Method for reducing agglomeration and pulverization of compound fertilizer and compound fertilizer

A compound fertilizer and agglomeration technology, applied in the direction of urea compound fertilizer, inorganic fertilizer, fertilizer mixture, etc., can solve the problems of reducing compound fertilizer agglomeration and pulverization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

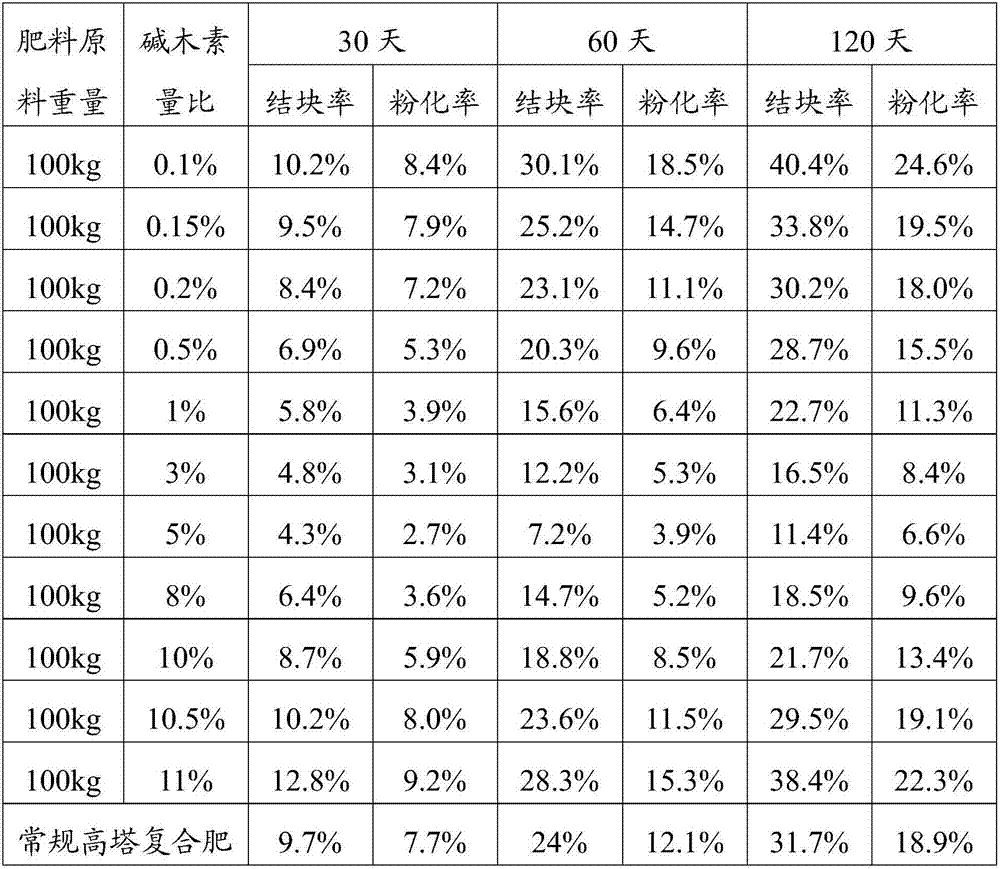

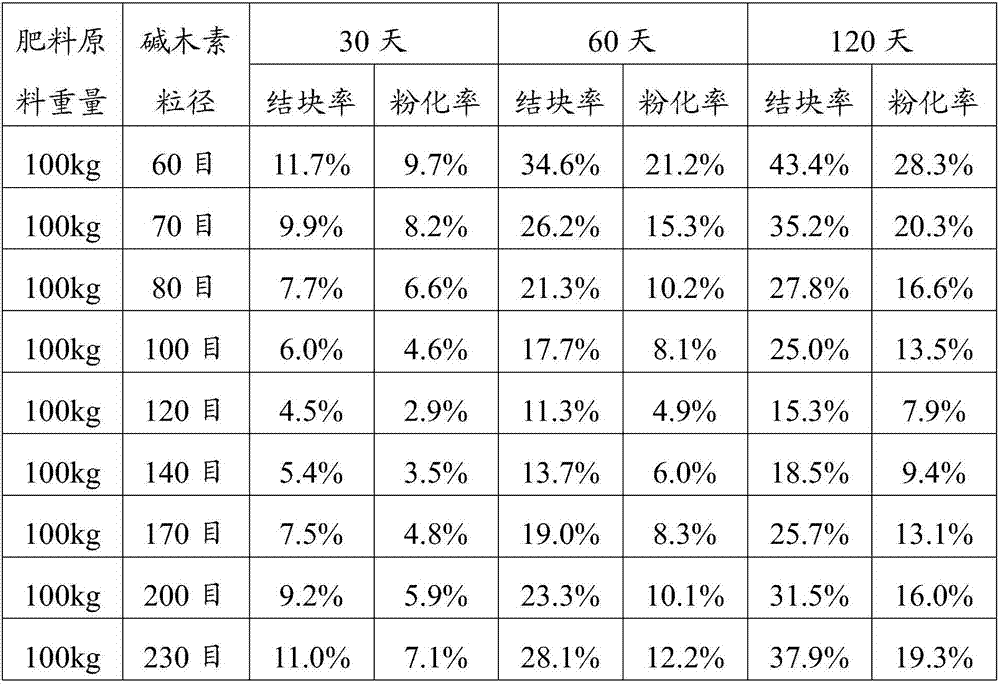

Examples

Embodiment 1

[0028] S00, calculation and acquisition of raw materials: According to the nominal 16-16-16 of N-P-K content, obtain urea, superphosphate and potassium sulfate raw materials required for 100kg fertilizer preparation, and 5kg (5% of fertilizer weight) alkali lignin (pH is 9.8 , It is required to pass through 80 mesh sieve to remove the sieve residue);

[0029] S10, slurry preparation: heat and melt solid urea to form a molten liquid, then add the corresponding mixture of potassium sulfate, alkali lignin and necessary additives to the molten liquid, and then add the corresponding superphosphate after the material is evenly melted to prepare into a mixed slurry;

[0030] S20, sending the mixed slurry into a high-tower granulator for spraying and granulation, spraying the granulated material entering the granulation tower through the granulator, and collecting the granular material falling into the bottom of the tower;

[0031] S30, cooling the dried, screened and surface-treated...

Embodiment 2

[0036] S00, calculation and acquisition of raw materials: According to the nominal 16-16-16 of N-P-K content, obtain urea, superphosphate and potassium sulfate raw materials required for 100kg fertilizer preparation, and 5kg (5% of fertilizer weight) ammoniated alkali lignin (alkali Ammonia product of lignin treated with ammonia water or ammonium sulfate, molecular weight 20,000-50,000, pH 10.8, 100-mesh sieve, removal of sieve residue, water content less than 10%, organic matter content ≥ 50%, insoluble matter ≤ 5%);

[0037] S20, sending the mixed slurry into a granulator for spraying and granulation, spraying the granulated material entering the granulation tower through the granulator, and collecting the granular material falling into the bottom of the tower;

[0038] S30, cooling the dried, screened and surface-treated compound fertilizer granules to about 45° C., and bagging them.

[0039] S40, according to the detection standards and methods of compound fertilizer caki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com