Patents

Literature

35results about How to "Strong charging and discharging ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

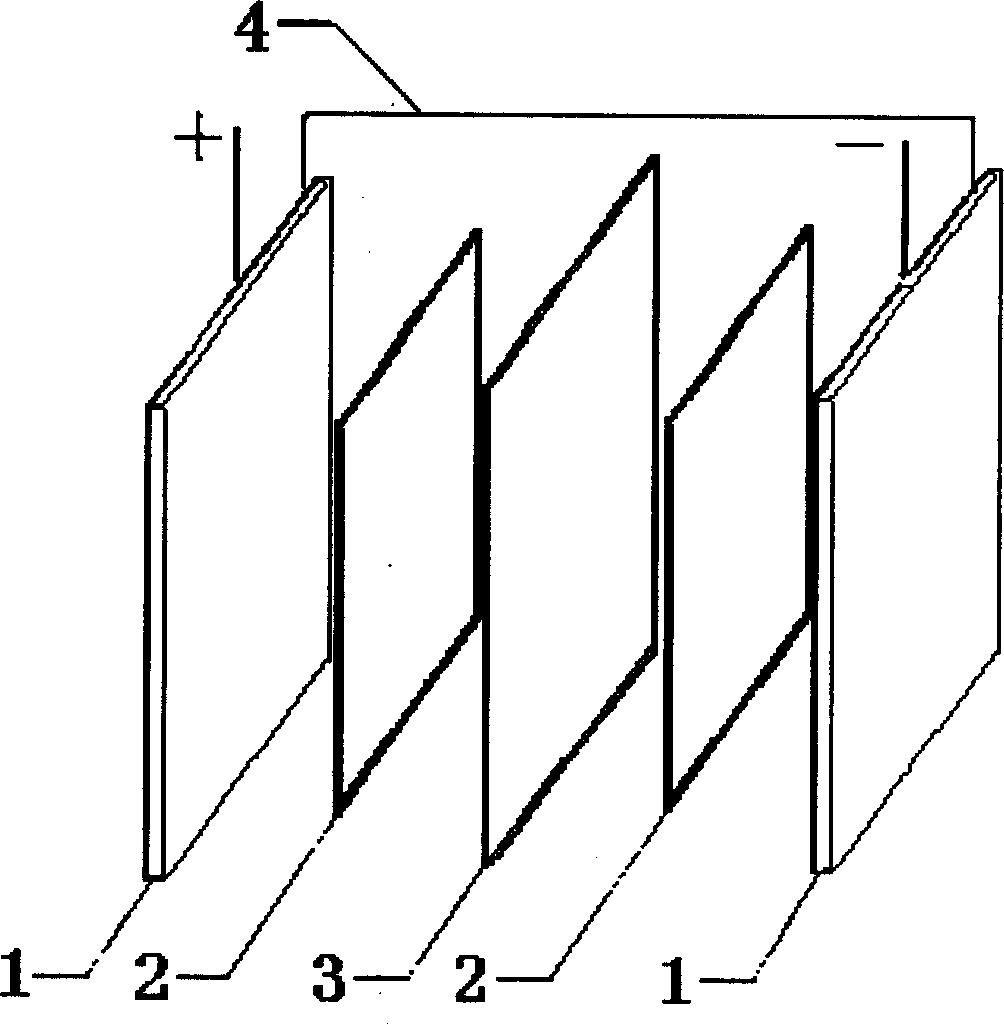

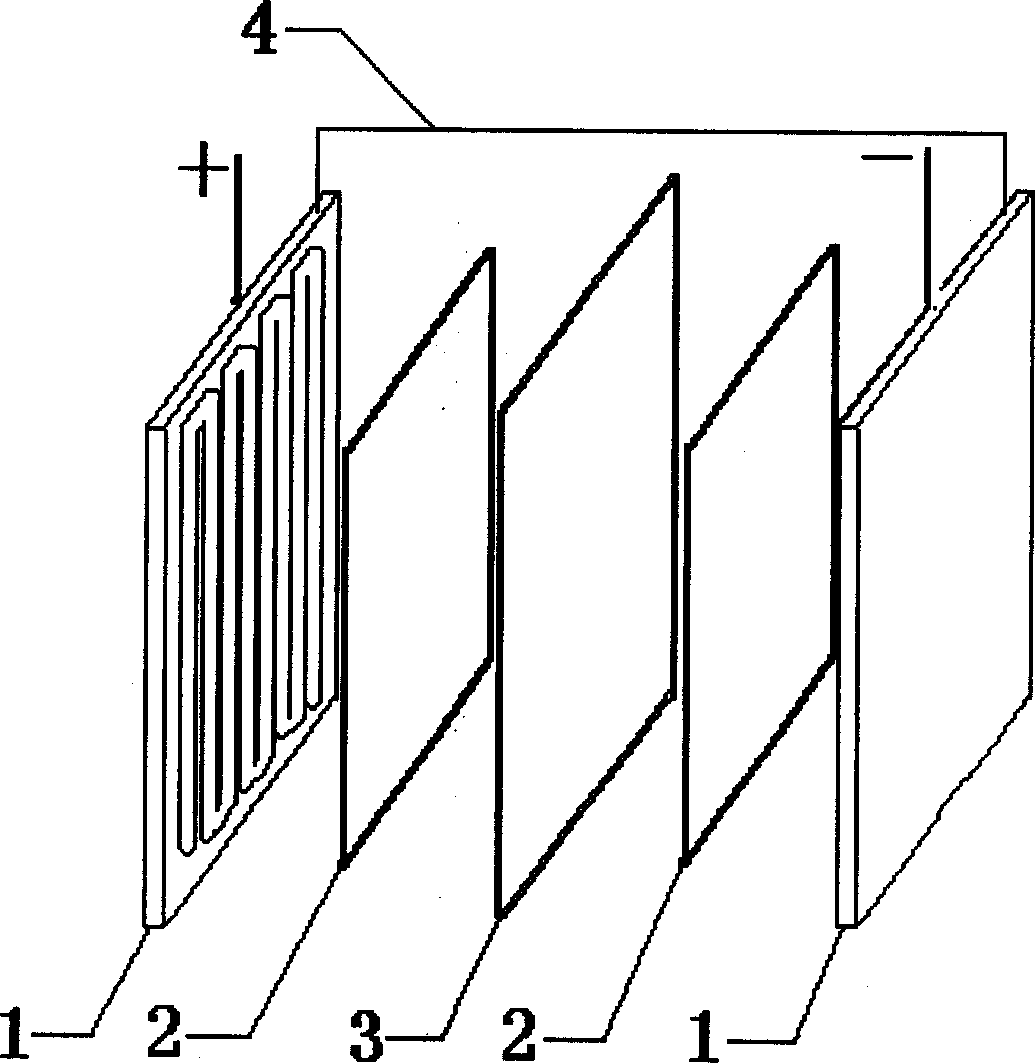

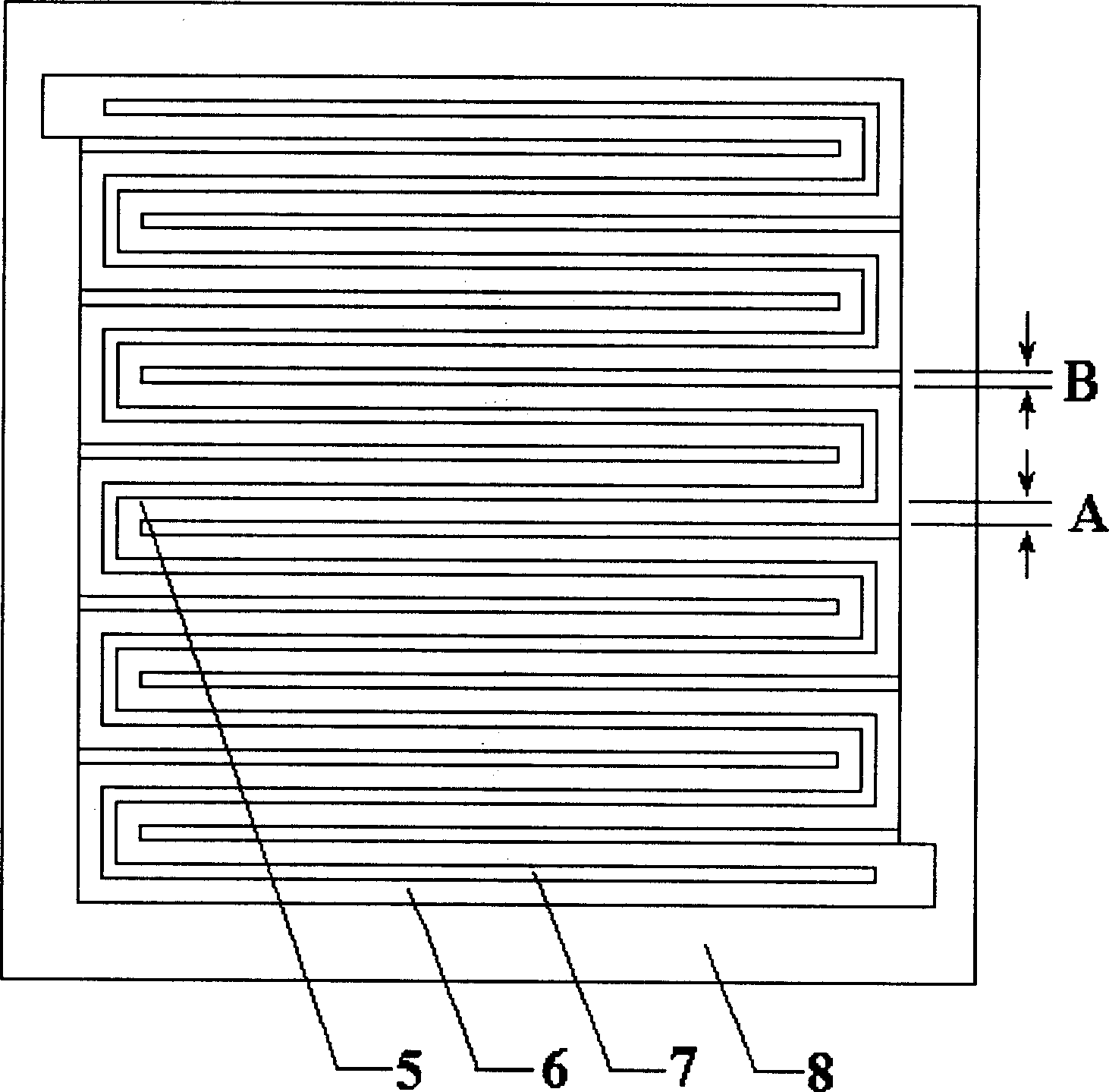

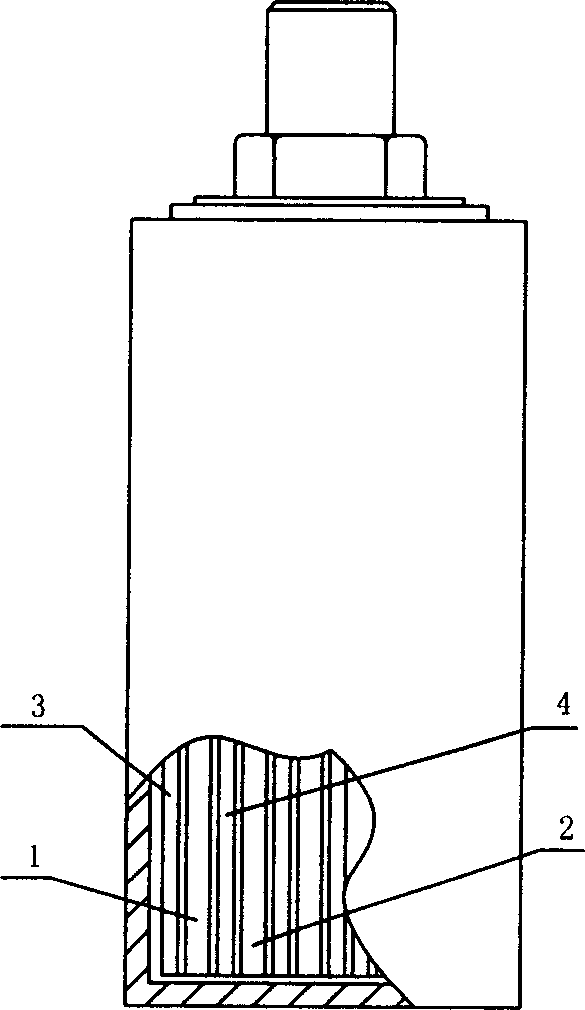

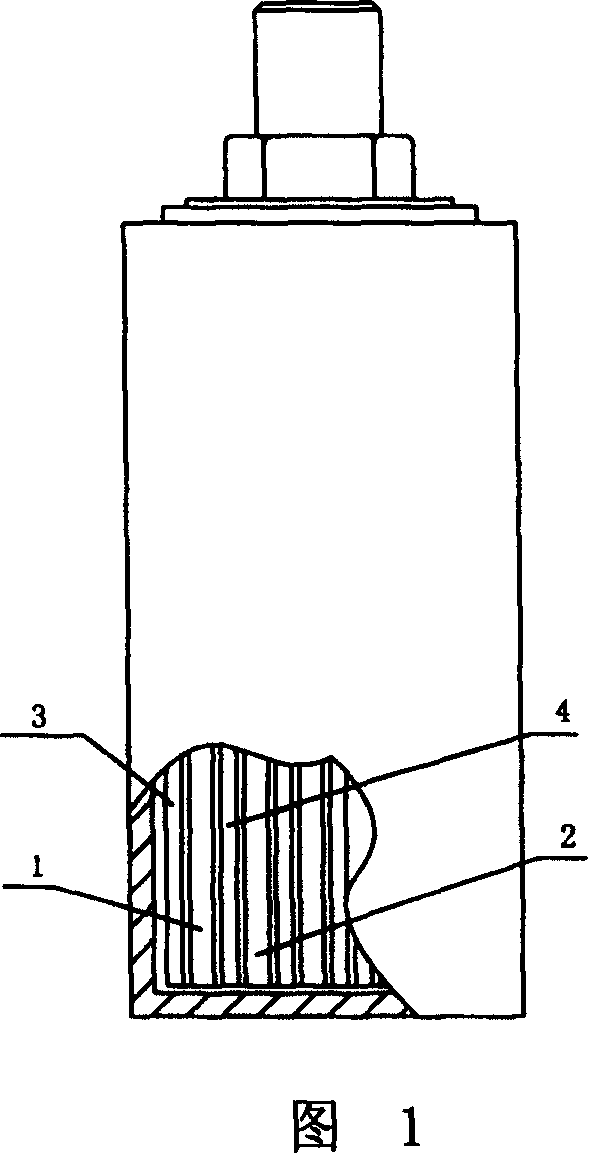

Current collection plate for all vanadium redox flow battery

InactiveCN1845368AAvoid deformationReduce polarizationElectrode carriers/collectorsFuel cellsEpoxyVanadium redox battery

The structure of a collecting board for full-vanadium redox fluid cell comprises: the high-density graphite plate dipped by epoxy resin or phenol resin, and a S-shaped flow field with width rate of ridge and channel as 1:0.5~6 and the rate between the channel depth to channel width as 1:1~5. The advantages of this invention include: 1) small resistance, stable chemical property, and strong ability to bear large current charge / discharge; 2) strong rigidity and intensity; 3) smooth flow of the electrolyte, and little polarization on cell.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

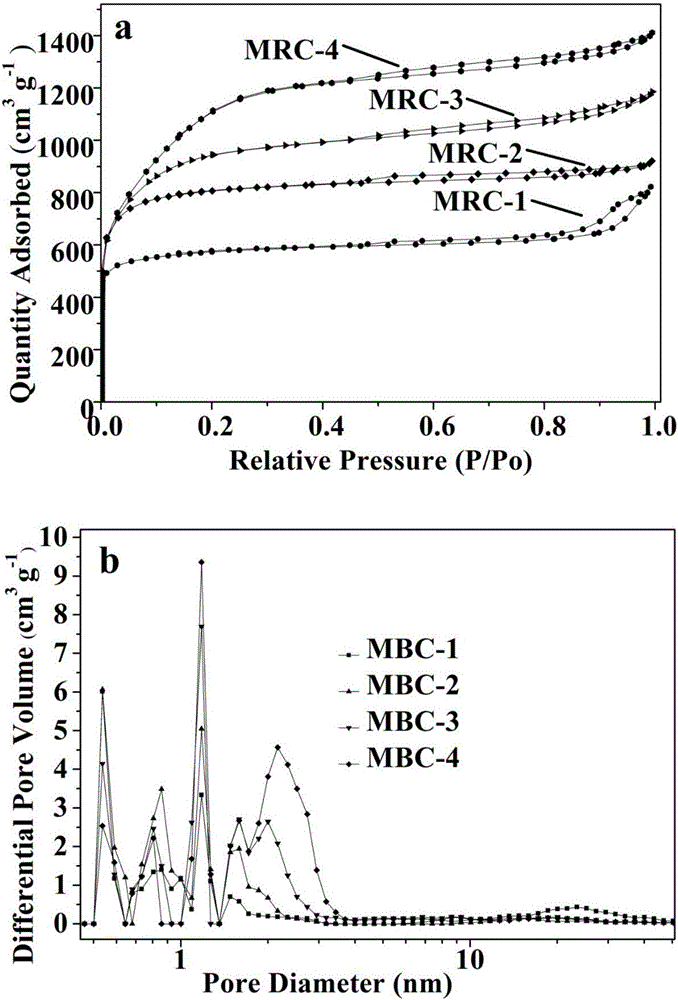

Super capacitor device containing millet-husk-based porous active carbon material

InactiveCN106276888ALow ashLow wettability of the surfaceHybrid capacitor electrodesMicrowave methodFiltration

The invention discloses a super capacitor device containing a millet-husk-based porous active carbon material. The millet-husk-based porous active carbon material is prepared by uniformly mixing dried millet husks and an activator, performing carbonization and activation with a microwave device in the protection of an inert gas, adding distilled water to obtained black powder for suction filtration washing till the pH value is 6.4-7, and performing drying to obtain black powder. The black powder is the prepared millet-husk-based porous active carbon material. The millet-husk-based porous active carbon material (an active substance) prepared through the microwave method is mixed with a binder according to a certain mass ratio, distilled water is added for mixing to prepare a thick liquid, and the thick liquid is repeatedly rolled to obtain a sheet electrode material. The electrode material is put on a current collector with the corresponding size, cold pressing is carried out at 1-40 Mpa for 10-200 s, and drying is performed at 120 DEG C to obtain an electrode plate of the super capacitor device. The electrode material in the electrode plate is more than 14 mg per square centimeter. An electrode plate, a membrane, and an electrode plate are assembled into a sandwich structure, then different electrolytes are dropwise added, so that the super capacitor device is assembled.

