Patents

Literature

30results about How to "Increased maximum power density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

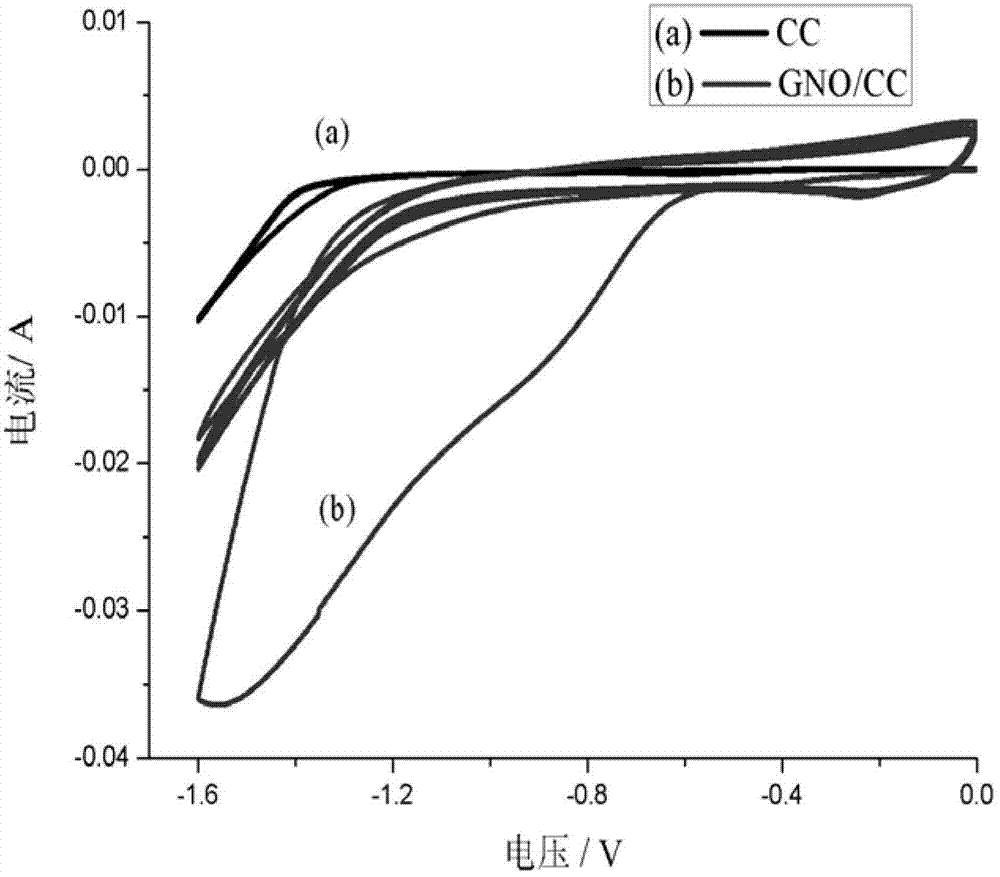

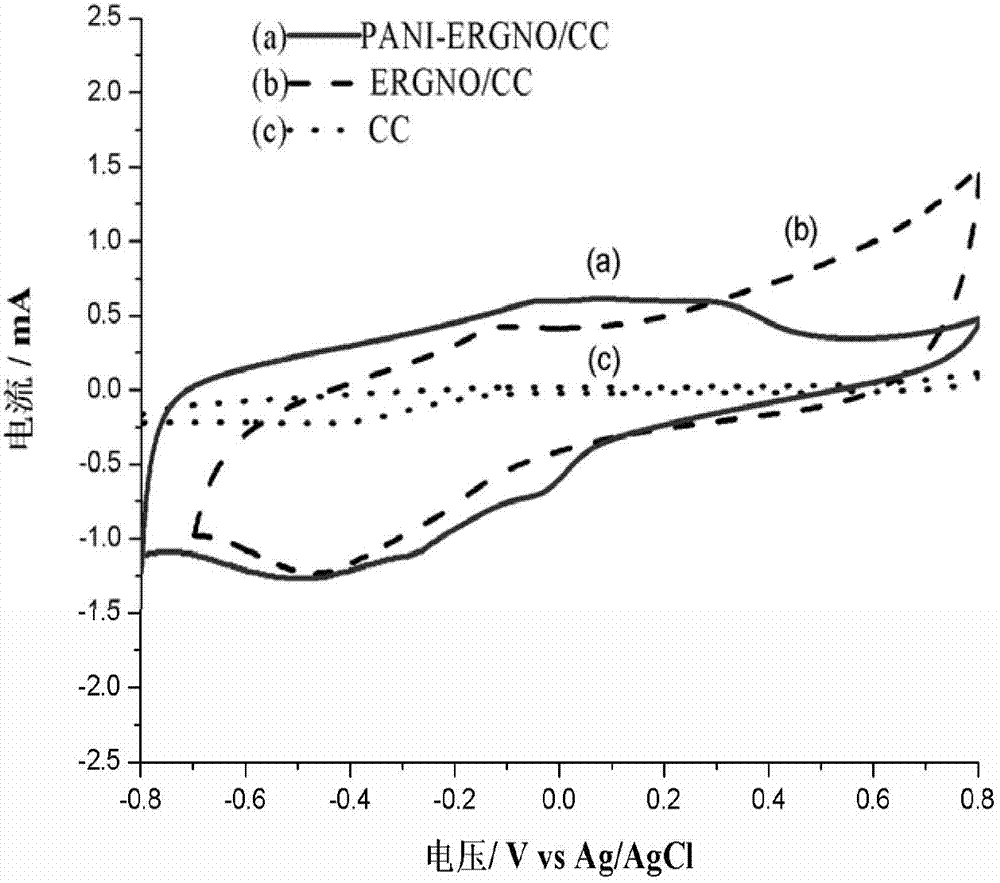

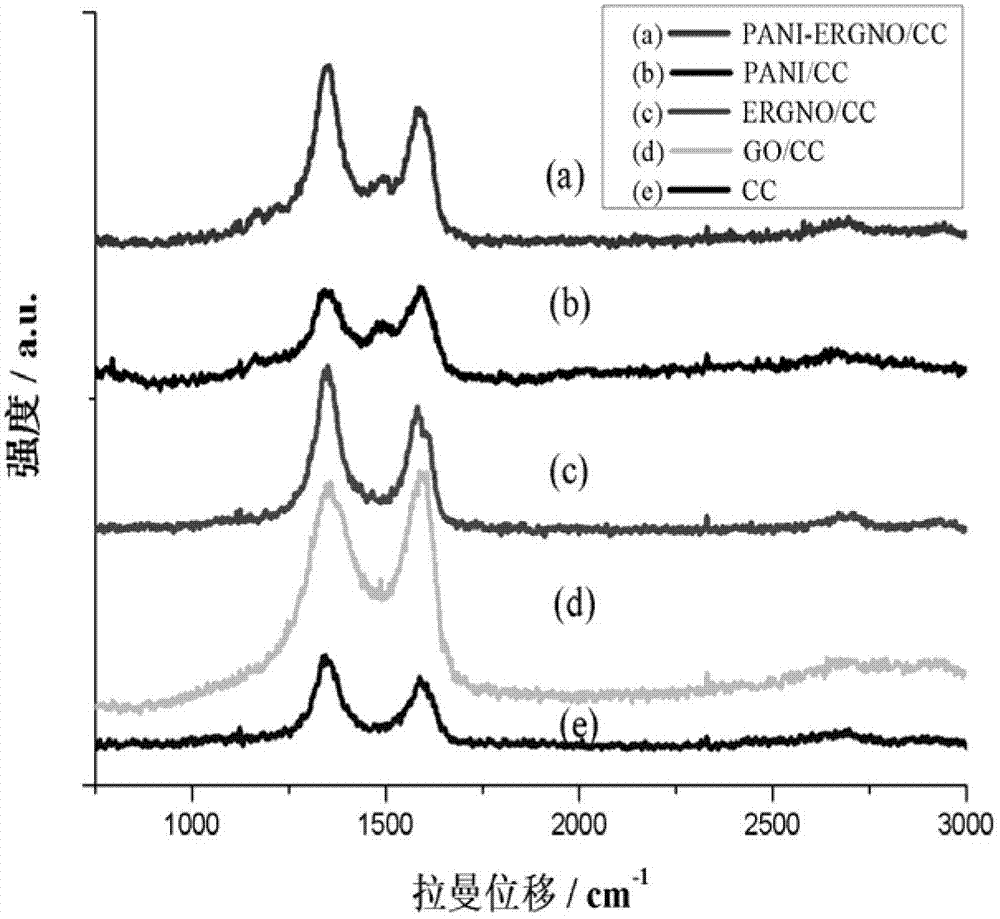

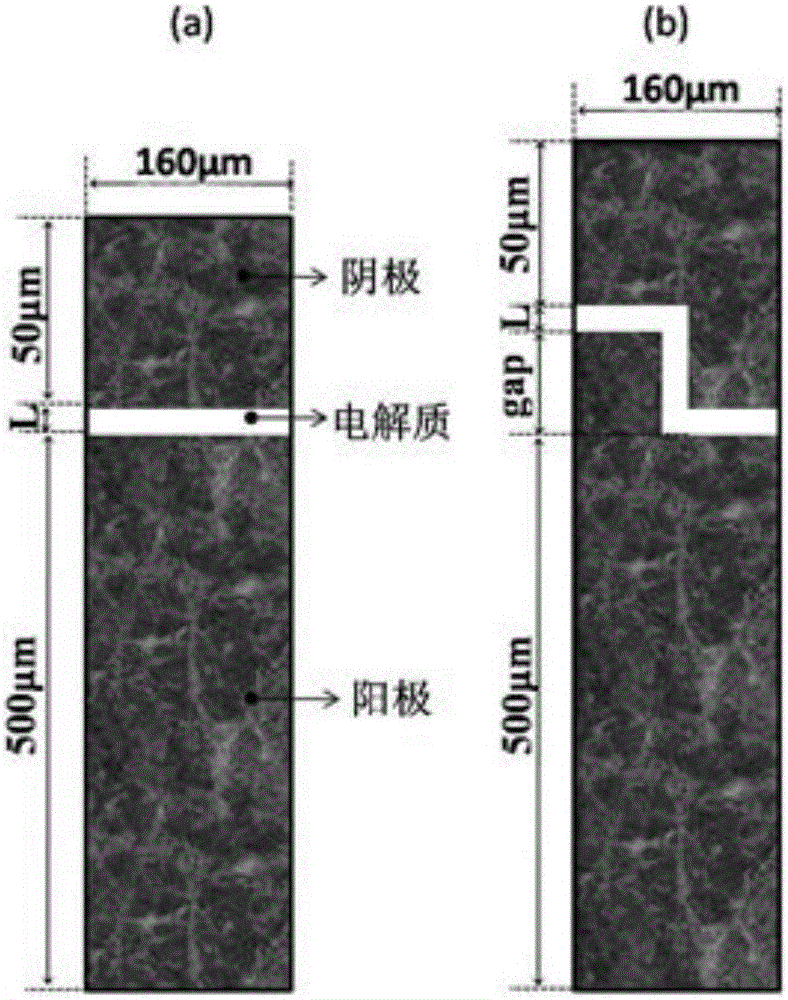

Preparation and application of graphene/substrate electrode and polyaniline-graphene/substrate electrode

InactiveCN102760888ASimple processNo pollution in the processCell electrodesMicrobial fuel cellFuel cells

The invention discloses preparation and application of a graphene / substrate electrode and a polyaniline-graphene / substrate electrode and belongs to the technical field of electrodes. The preparation comprises the following steps of: dispensing a graphene oxide aqueous solution on a substrate; reducing a graphene oxide / substrate electrode by employing a three-electrode system and cyclic voltammetry to obtain the graphene / substrate electrode; soaking the graphene / substrate electrode in a polyaniline aqueous solution; and taking out and drying to obtain the polyaniline-graphene / substrate electrode. The method is simple in process, convenient, rapid, green and free from pollution, and the power output of a microbial fuel cell can be obviously improved.

Owner:BEIJING UNIV OF TECH

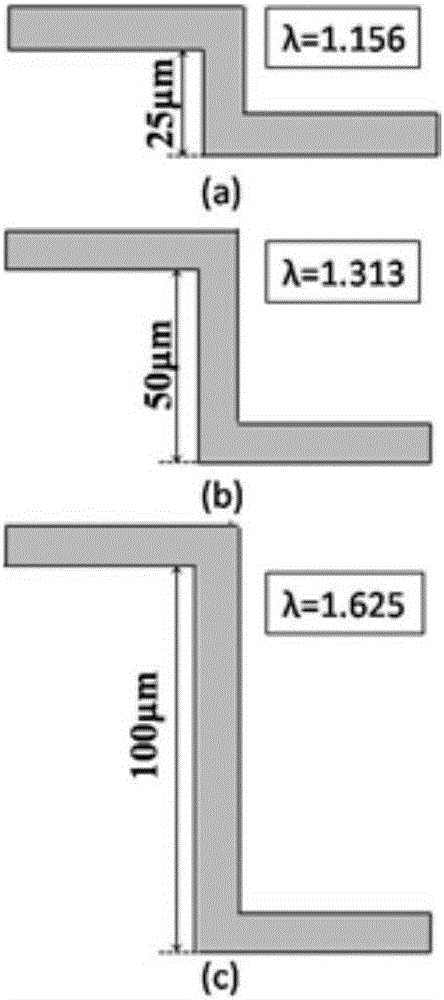

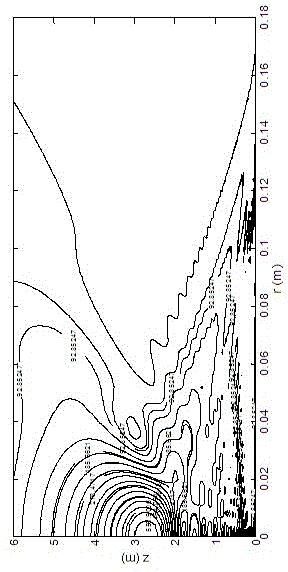

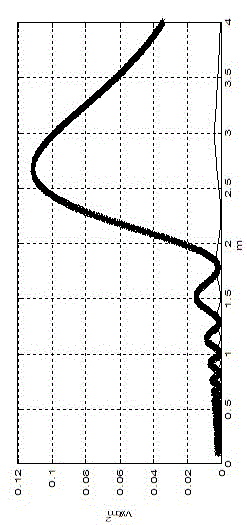

Rectangular electrode/electrolyte interface based SOFC (solid oxide fuel cell) simulation method

InactiveCN106383977AIncreased Active Response Area AreaReduce activation lossDesign optimisation/simulationSpecial data processing applicationsIonElectrochemical response

Owner:中博源仪征新能源科技有限公司

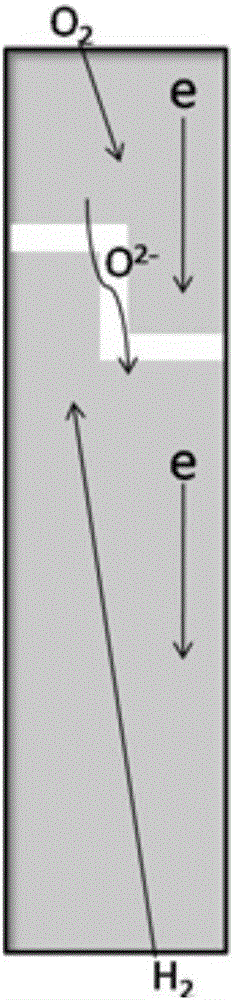

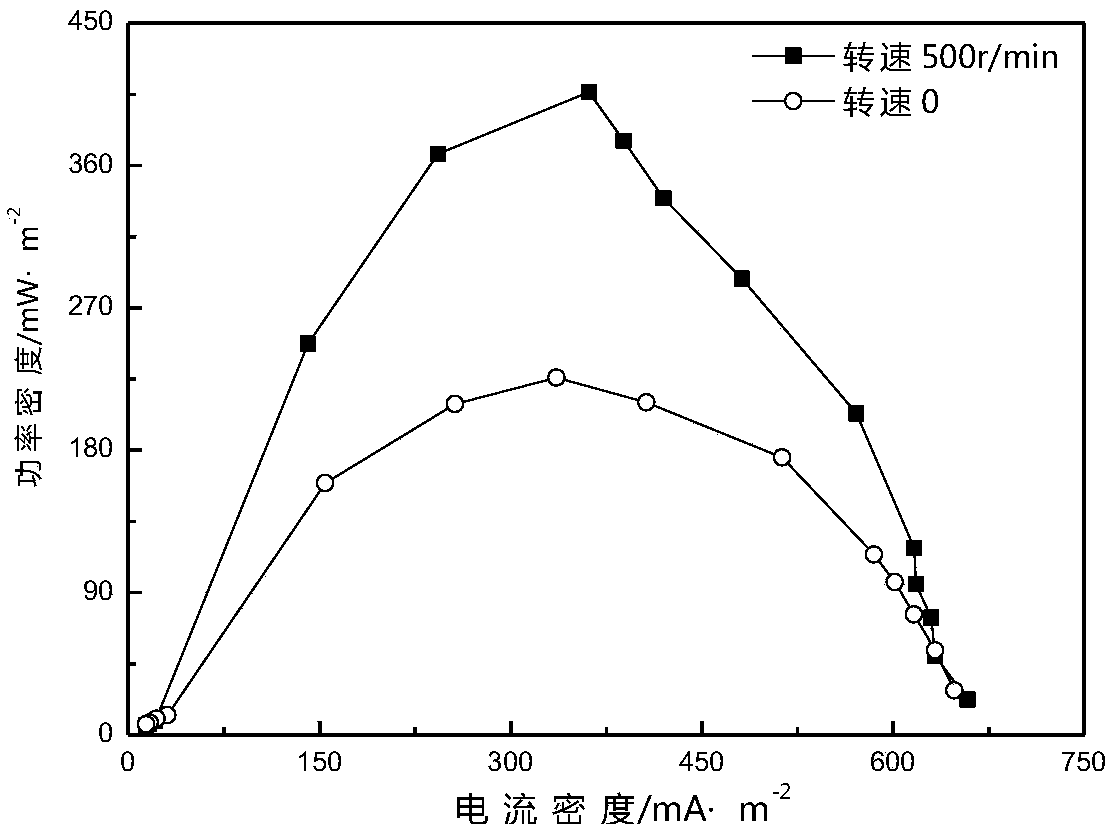

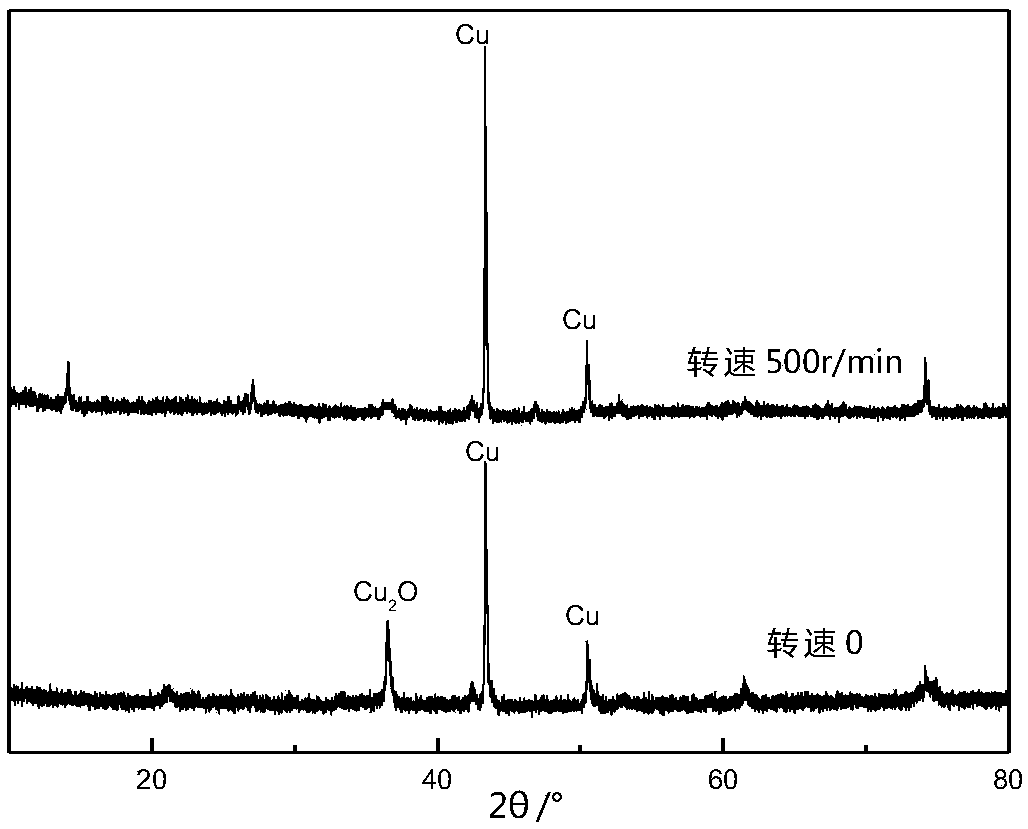

Microbial fuel cell for processing acid copper-containing waste water of mine, and copper recycling method

InactiveCN107946623AImprove microenvironmentHigh removal rateWaste water treatment from quariesTreatment by combined electrochemical biological processesSucroseEffective volume

The invention discloses a microbial fuel cell for processing acid copper-containing waste water of mine, and a copper recycling method. Processing of the acid copper-containing waste water of mine bythe microbial fuel cell comprises the following three steps (1) enrichment of a positive electrode electrochemical active microorganism: dewatered sludge is a positive electrode inoculum, and a culture domestication liquid taking sucrose as the main part is added for performing domestication for seven days to obtain a positive electrode culture; the main components of a positive electrode substrate comprise residual sludge, glucose and the like; and the volume ratio of the positive electrode culture to the substrate is 1:1 to 1:4; (2) establishment of an MFC system: the effective volume of theMFC is 100-250mL; the spacing between a positive electrode carbon brush and a negative electrode carbon brush is 4-6cm; and after the output voltage of the MFC reaches 400-600mV, a positive electrodestirring apparatus is started at the rotary speed of 450-550r / min and at the maximum power density of 580.8mW / m<2>; and (3) processing of the acid copper-containing waste water of mine and copper recycling in a negative electrode room: a negative electrode is taken out after operation for 25-30 days; a negative electrode reduction product is collected, and detection proves that the product is elementary copper; after the reaction, the negative electrode liquid is 6.5-6.9 in pH value; and negative electrode Cu<2+> removal ratio is 92.2%.

Owner:JIANGSU UNIV OF TECH

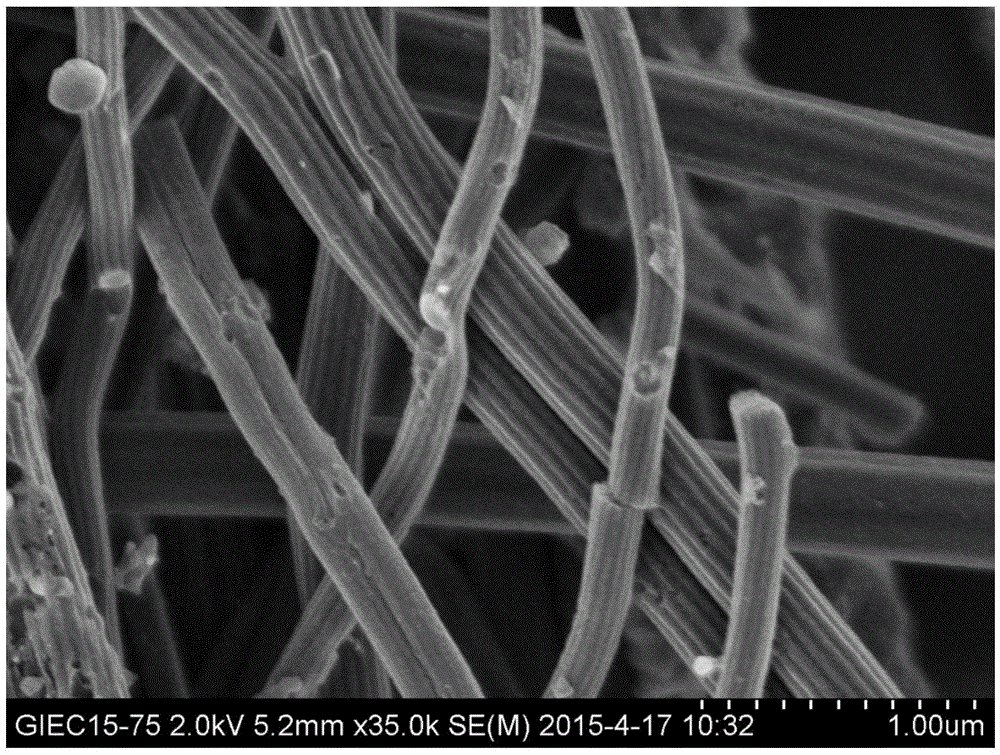

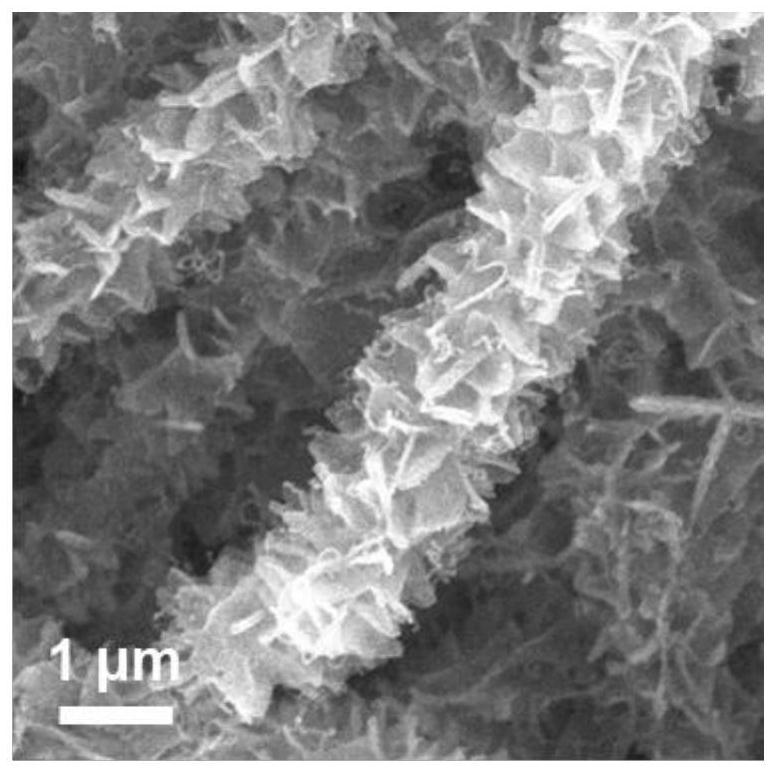

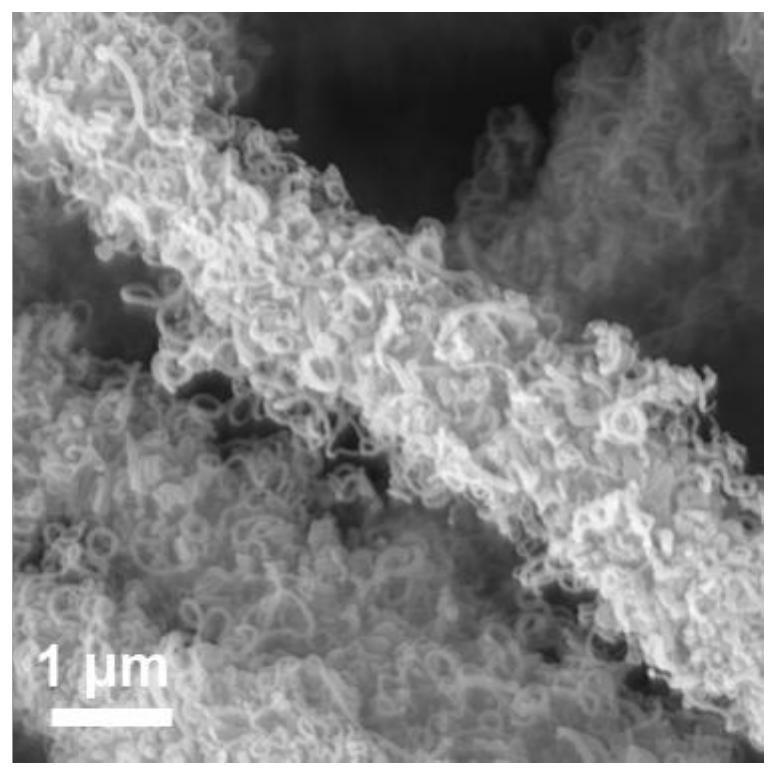

Cobweb-based porous activated carbon fiber material and application

The invention discloses a cobweb-based porous activated carbon fiber material and an application. The preparation method comprises the follow steps: collecting a cobweb in an environment and removing impurities in the cobweb; ultrasonically cleaning the cobweb with deionized water, hydrochloric acid and ethanol in sequence for 20-40 minutes, cleaning the cobweb with ultrapure water and drying the cobweb; pre-carbonizing the dried cobweb at 200-400 DEG C, naturally cooling the cobweb to room temperature and mixing the cobweb with an activating reagent; and grinding the mixture evenly, and carbonizing the mixture at 700-1,000 DEG C to obtain the porous activated carbon fiber. The porous activated carbon fiber prepared by the method can be used as a microbial fuel cell cathode catalyst and an electrode material, is low in cost, simple in method, stable in performance and good in activity, and provides a new thought for resource utilization of natural waste.

