Patents

Literature

66results about How to "High Salt Rejection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite reverse osmosis membrane having a separation layer with polyvinyl alcohol coating and method of reverse osmotic treatment of water using the same

InactiveUS6177011B1High Salt RejectionPermit practical desalinationGeneral water supply conservationWater/sewage treatment bu osmosis/dialysisZeta potentialWater use

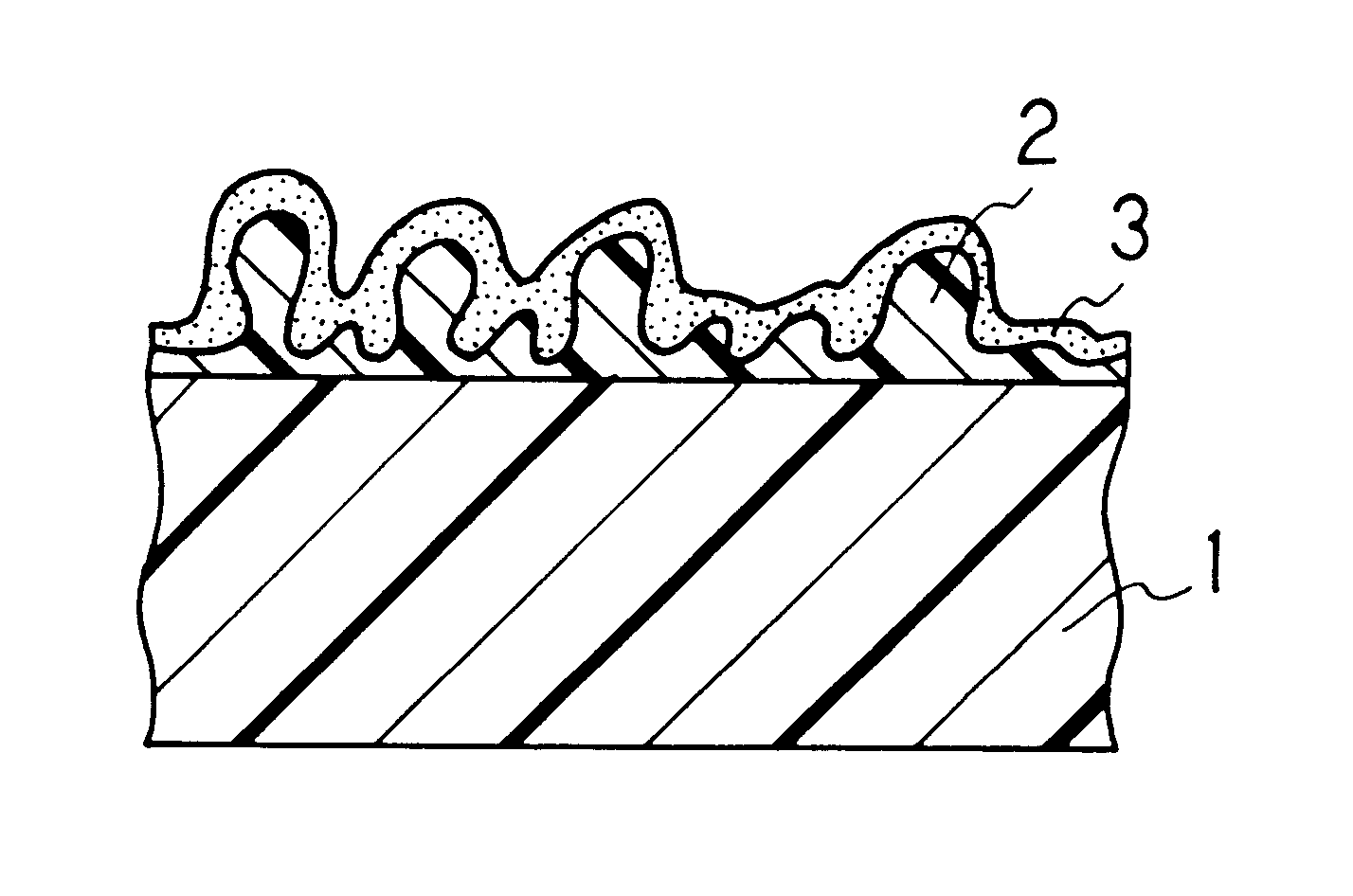

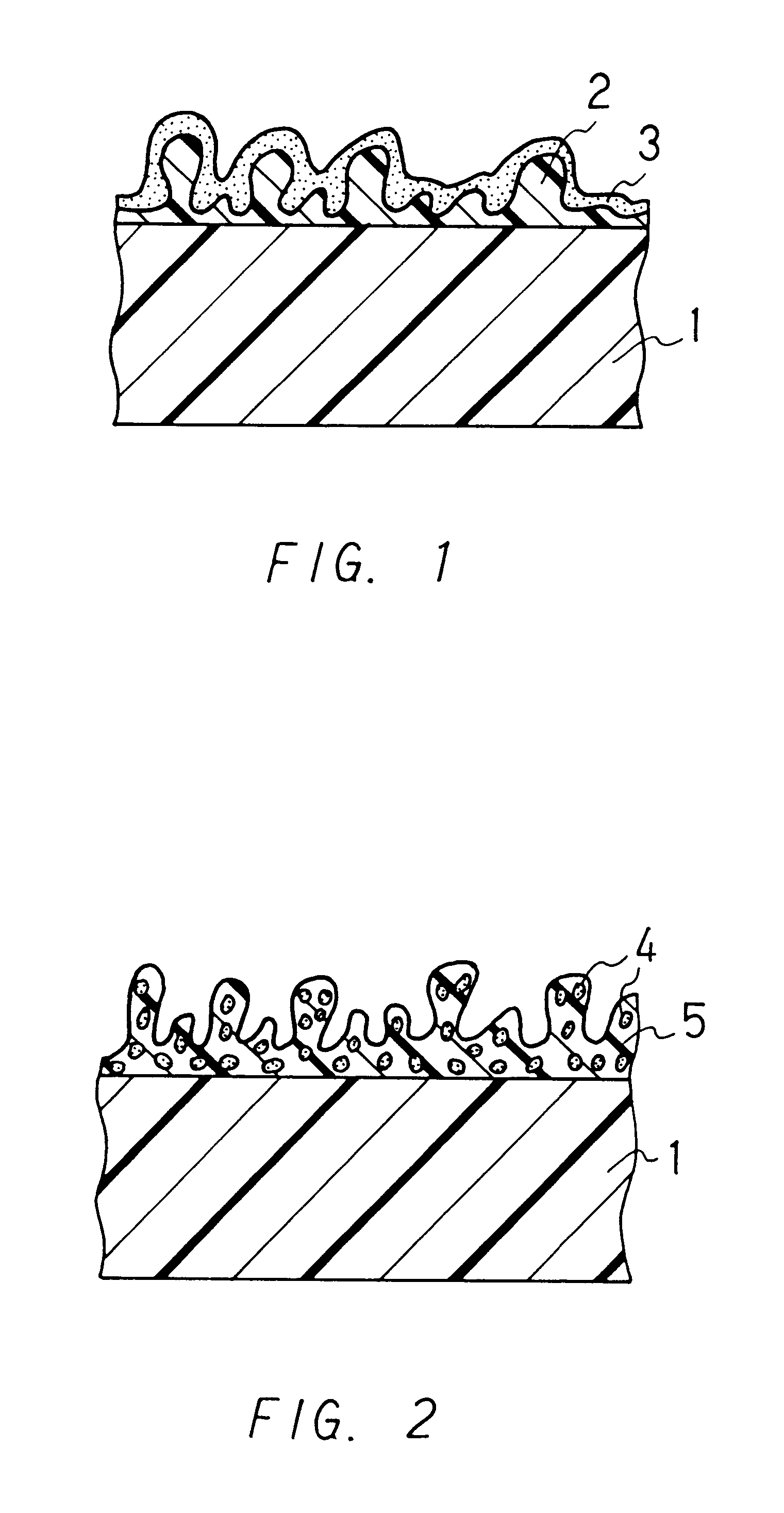

A reverse osmosis composite membrane that has a high salt rejection, a high water permeability, and a high fouling tolerance, and permits practical desalination at a relatively low pressure is provided by coating the surface of a reverse osmosis membrane of aromatic polyamide with polyvinyl alcohol (PVA), for example, and controlling the surface zeta potential of the separation layer within±10 mV at pH 6. This reverse osmosis composite membrane is electrically neutral and controls the electrical adsorption of membrane-fouling substances having a charge group present in water. Therefore, a high separation property can be maintained without fouling the membrane even if water containing a surfactant or a transition metal component is supplied as raw water.