Owner:YANGZHOU UNIV

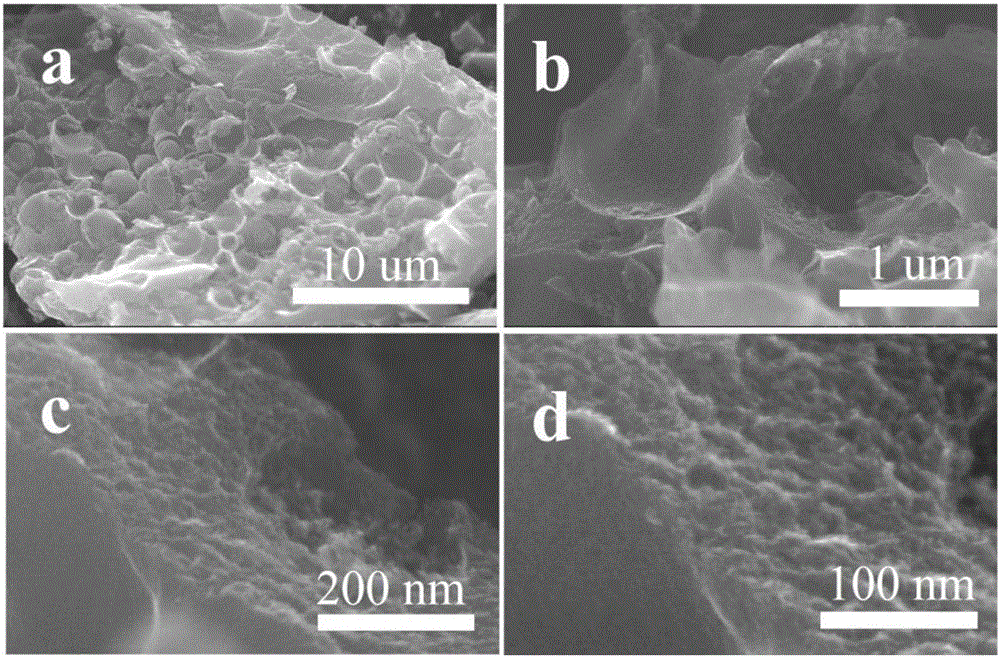

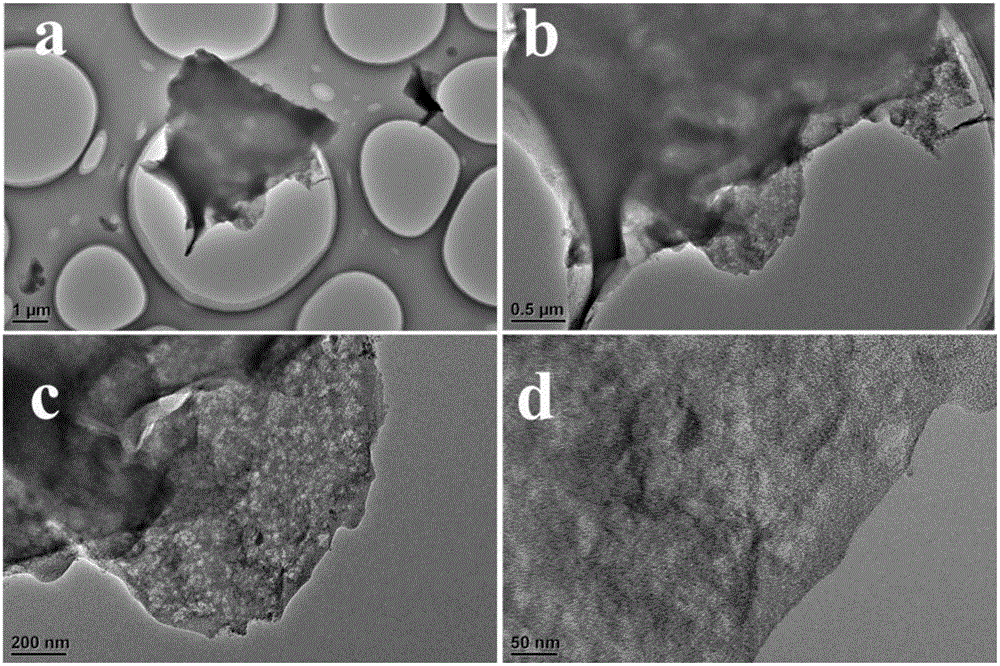

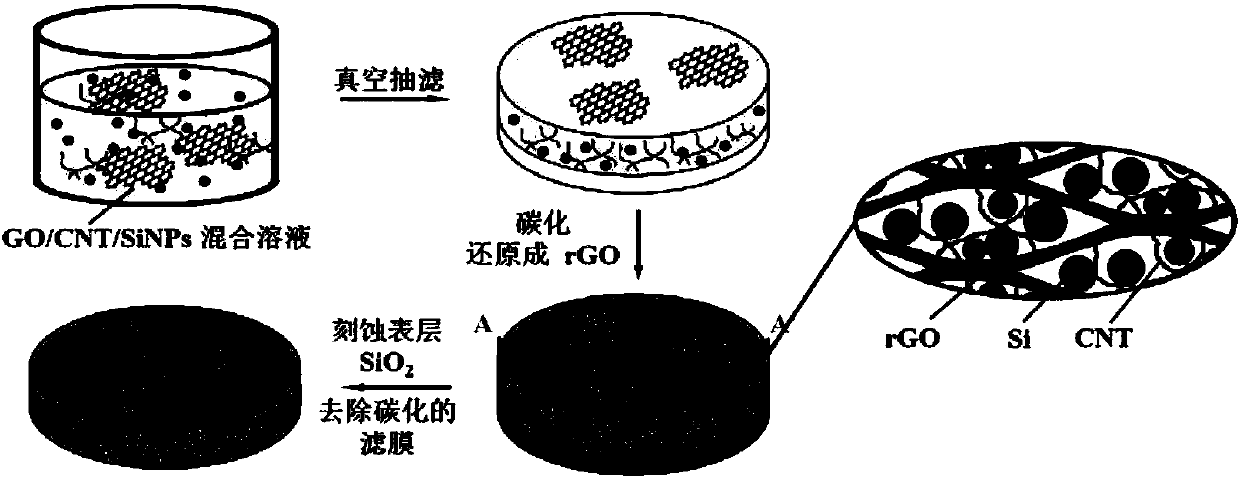

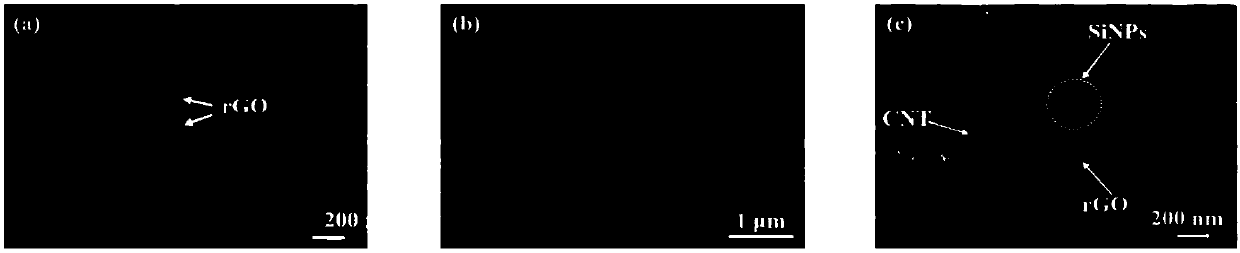

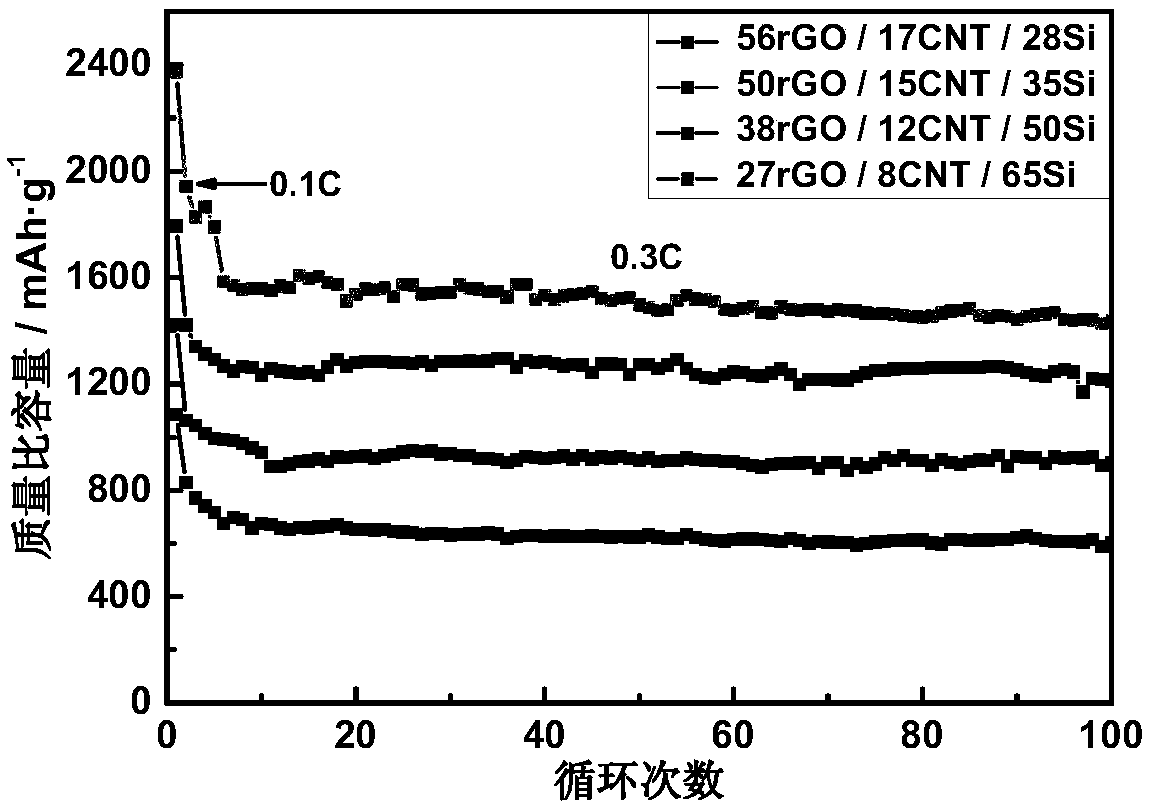

Composite silicon-carbon electrode material with shelly structure

InactiveCN107946570AIncrease capacityImprove cycle performanceCell electrodesSecondary cellsSpatial partitionCarbon nanotube

The invention provides a composite silicon-carbon electrode material with a shelly structure. The composite silicon-carbon electrode material is composed of reduced graphene oxide, silicon nanoparticles and carbon nanotubes, wherein the silicon nanoparticles are dispersed among multiple layers of the reduced graphene oxide; gaps are left between the silicon nanoparticles and the reduced graphene oxide; and the carbon nanotubes prop open the reduced graphene oxide and allow the reduced graphene oxide to include the silicon nanoparticles like shells. The invention also provides preparation and application of the composite silicon-carbon electrode material with the shelly structure. According to the invention, the shelly structure is formed among the layers of the reduced graphene oxide, thecarbon nanotubes provides support among the layers of the reduced graphene oxide and spatial partition for the silicon nanoparticles, so reserved space is left for the volume expansion of silicon during charging and discharging of a battery, and the structural integrity of an active material of a negative electrode can be better maintained; and thus, the battery is allowed to have high capacity which is hard to attenuate, good cyclicity and long service life.

Owner:TSINGHUA UNIV

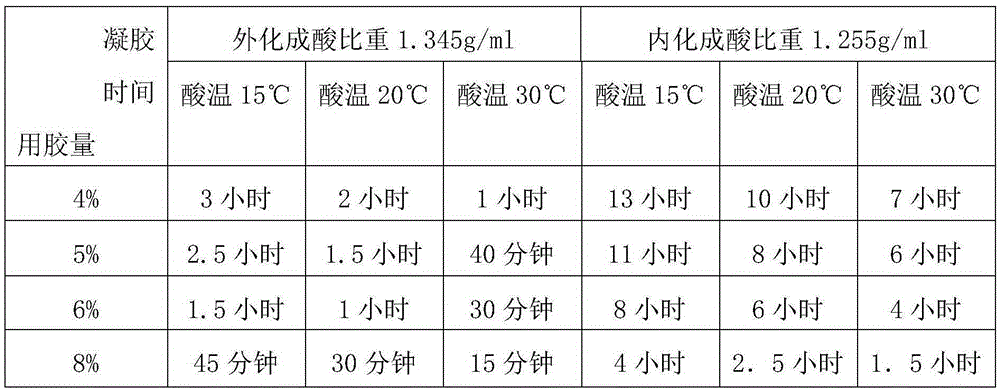

Vehicle battery positive plate lead paste formula

InactiveCN103236523AIncrease specific energyIncrease low temperature capacityLead-acid accumulator electrodesFiberGas phase

The invention provides a vehicle battery positive plate lead paste formula, and relates to a storage battery for vehicle. At present, the lead acid battery faces a dilemma of low specific energy and short life in the technology requirement. The vehicle battery positive plate lead paste formula is characterized in that, the positive plate lead paste formula contains: lead powder 100 kg, short fiber 0.03-0.10 kg, tetracid base type lead sulphate particle 500-1000 g, active carbon 1300-1700 g, carboxymethylcellulose sodium 100-200 g, conductive graphite 200-300 g, polyacrylamide 100-150 g, gas phase silica powder 100-200 g, deionized water 10000-13000g, and 1.30-1.40 g / cm<3> (25 DEG C) sulfuric acid 8000-9000 ml. The invention has the beneficial effects of high specific energy, strong heavy current charge and discharge capability, high low temperature capacity and lasting cycle.

Owner:SHANDONG SACRED SUN POWER SOURCES

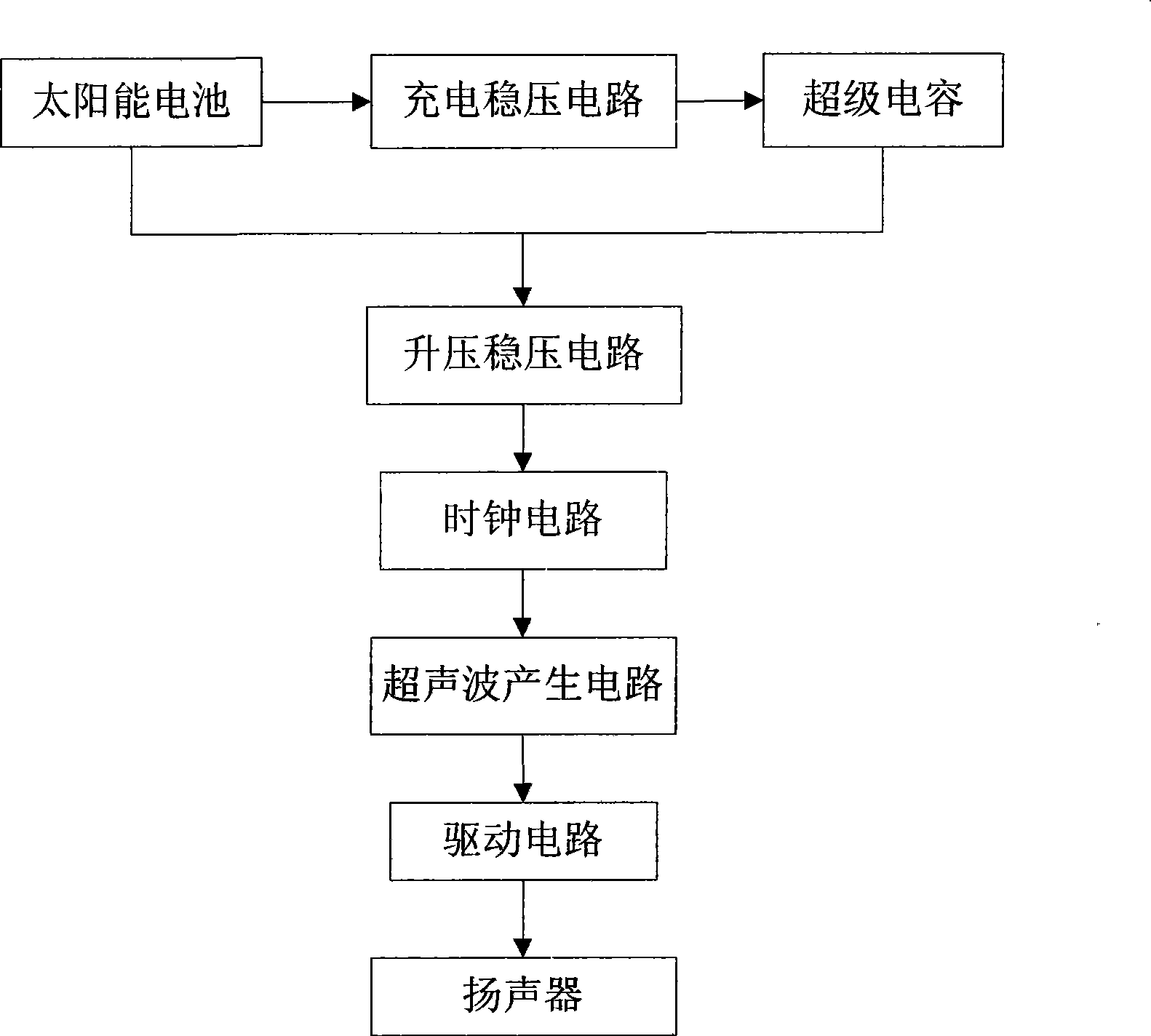

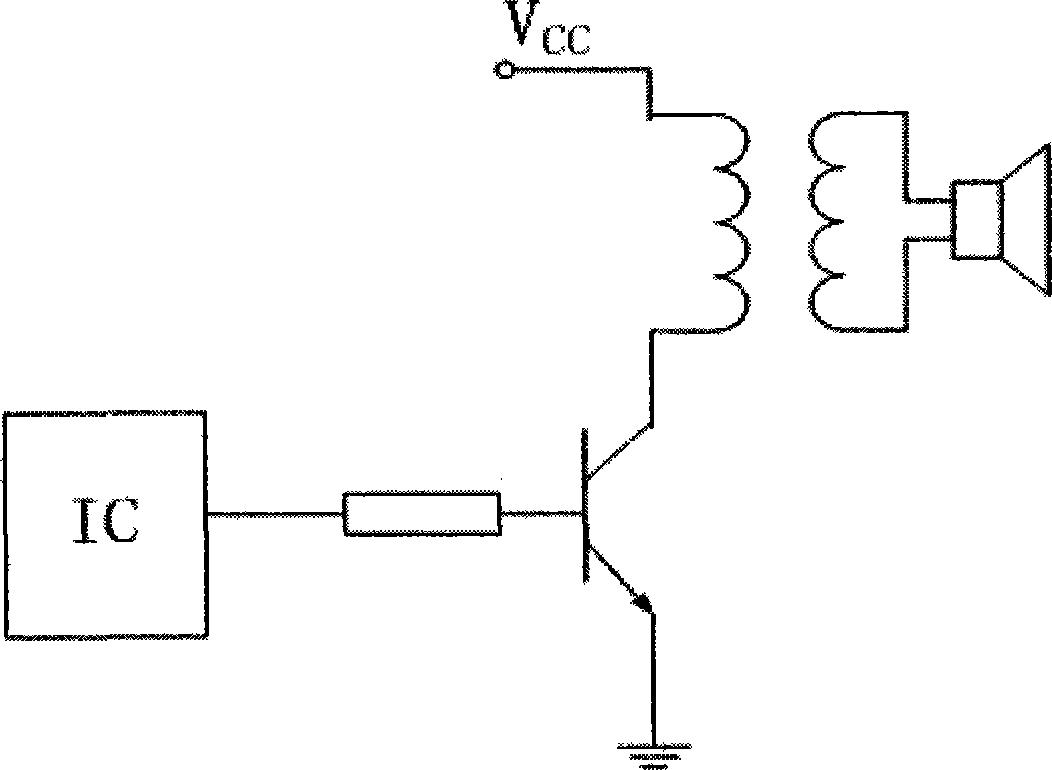

Solar supersonic wave bird driving device for electric power line

InactiveCN101366373ASolve problems where active devices cannot be usedConvenience to workOverhead installationElectrical storage systemCapacitanceTransformer

The invention relates to a solar ultrasonic scarer for a power transmission line for effectively driving off birds on the power transmission line. The device adopts a solar panel as an energy source and a super capacitor as an energy-storing device and utilizes intermissive and large-volume supersonic waves to drive off the birds; the solar panel charges the super capacitor through a voltage stabilizing circuit; the super capacitor is directly connected with a main circuit in the line without regarding control circuits for preventing overshoot and overfall, providing temperature compensation, and the like; a timing chip is used in a main line, controls a supersonic wave generating circuit, and gives out supersonic waves the instant sound pressure level of which is not lower than 90 decibels at regular intervals, and the birds can not adapt to the intermissive supersonic waves, so high effect of driving off the birds is always maintained; and a loudspeaker is driven to give out the large-volume supersonic waves through power amplification and boost of a transformer.

