Storage battery electrolyte prepared by organic silicon and inorganic silicon

An electrolyte and inorganic silicon technology, applied in lead-acid batteries, silicon organic compounds, non-metallic conductors, etc., can solve problems such as environmental pollution, sulfuric acid mist escape, and short service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

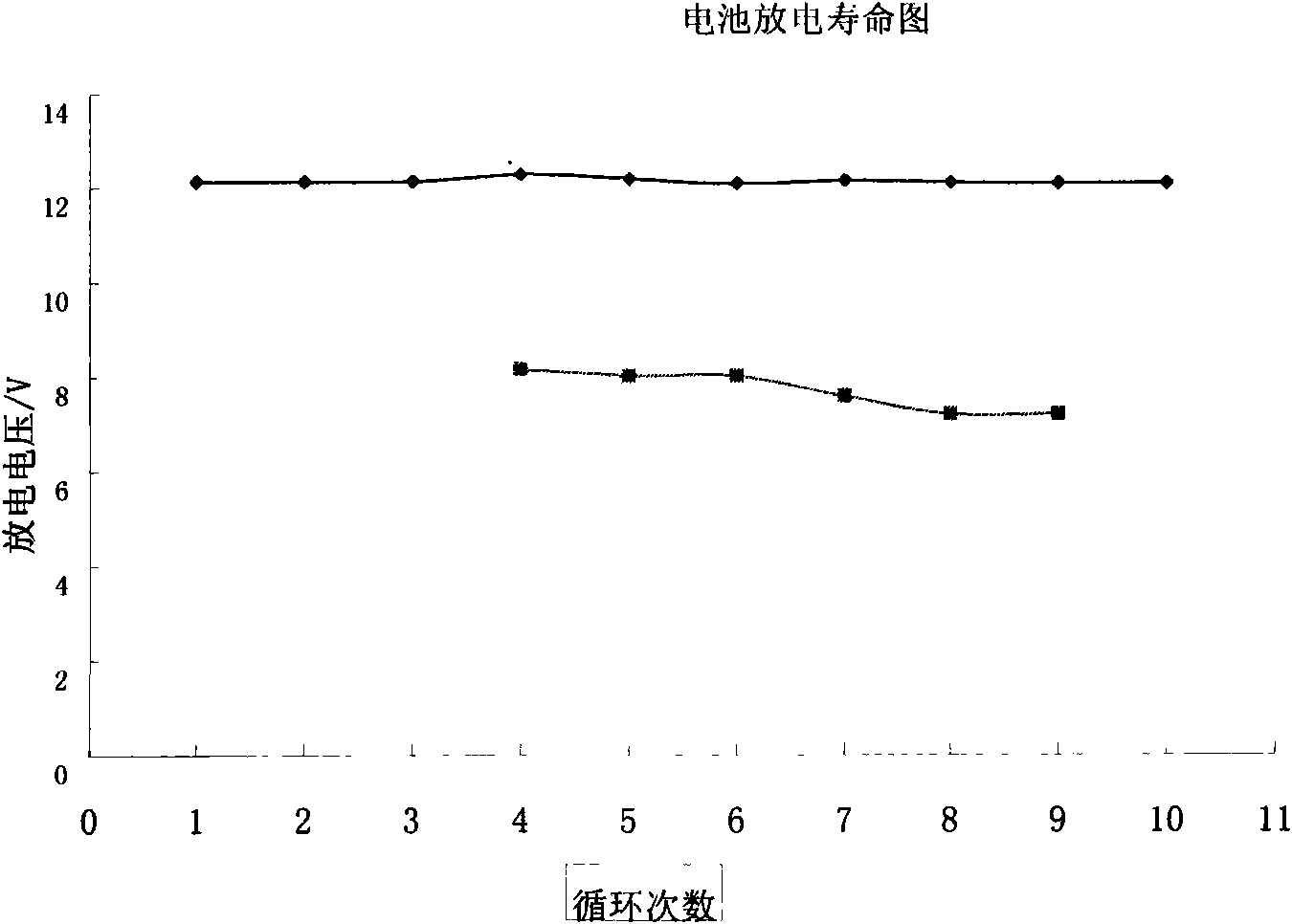

Image

Examples

Embodiment 1

[0017] A storage battery electrolyte composed of organosilicon and inorganic silicon, the composition of which is as follows in parts by weight:

[0018] (1) Silica sol SiO 2 .XH 2 O: 10 copies

[0019] (2) Hydrogen silicone oil (CH 3 ) 3 Si-O-(HSiCH 3 -O-)n-Si(CH 3 ) 3 : 10 servings

[0020] (3) polyethylene glycol HO-(CH 2 CH 2 ) n -OH: 1 part

[0021] (4) Deionized water or distilled water: 15 parts.

[0022] The preparation method of the battery electrolyte composed of organosilicon and inorganic silicon is to mix the weighed components (2) and (3) and 15 parts of deionized water or distilled water together to form a uniform paste, add (1) Components, add water to dilute to the corresponding concentration while stirring. Dilute with sulfuric acid and water before assembling the battery, the diluted concentration is 3 times, and the density of the electrolyte used is 1.26g / cm 3 . Stir evenly and put it into a battery case equipped with polar plates and AGM se...

Embodiment 2

[0024] A storage battery electrolyte composed of organosilicon and inorganic silicon, the composition of which is as follows in parts by weight:

[0025] (1) Silica sol SiO 2 .XH 2 O: 40 copies

[0026] (2) Hydrogen silicone oil (CH 3 ) 3 Si-O-(HSiCH 3 -O-)n-Si(CH 3 ) 3 : 5 servings

[0027] (3) polyethylene glycol HO-(CH 2 CH 2 ) n -OH: 0.5 parts

[0028] (4) Deionized water or distilled water: 15 parts.

[0029] The preparation method of the battery electrolyte composed of organosilicon and inorganic silicon is to mix the weighed components (2) and (3) and 15 parts of deionized water or distilled water together to form a uniform paste, add (1) Components, add water to dilute to the corresponding concentration while stirring. Dilute with sulfuric acid and water before assembling the battery, the diluted concentration is 3 times, and the density of the electrolyte used is 1.26g / cm 3 . Stir evenly and put it into a battery case equipped with polar plates and AGM ...

Embodiment 3

[0031] A storage battery electrolyte composed of organosilicon and inorganic silicon, the composition of which is as follows in parts by weight:

[0032] (1) Silica sol SiO 2 .XH 2 O: 50 copies

[0033] (2) Hydrogen silicone oil (CH 3 ) 3 Si-O-(HSiCH 3 -O-)n-Si(CH 3 ) 3 : 40 servings

[0034] (3) polyethylene glycol HO-(CH 2 CH 2 ) n -OH: 10 parts

[0035] (4) Deionized water or distilled water: 20 parts.

[0036] The preparation method of the battery electrolyte composed of organosilicon and inorganic silicon is to mix the weighed components (2) and (3) and 15 parts of deionized water or distilled water together to form a uniform paste, add (1) Components, add water to dilute to the corresponding concentration while stirring. Dilute with sulfuric acid and water before assembling the battery, the diluted concentration is 3 times, and the density of the electrolyte used is 1.29g / cm 3 . Stir evenly and put it into a battery case equipped with polar plates and AGM ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com