Owner:NITTO DENKO CORP

Cellulose acetate nanofiltration membrane and preparing method thereof

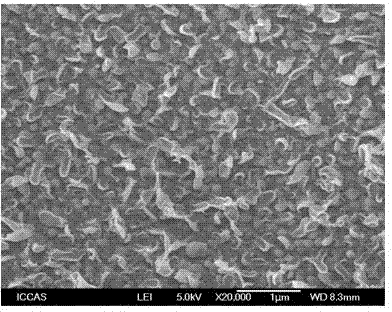

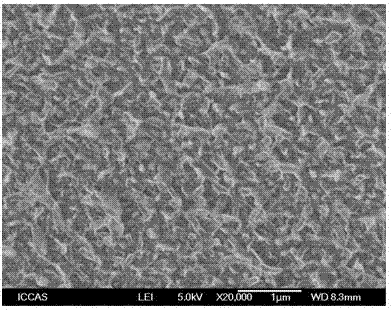

The invention discloses a cellulose acetate nanofiltration membrane and a preparing method thereof. The preparing method of the cellulose acetate nanofiltration membrane includes the steps that cellulose acetate serves as a raw material, an organic metal framework compound and a small molecule pore-forming agent serve as a mixed additive, the raw material and the mixed additive are dissolved through a solvent to prepare a cellulose acetate membrane casting solution, a dry and clean glass plate with a supporting layer is coated with the prepared membrane casting solution to form a plate nascent-state membrane or the prepared membrane casting solution and a medium with an inner fiber cavity are extruded through a spinneret plate to obtain a hollow fiber nascent-state membrane, the hollow fiber nascent-state membrane is solidified and subjected to heat treatment, and the cellulose acetate nanofiltration membrane is prepared. As the cellulose acetate nanofiltration membrane is prepared through the organic metal framework compound, the porosity factor of the cellulose acetate nanofiltration membrane is increased, and the water flux is improved; the amine-modified organic metal framework compound is introduced into the formula of the membrane casting solution of the cellulose acetate, the nanofiltration membrane can show charged positive electricity after cross-linking, separation of amino acid with positive charges and protein with positive charges can be promoted, and the reject rate of the nanofiltration membrane is increased.

Owner:INST OF CHEM CHINESE ACAD OF SCI

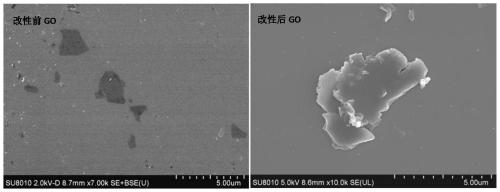

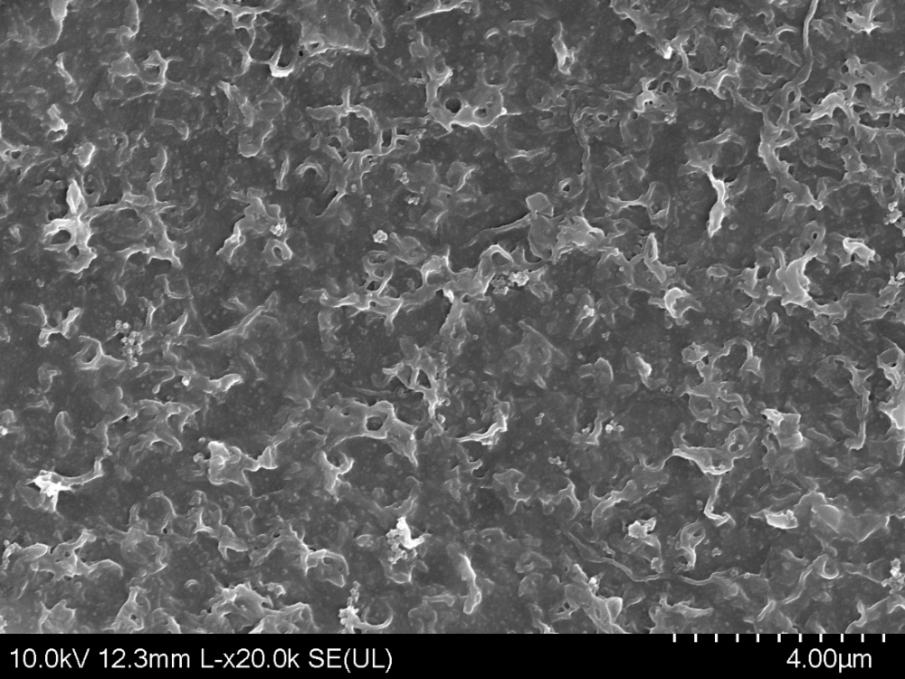

Preparation method of amino-modified graphene oxide composite positive permeable film

InactiveCN103861472AHigh mechanical strengthGood chemical stabilitySemi-permeable membranesDiamineDimethyl formamide

The invention provides a preparation method of an amino-modified graphene oxide composite positive permeable film. The method is characterized by comprising the following specific steps: mixing graphene oxide, dimethyl formamide, organic amine and dicyclohexyl carbimide, and performing ultrasonic treatment; reacting for 40-50 hours at the temperature of 100-150 DEG C; adding absolute ethyl alcohol, and standing and filtering to obtain a precipitate; washing and drying the precipitate to obtain amino-modified graphene oxide; mixing the amino-modified graphene oxide with a solvent, performing ultrasonic treatment, and adding an additive and a film formation polymer into a mixed solution to prepare a casting film solution; de-foaming to prepare a base film through a phase inversion method, and immersing the base film in pure water for later use; and pouring a metaphenylene diamine solution and trimesoyl chloride to the surface of the base film, performing a contact reaction, washing the surface of the film with an organic solvent, and drying the film to obtain the amino-modified graphene oxide composite positive permeable film. The amino-modified graphene oxide composite positive permeable film is high in mechanical strength, high in chemical stability, large in permeation flux of the pure water, and high in salt rejection rate.

Owner:DONGHUA UNIV

High-temperature resistance polyamide composite membrane and preparation method thereof

InactiveCN103111195AImprove high temperature resistanceGood acid and alkali resistanceSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisPolymer scienceIndustrial waste water

The invention discloses a high-temperature resistance polyamide composite membrane and a preparation method thereof. The high-temperature resistance polyamide composite membrane is composed of a non-woven fabric layer, a porous supporting layer and a polyamide layer, wherein a porous supporting membrane material is prepared by adding one or more of a solubility high-temperature resistance polymer P1 and a commodity polymer P2 for preparation of a porous membrane material to a certain solvent and a pore-foaming agent and at least contains the P1. The polyamide composite membrane prepared by the method has very good high-temperature resistance performance and can be widely applied to water treatment composite membrane treatment devices needing to run at a high temperature in industries such as industrial wastewater treatment, petrochemical wastewater treatment, food, medicines and the like.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Method for preparing polyvinylidene fluoride composite cellulose acetate forward osmosis membrane

ActiveCN102580562AHigh water fluxHigh Salt RejectionSemi-permeable membranesConcentration polarizationFiltration

The invention relates to a method for preparing a polyvinylidene fluoride composite cellulose acetate forward osmosis membrane. The conventional product has a serious inside concentration polarization phenomenon and low actual flux. The method comprises the following steps of: preparing a polyvinylidene fluoride cast membrane solution from polyvinylidene fluoride and additive; preparing a cellulose acetate cast membrane solution from cellulose acetate, cellulose triacetate and molecular sieve; and uniformly coating the polyvinylidene fluoride cast membrane solution on a non-woven fabric to obtain a hydrophilic polyvinylidene fluoride micro-filtration base membrane, drying or naturally drying in air to form a dry hydrophilic polyvinylidene fluoride membrane, uniformly coating the cellulose acetate cast membrane solution on the dry hydrophilic polyvinylidene fluoride membrane, and thus obtaining the composite forward osmosis membrane. The forward osmosis membrane prepared by the method has high mechanical strength and solvent tolerance, high water flux and high salt intercepting rate, and can be applied in the fields of desalting of seawater and brine, softening of hard water, first-aid water bags and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