Owner:ZHENGZHOU UNIV

Waste lead-acid storage battery repair activator and preparation method thereof

ActiveCN111180805AEffective protectionNot prone to delaminationLead-acid accumulatorsSecondary cells servicing/maintenanceElectrolytic agentCarbon nanotube

The invention discloses a waste lead-acid storage battery repair activator and a preparation method thereof. The activator is prepared from 15-30 parts by weight of mother liquor, 3-5 parts by weightof carbon nano tubes, 4-7 parts by weight of sodium sulfate, 5-8 parts by weight of cobalt sulfate, 4-9 parts by weight of copper sulfate and 50-70 parts by weight of deionized water, wherein the mother liquor is prepared from 0.2-0.8 wt% of super absorbent resin, 0.5-3 wt% of fumed silica and the balance of deionized water. According to the waste lead-acid storage battery repair activator, decomposition of originally non-conductive lead sulfate is accelerated, it is guaranteed that the temperature of the storage battery is not excessively increased when high-frequency current is activated, the storage battery is effectively protected, and due to the fact that the activating agent is made of super absorbent resin according to the multi-encapsulation theory, electrolyte molecules are wrapped with one another, and the layering phenomenon is not likely to happen.

Owner:内蒙古华贵科技开发有限公司

Start-up battery, application device and server

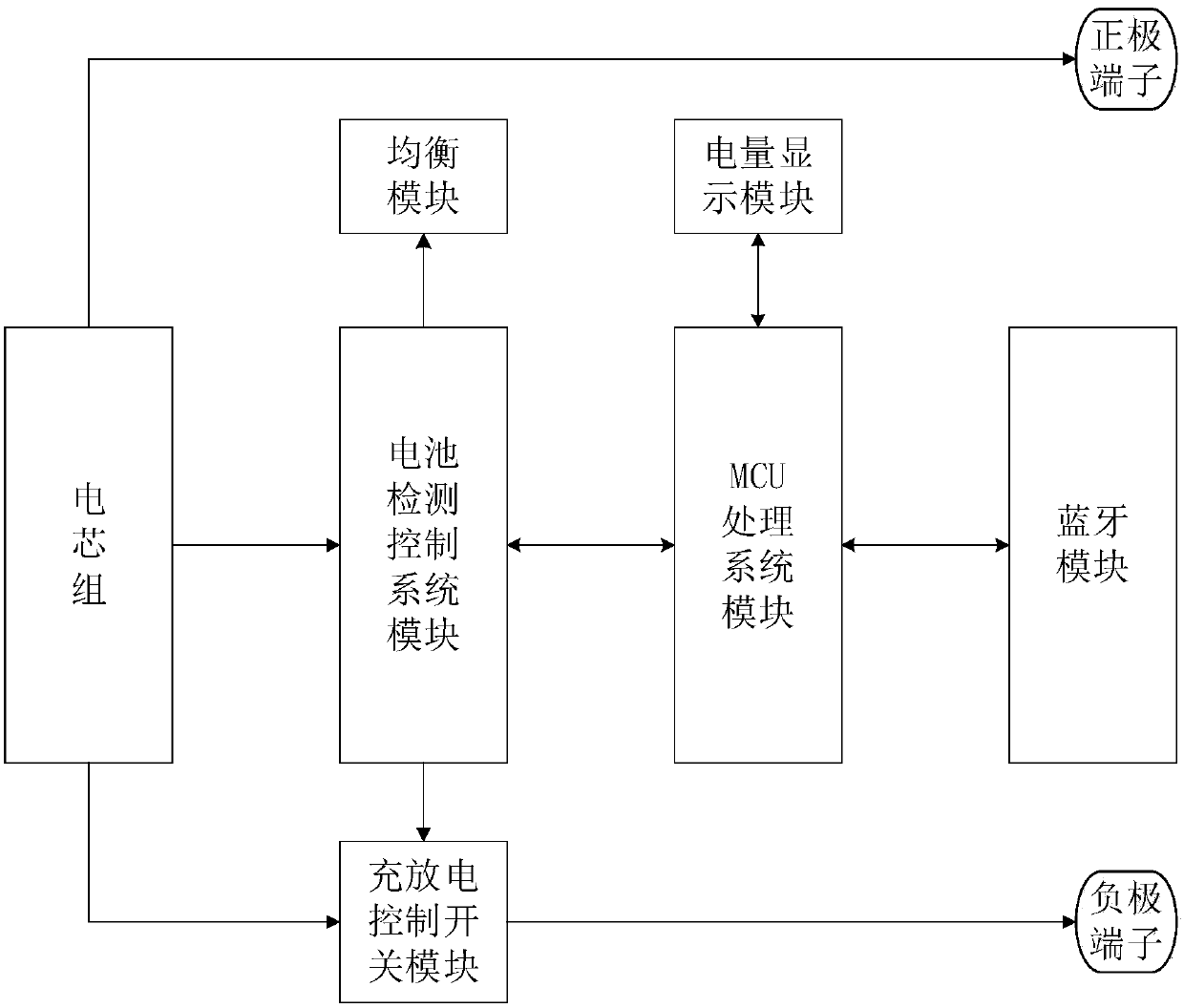

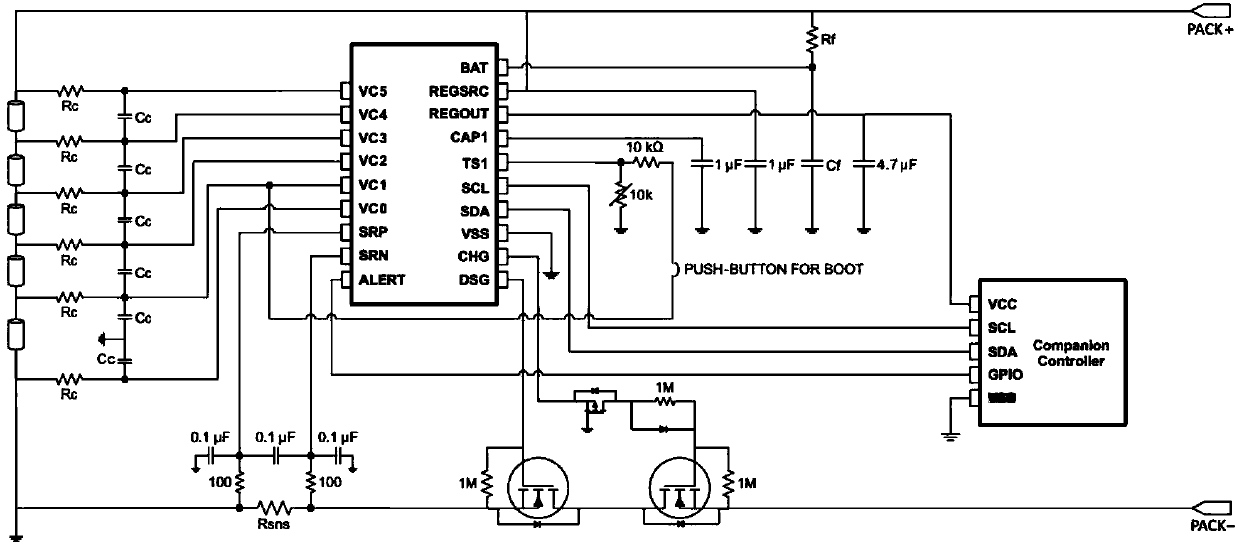

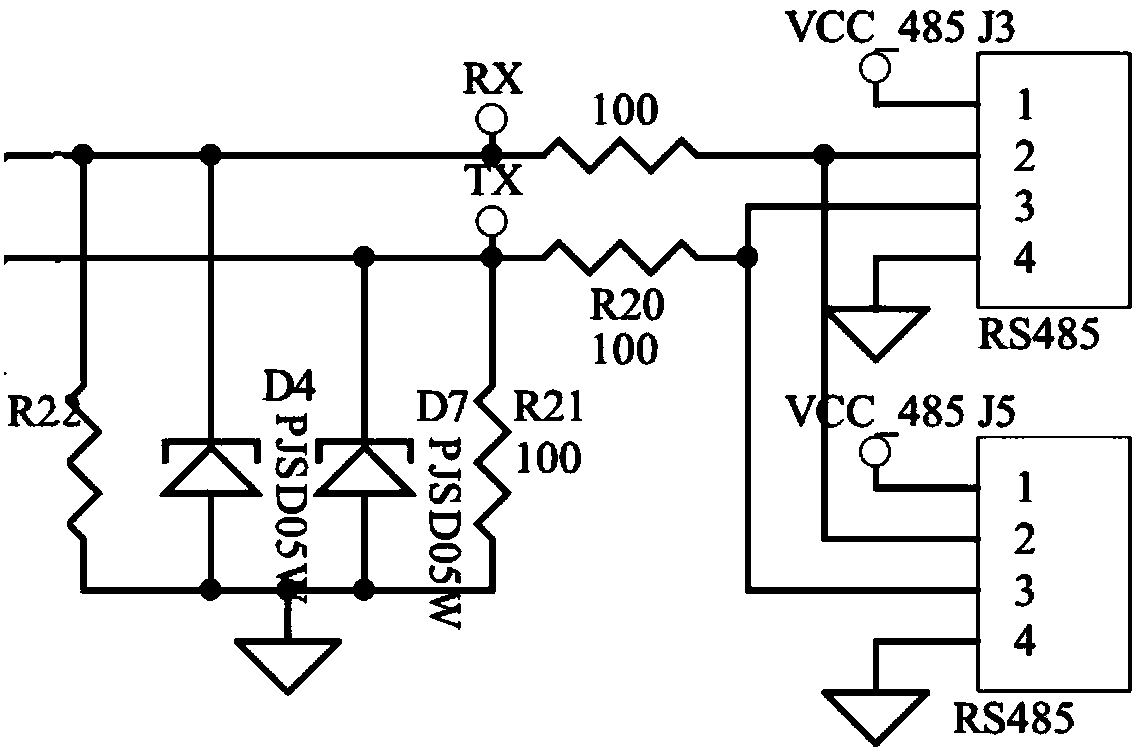

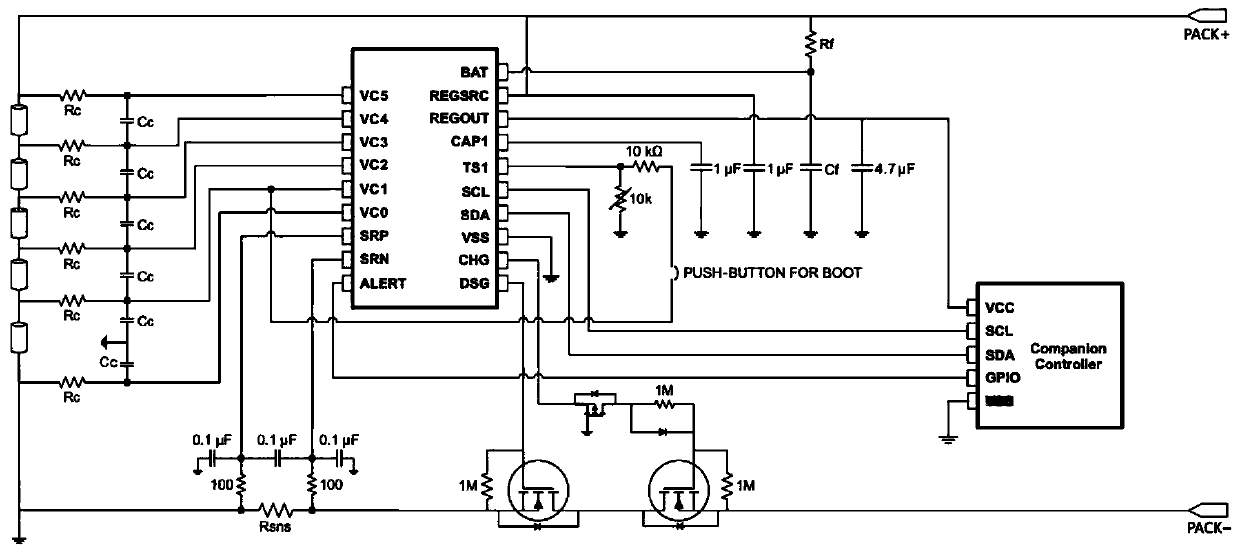

PendingCN107706999AStrong charging and discharging abilityRealistic choiceParallel/serial switchingElectric powerCommunication interfaceControl system

The invention provides a start-up battery, an application device and a server. The start-up battery at least comprises the following modules, components and positive and negative terminals for connecting the application device: a battery pack which is formed by lithium batteries connected in series; a battery detection control system module which comprises an equalizing module and a charging and discharging control switch module and is used for detecting the voltage, the current and the temperature of the battery pack, wherein the equalizing module is used for regulating the voltage differenceof the battery pack, and the charging and discharging control switch module is used for controlling charging and discharging of the battery pack; an MCU processing system module which is connected with the battery detection control system module and a communication interface module for data communication; and the communication interface module which is connected to the server for data transmission with each other through the data link. The start-up battery obtains the circuit protection parameter and the battery parameter for modifying the start-up battery through a Bluetooth module to control the power supply and the power-off condition of the start-up battery so as to prolong the life of the start-up battery.

Owner:GUANGZHOU THALES TECH CO LTD

Lead-tin alloy for long-life lead-acid storage-battery plate grid

The invention discloses a lead-tin alloy for a long-life lead-acid storage-battery plate grid, which comprises the following components in mass percentage: 0.7+ / -0.1 percent of metallic tin and the balance of metallic lead. When the plate grid made of the lead-tin alloy is used, the problems of serious water loss, large self-discharged electricity, large grains, no corrosion resistance and poor charge acceptance capability can not exist, the service life of a battery is prolonged to a large extent, and the quality of the battery is improved to a large extent.

Owner:JIANGSU LEOCH BATTERY

Preparation process of maintenance-free lead storage battery grid lead-bismuth alloy

InactiveCN109786758AStable contentNo generationElectrode carriers/collectorsLead bismuthSelf-discharge

The invention discloses a preparation process of a maintenance-free lead storage battery grid lead-bismuth alloy, wherein the lead-bismuth alloy contains metal lead and metal antimony, the mass percentage of antimony in the lead-bismuth alloy is 0.5+ / -0.1%, and the balance is lead. The grid using the lead-bismuth alloy does not have the problems of serious water loss, large self-discharge, large and no corrosion resistance particles and poor charging acceptance capability, which greatly improves the service life and quality of the battery.

Owner:李彤

Storage battery electrolyte prepared by organic silicon and inorganic silicon

InactiveCN101552354AIncrease capacityExplosiveSilicon organic compoundsNon-metal conductorsPolymer scienceSilicic acid

The invention relates to a storage battery electrolyte prepared by organic silicon and inorganic silicon, which is mainly prepared by inorganic silicic acid and a macromolecular compound, wherein the inorganic silicic acid has obvious thixotropy and does not flow in the static state or the discharging process to achieve the effects of no-overflow and sealing; and inside semi fluid in the charging process enables the conduction to be more smooth to achieve the high capacity of a battery, and the power is strong. The organic polymer is divided into two kinds, and a hydrophobic organosilicon polymer enables the surface of an inorganic particle to be hydrophobized so as to achieve the purposes of no overflow, no condensation and no deposit by being combined with an AGM diaphragm; and the other kind of carbon-oxygen macromolecule forms a surface film on the outermost layer, so the water of the electrolyte cannot volatilize, the acidic material cannot be escaped out to achieve the purpose of free maintenance for life of the battery. The liquid film model with the three-layer structure enables the battery to become a high-performance storage battery with good low-temperature start, strong power, large energy, long service life and free maintenance.