Owner:GUANGDONG INST OF ECO ENVIRONMENT & SOIL SCI

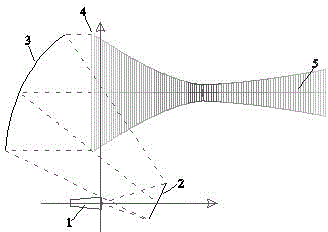

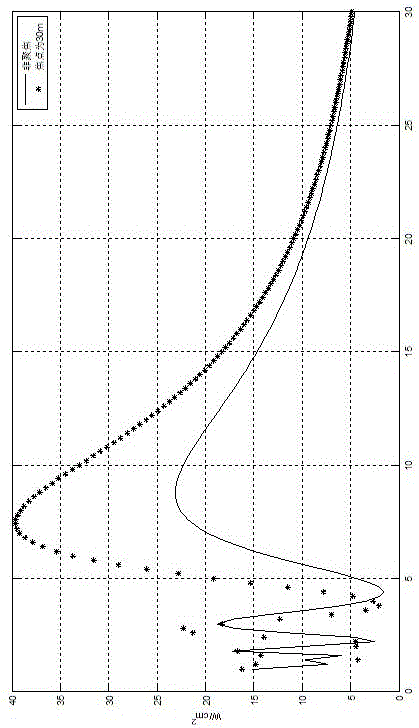

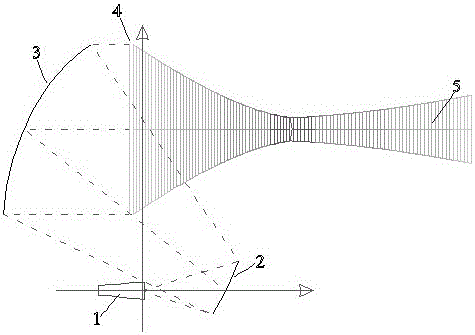

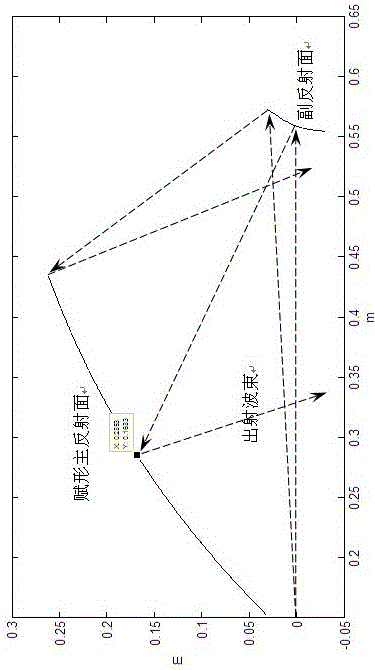

Millimeter-wave dual reflector antenna capable of focusing near-field wave beam

ActiveCN104103911AImprove power densityIncreased maximum power densityAntennasEffective powerParaboloid

The invention discloses a millimeter-wave dual reflector antenna capable of focusing a near-field wave beam. The antenna comprises a main reflector, an auxiliary reflector and a feed source, wherein a wave beam emitted by the feed source is reflected by the auxiliary reflector to the main reflector, and then emitted; a curved surface of the main reflector is a revolution paraboloid; and a central point of the main reflector is located at an intersection point of an emitting central axis of the auxiliary reflector and an axis of a radiation wave beam. The antenna is simple in structure and mature to process; the power density of a near-field region axis of the antenna is improved; the maximum power density of the axis is improved greatly under the same input power; a distance range of an effective power threshold is expanded; the efficiency of the antenna is improved; and a near-field gain of the antenna is increased.

Owner:中久安特装备有限公司

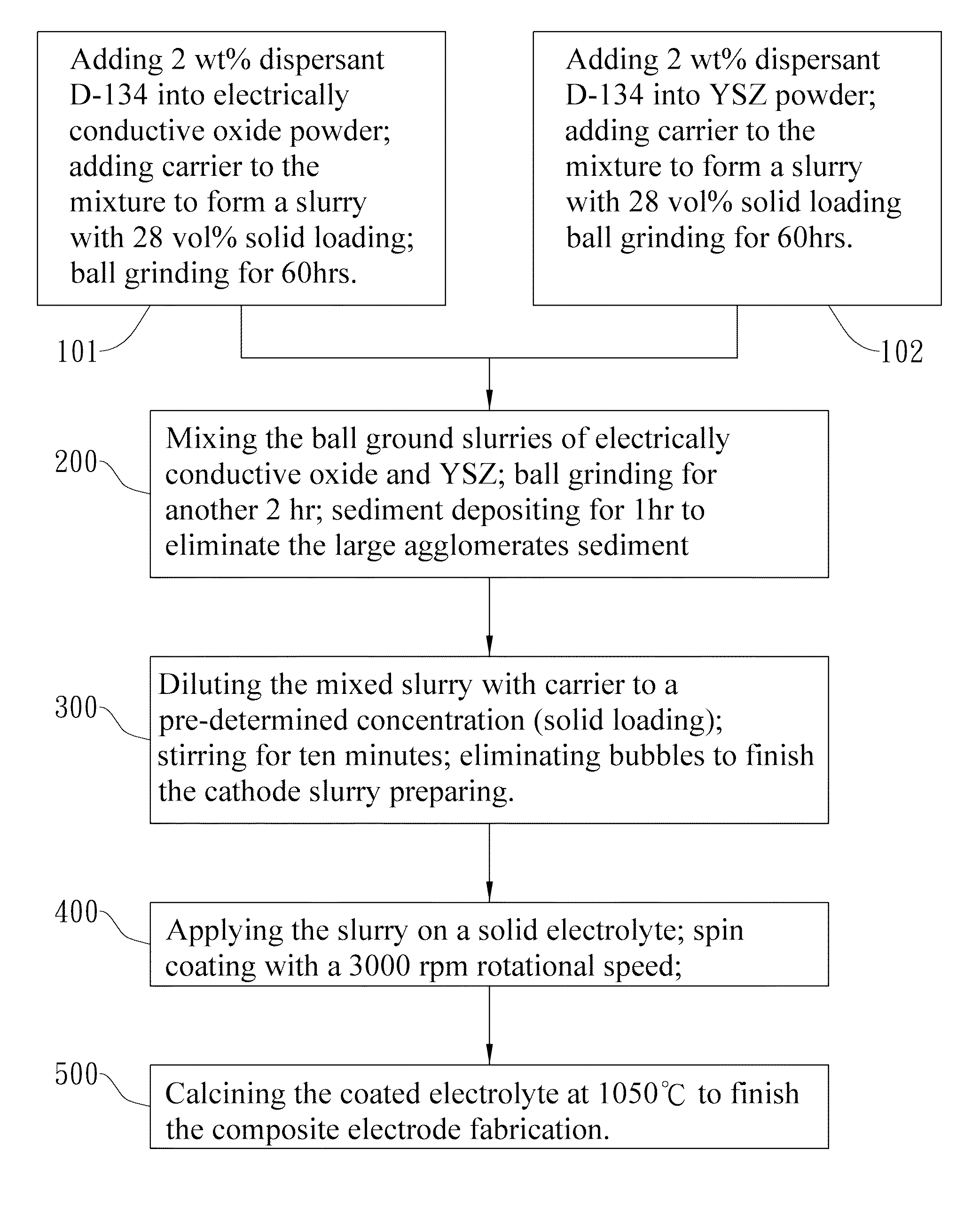

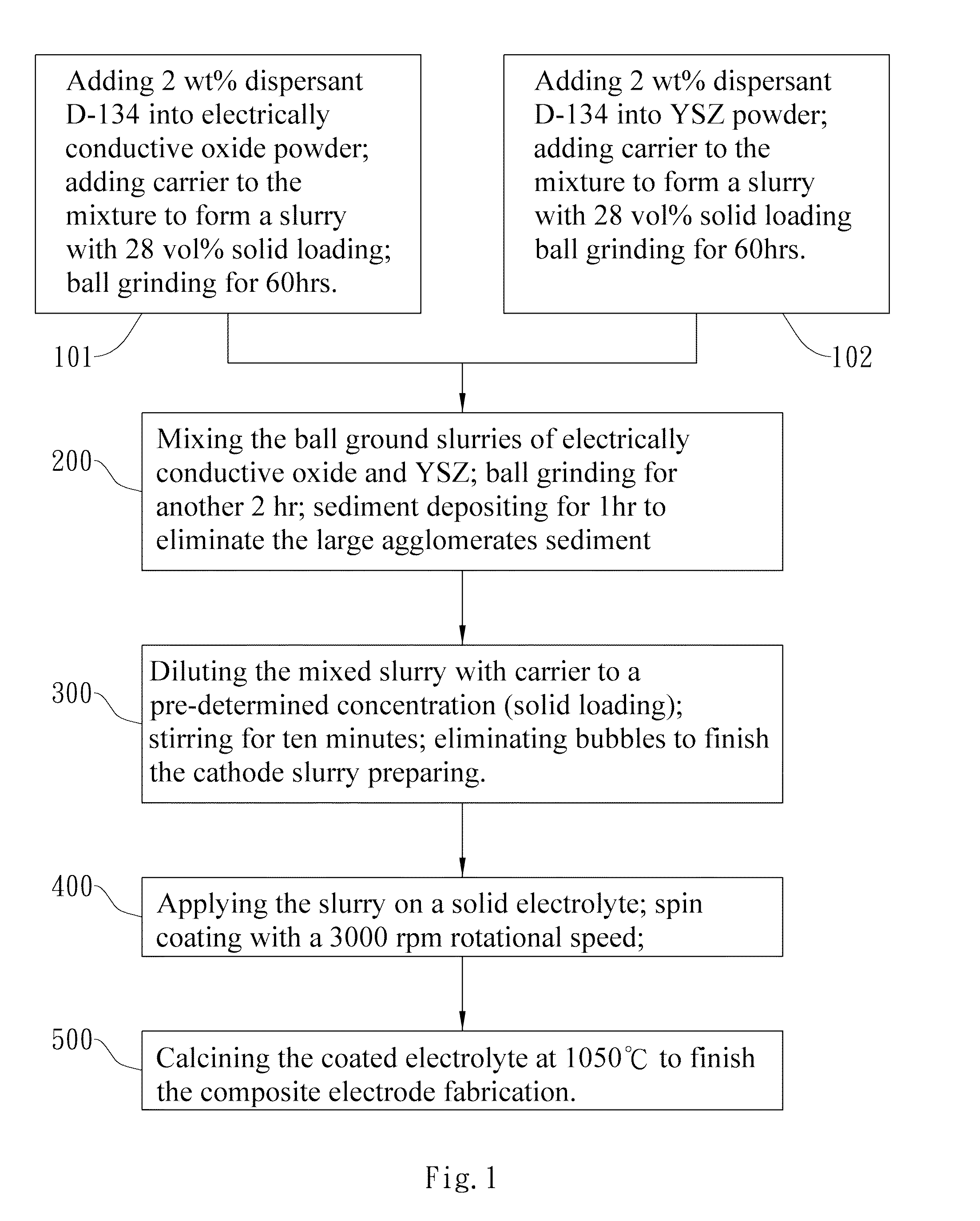

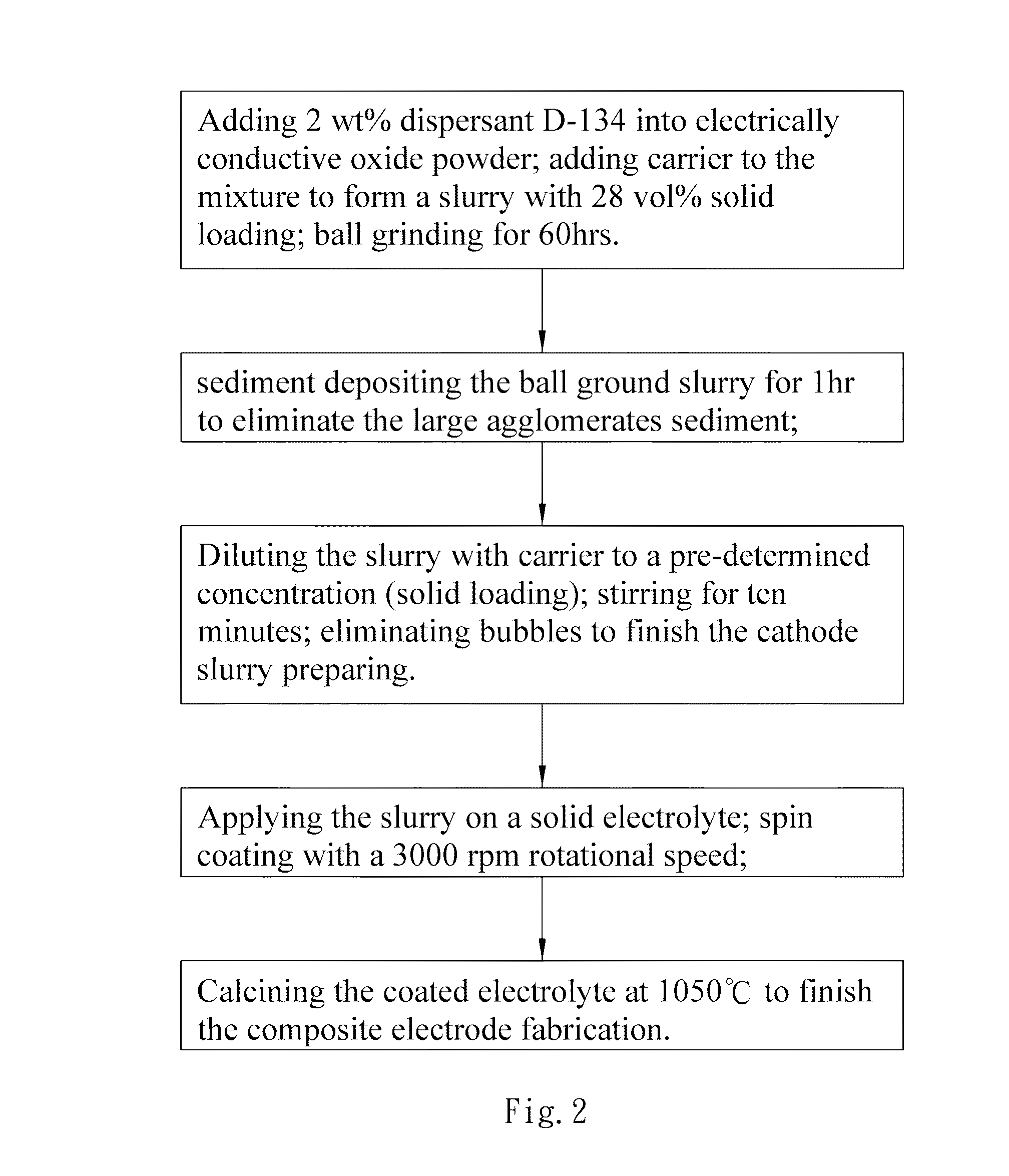

Porous oxide electrode layer and method for manufacturing the same

InactiveUS20140113213A1Reduce crackingImprove conductivityCell electrodesSolid electrolyte fuel cellsPorous substrateSlurry

This invention provides a method for manufacturing porous oxide electrode layer, comprising: preparing an electrode slurry containing an electrically conductive oxide material powder, a dispersant, water and a moisture agent; spin coating the electrode slurry on a surface of a thin electrolyte or a porous substrate and simultaneously controlling the thickness and uniformity of the electrode layer on the fine electrolyte or the porous substrate; and calcining the electrode layer on the fine electrolyte or the porous substrate to form a porous electrode.

