Method of synchronously degrading excess sludge and treating hexavalent chromium wastewater

A technology for excess sludge and hexavalent chromium, applied in biological sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of high treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0011] Specific embodiments: a method for synchronously degrading excess sludge and treating hexavalent chromium wastewater according to the present embodiment is carried out in the following steps:

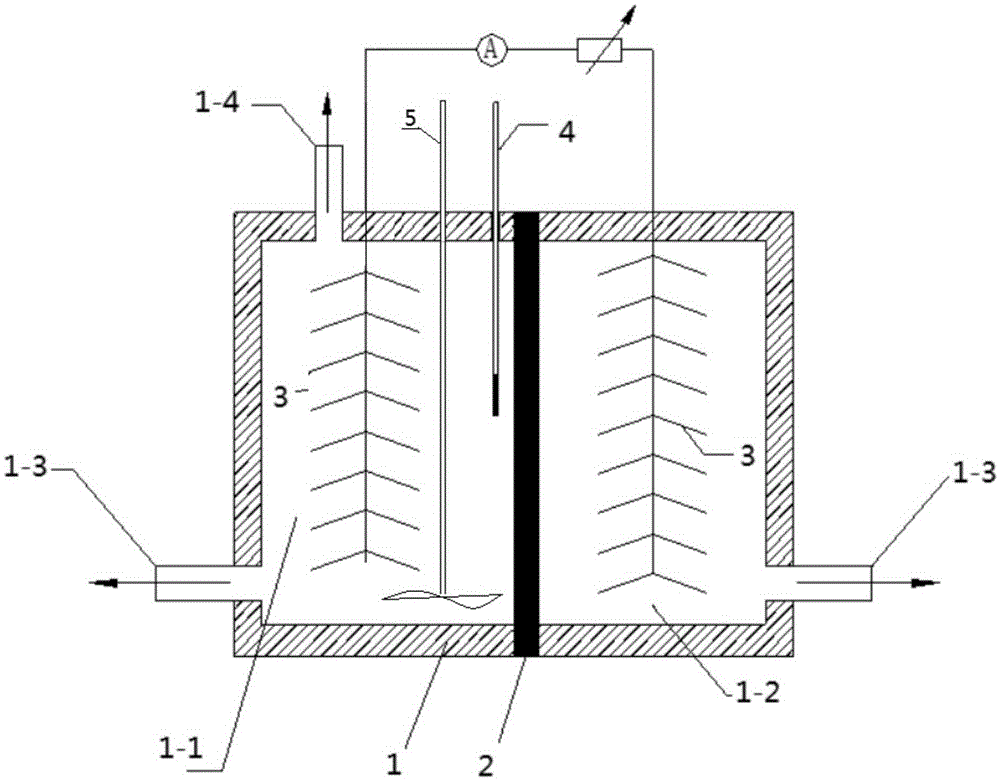

[0012] 1. Build a double-cell structure reactor: the double-cell structure reactor is composed of a shell 1, a cation exchange membrane 2, a carbon fiber brush 3, a reference electrode 4 and a stirrer 5, and the cation exchange membrane 2 is set in the shell 1. Housing 1 is divided into anode chamber 1-1 and cathode chamber 1-2, the carbon fiber brush 3 that is arranged in the anode chamber 1-1 is an anode, the carbon fiber brush 3 that is arranged in the cathode chamber 1-2 is a cathode, in the anode chamber 1-1 and the bottom of the cathode chamber 1-2 are respectively provided with a sampling tube 1-3, and the top of the anode chamber is provided with a gas collector 1-4; the anode and the cathode are connected through an external circuit; the reference electrode 4 penetrates i...

specific Embodiment approach 2

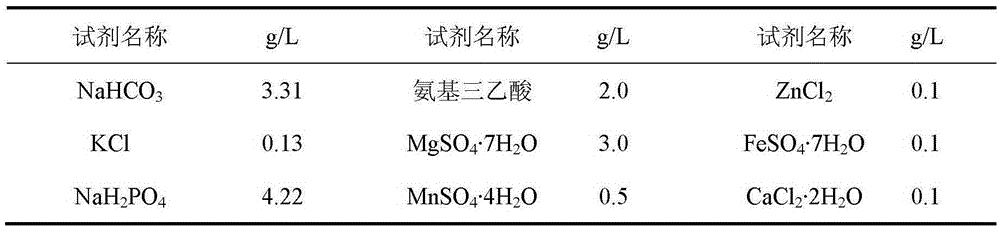

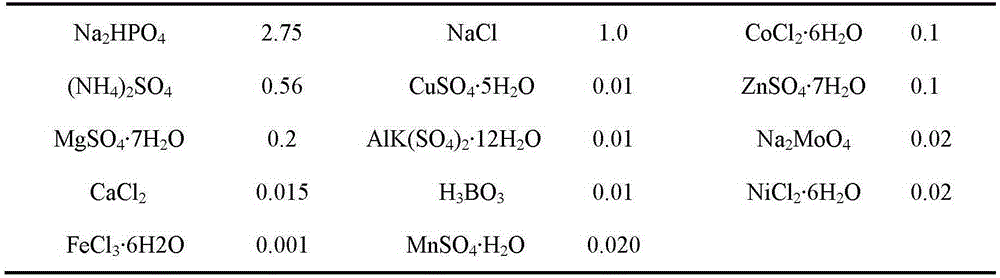

[0015] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the composition and proportioning ratio of the nutrient solution in step two are as shown in Table 1:

[0016] The composition and proportioning ratio of table 1 nutrient solution

[0017]

[0018]

[0019] Others are the same as the first embodiment.

specific Embodiment approach 3

[0020] Specific embodiment three: what this embodiment is different from specific embodiment one or two is that potassium ferricyanide catholyte is according to potassium ferricyanide (K 3 [Fe(CN) 6 ] concentration of 30 ~ 35g / L, potassium dihydrogen phosphate (KH 2 PO 4 ) with a concentration of 25-30 g / L, which is prepared by adding potassium ferricyanide and potassium dihydrogen phosphate into water; the others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com