Breathable knitted spacer fabric friction generator and preparation method thereof

A technology of friction generators and spacer fabrics, applied in the direction of friction generators, etc., can solve the problems of friction generators such as general air permeability and tensile properties, achieve excellent physical and mechanical properties, increase effective contact area, and facilitate friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

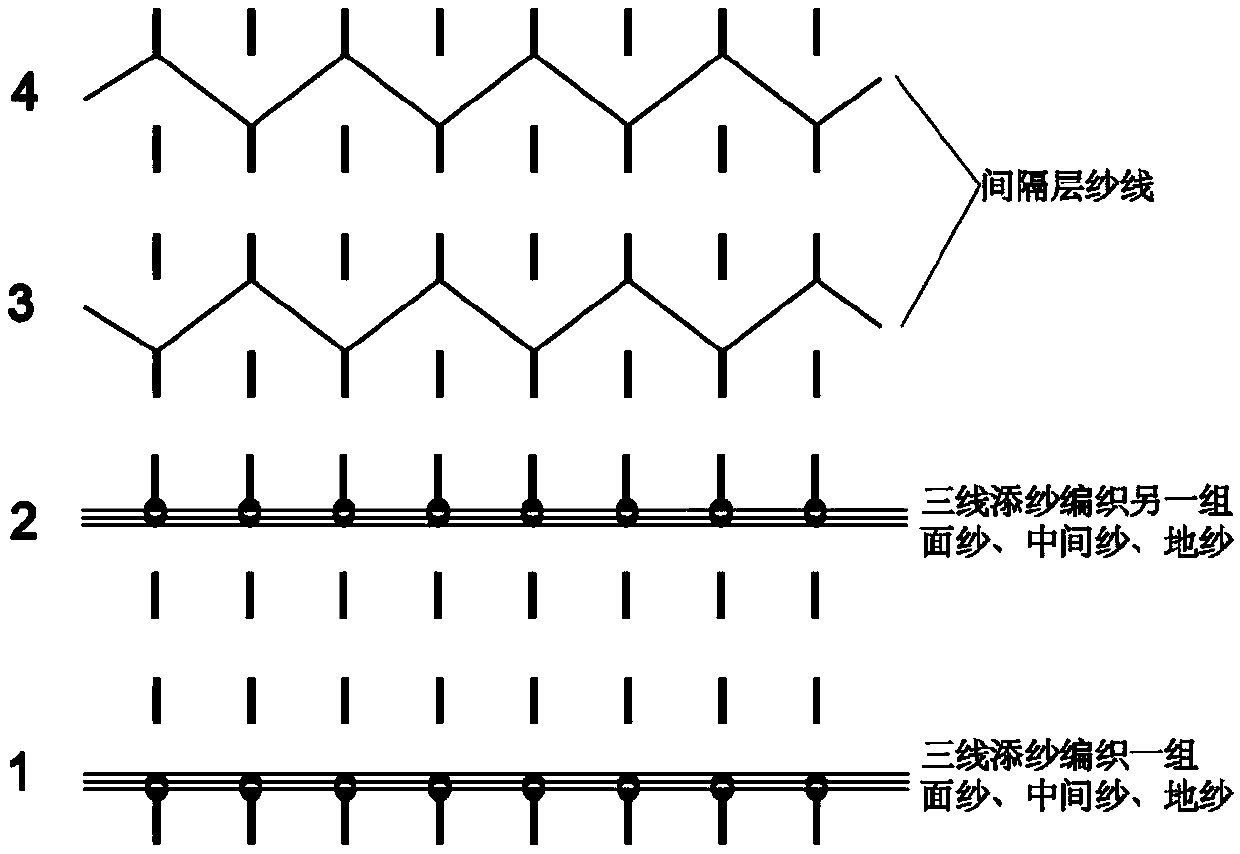

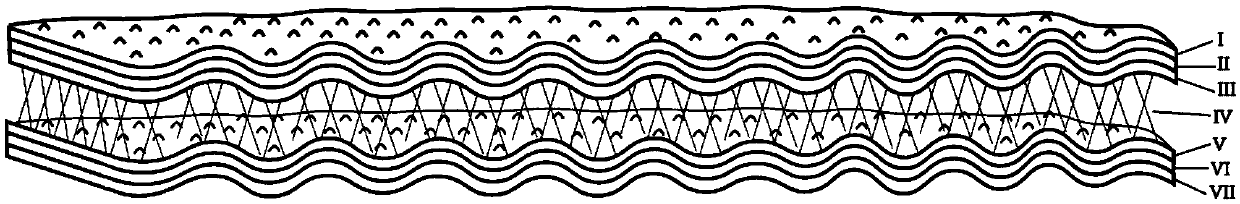

[0046] The preparation method of the air-permeable knitted spacer fabric friction generator uses a computerized flat knitting machine to weave, and the weaving diagram is as follows figure 1 As shown, the 1st way is a group of veil, middle yarn and ground yarn to be looped on the front needle bed in the way of three-line plating, and the second way is another set of veil, middle yarn and ground yarn to be looped on the back needle in the way of three-line plating. The bed is formed into a loop, the 3rd and 4th way are the full-needle tuck of the spacer layer yarn, and the 4-way weaving forms a row of fabric, which is a cycle. The specific steps are as follows:

