Composite anode for direct methanol fuel cell and method for making the same

A methanol fuel cell and composite anode technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of low power density of fuel cell systems, slow methanol electrooxidation rate, poor performance of battery systems, etc., to improve performance and Its stability, increased maximum power density, and ease of handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

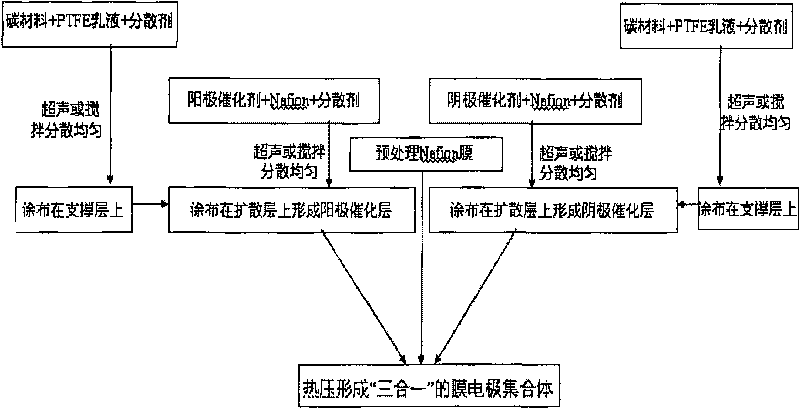

Method used

Image

Examples

Embodiment 1

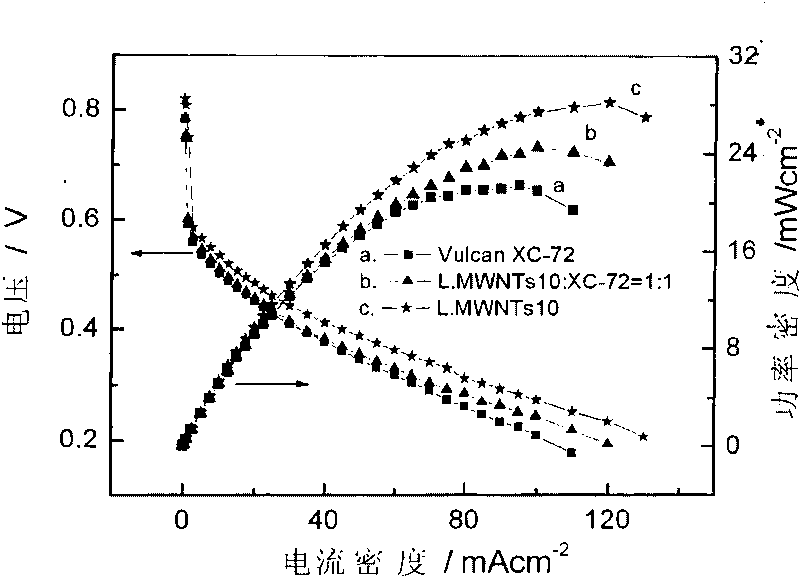

[0024] Embodiment 1 Different carbon materials are used as preparation and application of anode MPL

[0025] 1. Weigh 19.8mg of Vulcan XC-72 into container a, put 19.7mg of MWNTs into container b, add 9.8mg of Vulcan XC-72 and 9.8mg of MWNTs into container c, and then add 40mg of mass hundreds of A PTFE emulsion with a concentration of 12.4wt% and a mixture of 1 mL of water and isopropanol (the volume ratio of isopropanol to water is 1:1) were used as a binder and a dispersant, and ultrasonically dispersed for 2 hours to obtain a uniform slurry.

[0026] 2. take by weighing 80.3mg Pt-Ru black, add 100mg ultrapure water after all catalysts are wetted, add the Nafion solution that 267.3mg mass ratio concentration is 5.3wt%, then add the mixed solution of 3mL water and isopropanol (isopropanol The volume ratio of propanol and water is 1:1) as a dispersant, and the temperature is controlled below 40°C for ultrasonic dispersion for 2 hours.

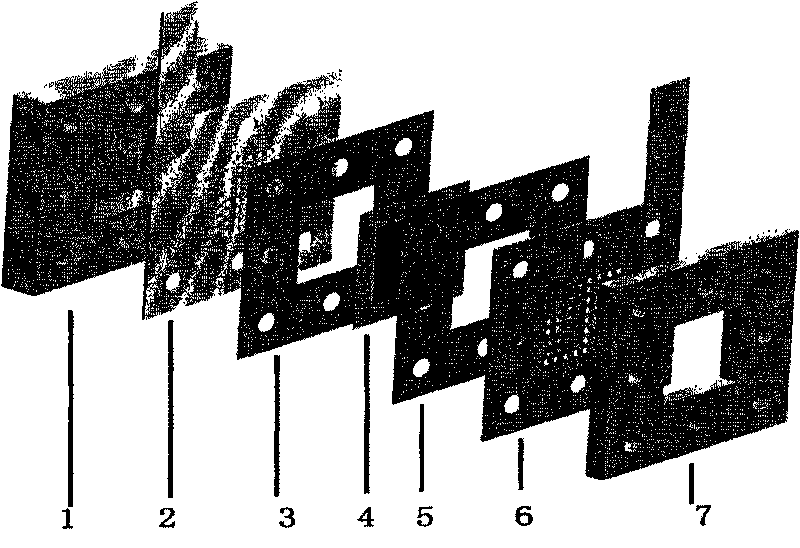

[0027] 3. Take 3 pieces of carbon pape...

Embodiment 2

[0031] Example 2 Preparation and application of different types of carbon nanotubes as anode MPL

[0032] 1. Weigh 20mg of S.MWNTs, L.MWNTs, L.SWMTs, L.DWNTs (where S means short tube, L means long tube, and the carbon nanotubes used are all products of Shenzhen Nanometer Port Co., Ltd., with a purity greater than 95 %) is placed in container A, B, C, D, then respectively in 4 containers, add 40mg mass ratio concentration and be the mixed solution of 12.4wt.% PTFE emulsion and 1mL water and isopropanol (the mixture of isopropanol and water The volume ratio is 1:1) as the binder and dispersant, and the uniform slurry can be obtained by ultrasonic dispersion for 2 hours.

[0033] 2. take by weighing 110mg Pt-Ru black, add 140mg ultrapure water after all catalysts are wetted, add the Nafion solution that 367mg mass ratio concentration is 5.3wt.%, then add the mixed solution of 4mL water and isopropanol (isopropanol The volume ratio of alcohol and water is 1:1) as a dispersant, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com