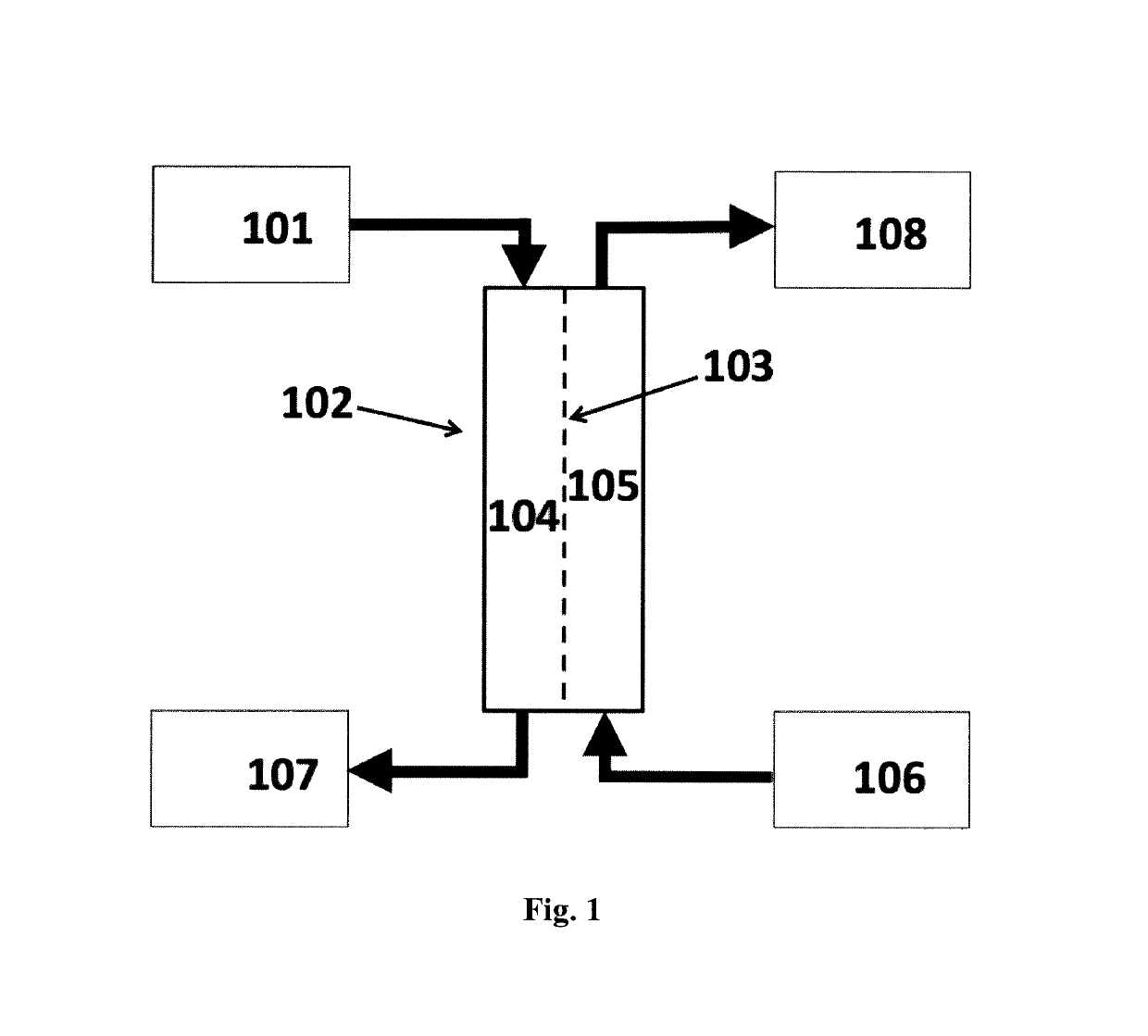

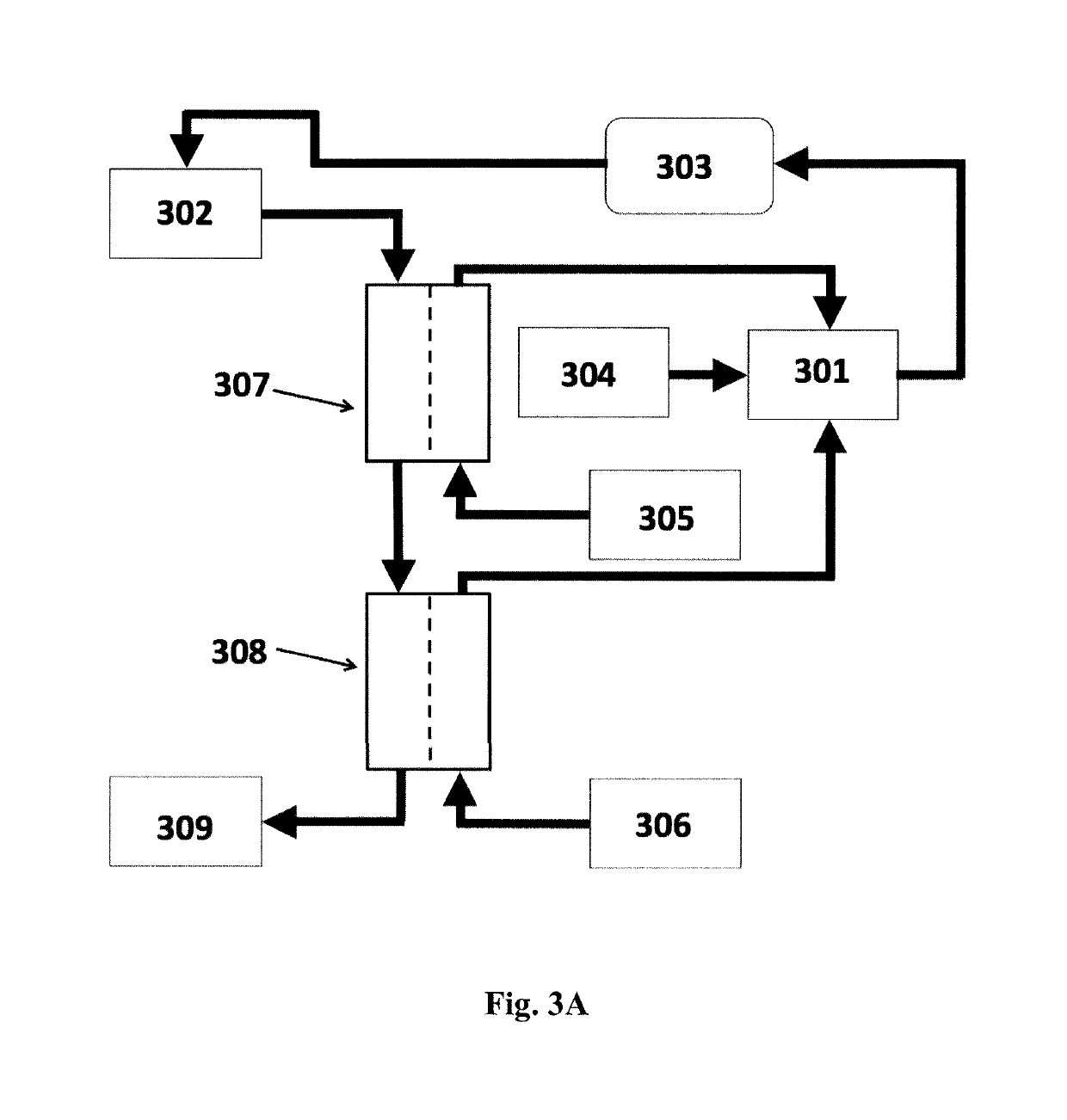

Systems for utilizing the water content in fluid from a renal replacement therapy process

