Biomass-based activated carbon coated iron carbide three-dimensional porous microbial fuel cell anode material, anode and preparation methods

A technology based on activated carbon and anode materials, applied in biochemical fuel cells, battery electrodes, circuits, etc., can solve the problems of accelerated extracellular interface electron transfer, unfavorable microbial adhesion and growth, high modification cost, and achieve improved interface electron transfer rate, The effect of reducing anode electron transfer resistance and high affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

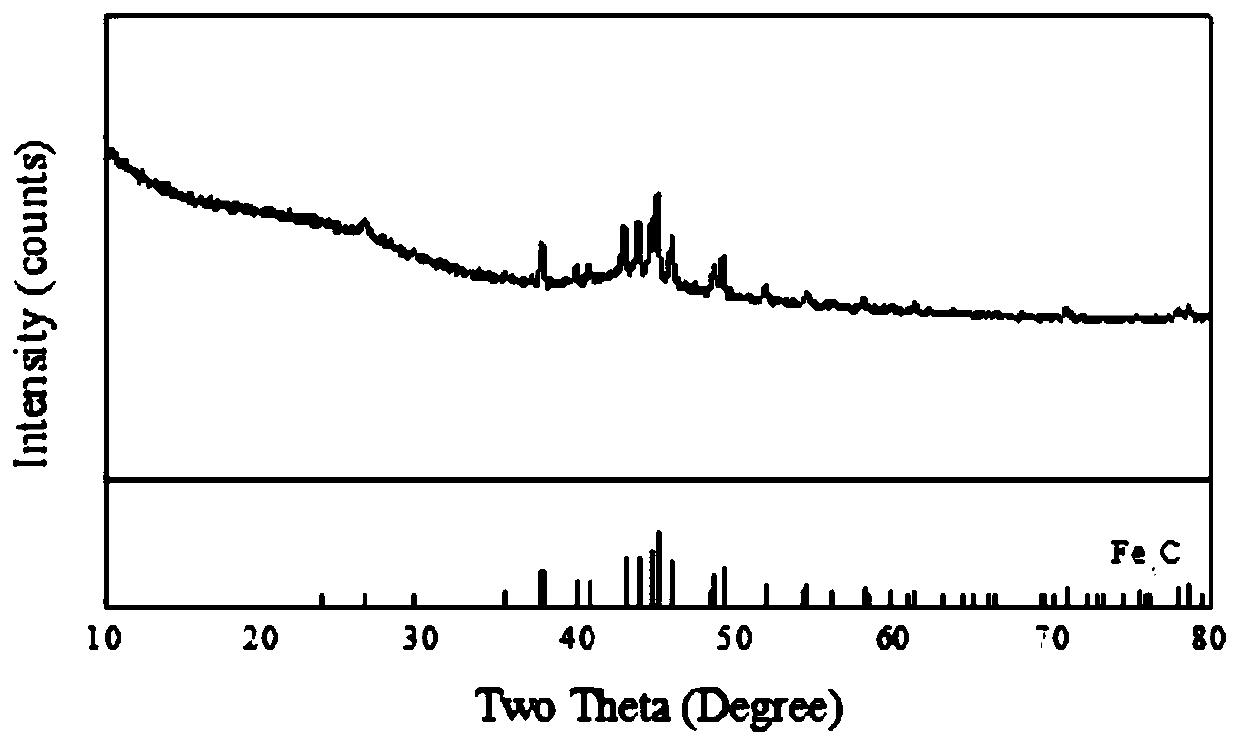

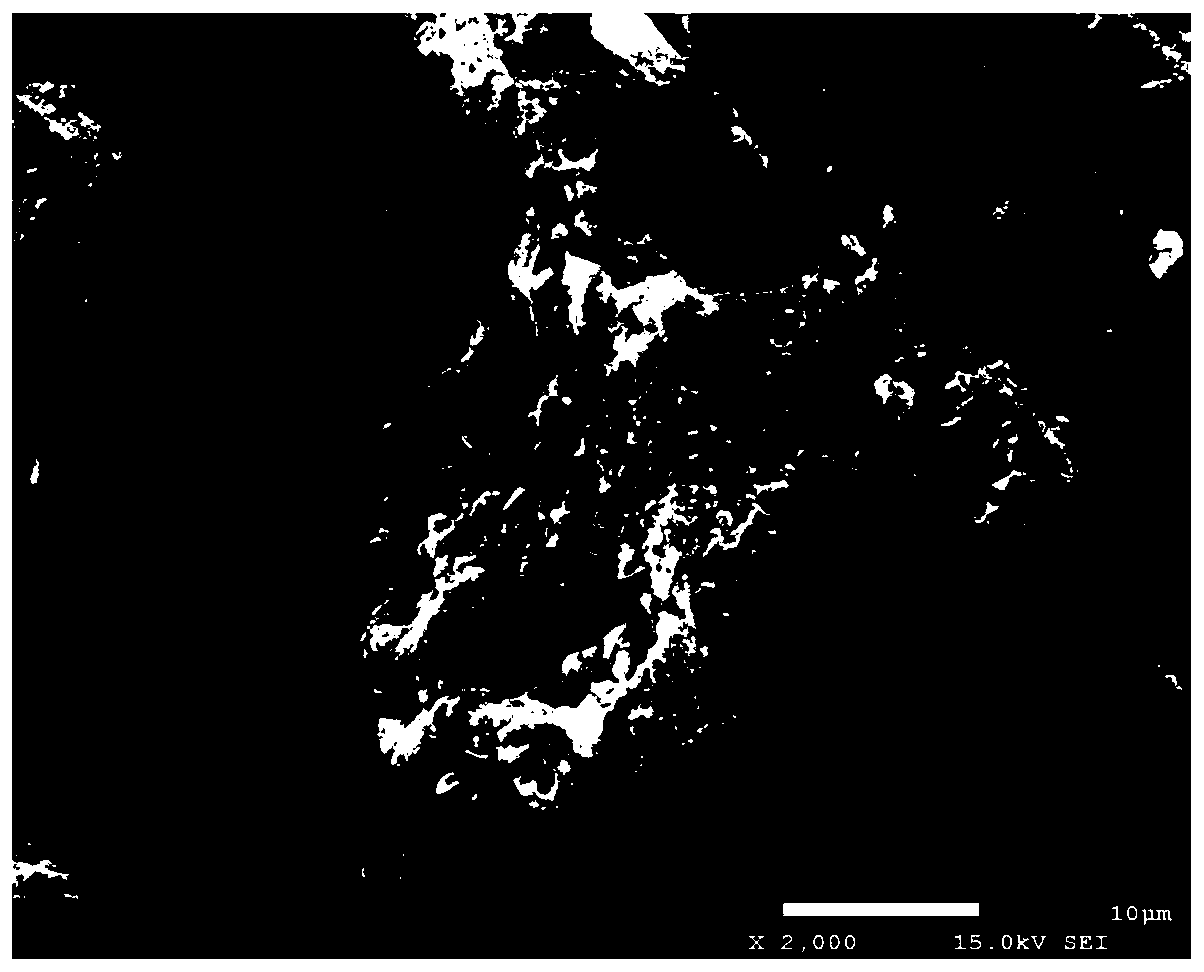

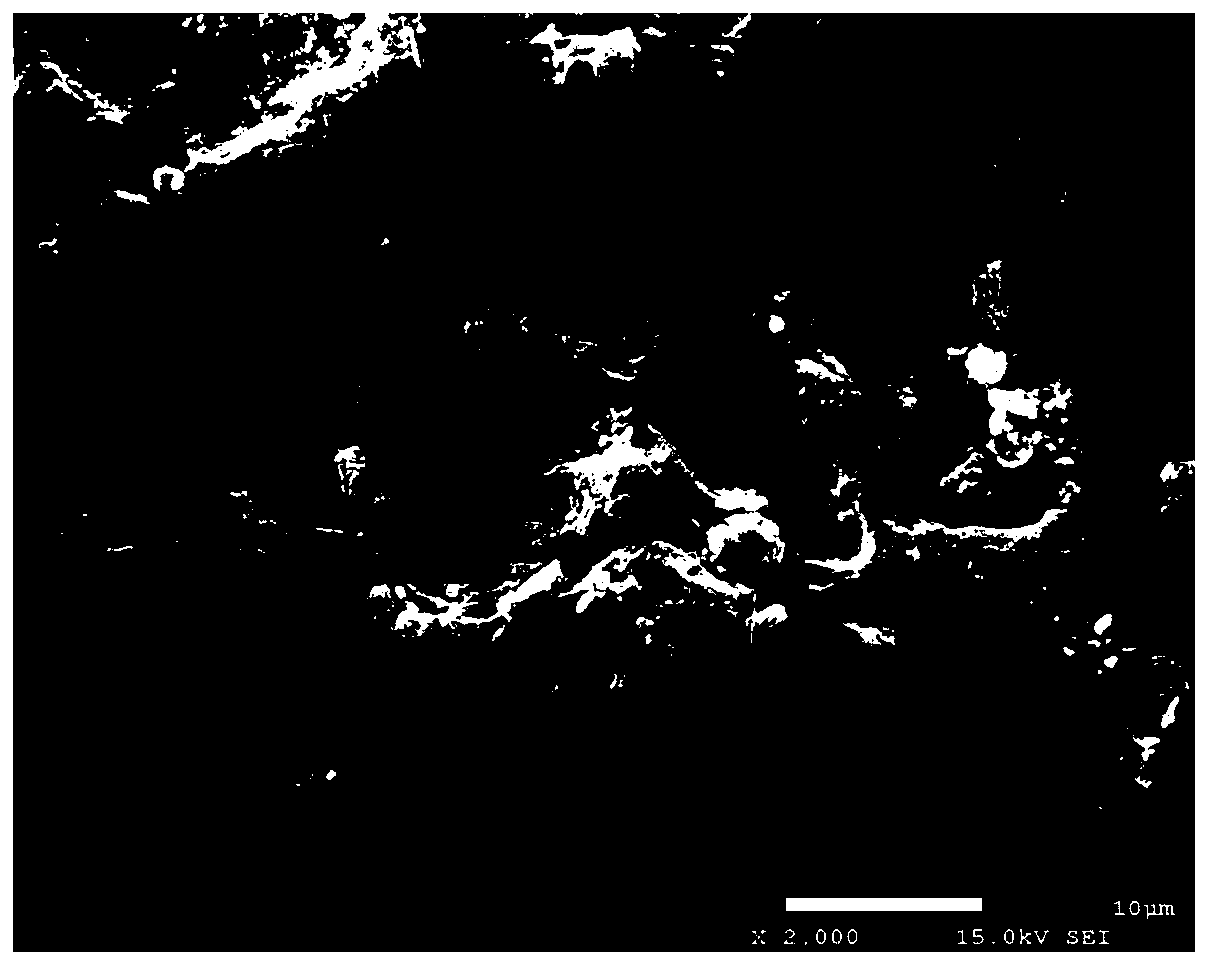

[0043] In this embodiment, the preparation method of the iron carbide three-dimensional porous microbial fuel cell anode material and the anode provided by the biomass-based activated carbon coating is as follows:

[0044] (1) Dry the distiller's grains as the biomass raw material, then carbonize at 450°C for 1.5h, cool to room temperature to obtain carbonized material, and add 2mL of K to every 1g of carbonized 2 CO 3 The ratio of the solution is to add K with a concentration of 1mol / L 2 CO 3 solution, and then add ferric chloride