dregs with acid or alkali, bleaching, dewatering, baking, pulverizing to obtain insoluble edible fibres, and proportionally mixing soluble with insoluble edible fibres (4:1).

Owner:SOUTH CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI +1

Automatic bonding and stamping die in stator and rotor core dies

InactiveCN111515288AHigh positioning accuracyGuaranteed machining accuracyShaping toolsMetal-working feeding devicesPhysicsStator

The invention relates to the technical field of stamping dies, in particular to an automatic bonding and stamping die in stator and rotor core dies. The shortcomings in the prior art are overcome, andthe automatic adhesive stamping die comprises a base; a lower die, guide pillars arranged symmetrically, and fixing plates arranged symmetrically are fixed to the top of the base by bolts separately;a top plate is fixedly installed on the tops of the guide pillars, and a lift pressing plate is slidably arranged at the exteriors of the guide pillars; after completion of stamping and bonding treatment through inner workpieces, the pressure held by a second pressure sensor is reduced due to coating melting, and fed back to the interior of a discharging cylinder through pressure reduction signals, so that the discharging cylinder acts once to pull a discharge sliding seat to slide toward the both sides in a side groove; thus, a product falls down through a material falling slot automatically, and automatic discharge is achieved; bonding treatment is finished in the die through the stamping die, so that the stamping die does not need to be placed in heating equipment for processing; and alarge amount of operation time and manpower are saved, and the production efficiency is high.

Owner:昆山铭钜精密模具有限公司

Preparation method of dried pumpkin

InactiveCN103330163AChange the processing methodGreat tasteFood preparationPumpkin seedAdditive ingredient

The invention discloses a preparation method of dried pumpkin, and belongs to the field of food processing. The method comprises the following steps that mature pumpkin which is intact in appearance and fresh is selected and cleaned; the pumpkin is peeled off and deseeded, and subjected to sac removal and root hair removal; only pumpkin meat is reserved; the pumpkin meat is cut into pieces; the small pumpkin meat is cut into slices; the pumpkin slices are put into hot water and blanched for 30-180s; the pumpkin slices are taken out, put into cold water, and cooled to a room temperature; the pumpkin slices are taken out and drained off; the pumpkin slices are placed in a dish, and put into a vacuum drier for low-temperature drying; and the dried pumpkin slices are taken out and packaged. The method has the benefits that a processing method of the traditional pumpkin is changed; a taste of the dried pumpkin is improved; the dried pumpkin is more fragrant and crisper; and nutritional ingredients of the dried pumpkin are reserved.

Owner:陈武义

Method for manufacturing aluminum sheet circle blank for cold extrusion by aluminum rod

ActiveCN102319984AReduce manufacturing costChange the processing methodMetal-working apparatusManufacturing technologyPunching

The invention relates to the technical field of manufacturing of an aluminum sheet circle, in particular to a method for manufacturing an aluminum sheet circle blank for cold extrusion by an aluminum rod. The method comprises the following steps of: (1) selecting the aluminum rod serving as the raw material; (2) carrying out axial cold deformation on the aluminum rod; (3) carrying out secondary axial cold deformation by a cold header or an automatic splitting punching machine, so that a crystal structure and a displacement direction, which are generated by extrusion, can be matched with the crystal structure and the displacement direction of the product, which are required when the product is applied to a cold extrusion aluminum tube or aluminum tank production process; (4) processing a wagon chamfer angle of a cold heading blank; (5) carrying out annealing processing, wherein commonly, a temperature is selected in the range of 460 DEG C to 520 DEG C and the constant temperature time is selected in the range of 3 to 8 hours; (6) carrying out surface processing, so that the aluminum sheet circle has better lubricant adhesive ability; and (7) packaging a finished product. Due to theadoption of the method, the production cost of the aluminum sheet circle is greatly reduced, the return times are reduced, the yield is improved and the product obtains the maximum elongation by axial cold deformation for twice.

Owner:SHANGHAI YUNDAO ALUMINUM

Lock body machining process

The invention relates to a process of preparing lock, comprising following steps: discharging oxygen, annealing and magnetic cobbing metallic powdered ore, matching alloy, fitting with presser and mold, extruding matched material to blank, putting blank into high temperature furnace for sintering, hardening and getting product. The process changes current preparing type, increases production efficiency, improves handling accuracy and quality, and greatly saves material and energy.

Owner:郑勇进

Improved process for machining crankshaft oblique oil hole

InactiveCN103240434AAccurate and efficient completionAccurate and effective process requirementsCrankshaftPetroleum engineering

The invention provides an improved process for machining a crankshaft oblique oil hole. The improved process includes: firstly a stepwise centering chamfering drill is used for machining a tapered blind hole at the corresponding position on a cylindrical surface of a crankshaft, and then an ordinary gun drill performs machining of the crankshaft oblique oil hole through a lead hole provided by the tapered blind hole. The improved process enables a machining method which drills first and then chamfers in a traditional process to be changed, service life of the ordinary gun drill is one time of that of a special gun drill, using effects of the ordinary gun drill and the special gun drill before coping and after coping have no difference, and therefore the improved process for machining the crankshaft oblique oil hole can reduce cost consumption of cutters greatly, is safe and reliable, and has great popularization value.

Owner:李立军

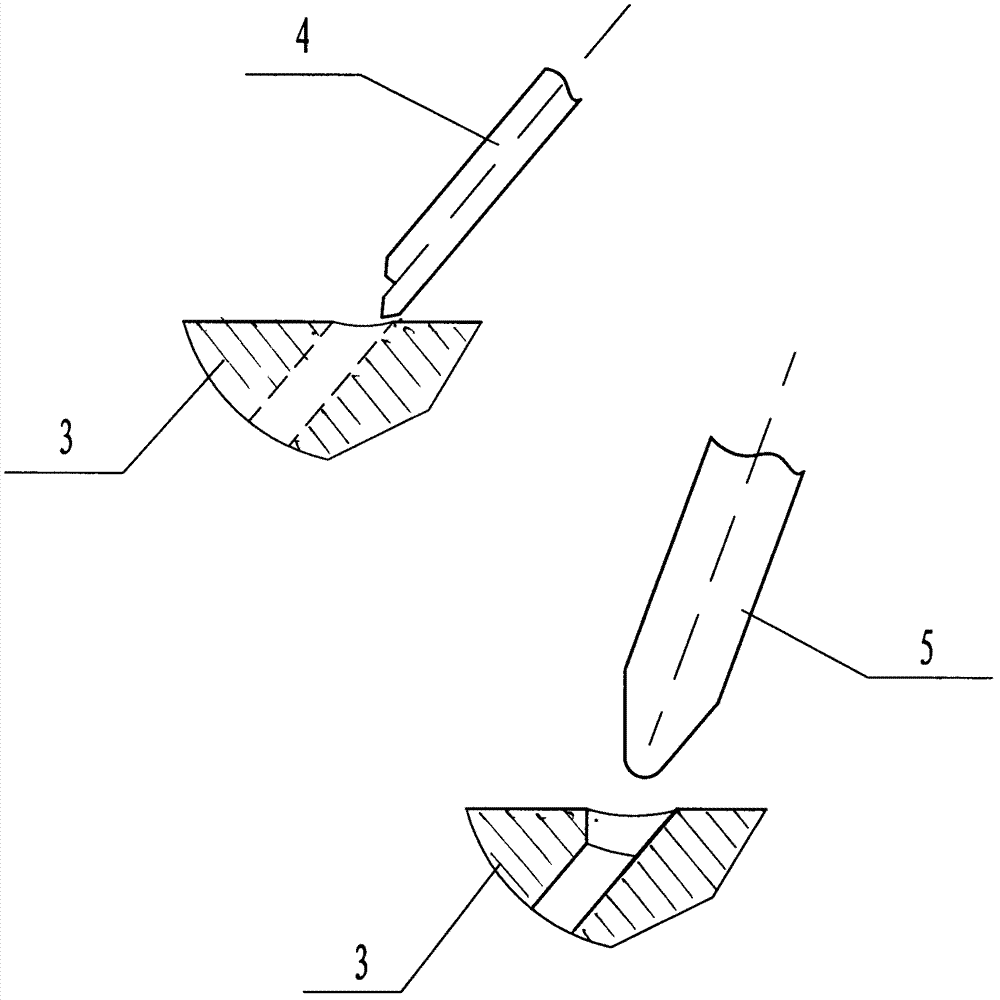

Fish powder production process

InactiveCN106579073AImprove qualityAvoid secondary heating energy consumptionFood scienceFresh fishRoom temperature

The invention discloses a fish powder production process, which comprises: 1, feeding fresh fish into a mincing machine, and cutting into fish blocks; 2, feeding the fish blocks into a presser, carrying out pressing dewatering, and extruding to obtain flaky fish meat cake, wherein the water content in the flaky fish meat cake is reduced to below 45%; 3, feeding the flaky fish meat cake into a baking line, and heating the flaky fish meat cake to prepare a dried cake, wherein the water content in the dried cake is reduced to 1-5%; 4, removing the dried cake from the baking line, and cooling to a room temperature; and 5, carrying out breaking grinding on the dried cake to obtain the fish powder. According to the present invention, the original processing method using a lot of steam is changed, such that the energy is saved, the quality of the fish powder is improved, the process is simplified, and the energy consumption due to the secondary heating on the fish water is avoided.

Owner:威海中科鼎元节能科技有限公司

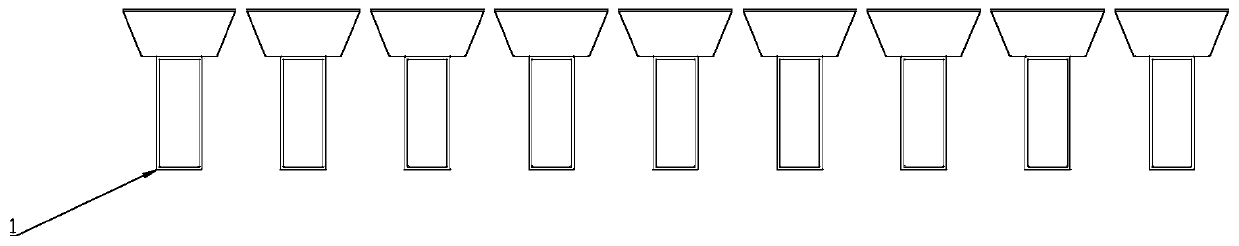

Method for processing gas film holes with continuous rows of integral special electrodes

PendingCN113102848AImprove processing efficiencyChange the processing methodMolding machineEngineering

The invention is suitable for the field of engine blade machining equipment, and particularly relates to a method for processing gas film holes with continuous rows of integral special electrodes, which comprises the following steps: adjusting a special electrode chuck according to the hole number, spacing and hole diameter of gas film holes of a blade; installing an electrode capable of machining the corresponding hole diameter on the electrode chuck; aligning the electrode chuck and a tooling, and determining the angle positions of the gas film holes; adjusting machining parameters, and machining a part gas film hole on an electric spark forming machine; multiple electrodes are distributed in an equal-interval row shape and used for machining a whole row of gas film holes; a plurality of limiting plates are arranged and are used for clamping the electrodes; the plurality of limiting plates detachably clamp the electrodes; the multiple electrodes distributed in the row shape at equal intervals are detachably clamped through the multiple limiting plates, and the gas film hole processing efficiency is improved; when the processing of the gas film holes interferes with the blade, an interference area can be avoided through the technology; and the gas film hole processing method is changed, and electric spark small hole machining is changed into electric spark forming machining.