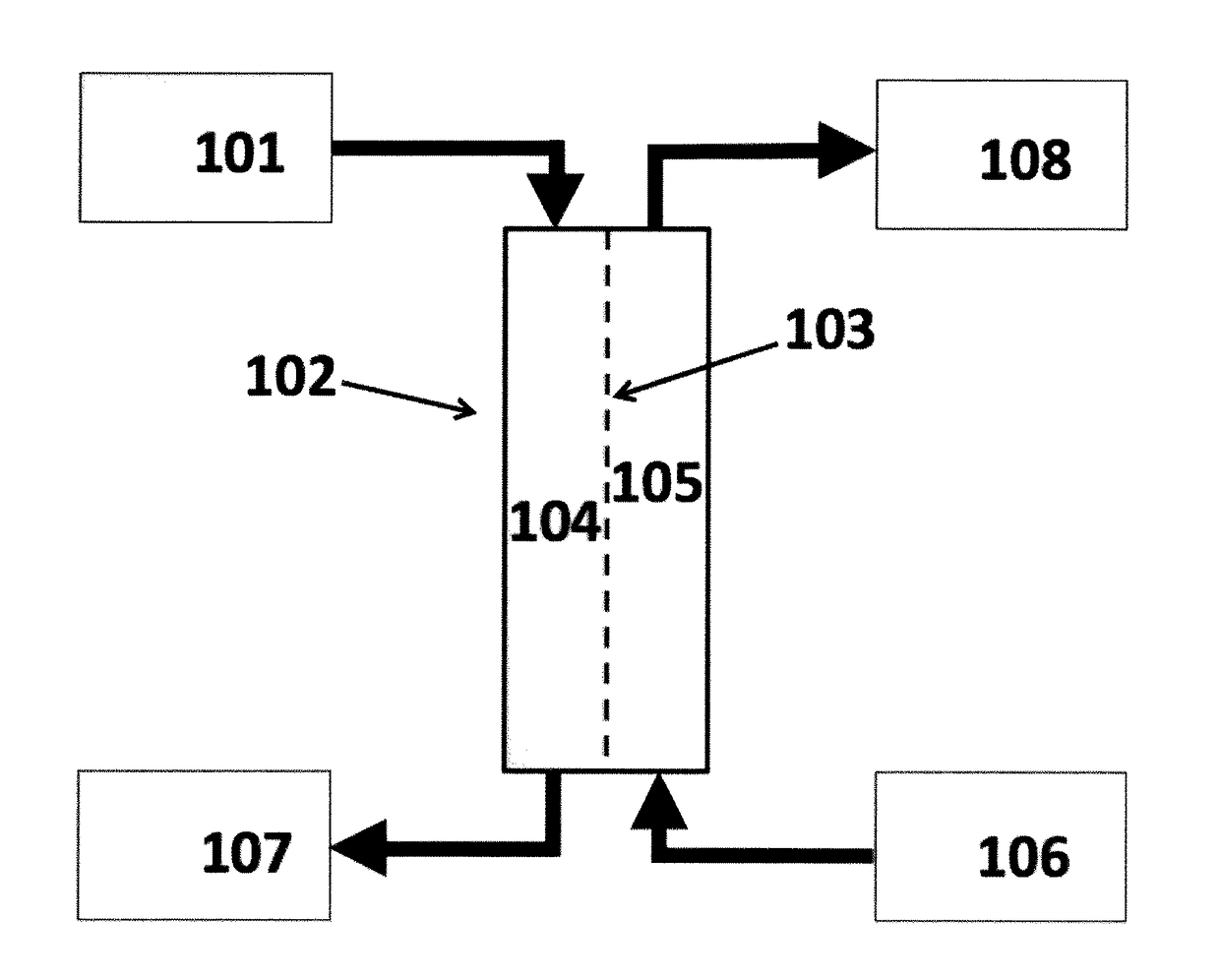

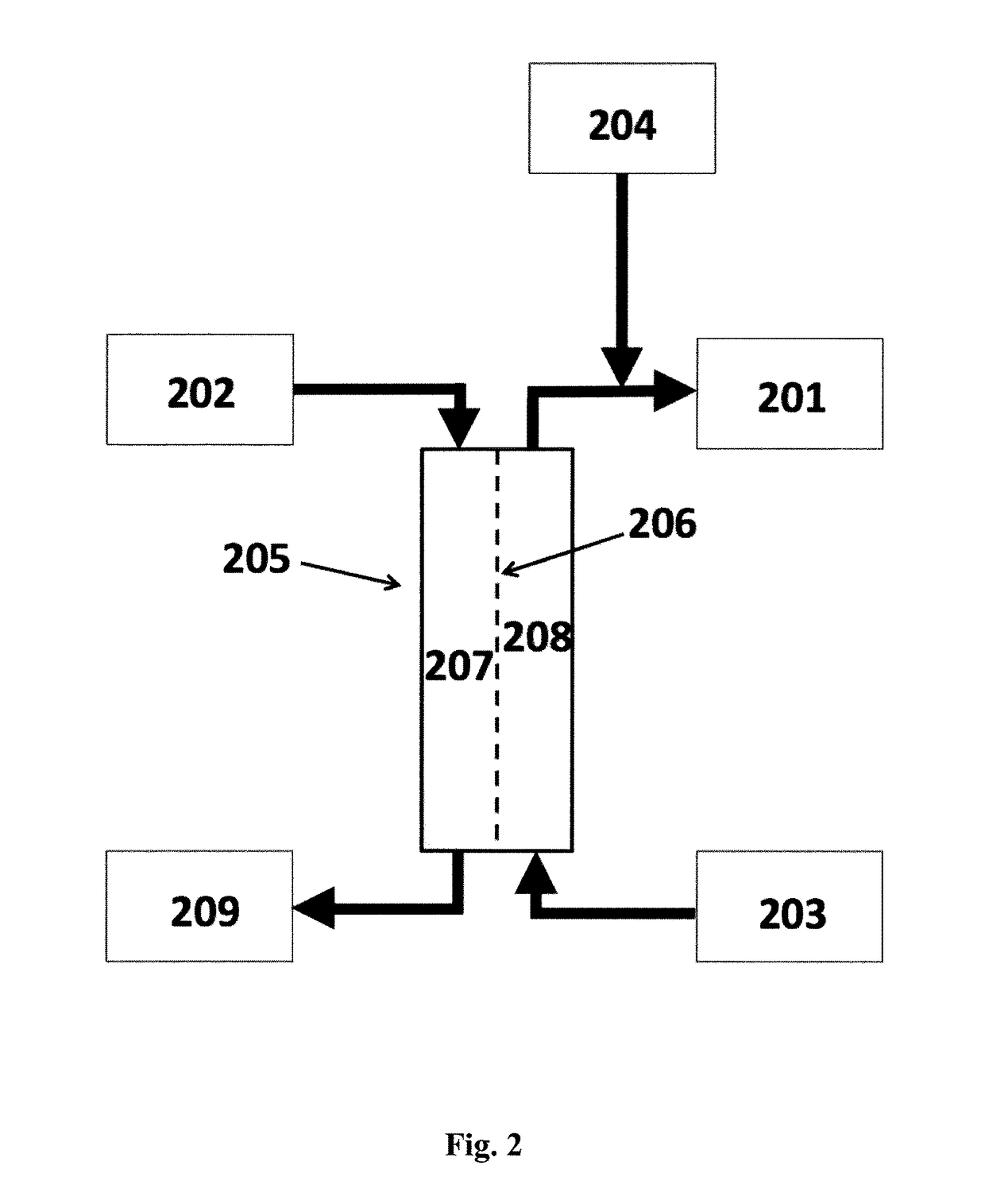

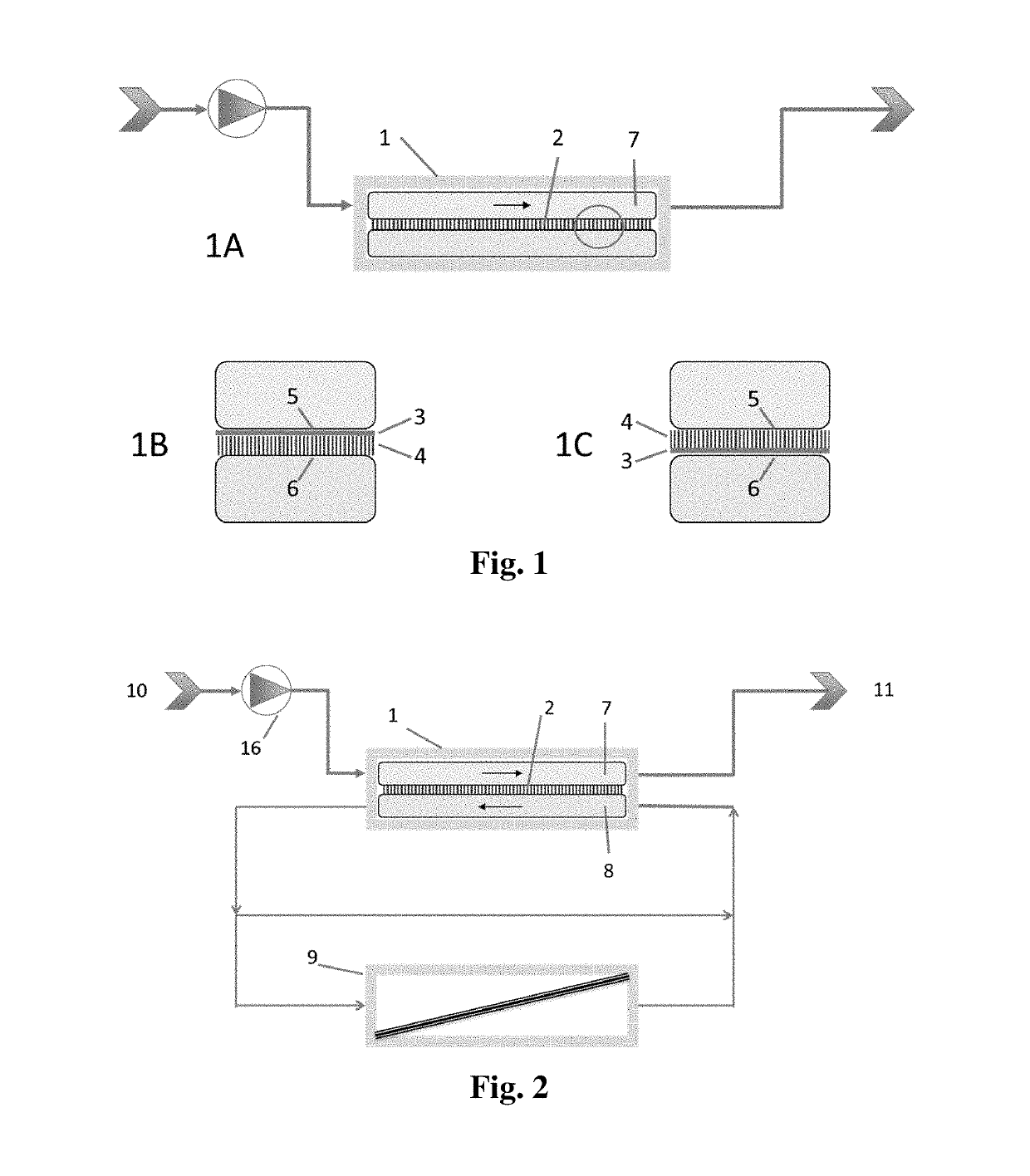

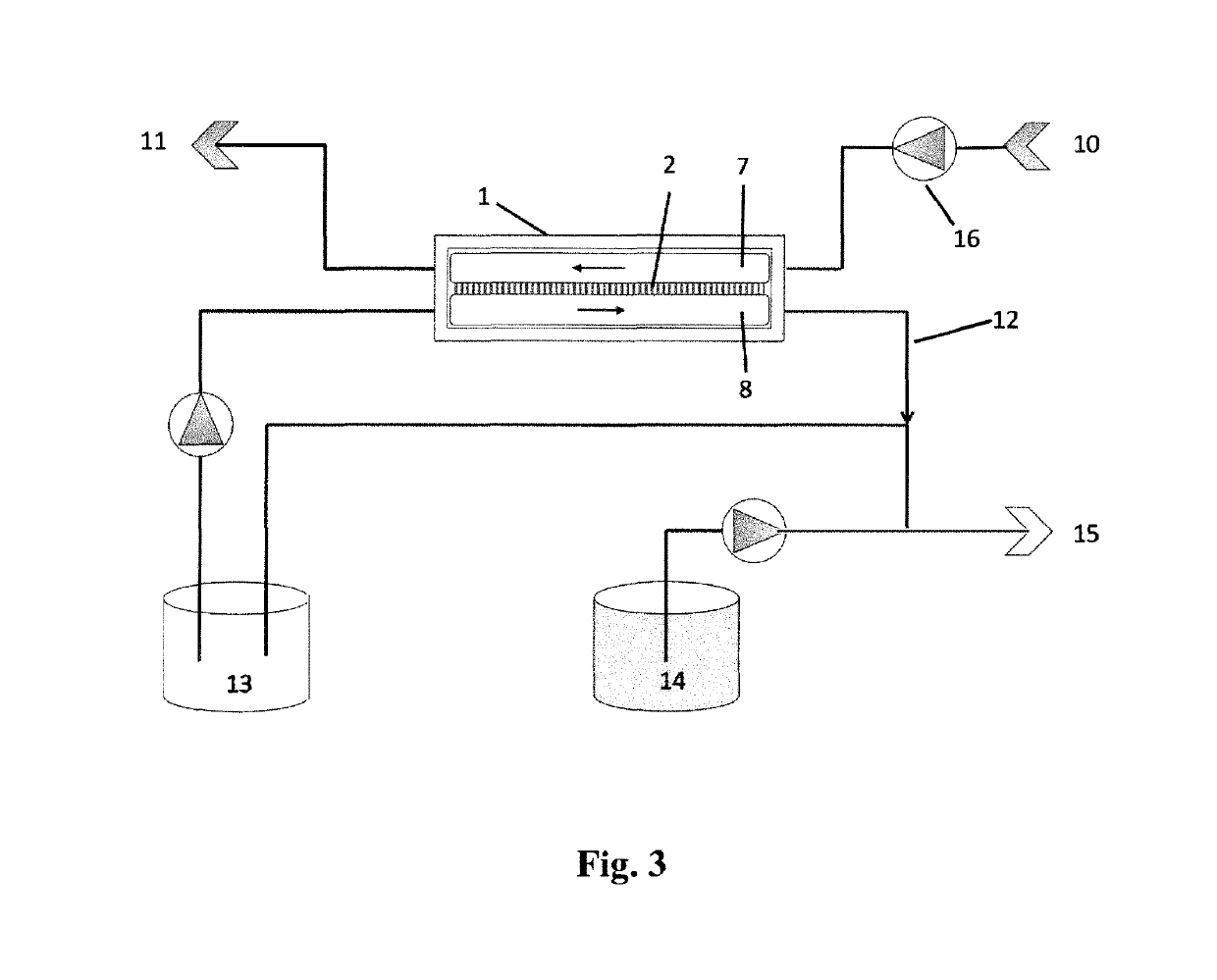

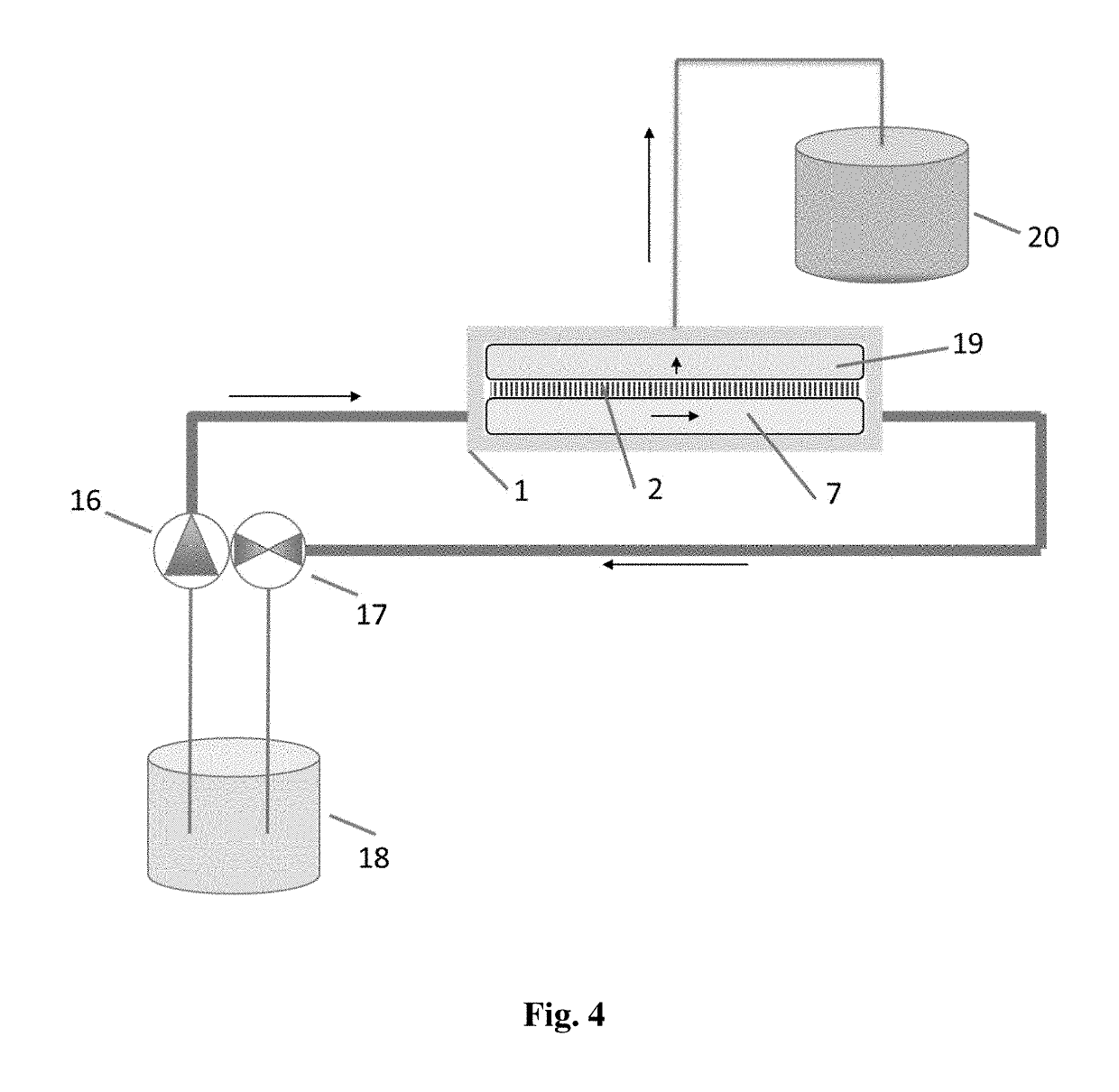

ActiveUS20170065762A1High Salt RejectionReduce energy consumptionHaemofiltrationUltrafiltrationHaemodialysis machineNephropathy

The present invention relates to systems, methods and uses for recycling at least a part of water lost during various renal replacement therapy processes, e.g. in the preparation of a fresh dialysate solution or fresh reconstitution fluid for kidney disease dialysis and hemofiltration by utilizing water from the spent fluids. The system of the invention is useful in hemodialysis and in peritoneal dialysis as well as in hemofiltration for reuse of water from filtrates and spent fluids. In addition, the system of the invention is useful in the development of a renal assist device or artificial kidney.