Owner:ANSHAN DUOBIAO STOCK +1

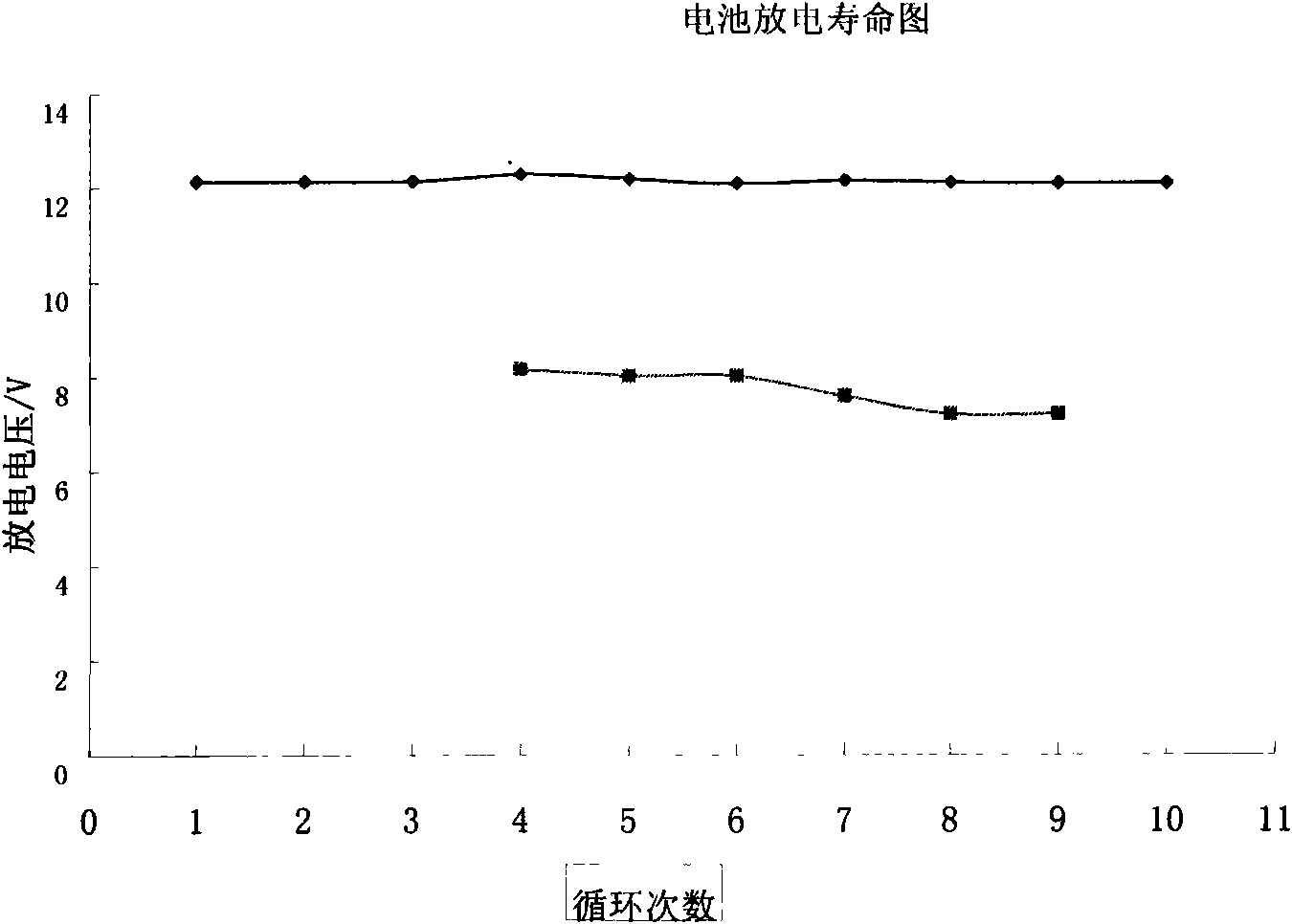

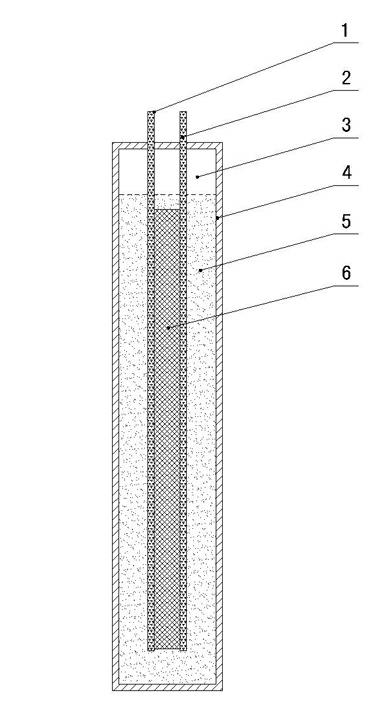

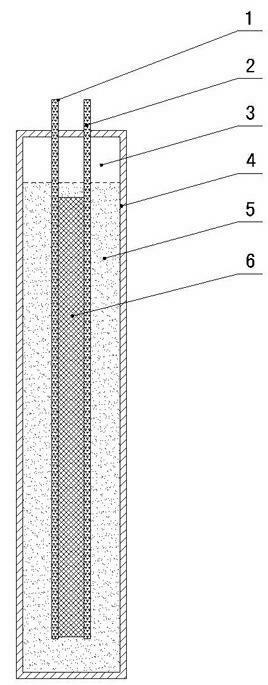

Titanium material capacitance battery

InactiveCN102544600APolarization time is shortShorten the formation timeFinal product manufactureSecondary cellsFluoroboric acidPower storage

The invention discloses a titanium material capacitance battery. The titanium material capacitance battery comprises positive plates, negative plates and a shell, wherein a group of positive plates and negative plates or multiple groups of positive plates and negative plates are arranged in the shell; polymer electrolyte is injected into the shell; a sealing hollow layer is reserved in the shell; the positive plates and the negative plates are manufactured by titanium microplates processed by titanium powder and provided with air permeability, or titanium oxide microplates sintered by the titanium powder, or titanium meshed plates, or titanium foil plates, or surface titanized nickel plates; sponge is arranged among the positive plates and the negative plates; the polymer electrolyte is prepared by adding 1.0 to 2.5 percent of C16H33(CH3)N<+> serving as an additive into a lead tetrafluoroborate solution; and the Pb<2+> content is 20 to 35 percent, the free boric acid content is 1.5 to 3.5 percent and the free fluoroboric acid content is 1.0 to 1.5 percent. By adoption of the structure, the titanium material capacitance battery has the advantages of simple process, large capacity, light weight, long life, low cost, safety, environmental friendliness and the like and can be widely applied in the fields of electric vehicles, electric automobiles, buses, power storage stations, aerospace and national defense.

