Laser embroidery integrated machine and processing method

An all-in-one machine and laser technology, which is applied in the field of embroidery equipment and textile processing equipment, can solve the problems of long mold production cycle, high cost, and waste products, and achieve the effect of saving loading and unloading time and labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

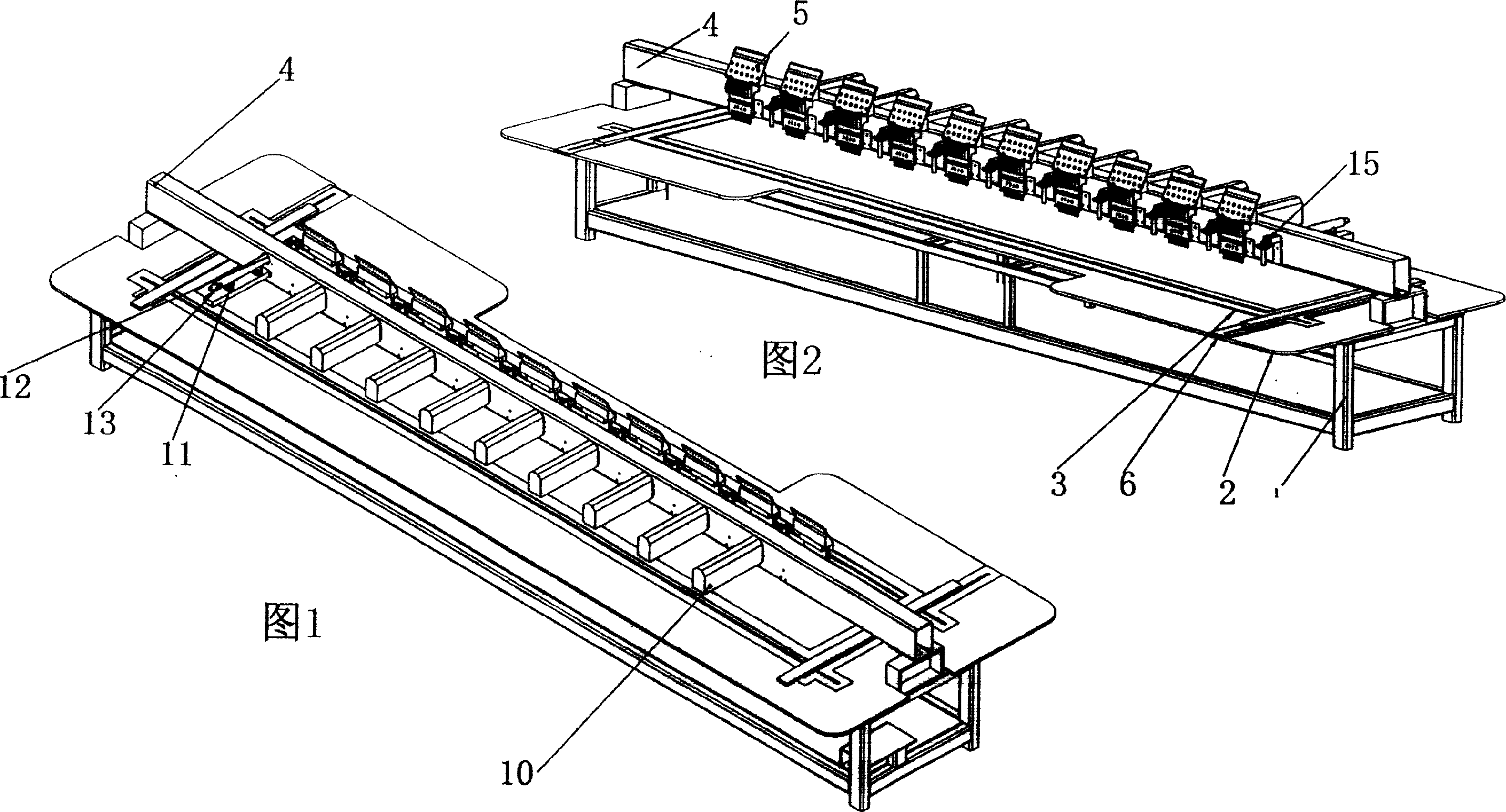

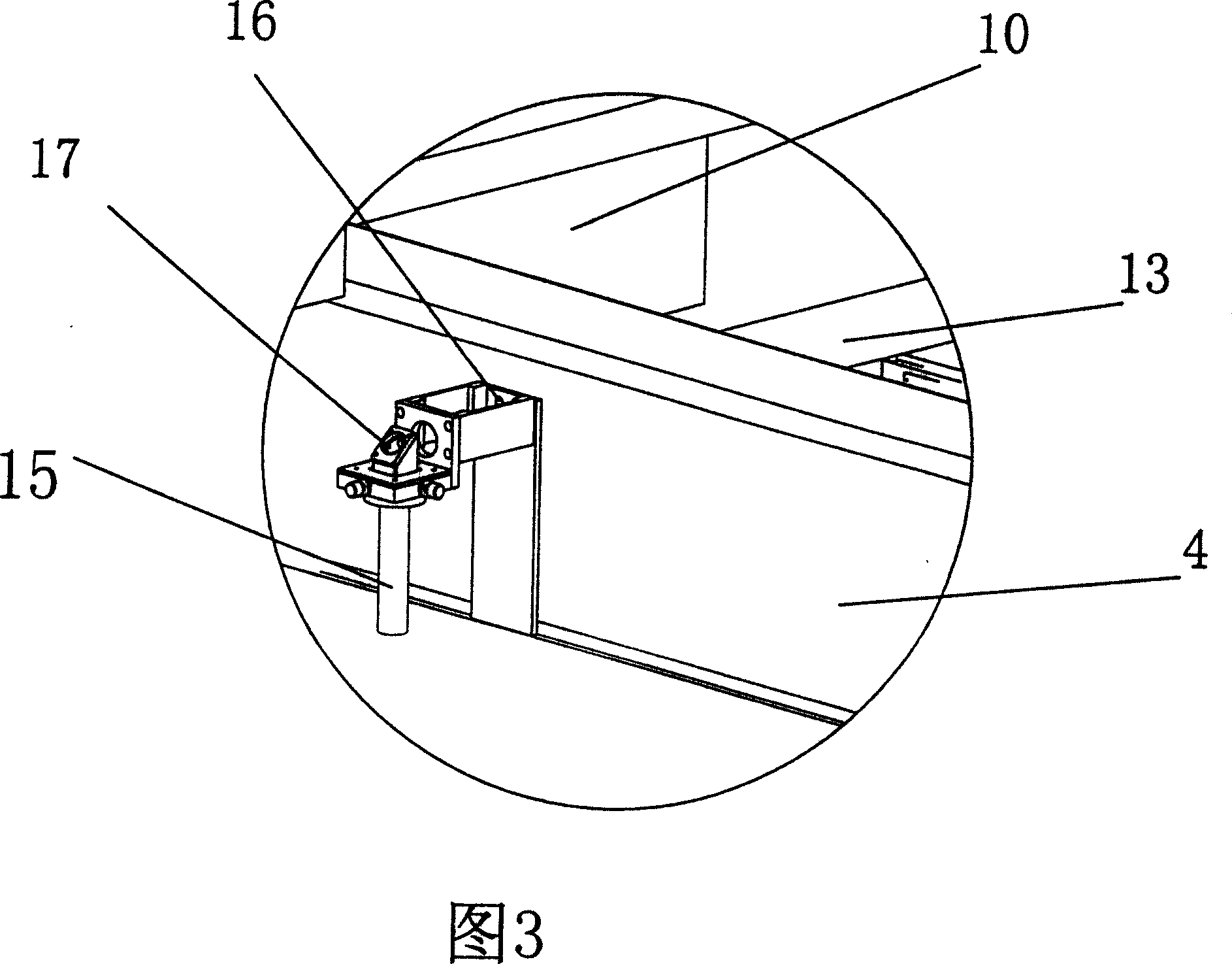

[0024] It is to install the laser tube perpendicular to the beam in the horizontal plane, as shown in Figure 1, the beam 4 is connected to the laser tube cover 10, the laser tube cover 10 is set perpendicular to the beam in the horizontal plane, and the laser tube cover 10 is equipped with a laser tube bracket 11 , the laser tube bracket 11 is connected with the beam 4, the beam 4 is provided with a laser tube hole 12, the laser tube 13 passes through the laser tube hole 12, and the laser tube 13 is fixed on the laser tube bracket 11. As shown in FIGS. 2 and 3 , the laser cutting head support 14 is connected to the front of the beam 4 , and the laser cutting head 15 is connected to the support 14 . The beam 4 is provided with an optical path hole 16 at the front, and the laser cutting head 15 is provided with a mirror 17 for receiving the laser output from the laser tube 13 . It is a multi-head setting, and a laser cutting head 15 is set correspondingly beside each embroidery ...