Owner:贵州安吉华元科技发展有限公司

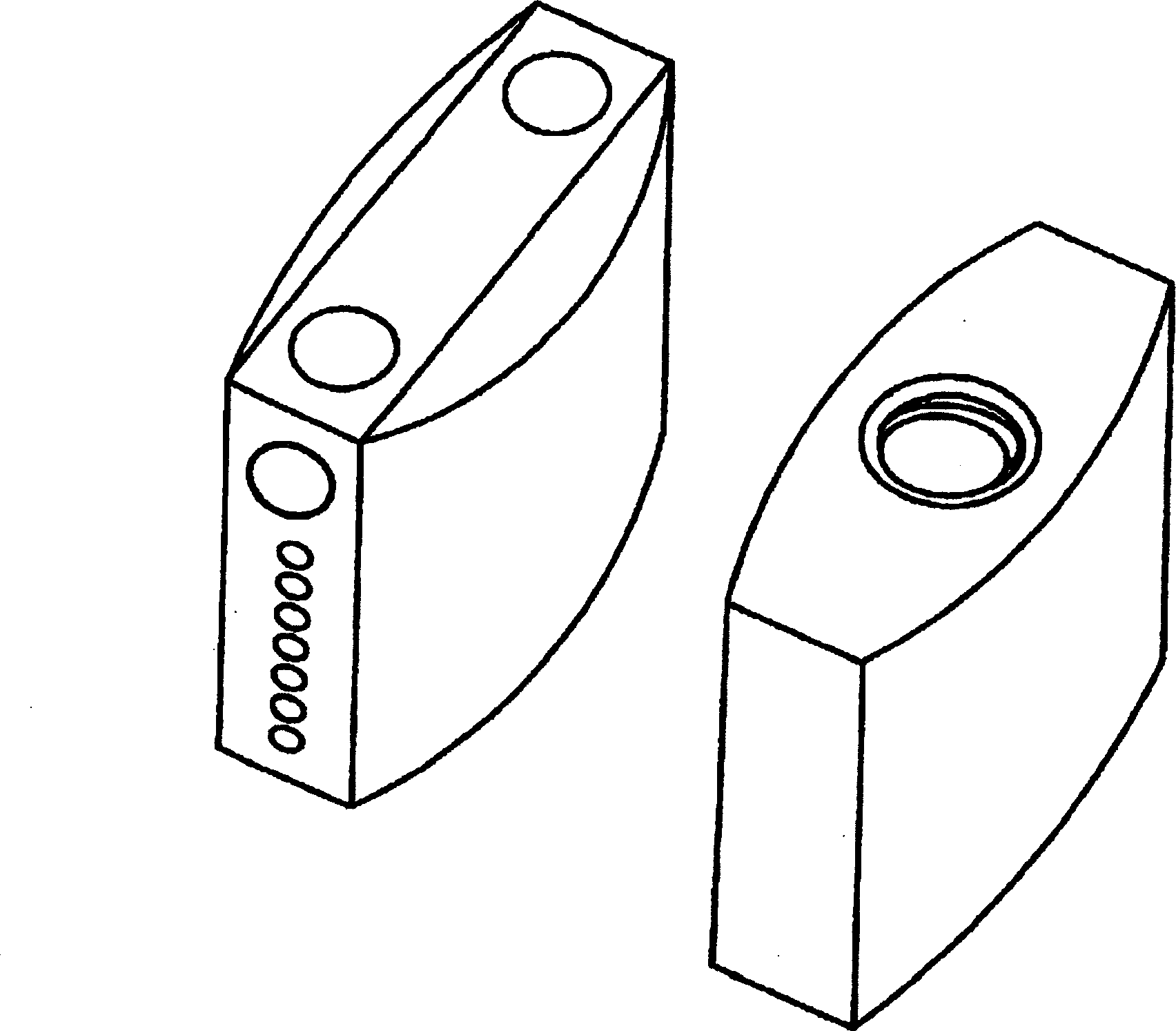

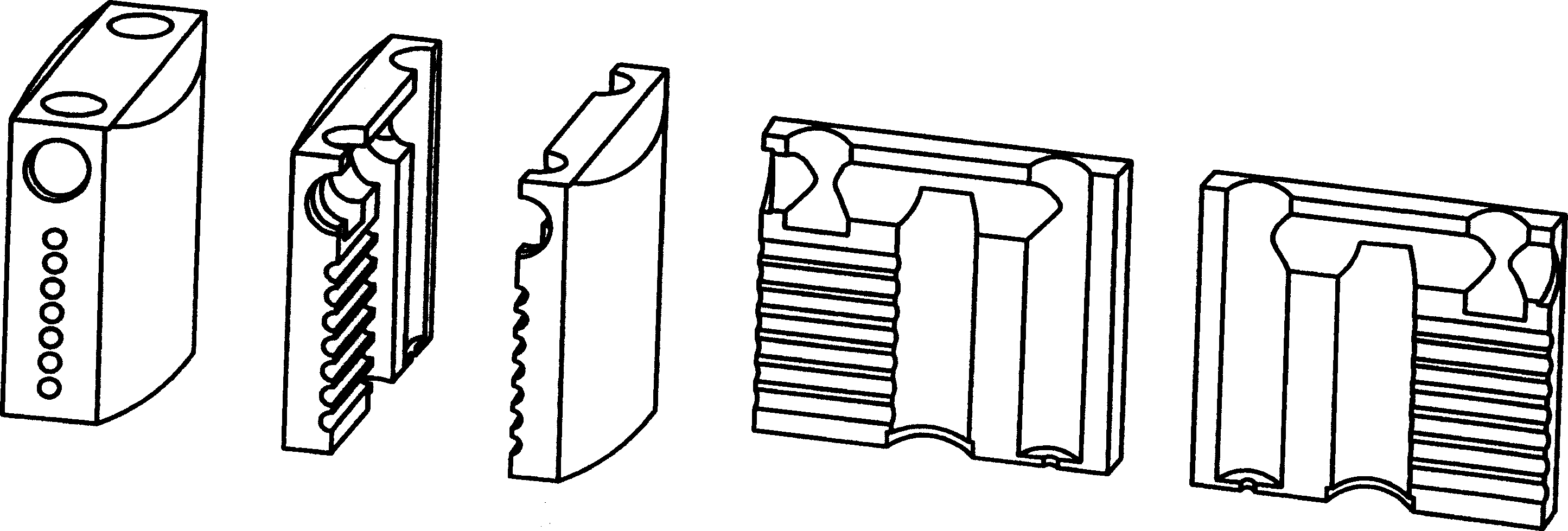

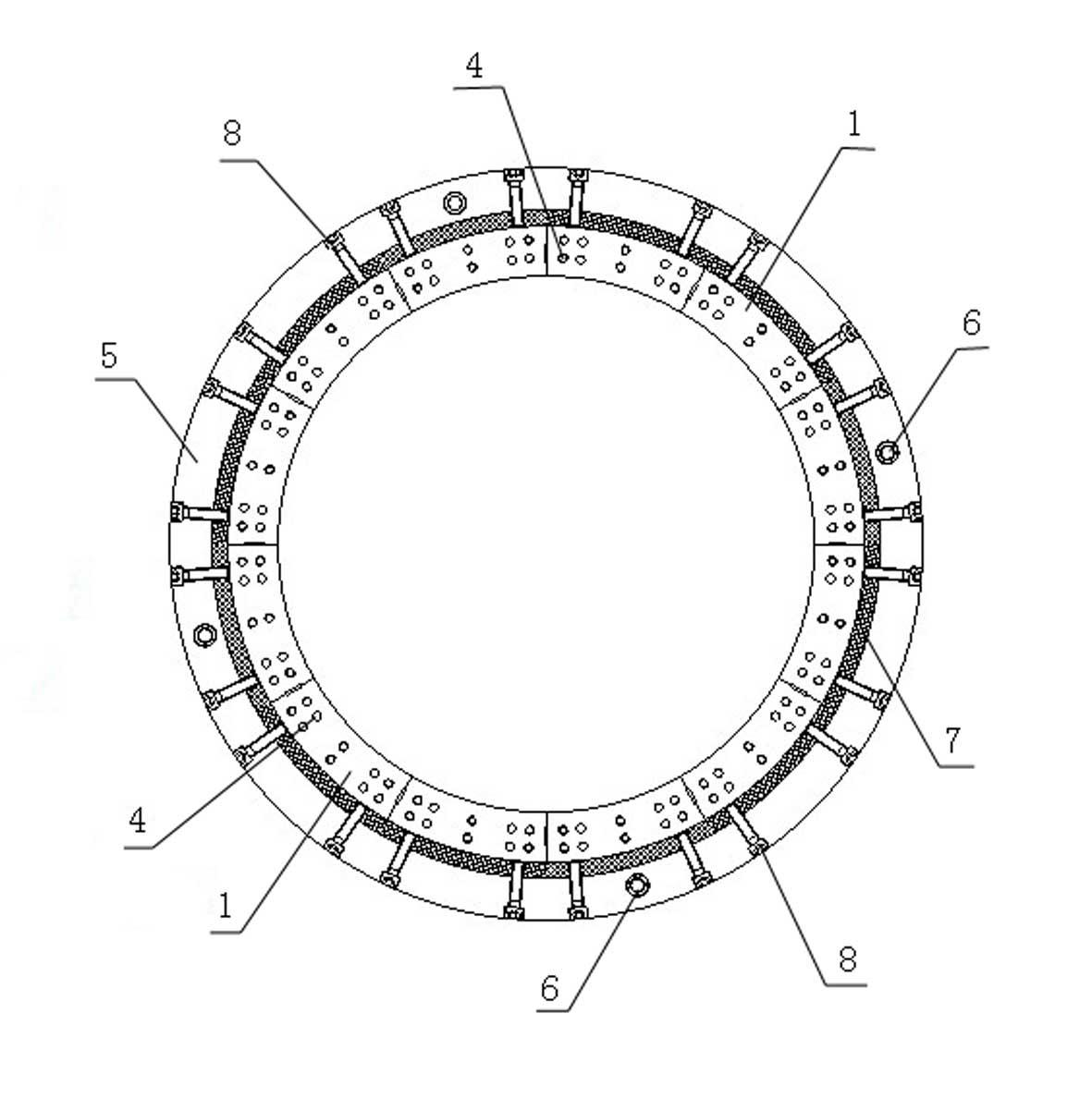

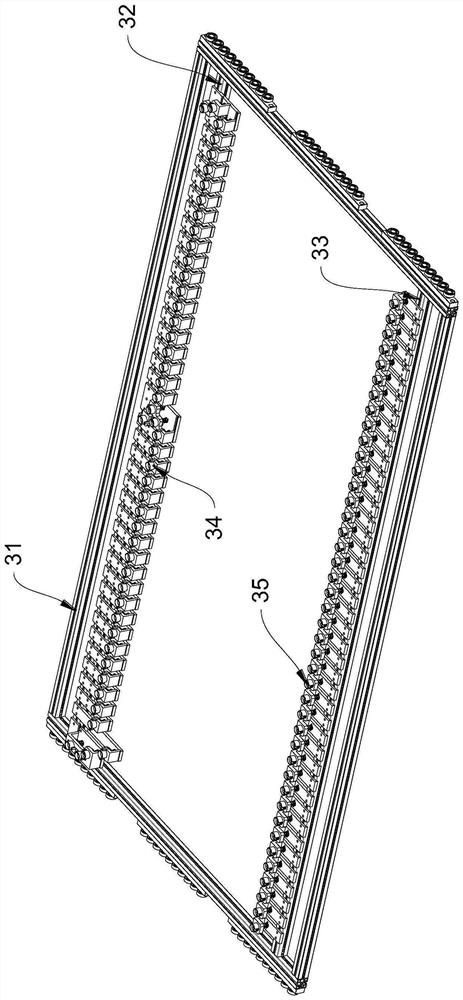

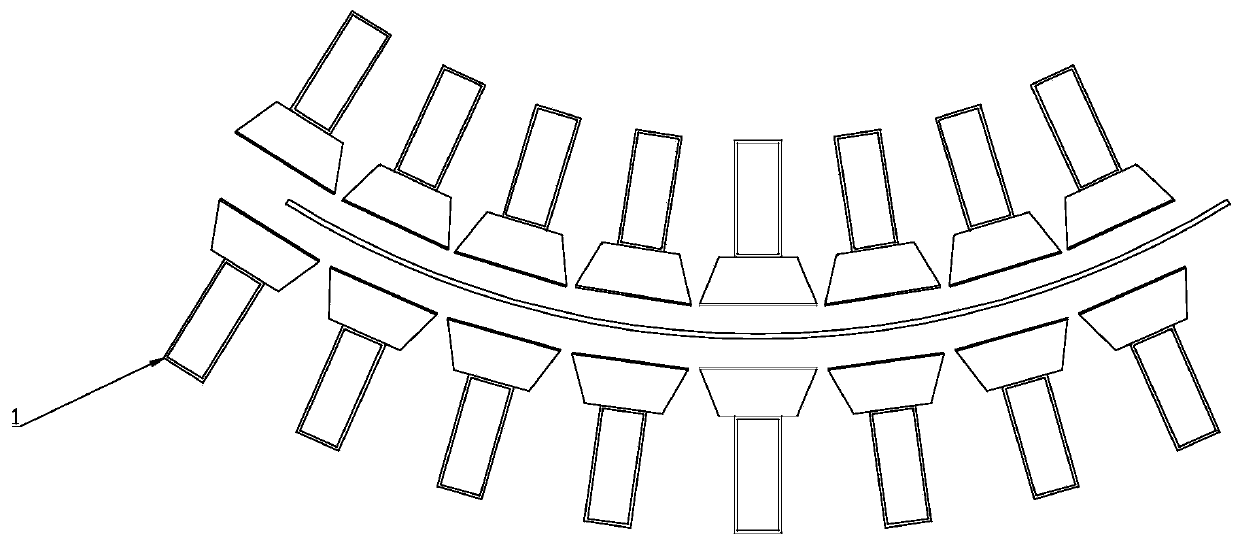

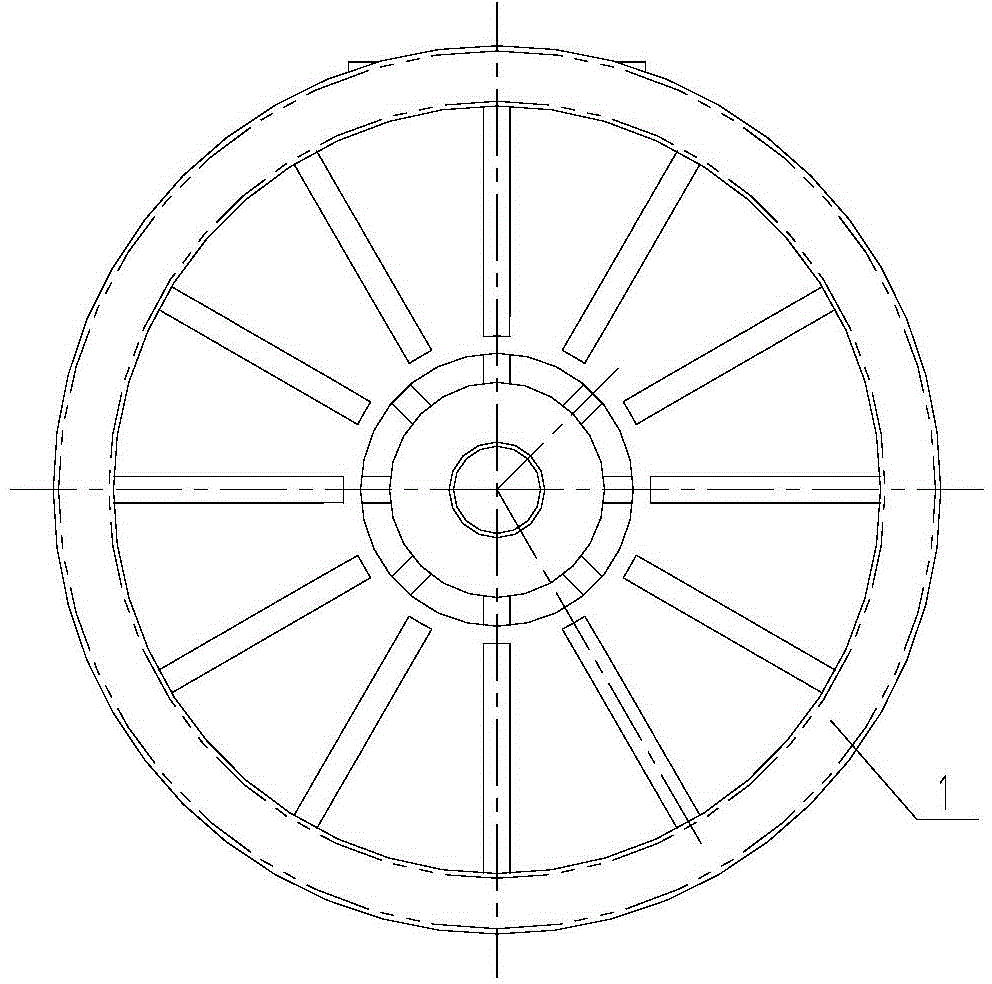

Female mold split block assembly of large-scale double punching mold

The invention relates to the field of a motor punching sheet double punching mold, in particular to a female mold split block assembly of a large-scale double punching mold. The female mold split block assembly comprises a female mold split block and a fixing device, wherein the fixing device comprises a fixing plate, the female mold split block is fixedly arranged on the fixing plate through a plurality of screws, the fixing device also comprises a hoop, a low-melting-point alloy layer and a plurality of regulating screws, the hoop is arranged on the outer periphery of the female mold split block, the low-melting-point alloy layer is arranged between the female mold split block and the hoop, the hoop is fixedly arranged on the fixing plate through the screws, and the regulating screws pass through the hoop and the low-melting-point alloy layer from outside to inside in the radial direction until the bottoms of the regulating screws are tightly pasted with two ends of the outer side of the single female mold split block. The female mold split block assembly of the large-scale double punching mold has the characteristic that the female mold split block assembly can be respectively processed on a plurality of ordinary machine tools, the time is effectively saved, the work efficiency is improved, the requirement on processing equipment is not high, and the maintenance is convenient through the arrangement of the low-melting-point alloy layer.