Owner:NAT TAIWAN UNIV

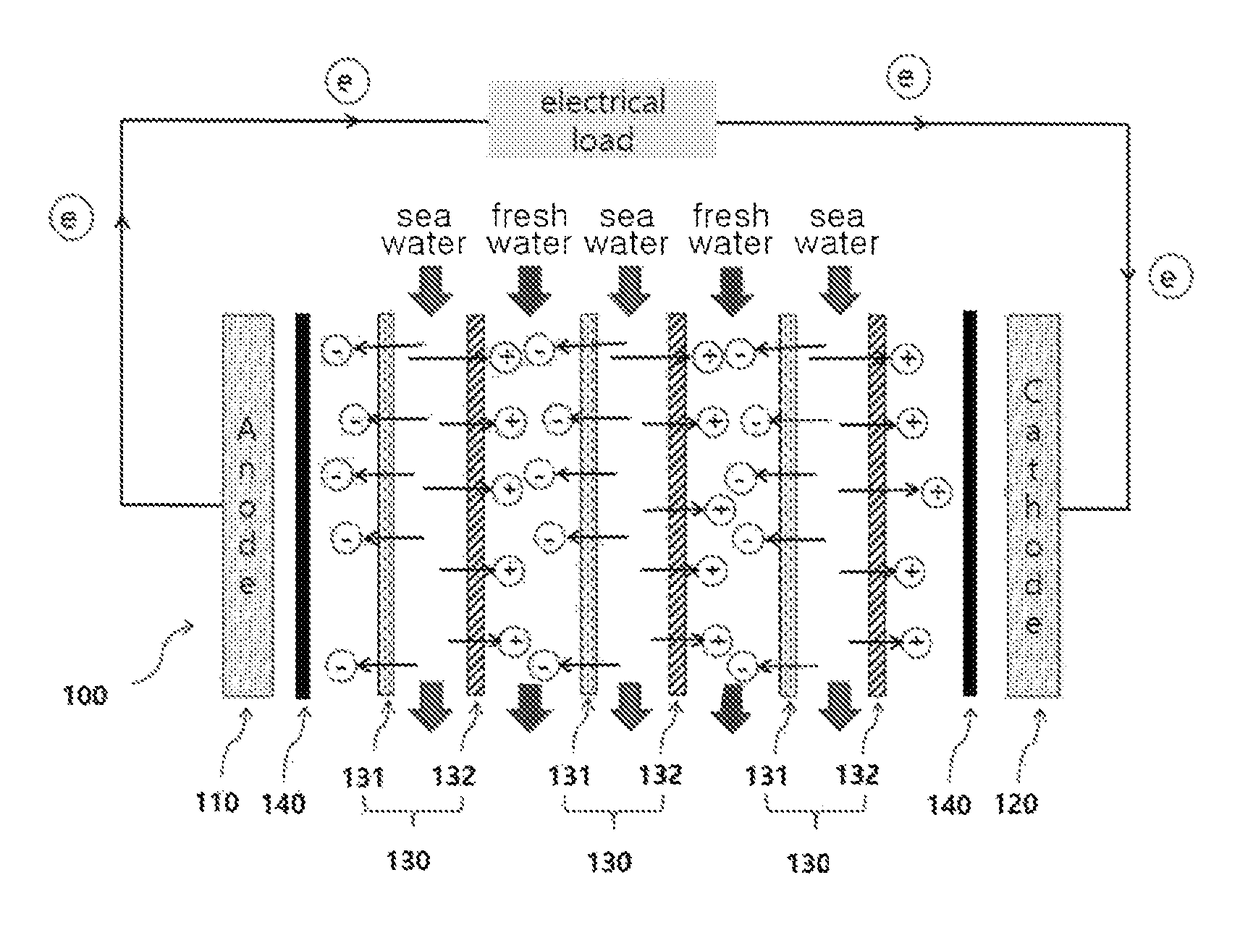

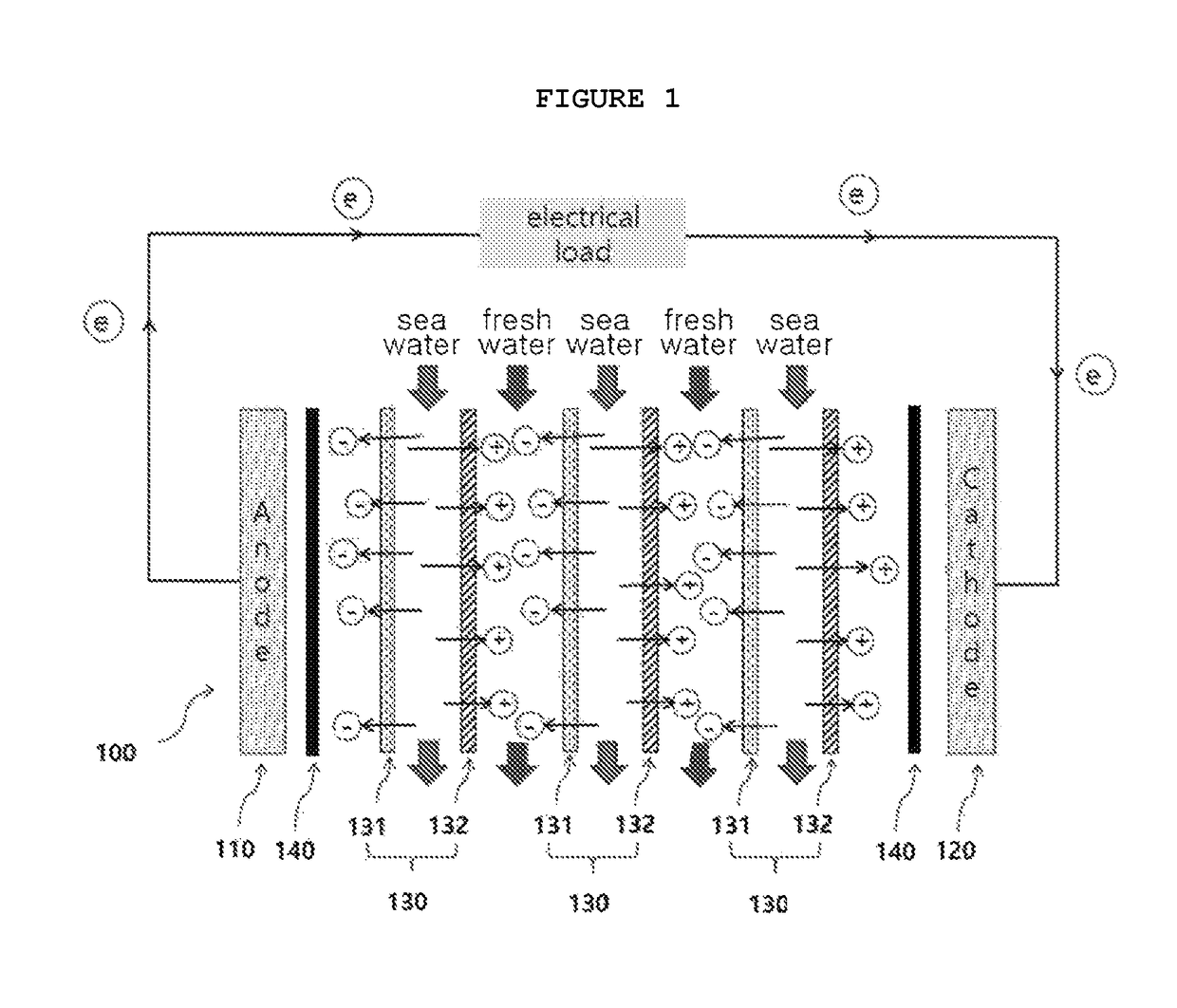

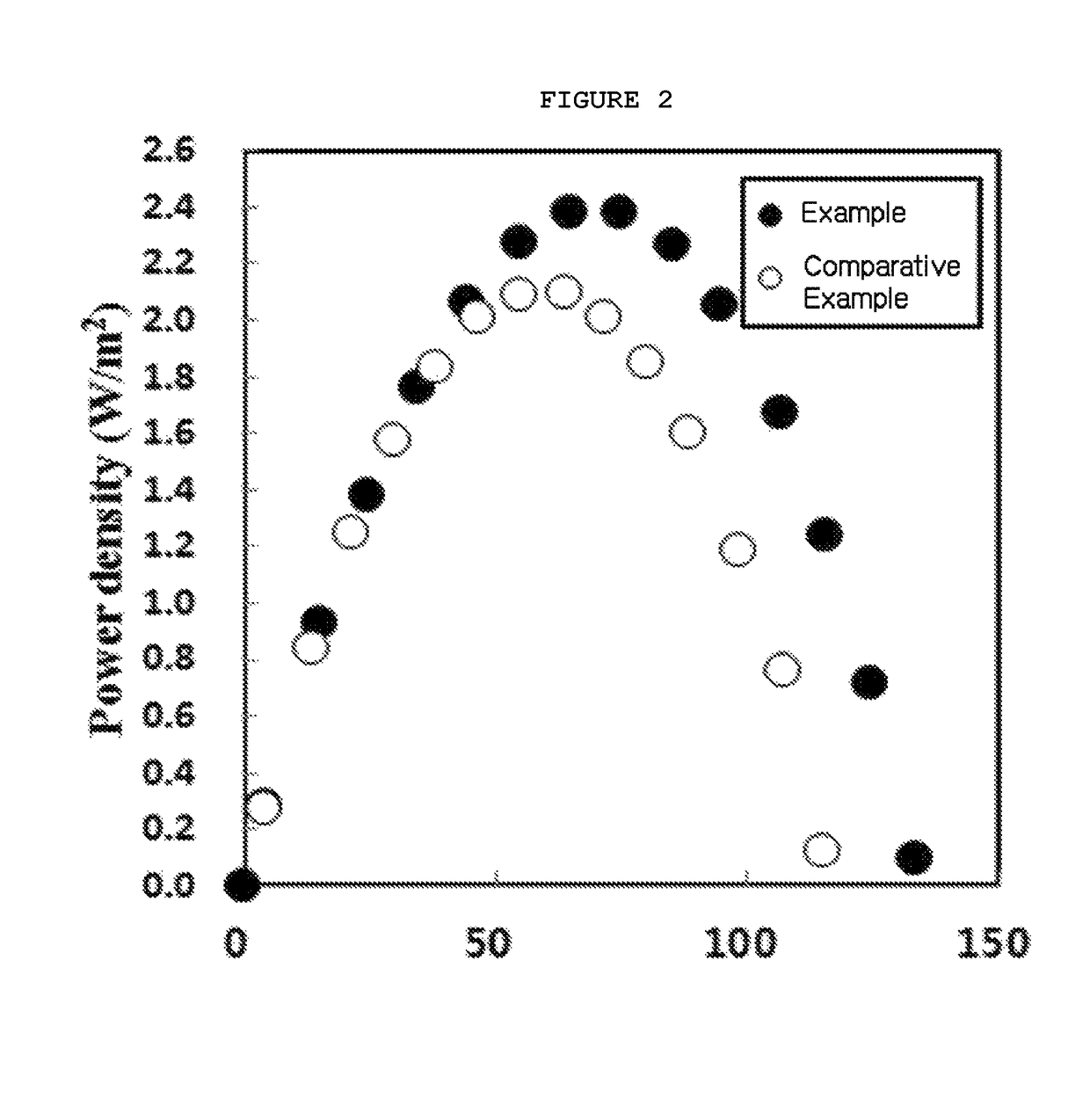

Reverse electrodialysis device having enhanced maximum power density with ultra-thin ion exchange membranes

ActiveUS9982104B2Improve ionic conductivityGood water and heat resistanceCellsSemi-permeable membranesPolymer electrolytesPolymer substrate

Owner:TORAY ADVANCED MATERIALS KOREA

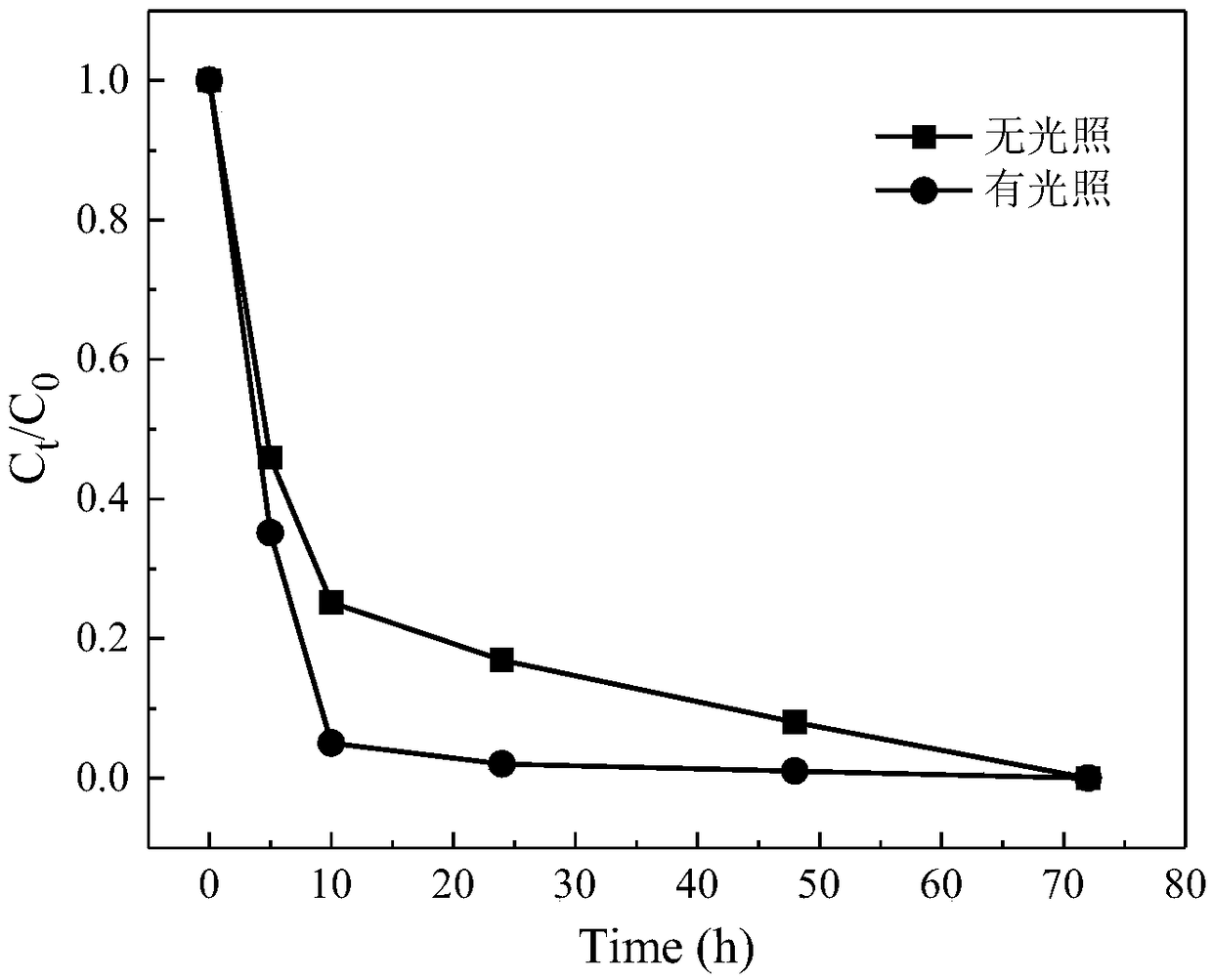

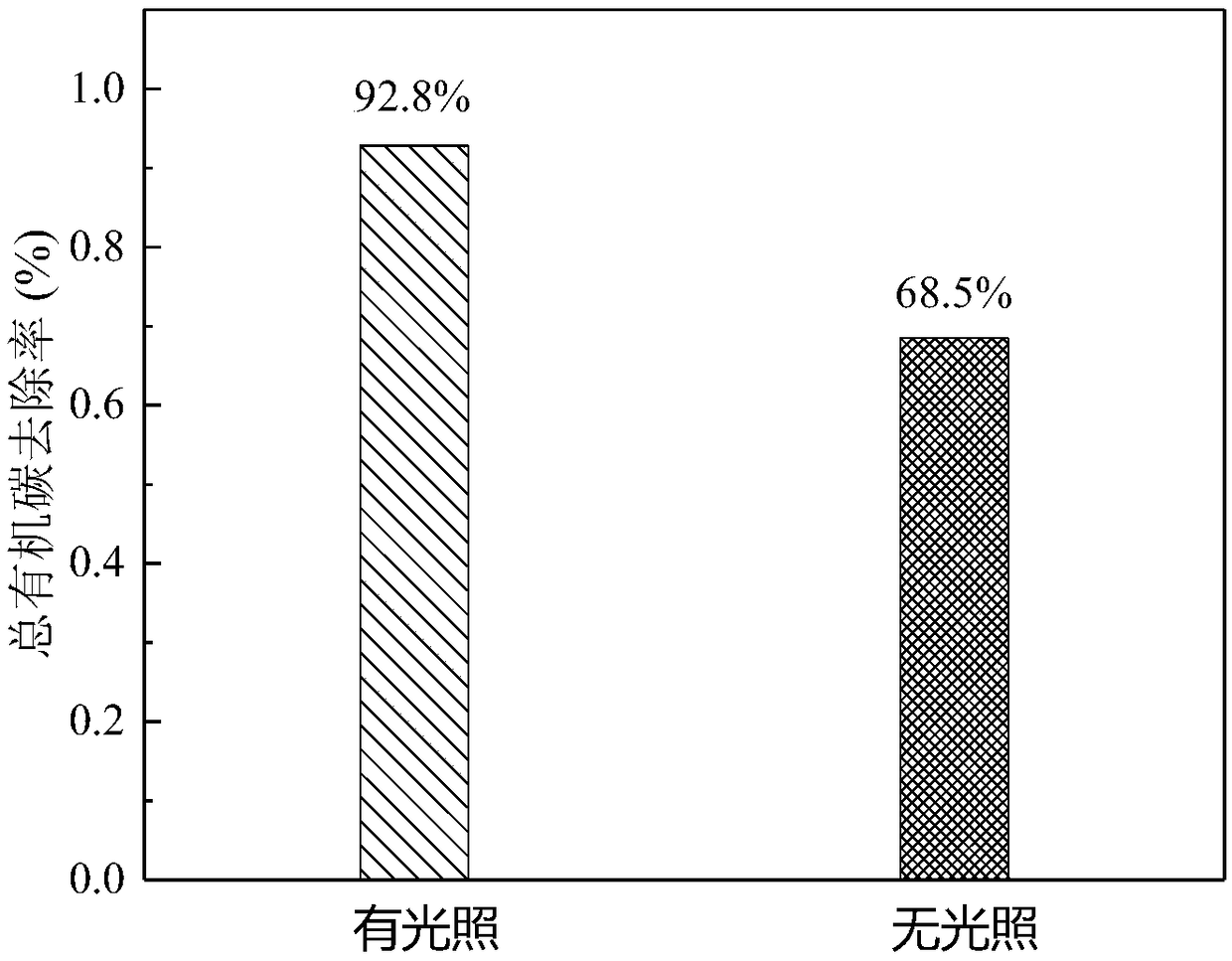

Microbial fuel cell with photocatalytic material loaded on positive electrode and preparation method and application of microbial fuel cell

PendingCN109160594AImproved degradation efficiency and mineralizationReduce recombination rateTreatment by combined electrochemical biological processesCell electrodesChlorophenolEngineering

The invention discloses a microbial fuel cell with a photocatalytic material loaded on a positive electrode and a preparation method and application of the microbial fuel cell, and belongs to the technical field of environment water pollution treatment and energy recovery. The photocatalytic material is loaded on the positive electrode of the microbial fuel cell, a negative electrode is an air electrode; and a resistor is connected between the positive electrode and the negative electrode. The preparation method comprises the following steps: dissolving the photocatalytic material, coating onthe surface of a carbon electrode, heating to obtain the carbon electrode loaded with the photocatalytic material, taking the carbon electrode as the positive electrode and the air electrode as the negative electrode, connecting the resistor between the positive electrode and the negative electrode; connecting the positive electrode, the negative electrode and the resistor in series, putting in areactor, and forming the microbial fuel cell with the photocatalytic material loaded on the positive electrode. The microbial fuel cell with the photocatalytic material loaded on the positive electrode can rapidly thoroughly degrade the organic matters like chlorophenols, and the electricity generation performance of the fuel cell is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

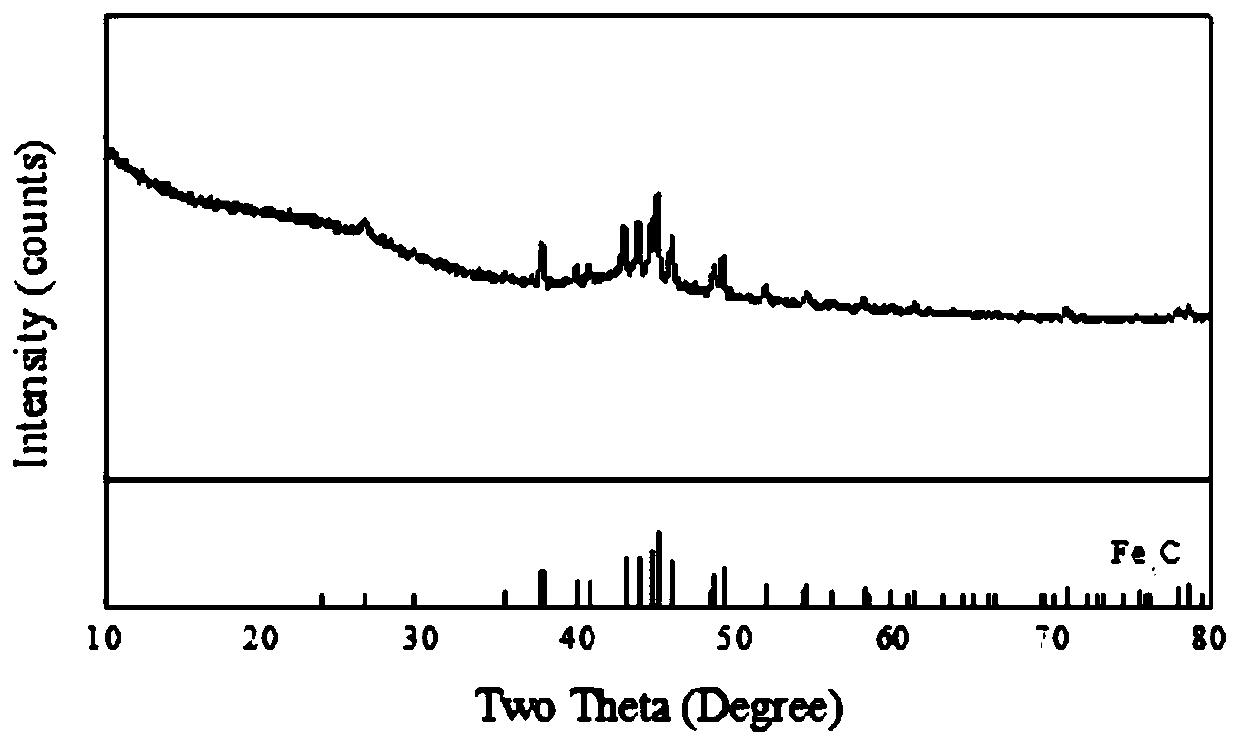

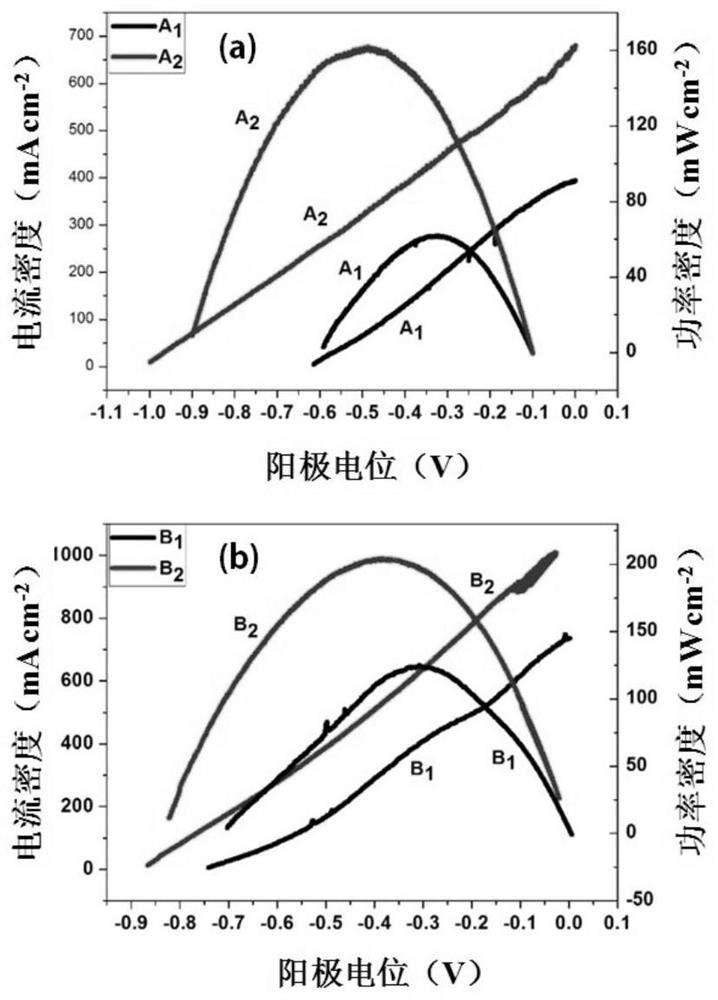

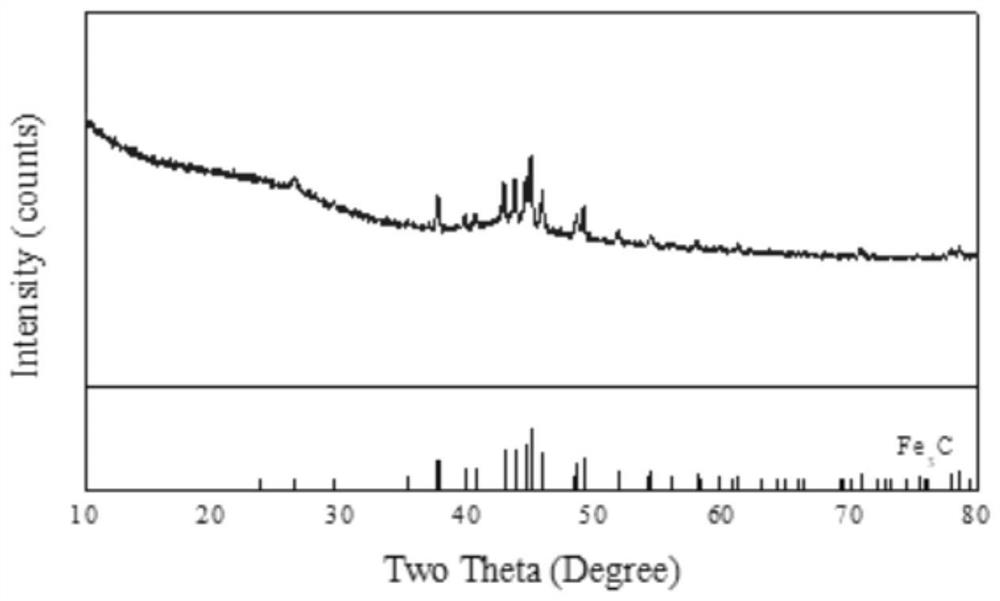

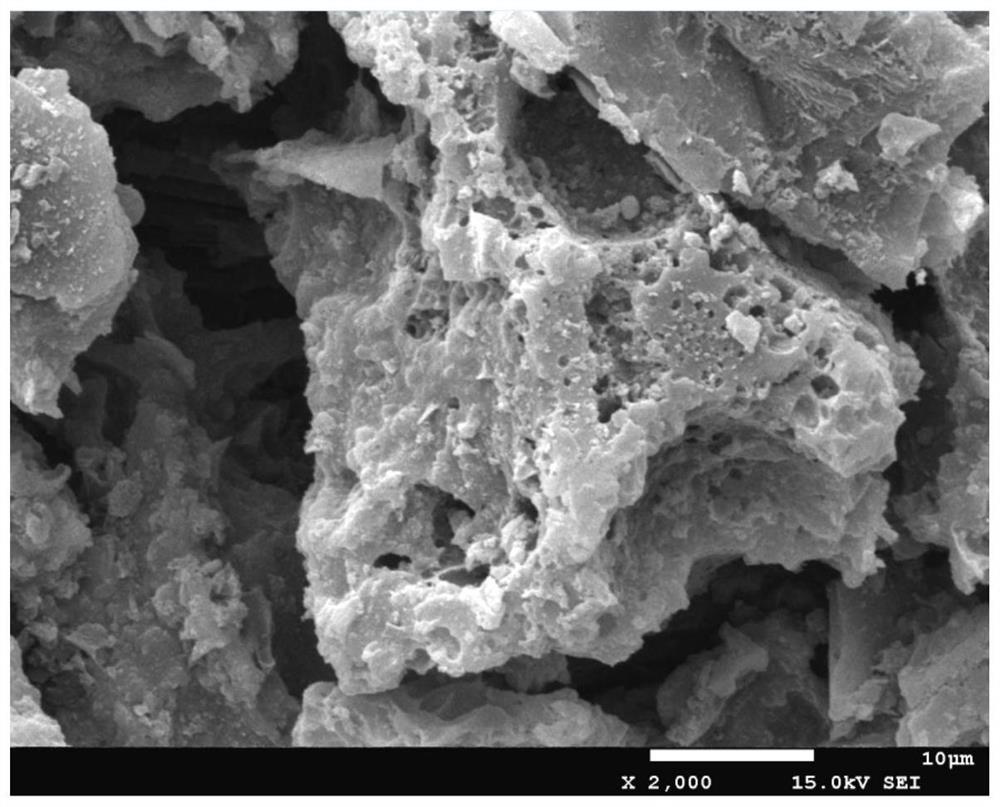

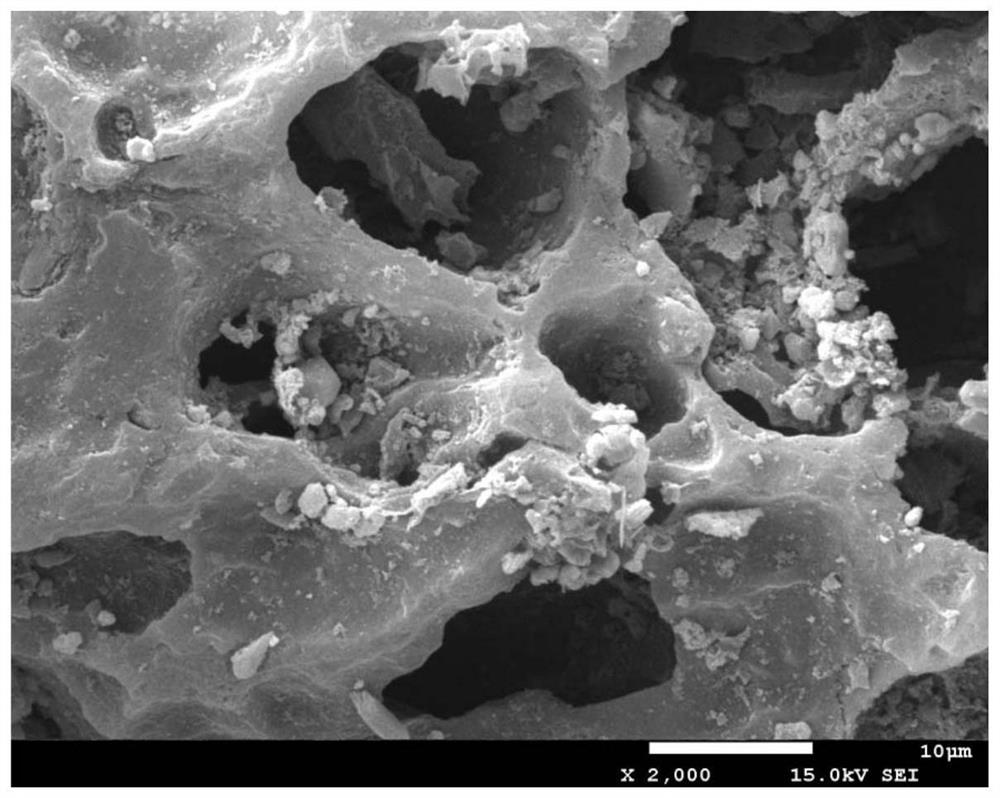

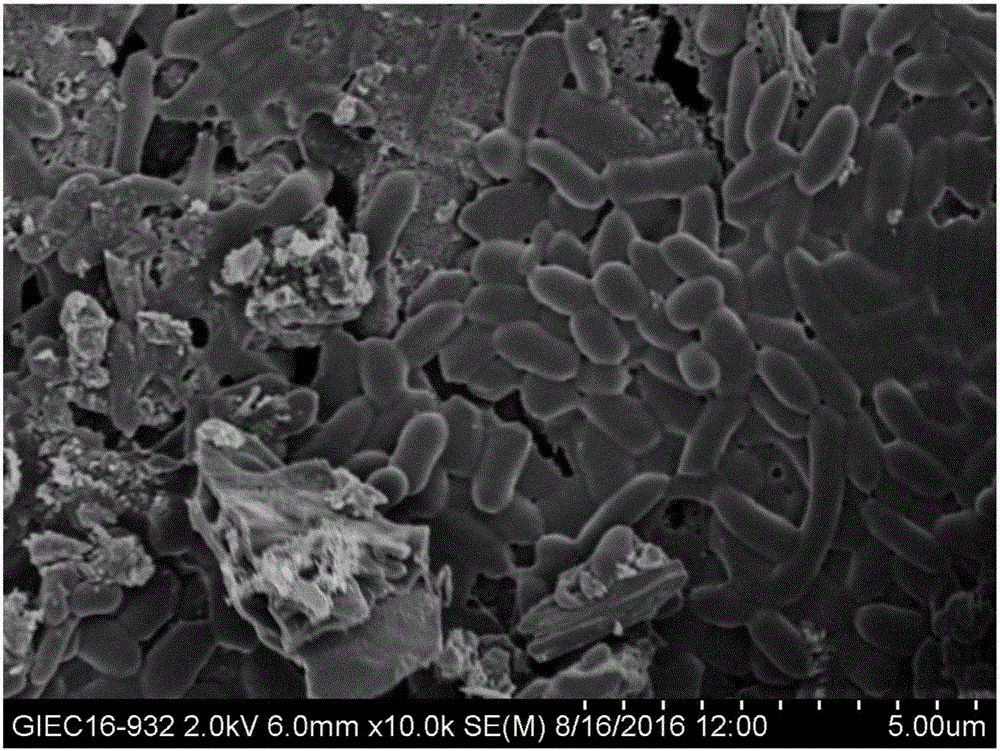

Biomass-based activated carbon coated iron carbide three-dimensional porous microbial fuel cell anode material, anode and preparation methods

ActiveCN110752378AGood antioxidantFacilitates electron conductionCell electrodesBiochemical fuel cellsActivated carbonPorous network

The invention provides a biomass-based activated carbon coated iron carbide three-dimensional porous microbial fuel cell anode material, which is composed of biomass-based activated carbon and iron carbide, wherein iron carbide is distributed in the biomass-based activated carbon and is coated by the biomass-based activated carbon to form micron-sized activated carbon-coated iron carbide particles, and the anode material has a three-dimensional porous network structure consisting of micron and nano composite holes. The invention also provides a microbial fuel cell anode based on the anode material, and preparation methods of the anode material and the anode. According to the invention, the problems of unfavorable attached growth of microorganisms and high modification cost of the existingmodified three-dimensional carbon-based electrode are solved, and the attached growth of an anode biological membrane can be promoted and the electron transfer of an extracellular interface can be accelerated while the cost of the microbial fuel anode is reduced.

