Lock body machining process

A technology of lock body and process, applied in the field of metal locks and lock body processing technology, can solve the problems of reduced pass rate, waste, processing waste, etc., to improve processing accuracy and quality, save materials and energy, and reduce manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] Make iron lock body or copper lock body.

[0022] 1. Take iron ore powder or copper ore powder for oxygen exhaust, annealing and magnetic separation.

[0023] 2. Ingredients according to the alloy ratio (see the table below): Table 1

[0024] 3. Put the well-proportioned materials into the cavity of the lock body mold made according to the design requirements, and then install the mold on the press, which can be a punch press, hydraulic press, etc.

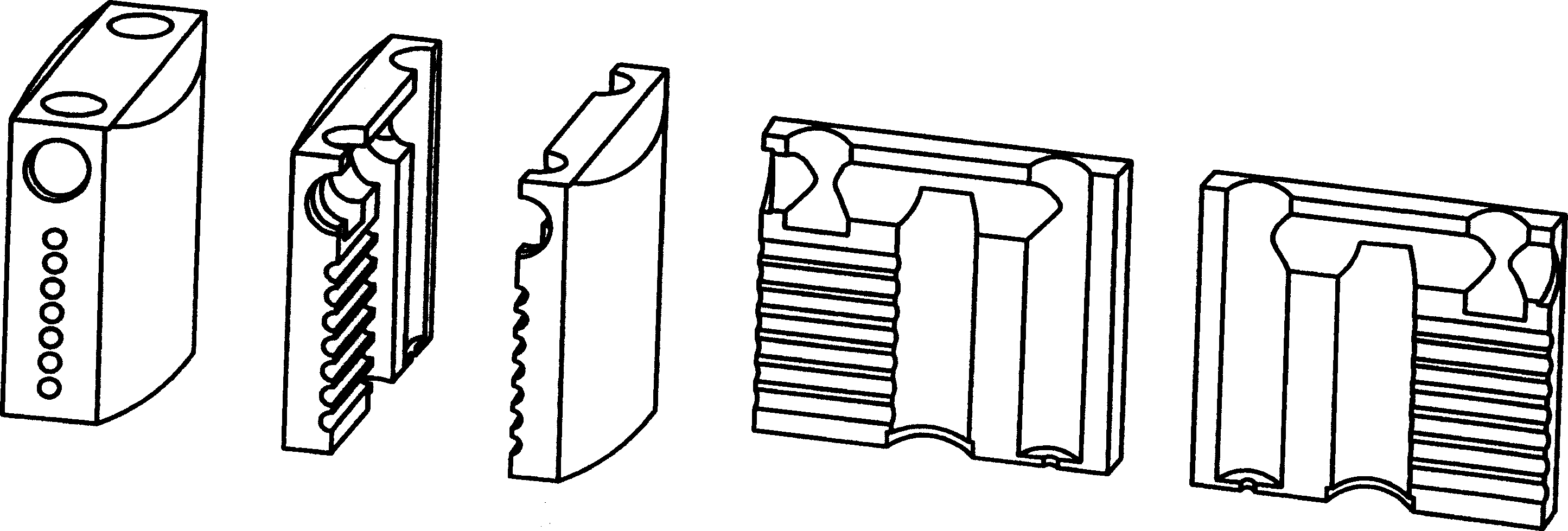

[0025] 4. Start the press, and extrude the material with a good ratio in the mold cavity (see Table 1) into a blank under high pressure, see figure 2 , are the two half-side embryos of the matching lock body.

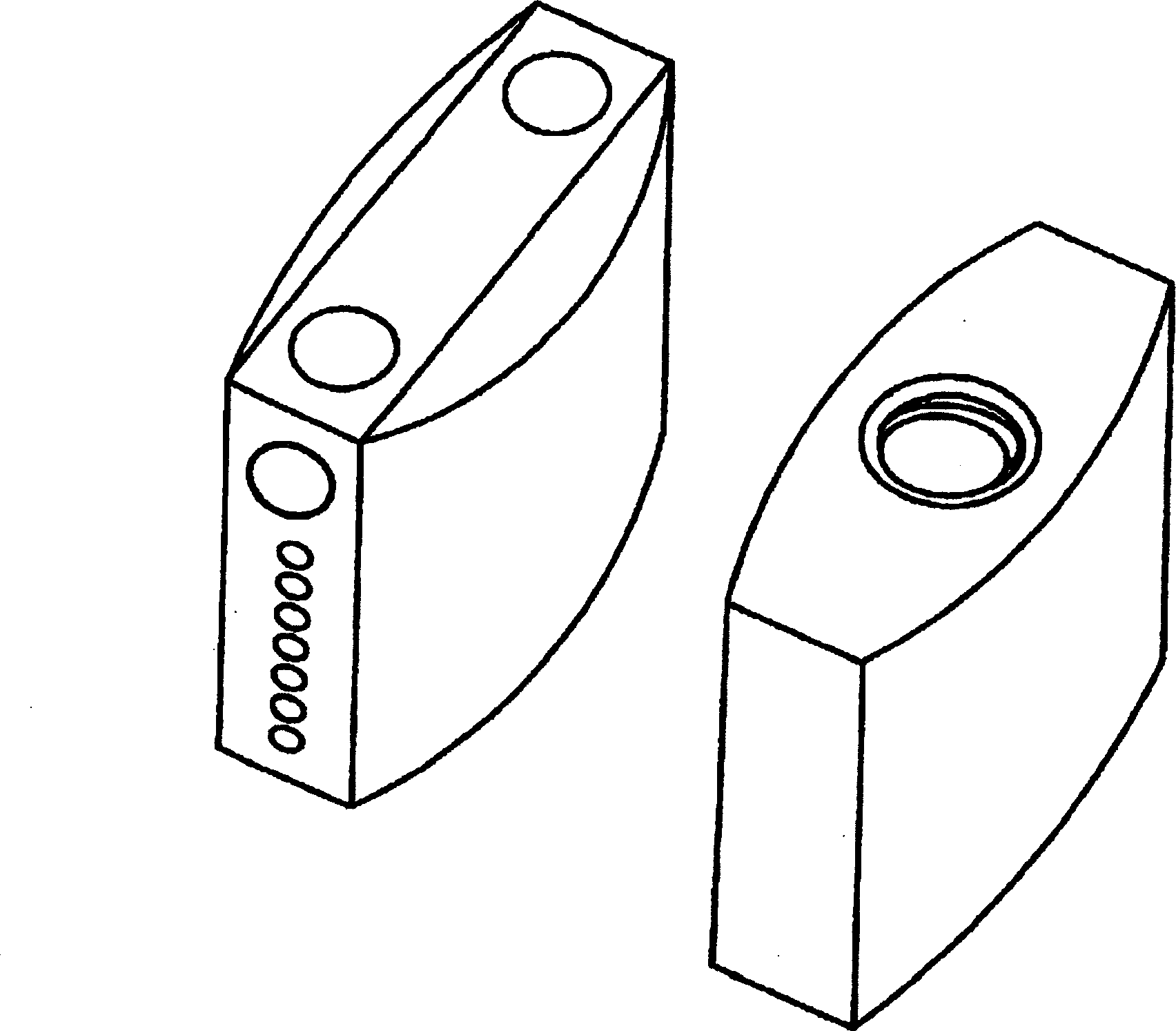

[0026] 5. Then, the two halves of the iron lock body or copper lock body extruded into the blank form in step 4) are matched to form a whole lock body, and put into a high-temperature furnace for heat preservation and sintering (see Table 1). After sintering and solidification, finished product, see figure 1 sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com