Acidic soil conditioner, preparation method and application thereof

A technology of acidic soil and conditioner, applied in the field of soil improvement and fertilizer, can solve the problems of lack of ideal soil conditioner and broad-spectrum of conditioner, improvement of root micro-ecology, etc., so as to improve the quality of agricultural products and promote the absorption and utilization of nutrients , enhance the effect of root vitality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

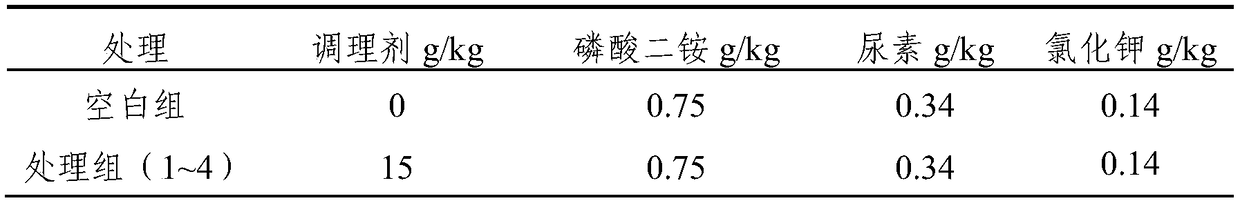

Embodiment 1

[0032] This embodiment provides an acidic soil conditioner, in parts by mass, including 20 parts of gasification fine slag, 10 parts of boiler coarse ash, 23 parts of boiler fine ash, 9 parts of red mud, 12 parts of bentonite, 8 parts of alginic acid, 4 parts of glucoamylase treatment and 6 parts of amino acid biochar.

[0033] The preparation method of above-mentioned acidic soil conditioner, comprises the following steps:

[0034] (1) Each raw material is pulverized, ground, air-dried and sieved respectively, and reserved for later use;

[0035] (2) Configure according to the ratio of each raw material, mix and stir evenly;

[0036] (3) Extruding and granulating the homogeneously mixed material to obtain columnar granules with a length of 8-12 mm and a particle diameter of 3-5 mm;

[0037] (4) The extruded particles are rounded, dried, cooled, and screened, and finally bagged into finished products.

Embodiment 2

[0039] This embodiment provides an acidic soil conditioner, in parts by mass, including 15 parts of gasification fine slag, 12 parts of gasification coarse slag, 7 parts of boiler coarse ash, 20 parts of boiler fine ash, 20 parts of lignite, and 8 parts of red mud 10 parts of bentonite, 6 parts of polyglutamic acid, 5 parts of glucoamylase treatment and 5 parts of amino acid biochar. The preparation method is the same as in Example 1.

Embodiment 3

[0041] The present embodiment provides an acidic soil conditioner, in parts by mass, comprising 15 parts of gasification fine slag, 10 parts of gasification coarse slag, 5 parts of boiler coarse ash, 12 parts of boiler fine ash, 13 parts of lignite, and 5 parts of peat soil 6 parts of red mud, 10 parts of bentonite, 6 parts of potassium fulvic acid, 4 parts of polyglutamic acid, 3 parts of amino acid biochar and 5 parts of glucoamylase treatment. The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com