Composite silicon-carbon electrode material with shelly structure

A silicon-carbon composite, electrode material technology, applied in battery electrodes, structural parts, circuits, etc., can solve the problems of fast capacity decay, limited electron conduction rate, easy fragmentation, etc., to achieve fast charge and discharge rate, shorten the transmission path. , the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

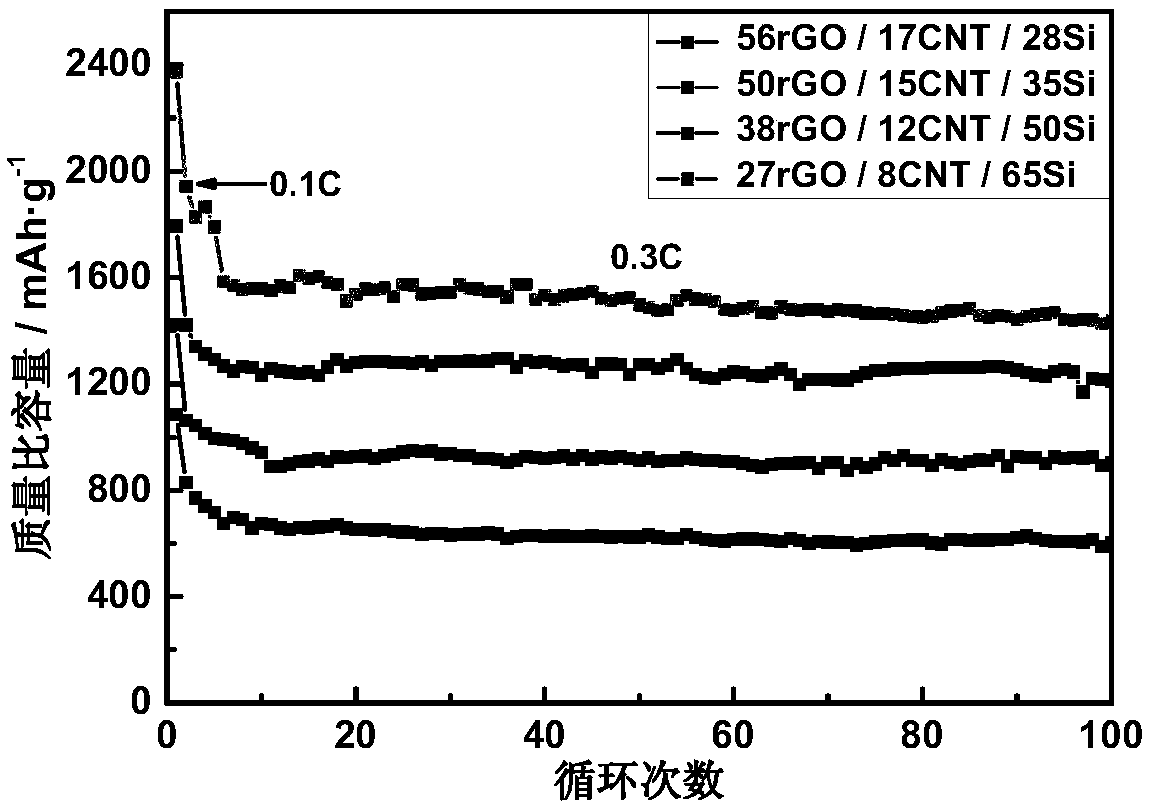

[0035] In this example, a material with silicon content accounting for 28 wt% of the material mass was prepared.