Owner:CRRC YONGJI ELECTRIC CO LTD

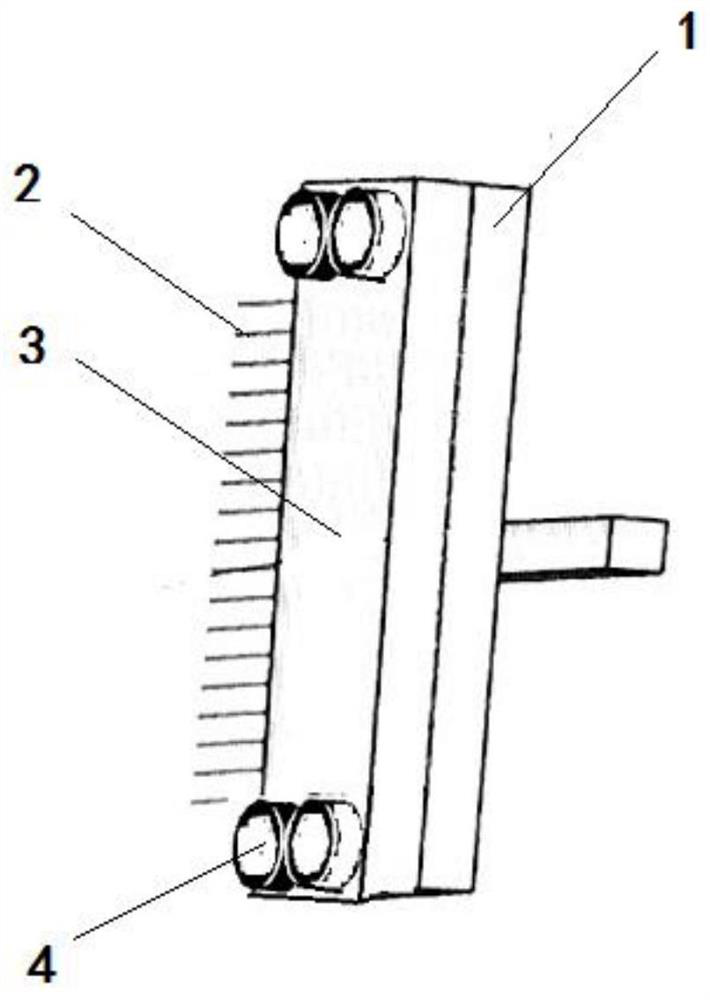

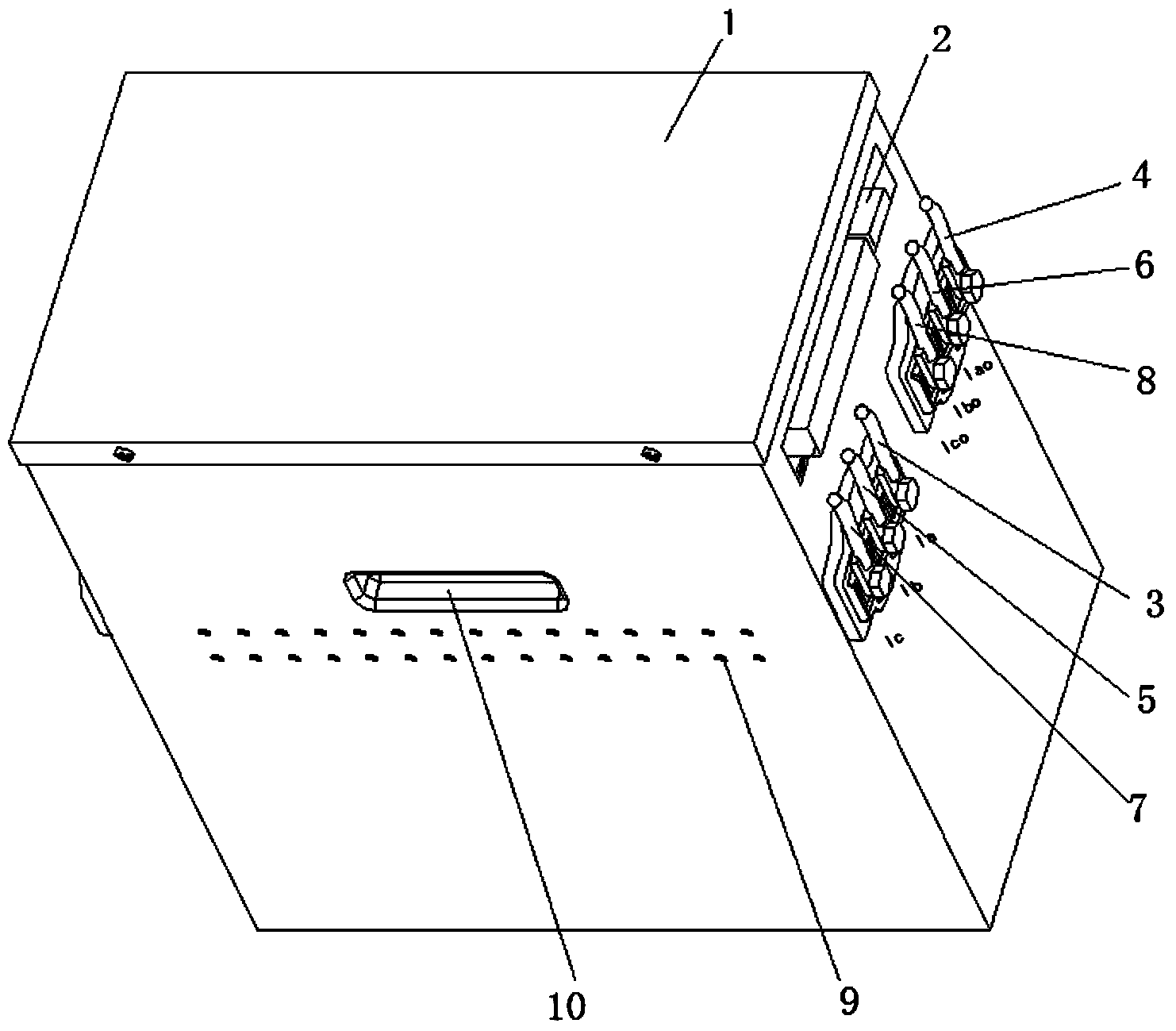

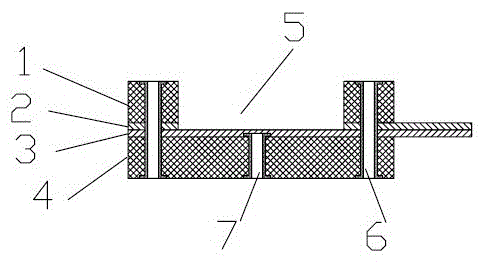

Current isolation mutual inductor

ActiveCN103592491ASimple structureSimple current input and output wiringTransformersVoltage/current isolationPower flowAssembly line

The invention discloses a current isolation mutual inductor. The current isolation mutual inductor comprises a mutual inductor shell used for avoiding external signal interference, a permalloy iron core I, a permalloy iron core II, and a winding W1, a winding W2, a winding W3, a winding W4 and a winding W5 of the permalloy iron core I and the permalloy iron core II. The current isolation mutual inductor further comprises an electronic compensating circuit used for compensating for the magnetic potential. The permalloy iron cores, the windings of the permalloy iron cores and the electronic compensating circuit are arranged in the mutual inductor shell. The electronic compensating circuit comprises a power module, an operational amplifier circuit, an open circuit detection circuit and an alarm circuit. The current isolation mutual inductor has the advantages that detection of a three-phase direct access type electricity meter can be completed when a three-phase assembly line and a three-phase equipotential calibration device are not unhooked or can not be unhooked in the calibration process, the current isolation mutual inductor is simple in overall structure and elegant and attractive in appearance, line outgoing and line incoming are standard, the current input and output wiring mode is simple and reliable, and the current isolation mutual inductor is convenient to use.