Owner:ZHEJIANG SHIFENG NEW ENERGY DEV

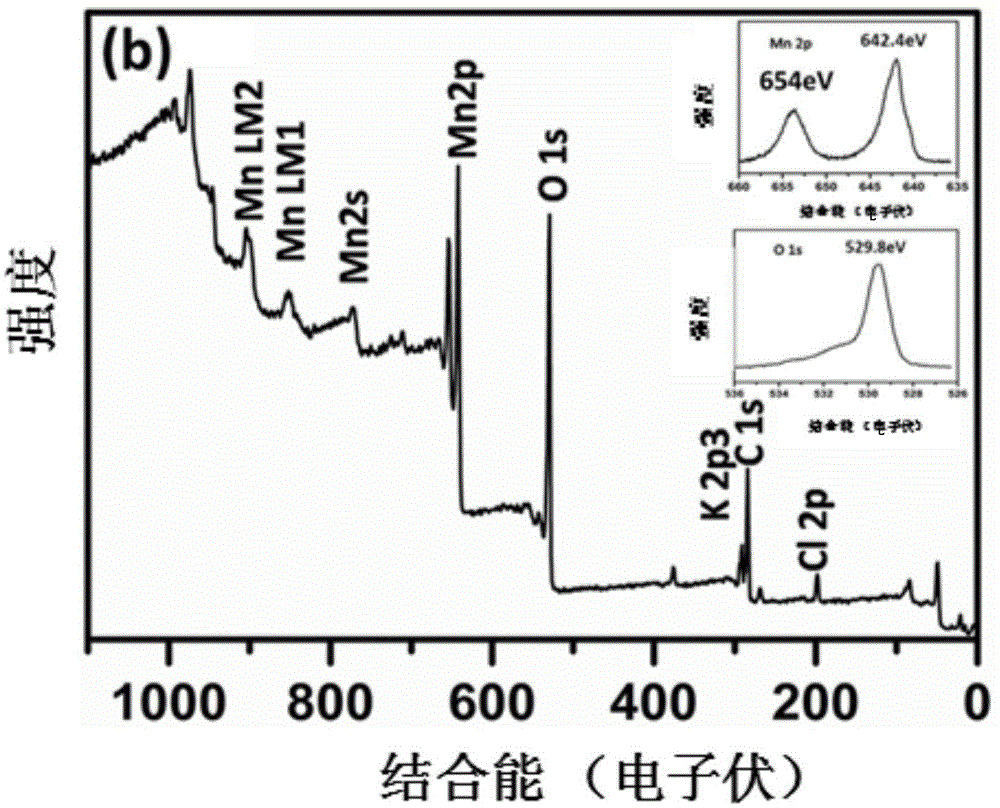

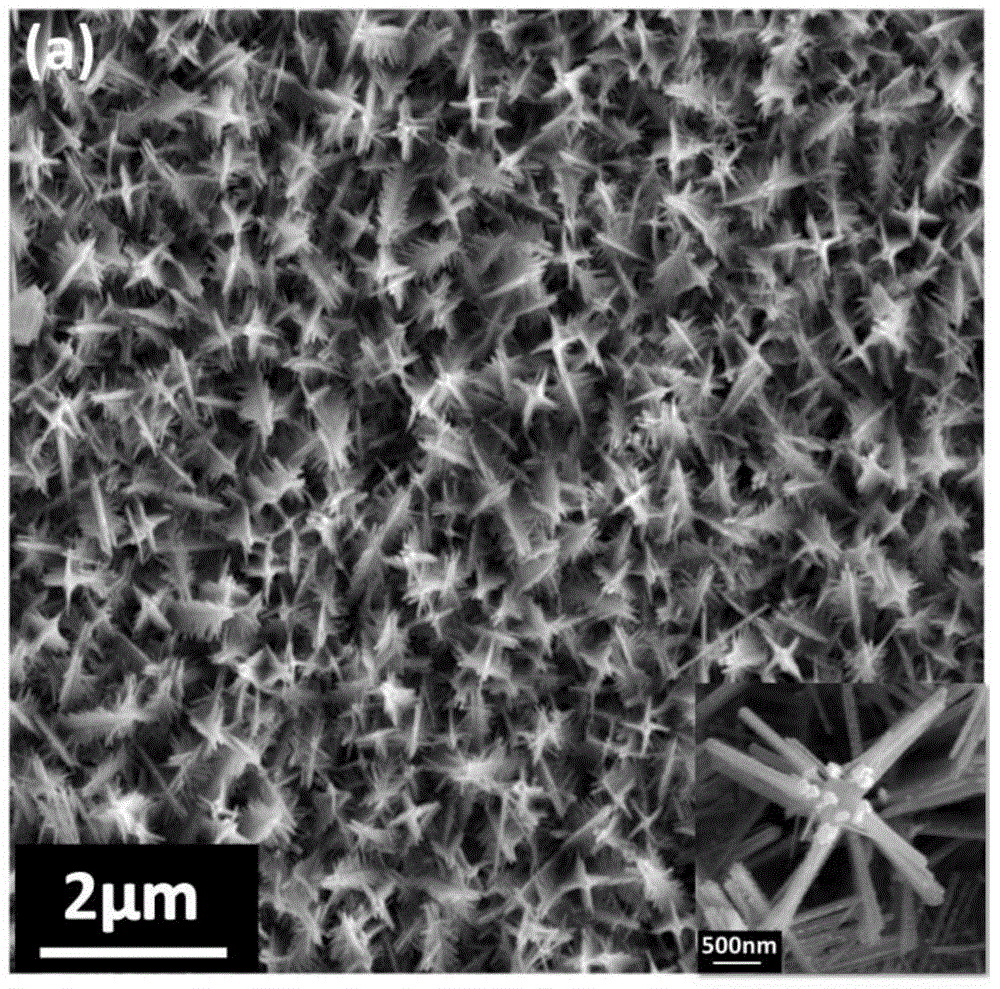

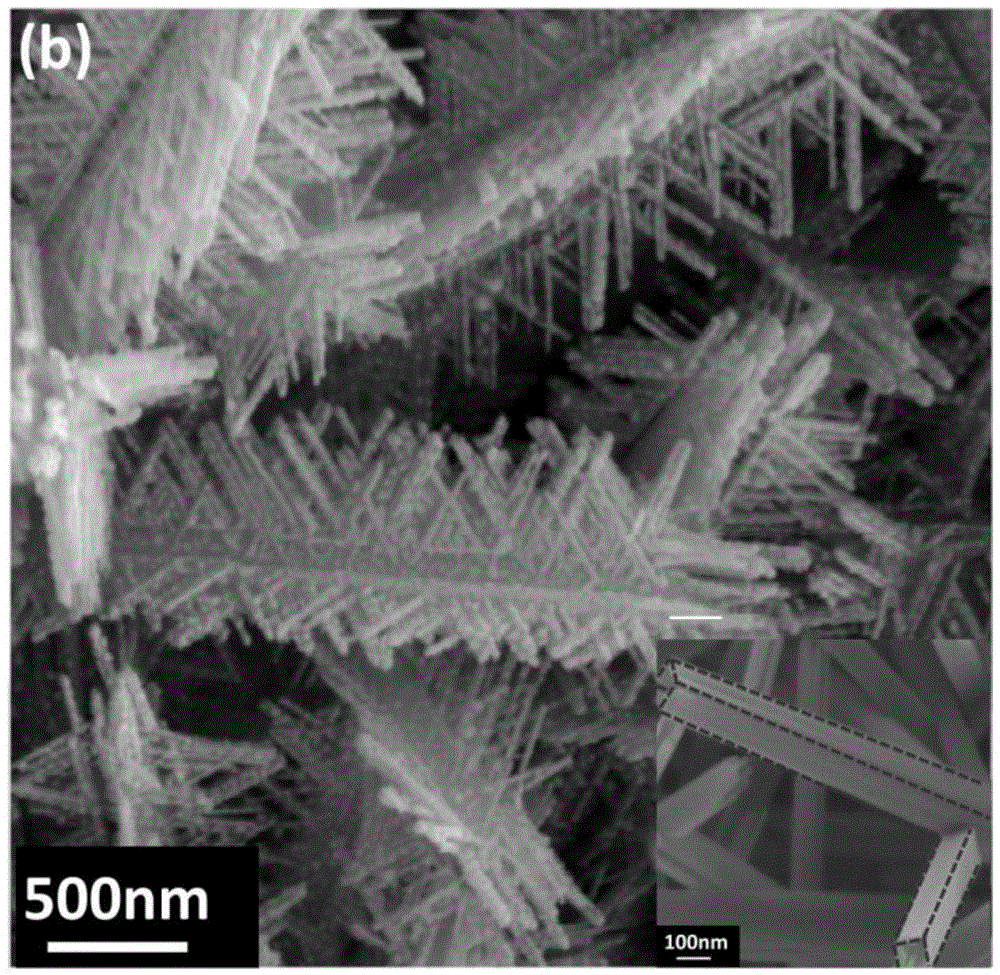

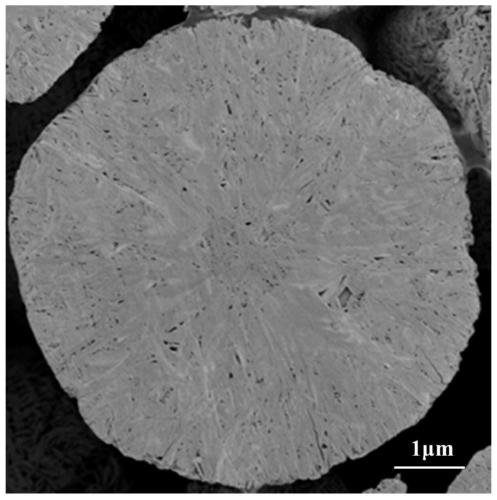

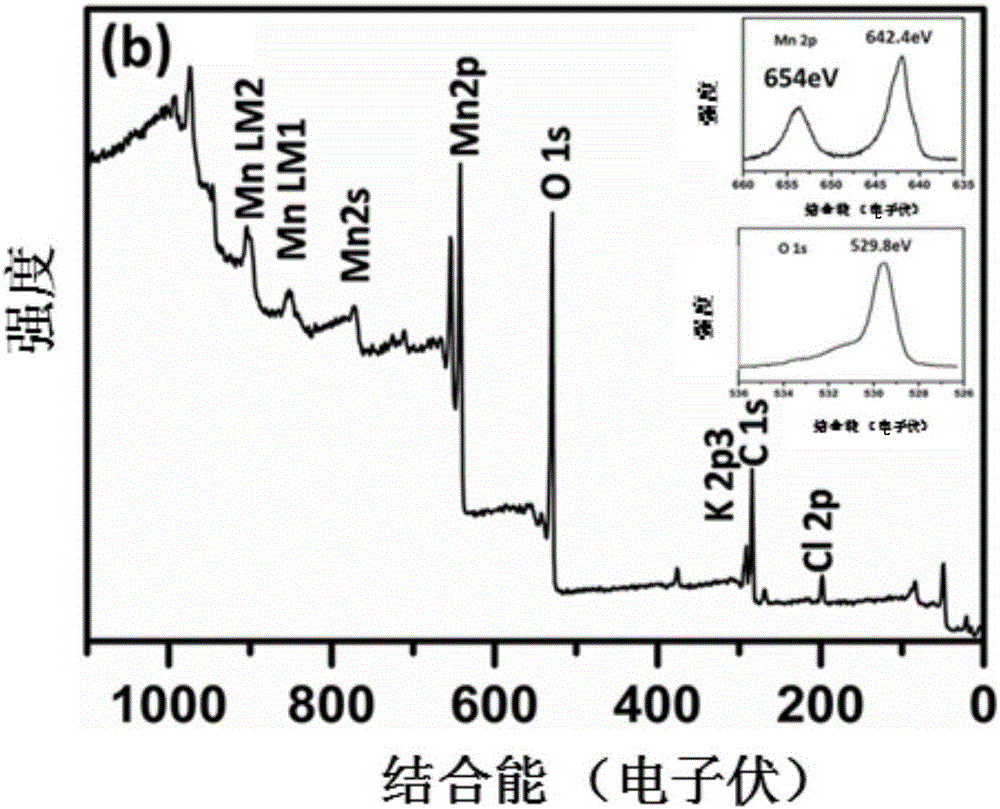

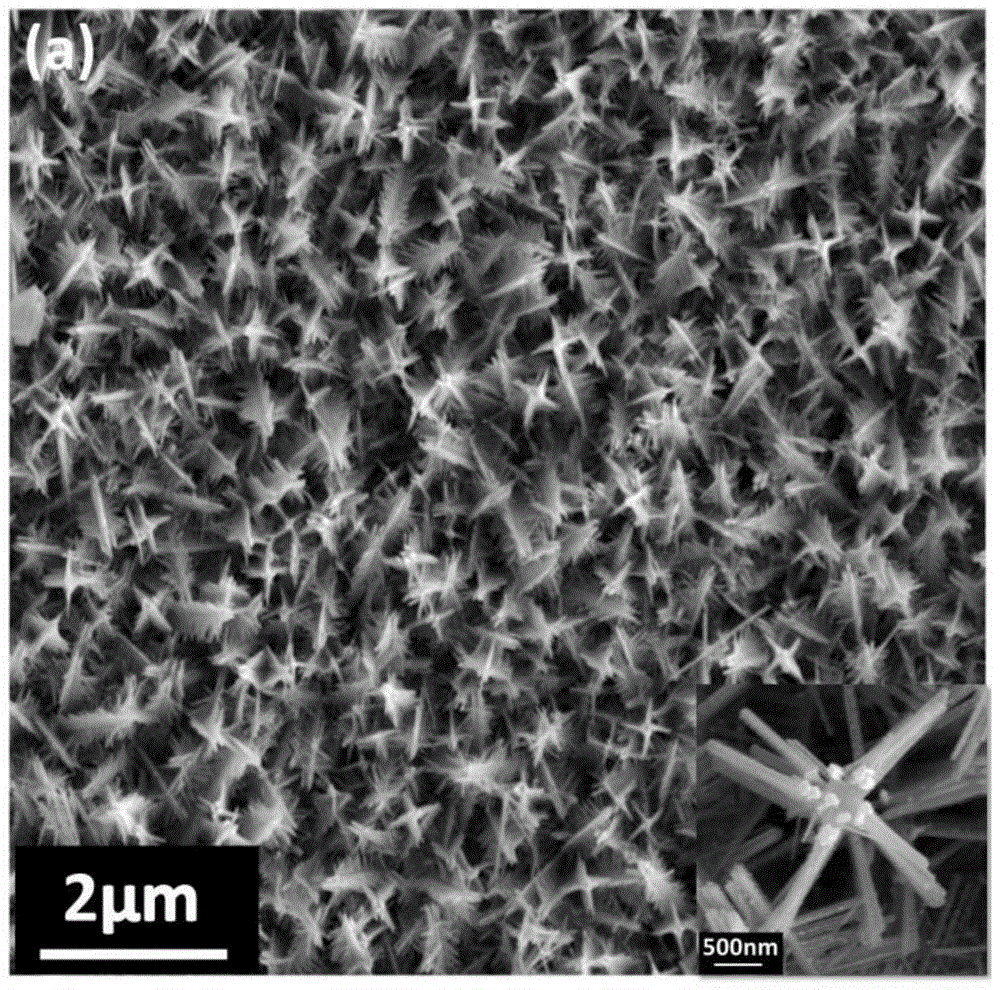

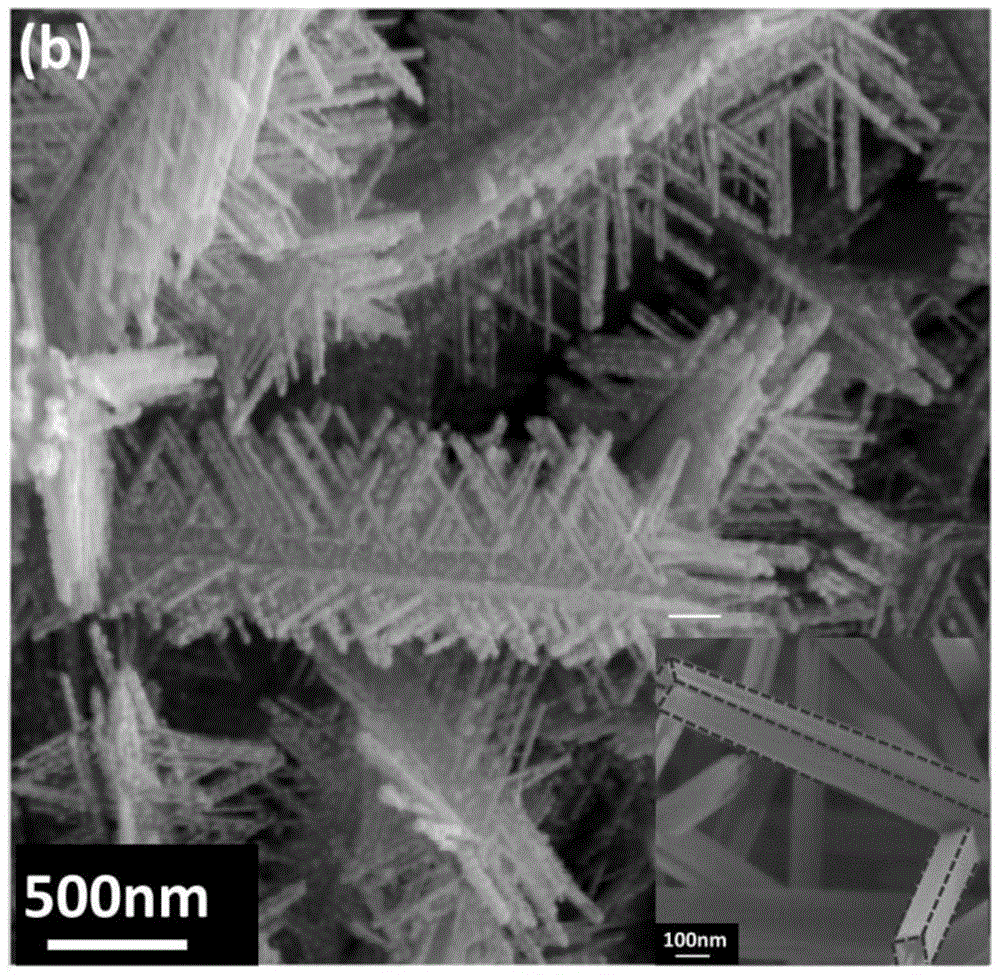

Manganese dioxide dendritic nano array electrode material and preparation method

InactiveCN104658763AImprove conductivityLarge specific surface areaMaterial nanotechnologyHybrid capacitor electrodesManganeseSingle crystal

The invention provides a manganese dioxide dendritic nano array electrode material and a preparation method. Four columns of monocrystal manganese dioxide square nano tube branches grow on four side ridges of a monocrystal manganese dioxide square nano tube trunk of each dendritic manganese dioxide array unit; an included angle between the axial direction of each branch and the axial direction of the trunk ranges from 57 degrees to 62 degrees. The electrode material is synthesized by a two-step hydrothermal method; in the first hydrothermal method process, a single-polished silicon slice is used as a substrate for growing a nano array preliminarily; in the second hydrothermal method process, a single-polished silicon slice with the monocrystal manganese dioxide square nano tube trunk is used as a substrate for growing the nano array secondarily; during secondary growth, the polished surface of the single-polished silicon slice with the monocrystal manganese dioxide square nano tube trunk is placed downwards; during secondary growth, three single-polished silicon slices with the monocrystal manganese dioxide square nano tube trunks are provided; the concentration of raw materials in the secondary growth is lower than that of the raw materials in the preliminary growth.

Owner:NORTHWEST UNIV(CN)

Lithium ion battery processing method

PendingCN113471548AEasy to chooseReduce manufacturing costElectrode rolling/calenderingFinal product manufactureEngineeringLithium-ion battery

The invention belongs to the technical field of lithium ion battery processing, particularly relates to a lithium ion battery processing method, and solves the problems in the prior art that in order to improve the energy density of a lithium ion battery, a thin diaphragm is often selected and used so as to store more electric energy in a limited volume, the reduction of the thickness of the diaphragm increases the production difficulty of the diaphragm, quality defects are easily caused, a positive electrode and a negative electrode cannot be effectively isolated by the diaphragm, and then short circuit and explosion of the battery are caused. The lithium ion battery is composed of a positive electrode, a negative electrode, a diaphragm and an electrolyte, wherein the positive electrode and the negative electrode are soaked in the electrolyte and are separated by the diaphragm. According to the lithium ion battery processing method provided by the invention, the capacity and the safety of the lithium ion battery are improved by optimizing the overall component of the lithium ion battery, potential safety hazards and equipment damage caused by purely reducing the thickness of the diaphragm in the prior art are avoided. The method is simple to operate, low in cost and suitable for large-scale production.

Owner:淮北享锂电子科技有限公司

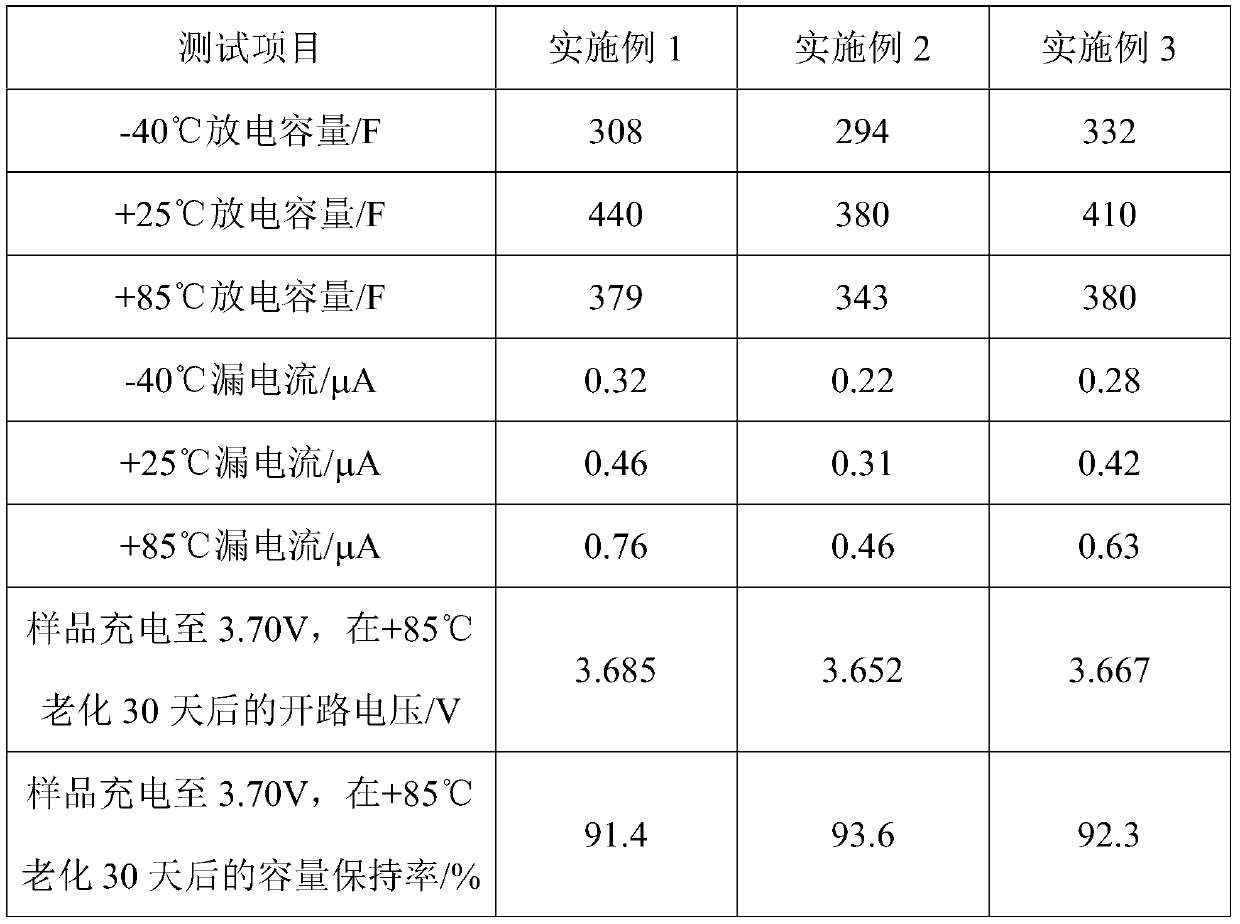

Super lithium ion battery capacitor

PendingCN111081479AExcellent voltage (charge) retentionGood capacity retentionHybrid capacitor electrolytesHybrid capacitor electrodesElectric capacityHigh energy

The invention discloses a super lithium ion battery capacitor. The super lithium ion battery capacitor comprises a capacitor shell, an organic electrolyte located in the capacitor shell, and a batterycell formed by a positive plate, a negative plate and a diaphragm, wherein the positive plate comprises LiNi0.9Co0.09W0.01O2; and the negative plate comprises soft carbon and an artificial graphite material. In view of the problems of low energy density, short service life and narrow applicable voltage range of a super capacitor battery in the prior art, the lithium ion battery capacitor disclosed by the invention has the advantages of high energy density, long service life, strong high-current charge-discharge capacity, wider use temperature range and voltage range, extremely low leakage current (self-discharge rate), and very excellent voltage (charge) retention rate and capacity retention rate.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Fabrication method of maintenance-free batter grid alloy

InactiveCN109755584ANot easy to oxidizeNot easy to loseElectrode carriers/collectorsTitaniumTitanium alloy

The invention discloses a fabrication method of maintenance-free batter grid alloy. Lead titanium alloy comprises metal lead and metal titanium, the titanium mass percent of the lead titanium alloy accounts for 0.5+ / -0.1%, and the balance is lead. By using the grid of the lead titanium alloy, the problems of serious water loss, large self-discharging, large particle, no corrosion resistance and poor charging acceptance capability are prevented, the service lifetime of the battery is prolonged to a great extent, and the quality of the battery is prolonged.

Owner:张志炜

A kind of manganese dioxide dendritic nano-array electrode material and its preparation method

InactiveCN104658763BImprove conductivityLarge specific surface areaHybrid capacitor electrodesHybrid/EDL manufactureSingle crystalManganese oxide

The invention provides a manganese dioxide dendritic nanoarray electrode material and a preparation method. Each dendritic manganese dioxide array unit has four rows of single crystals grown on the four side edges of the backbone of a single crystal manganese dioxide square nanotube. Manganese dioxide square nanotube branches; the angle between the axis of the branches and the axis of the main trunk is in the range of 57° to 62°. It is synthesized using a two-step hydrothermal method; in the first step of the hydrothermal method, a single-polish silicon wafer is used as a substrate to grow the nanoarray at once; in the second step of the hydrothermal method, a single crystal manganese dioxide square nanotube backbone is grown. The single-polished silicon wafer is used as a substrate for secondary growth of the nanoarray; during the secondary growth, the single-polished silicon wafer with the single crystal manganese dioxide square nanotube backbone is placed with the polished side downward; during the secondary growth, the growth is The single-crystal manganese dioxide square nanotube has three single-throw silicon wafers; the concentration of raw materials in the secondary growth is lower than that in the primary growth.

Owner:NORTHWEST UNIV

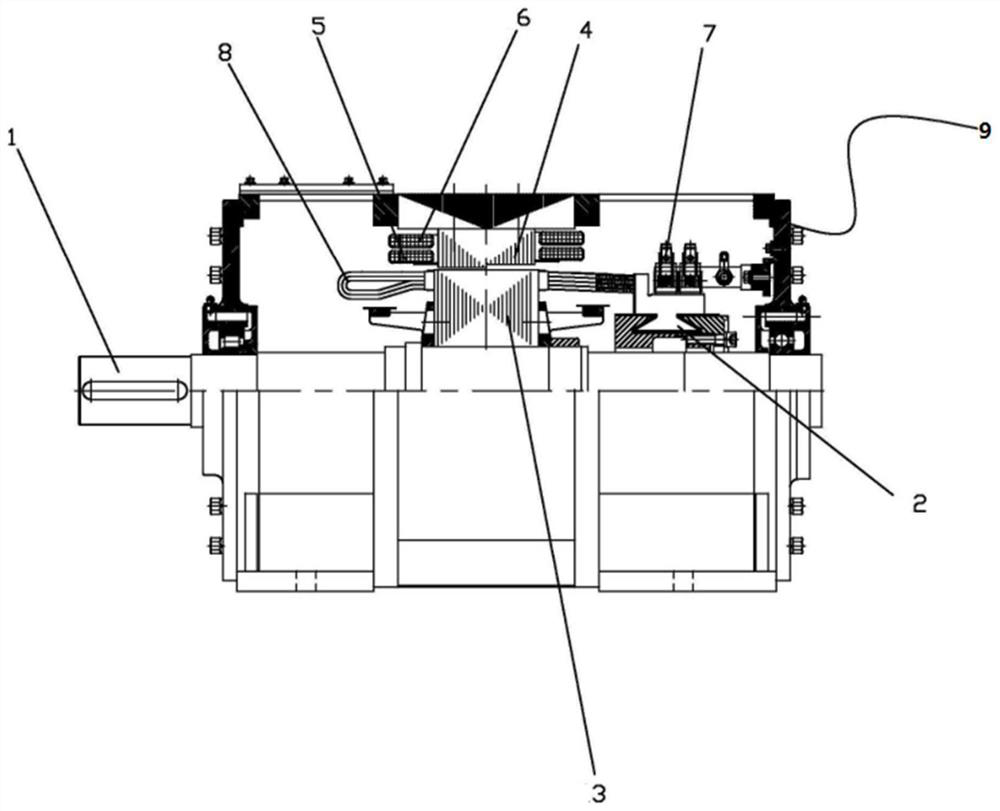

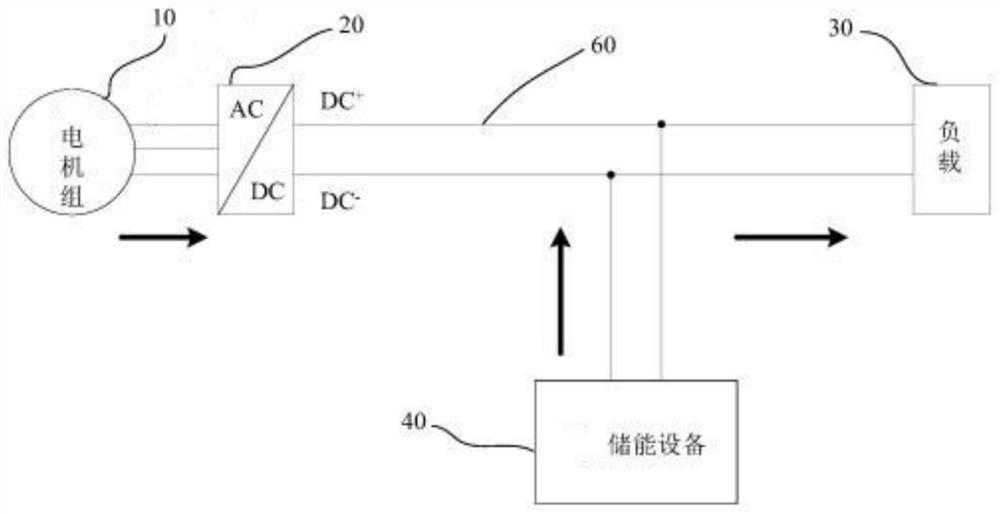

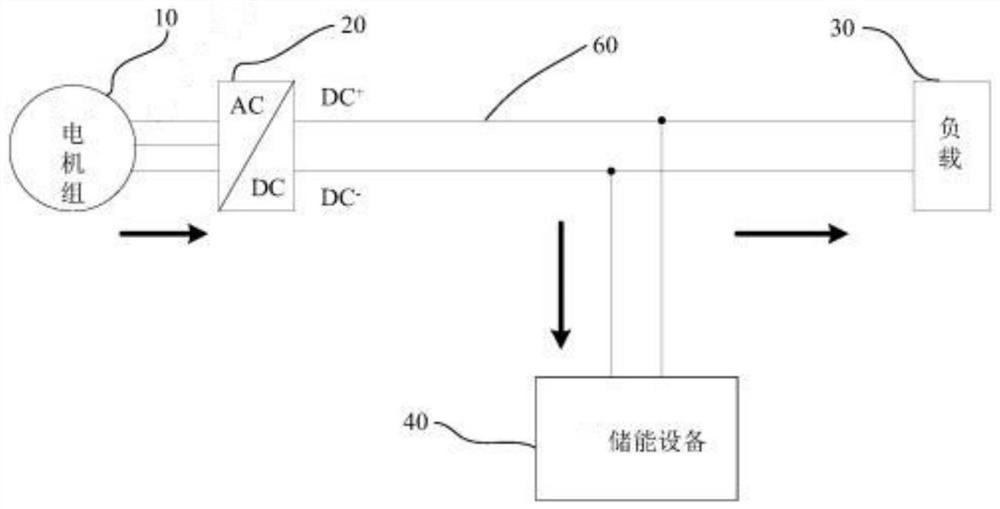

A Double Excitation Winding DC Motor

ActiveCN111477468BImprove cycle lifeIncrease energy densityCarbon fibresHybrid capacitor electrodesSolid state electrolyteFiber

