CO2 mineralizing power generation method using sodium bicarbonate as alkaline leaching agent

A sodium bicarbonate and alkaline technology, applied in the field of electrochemistry, can solve the problem that the mineralization battery power generation technology cannot be applied to low-alkaline industrial solid waste raw materials, etc., and achieve the effect of improving power generation performance and accelerating the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

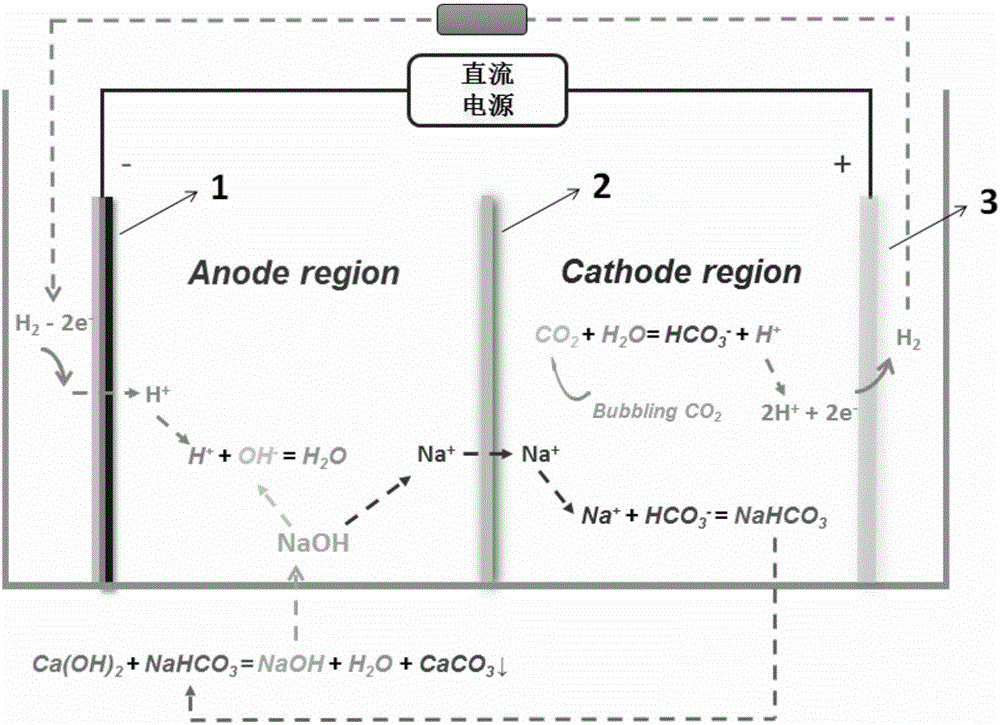

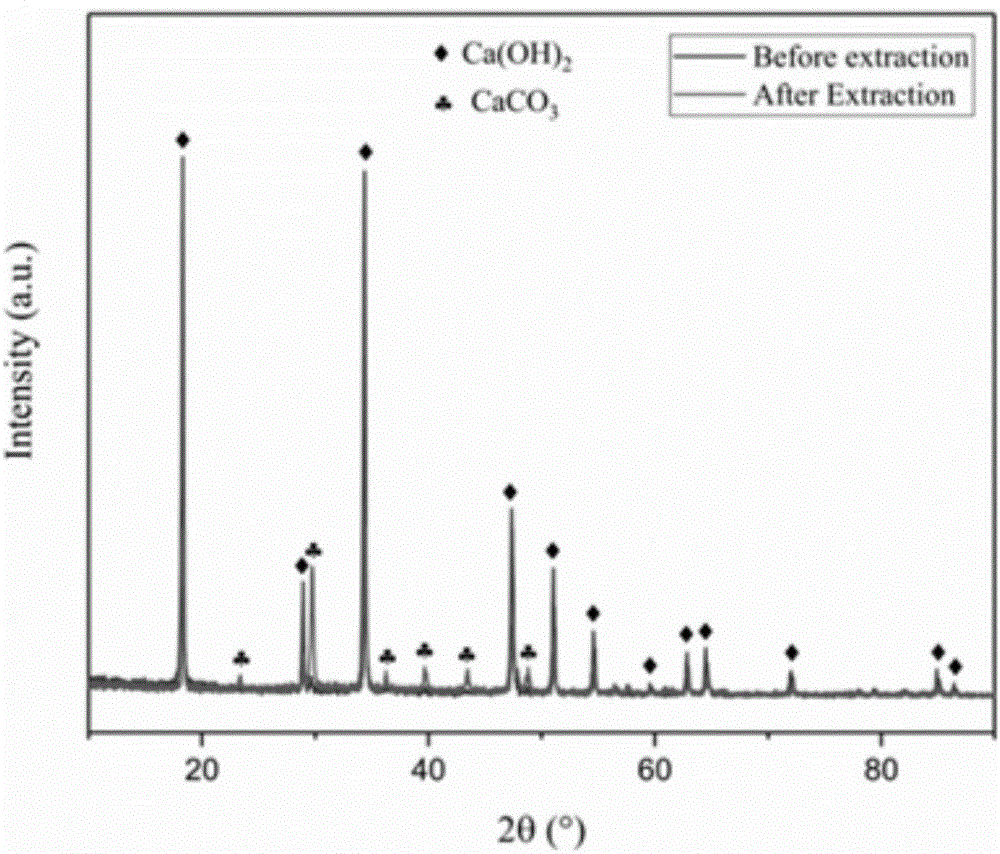

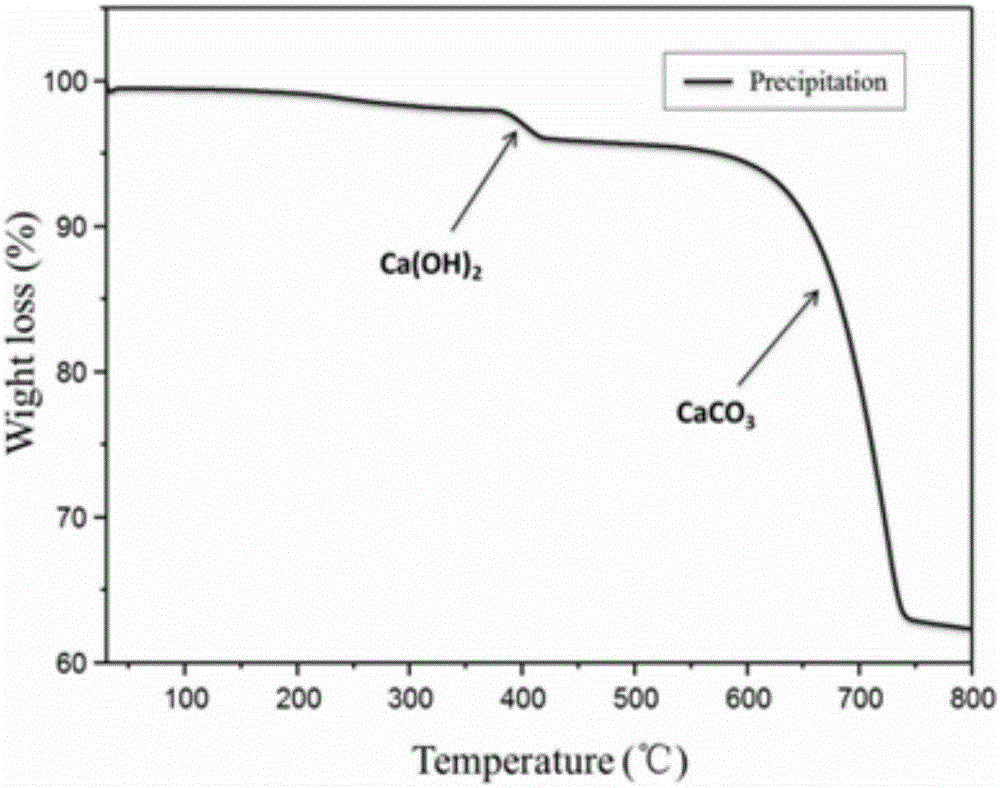

[0042] This embodiment uses NaHCO 3 CO as an alkaline leaching agent 2 Chemical reaction process reference of mineralization power generation method figure 1 . in as CO 2 In the shell container of the mineralization battery, the cation exchange membrane 2 that only allows cations to pass through and can prevent anions from passing through is divided into two regions, the anode region and the cathode region. At the same time, the hydrogen diffusion electrode 1 is used as an anode electrode, and the electrode 3 carrying Pt / C on carbon cloth is used as a cathode electrode. Prepare 100ml of 1mol / L NaCl and 1mol / L NaHCO 3 Then gradually add 2g calcium carbide slag to the solution to form a suspension, and after stirring at a speed of 300rpm for 20min, the suspension is filtered, and the filtrate circulates between the storage tank and the anode area at a rate of 20ml / min , after drying the filter residue at 60°C, use XRD and thermogravimetric balance to analyze the composition...

Embodiment 2