Owner:国网山东省电力公司营销服务中心(计量中心) +2

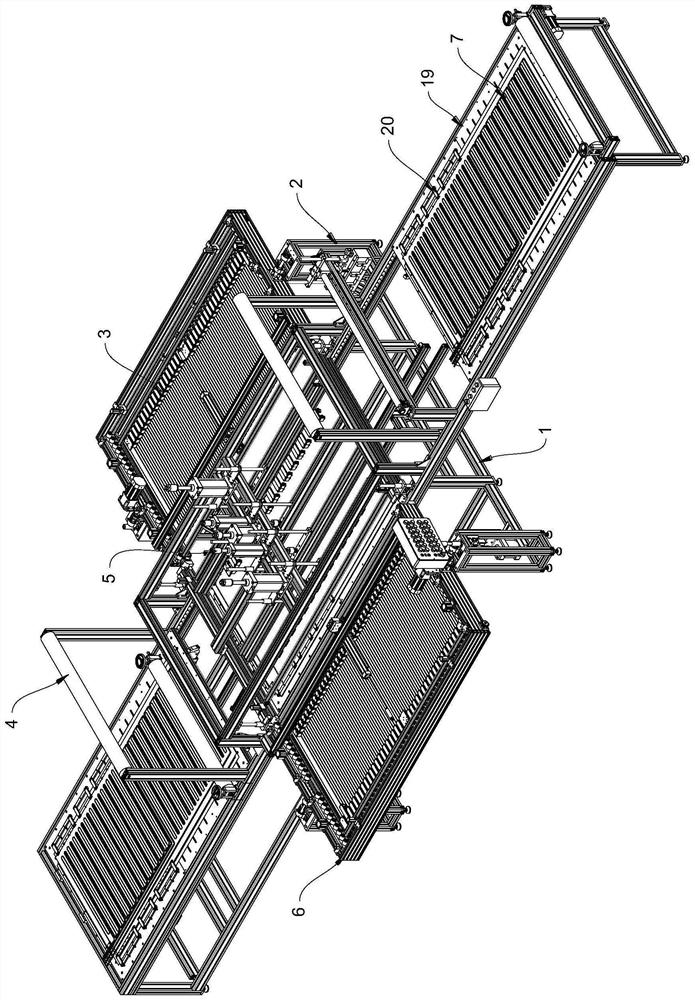

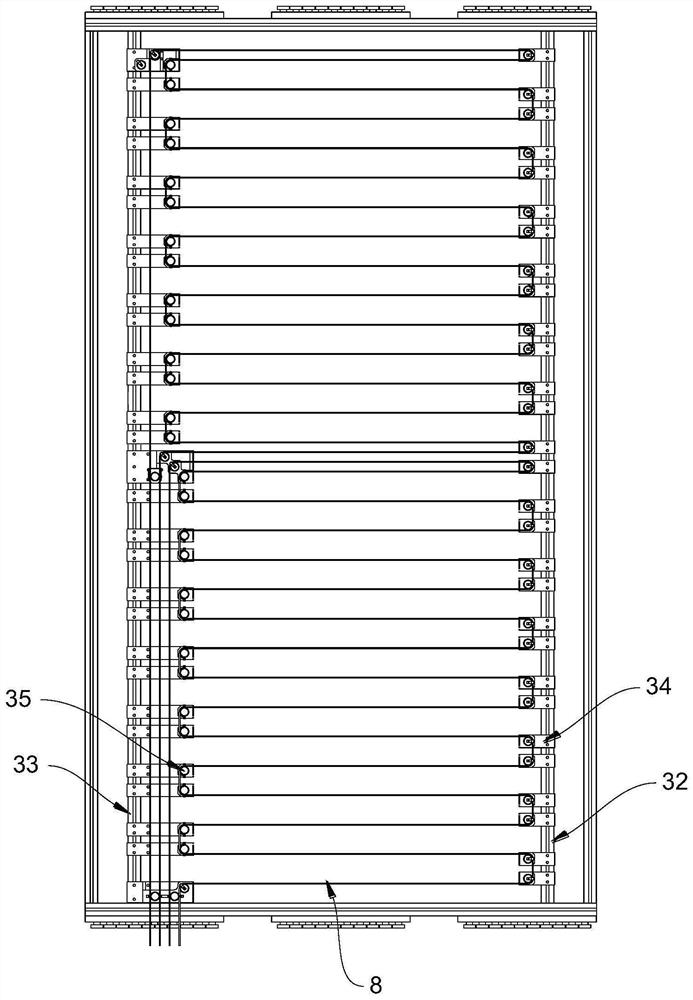

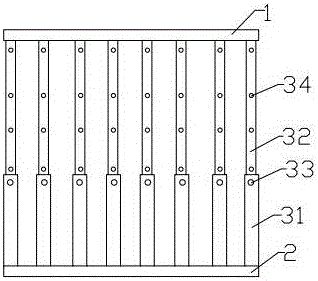

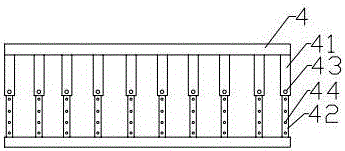

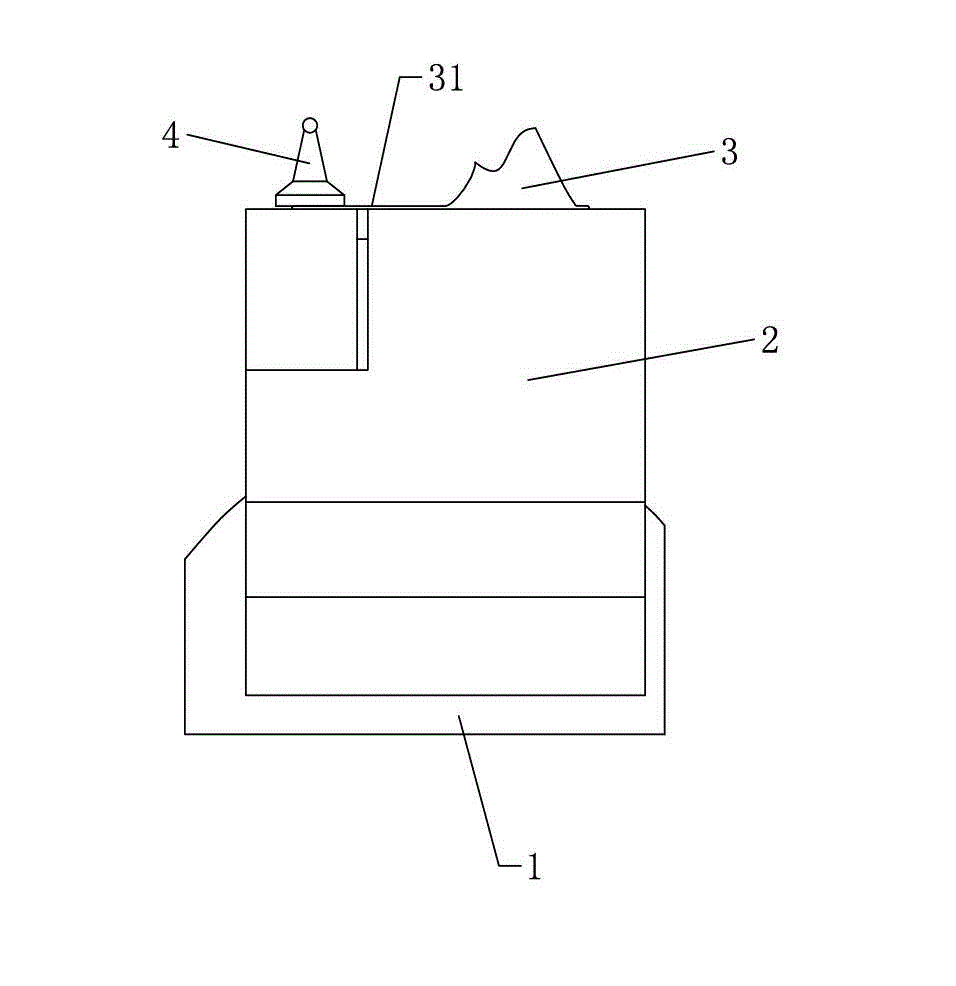

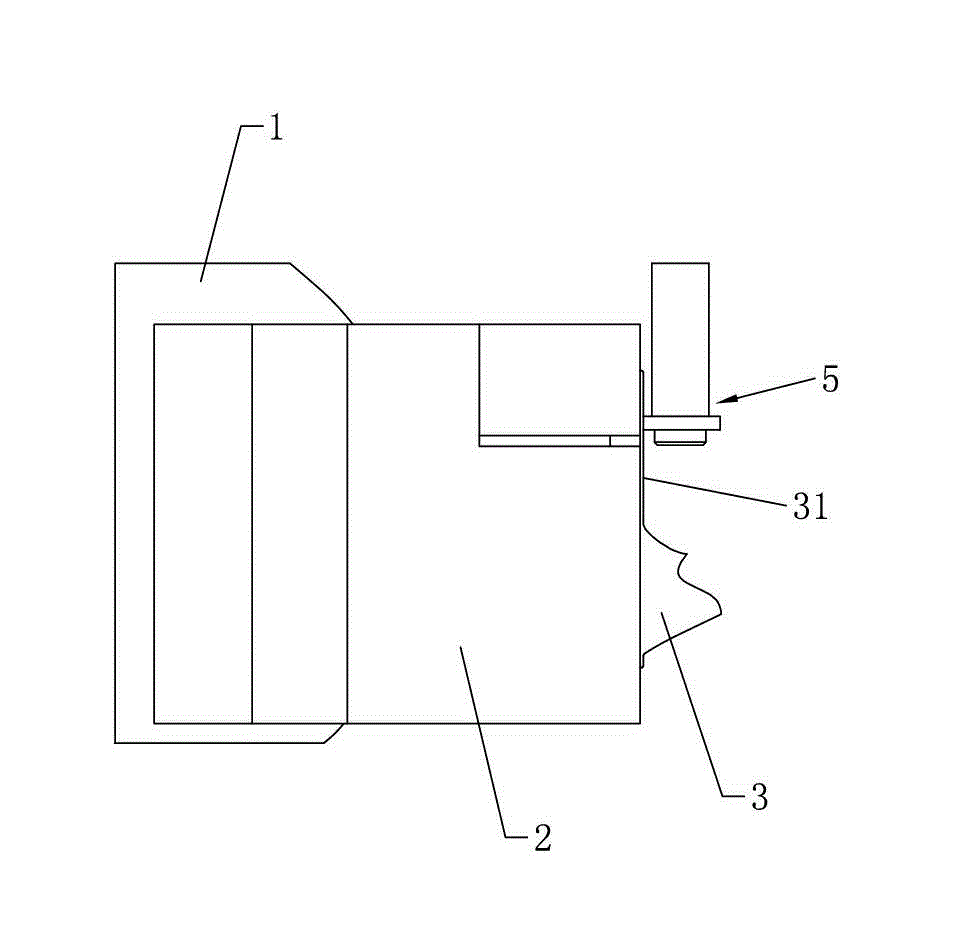

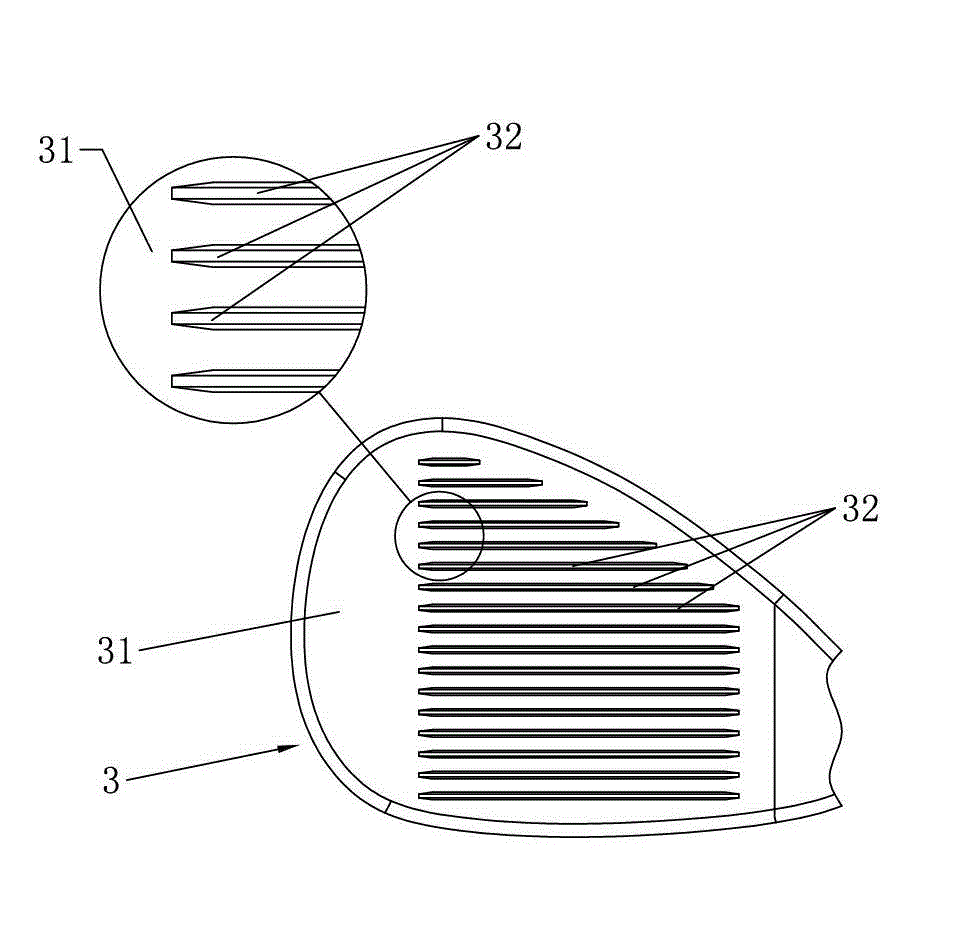

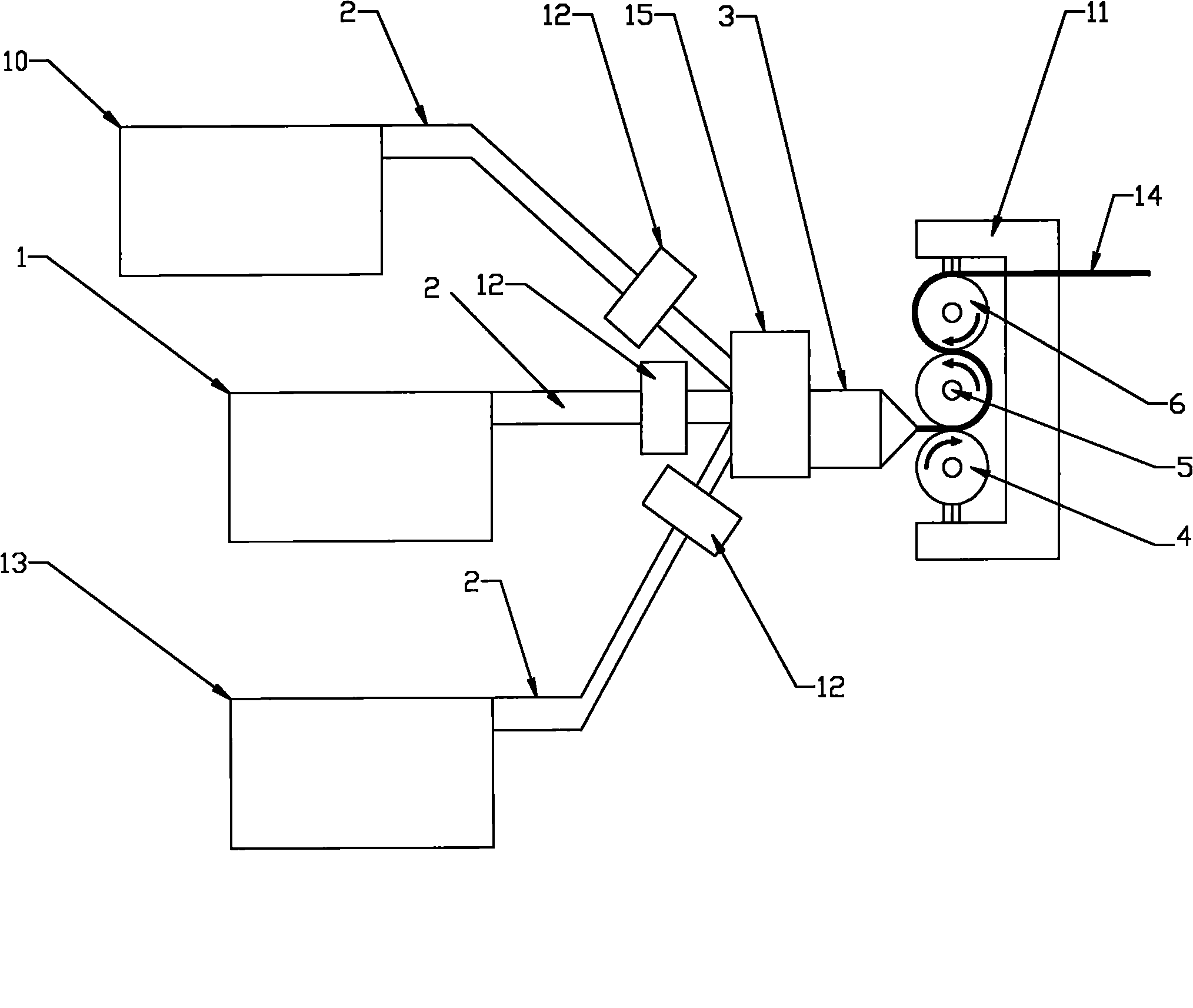

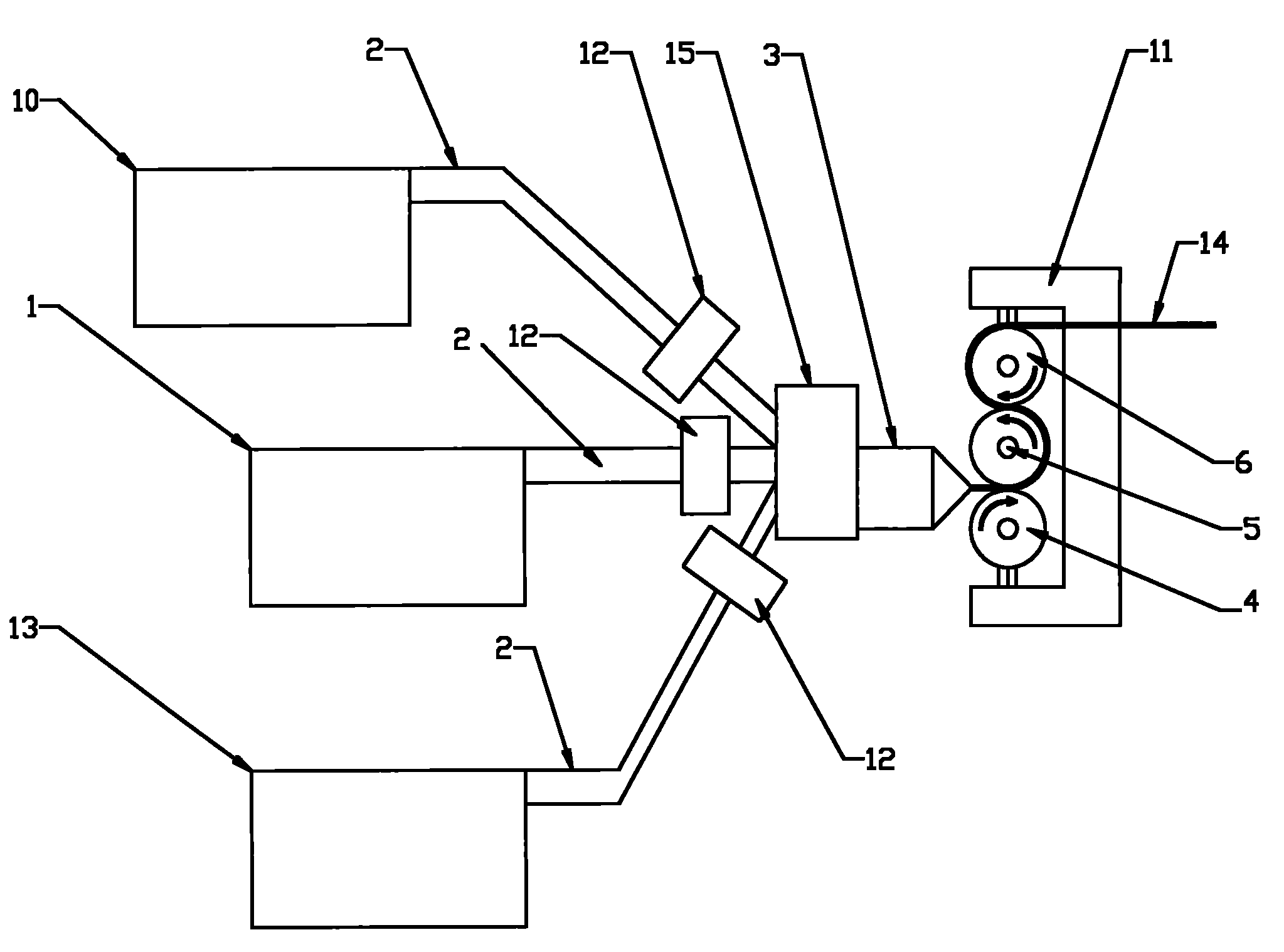

Flexible heating component machining equipment, machining process and flexible heating component

PendingCN112804776AOvercoming Productivity InefficienciesRealize fast processingLaminationLamination apparatusMachining processManufacturing engineering

Flexible heating component machining equipment relates to the field of flexible heating appliance machining and comprises a rack, a glue spraying mechanism, a wiring mechanism and a composite mechanism, wherein the glue spraying mechanism is arranged on the rack and is used for covering the lower-layer fabric with the hot melt glue; the wiring mechanism is used for fixing the heating wire; the wiring mechanism is movably arranged on the rack, so that the heating wire is adhered to the lower-layer fabric; and the compounding mechanism is used for bonding the upper-layer fabric to the lower-layer fabric so as to cover the heating wires. Automatic production of a flexible heating component can be achieved, the production efficiency is improved, and the labor cost is reduced. According to the machining process, a processing method of a traditional flexible heating part is changed, and one or more heating regions can be arranged on fabrics of different sizes and different materials; and the flexible heating part can fix the position of the heating wire between the two layers of fabrics, so that the heating wire is prevented from displacing in the use process.

