A Double Excitation Winding DC Motor

A double excitation winding, DC motor technology, applied in the direction of DC commutator, hybrid/electric double layer capacitor manufacturing, electric components, etc., can solve the problem that the energy density is less than one tenth of that of the battery, the transition metal oxide is expensive, Affect the energy storage effect of DC motors, etc., to achieve the effects of increasing effective specific surface area, increasing electrical conductivity, and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: The preparation method of the electrode material in the DC motor with double excitation windings and its energy storage equipment

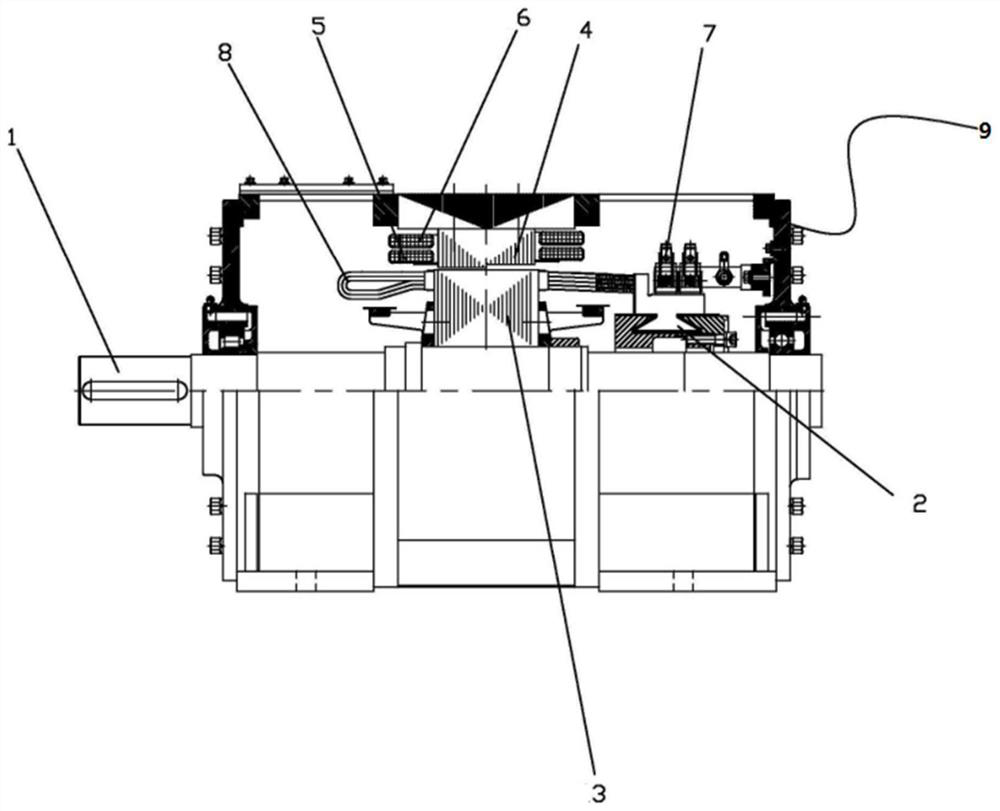

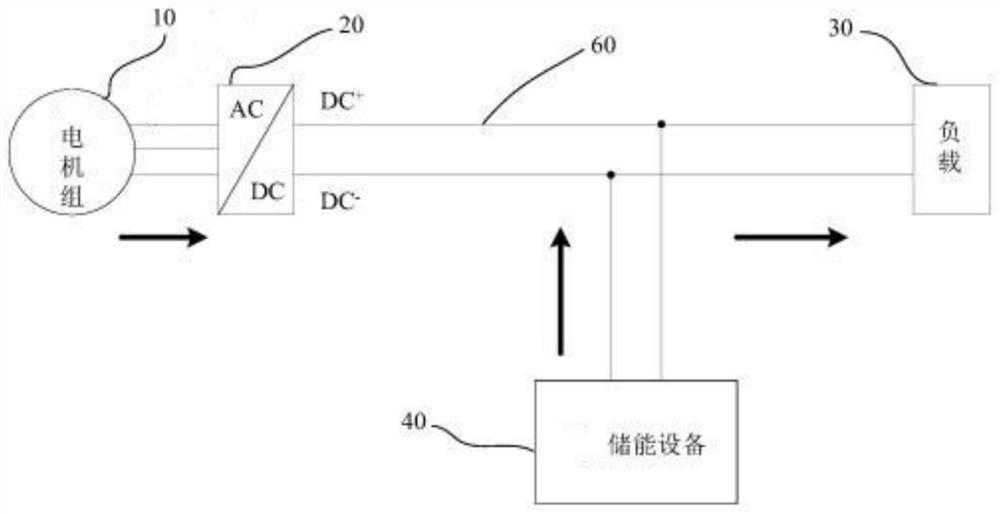

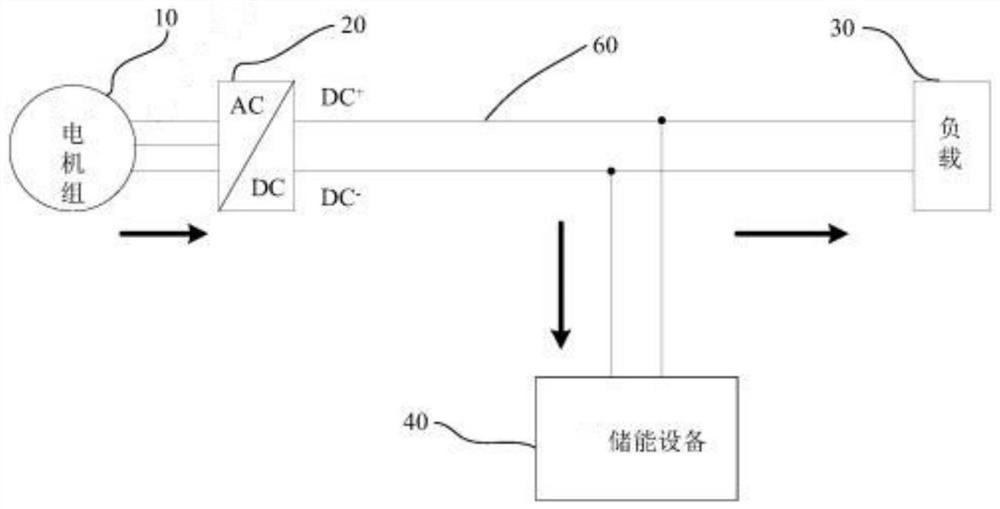

[0035] Such as figure 1 As shown, the double-field winding DC motor includes a motor housing 9, the motor housing 9 is provided with a rotating shaft 1 and a brush device 2, the rotating shaft 1 is provided with a motor rotor 3, and the motor housing 9 is located on the motor rotor 3 A motor stator 4 is arranged on the outer side of the motor stator 4, and a first field winding 5 and a second field winding 6 are arranged on the motor stator 4 parallel to the rotating shaft 1, and the motor housing 9 is also provided with a motor housing 9 for controlling the first field winding 5 and the second field winding. The commutator 7 for the electric energy conversion output of the two field windings 6, the motor rotor 3 is also provided with a single armature winding 8 and an energy storage device (not shown in the figure), and the e...

Embodiment 2

[0045] Example 2: Preparation method of electrode material in double-field winding DC motor and its energy storage device

