Self-healing high-voltage dry-type capacitor

A capacitor and self-healing technology, applied in the field of capacitors, can solve problems such as increased charge and discharge time, and achieve the effects of increasing power, increasing maximum power density, and increasing diffusion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

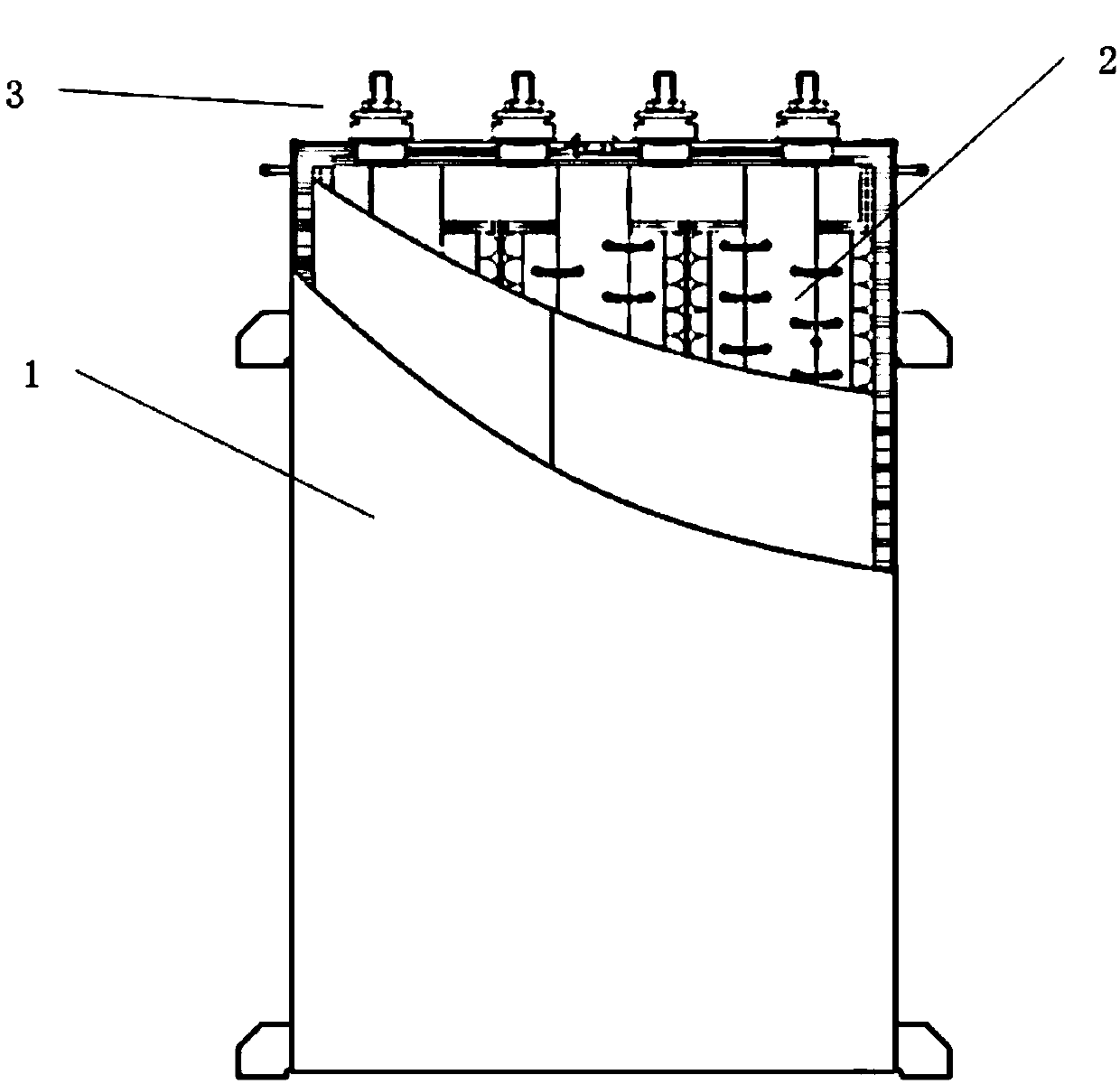

[0029] please see figure 1 Cooperate Figure 6 The presented content, the present invention is about a self-healing high-voltage dry capacitor, which is characterized in that it includes:

[0030] Housing 1, self-healing high-voltage dry-type capacitor body 2, the self-healing high-voltage dry-type capacitor body 2 is arranged in the housing 1, and the self-healing high-voltage dry-type capacitor body 2 includes a pole plate 21, The pole plate 21 includes a substrate 211, and an activated carbon cloth (activated carbon cloth, ACC) 212 is arranged on the surface of the substrate 211. The material of the activated carbon fiber cloth 212 is made of polyacrylonitrile (polyacrylonitrile, PAN). The surface of the activated carbon fiber cloth 212 is provided with carbon nanotubes (Carbon Nanotube, CNT) 213 .