Owner:AQUAPORIN AS

Composite forward osmosis membrane and preparation method thereof

The present invention relates to a composite forward osmosis membrane and a preparation method thereof. The composite forward osmosis membrane comprises an ion exchange resin doped polymer support layer and a polyamide active layer compounded on the polymer support layer surface, wherein a mass ratio of the ion exchange resin to the polymer in the polymer support layer is (0.1-25):(5-40). The preparation method comprises: doping ion exchange resin micro-particles in a polymer solution, preparing a composite forward osmosis membrane support layer containing the ion exchange resin by using a non-solvent induction phase separation method, and compounding an active layer adopting polyamine and poly acyl chloride on the surface of the composite forward osmosis membrane support layer containing the ion exchange resin by using an interfacial polymerization method so as to prepare the composite forward osmosis membrane, wherein the prepared composite forward osmosis membrane can be adopted as the osmosis membrane for seawater desalination and other processes. Compared with the method in the prior art, the method of the present invention has advantages of economy, high efficiency, high water flux, high salt trapping rate, and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

Preparation method of positively charged polyamide/TiO2 ceramic hollow fiber composite nano-filtration membrane and nano-filtration membrane

ActiveCN108554187AHigh Salt RejectionSimple preparation processMembranesSemi-permeable membranesHollow fibreFiber

The invention relates to a preparation method of a positively charged polyamide / TiO2 ceramic hollow fiber composite nano-filtration membrane. The composite nano-filtration membrane comprises a supporting layer, a middle layer and a separation layer. The preparation method comprises the following steps that 1, a ceramic base membrane is prepared; 2, the base membrane is preprocessed; 3, titanium sol is prepared; 4, the base membrane is coated with the sol; 5, the sol is sintered; 6, an aqueous phase and an organic phase solution are prepared; 7, an interfacial polymerization reaction is conducted to obtain the final composite nano-filtration membrane. The invention further provides the nano-filtration membrane obtained through the method. The method has the advantages that the process is simple, the membrane separation performance is good, and the industrial practical application value is remarkable.

Owner:EAST CHINA UNIV OF SCI & TECH

Preparation method of alumina/oxidized graphene/polyvinyl alcohol composite nanofiltration membrane

ActiveCN110280144AHigh Salt RejectionIncreased pure water fluxSemi-permeable membranesMembranesChemistryNanofiltration

The invention discloses a preparation method of an alumina / oxidized graphene / polyvinyl alcohol composite nanofiltration membrane. The preparation method comprises following steps: Hummers method is adopted to prepare oxidized graphene, homogeneous precipitation method is adopted to cover an formed oxidized graphene layer with an amorphous nanometer alumina thin layer uniformly so as to obtain a monomer used for layer by layer self assembling; polyethersulfone is taken as a substrate, is coated with a layer of polyvinyl alcohol, and is coated with a layer of the nanometer alumina / oxidized graphene composite monomer, alternative coating of the above two monomers is carried out so as to obtain the nanometer alumina / oxidized graphene / polyvinyl alcohol composite nanofiltration membrane. The surface of the nanometer alumina / oxidized graphene / polyvinyl alcohol composite nanofiltration membrane contains a large amount of hydrophilic groups such as hydroxyl and carboxyl, so that pure water flux is high; and at the same time, the film surface is negatively charged, so that film layer salt retention rate is increased.

Owner:SANDA FILM SCI & TECH XIAMEN

Preparation method of hydrophilic anti-pollution aromatic polyamide reverse-osmosis membrane

InactiveCN109621752AGood chemical stabilityImprove physical stabilityMembranesReverse osmosisPolyamideReverse osmosis

The invention relates to a preparation method of a hydrophilic anti-pollution aromatic polyamide reverse-osmosis membrane, and belongs to the technical field of modification preparation of high-performance reverse-osmosis membranes. The preparation method includes the following steps that a polysulfone-base membrane is soaked in deionized water, then blow-dried, and fixed in a polytetrafluoroethylene frame, and a water solution of m-phenylenediamine and dimethyl diallyl ammonium chloride is poured onto the surface of the polysulfone-base membrane; an n-hexane solution of trimesoyl chloride isthen poured for an interface polymerization reaction; a water solution of hydrophilic olefin type monomers is poured onto the surface of the membrane, irradiation treatment is conducted with gamma-rays, and a modified membrane is obtained; the modified membrane is cleaned and dried. The preparation method has the advantages that macromolecule hydrophilic dimethyl diallyl ammonium chloride is grafted onto the surface of a polyamide separation layer, accordingly, good hydrophilicity is realized, the overall roughness of the surface of the reverse-osmosis membrane is reduced, and depositing and adsorbing of contaminants on the surface of the membrane can be reduced. Meanwhile, the macromolecule hydrophilic dimethyl diallyl ammonium chloride is grafted onto the surface of the polyamide separation layer to form a specific water channel, and therefore the performance of the reverse-osmosis membrane is improved.

