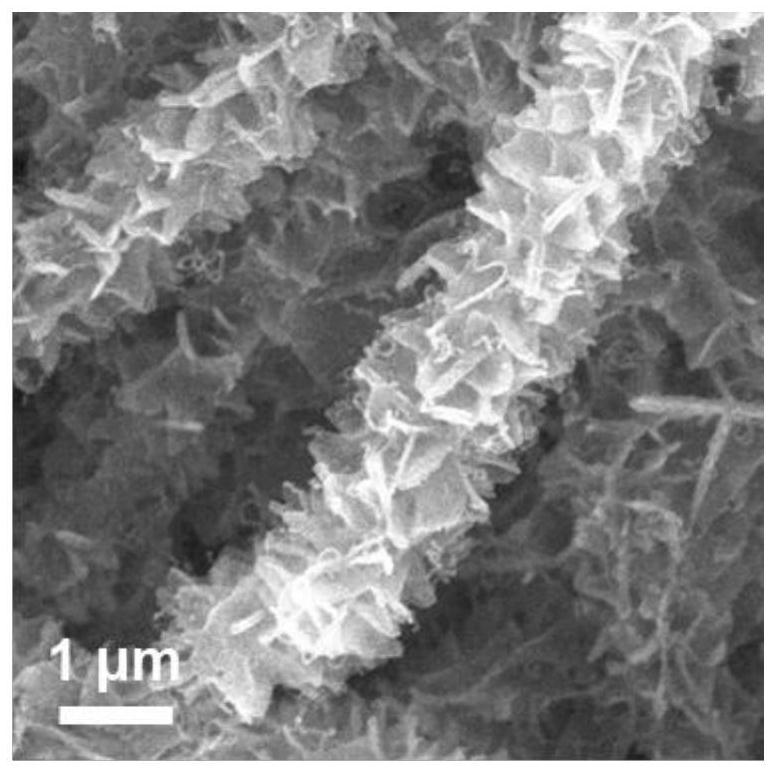

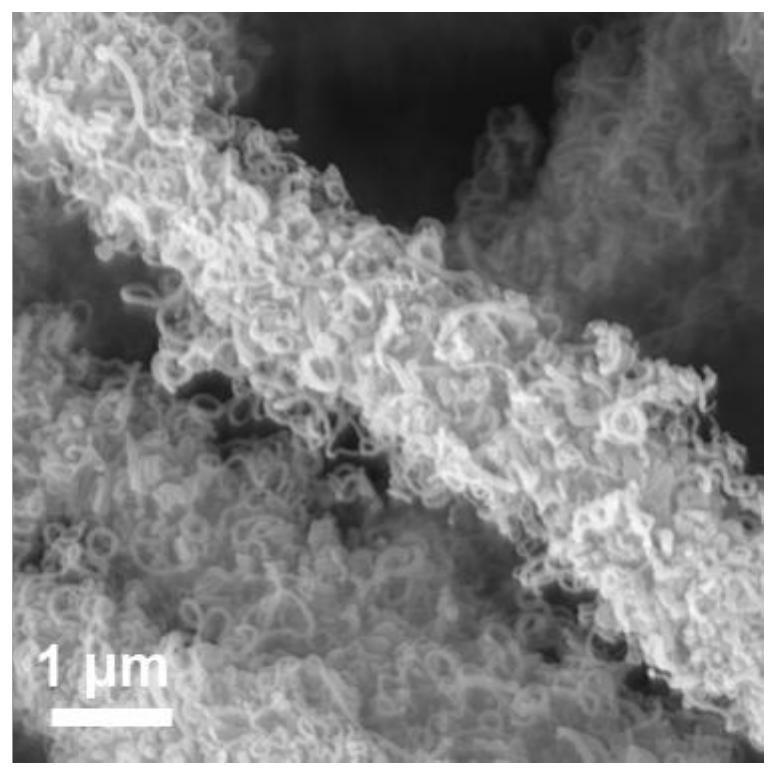

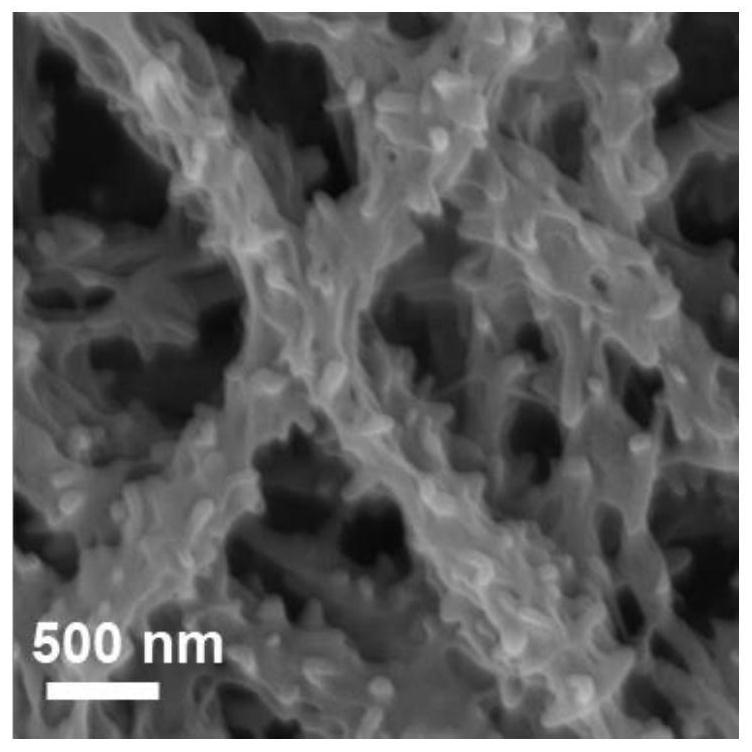

Flexible self-supporting Co-embedded N-doped three-dimensional porous carbon-based material as well as preparation method and application thereof

A three-dimensional porous, carbon-based material technology, applied in the field of electrocatalysis, can solve the problems of less pores, poor mass transfer effect, and inability to realize flexible self-support, and achieve the effect of high specific surface area and rich pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Dissolve 1 g of polyacrylonitrile with a weight average molecular weight of 200,000 in 5 mL of N,N-dimethylformamide (DMF), and 2 g of ZnO in 5 mL of N,N-dimethylformamide (DMF) , the two were stirred and mixed for 24 hours to obtain a spinning solution, and electrospinning was performed on the spinning solution to obtain a ZnO / PAN fiber membrane;

[0044] Among them, during electrospinning, the positive pressure is 16KV, the negative pressure is 1KV; the injection speed is 0.18mm / min; the receiving distance between the needle and the drum is 16cm;