Embodiment 2

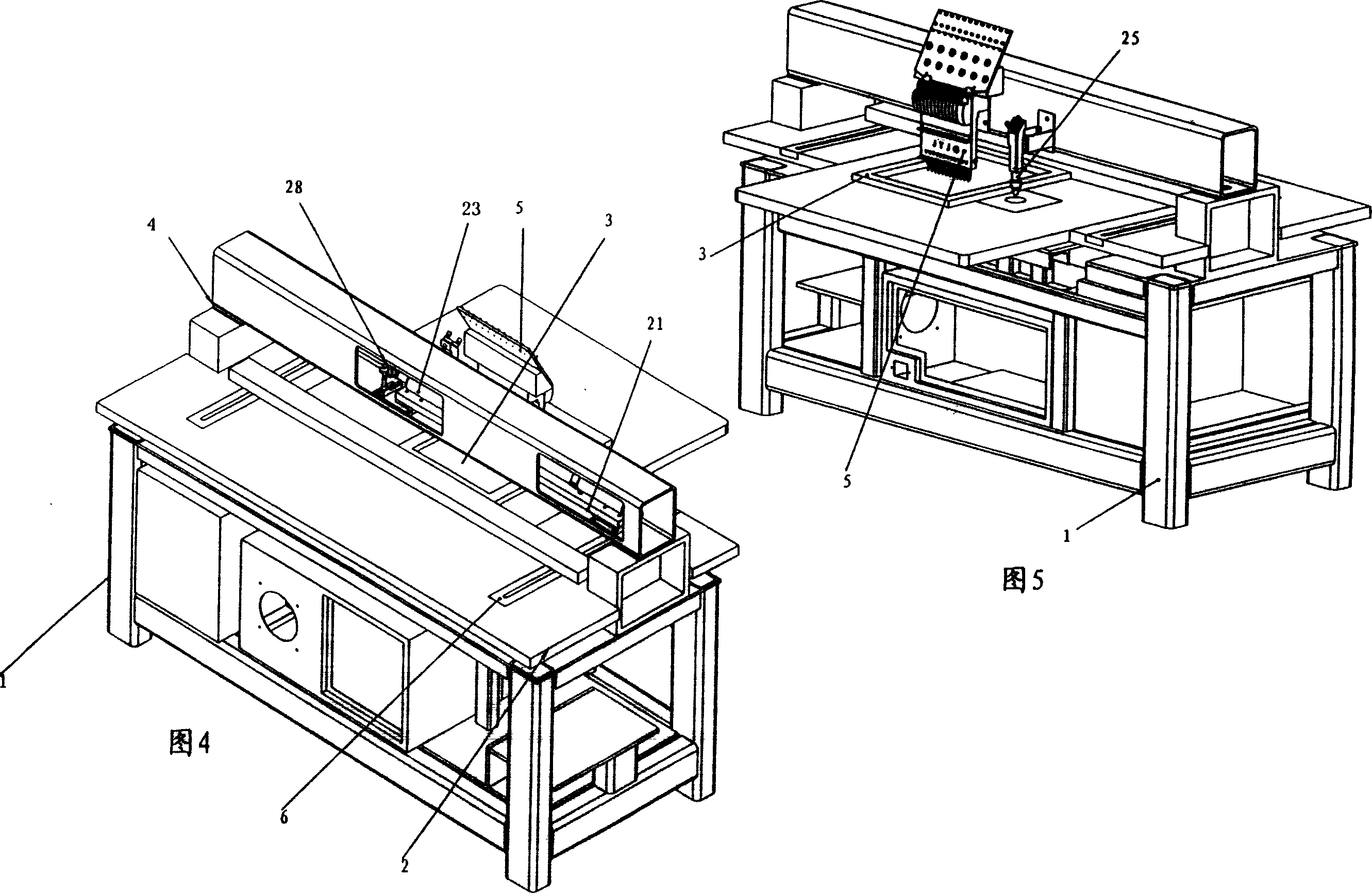

[0026] It is to set the laser tube in the beam. As shown in FIG. 4 , a laser tube bracket 21 is arranged in the beam 4 , the laser tube 23 is fixed on the laser tube bracket 21 , and a reflector 28 is arranged in front of the laser tube 23 (as shown in FIG. 7 ). As shown in Figures 5 and 6, the front of the crossbeam 4 is connected to the laser cutting head support 24, the laser cutting head 25 is connected on the support 24, the crossbeam 4 offers a light hole 26, and the laser cutting head 25 is provided with a laser for receiving the output of the laser tube. Mirror 27. It is a single-head setting, and a laser cutting head 25 is set beside an embroidery device 5 .

Embodiment 3

[0028] It is to set the laser tube parallel to the beam behind the beam. As shown in Figure 8, a laser tube bracket 31 is arranged behind the beam 4, and the laser tube 33 is fixed on the laser tube bracket 31 parallel to the beam 4, and a reflector 38 is provided in front of the laser tube 33 (as shown in Figure 11). Hole 32. As shown in Figures 9 and 10, the front of the crossbeam 4 is connected to the laser cutting head support 34, and the laser cutting head 35 is connected on the support 34. The front of the crossbeam 4 is provided with an optical path through hole 36, and the laser cutting head 35 is provided with a socket for receiving the output of the laser tube. Mirror 37 for the laser. The laser tube bracket can be connected to the laser tube cover, and the laser tube is arranged in the laser tube cover (not shown in the figure). It is also a multi-head setting, and a laser cutting head 35 is set correspondingly beside each embroidery device 5, and the number of la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com