Owner:SICHUAN UNIV

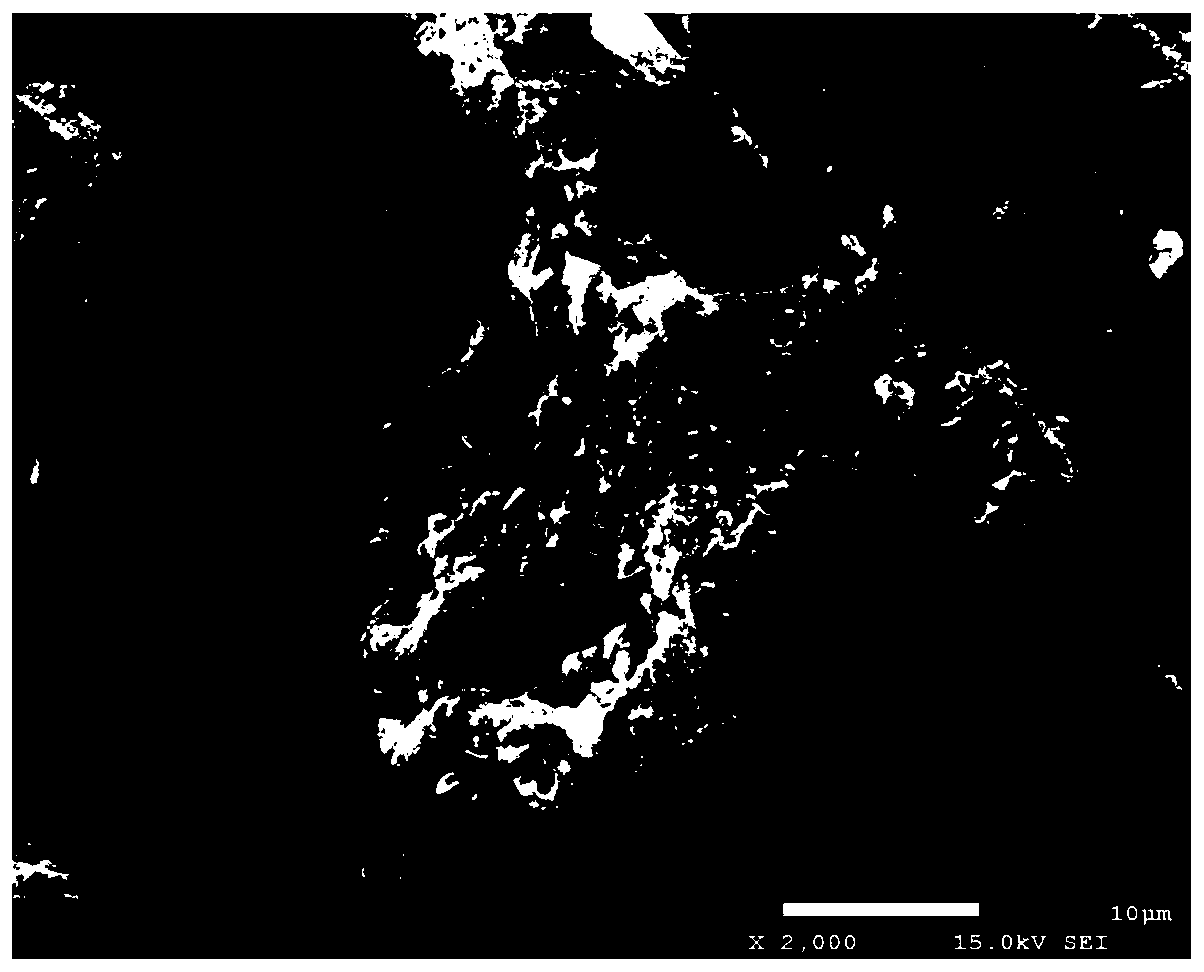

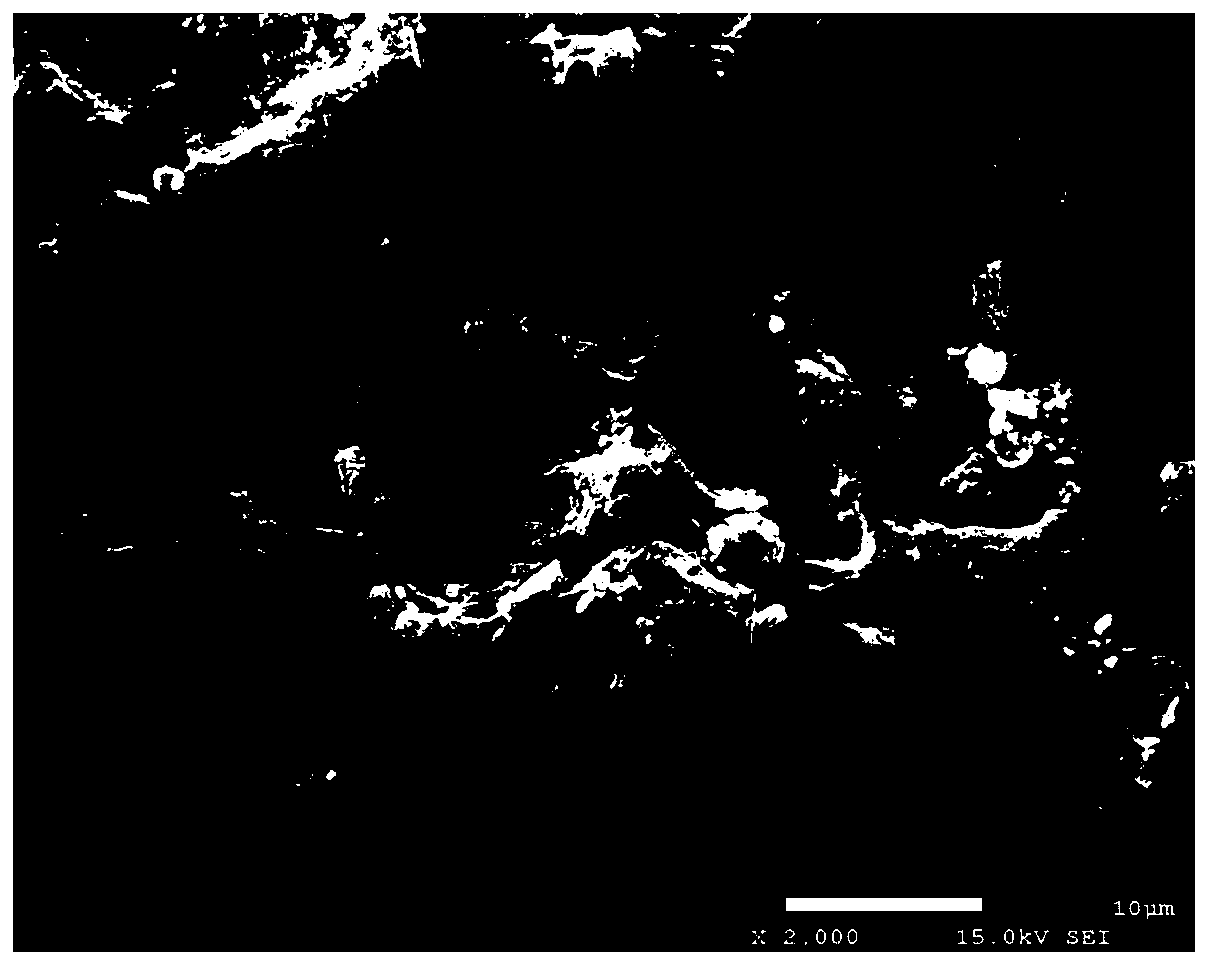

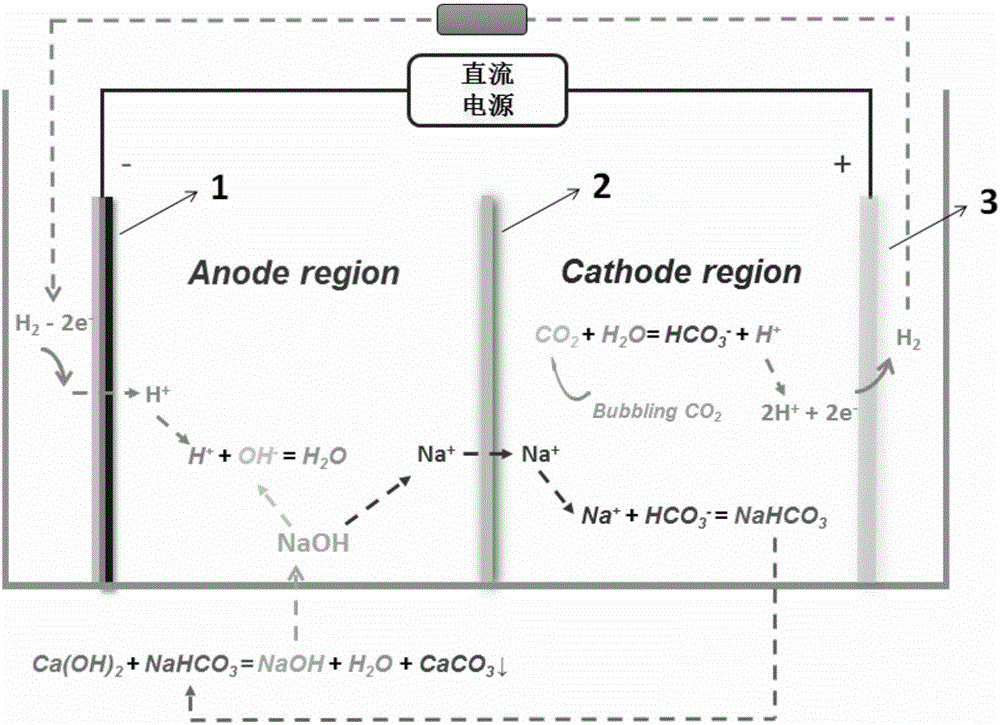

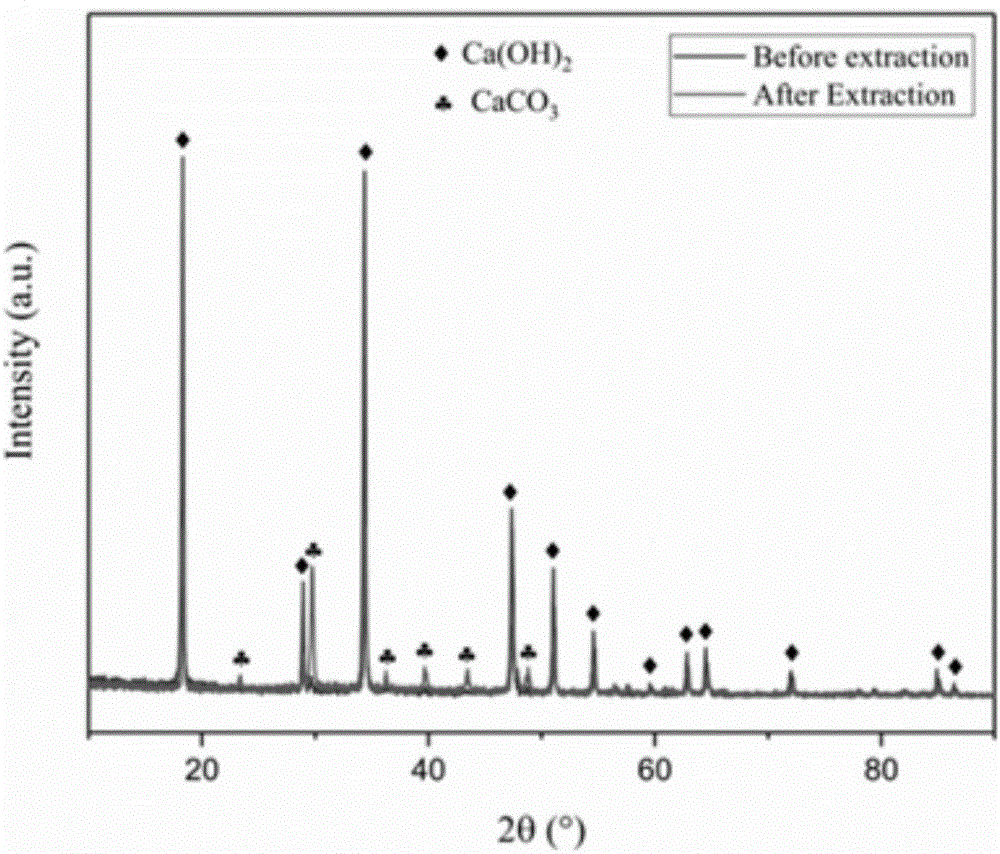

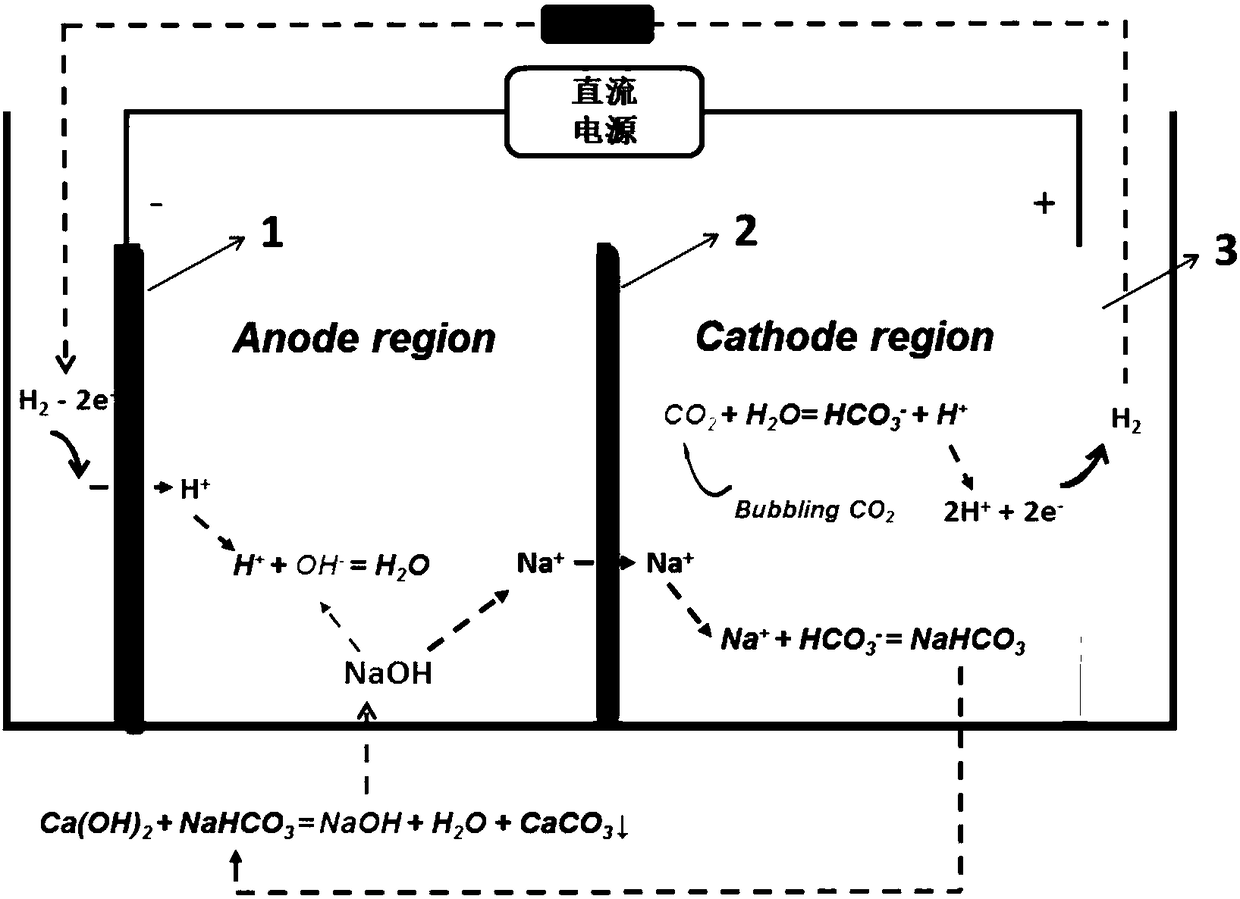

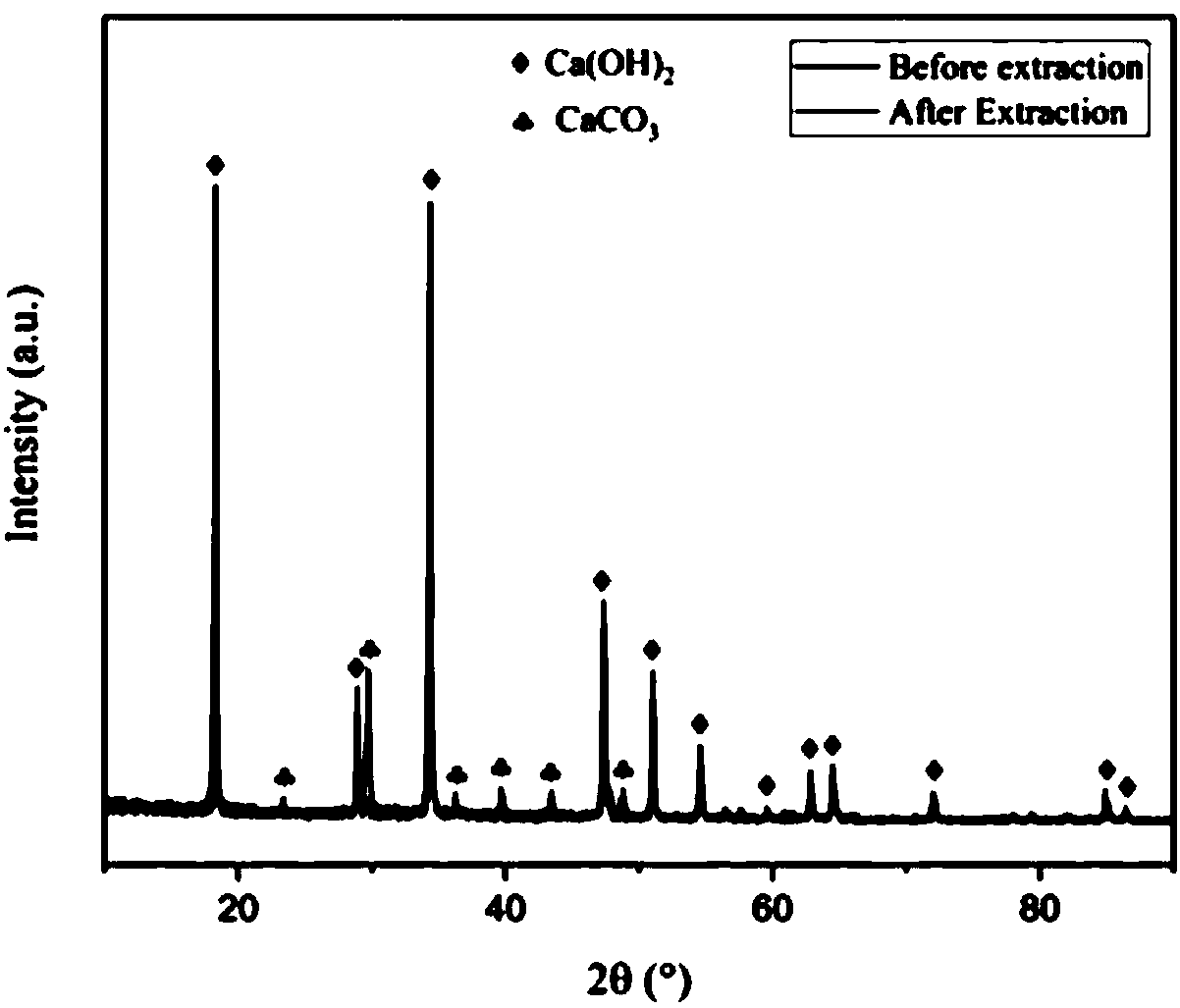

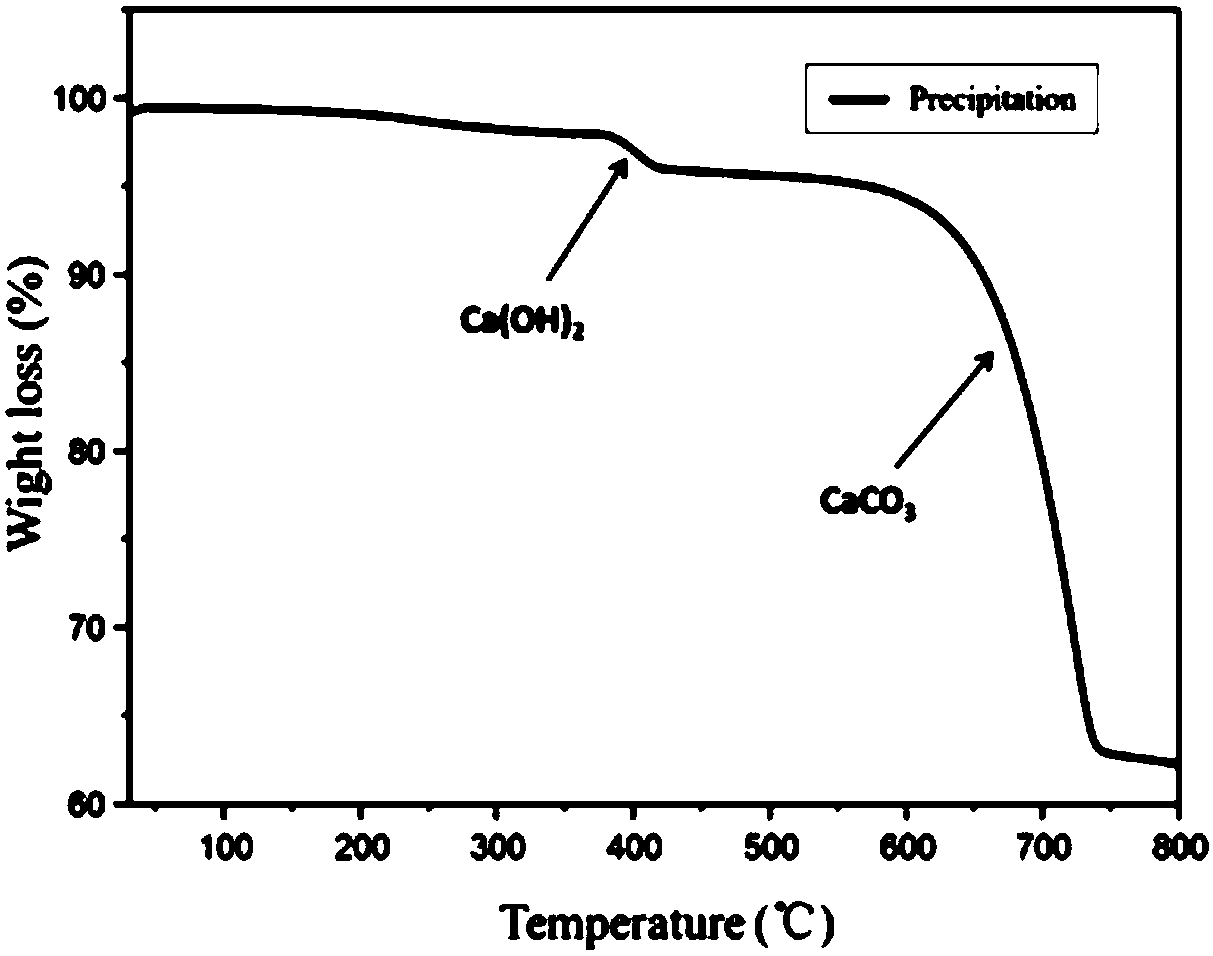

CO2 mineralizing power generation method using sodium bicarbonate as alkaline leaching agent

ActiveCN107437629AFacilitate hydrolytic transformationImprove power generation performanceElectrogenerative processesFuel cellsSupporting electrolyteSodium bicarbonate

The invention discloses a CO2 mineralizing power generation method using sodium bicarbonate as an alkaline leaching agent, a battery is divided into a positive electrode zone and a negative electrode zone by a cation exchange membrane, the negative electrode zone contains a supporting electrolyte, the positive electrode zone contains a leaching solution formed by alkaline solid waste and the sodium bicarbonate, after a conductive path is formed by a positive electrode and a negative electrode, CO2 is introduced into the negative electrode for ionization into H<+> and HCO3<->, the H<+> is reduced into H2, the H2 is recycled back to the positive electrode, and oxidized into the H<+>, the H<+> and OH<-> of a positive electrode liquid are neutralized, and the sodium bicarbonate is generated from the HCO3<-> and Na<+> from the positive electrode zone. The sodium bicarbonate in a negative electrode liquid is continuously generated and circulated to the positive electrode zone, caustic soda is extracted, suspension is filtered and leached, filtrate is used as a positive electrode electrolyte, and the positive electrode liquid with the OH<-> consumed is recycled to the negative electrode zone. By means of heating, the CO2 mineralizing power generation method can improve the electricity production performance, is suitable for power generation of weak alkaline solid waste, can be applied to steel making industry to achieve three purposes of emission reduction, solid waste treatment and power generation, and has high practical value.