Owner:成都彩虹电器(集团)股份有限公司

Guard railing used for windows with extending and contracting functions

InactiveCN106437464AImprove versatilityReduce non-standardFixed grillesArchitectural engineeringOuter Cannula

The invention discloses a guard railing used for windows with an extending and a contracting functions. The guard railing comprises an upper concave groove beam, a lower concave groove beam and a longitudinal stand column, wherein the lengthways stand column is arranged between the upper concave groove beam and the lower concave groove beam, horizontal pipes are connected with both an open end of the upper concave groove beam and an open end of the lower concave groove beam, the lengthways stand column comprises an outer casing pipe and a telescopic pipe, wherein the outer casing pipe is arranged on the top of the lower concave groove beam and extends upward, one end of the telescopic pipe is arranged at the bottom of the upper concave groove beam and the other end of the telescopic pipe is arranged inside the outer casing pipe in a sleeved mode and moves up and down along the outer casing pipe, the outer sides of the horizontal pipes are provided with radial casing pipes which point toward the stand column, and radial telescopic pipes are arranged on inner side walls of the upper concave groove beam and the lower concave groove beam. The guard railing used for windows with the extending and contracting function can stretch to the space between Y axial direction and Z axial direction so that a user can regulate the railing according to external dimensional requirement the window by himself or herself, thus improving universality of the guard railing, lowering non-standard characteristic of the manufacturing of the guard railing and thoroughly changing the traditional processing method of 'one window with one measurement'.

