Preparation method for nanoscale silicon oxide composite dispersion liquid

A nano-silica, compound dispersion technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of poor stability of nano-silica sol, unsatisfactory colloidal state, high colloid usage, etc. problems, to achieve the effect of stability, gel hydration reduction, and strong gel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

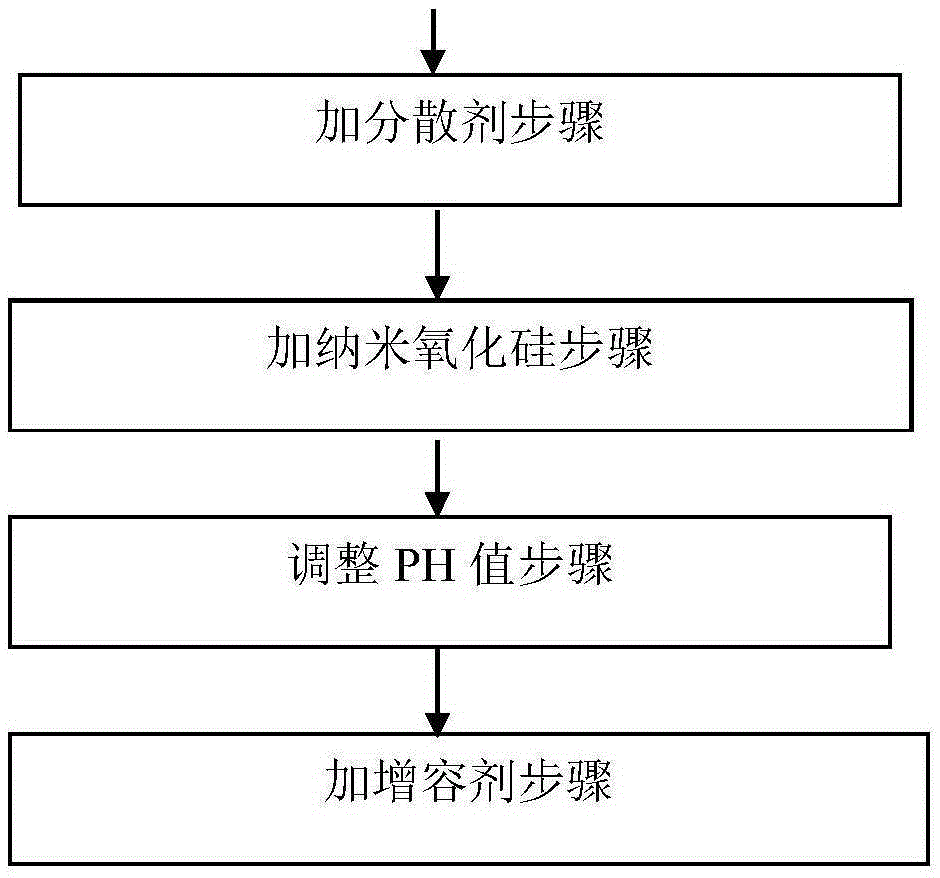

[0045] Embodiment 1, preparation method of nano-silica composite dispersion liquid, such as figure 1 As shown, the order includes adding dispersant step, adding nano silicon oxide step, adjusting pH value step and adding compatibilizer step:

[0046] (1) Step of adding dispersant: add deionized water into the reaction kettle, then add 6% dispersant and 0.1% stabilizer accounting for the mass percentage of nano-silica powder, and stir for 15 minutes at a temperature of 20°C; The dispersant is sodium polycarboxylate; the stabilizer is hydroxymethyl cellulose;

[0047] (2) Step of adding nano-silica: in the liquid obtained in step (1), add nano-silica powder, the nano-silica powder accounts for 5% of the mass percent of the nano-silica composite dispersion, at 20°C, Stir for 10 minutes; the particle size of the nano silicon oxide powder is 5-10nm, and its specific surface area is 1128㎡ / g;

[0048] (3) The step of adjusting the pH value: adding lye to the liquid obtained in step...

Embodiment 2

[0051] Embodiment 2, the preparation method of nano-silica composite dispersion liquid, the sequence includes adding dispersant step, adding nano-silica step, adjusting pH value step and adding compatibilizer step:

[0052] (1) Step of adding dispersant: add deionized water in the reaction kettle, then add 0.5% dispersant and 5% stabilizer accounting for the mass percentage of nano-silica powder, and stir for 15 minutes at 35°C; Described dispersant is alkyl polyoxyethylene ether (Pingping adds O); Described stabilizing agent is polyvinyl alcohol;

[0053] (2) Step of adding nano-silicon oxide: in the liquid obtained in step (1), add nano-silicon oxide powder, the nano-silicon oxide powder accounts for 8% by mass of the nano-silicon oxide composite dispersion liquid, at a temperature of 50 ° C , stirring for 5 minutes; the particle size of the nano-silica powder is 5-10nm, and its specific surface area is 1100㎡ / g;

[0054] (3) The step of adjusting the pH value: adding lye to...

Embodiment 3

[0057] Embodiment 3, the preparation method of nano-silica composite dispersion liquid, the sequence includes adding dispersant step, adding nano-silica step, adjusting pH value step and adding compatibilizer step:

[0058] (1) Step of adding dispersant: add deionized water to the reaction kettle, then add 3% dispersant and 2% stabilizer accounting for the mass percentage of nano-silica powder, and stir for 10 minutes at a temperature of 50°C; The dispersant is glycerin; the stabilizer is hydroxyethyl cellulose;

[0059] (2) Step of adding nano-silicon oxide: in the liquid obtained in step (1), add nano-silicon oxide powder, the nano-silicon oxide powder accounts for 11% of the mass percentage of the nano-silicon oxide composite dispersion liquid, at a temperature of 40 ° C , stirring for 8 minutes; in the nano-silica powder, the nano-silica particle size is 5-10nm, and its specific surface area is 1160㎡ / g;

[0060] (3) Step of adjusting the pH value: adding lye to the liquid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com