[0047] This embodiment uses NaHCO 3 CO as an alkaline leaching agent 2 Chemical reaction process reference of mineralization power generation method figure 1 . in as CO 2 In the shell container of the mineralization battery, the cation exchange membrane 2 that only allows cations to pass through and can prevent anions from passing through is divided into two regions, the anode region and the cathode region. At the same time, the hydrogen diffusion electrode 1 is used as an anode electrode, and the electrode 3 carrying Pt / C on carbon cloth is used as a cathode electrode. Prepare 100mL of 1mol / L NaCl+1mol / L NaHCO 3 Then gradually add 5g calcium carbide slag to the solution to form a suspension, and after stirring at a speed of 200rpm for 50min, the suspension is filtered, and the filtrate circulates between the storage tank and the anode area at a rate of 20ml / min , after the filter residue was dried at 80°C, the composition change and salinity of the filter residue were an...

Embodiment 3

[0052] This embodiment uses NaHCO 3 CO as an alkaline leaching agent 2 For the chemical reaction process of mineralization power generation method see figure 1 . in as CO 2 In the shell container of the mineralization battery, the cation exchange membrane 2 that only allows cations to pass through and can prevent anions from passing through is divided into two regions, the anode region and the cathode region. At the same time, the hydrogen diffusion electrode 1 is used as an anode electrode, and the electrode 3 carrying Pt / C on carbon cloth is used as a cathode electrode. Use steel slag with a free CaO content of only 1.06% as raw material, add 200g steel slag to 100ml 0.2mol / L NaHCO 3 After the solution was stirred at 300rpm for 20min, the suspension was filtered, and the leached filtrate was circulated between the storage tank and the anode area at a rate of 20ml / min for the test of power generation performance and continuous power generation. Add 80ml of sodium bicarbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com