Owner:张家港集优特防护设施有限公司

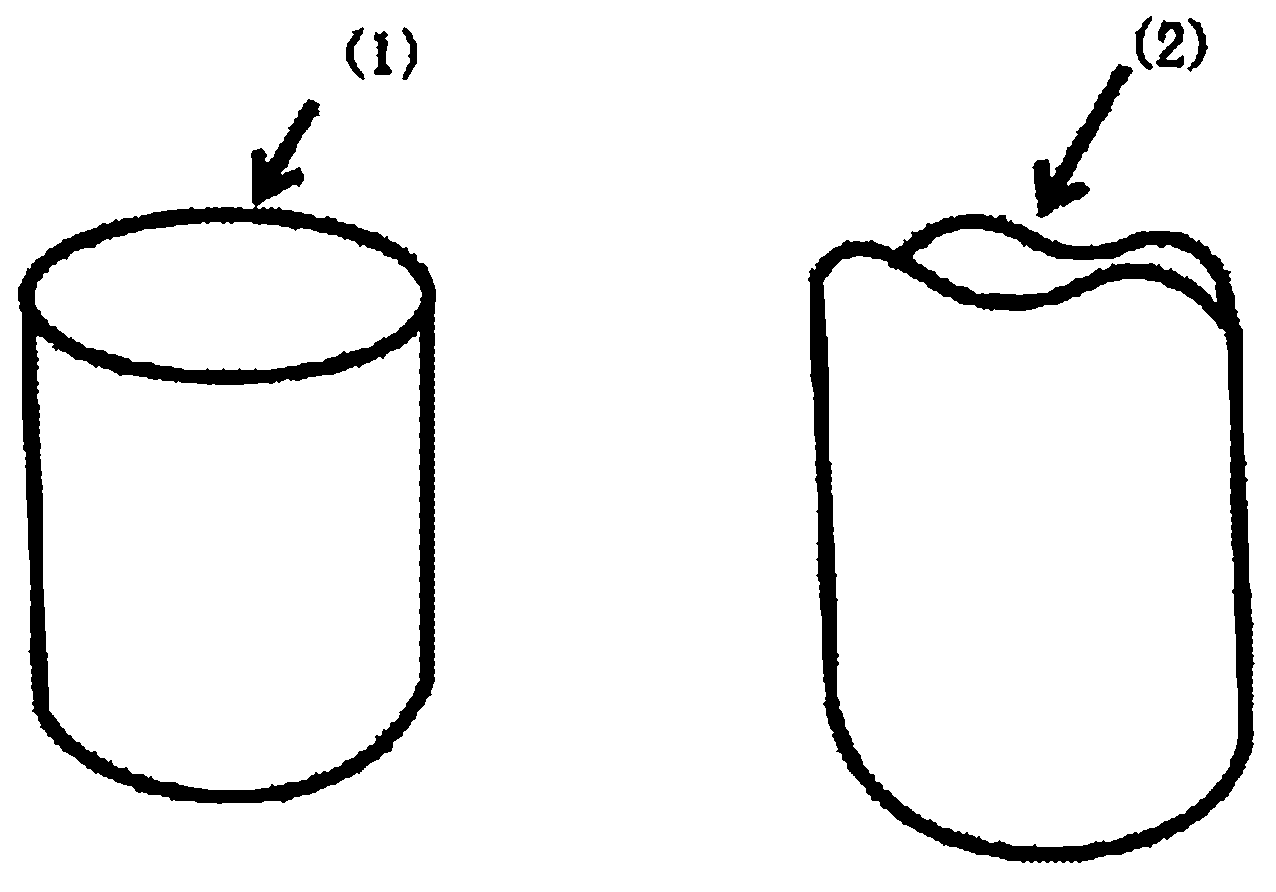

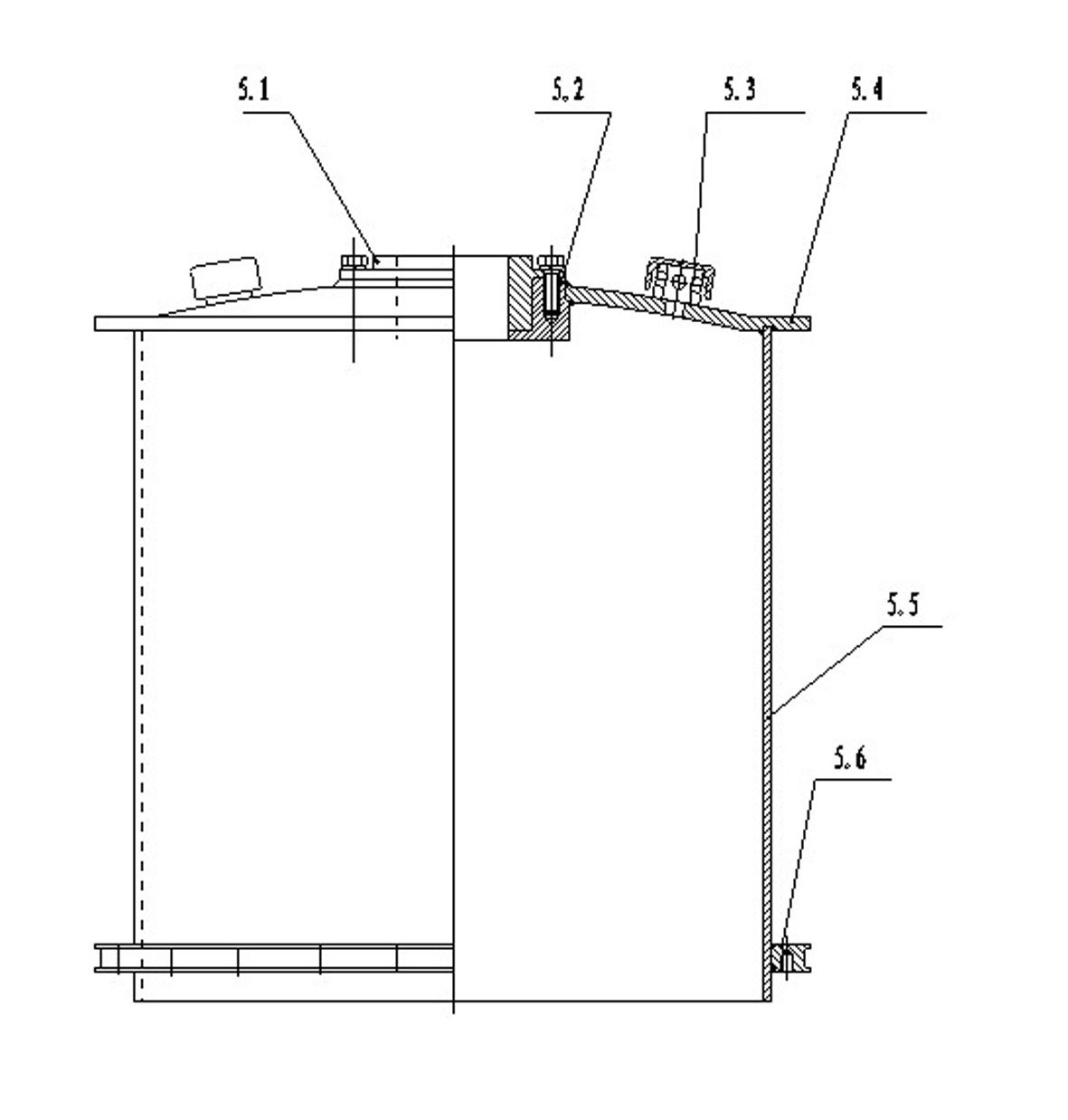

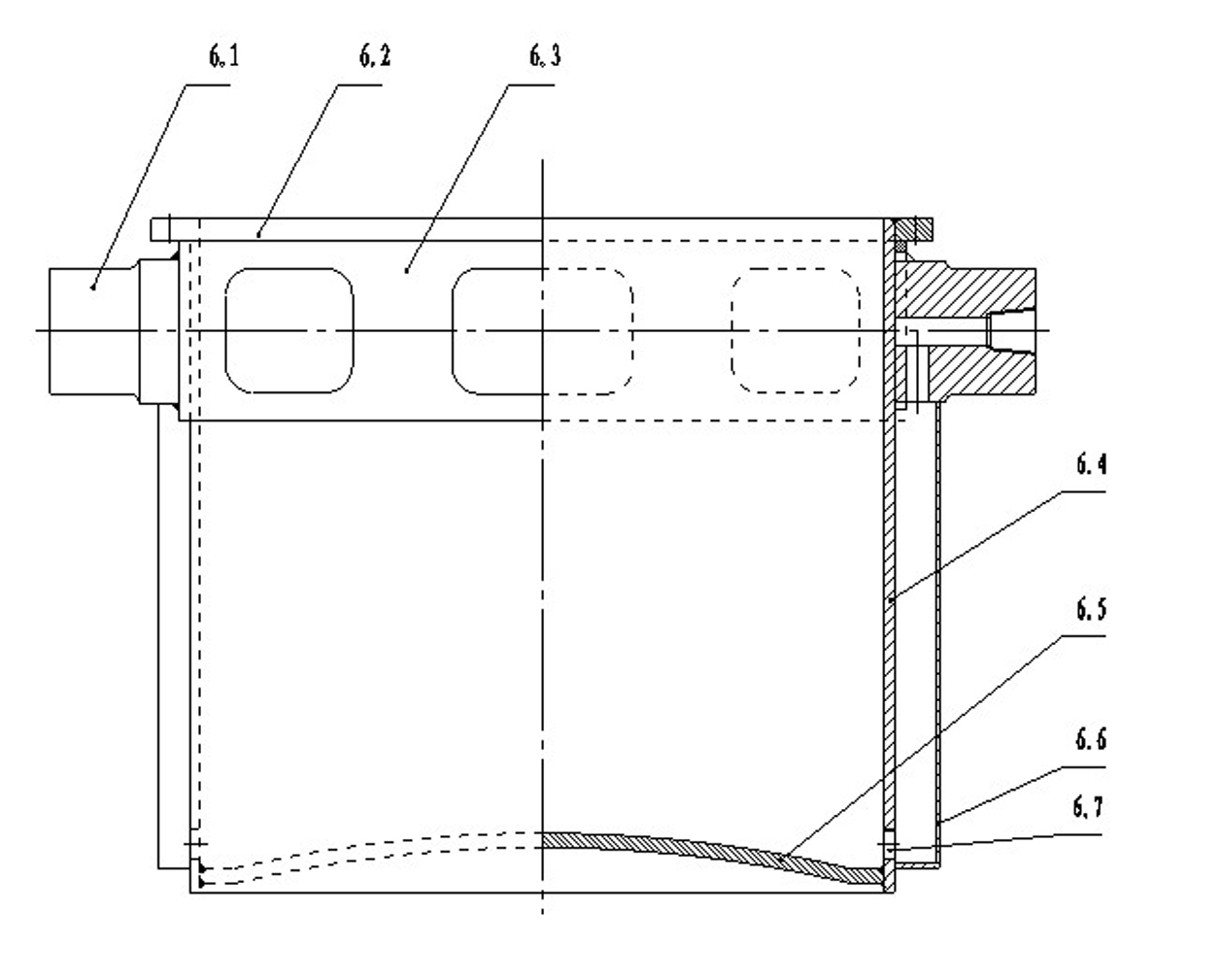

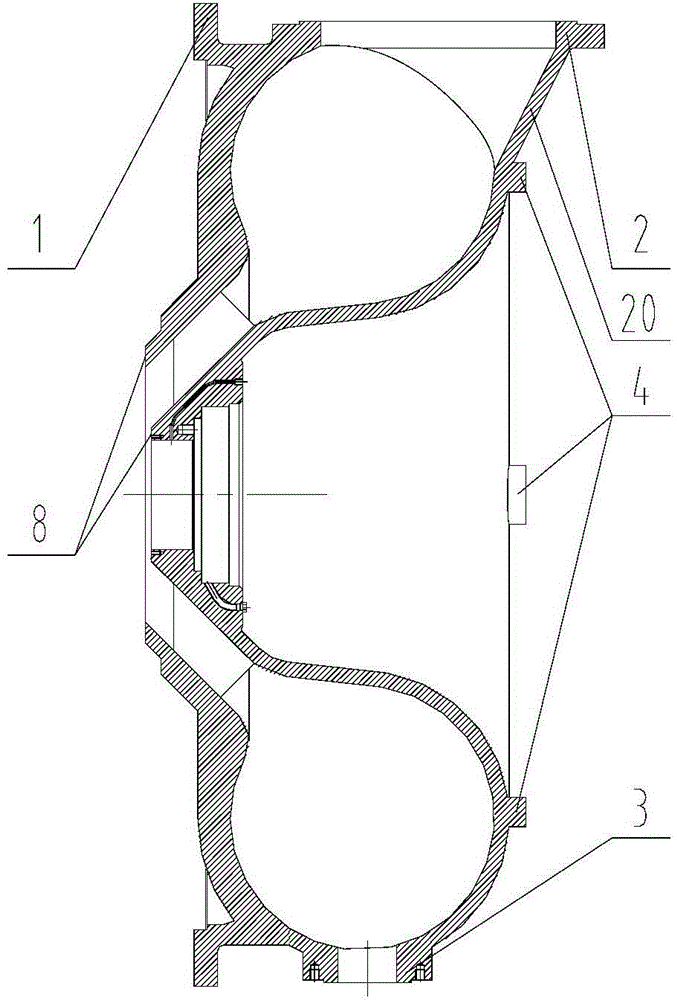

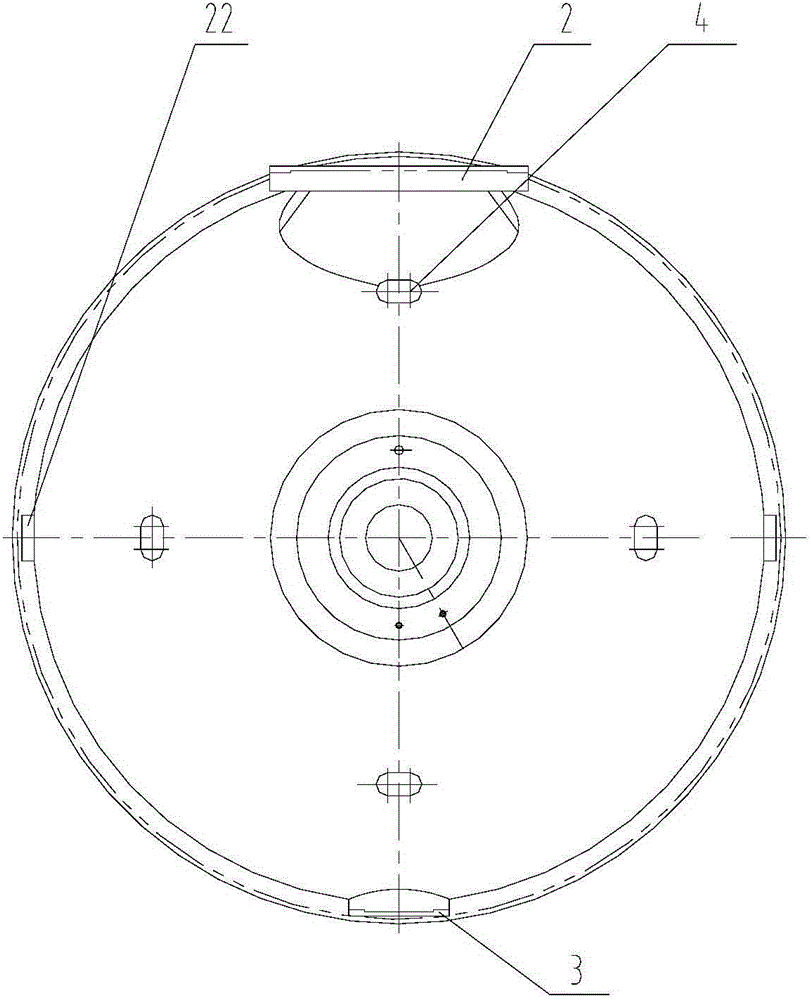

Tilting air cylinder

InactiveCN101979882AChange the processing methodReduce scrap rateFluid-pressure actuatorsTipping wagonsEngineeringCylinder block

The invention belongs to the technical field of rail wagons, and particularly discloses a tilting air cylinder, which solves the problems of difficulty in machining, inconvenience of mounting, unsmooth work process, relatively lower air pressure bearing capacity in work, a plurality of casting defects of castings, and the like of the conventional tilting air cylinder of an automatic dumping vehicle. In the tilting air cylinder, an outer cylinder and a middle cylinder are both formed by assembling and welding independently-molded components; an outer cylinder body of the outer cylinder has a tubular structure formed by coiling and welding a board; an inner cylinder barrel of the middle cylinder also has a tubular structure formed by coiling and welding the board; a lug is provided with a gas passage; one end of the gas passage is connected with a main air pipe, and the other end of the gas passage is connected with an inlet pipe of the outer cylinder body; and the lower end of the inlet pipe is communicated with an air inlet at the bottom of the outer cylinder body. The tilting air cylinder has the advantages of reducing the rejection rate and the production cost, avoiding the casting defects of the original castings, reducing dead weight, improving the appearance quality, eliminating own swing and avoiding further faults.