[0031] Since the carbon nanotubes 213 contribute to the diffusion rate of ions in the electrode 21, the shortcomings of the conventional activated carbon fiber cloth are impr...

Embodiment 2

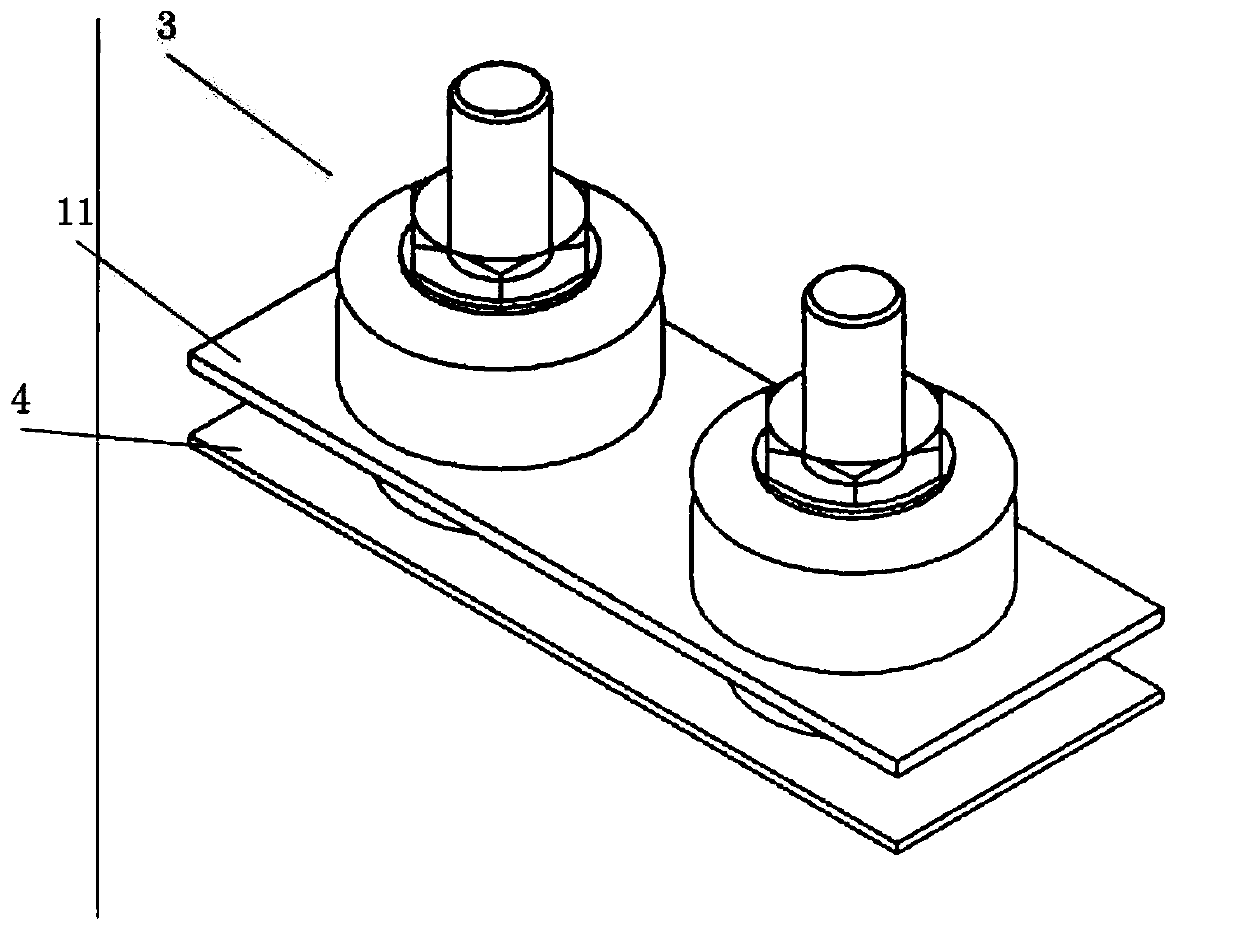

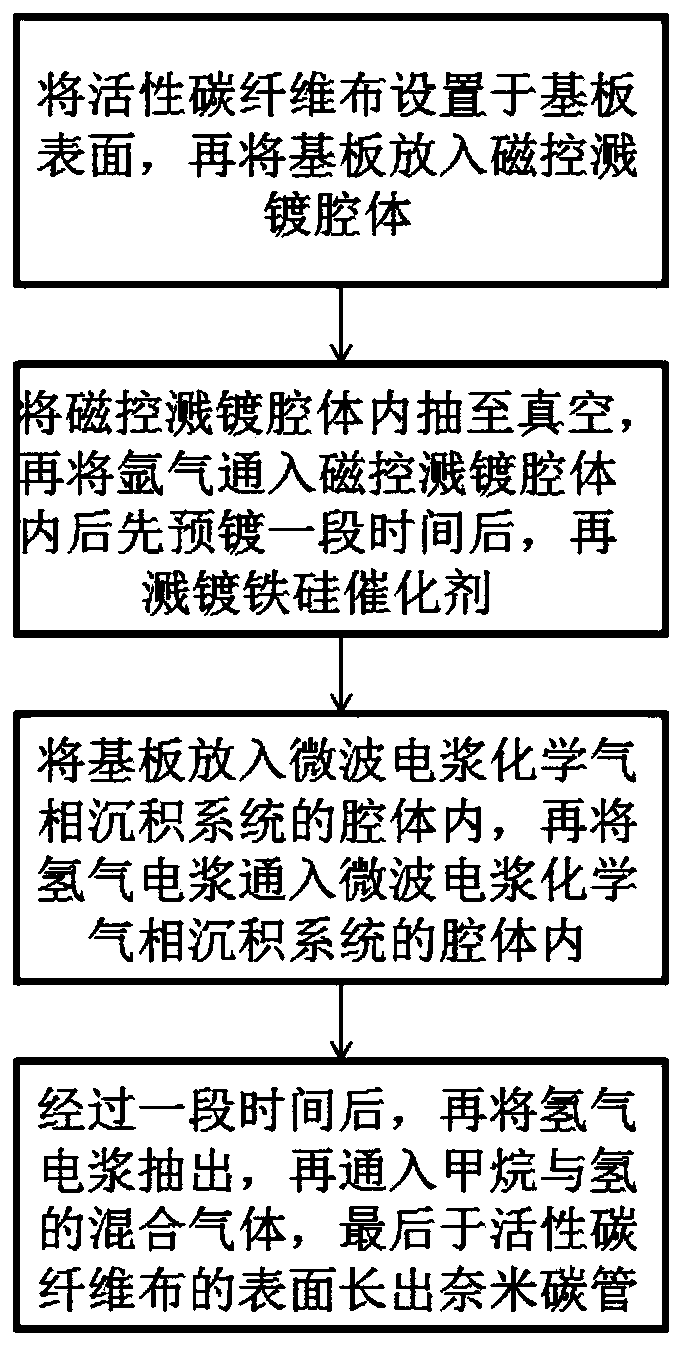

[0033] please see figure 2 Cooperate Figure 6 Presented content, the following begins to introduce the manufacturing method of the polar plate 21:

[0034] First, the activated carbon fiber cloth 212 is arranged on the surface of the substrate 211, wherein the specific surface area of the activated carbon fiber cloth 212 is preferably 1126m 2 / g, the average fiber diameter is preferably 6-7 μm. Put the substrate 211 into the magnetron sputtering chamber, and then evacuate the magnetron sputtering chamber to a vacuum, preferably to a vacuum degree of 2*10 -5 torr so far. Next, argon gas is passed into the magnetron sputtering chamber as a working gas, and after pre-plating for a period of time, iron-silicon (Fe—Si) catalyst is sputtered.

[0035] Put the substrate 211 into the cavity of a microwave plasma chemical vapor deposition system (Microwave Plasma Chemical Vapor Deposition, MPCVD), and then preferably pump the cavity of the microwave plasma chemical vapor deposi...

Embodiment 3

[0037] please see image 3 , the electrolyte of the self-healing high-voltage dry capacitor body is preferably a copolymerized polymer of polyacrylonitrile grafted block polyetherdiamine. In the container, mix cerium ammonium nitrate and nitric acid aqueous solution and then add it into the container, and then add the acrylonitrile into the container after the reaction is completed, and after standing for a period of time, finally obtain the polyacrylonitrile grafted block polyether diamine copolymerized polymer, and then the polyacrylonitrile-grafted block polyether diamine copolymerized polymer was washed several times with polymer water and acetone, and then placed in a ventilated place for drying. After the drying is completed, it is put into dimethylamide for final purification and precipitation. In this way, using the polyacrylonitrile-grafted block polyetherdiamine copolymer polymer as a colloidal electrolyte has better energy storage performance, can increase the capa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com