The invention discloses a double-excitation-winding energy-saving direct-current motor, and relates to the technical field of energy-saving direct-current motors. According to the double-excitation-winding energy-saving direct-current motor, the first exciting winding and the second exciting winding are respectively controlled by the commutator; mOTOR LOAD CHANGE, matching energy storage equipment, wherein the energy storage equipment is used for storing energy to form a separately excited direct-current generator and a series excited direct-current motor respectively, residual energy in the system is converted into electric energy capable of being effectively utilized, the energy storage equipment is set as a supercapacitor, and the supercapacitor is composed of a polyacetylene derivative / nano-cellulose-based porous carbon fiber composite electrode material, an organic solid electrolyte and an organic diaphragm. According to the motor, the polyacetylene derivative / nanocellulose-basedporous carbon fiber composite electrode material is used as the electrode material of the energy storage equipment, so that the conductivity, specific capacitance and cycle service life of the energystorage equipment are improved, an excellent energy storage effect is achieved, the service life of the double-excitation-winding energy-saving direct current motor is prolonged, and the cost is reduced.

Owner:无锡中基电机制造有限公司

Battery

InactiveCN1794508AImprove performanceLower internal resistanceAlkaline accumulatorsFinal product manufactureEngineeringEnergy density

Owner:BAILE ELECTROTHERMIC ELECTRIC APPLIANCE JIANGSU

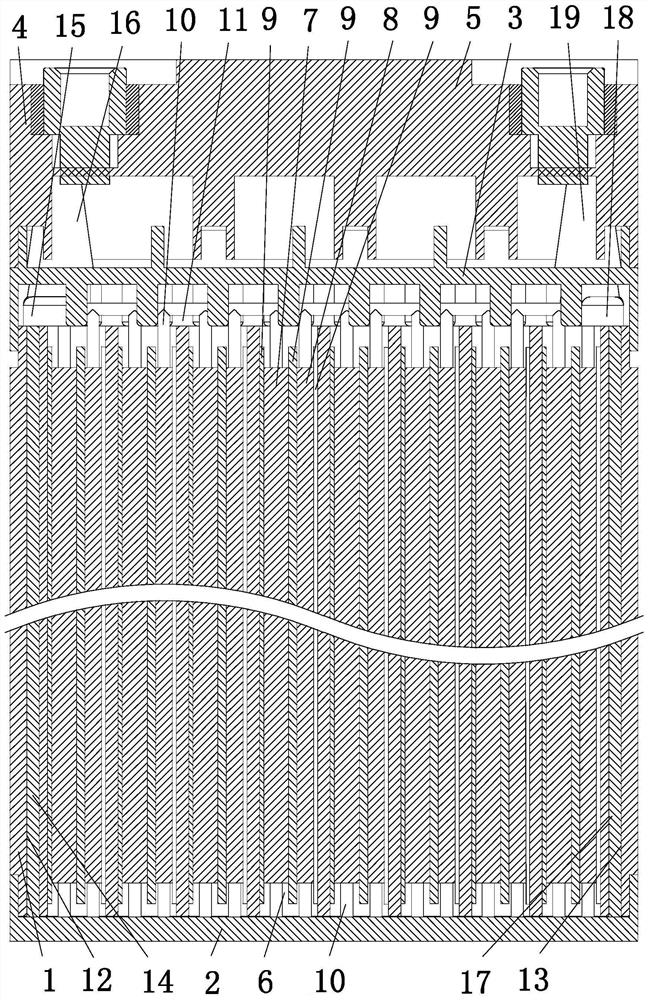

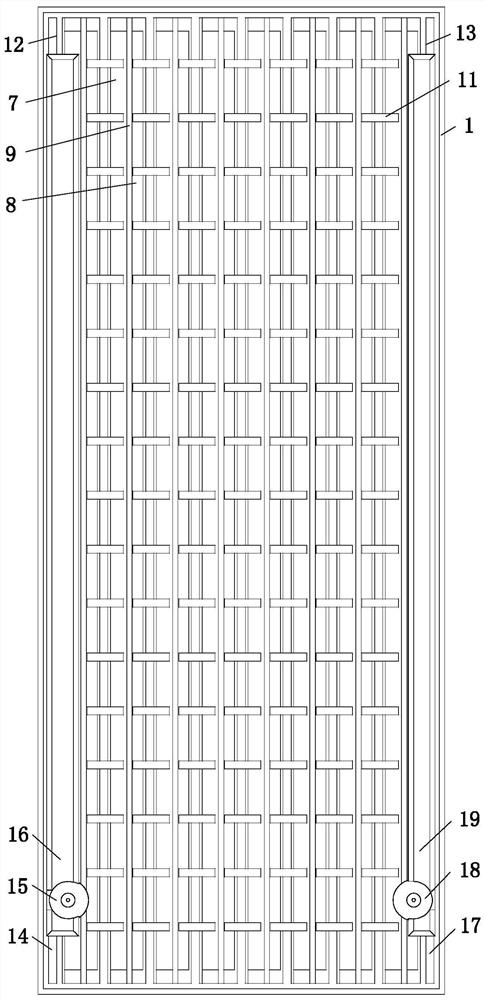

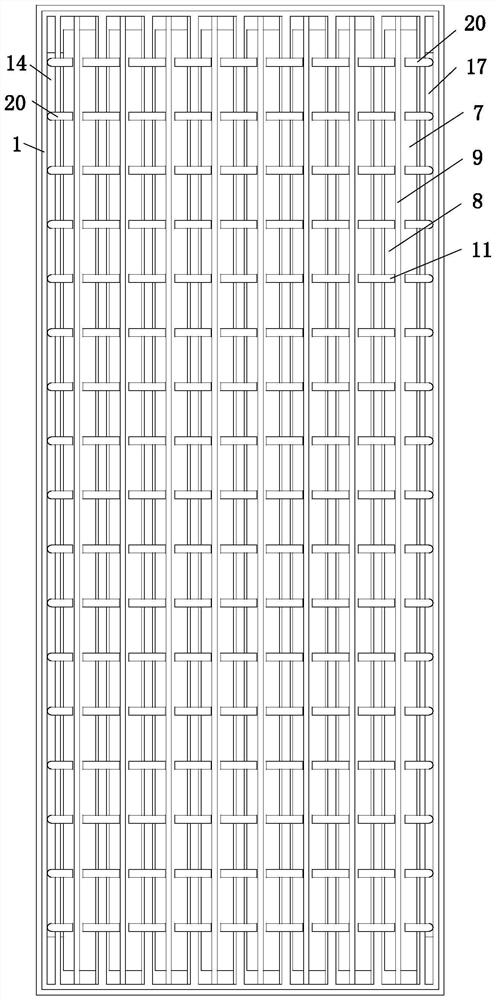

Battery pole plate manufacturing process

InactiveCN111640963AStrong charging and discharging abilityGood dispersionCollectors/separatorsFiberCarbon fibers

The invention discloses a battery pole plate manufacturing process, and particularly relates to the technical field of battery processing. The battery pole plate manufacturing process comprises the steps of S1, mixing polylactide, styrene resin, nylon, polycarbonate, polyether-ether-ketone and carbon fibers to obtain a printing base material; and S2, printing the printing base material obtained inthe step S1 on positive and negative current collectors by using a 3D printing fusing deposition technology. According to the invention, the printing base material is printed on the positive and negative current collectors by using the 3D printing fusing deposition technology, then a complete battery positive electrode and a complete battery negative electrode are manufactured through a 3D layered entity manufacturing technology, the positive and negative electrode materials of the battery are highly embedded with the foil, a trace amount of adhesive is not used, powder never falls off, the material dispersibility is better, the ion migration resistance formed by the adhesive in the traditional process is removed, the charging and discharging capacity of the battery is more excellent, finally, the equipment investment can be reduced, the manufacturing process is simplified, and the manufacturing cost is greatly reduced.

Owner:陕西中丰新能源有限公司

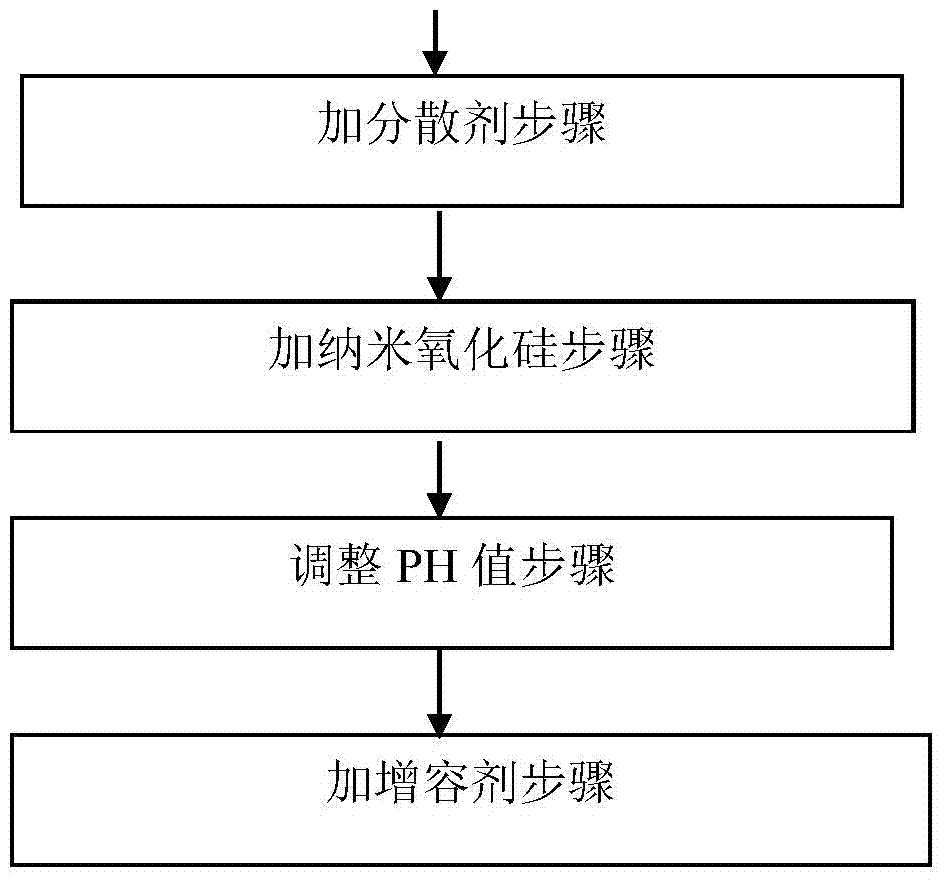

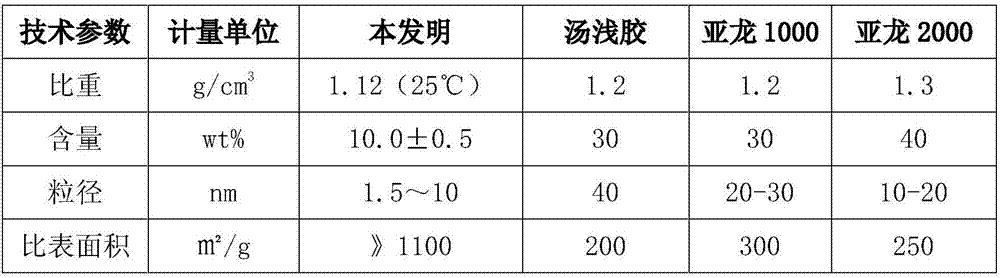

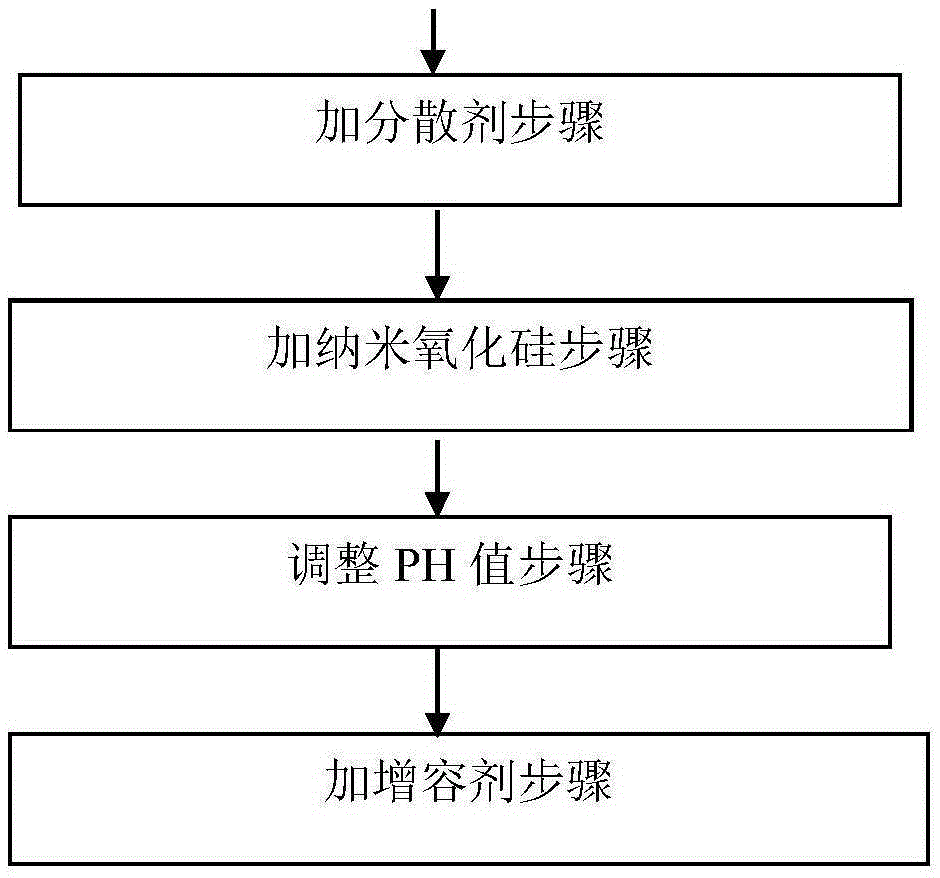

A kind of preparation method of nano silicon oxide composite dispersion liquid

ActiveCN105355987BGood dispersionSmall particle sizeMaterial nanotechnologyFinal product manufactureNano siliconOxide composite