Owner:CRRC TAIYUAN CO LTD

Four-face enclosed box bending mold and using method thereof

ActiveCN106424372AChange the processing methodReduce processing difficultyShaping toolsMechanical engineeringEngineering

The invention discloses a four-face enclosed box bending mold and a using method thereof and belongs to the field of bending molds. The problems that in the prior art, during bending forming of specified structures, the bending precision is poor, and the labor intensity is high are solved. The mold comprises an upper mold body which comprises an upper mold base, an upper mold tool, a rotary tool base and a rotary tool. The upper mold tool is fixed to one side of the upper mold base. A rotary cavity is formed in the lower end of the upper mold tool. The rotary tool base is fixed to the outer side of the upper mold tool, and one end of the rotary tool base stretches out of the rotary cavity. The rotary tool is arranged in the rotary cavity and rotatably and fixedly arranged on the rotary tool base. By adoption of the mold, the bending precision can be effectively improved, the convenience of operation is improved, and therefore the production efficiency is improved, and the machining efficiency and quality can be further improved.

Owner:ANHUI LIYUAN NUMERICAL CONTROL CUTTING TOOL & PATTERNS MFG

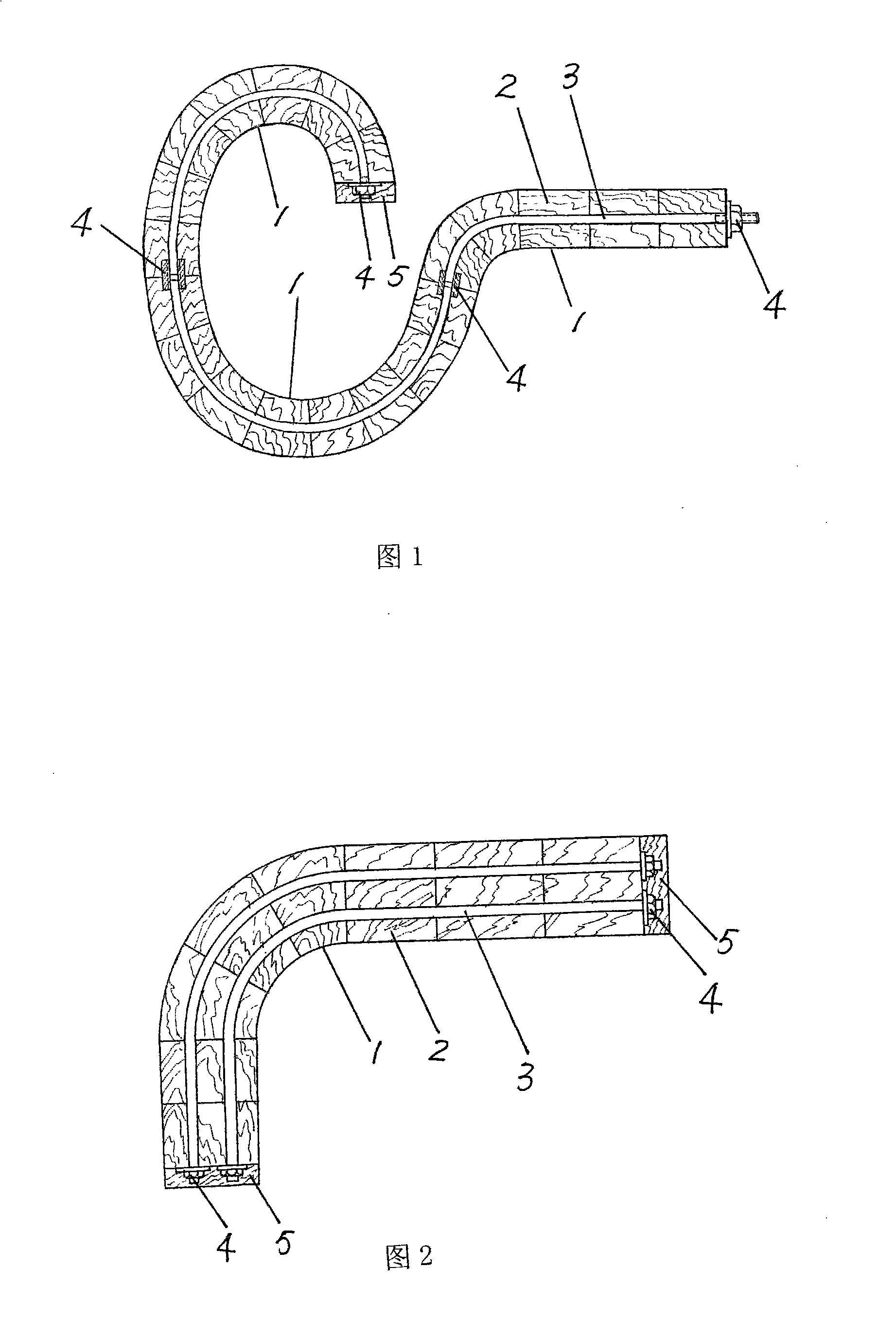

Furniture frame and producing method

InactiveCN101283862AUnique structureStrong and stable structureWood working apparatusFurniture partsSolid woodAdhesive

The invention relates to a furniture frame and the fabrication process thereof, in particular to the frame of wood furniture and the fabrication process thereof. The furniture frame comprises one or more small frame segments (1) connected with each other, and a cover (5) at the end head position, wherein each small frame segment (1) includes a plurality of small wood blocks (2) having holes at the middle positions and tightly connected with each other in series through a steel bar (3); the steel bar (3) is provided with screws at the end heads; the screws are connected with nuts (4); the small frame segments are connected with each other through screw threads and with the cover through screw threads. The fabrication method comprises following steps: (1) cleaving a plate material into strips; (2) cutting the strips at a cutting angle of 0 to 45 DEG; (3) cutting the strips into small blocks; (4) punching holes at the middle positions of the strips; (5) passing a steel bar with screws at both ends through the holes to sequentially connect the plurality of small blocks; and (6) applying adhesives at the joints between the small blocks, tightening, screwing nuts on the screws, and leveling.

Owner:杨荣发

Method for manufacturing aluminum sheet circle for soft aluminum tube by aluminum rod

InactiveCN102581559AReduce manufacturing costChange the processing methodMetal-working apparatusPunchingMaterials science

The invention relates to a production method for manufacturing an aluminum sheet circle for a soft aluminum tube by an aluminum rod, in particular to a method for extruding and punching the aluminum sheet circle. The method comprises the following steps of: selecting a raw material: the aluminum rod; carrying out axial cold deformation (wire drawing and drawing) on the aluminum rod; utilizing a cold heading machine or an automatic slitting punching machine to carry out directional extrusion on a cracked layer formed on a split blank, so as to shorten the area of the cracked layer to a corresponding range; carrying out secondary cold heading molding; carrying out complete annealing treatment on the aluminum sheet circle; carrying out surface treatment on a finished product; and checking and packaging. Compared with the prior art, a material returning phenomenon caused by punching through a traditional process is avoided and a directional extrusion and passivation technology is utilized, so that a turning procedure for overcoming the defects of pocking marks, pinholes and the like of the finished soft aluminum tube, which are caused by cutting off a cutting surface of the blank, is saved; the production yield is improved to be more than 99% from 60-70% of the traditional process, and the automatic production is wholly realized, so that the production efficiency is improved.

Owner:顾平

Golf ball iron rod batter side and method for machining groove of batter side

ActiveCN102974874AChange structureChange the processing methodMilling cuttersMilling equipment detailsMilling cutterGolf Ball

The invention discloses a golf ball iron rod batter side and a method for machining a groove of the batter side. The machining method comprises the following steps of: clamping a blank on a clamp of a four-axis working machine tool worktable; then milling a batter side of the blank through a face milling cutter; and finally, rotating the four-axis working machine tool worktable for 90 degrees so as to rotate a golf ball iron rod for 90 degrees, and machining the groove through a groove modeling machining tool perpendicular to a normal direction of the batter side. The groove modeling machining tool comprises a tool handle and a groove modeling and rolling blade, wherein the groove modeling and rolling blade comprises a base part and blade parts which are arranged on edges of the base part and are annularly and uniformly distributed. According to the golf ball iron rod batter side and the method, the groove machining mode of the batter side is changed, the structure of the groove modeling and machining tool is changed, and the machining method is matched with the groove modeling and machining tool with the structure; and according to the machining method, the phenomena of tool breakage and the like can be effectively avoided, the production and machining cost is reduced, and the quality accuracy and the stability of the groove of a product are improved.

Owner:DONGGUAN YICHENG PRECISION MOLD

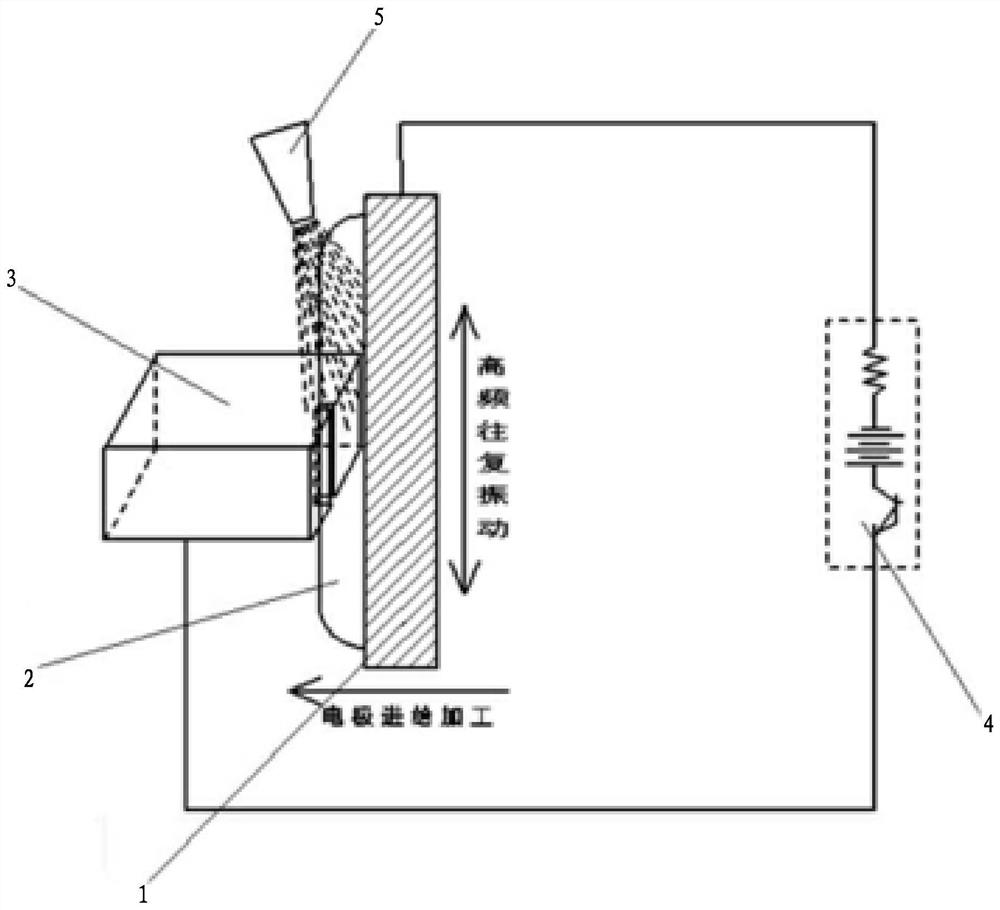

Electrical discharge machining method of sheet electrolysis with high-frequency vibration

InactiveCN111975148AChange the processing methodEffective processing and trimmingElectrolysisConductive materials

The invention discloses an electrical discharge machining method of sheet electrolysis with high-frequency vibration. The electrical discharge machining method comprises the following steps of (1) vertically and fixedly installing a sheet on the front end of a clamping substrate, wherein the sheet is used as a conducting material; (2) respectively connecting the clamping substrate and a to-be-processed workpiece 3 with the anode and cathode of a pulsed power supply; (3) driving the sheet to horizontally move to the to-be-processed workpiece by the clamping substrate during processing so as toform feed processing, and driving the sheet to do reciprocating vibration in a vertical direction by the clamping substrate at the same time, wherein the sheet makes line contact with the to-be-processed workpiece; and (4) spraying a processing solution to the contact surface between the sheet and the to-be-processed workpiece. According to the electrical discharge machining method, the sheet is used as an electrode during processing, the sheet can be processed with the thickness smaller than the diameter of a wire electrode, so that a small narrow groove gap can be generated, and additionally, large current can pass through the sheet, so that the processing efficiency is improved. The high-frequency vibration of a sheet cutter is increased during processing, so that composite processing is formed, and the problems of liquid discharge and chip removal are solved.