[0047] (1) A set of veil (made of insulating yarn, made of polyester fibers), intermediate yarn (made of conductive yarn, made of silver fibers) and ground yarn (made of triboelectric negative yarn) thread, which is made of polytetrafluoroethylene fibers) is formed into a loop on the front needle bed, and the left and ...

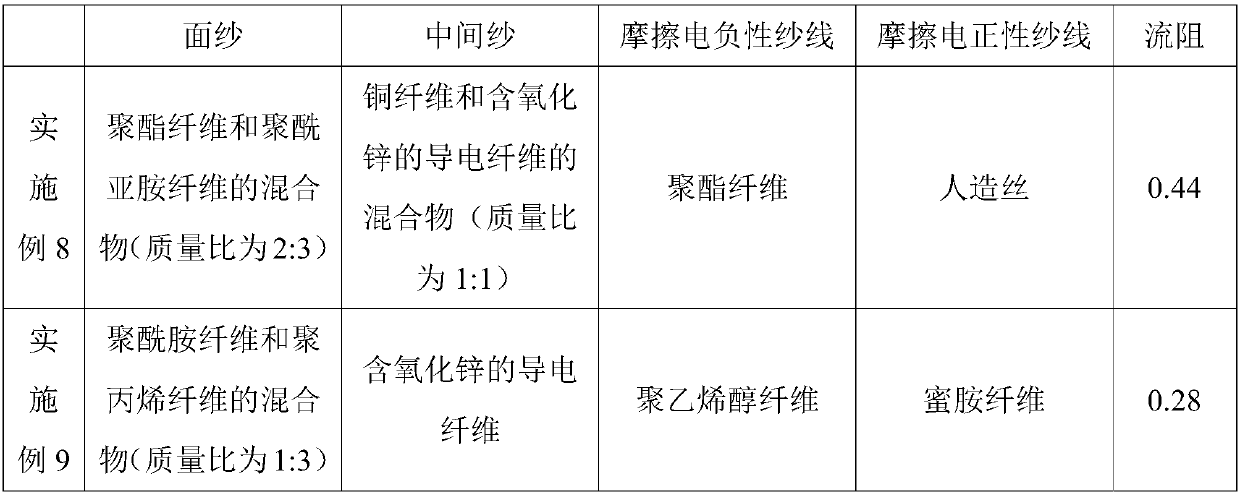

Embodiment 2

[0055] The preparation method of the breathable knitted spacer fabric friction generator uses a computerized flat knitting machine to weave, and the specific steps are as follows:

[0056] (1) A set of veil (made of insulating yarn, made of polyamide fibers), middle yarn (made of conductive yarn, made of copper fibers) and ground yarn (made of triboelectric negative yarn) , made of polytetrafluoroethylene fibers) is formed in the front needle bed, and the left and right positions and height positions of the guide holes are adjusted, so that the longitudinal angles of the lapping yarns, intermediate yarns and ground yarns of the lapping yarns are sequentially increased. The yarn behind the circle is exposed on the front of the fabric, the ground yarn is exposed on the reverse side of the fabric, and the intermediate yarn is located between the surface yarn and the ground yarn. Among them, the specific implementation method of adjusting the left and right positions and the height...

Embodiment 3

[0063] A method for preparing a breathable knitted spacer fabric friction generator, the specific steps are as follows:

[0064] (1) A set of veil (made of insulating yarn, made of polyamide fibers), intermediate yarn (made of conductive yarn, made of conductive fibers containing zinc oxide) and ground yarn (made of friction Electronegative yarn, gathered by polyvinyl chloride fiber) adopts the method identical with embodiment 2 to carry out knitting on front needle bed;

[0065] (2) Put another set of veil (the material is the same as step (1)), intermediate yarn (the material is the same as step (1)) and ground yarn (the material is triboelectric positive yarn, gathered by melamine fibers) Knitting is carried out on the rear needle bed, and the relationship and adjustment method of the longitudinal angle of the three yarn lap yarns are the same as those of the first group of yarns;

[0066] (3) Alternately tuck the spacer wires (the material is made of polypropylene fibers)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com