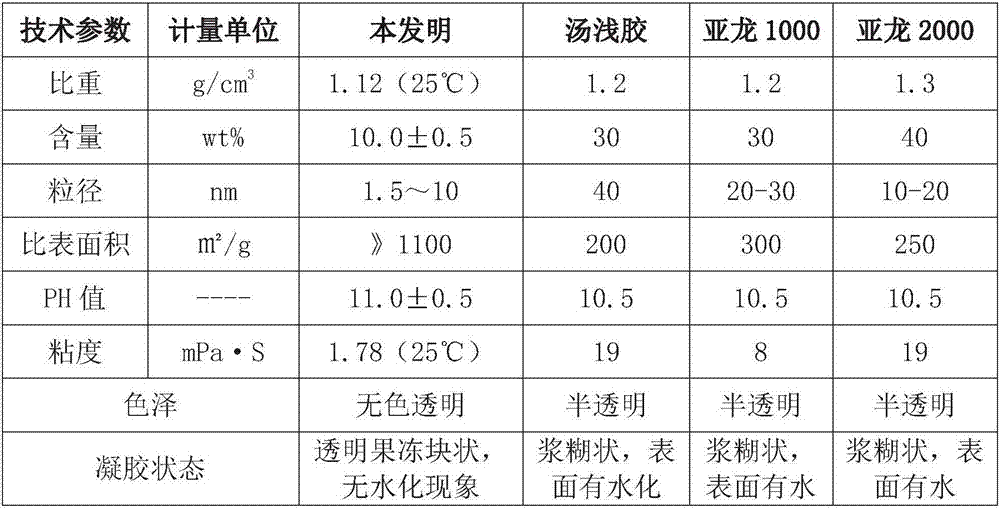

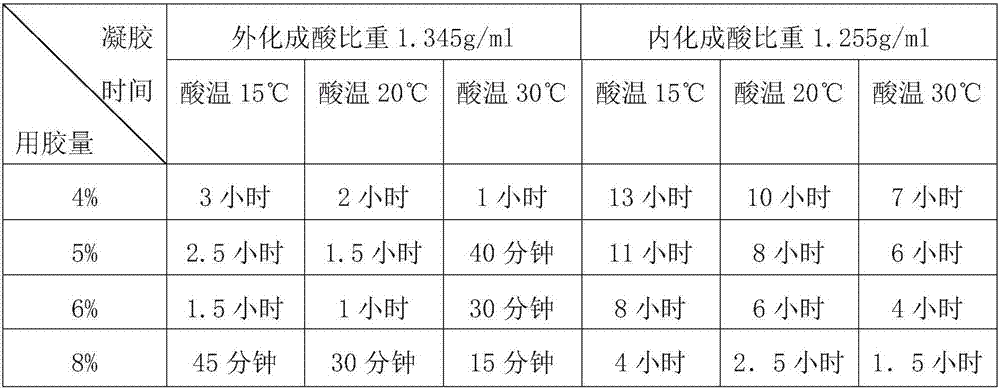

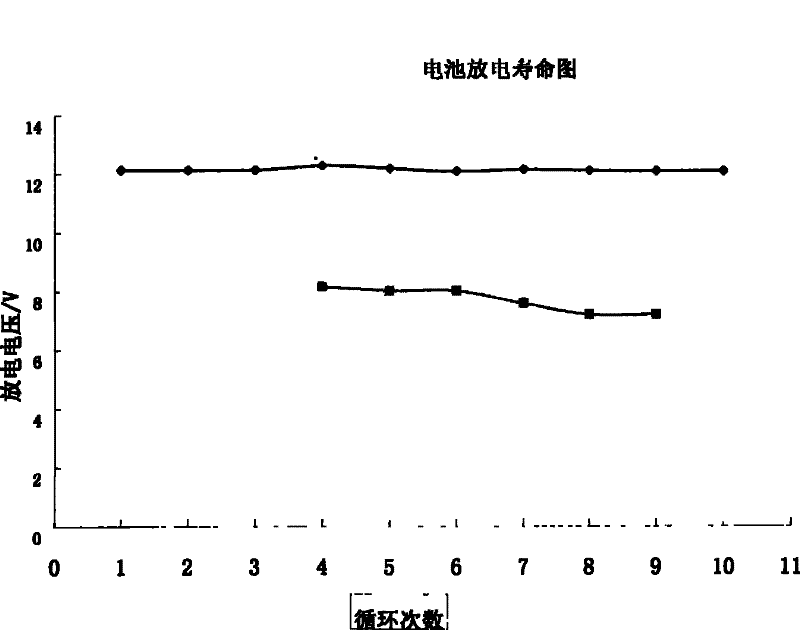

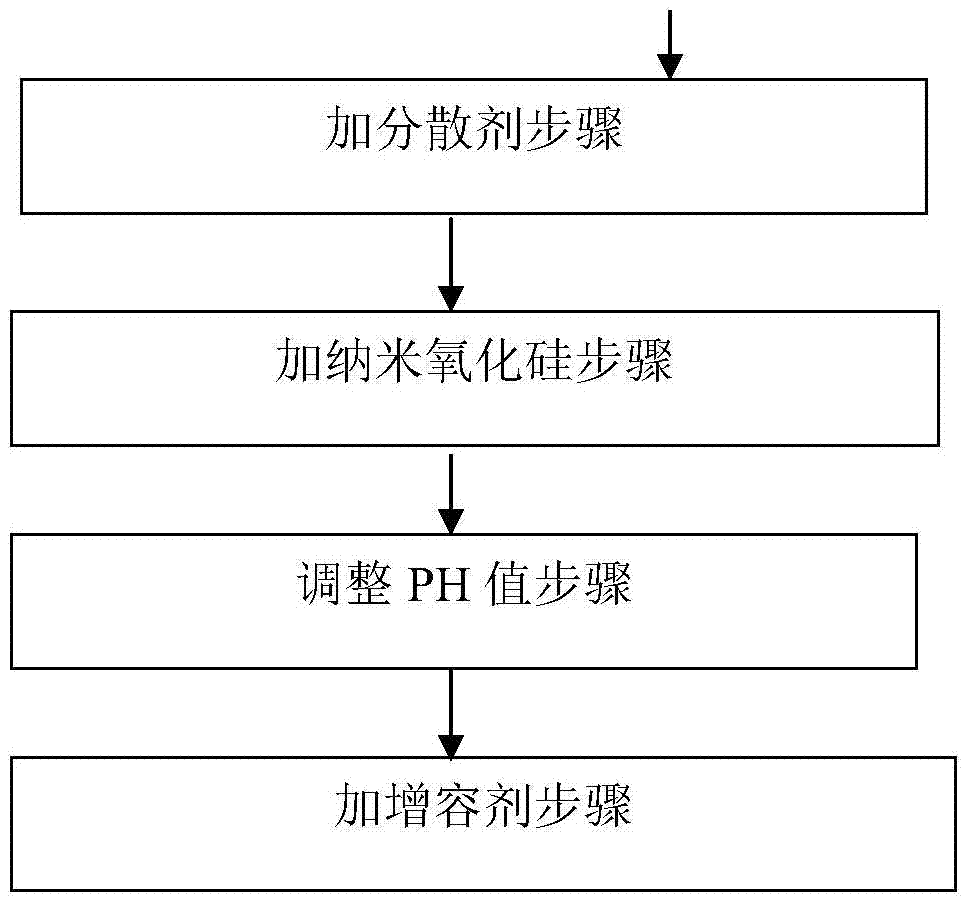

A method for preparing a nano-silica composite dispersion liquid belongs to the technical field of nano-material preparation and solves the problems of poor stability of the existing nano-silica sol, easy demulsification, unsatisfactory colloidal state, and high colloid usage. The sequence of the present invention includes a step of adding a dispersant, a step of adding nano-silicon oxide, a step of adjusting the pH value and a step of adding a compatibilizer; the prepared nano-silicon oxide composite dispersion liquid is a colorless and transparent liquid with a pH value of 9 to 12,25 The specific gravity at ℃ is 1.07-1.13g / cm3, and the viscosity at 25 ℃ is 1.71-1.78mPa·S; the present invention solves the problems of difficulty in adding glue and unsatisfactory gelling state of existing domestic and foreign colloidal electrolyte products, Effectively improve the quality of traditional storage battery products.

Owner:上饶市安纳拓新材料有限公司

A kind of waste lead-acid battery repair activator and preparation method thereof

ActiveCN111180805BIncrease capacityHigh strengthLead-acid accumulatorsSecondary cells servicing/maintenanceElectrolytic agentCarbon nanotube

The invention discloses an activator for repairing waste lead-acid batteries and a preparation method thereof. The activator comprises 15-30 parts by weight of mother liquor, 3-5 parts by weight of carbon nanotubes, 4-7 parts by weight of sodium sulfate, and 5 parts by weight of cobalt sulfate. ‑8 parts by weight, 4‑9 parts by weight of copper sulfate, and 50‑70 parts by weight of deionized water, wherein the mother liquor includes 0.2‑0.8 weight percent superabsorbent resin, 0.5‑3 weight percent fumed silica and the rest Measure deionized water. The repair activator for waste lead-acid batteries of the present invention, on the one hand, accelerates the decomposition of the originally non-conductive lead sulfate; The activator is made of super absorbent resin according to the multi-encapsulation theory, so that the electrolyte molecules are wrapped around each other and it is not easy to cause delamination.

Owner:内蒙古华贵科技开发有限公司

Battery electrolyte composed of organic silicon and inorganic silicon

InactiveCN101552354BIncrease capacityExplosiveNon-metal conductorsSilicon organic compoundsPolymer scienceSilicic acid

The invention relates to a storage battery electrolyte prepared by organic silicon and inorganic silicon, which is mainly prepared by inorganic silicic acid and a macromolecular compound, wherein the inorganic silicic acid has obvious thixotropy and does not flow in the static state or the discharging process to achieve the effects of no-overflow and sealing; and inside semi fluid in the charging process enables the conduction to be more smooth to achieve the high capacity of a battery, and the power is strong. The organic polymer is divided into two kinds, and a hydrophobic organosilicon polymer enables the surface of an inorganic particle to be hydrophobized so as to achieve the purposes of no overflow, no condensation and no deposit by being combined with an AGM diaphragm; and the other kind of carbon-oxygen macromolecule forms a surface film on the outermost layer, so the water of the electrolyte cannot volatilize, the acidic material cannot be escaped out to achieve the purpose of free maintenance for life of the battery. The liquid film model with the three-layer structure enables the battery to become a high-performance storage battery with good low-temperature start, strong power, large energy, long service life and free maintenance.

Owner:ANSHAN DUOBIAO STOCK +1

Cylindrical lithium-ion battery and its manufacturing process

ActiveCN112652822BStrong charging and discharging abilityImprove high rate discharge performanceElectrode thermal treatmentFinal product manufactureFiberManufacturing technology

The application relates to the technical field of lithium-ion batteries, and specifically discloses a cylindrical lithium-ion battery and a manufacturing process thereof. The manufacturing process of the cylindrical lithium-ion storage battery of the present application includes the following steps: uniformly mixing the first solvent and the first substrate to obtain an inner layer spinning solution; uniformly mixing the second solvent and the second substrate to obtain a middle layer spinning solution; uniformly mixing the third solvent and the third matrix to obtain an outer layer spinning solution; using the obtained inner layer spinning solution, middle layer spinning solution, and outer layer spinning solution to perform three-channel coaxial electrospinning to obtain composite fibers; Under the protection of an inert atmosphere, the composite fiber is kept at 700-900° C. for 8-10 hours to obtain a composite negative electrode material; a cylindrical lithium-ion battery is prepared by using the composite negative electrode material as the negative electrode active material. The cylindrical lithium-ion storage battery prepared by the application has excellent charging and discharging performance, and has very good high-rate discharging capability.

Owner:深圳市言九电子科技有限公司

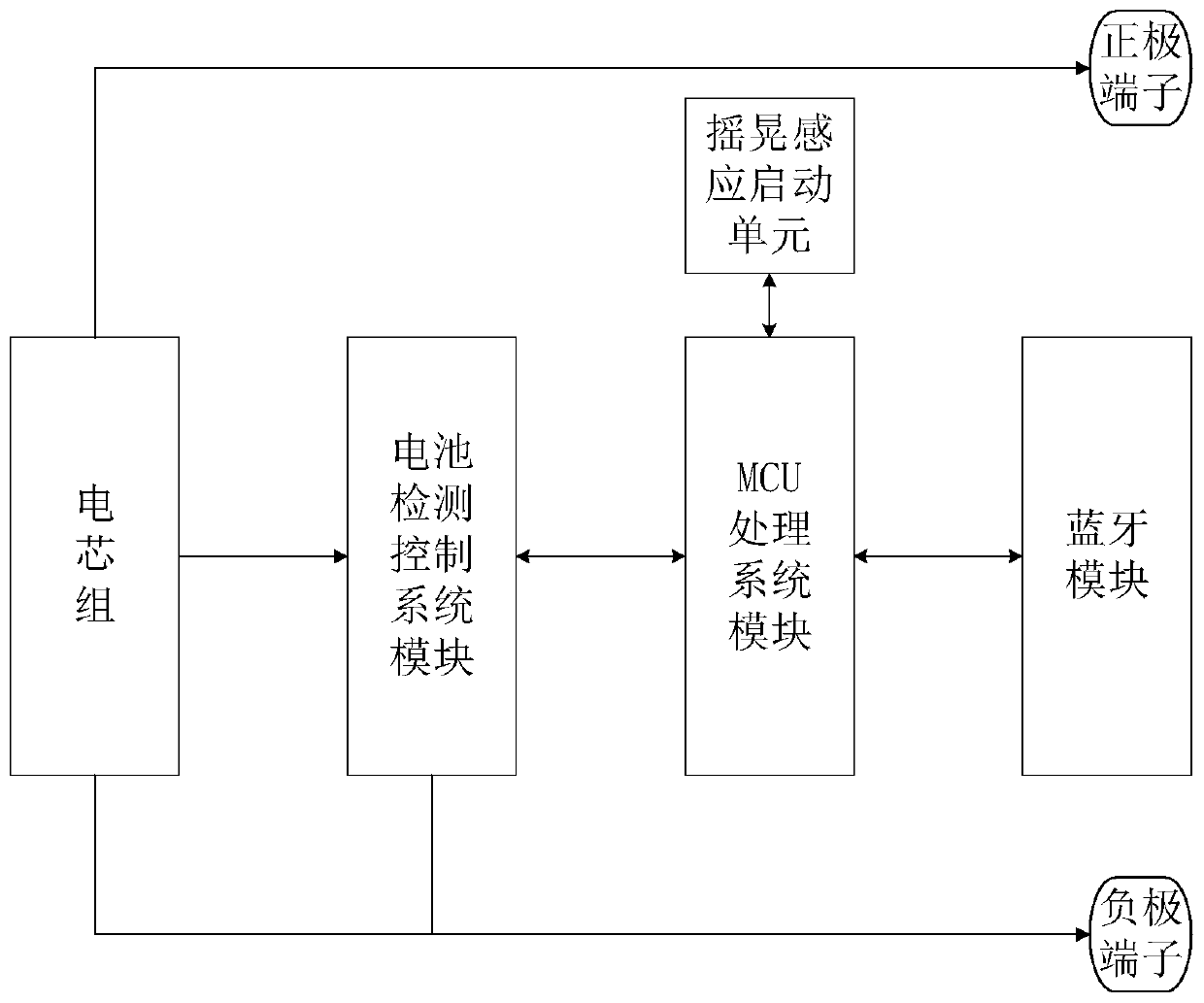

Crank-Start Batteries, Apps and Servers

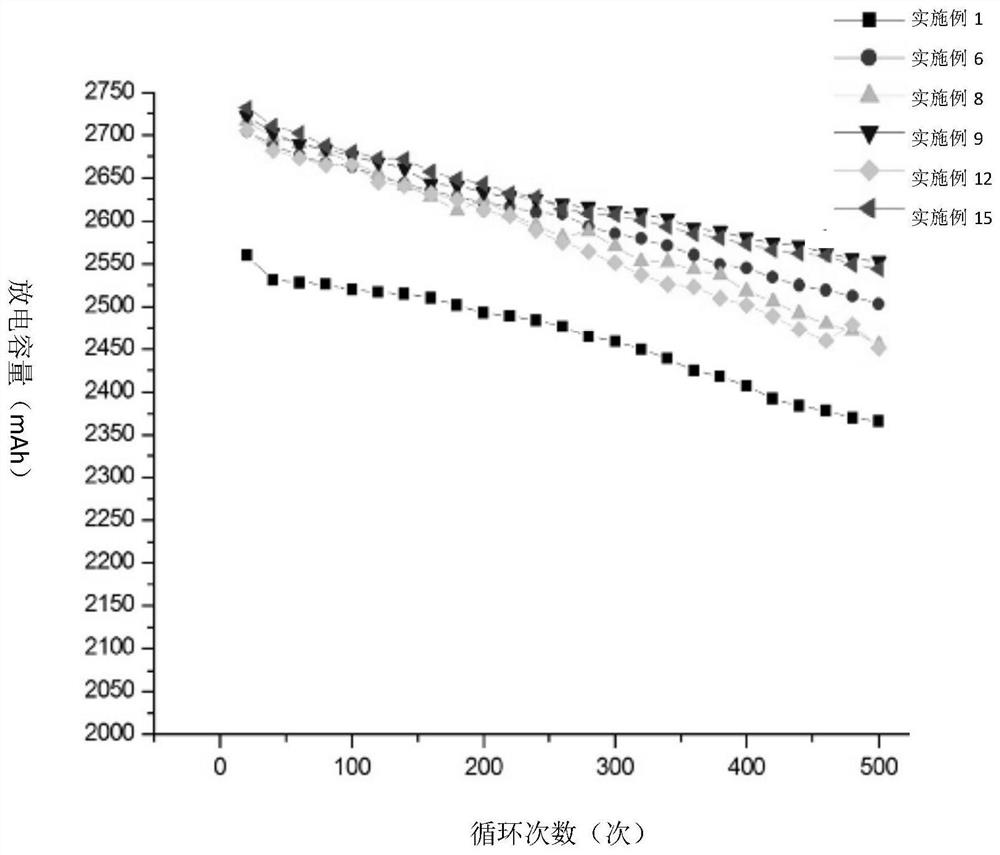

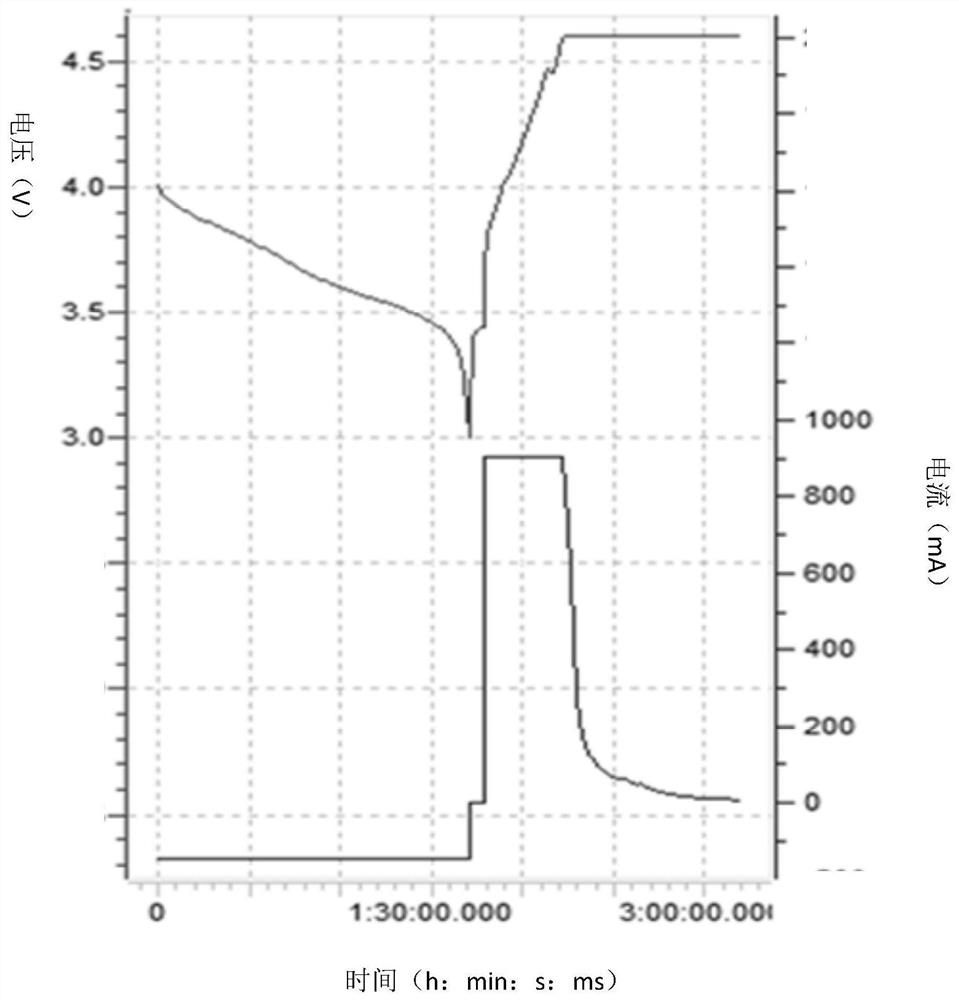

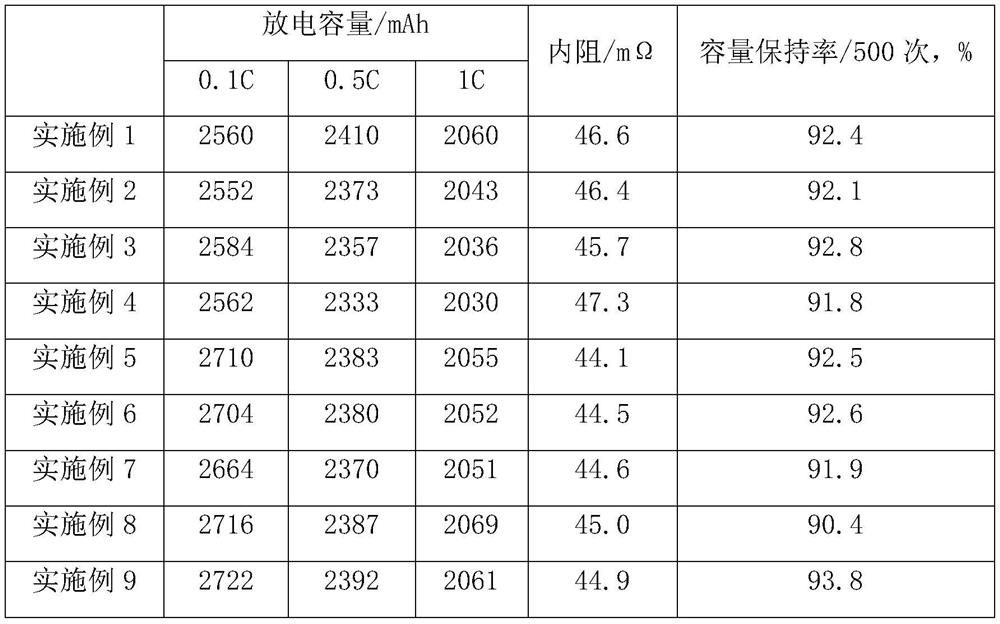

ActiveCN108054446BEasy and convenient travel experienceStrong charging and discharging abilityCells structural combinationBatteriesStart stopControl system