Owner:GUANGDONG UNIV OF TECH

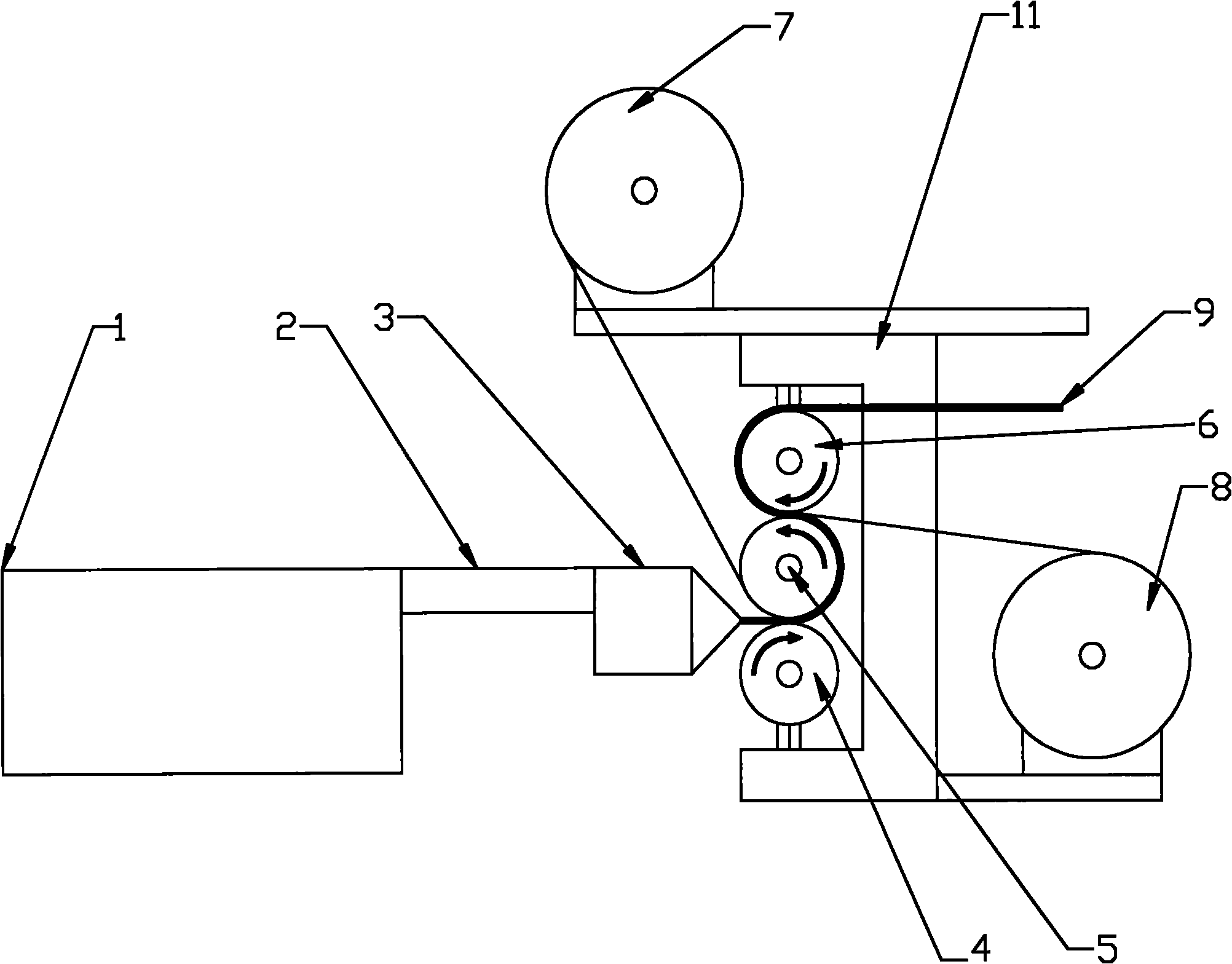

Making machine of PVC (Polyvinyl Chloride) foaming plate

InactiveCN101913241ARealize the processing methodChange the processing methodFlat articlesProcess equipmentPolyvinyl chloride

The invention relates to processing equipment of a PVC (Polyvinyl Chloride) foaming plate, in particular to a making machine of the PVC foaming plate. The making machine of the PVC foaming plate is characterized in that three tangent felt wrapped rolls (4, 5, 6) are arrayed on a vertical machine frame (11) from bottom to top; an extruder (1) positioned at one side of the machine frame (11) enters one inlet of a proportional valve (15) through a flow passage (2) and a constant rate pump (12); a surface enhancement layer extruder (10) and a surface beauty layer extruder (13) are respectively arranged above and below the extruder (1) and respectively enter another two inlets of the proportional valve (15) through respective flow passages (2) and constant rate pumps (12); one outlet of the proportional valve (15) is communicated with a plain end mould (3); and the outlet of the plain end mould (3) corresponds to a notch between the felt wrapped roll (4) and the felt wrapped roll (5). The invention fills the blank of production processing equipment in the field, changes the traditional PVC foaming processing mode, cancels the extrusion of an upper layer and a lower layer and the compounding form of a finished membrane during processing, greatly reduces the product density, lowers the product cost and has very tremendous economic value.

Owner:上海嘉倍德塑胶机械有限公司

A sinking type rigid-flex board and its manufacturing method

ActiveCN103118489BChange the processing methodReduce production processPrinted circuit assemblingPrinted circuits structural associationsAdhesiveMechanical engineering

A sinking type rigid-flex board and its manufacturing method, which at least consists of a printed circuit board and an upper and lower two layers of flexible substrates thermosetting adhesive Pressing to make a rigid-flex board, the sensor position on the rigid-flex board is provided with grooves; a lower printed circuit board is provided under the lower flexible substrate, and the printed circuit board has two flexible upper and lower layers. The base plate and the lower printed circuit board are laminated by thermosetting glue; the present invention adopts the design scheme of the sunken rigid-flex board, and changes the design of the traditional printed circuit board by adding grooves to the rigid-flex board. The advanced processing method reduces the module manufacturing process, improves the flexibility of assembly, and provides more space for the development of thin packaging, especially in the consumer field.

Owner:NINGBO SUNNY OPOTECH CO LTD

Tempered curved glass and equipment with stress pattern weakening effect

PendingCN110372191AGood lookingQuality improvementGlass tempering apparatusEngineeringToughened glass

The invention relates to the technical field of glass tempering, in particular to a method for weakening a stress pattern of tempered curved glass and tempered curved glass equipment of the method. Anoriginal split type air box is replaced by a penetrating continuous reversible deformed cavity as a wind grid; a fluid smoothing structure is arranged in the cavity to reduce fluid resistance; a windair flow orienteering stabilizing structure is arranged outside the cavity for constraining the direction of the jet air flow, the flow velocity and the flow rate; and a docking device which can be changed according to the change of curvature of the curved surface of the cavity is arranged between the cavity and an air supply source. The wind grid composed of each of the independent wind boxes inthe wind grid is replaced by a flexible wind grid which mutually penetrates to form the continuous wind grid perpendicular to the moving direction of the glass, the wind grid blows the tempered glassin the glass movement, the strip-shaped stress pattern left in the wind grid cooling process of the prior art can be eliminated, and the appearance and quality of the tempered glass is greatly improved.

Owner:LUOYANG LANDGLASS TECH CO LTD

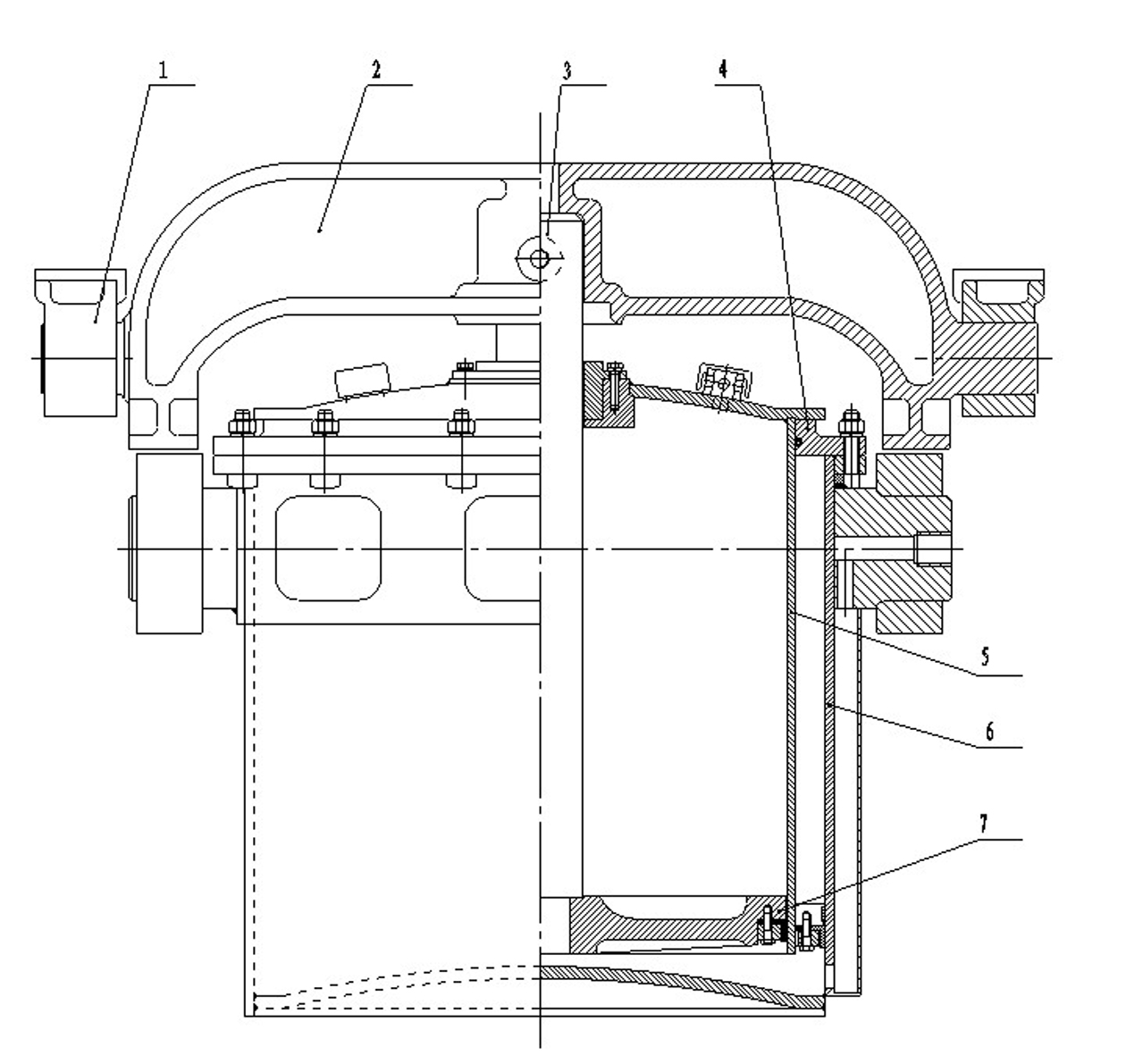

Clamping and processing method for organic working medium generator shell

ActiveCN104815992AAvoid vibrationAvoid shockTailstocks/centresAuxillary equipmentPulp and paper industryThermodynamics

The invention discloses a clamping and processing method for an organic working medium generator shell. The method includes: 1) drawing an aligning line; 2) polishing and flattening the boss end surface of the small end of the shell; 3) roughly turning the large end of the shell; 4) roughly turning the small end of the shell; 5) fine turning the large end of the shell; and 6) fine turning the small end of the shell. The clamping and processing method for the organic working medium generator shell is more convenient to clamp, easy to align, high in positioning accuracy, higher in accuracy of the dimension of the processed shell, and capable of improving the percent of pass of parts and preventing safety accidents.

Owner:CHONGQING JIANGJIN SHIPBUILDING IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com