[0046] The components of the DC motor with double excitation windings are the same as those in Embodiment 1, and refer to Embodiment 1 for the specific structure.

[0047] The supercapacitor is composed of polyacetylene derivative / nanocellulose-based porous carbon fiber composite electrode material, organic solid electrolyte and organic separator, wherein the organic solid electrolyte is PVA / H 2 SO 4 , the organic membrane is a cellulose membrane.

[0048] The preparation method of polyacetylene derivative / nanocellulose-based porous carbon fiber composite electrode material comprises the following steps:

[0049] (1) Preparation of dendritic polyacetylene derivatives: under nitrogen, place 9g of 4-ethylphenylacetylene monomer in 100mL of tetrahydrofuran until completely dissolved, then add 2.7g of 3,5-dichloropyridine and 0.72g of Mo Carbene catalyst, ...

Embodiment 3

[0055] Embodiment 3: The preparation method of the electrode material in the DC motor with double excitation windings and its energy storage equipment

[0056] The components of the DC motor with double excitation windings are the same as those in Embodiment 1, and refer to Embodiment 1 for the specific structure.

[0057] The supercapacitor is composed of polyacetylene derivative / nanocellulose-based porous carbon fiber composite electrode material, organic solid electrolyte and organic separator, wherein the organic solid electrolyte is PVA / H 3 PO 4 , the organic membrane is a cellulose membrane.

[0058] The preparation method of polyacetylene derivative / nanocellulose-based porous carbon fiber composite electrode material comprises the following steps:

[0059] (1) Preparation of dendritic polyacetylene derivatives: under nitrogen, place 6g of 1,6-heptadiyne monomer in 100mL of tetrahydrofuran until completely dissolved, then add 1.5g of 3,5-dichloropyridine and 0.36g of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com