Owner:SICHUAN UNIV

Application of sulfonated polyaryletherketone as binder in membrane electrode of proton exchange membrane fuel cell, membrane electrode and preparation method

PendingCN113161557AIncreased maximum power densityCell electrodesFuel cellsPtru catalystPhysical chemistry

The invention belongs to the technical field of fuel cells, and particularly relates to application of sulfonated polyaryletherketone as a binder in a membrane electrode of a proton exchange membrane fuel cell. According to the invention, the sulfonated polyaryletherketone as a binder can be completely dissolved in a low-boiling-point solvent, and the problem that a high-boiling-point solvent is difficult to remove after the binder is dissolved in the high-boiling-point solvent, so that a large amount of the high-boiling-point solvent is remained on a catalyst layer and the catalyst is poisoned is solved. The sulfonated polyaryletherketone is used as a binder of a catalyst layer, so that the interfacial compatibility of the catalyst layer and a proton exchange membrane is improved, an excellent three-phase reaction interface of fuel gas, water and a catalyst can be constructed, and proton transfer, material transportation and charge transfer in the catalyst layer are smoothly carried out. Meanwhile, the proton conductivity of sulfonated polyaryletherketone is excellent, so that high-efficiency transfer of protons in a catalyst layer of the proton exchange membrane fuel cell is guaranteed, and the power of the proton exchange membrane fuel cell is greatly improved.

Owner:JILIN UNIV

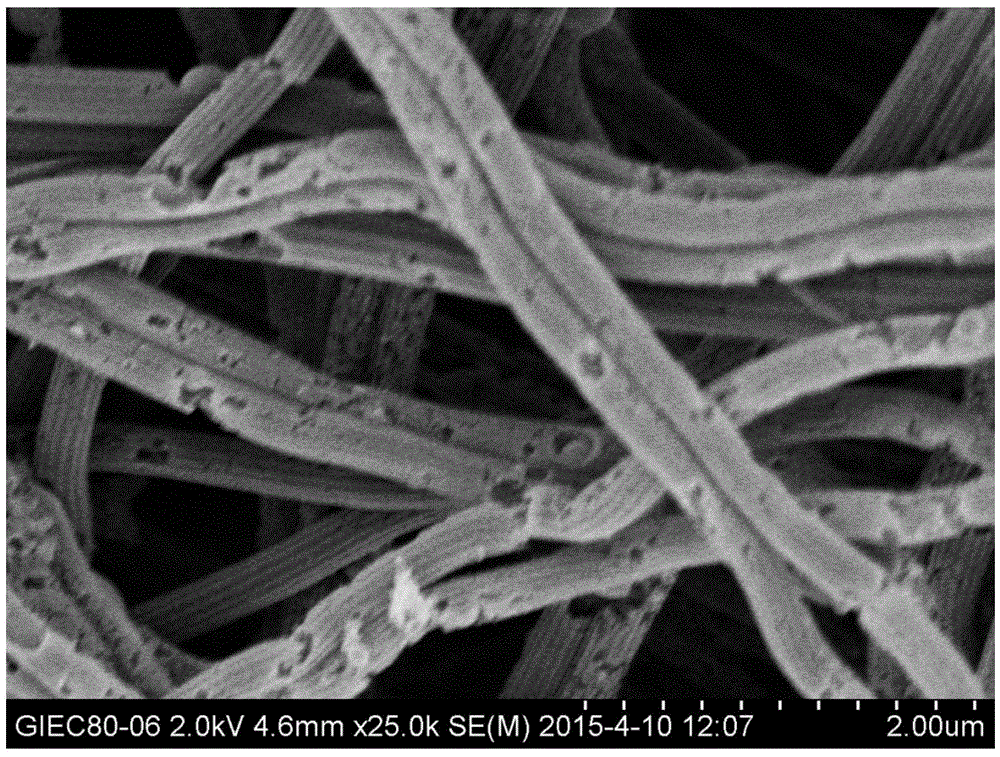

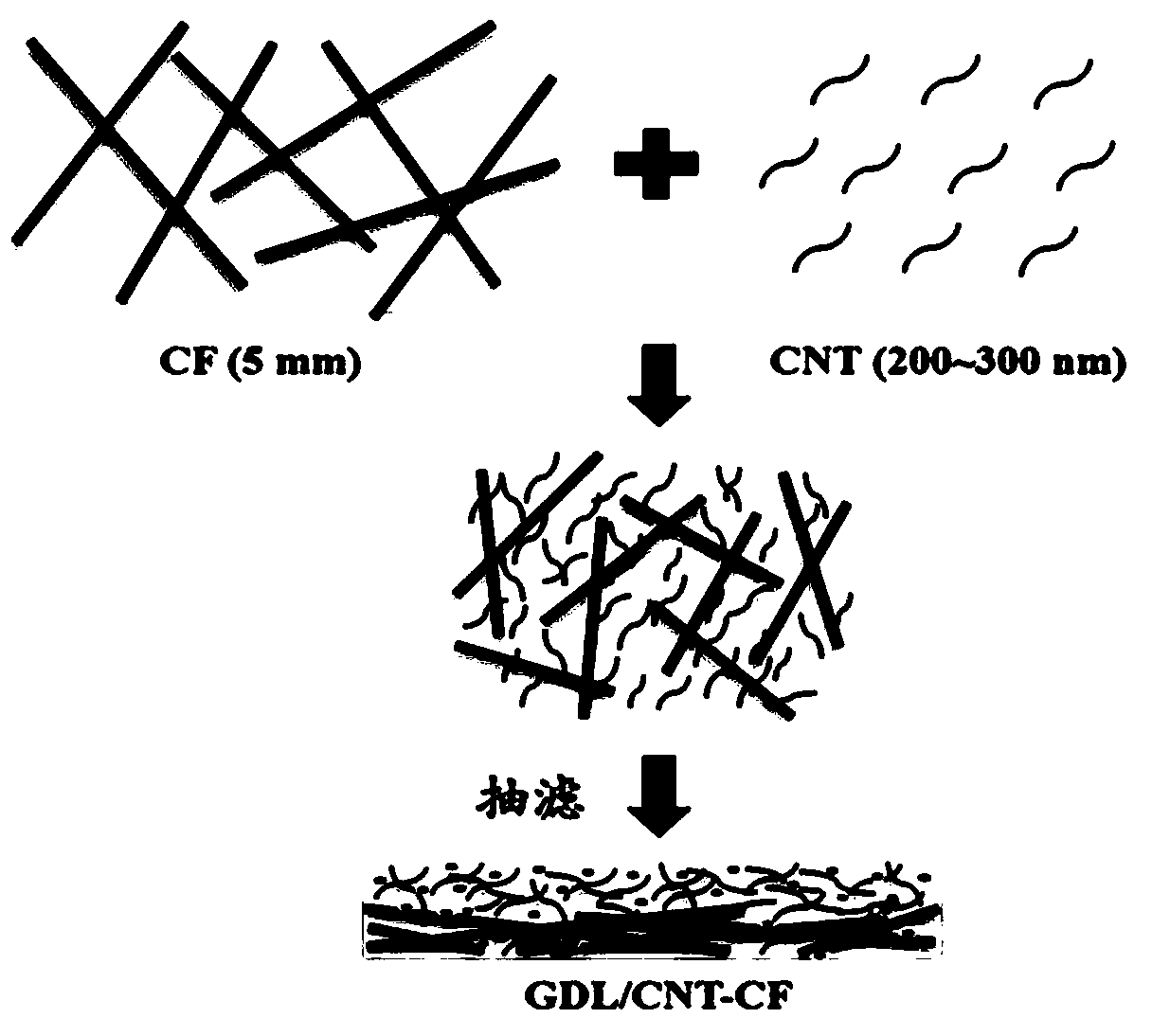

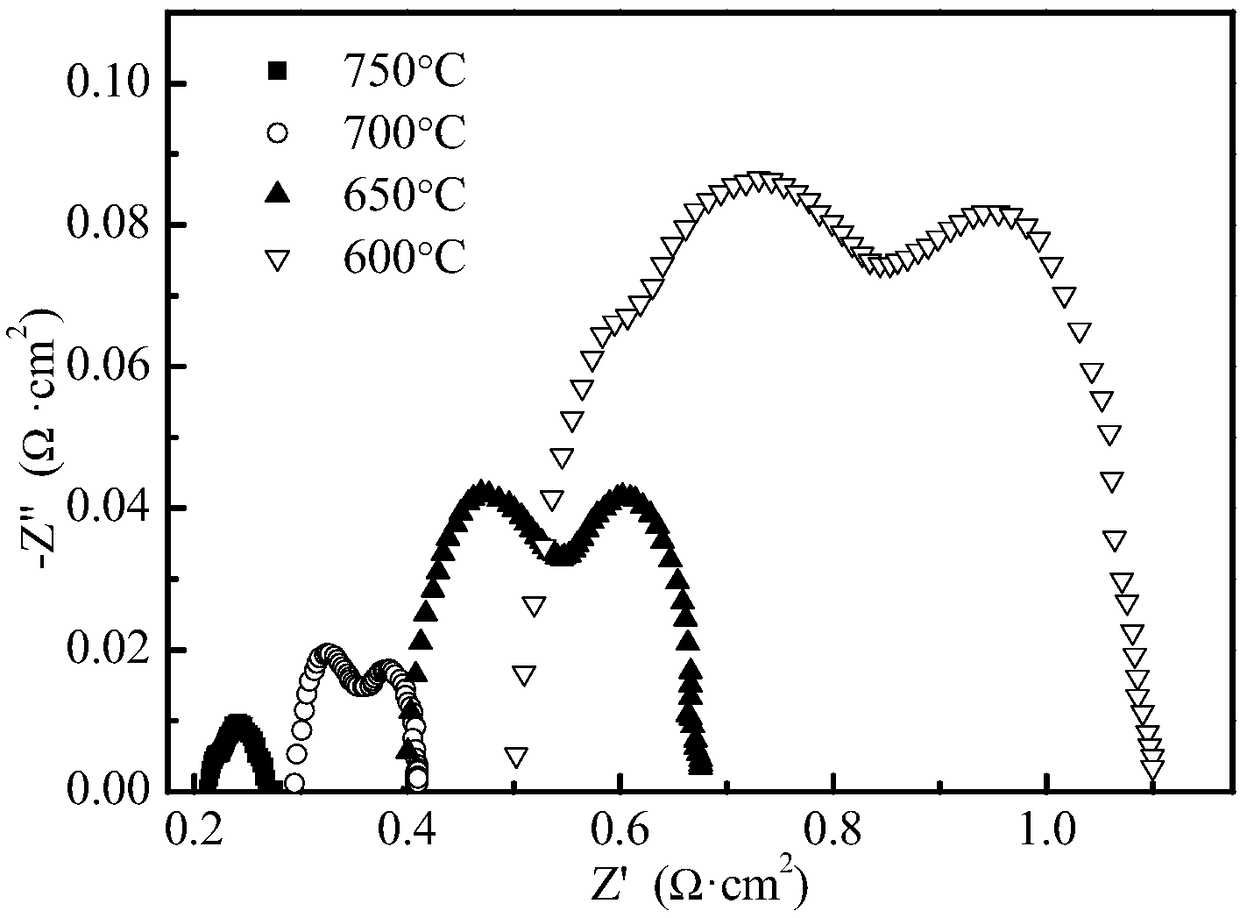

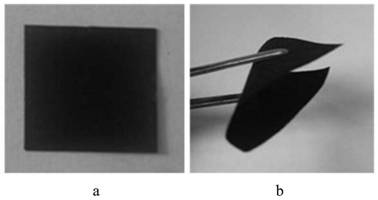

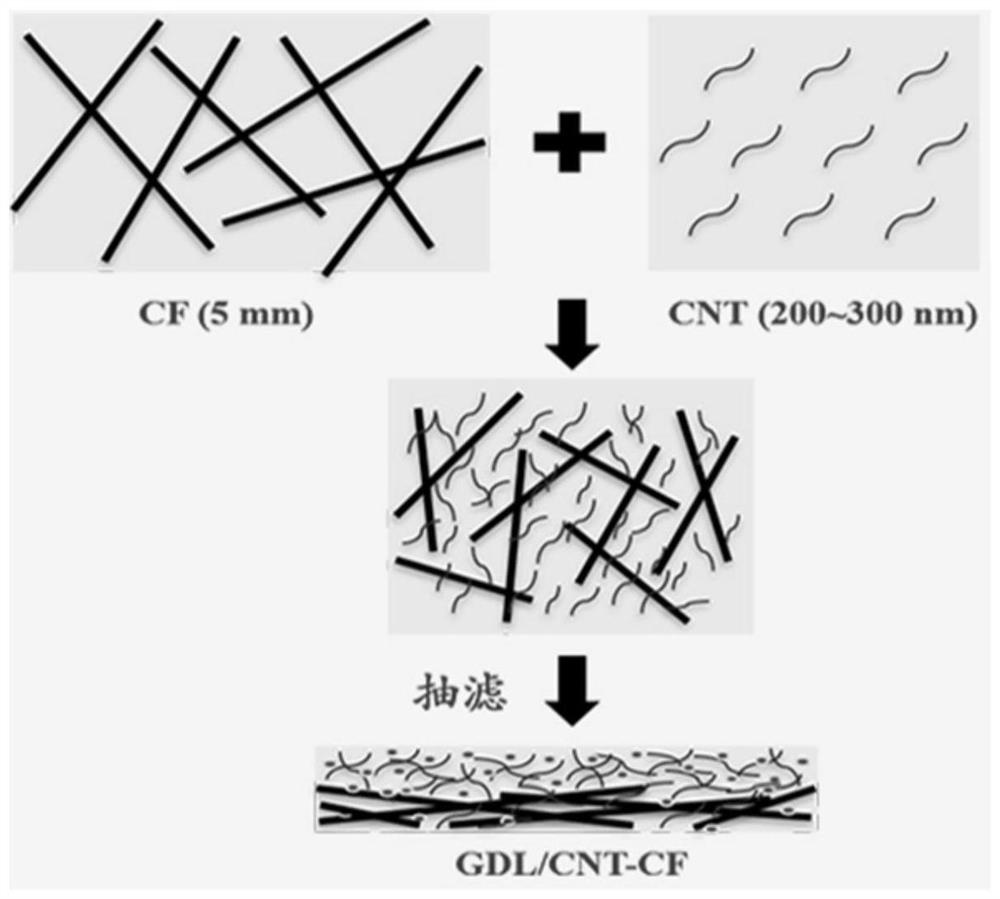

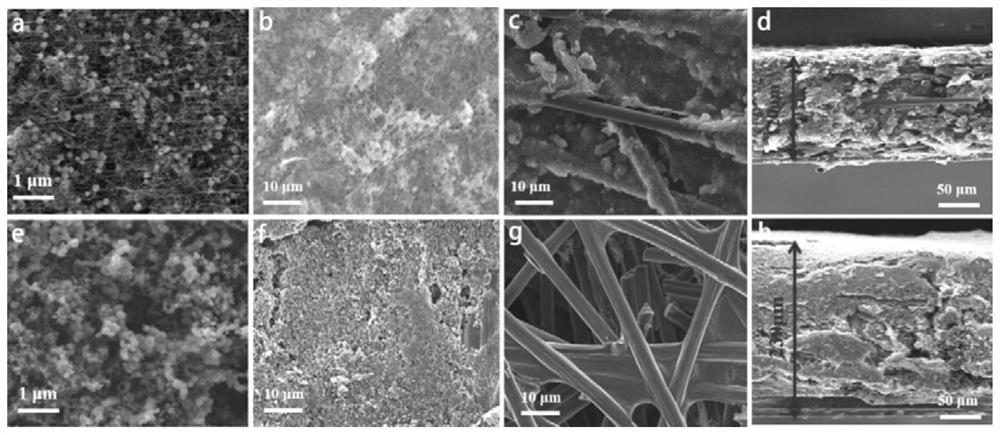

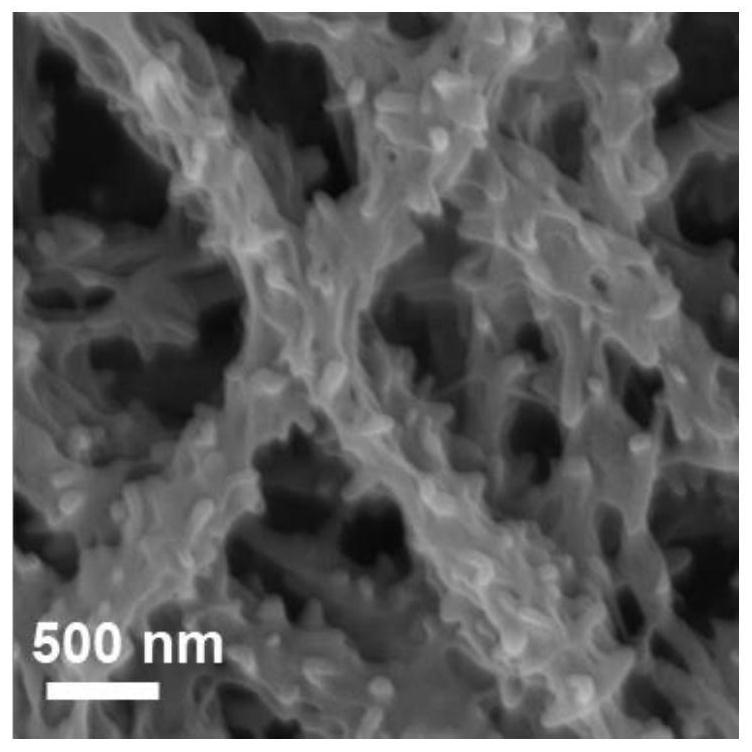

Integrated diffusion layer of fuel cell and preparation method thereof, and application of integrated diffusion layer of fuel cell

ActiveCN110600749AEvenly dispersedEasy transferFuel and primary cellsCell electrodesFiberCarbon fibers

The invention relates to a gas diffusion layer of a fuel cell, in particular to an integrated diffusion layer and a preparation method thereof and application of an integrated diffusion layer. According to the preparation method, the novel integrated diffusion layer is prepared by taking carbon fibers as a skeleton, compounding multi-walled carbon nanotubes, taking nitrogen methyl pyrrolidone as adispersing agent for dispersing at a high speed and taking polytetrafluoroethylene (PTFE) as a binder and a water repellent through a reduced pressure suction filtration forming method in one step. The integrated diffusion layer replaces a traditional diffusion layer composed of carbon paper and a micropore layer, and when the integrated diffusion layer is applied to a cathode of a direct methanol fuel cell or serves as an anode diffusion layer and a cathode diffusion layer at the same time, the maximum power density of a single cell is improved by 20% and 35% compared with a commodity diffusion layer. The integrated diffusion layer is applied to a zinc-air battery oxygen electrode, the maximum power density reaches up to 200mA cm-2, and a potential direction is provided for exploration of a high-performance and low-cost novel diffusion layer process and material of a fuel cell.

Owner:DALIAN JIAOTONG UNIVERSITY

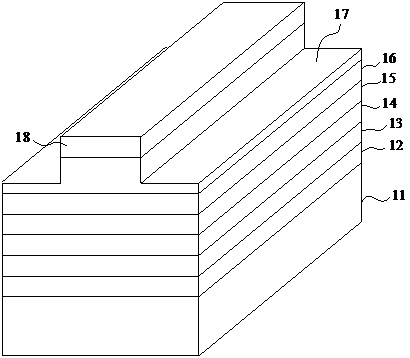

Edge-emitting high-power laser and manufacturing method thereof

InactiveCN112290384AIncrease output powerImprove reliabilityLaser detailsLaser active region structureErbium lasersHigh power lasers

The invention relates to an edge-emitting high-power laser and a manufacturing method thereof, the edge-emitting high-power laser comprises an N-type substrate, an N-type buffer layer, an N-type covering layer, a lower waveguide layer, an active layer, an upper waveguide layer, a P-type covering layer and a P-type ohmic contact layer which are sequentially stacked, wherein the lower waveguide layer and the active layer are not doped; the whole active layer presents tensile stress, and the value of the tensile stress is within a threshold range; and the P-type covering layer and the P-type ohmic contact layer form a ridge-shaped ridge waveguide through etching. According to the edge-emitting high-power laser, the active layer with tensile stress is adopted, so that a non-absorption window can be naturally formed on the end face, heating caused by end face absorption can be well reduced, the threshold value of damage to the end face of the laser is increased, and the output power and reliability of the laser are improved.

