Driving assembly for high-power gas discharge lamps

A technology of gas discharge lamps and discharge lamps, applied in the field of drivers, can solve problems such as time-consuming, expensive, and expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

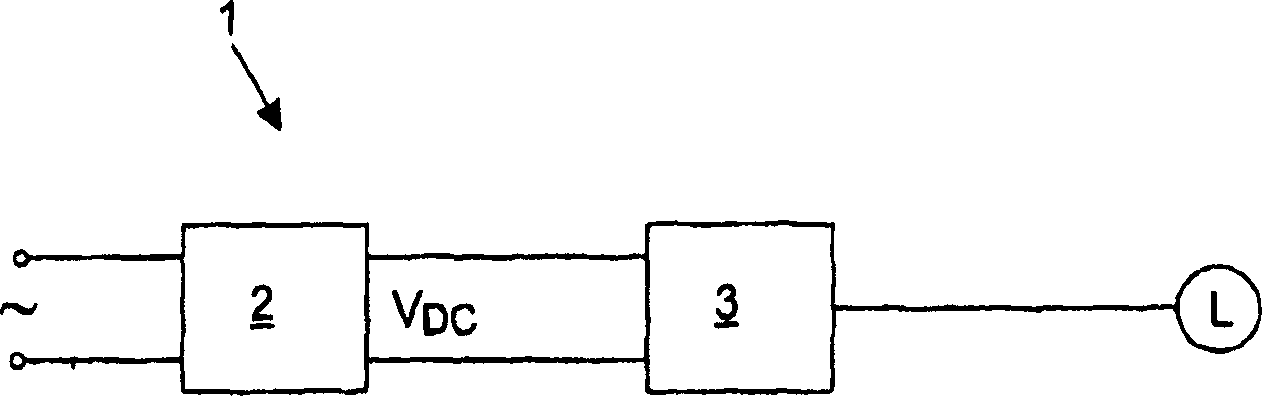

[0015] Figure 1A is a block diagram schematically representing a general two-stage design of a prior art gas discharge lamp driver 1 for a lamp L. FIG. This driver 1 comprises a first stage 2, also denoted pre-regulator, having an input for receiving an AC mains voltage, typically of the order of about 230V. The pre-regulator comprises rectification means for rectifying the input voltage, and an up-transformer for up-converting the rectified voltage into a DC voltage, in particular of the order of 400V or above.

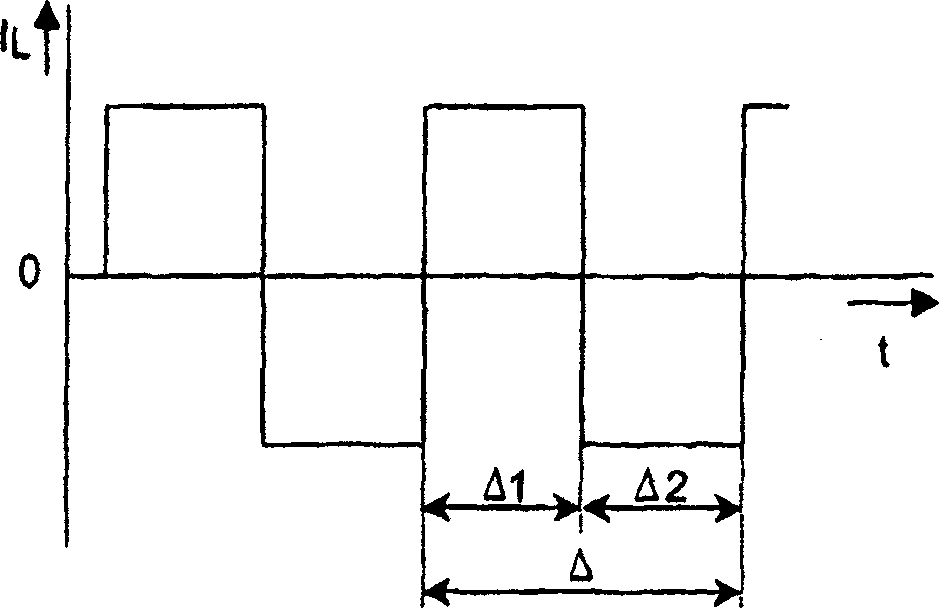

[0016] The second stage 3 has an input receiving a DC voltage from a pre-regulator and has an output connected to a lamp L. This second stage, also denoted forward commutator, is designed to generate an alternating DC current at its output, ie a current of substantially constant magnitude but with alternating direction. Figure 1B The shape of the current IL flowing through the lamp L is schematically represented as a function of time t, here any superimposed high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com