Owner:HARBIN INST OF TECH

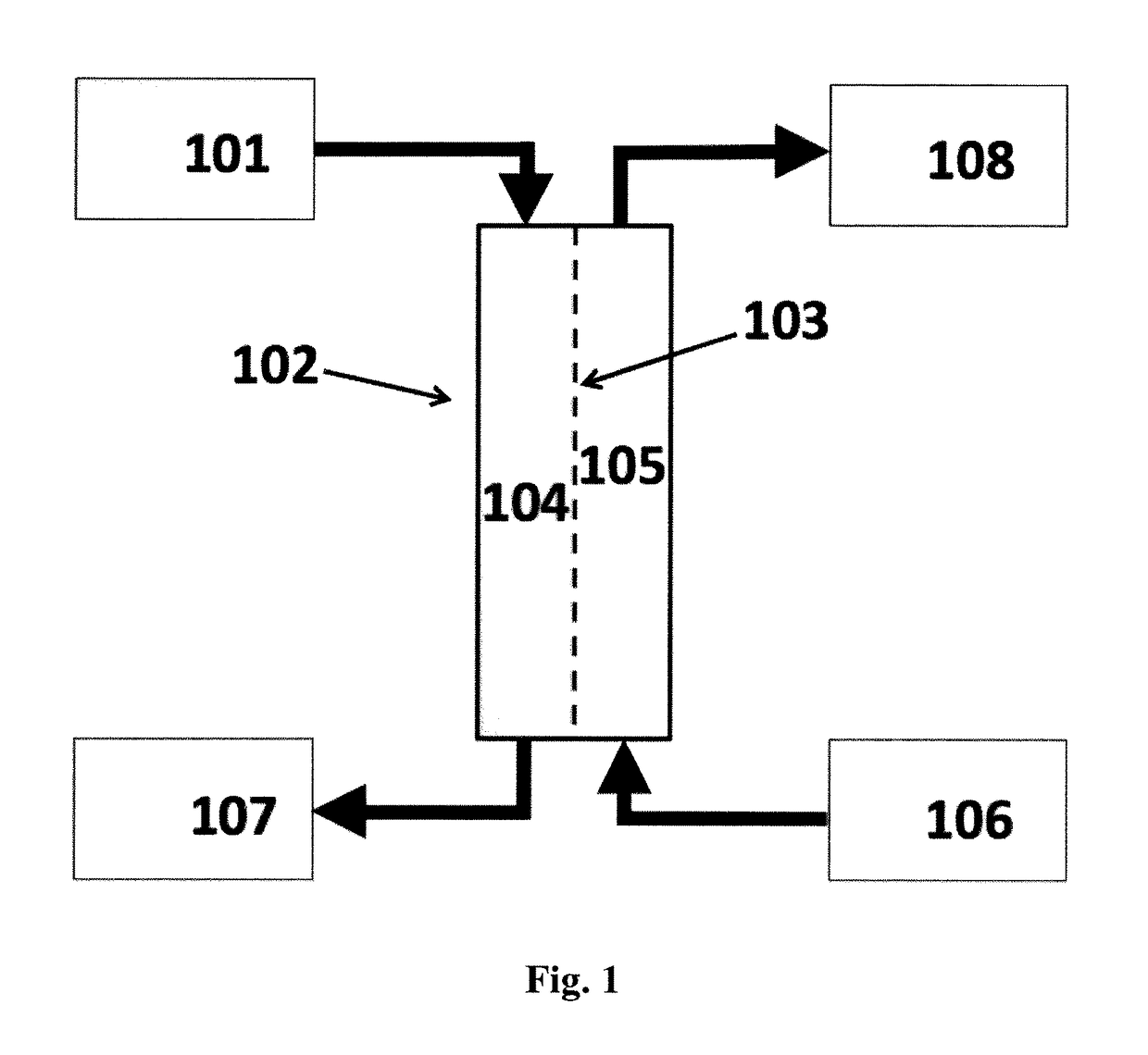

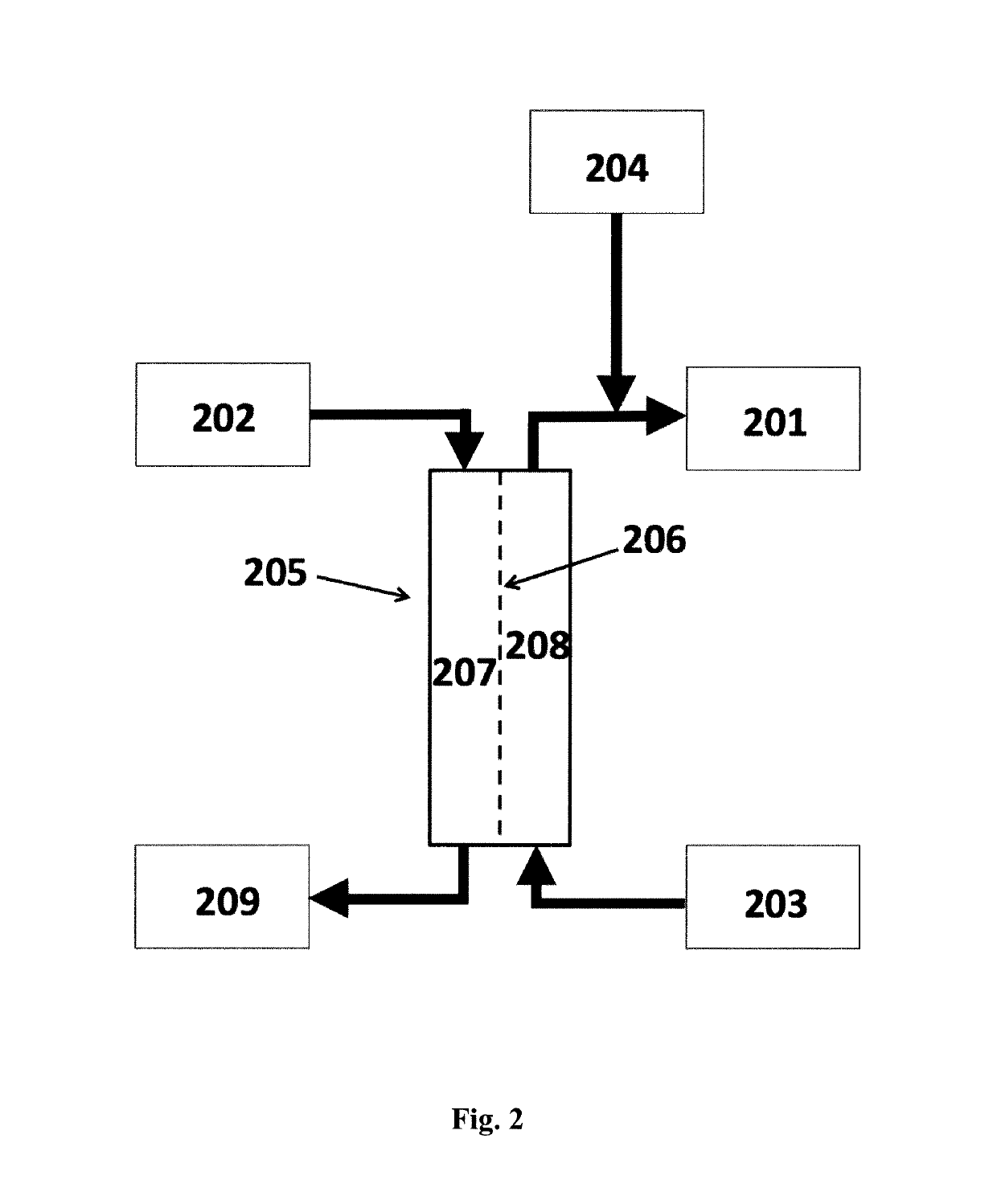

Systems for water extraction

ActiveUS20190184344A1Highly efficient water fluxHigh Salt RejectionMembranesSeawater treatmentEnvironmental engineeringAquaporin

The present invention relates to a water extraction system comprising a flow cell comprising a membrane; said membrane comprising an active layer comprising immobilized aquaporin water channels and a support layer, and said membrane having a feed side and a non-feed side; and an aqueous source solution in fluid communication with the feed side of the membrane.

Owner:AQUAPORIN AS

Amphoteric composite forward osmosis membrane as well as preparation method and application thereof

InactiveCN110841494AQuick evacuationIncrease water fluxSemi-permeable membranesGeneral water supply conservationPolyamidePolyvinylidene difluoride

The invention relates to an amphoteric composite forward osmosis membrane. According to the amphoteric composite forward osmosis membrane, an adopted porous support membrane is a super-hydrophilic polyvinylidene fluoride membrane; a polyamide layer is formed on the porous support membrane, and a zwitterionic layer is formed on the polyamide layer. In the present invention, the zwitterionic layer is formed by amido groups through zwitterionic reaction; through cooperation with the super-hydrophilic characteristic of the polyvinylidene fluoride membrane prepared through water vapor induced phaseseparation, the strong hydration and the charging performance of a catechol derivative modified graphene oxide nano-water channel and the zwitterionic skin layer, the water flux of the composite forward osmosis membrane is greatly improved while a low back-mixing salt flux is kept.

Owner:吾净科技(深圳)有限公司

Preparation method of mineralization modified thin layer composite forward osmosis membrane

InactiveCN107961682AReduce roughnessSmall negative surface chargeSemi-permeable membranesThin layerActive layer

The invention discloses a preparation method of a mineralization modified thin layer composite forward osmosis membrane. The preparation method particularly includes the steps of: firstly, preparing apolyamide thin layer composite forward osmosis membrane through interface polymerization; and performing alternate immersion to perform mineralization modification so as to deposit a layer of mineralized substance on the surface of the polyamide active layer, thereby producing the mineralization modified thin layer composite forward osmosis membrane which is higher in water flux, higher in salt interception rate and stronger antifouling performance. The preparation method is simple. The membrane has great practical application prospect and commercial development value in various fields of water treatment.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

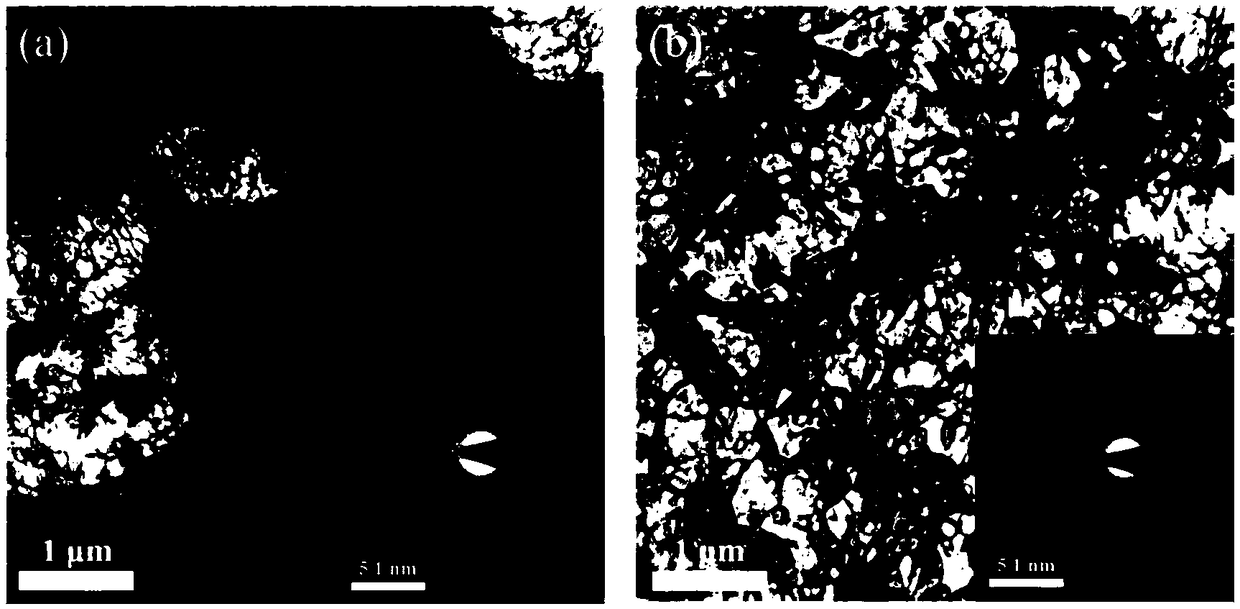

Metal-organic framework nanosheet modified forward osmosis film and preparation method and application thereof