solution to make the mass ratio of iron to carbide 10%, and ultrasonically mix in a water bath for 30 minutes under the condition of 40kHz, so that iron ions are fully absorbed into the pore structure of the carbide, and then dried at 100°C. A mixture of carbonized materials is obtained.

[0045] (2) Place the carbonized material mixture obtained in step (1) in a crucible that can circulate gas, and 2 Treat at a constant temperature of 850°C for...

Embodiment 2

[0048] In this embodiment, the preparation method of the iron carbide three-dimensional porous microbial fuel cell anode material and the anode provided by the biomass-based activated carbon coating is as follows:

[0049] (1) Dry the distiller's grains as the biomass raw material, then carbonize at 550°C for 2 hours, cool to room temperature to obtain carbonized material, add KOH solution with a concentration of 3mol / L according to the ratio of 3mL KOH solution per 1g of carbonized material, and then add nitric acid The iron solution has a mass ratio of iron to carbide of 2%, and is ultrasonically mixed in a water bath at 40 kHz for 30 minutes to fully absorb iron ions into the pore structure of the carbide, and then dry at 100°C to obtain a mixture of carbides.

[0050] (2) Place the carbonized material mixture obtained in step (1) in a crucible that can circulate gas, and 2 Treat at a constant temperature of 700°C for 1 hour in the atmosphere. During the constant temperatur...

Embodiment 3

[0054] In this embodiment, the preparation method of the iron carbide three-dimensional porous microbial fuel cell anode material and the anode provided by the biomass-based activated carbon coating is as follows:

[0055] (1) Dry the distiller's grains as the biomass raw material, then carbonize at 500°C for 1 hour, cool to room temperature to obtain carbonized material, add KOH solution with a concentration of 2mol / L according to the ratio of 5mL KOH solution per 1g of carbonized material, and then add nitric acid The mass ratio of iron to carbide is 5% in the iron solution, ultrasonically mixed in a water bath at 40 kHz for 30 minutes, so that iron ions are fully absorbed into the pore structure of the carbide, and then dried at 100°C to obtain a mixture of carbides.

[0056] (2) Place the carbonized material mixture obtained in step (1) in a crucible that can circulate gas, and 2 Treat at a constant temperature of 800°C for 1 hour in the atmosphere. During the constant tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com