Owner:江西铭德半导体科技有限公司

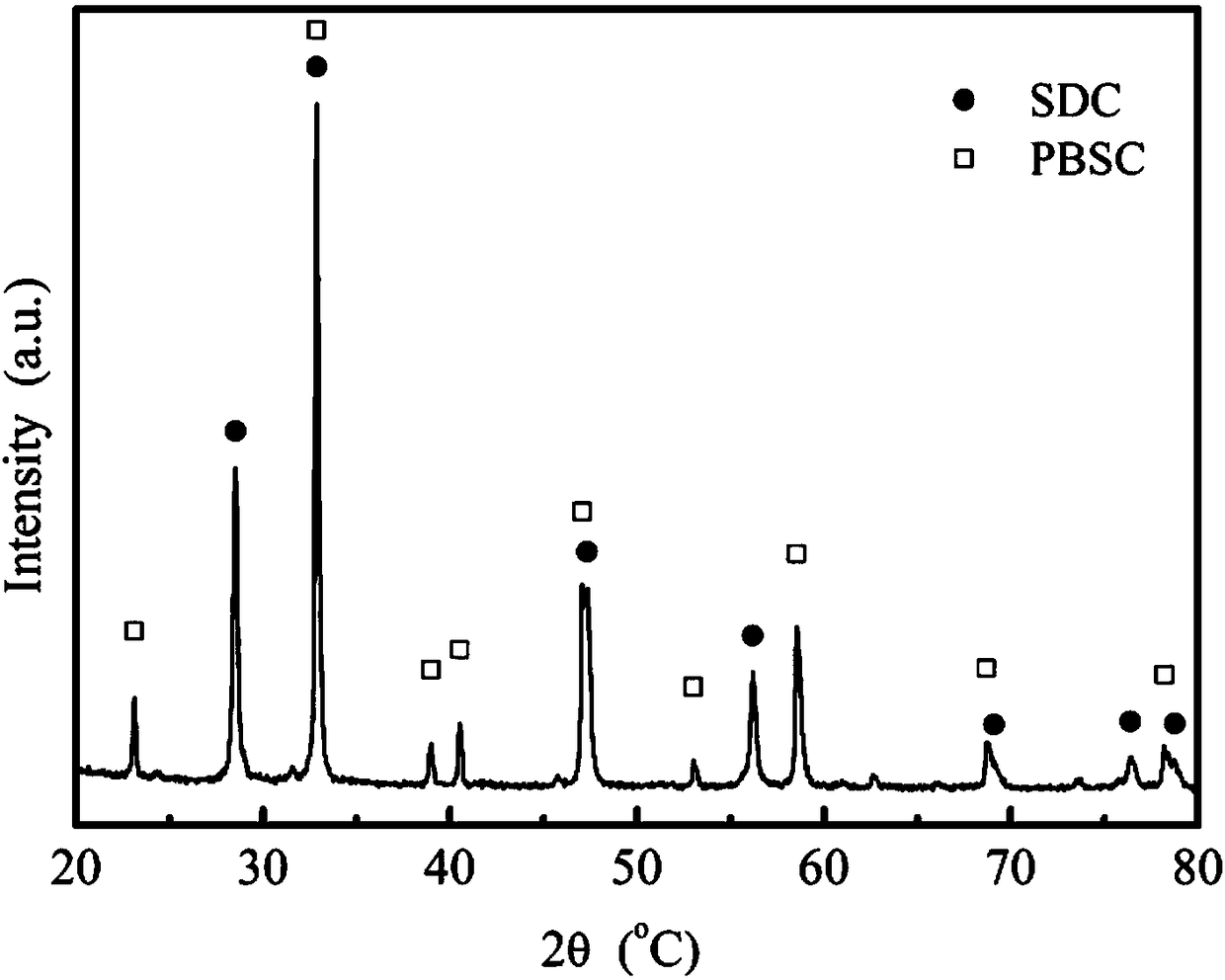

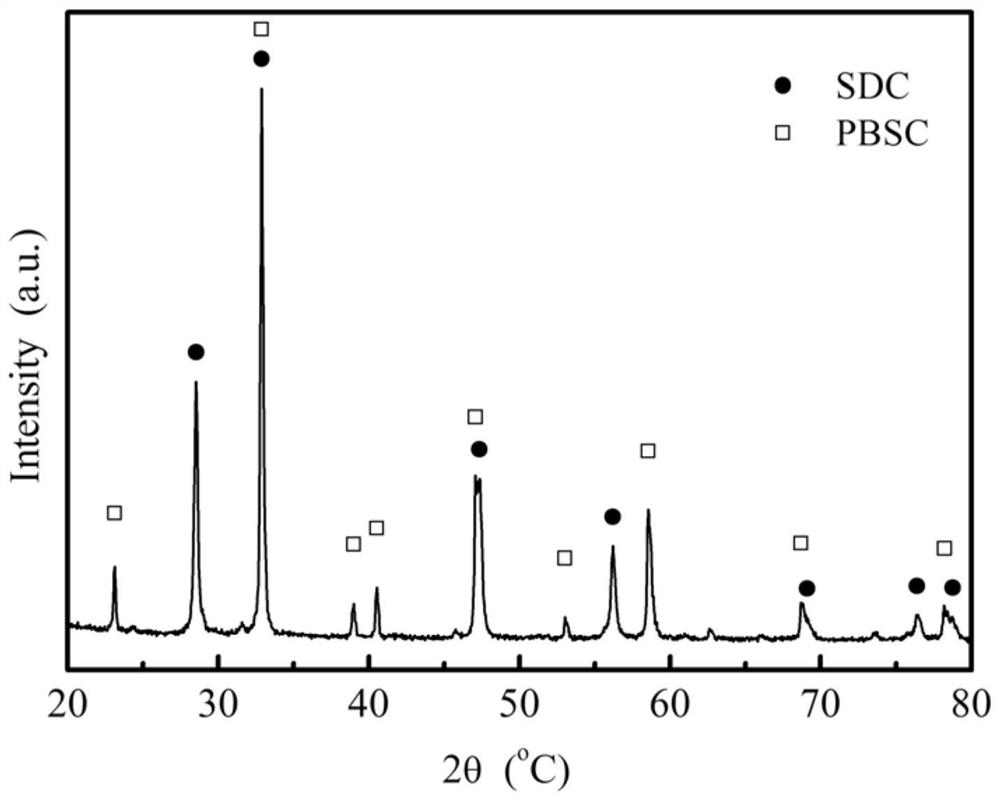

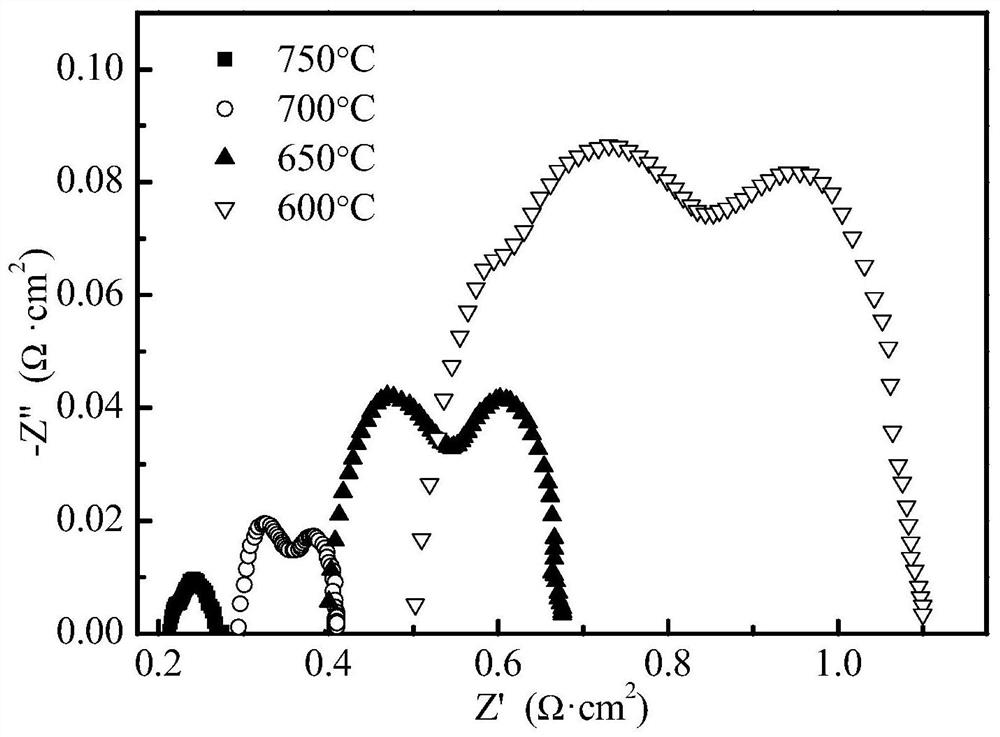

Novel proton blocking composite cathode material and preparation method and application thereof

InactiveCN108258250AIncrease the open circuit voltageLower polarization resistanceCell electrodesFuel cellsComposite cathode

The invention discloses a novel proton blocking composite cathode material and a preparation method and application thereof. The cathode material adopts a molecular formula of (1-x)PrBa0.5Sr0.5Cu2O5-delta-xCe0.8Sm0.2O2-delta, wherein x is 0.1-0.5. The novel proton blocking composite cathode material provided by the invention can be used as the cathode material for a fuel battery; due to use of a PBSC-SDC composite cathode material, a prepared single battery not only has relatively high open circuit voltage and relatively low polarization resistance, so that relatively high maximum power density can be outputted; the prepared single battery also has good thermal matching, so that improvement on the thermal stability of the single battery is facilitated.

Owner:ZHENGZHOU UNIV

A fuel cell integrated diffusion layer and its preparation method and application

ActiveCN110600749BEvenly dispersedEasy transferFuel and primary cellsCell electrodesFiberCarbon fibers

The invention relates to a fuel cell gas diffusion layer, in particular to an integrated diffusion layer and its preparation method and application. The preparation method of the present invention uses carbon fiber as the skeleton, composites multi-walled carbon nanotubes, uses nitrogen methyl pyrrolidone as the dispersant to disperse at high speed, polytetrafluoroethylene (PTFE) as the binder and water-repellent agent, and adopts vacuum suction filtration molding method A new one-piece diffusion layer is made in one step. The integrated diffusion layer of the present invention replaces the traditional diffusion layer composed of carbon paper and microporous layer, and when it is applied to the cathode of a direct methanol fuel cell or as the cathode and anode diffusion layer at the same time, the maximum power density of a single cell is compared with that of a commercial diffusion layer. Improvements of 20% and 35%, respectively. The integrated diffusion layer of the present invention is applied to the oxygen electrode of zinc-air battery, and the maximum power density is as high as 200mA cm ‑2 , which also provides a potential direction for the exploration of new diffusion layer processes and materials with high performance and low cost for fuel cells.

Owner:DALIAN JIAOTONG UNIVERSITY

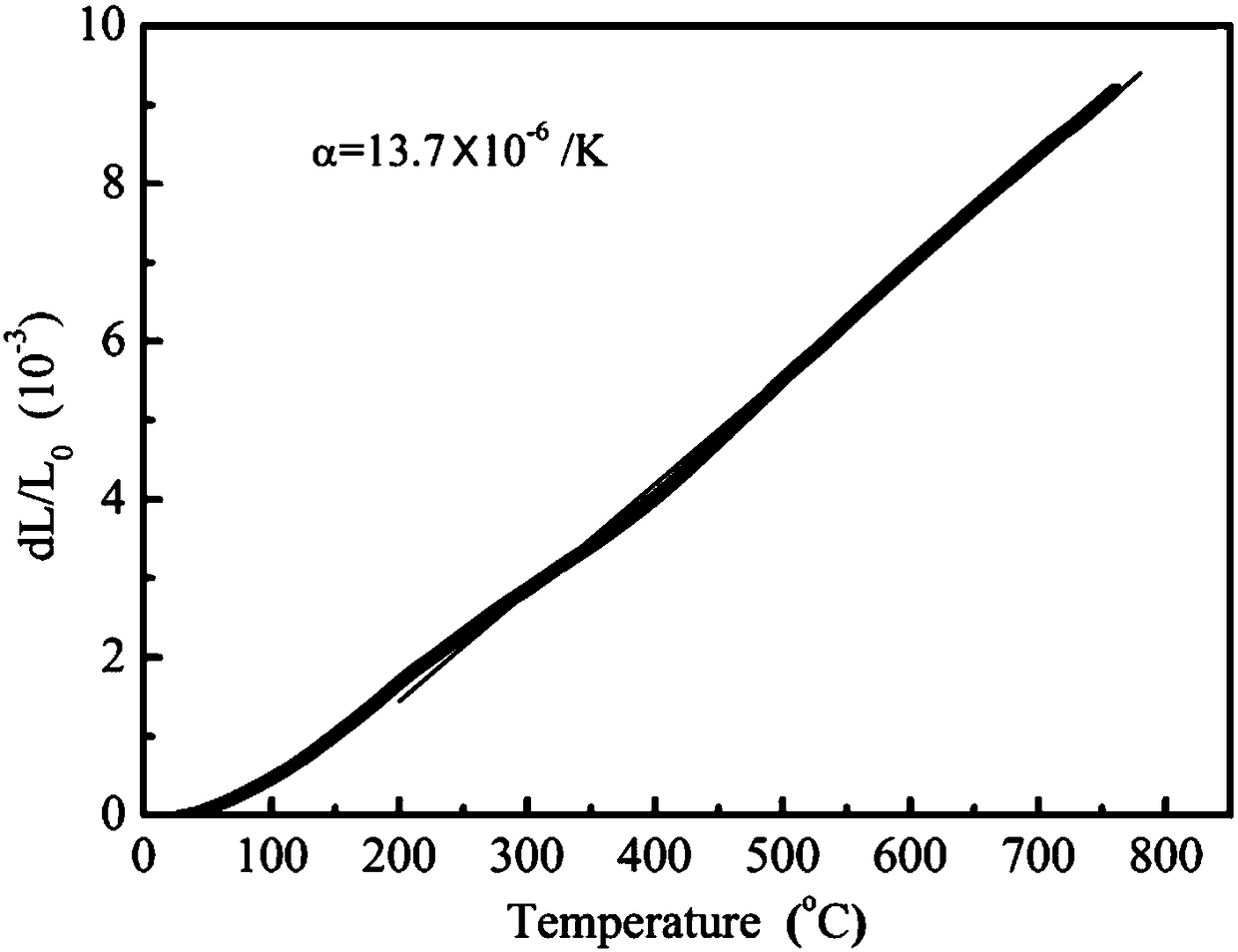

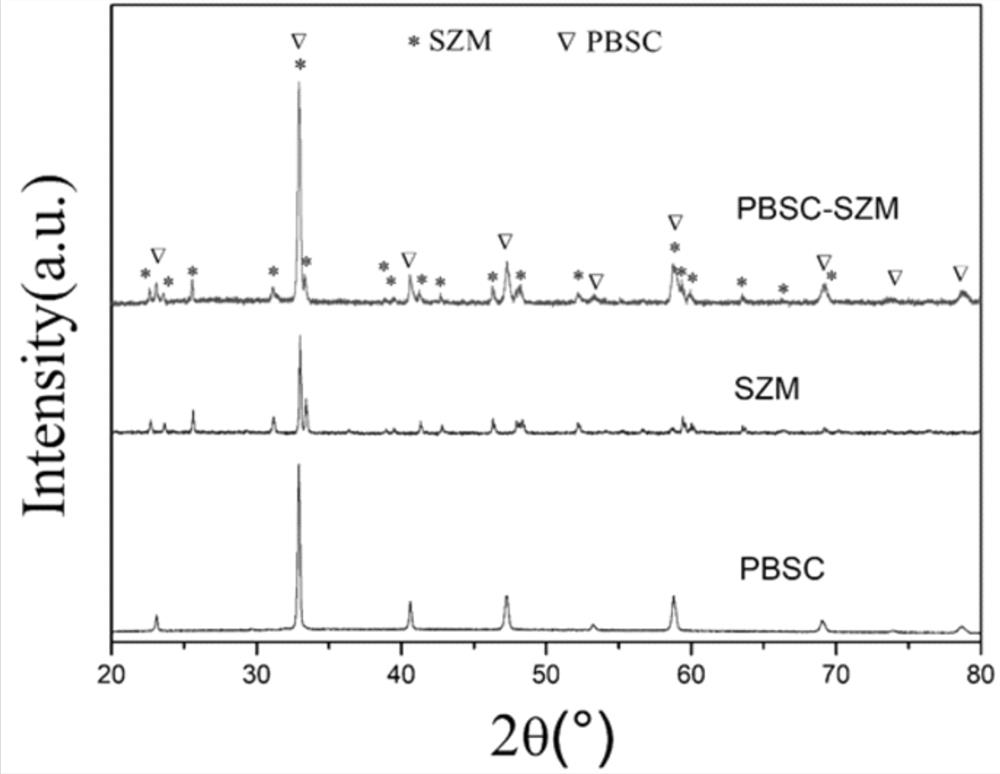

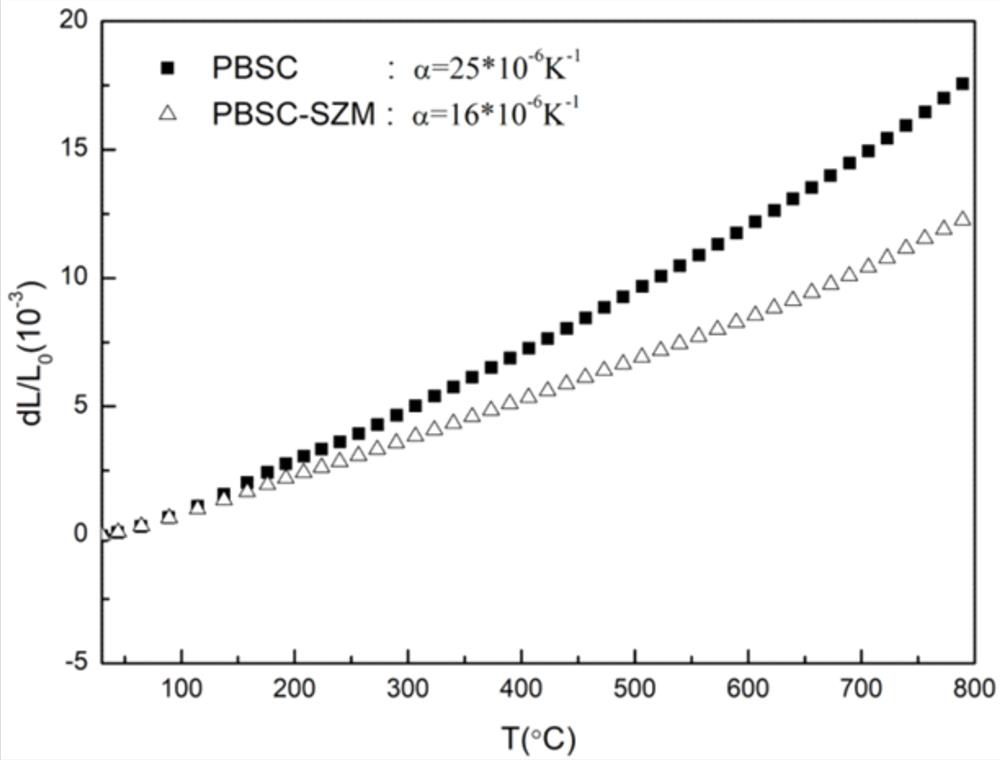

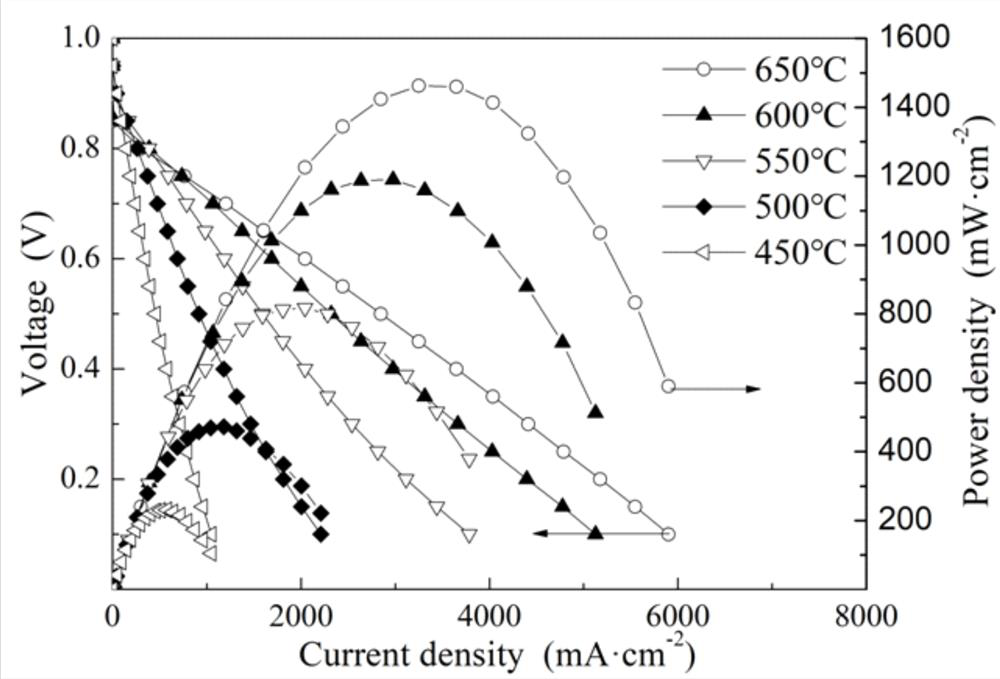

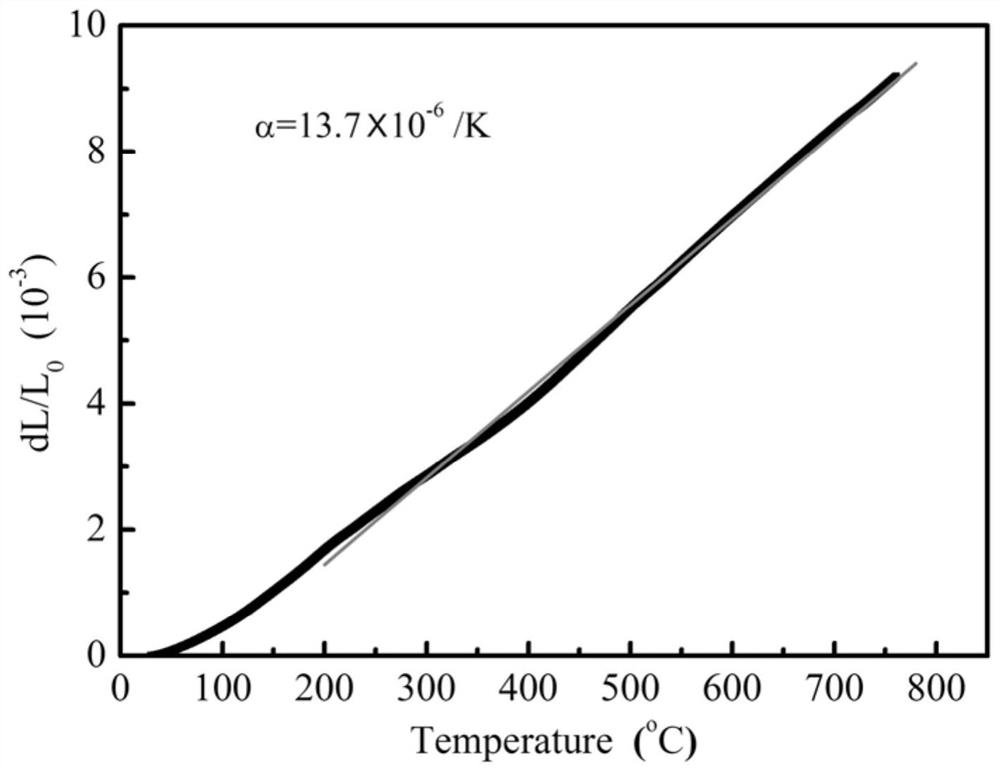

SOFC composite cathode material containing abnormal thermal expansion behavior material as well as preparation method and application of SOFC composite cathode material

PendingCN113903924ALower polarization resistanceGood heat matchingCell electrodesThermal dilatationElectrical resistance and conductance

The invention discloses an SOFC composite cathode material containing an abnormal thermal expansion behavior material as well as a preparation method of the SOFC composite cathode material. The SOFC composite cathode material containing the abnormal thermal expansion behavior material comprises the following components: PrBa0. 5Sr0. 5Co2O5 + delta and Sm0.85Zn0.15 MnO3, the mass percent wt1 of the PrBa0. 5Sr0. 5Co2O5 + delta is 70-90%, the mass percent wt2 of the Sm0.85Zn0.15 MnO3 is 10-30%, and the sum of wt1 and wt2 is 100%. An O-SOFC single cell composed of the PBSC-SZM, a conventional electrolyte material SDC and an anode material NiO-SDC has relatively low polarization resistance, and can output relatively high maximum power density; the thermal expansion coefficient of the PBSC-SZM cathode material is equivalent to the thermal expansion coefficient of SDC, so that the PBSC-SZM cathode material has good thermal matching property; the O-SOFC single cell composed of the PBSC-SZM, the conventional electrolyte material SDC and the anode material NiO-SDC has better long-term stability, the performance of the O-SOFC single cell can be kept not to be obviously reduced after long-term work, and meanwhile, the O-SOFC single cell further shows that the cathode and the electrolyte have good thermal matching performance.

Owner:ZHENGZHOU UNIV

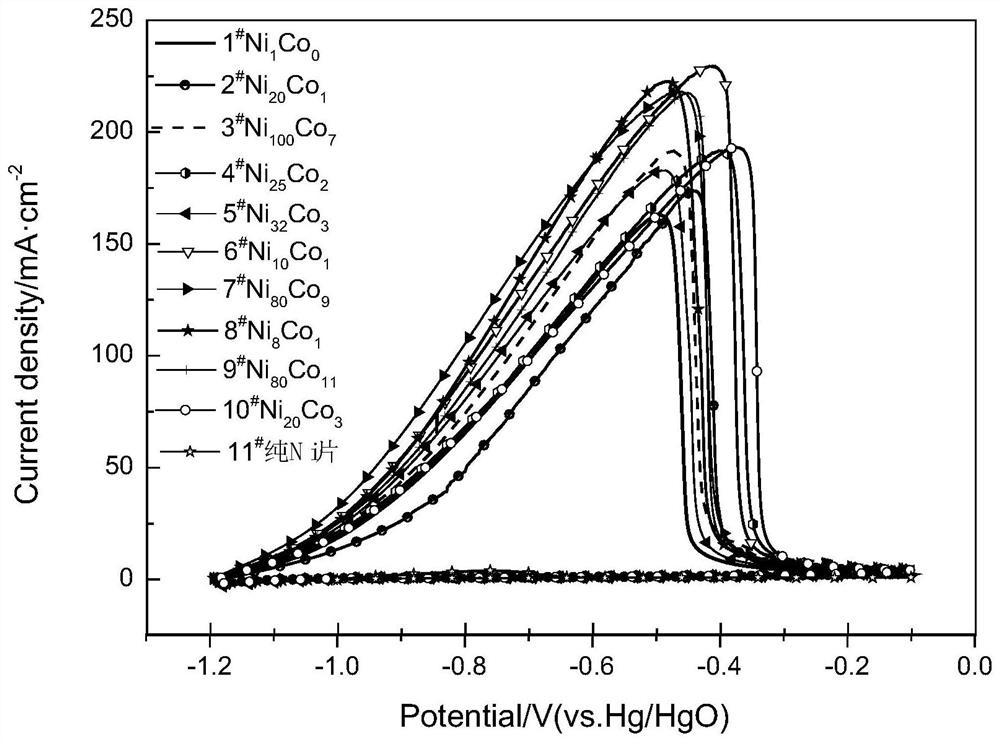

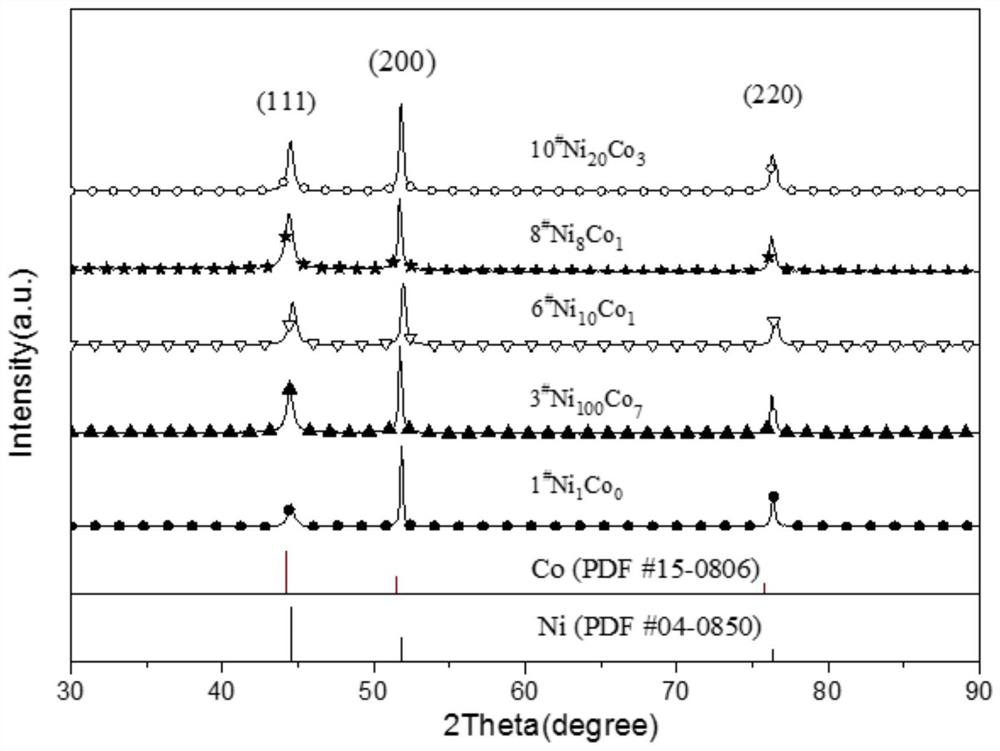

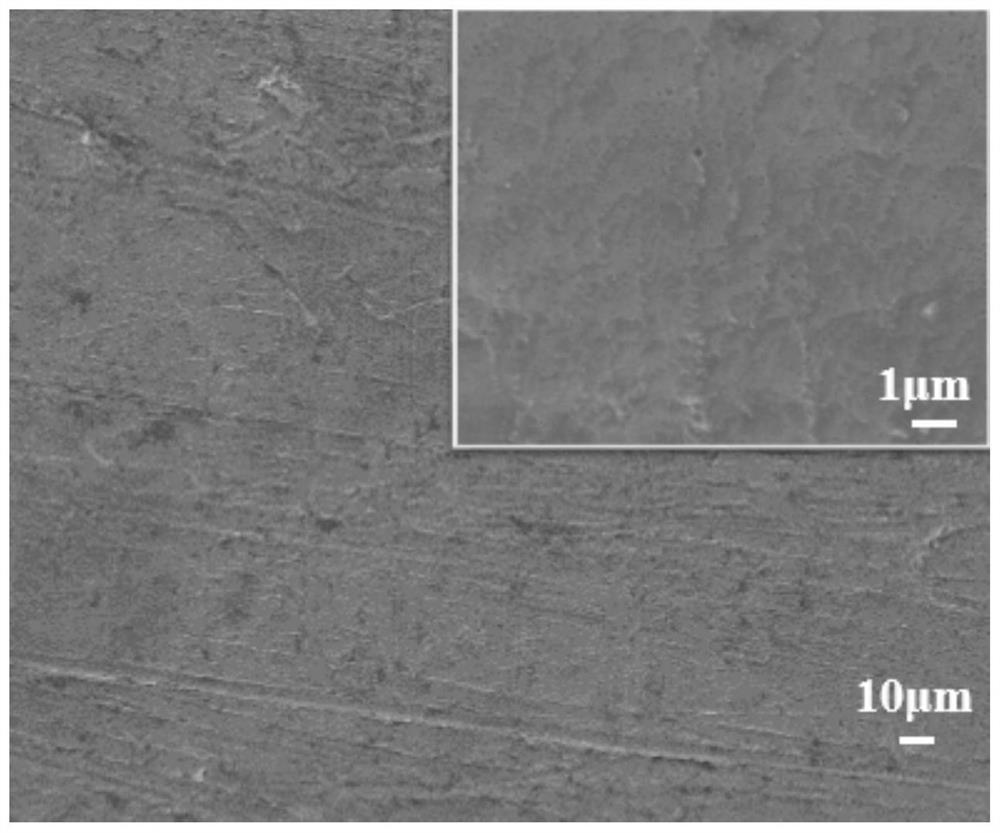

A nickel-cobalt binary catalyst promoting the direct oxidation of sodium borohydride

