Soil conditioner and preparation method thereof

The technology of soil conditioner and granule is applied in the field of soil conditioner and its preparation, and can solve the problems of complicated preparation process, high production cost, and difficulty in being stored for a long time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

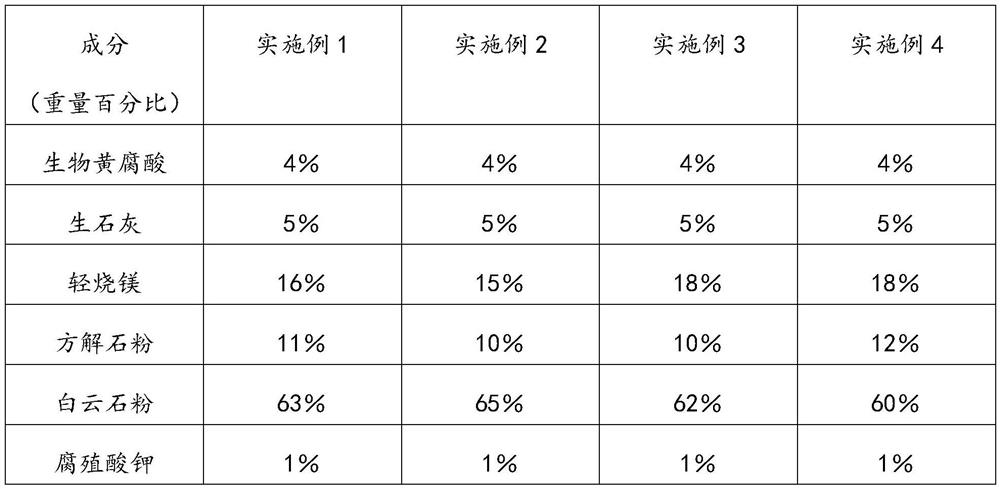

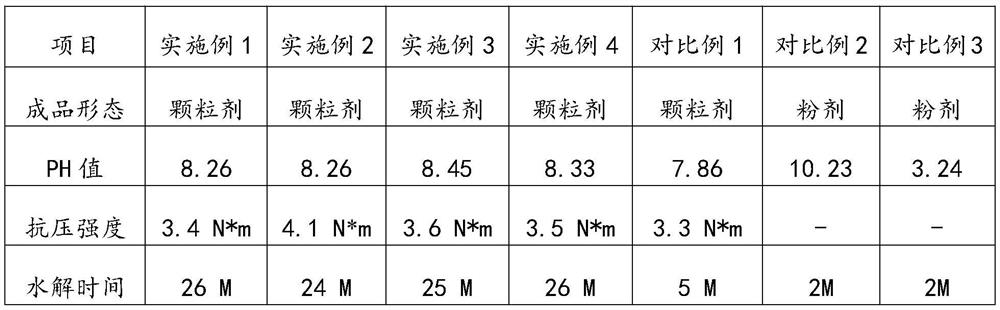

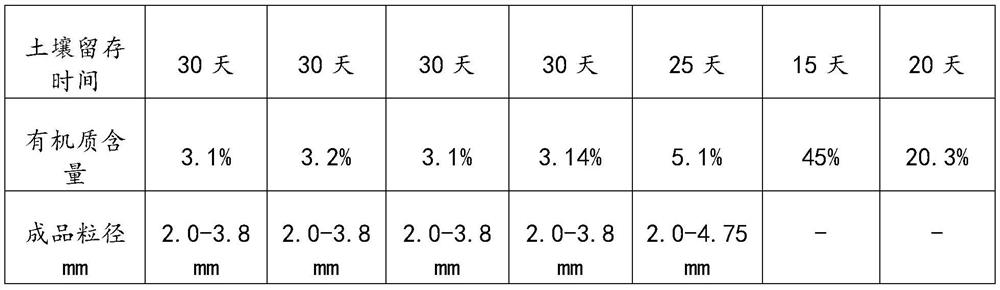

Examples

preparation example Construction

[0040] A preparation method of soil conditioner, comprising the following steps:

[0041] (1) Calcite powder and dolomite powder are mixed uniformly to obtain mixed powder;

[0042] (2) Add 20% water to the mixed powder and adjust to muddy state;

[0043] (3) add biological fulvic acid and potassium humate to the mud of step (2), stir;

[0044] (4) add unslaked lime, lightly burned magnesium in the mud of step (3), stir;

[0045] (5) When the slurry in step (4) is dehydrated from heat to dry mud, granulate;

[0046] (6) leave the granular soil conditioner obtained in step (5) to stand, and solidify and form after the second exotherm, to obtain a finished soil conditioner with a particle size of 2.0-3.8mm;

[0047] (7) Inspection, packaging and storage of the finished soil conditioner.

[0048] The first exothermic peak is formed when the light-burned magnesium is added to the mud, and the hydration exotherm occurs within 240 minutes after the light-burned magnesium is adde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com