Combined organic sodium sulfonate salt flotation agent

A combined technology of organic sodium sulfonate, applied in flotation, solid separation, etc., can solve the problems of low recovery rate, high impurity content, and low beneficiation efficiency in ore dressing plants, and achieve good chemical stability, less impurities, The effect of high flotation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

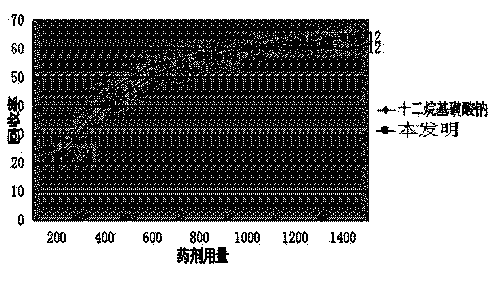

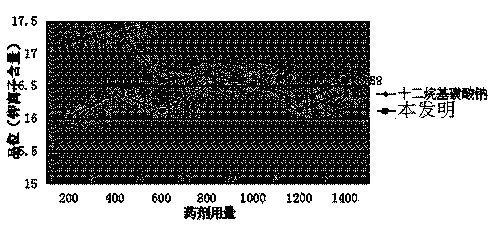

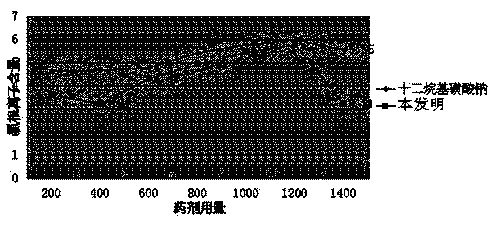

[0027] 1. Purpose of the test: To investigate the collection capacity and selectivity of the present invention for potassium-containing minerals in the ore pulp converted from potassium mixed salts.

[0028] 2. Test raw material: The raw material is taken from the overflow port of the conversion tank of the soft potash system, and is flotation after filtration and pulping.

[0029] 2.1 The raw material composition is shown in Table 1:

[0030] Table 1 (raw material ion composition)

[0031]

[0032] 3. Test drug:

[0033] 3.1 The present invention can be used at a concentration of 5%, its active ingredient is 60%, the color is light yellow, the viscosity is high, and the dissolution rate is slow. When preparing the medicament, it needs to stand still for half an hour before the medicament can be completely dissolved.

[0034] 3.2 Sodium dodecyl sulfonate currently used in the existing potash industry should be used at a concentration of 5%.

[0035] 4. Test equipment: XF...

Embodiment 2

[0072] 1. Purpose of the test: To investigate the collection capacity and selectivity of the present invention for potassium-containing minerals in the ore pulp converted from potassium mixed salts.

[0073] 2. Test raw material: The raw material is taken from the overflow port of the conversion tank of the soft potash system, and then flotation is carried out after filtration and slurry adjustment.

[0074] 2.1 The raw material composition is shown in Table 6:

[0075] Table 6 (raw material ion composition)

[0076]

[0077] 3. Test drug:

[0078] 3.1 The present invention is used at a concentration of 5%. The color of the present invention is light yellow, and the dissolution rate is relatively slow. When preparing the medicament, it needs to stand still for half an hour before the medicament can be completely dissolved.

[0079] 3.2 Sodium dodecyl sulfonate currently used should be used at a concentration of 5%.

[0080] 4. Test equipment: XFD-63 single tank flotation...

Embodiment 3

[0106] 1. Purpose of the test: To investigate the collection ability and selectivity of the present invention for potassium-containing minerals in the slurry after conversion of potassium mixed salts.

[0107] 2. Test raw material: The raw material is taken from the overflow port of the conversion tank of the soft potash system, and then flotation is carried out after filtration and slurry adjustment.

[0108] 2.1 The raw material composition is shown in Table 10:

[0109] Table 10 (Raw material ion composition)

[0110]

[0111] 3. Test drug:

[0112] 3.1 The present invention is used at a concentration of 5%. The color of the present invention is light yellow, and the dissolving speed is relatively slow.

[0113] 3.2 Sodium dodecyl sulfonate currently used should be used at a concentration of 5%.

[0114] 4. Test equipment: XFD-63 single tank flotation machine with a volume of 1.0L, 2X-3 rotary vane vacuum filter.

[0115] 5. Brief description of the test process

[01...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com