[0045] (2) Cut the ZnO / PAN fiber membrane into 3 pieces with a size of 1cm×2cm×0.05cm, each with a mass of 0.05g, immerse it in 15mL of 2-methylimidazole solution containing 0.5g for 10min, and then add the 0.1115g of Zn(NO 3 ) 2 and 0.1091g of Co(NO 3 ) 2 The mixed solution of metal salts formed by dissolving in 15 mL of deionized water was stirred for 40 min. After the reaction, washed with deionized water and fre...

Embodiment 2

[0052] (1) Dissolve 2 g of ZnO and 1 g of polyacrylonitrile with a weight average molecular weight of 200,000 in 10 mL of N,N-dimethylformamide (DMF), and stir and mix for 24 hours to obtain a spinning solution. Carry out electrospinning to obtain ZnO / PAN fiber membrane;

[0053] Among them, during electrospinning, the positive pressure is 16KV, the negative pressure is 1KV; the injection speed is 0.18mm / min; the receiving distance between the needle and the drum is 16cm;

[0054] (2) Cut the ZnO / PAN fiber membrane into 3 pieces with a size of 1cm×2cm×0.05cm, each with a mass of 0.05g, immerse it in 15mL of 2-methylimidazole solution containing 0.5g for 10min, and then add the 0.1487g of Zn(NO 3 ) 2 and 0.0727g of Co(NO 3 ) 2 The mixed solution formed by dissolving in 15 mL of deionized water was stirred and reacted for 40 min. After the reaction, washed with deionized water and freeze-dried for 5 h to obtain CoZnZIF@ZnO / PAN;

[0055] (3) Put the melamine and CoZnZIF@ZnO / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com