ActiveCN109994744BImprove performanceIncreased maximum power densityCell electrodesPtru catalystCobalt catalyst

A kind of nickel-cobalt binary catalyst that promotes the direct oxidation of sodium borohydride is characterized in that: (1) under normal temperature and pressure, prepare 0.2mol / dm 3 nickel chloride (NiCl 2 ·6H 2 O), 0.0000~0.0300mol / dm 3 Cobalt Chloride (CoCl 2 ·6H 2 O) and 4mol / dm 3 Ammonium chloride (NH 4 The mixed solution of Cl) is an electrodeposition solution; (2) Assembling a two-electrode system: a 1cm×2cm polished Ni sheet is placed in the above solution as a cathode, wherein the working area of the Ni sheet is 1cm×1cm, and a carbon rod (3) Using the constant current method, in a constant temperature water bath at 298.15K, with a deposition current of 2A, and a deposition time of 20s, deposit Ni and Co on the above smooth Ni sheet. The nickel-cobalt catalyst prepared by electrodeposition has a porous structure, and the addition of cobalt makes the catalyst have a larger average pore size and porosity, which significantly increases the specific surface area, increases the number of catalytic active sites, and reduces the resistance to be overcome in the direct oxidation reaction. The charge transfer of the electrode reaction is enhanced; at the same time, the discharge potential of the fuel is reduced, the discharge efficiency of the fuel is significantly improved, and the oxidation performance of the fuel is improved.

Owner:CHONGQING UNIV

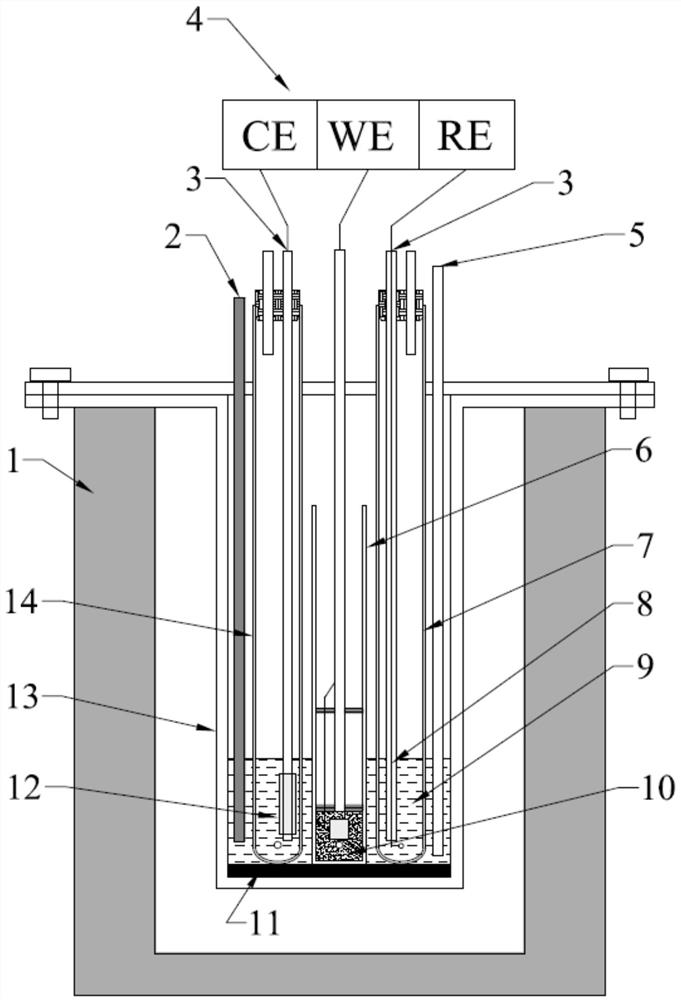

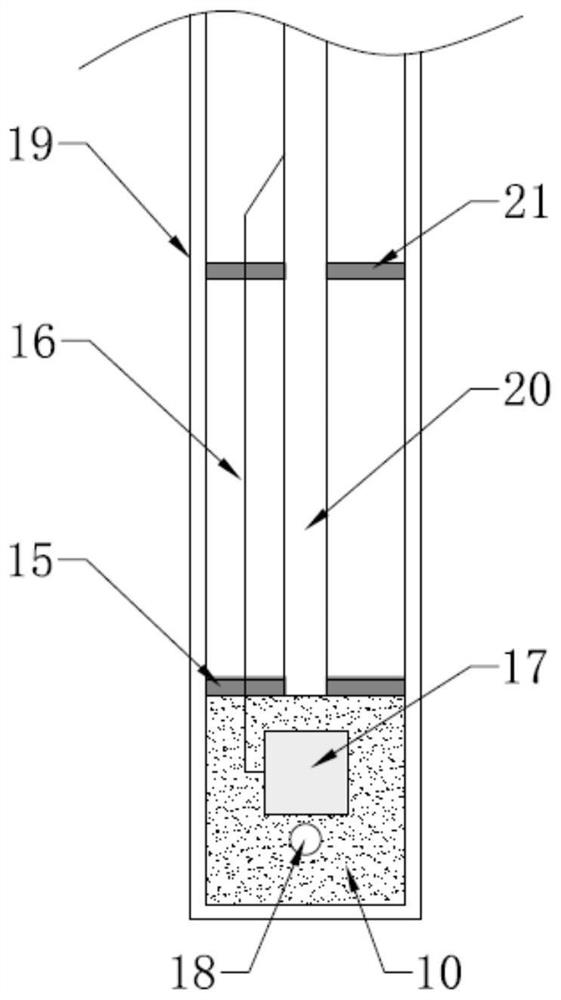

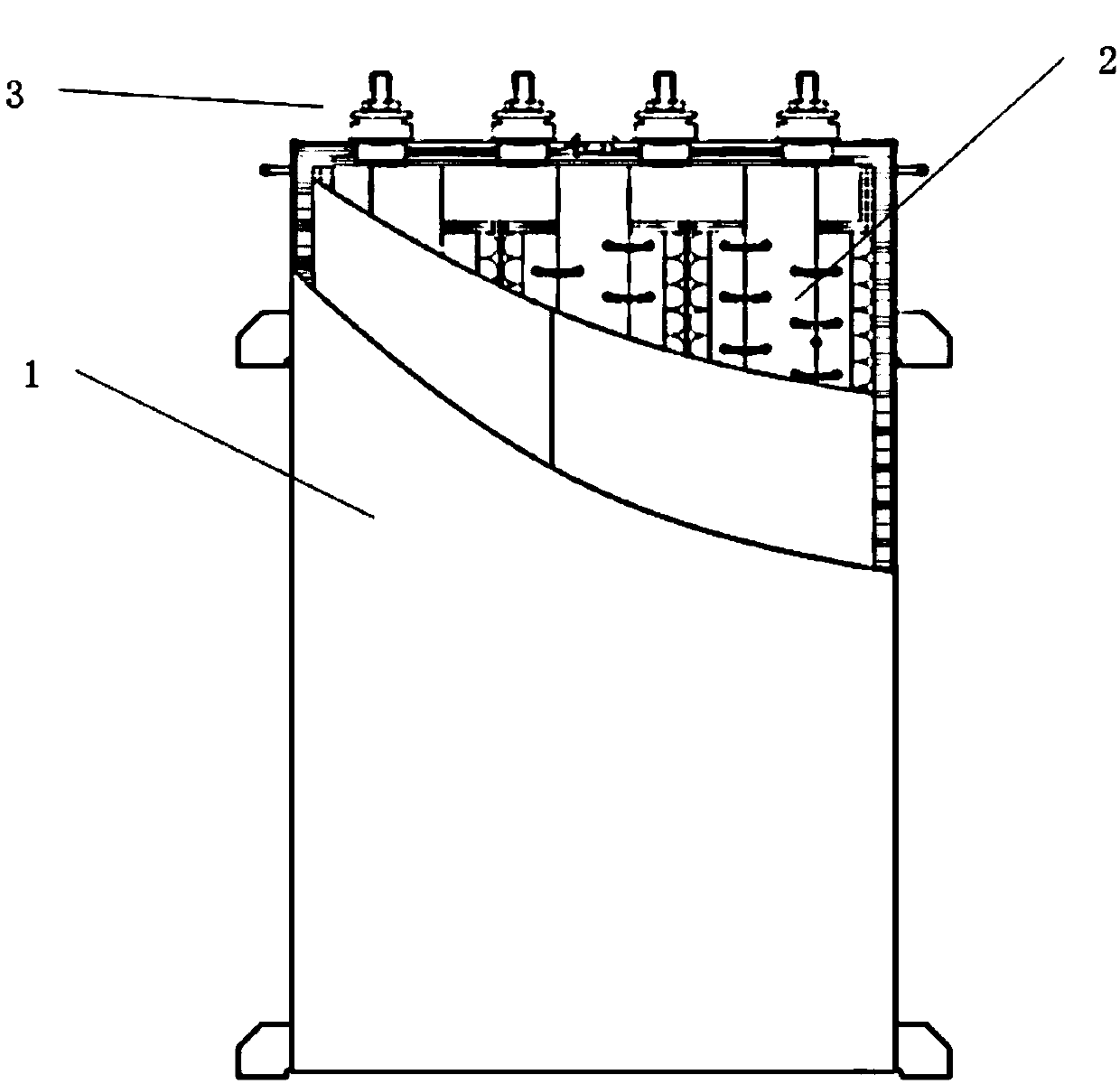

A High Power Density Molten Carbonate Direct Coal/Carbon Fuel Cell

ActiveCN110707347BIncreased electro-oxidation reaction rateAct as catalystCell electrodesFused electrolyte fuel cellsPtru catalystFuel cells

The invention provides a high power density molten carbonate direct coal / carbon fuel cell, comprising a battery body and a heating furnace for heating the battery body, a working electrode, a counter electrode and a reference electrode are installed in the battery body, the The working electrode includes an anode chamber, a pick-and-place rod is inserted into the anode chamber, and a flow hole is opened on the anode chamber to communicate with the electrolyte in the inner cavity of the battery. The anode chamber is filled with coal / carbon fuel, and the coal / carbon fuel A current collector is buried, and the current collector is led out through a high-temperature resistant insulated wire; the composition of the coal / carbon fuel includes at least transition metal oxide and carbon powder. The invention adds certain transition metal oxides to the anode chamber to act as a catalyst, effectively promotes the electro-oxidation reaction of the anode, improves the performance of the anode, and further effectively improves the power density of the fuel cell.

Owner:HUAZHONG UNIV OF SCI & TECH

Biomass-based activated carbon-coated iron carbide three-dimensional porous microbial fuel cell anode material, anode and preparation method thereof

ActiveCN110752378BActivity does not affectHigh affinityCell electrodesBiochemical fuel cellsMicrobial fuel cellBiofilm

The invention provides a biomass-based activated carbon coated iron carbide three-dimensional porous microbial fuel cell anode material, which is composed of biomass-based activated carbon and iron carbide, wherein iron carbide is distributed in the biomass-based activated carbon and is coated by the biomass-based activated carbon to form micron-sized activated carbon-coated iron carbide particles, and the anode material has a three-dimensional porous network structure consisting of micron and nano composite holes. The invention also provides a microbial fuel cell anode based on the anode material, and preparation methods of the anode material and the anode. According to the invention, the problems of unfavorable attached growth of microorganisms and high modification cost of the existingmodified three-dimensional carbon-based electrode are solved, and the attached growth of an anode biological membrane can be promoted and the electron transfer of an extracellular interface can be accelerated while the cost of the microbial fuel anode is reduced.

Owner:SICHUAN UNIV

A Near-Field Beam Focusing Millimeter-Wave Dual-Reflector Antenna

ActiveCN104103911BImprove power densityIncreased maximum power densityAntennasEffective powerReflection nebula

The invention discloses a millimeter-wave dual reflector antenna capable of focusing a near-field wave beam. The antenna comprises a main reflector, an auxiliary reflector and a feed source, wherein a wave beam emitted by the feed source is reflected by the auxiliary reflector to the main reflector, and then emitted; a curved surface of the main reflector is a revolution paraboloid; and a central point of the main reflector is located at an intersection point of an emitting central axis of the auxiliary reflector and an axis of a radiation wave beam. The antenna is simple in structure and mature to process; the power density of a near-field region axis of the antenna is improved; the maximum power density of the axis is improved greatly under the same input power; a distance range of an effective power threshold is expanded; the efficiency of the antenna is improved; and a near-field gain of the antenna is increased.

Owner:中久安特装备有限公司

Flexible self-supporting Co-embedded N-doped three-dimensional porous carbon-based material as well as preparation method and application thereof

PendingCN114725406ALarge specific surface areaRich pore structureMaterial nanotechnologyFuel and primary cellsChemistryDoped carbon

The invention relates to a flexible self-supporting Co-embedded N-doped three-dimensional porous carbon-based material as well as a preparation method and application thereof, and belongs to the technical field of electro-catalysis. According to the material, flexible porous N-doped carbon nanofibers are used as a matrix, an N-doped carbon nanosheet array is loaded on the surface of the matrix, N-doped carbon nanotubes grow on the carbon nanosheet array, and Co nanoparticles are packaged in the N-doped carbon nanotubes; the Co element content is 2-3 wt%, the N element content is 6-10 at%, and the specific surface area is 350-700 m < 2 > g <-1 >. As an ORR / OER bifunctional catalyst, the material can effectively improve the mass transfer process in the catalysis process of the ORR / OER catalyst and enhance the ORR / OER catalytic activity. As a self-supported zinc air battery cathode material, the material shows ultrahigh maximum power density, specific capacity and rate capability in the discharge process.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

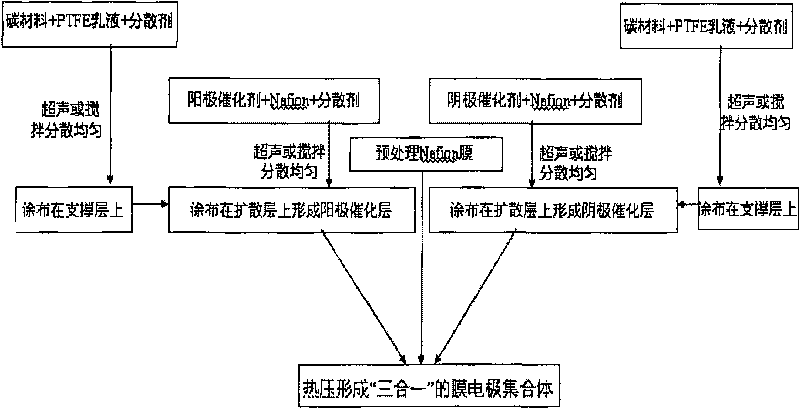

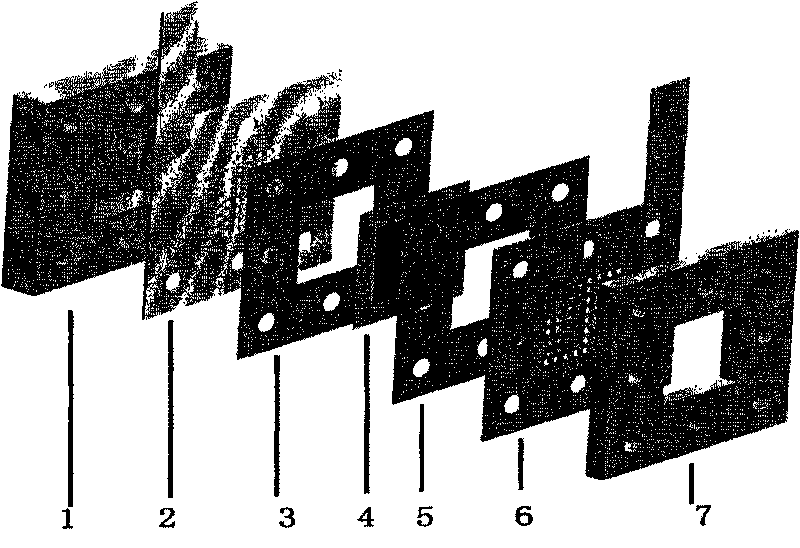

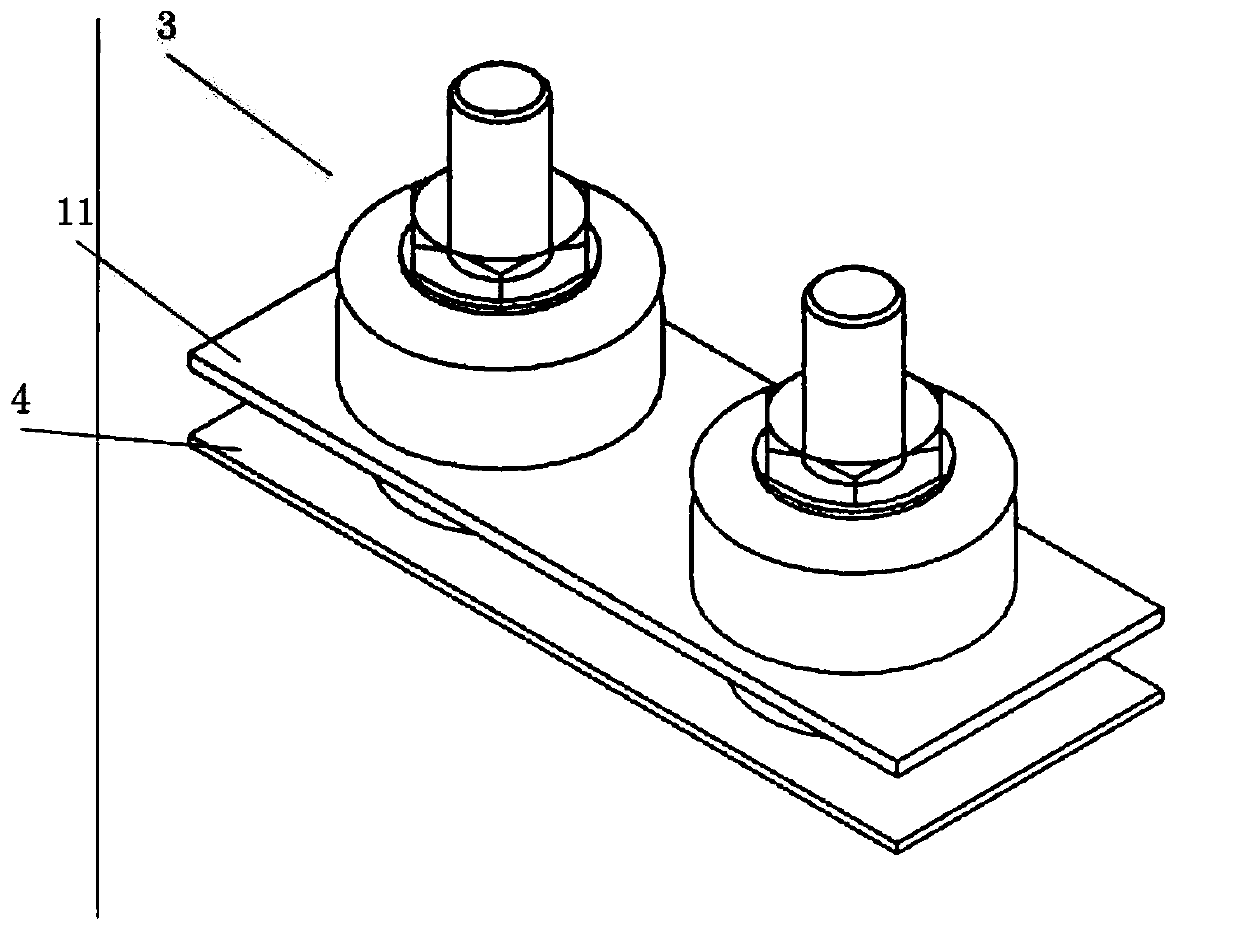

Composite anode for direct methanol fuel cell and method for making the same

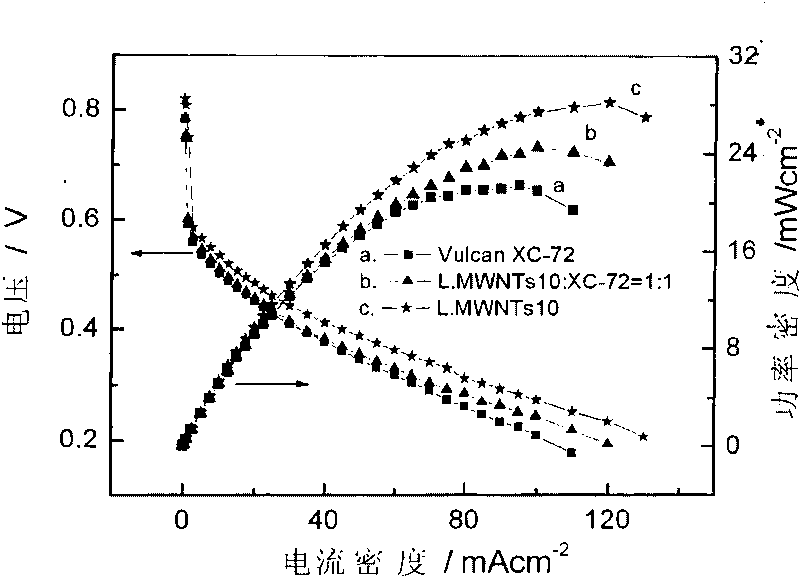

InactiveCN101286564BEasy transferIncreased maximum power densityCell electrodesPtru catalystInternal resistance

The invention provides a composite anode of a direct-methanol fuel cell and a manufacturing method thereof. The invention is characterized in that the composite anode is composed of a supporting layer, a diffusion layer and a catalyzing layer, wherein, the diffusion layer is the structure of a network channel which is composed of carbon nano-tubes. The typical characteristics of the preparation process are that: (1) a certain amount of the carbon nano-tubes or the carbon nano-tubes added with a certain amount of other carbon materials are dispersed in isopropanol aqueous solution to obtain a sizing agent (A); (2) a certain amount of polyfluortetraethylene latex is added into the (A) and evenly dispersed to form serosity (B); (3) the (B) is evenly coated on the supporting layer, and the diffusion layer (C) loaded by the supporting layer is formed after 300-350 DEG C high-temperature roasting; (4) the (C) is coated with a layer of PtRu catalyst and then heat pressed with a cathode and aNafion membrane to obtain a membrane electrode aggregation (MEA). Therefore, the transmission efficiency of the fuel at the anode is improved and the internal resistance of the battery is reduced so as to enhance the power density and service life of the battery.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