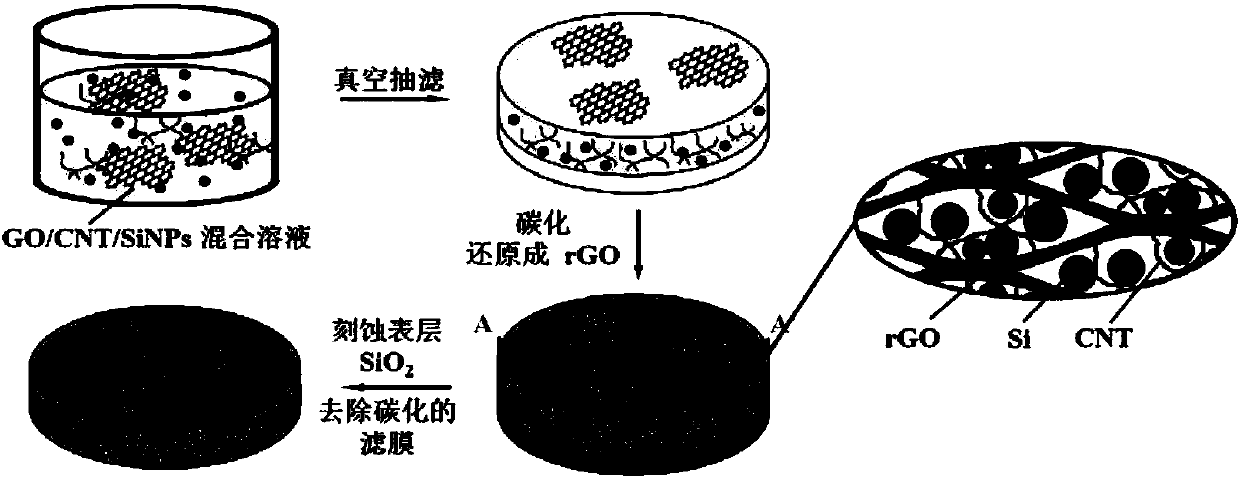

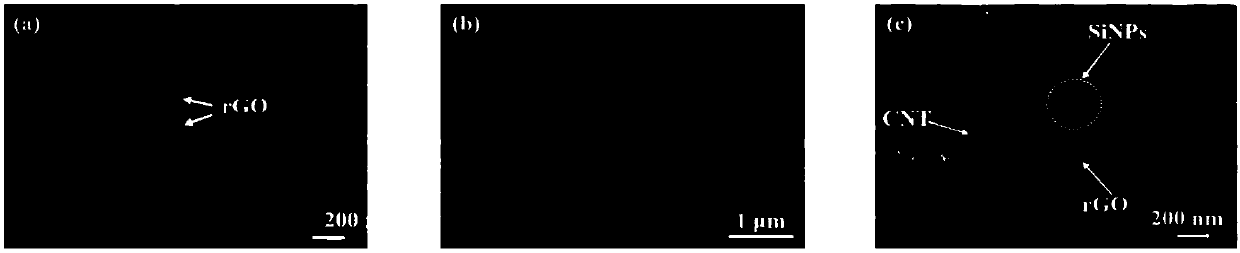

[0036] figure 1 Demonstrated the preparation process of "shell-like" structure silicon-carbon composite electrode materials by vacuum filtration method, in which SiNPs is nano-silicon particles (particle size 30-50nm), GO is graphene oxide, rGO is reduced graphene oxide, CNT is carbon nanotube (diameter 8-10nm, length 8-15μm), SiO 2 It is a silicon dioxide layer naturally oxidized on the surface of nano-silicon particles. The specific method is as follows:

[0037](1) Preparation of GO / CNT / SiNPs precursor solution: Take 50 mg of nano-silicon particles, carbon nanotubes, and graphene oxide and disperse them into 10 mL of aqueous solution to obtain an aqueous dispersion with a concentration of 5 mg / mL; : 3: 10 was ultrasonically mixed to obtain an aqueous solution mixture of 28 parts by mass of silicon nanoparticles, 17 parts by mass of carbon nanotubes, and 55 p...

Embodiment 2

[0043] In this embodiment, a material whose silicon content accounts for 35 wt% of the material mass is prepared. Step (1) is:

[0044] Preparation of GO / CNT / SiNPs precursor solution: Disperse 50 mg of nano-silicon particles, carbon nanotubes, and graphene oxide into 10 mL of aqueous solution to obtain an aqueous dispersion with a concentration of 5 mg / mL; the three aqueous dispersions were ultrasonically mixed in proportion, An aqueous solution mixture of 35 parts by mass of silicon nanoparticles, 15 parts by mass of carbon nanotubes, and 50 parts by mass of graphene oxide was obtained. Other operations are the same as in Example 1.

Embodiment 3

[0046] In this embodiment, a material whose silicon content accounts for 50 wt% of the material mass is prepared. Step (1) is:

[0047] Preparation of GO / CNT / SiNPs precursor solution: Disperse 50 mg of nano-silicon particles, carbon nanotubes, and graphene oxide into 10 mL of aqueous solution to obtain an aqueous dispersion with a concentration of 5 mg / mL; the three aqueous dispersions were ultrasonically mixed in proportion, An aqueous solution mixture of 50 parts by mass of silicon nanoparticles, 12 parts by mass of carbon nanotubes, and 38 parts by mass of graphene oxide was obtained. Other operations are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com