Microbial fuel cell for processing acid copper-containing waste water of mine, and copper recycling method

A fuel cell and microorganism technology, which is applied in the fields of biochemical fuel cells, water pollutants, water/sewage treatment, etc., can solve the problems of high energy consumption, failure to mention heavy metal recovery, and difficulty in directly recovering elemental copper.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

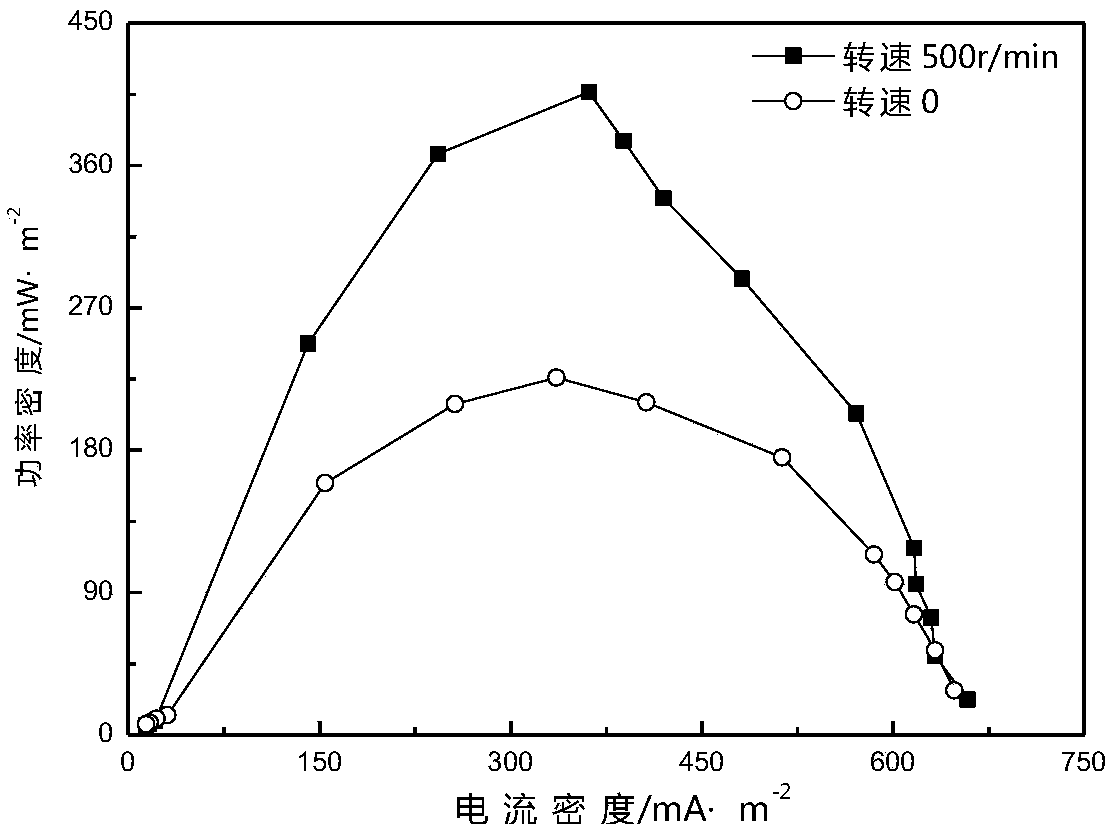

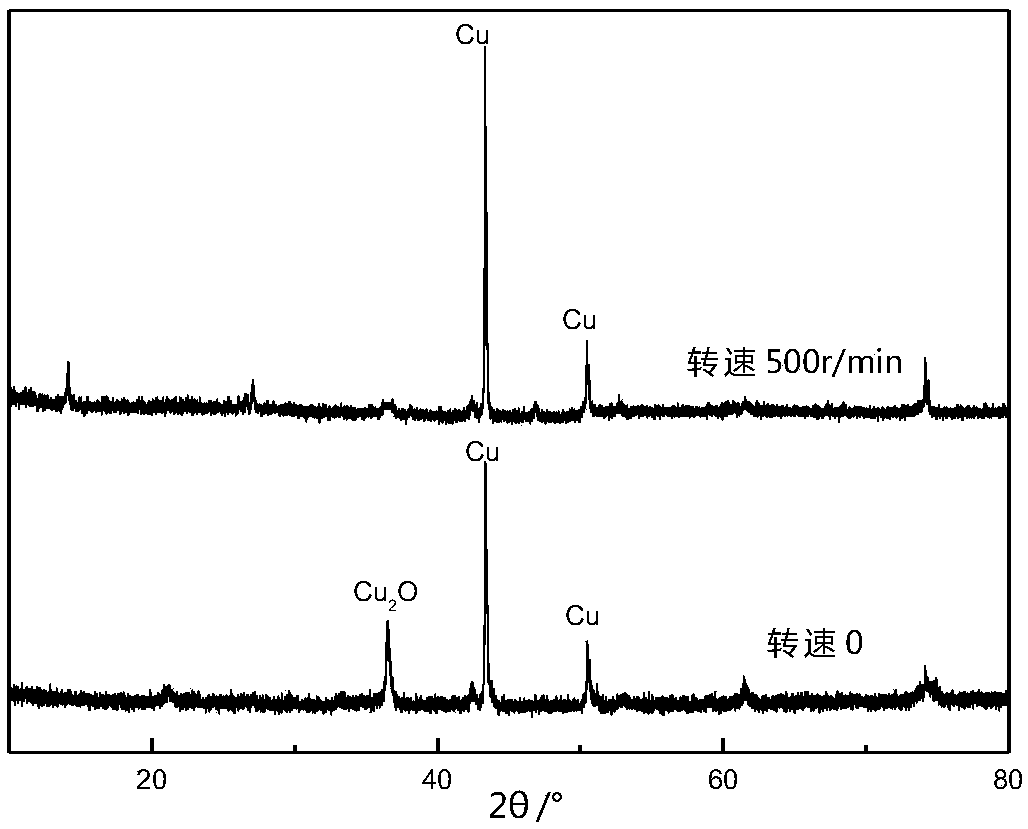

[0042] Two sets of MFC devices were selected, the effective volume was 100mL, and the volume ratio of the anode bacteria to the substrate was 1:3. The first group of MFC1 is added to stir at a speed of 500r / min, and the speed of the other group of MFC2 is 0. Using the steady-state discharge method, the power density curve is obtained by calculation and drawing (see figure 1 ). After running for 30 days, take out the cathode, collect the cathode reduction product, and utilize XRD diffractometer to detect the cathode product (see figure 2 ), the morphology of the cathode product is as image 3 shown. The power generation performance and wastewater treatment effect of the two groups of batteries are compared as shown in Table 1.

[0043] It can be seen from Table 1 that when the speed increases from 0 to 500r / min, the maximum open circuit voltage of MFC increases from 503mV to 522mV, and the maximum power density increases from 225mW / m 2 increased to 400mW / m 2 , the power ...

Embodiment 2

[0047] This example is the same as the first group of MFC1 in Example 1, except that the volume ratio of the anode bacteria species to the substrate is 1:1. Under these conditions, the open circuit voltage of the microbial fuel cell is 610mV, and the maximum power density is 580.8mW / m 2 , the anode COD removal rate is 38.8%, and the cathode Cu 2+ The removal rate was 92.2%.

Embodiment 3

[0049] The method of this example is the same as Example 2, except that the effective volume of the device is 250mL. Under these conditions, the open circuit voltage of the microbial fuel cell is 538mV, and the maximum power density is 304.2mW / m 2 , the anode COD removal rate is 32.1%, and the cathode Cu 2+ The removal rate is 89.8%, and the cathodic reduction product is copper.

[0050] Table 1 Microbial fuel cell power generation performance and wastewater treatment effect

[0051]

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com