The present invention provides a shaking start-up battery, an application device and a server. The start-up battery at least includes: a battery pack for power supply, used for checking the voltage, voltage and current of the battery pack, and adjusting the voltage of the battery pack The battery detection control system module, the MCU processing system module used to calculate the remaining power of the battery pack using the integral algorithm and display and issue the command to start and stop the battery pack discharge, the Bluetooth module for data transmission, and the connection to the application device Positive terminal and negative terminal; Wherein, the state MCU processing system module also includes a shaking induction starting unit for sending out an instruction to start the state starting type battery when shaking with a preset amplitude. In the present invention, the MCU processing system module is provided with a shake-sensing start-up unit that issues an instruction to start the start-up battery when the MCU processing system module is used to sense the shake with a preset amplitude, so that the start-up battery can be quickly sensed to discharge the application device, which can bring users more convenience. Convenient travel experience.

Owner:GUANGZHOU THALES TECH CO LTD

A New Laminated Wound Film Capacitor

ActiveCN106206013BReduce volumePromotes self-healingThin/thick film capacitorFixed capacitor dielectricEngineeringDielectric layer

Owner:FOSHAN CITY XINYUAN ELECTRONICS CO LTD

Battery

InactiveCN100364164CImprove performanceLower internal resistanceAlkaline accumulatorsFinal product manufactureEngineeringEnergy density

Owner:BAILE ELECTROTHERMIC ELECTRIC APPLIANCE JIANGSU

High-power lead storage battery

ActiveCN111668436AEasy to receiveAvoid the bottom-up phenomenon of utilizationCell component detailsVehicular energy storageStructural engineeringMechanical engineering

The invention relates to a high-power lead storage battery, which comprises a bus bar assembly, a shell, a bottom cover, a transition cover, an upper cover, a middle cover, a plurality of accommodating cavities, single batteries and two series assemblies, wherein the bottom cover is arranged at the lower end of the shell; the transition cover and the upper cover are sequentially arranged at the upper end of the shell; the middle cover is located in the upper cover and connected with the upper end of the transition cover; the plurality of accommodating cavities are formed in the shell side by side left and right and penetrate through the upper end and the lower end of the shell; the number of the single batteries is the same as that of the accommodating cavities, and the single batteries are arranged in the accommodating cavities in a one-to-one correspondence mode; and the two series assemblies are arranged on the upper sides and the lower sides of the single batteries respectively. The high-power lead storage battery is high in power density, high in high-current charging and discharging capacity and short in charging time under the condition of the same boundary dimension.

Owner:CHAOWEI POWER CO LTD

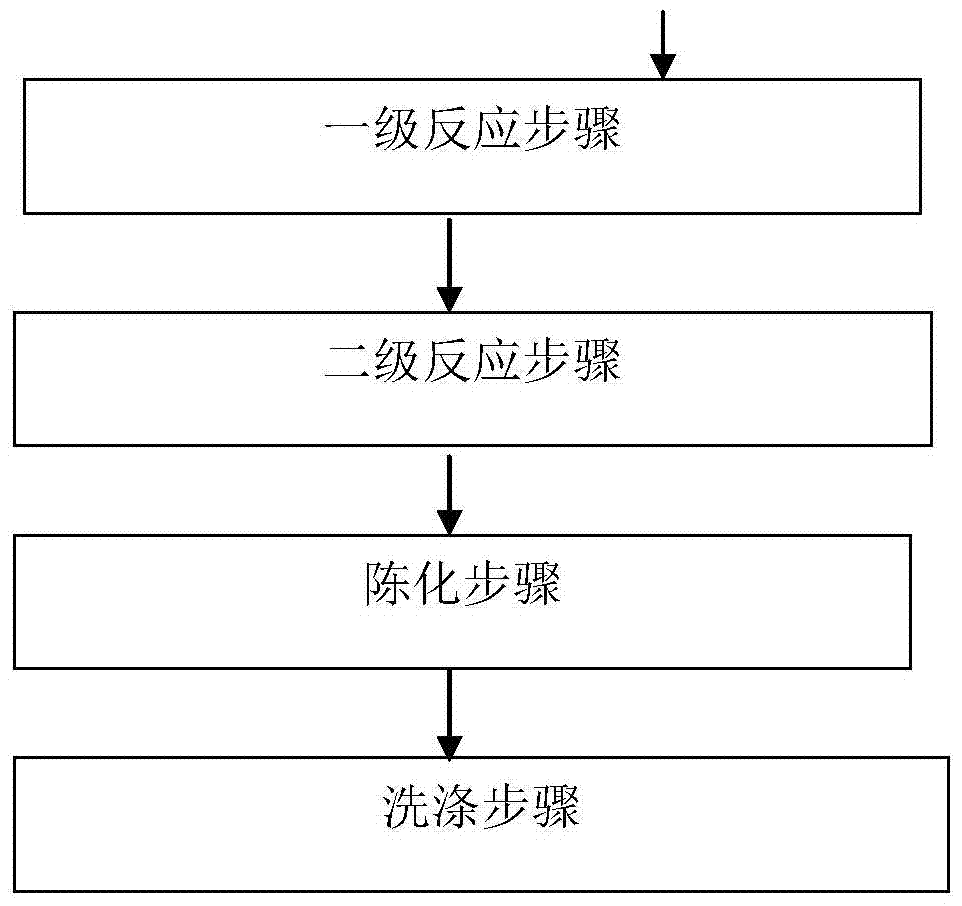

Nano-silica dispersion liquid, preparation method thereof, and preparation method of cake

ActiveCN105355985BViolent reactionThe reaction is exothermicMaterial nanotechnologyLead-acid accumulatorsFirst-order reactionHigh probability

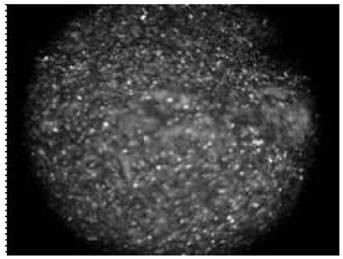

The invention discloses nanoscale silicon oxide composite dispersion liquid and a preparation method therefor, belongs to the technical field of nanomaterial preparation, and solves the problems of low stability, high probability of demulsification, non-ideal gel forming state, and high usage amount of gel in the existing nanoscale silicon oxide sol. The nanoscale silicon oxide composite dispersion liquid comprises nanoscale silicon oxide and deionized water, and the nanoscale silicon oxide composite dispersion liquid is colorless transparent liquid, the PH value of the composite dispersion liquid is 9-12, the specific gravity at the temperature of 25 DEG C is 1.07-1.13 g / cm3, and the viscosity at the temperature of 25 DEG C is 1.71-1.78 mPa.S; the preparation method for the nanoscale silicon oxide composite dispersion liquid comprises a step of adding a dispersing agent, a step of adding the nanoscale silicon oxide, a step of adjusting the PH value and a step of adding compatibilizer in sequence; the preparation method for the nanoscale silicon oxide cake material comprises a first-order reaction step, a second-order reaction step, an aging step and a washing step; and the obtained nanoscale silicon oxide cake material comprises nanoscale silicon oxide powder, the solid grain diameter of the nanoscale silicon oxide powder is 1.5-10 nm, and the specific surface area of the nanoscale silicon oxide powder is greater than or equal to 1, 100 m2 / g.

Owner:上饶市安纳拓新材料有限公司

Preparation method for nanoscale silicon oxide composite dispersion liquid

ActiveCN105355987AGood dispersionSmall particle sizeMaterial nanotechnologyFinal product manufactureHigh probabilityColloid

The invention discloses a preparation method for nanoscale silicon oxide composite dispersion liquid, belongs to the technical field of nanomaterial preparation, and solves the problems of low stability, high probability of demulsification, non-ideal gel forming state, and high usage amount of gel in the existing nanoscale silicon oxide sol. The preparation method comprises a step of adding a dispersing agent, a step of adding the nanoscale silicon oxide, a step of adjusting the PH value and a step of adding compatibilizer in sequence; and the prepared nanoscale silicon oxide composite dispersion liquid is colorless transparent liquid, the PH value of the composite dispersion liquid is 9-12, the specific gravity at the temperature of 25 DEG C is 1.07-1.13 g / cm3, and the viscosity at the temperature of 25 DEG C is 1.71-1.78 mPa.S. The preparation method for the nanoscale silicon oxide composite dispersion liquid effectively solves the problems of difficulty in adding gel and the non-ideal gel forming state in using domestic and overseas gel electrolyte products, so that the quality of the conventional storage battery product is improved.

Owner:上饶市安纳拓新材料有限公司

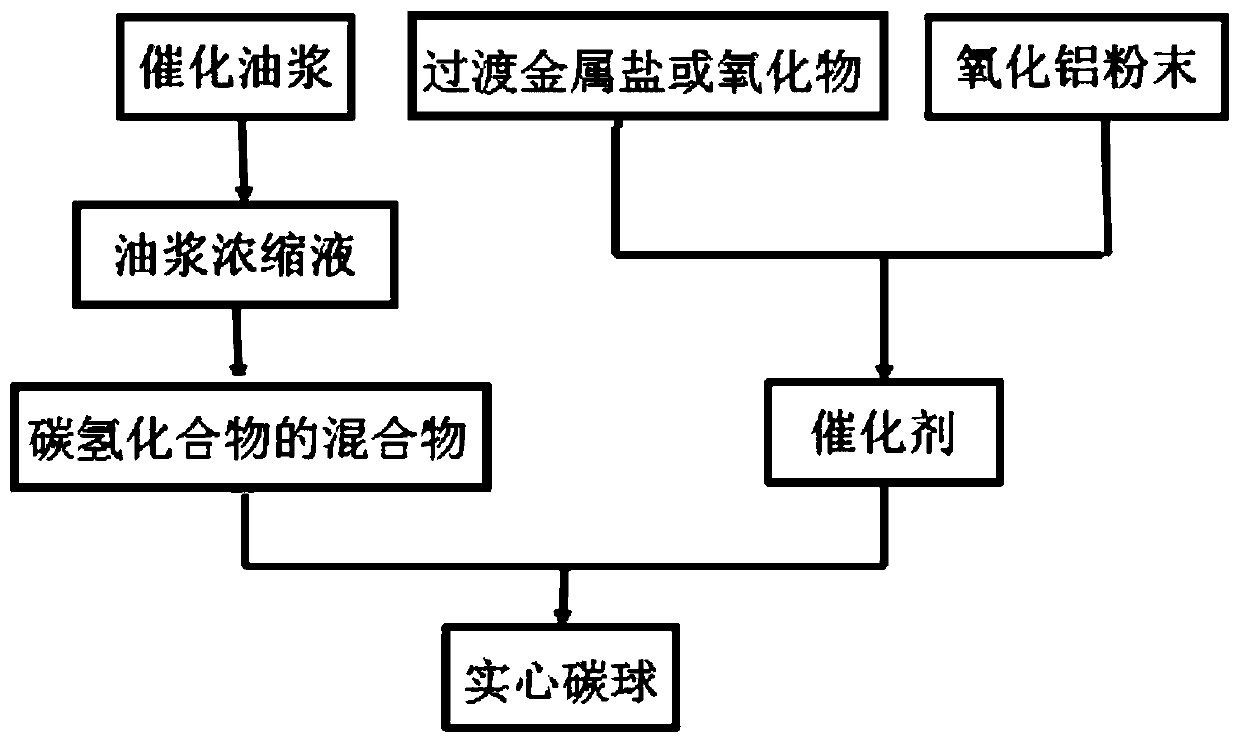

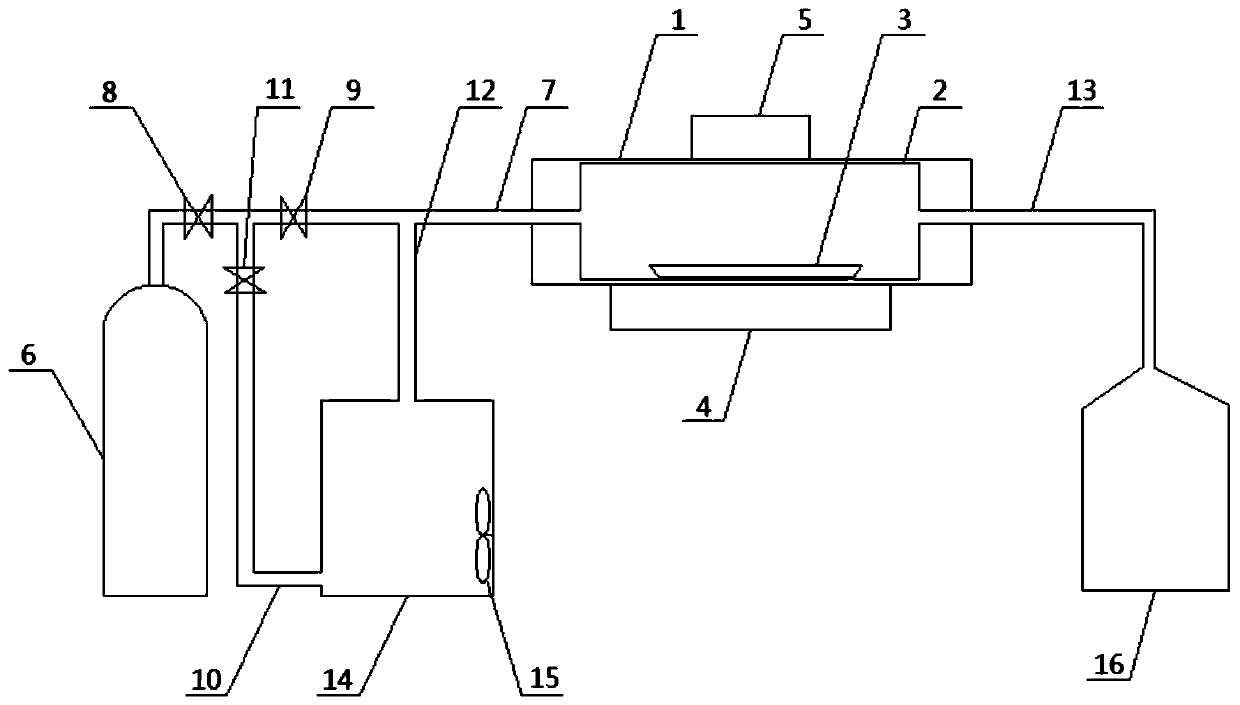

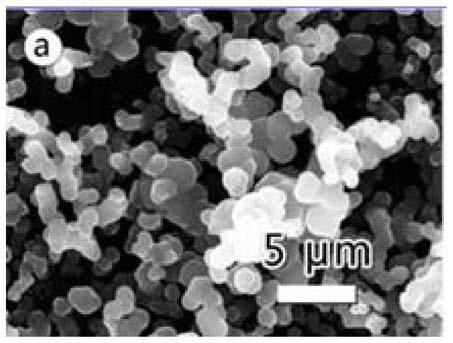

A method for preparing catalytic oil slurry-based solid carbon spheres and a new chemical deposition system

ActiveCN107892288BHigh puritySmall particle sizeCatalyst activation/preparationCarbon preparation/purificationSolid carbonHydrocarbon mixtures

The invention belongs to the field of carbon material preparation, and more specifically relates to a method used for preparing catalytic slurry oil based solid carbon spheres, and a novel chemical deposition system. According to the method, catalytic slurry oil is subjected to purifying impurity removing treatment firstly so as to obtain a hydrocarbon mixture which can be taken as a solid carbonsource in preparation of carbon materials through chemical deposition; the novel chemical deposition system is adopted, the hydrocarbon mixture is taken as a solid carbon source so prepare solid carbon spheres with certain specific surface area and uniform morphology; the catalytic slurry oil based solid carbon source can be combined with chemical substances containing nitrogen or phosphorus to prepare multi-functional nitrogen or phosphorus doped solid carbon spheres. The solid carbon spheres and the doped solid carbon spheres can be used in the fields such as lithium ion battery electrode material, catalyst carrier, porous conductive material, and energy storage materials. According to the method, full utilization of refinery plant heavy oil fluid catalytic cracking by-product catalyticslurry oil is realized, the added value of catalytic slurry oil is increased, and the using efficiency of catalytic slurry oil source is increased.

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com