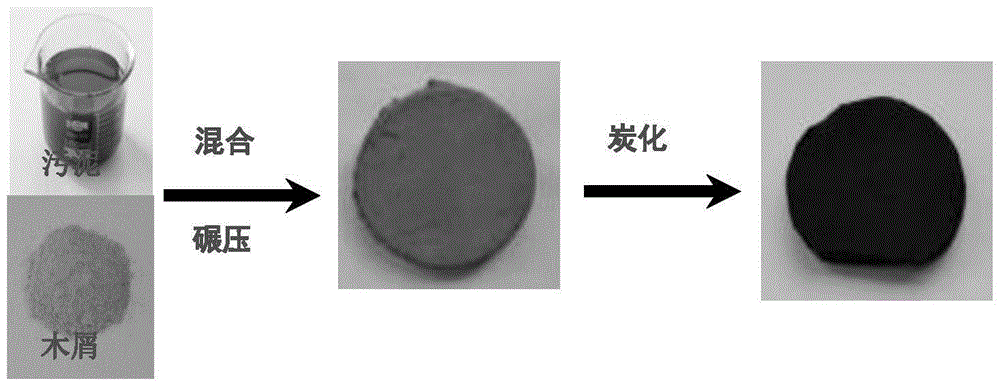

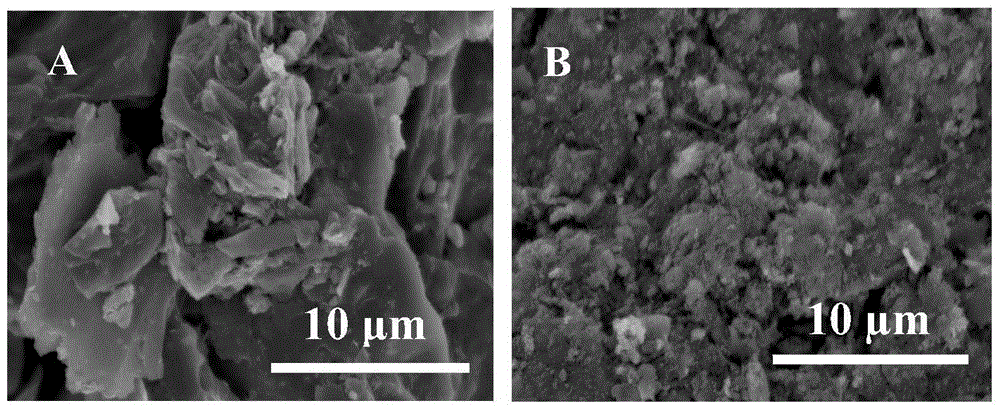

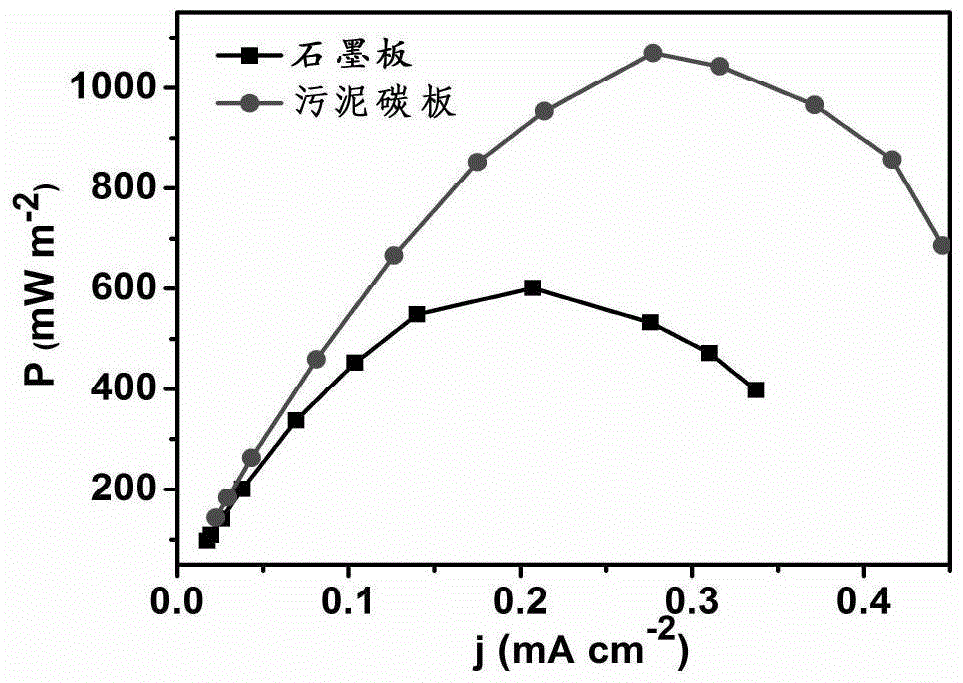

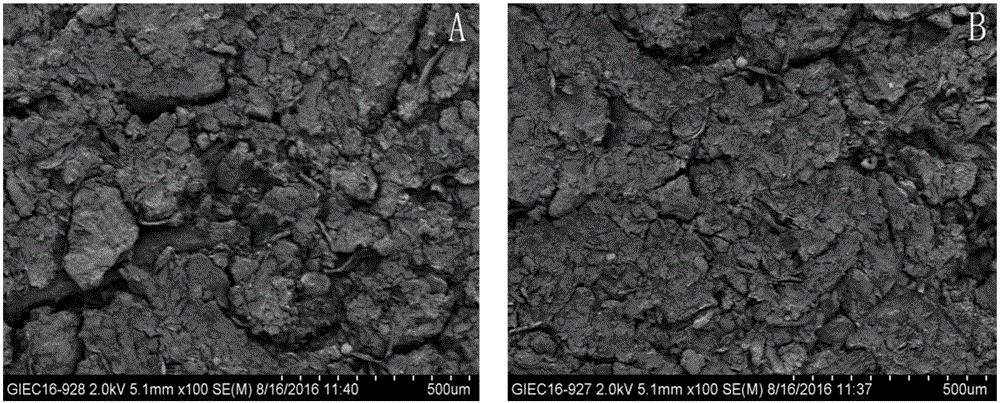

Preparation method and application of a sludge carbon plate electrode

ActiveCN104538644BLow costThe method is simple and fastCell electrodesBiochemical fuel cellsSludgeCarbonization

The invention discloses a preparation method and application of a sludge carbon plate electrode. The preparation method comprises the steps of uniformly mixing smashed wood flour and dried sludge powder at certain weight ratio, pouring the mixture into a mold, adding with a certain amount of moisture, grinding and shaping; and taking out, drying, and carrying out high-temperature gradient anaerobic carbonization to obtain a sludge carbon plate electrode material. According to the prepared electrode material, waste sludge in a sewage plant and discarded biomass wood flour are used as raw materials, the cost is low, the preparation method is simple and rapid, and the method can provide a new way for the sludge resourced technology. The sludge carbon plate electrode can be applied to a microbial fuel cell, and compared with the traditional graphite electrode, the sludge carbon plate electrode has the power density of the battery, which is improved nearly twice.

Owner:GUANGDONG INST OF ECO ENVIRONMENT & SOIL SCI

A Novel Proton Blocking Composite Cathode Material and Its Preparation Method and Application

InactiveCN108258250BIncrease the open circuit voltageLower polarization resistanceCell electrodesHeat stabilityOpen-circuit voltage

The invention discloses a novel proton blocking composite cathode material and its preparation method and application. The molecular formula of the cathode material is (1‑x)PrBa 0.5 Sr 0.5 Cu 2 o 5‑δ ‑xCe 0.8 SM 0.2 o 2‑δ , wherein, x=0.1~0.5. The novel proton-blocking composite cathode material provided by the present invention can be used as a cathode material for a fuel cell. Due to the use of the PBSC-SDC composite cathode material, the prepared single cell not only has a higher open circuit voltage and a lower polarization resistance, Can output higher maximum power density. It also has good thermal matching, which helps to improve the thermal stability of the single cell.

Owner:ZHENGZHOU UNIV

CO2 mineralization power generation method using sodium bicarbonate as alkaline leaching agent

ActiveCN107437629BFacilitate hydrolytic transformationImprove power generation performanceElectrogenerative processesFuel cellsElectricitySodium bicarbonate

Owner:SICHUAN UNIV

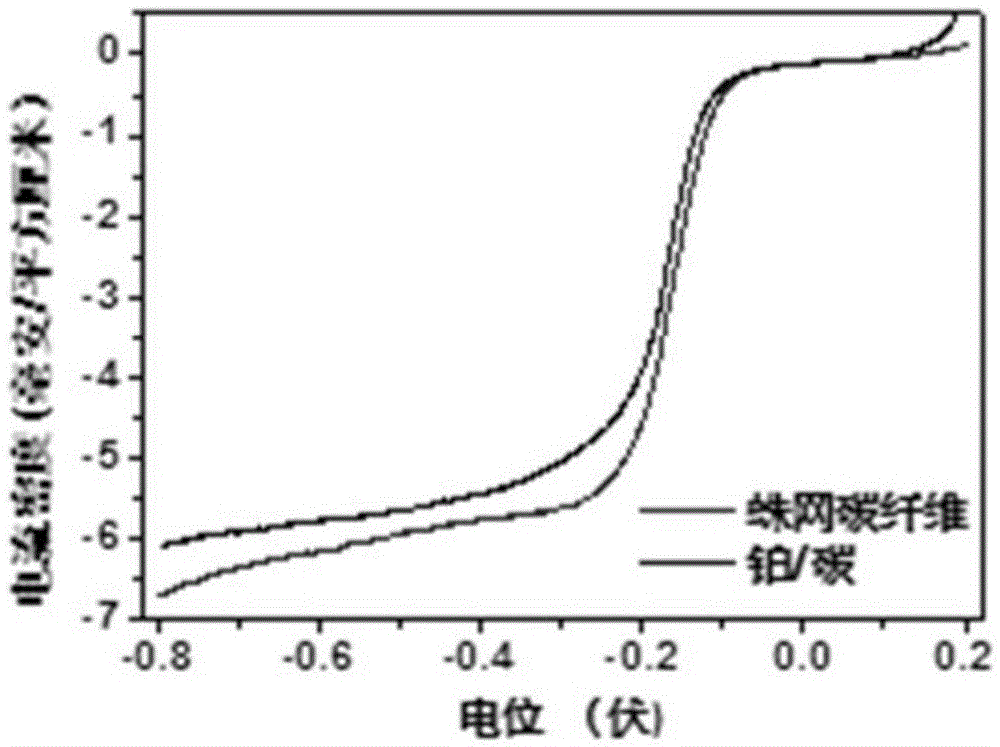

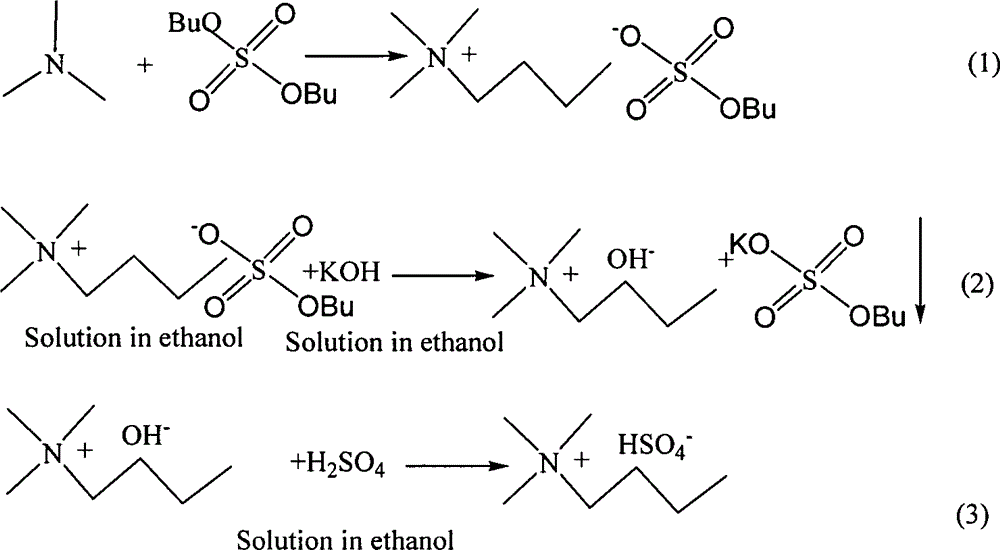

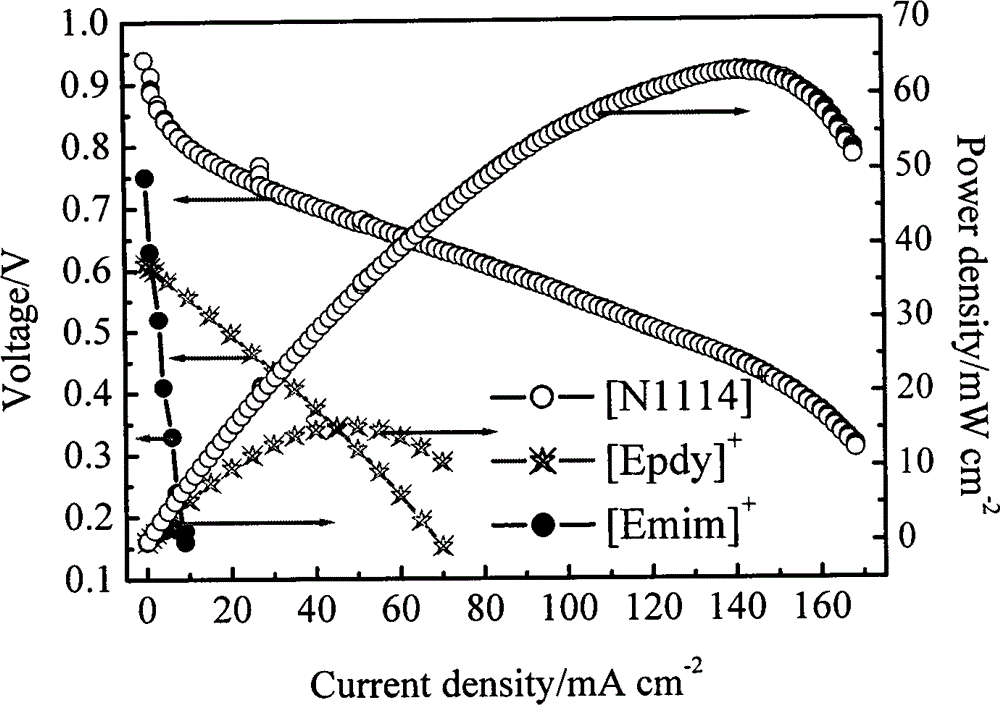

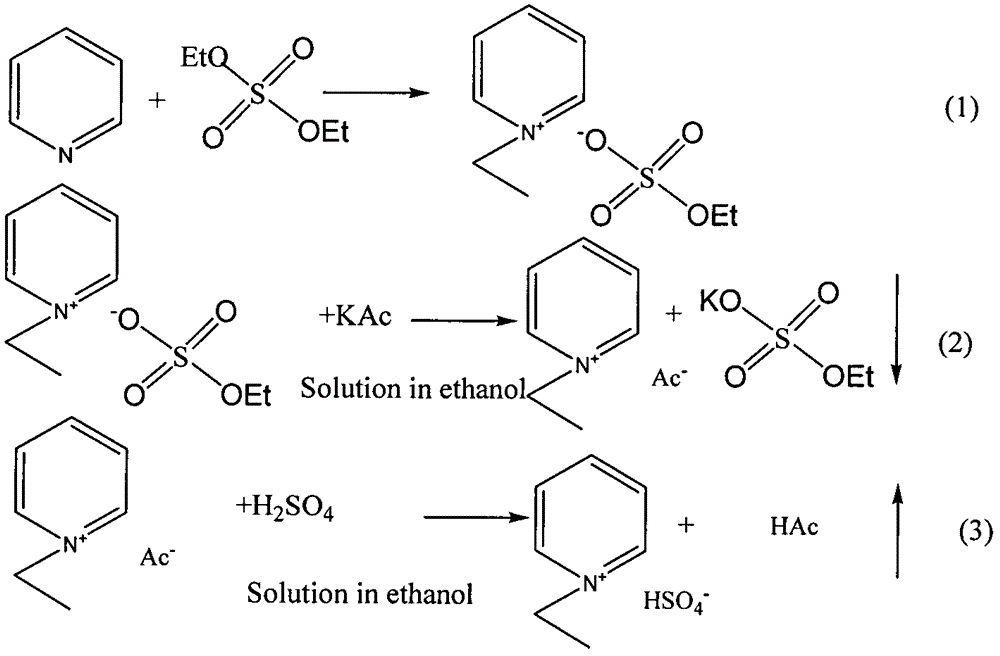

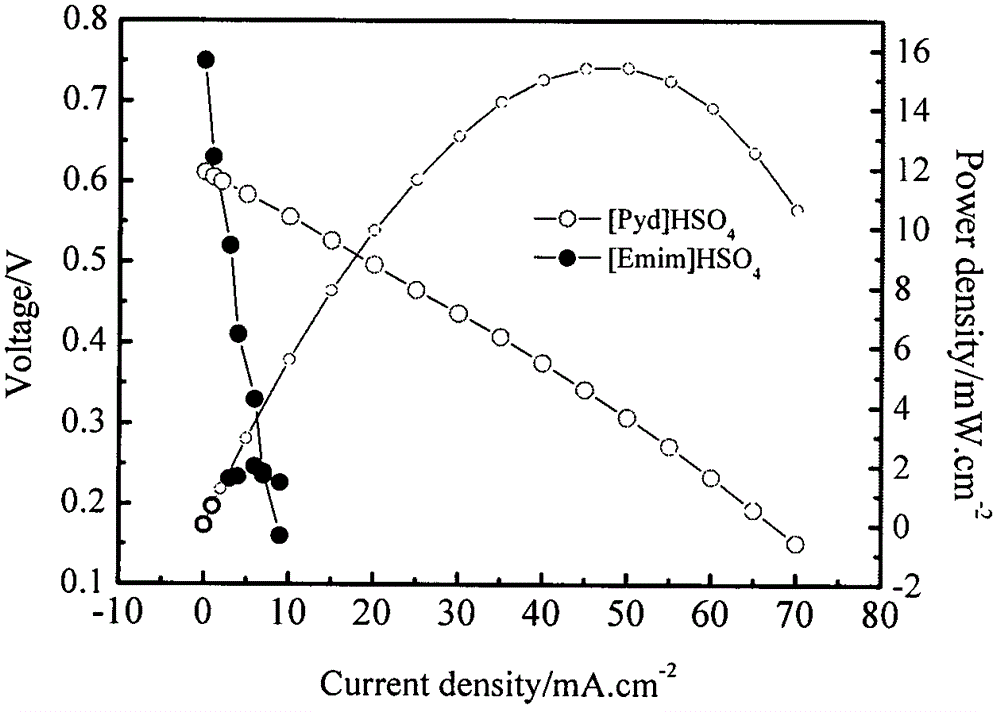

Tetra-allkylammonium ionic liquid for proton exchange membrane fuel cell

InactiveCN104393320ALow melting pointAvoid poisoningSolid electrolyte fuel cellsProtonProton exchange membrane fuel cell

A synthetic method of non-imidazolium-based ionic liquid for preparing proton exchange membrane fuel cell electrolyte is disclosed. The synthetic method comprises the steps of reacting sulfuric acid dialkyl ester with trimethyl amine; reacting the reaction product with a KOH or NaOH ethanol solution, and filtering out the generated precipitation to obtain a clear colorless solution; adding acid with a proton conducting function to the solution, and neutralizing the quaternary amine base to obtain the ionic liquid, the cation of which is a tetra-alkylammonium ion. According to the synthetic method of the non-imidazolium-based ionic liquid for preparing the proton exchange membrane fuel cell electrolyte, the unbeneficial influence of the imidazolium-based ionic liquid on a proton exchange membrane fuel cell catalyst is avoided, which can be proofed by an electrochemical method, such as a cyclic voltammetry method. The ionic liquid is supported to a PVDF membrane to perform a single-cell experiment, and the experimental results show that, when the ionic liquid is taken as the ionic liquid of an electrolyte, the performance is remarkably improved; compared with the imidazolium-based ionic liquid, the non-imidazolium-based ionic liquid has the advantage that the top power density can be improved by about 60 times.

Owner:TIANJIN POLYTECHNIC UNIV

Preparation method and application of waste bacteria stick carbon anode

ActiveCN106450361BIncreased maximum power densityEasy to prepareCell electrodesFinal product manufactureMicrobial fuel cellFuel cells

The invention discloses a preparation method of a waste bacterial rod carbon anode and application thereof in a microbial fuel cell. Compared with a traditional carbon brush anode, the maximum power density of the waste bacterial rod carbon anode can be improved by more than one time; the preparation method of the waste bacterial rod carbon anode is simple, a complex hydrochloric acid immersion cleaning step is omitted, the cost of raw materials is low, the waste bacterial rod carbon anode is suitable for large-scale commercial process, and a bran-new application mode is provided for resource utilization of waste bacterial rods.

Owner:FUJIAN AGRI & FORESTRY UNIV

Preparation method and application of waste bacterial rod carbon anode

ActiveCN106450361AImprove power densityEasy to prepareFinal product manufactureCell electrodesBacterial rodsResource utilization

The invention discloses a preparation method of a waste bacterial rod carbon anode and application thereof in a microbial fuel cell. Compared with a traditional carbon brush anode, the maximum power density of the waste bacterial rod carbon anode can be improved by more than one time; the preparation method of the waste bacterial rod carbon anode is simple, a complex hydrochloric acid immersion cleaning step is omitted, the cost of raw materials is low, the waste bacterial rod carbon anode is suitable for large-scale commercial process, and a bran-new application mode is provided for resource utilization of waste bacterial rods.

Owner:FUJIAN AGRI & FORESTRY UNIV

Self-healing high-voltage dry-type capacitor

InactiveCN111276330ALower internal resistanceIncreased diffusion rateFixed capacitor electrodesCapacitanceActivated carbon

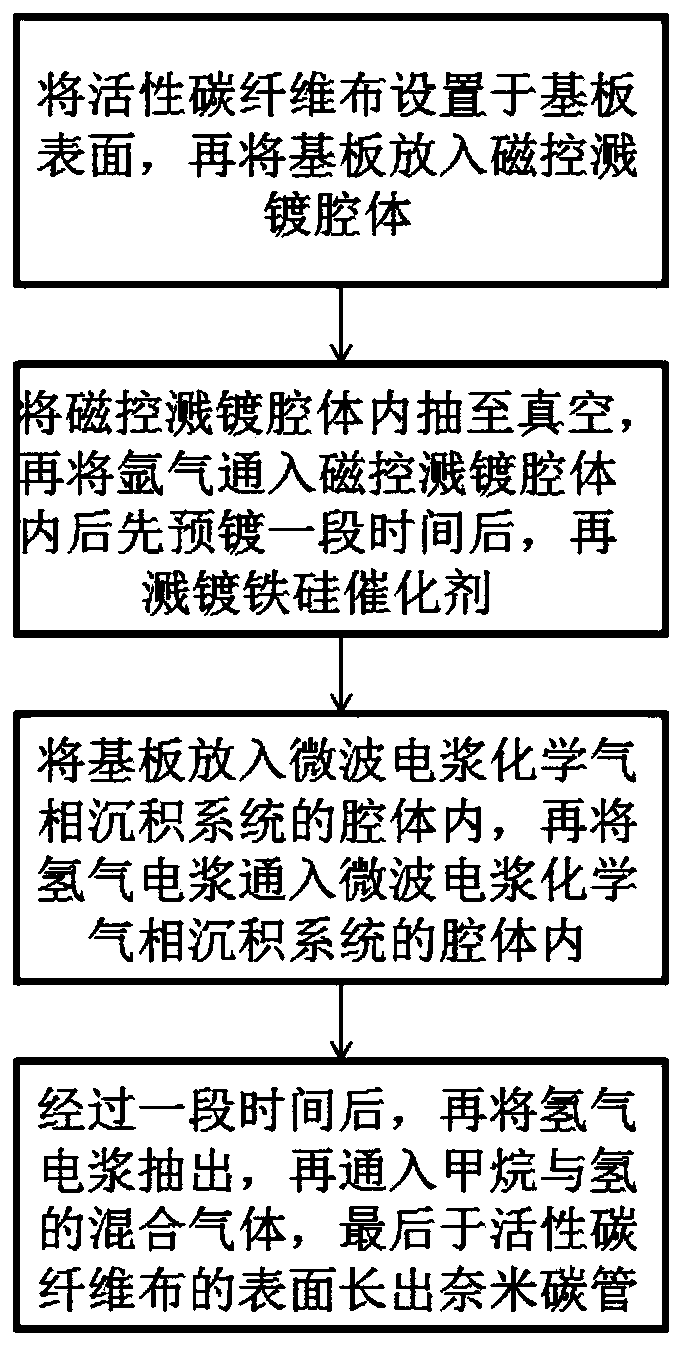

The invention discloses a self-healing high-voltage dry type capacitor. The self-healing high-voltage dry-type capacitor comprises a shell and a self-healing high-voltage dry-type capacitor body, wherein the self-healing high-voltage dry-type capacitor body is arranged in the shell, the self-healing high-voltage dry-type capacitor body comprises a polar plate, the polar plate comprises a substrate, activated carbon fiber cloth is arranged on the surface of the substrate, the activated carbon fiber cloth is made of polyacrylonitrile, and a nano carbon tube is arranged on the surface of the activated carbon fiber cloth. According to the invention, the characteristics of the carbon nanotubes are combined with the advantages of the activated carbon fiber cloth, so the carbon nanotube compositematerial has the advantages of high power density, rapid charging and discharging, large capacitance value, long service life and the like.

Owner:NINGBO JIANGBEI GOFRONT HERONG ELECTRIC

Non-imidazole ionic liquid for proton exchange membrane fuel cell electrolyte

InactiveCN104447514AAvoid poisoningImprove electrical performanceOrganic chemistrySolid electrolyte fuel cellsHigh power densityAdverse effect

The invention discloses a synthesis method for preparing a non-imidazole ionic liquid for a proton exchange membrane fuel cell electrolyte. The synthesis method comprises the following steps: dialkyl sulfate and pyridine react, a product generated after the reaction reacts with a KAC ethanol solution or an NaAC ethanol solution, the generated precipitate is removed by filtering to obtain a colorless and transparent solution, an acid with a proton conduction function is added in the solution, and the acetate of the salt is replaced to obtain the ionic liquid with cations as non-imidazole ions. The adverse effects of an imidazole ionic liquid on proton exchange membrane fuel cell catalysts are avoided, which can be verified through a cyclic voltammetry electrochemical method and other electrochemical methods. The ionic liquid is carried in a PVDF membrane to perform a single battery experiment, and the result shows that the ionic liquid is taken as the ionic liquid for the electrolyte, so that the performance is obviously improved, and compared with the imidazole ionic liquid, the highest power density can be improved by about 15 times.

Owner:TIANJIN POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com