Nano-silica dispersion liquid, preparation method thereof, and preparation method of cake

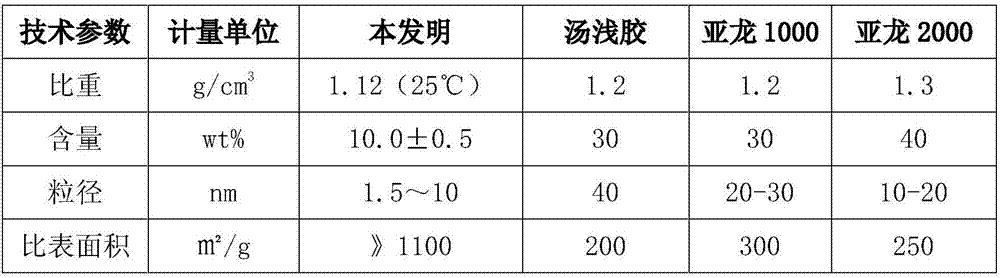

A technology of nano-silica and dispersion liquid, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc. It can solve the problems of poor stability of nano-silica sol, unsatisfactory colloidal state, and high colloid usage. problems, to achieve the effect of favorable stability, reduced gel hydration phenomenon, and strong gel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

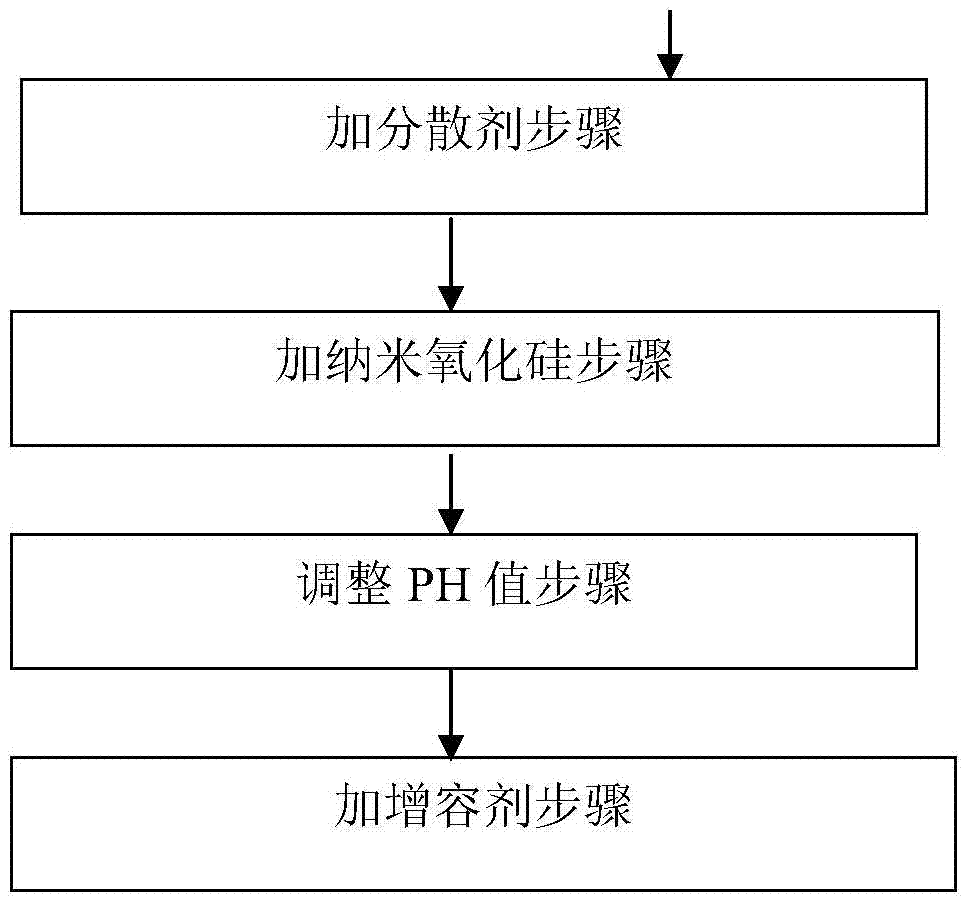

[0071] Embodiment 1, the preparation method of nano silicon oxide dispersion liquid, such as figure 1 As shown, the order includes adding dispersant step, adding nano silicon oxide step, adjusting pH value step and adding compatibilizer step:

[0072] (1) Step of adding dispersant: add deionized water to the reaction kettle, then add 6% dispersant and 0.1% stabilizer accounting for the mass percentage of nano-silica solids, and stir for 15 minutes at a temperature of 20°C; The dispersant is sodium polycarboxylate; the stabilizer is hydroxymethyl cellulose;

[0073] (2) Step of adding nano-silicon oxide: in the liquid obtained in step (1), add nano-silicon oxide cake, its solid nano-silicon oxide accounts for 5% of the mass percent of the nano-silicon oxide dispersion, at 20 ° C, Stir for 10 minutes; in the nano-silica cake, the nano-silica particle size is 1.5-10nm, and its specific surface area is 1128㎡ / g;

[0074] (3) The step of adjusting the pH value: adding lye to the l...

Embodiment 2

[0077] Embodiment 2, the preparation method of nano-silicon oxide dispersion liquid, the sequence includes adding dispersant step, adding nano-silicon oxide step, adjusting pH value step and adding compatibilizer step:

[0078] (1) Step of adding dispersant: add deionized water in the reaction kettle, then add 0.5% dispersant and 5% stabilizer accounting for the mass percentage of nano-silica solids, and stir for 15 minutes at 35°C; Described dispersant is alkyl polyoxyethylene ether (Pingping adds O); Described stabilizing agent is polyvinyl alcohol;

[0079] (2) Step of adding nano-silicon oxide: in the liquid obtained in step (1), add nano-silicon oxide cake, its solid matter accounts for 8% by mass of the nano-silicon oxide dispersion, and stir at a temperature of 50°C for 5 Minutes; in the nano-silica cake material, the nano-silica particle size is 1.5-10nm, and its specific surface area is 1100㎡ / g;

[0080] (3) The step of adjusting the pH value: adding lye to the liqui...

Embodiment 3

[0083] Embodiment 3, the preparation method of nano-silicon oxide dispersion liquid, the sequence includes adding dispersant step, adding nano-silicon oxide step, adjusting pH value step and adding compatibilizer step:

[0084] (1) Step of adding dispersant: add deionized water into the reaction kettle, then add 3% dispersant and 2% stabilizer accounting for the mass percentage of nano-silica solids, and stir for 10 minutes at a temperature of 50°C; The dispersant is glycerin; the stabilizer is hydroxyethyl cellulose;

[0085] (2) Step of adding nano-silicon oxide: in the liquid obtained in step (1), add nano-silicon oxide cake, its solid matter accounts for 11% of the mass percentage of nano-silicon oxide dispersion, and stir at 40°C for 8 Minutes; in the nano-silica cake, the nano-silica particle size is 1.5-10nm, and its specific surface area is 1160㎡ / g;

[0086] (3) Step of adjusting the pH value: adding lye to the liquid obtained in step (2), stirring for 30 minutes at a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com