ActiveCN109126480AIncrease water fluxHigh Salt RejectionSemi-permeable membranesPolyamideMetal-organic framework

The invention discloses metal-organic framework nanosheet modified forward osmosis film and a preparation method and application thereof. metal-organic framework nanosheets are introduced to an interfacial polymerization process for active layer preparation; a polyamide active layer containing metal-organic framework nanosheets is formed in situ on a support layer. An organic ligand to synthesizethe metal-organic framework nanosheets is terephthalic acid so that the metal-organic framework nanosheets have excellent hydrophilicity; compared with traditional inorganic nano materials, the metal-organic framework nanosheets are well compatible with polyamide film; extra pores are provided for mass transfer of the forward osmosis film polyamide active layer; water flux of the film can be further increased in the actual forward osmosis process; a higher water flux is attained under equal osmotic pressure, salt return mixing amount is lower, and anti-pollution performance is good.

Owner:TONGJI UNIV

Preparation method of graphene oxide base forward-osmosis membrane

InactiveCN105032207AHigh mechanical strengthGood solvent resistanceSemi-permeable membranesWater desalinationIndustrial waste water

The invention discloses a preparation method of a graphene oxide base forward-osmosis membrane. The preparation method includes the four steps that polysulfone membrane casting liquid even in dispersing of graphene oxide is prepared; a trimesoyl chloride hexane solution is prepared, wherein the mass percent of trimesoyl chloride is 0.05-5%; deionized water is used for removing the residual solution to obtain a polysulfone ultra-filtration bottom membrane; then the graphene oxide base forward-osmosis membrane is obtained. The prepared forward-osmosis membrane is high in mechanical strength, achieves solvent resistance and anti-polluting performance and has high water flux and a high salt retaining rate, the preparation method provides a new path for preparing the forward-osmosis membrane, and the forward-osmosis membrane can be used for the fields of first-aid water bags, plant protection boxes, sea water desalination, hard water softening and industrial waste water.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

Acid-resistant composite nanofiltration membrane and preparation method thereof

InactiveCN112642305AEasy to separateImprove hydrophilicityMembranesSemi-permeable membranesSulfonyl chlorideEngineering

The invention relates to an acid-resistant composite nanofiltration membrane and a preparation method thereof, and is characterized in comprising steps: taking vinyl polymers such as polytetrafluoroethylene and the like as a base membrane, and subjecting the surface of the membrane to carboxylation (-COOH) by an ultraviolet-induced graft polymerization method; then carrying out amidation reaction with water-based monomer polyamine; then carrying out interfacial polymerization reaction with an oil-phase monomer polysulfonyl chloride; and finally, forming the polysulfonyl chloride functional layer through thermocuring crosslinking. A new idea is provided for hydrophobic ultrafiltration membrane surface hydrophilic modification and acid salt solution or acid dye separation, the modified membrane has good hydrophilicity and acid resistance, high water flux and rejection rate can be kept in the nanofiltration separation process, and the modified membrane is expected to be used for seawater desalination or printing and dyeing wastewater treatment.

Owner:TIANJIN POLYTECHNIC UNIV +1

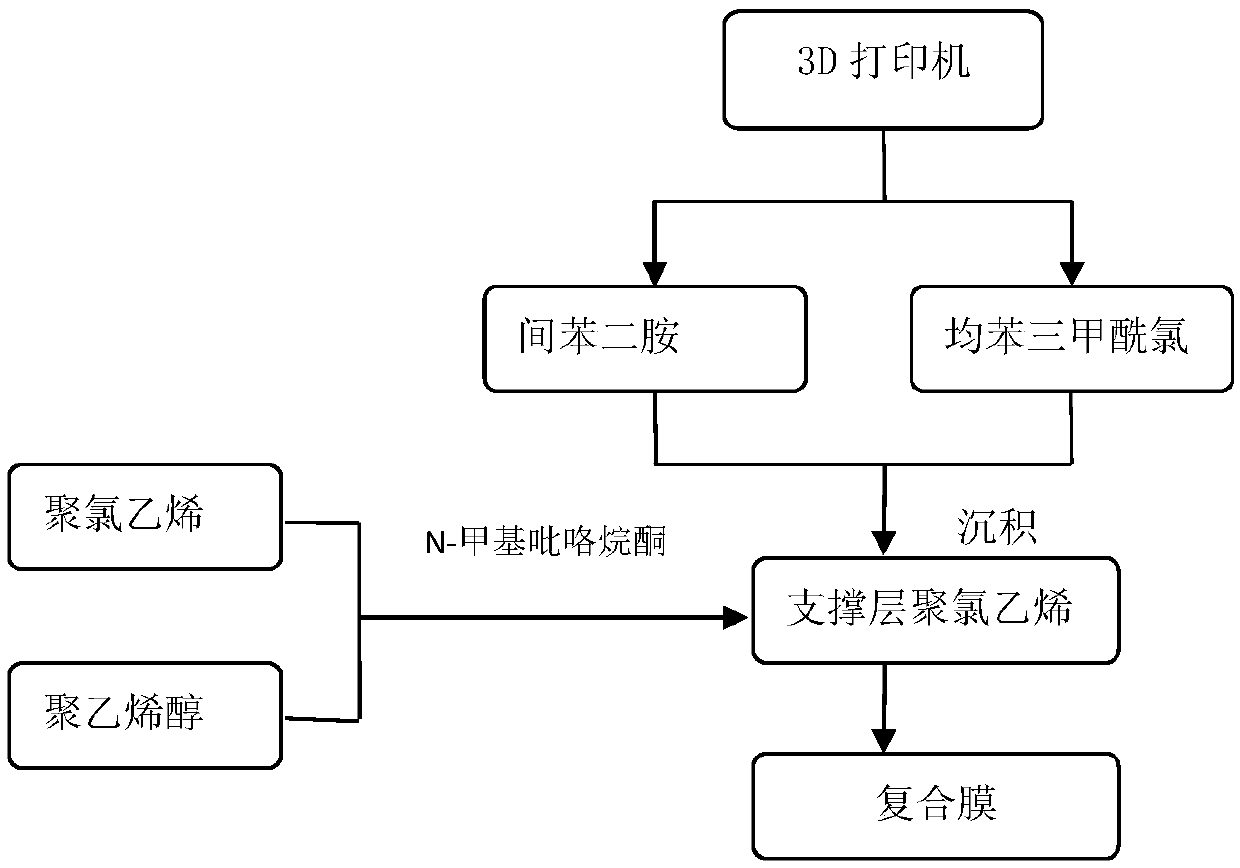

Preparation method of forward osmosis membrane based on 3D printing technology

ActiveCN109647221AImprove performanceLow priceSemi-permeable membranesPolymer sciencePolyvinyl alcohol

The invention discloses a preparation method of a forward osmosis membrane based on a 3D printing technology. The method comprises the following steps: (1) preparing a polyvinyl chloride supporting layer: mixing polyvinyl chloride, polyvinyl alcohol and N-methylpyrrolidone until the three substances are evenly stirred, standing the obtained mixture to defoam, uniformly forming a membrane by usinga membrane coating machine, and storing the membrane in deionized water for later use; and (2) preparing a polyvinyl chloride-polyamide composite membrane: preparing an n-hexane solution A containingtrimesoyl chloride and an aqueous solution B containing m-phenylenediamine, and sequentially depositing the solution B and the solution A on the polyvinyl chloride supporting layer by a 3D printer toobtain the composite membrane. The positive osmosis membrane prepared by the 3D printing technology has a controllable pore size and a controllable thickness; and the surface roughness of the membraneis reduced to about 2 nm from original about 80 nm (the surface roughness of membranes prepared through conventional interfacial polymerization methods), so the composite membrane is thin and smooth,thereby the water permeability and the salt rejection rate are greatly improved, good performances of the membrane are ensured, and the cost is reduced.

Owner:TIANJIN UNIV

Systems for utilizing the water content in fluid from a renal replacement therapy process

ActiveUS10293094B2Easy to replaceConveniently formedHaemofiltrationUltrafiltrationHaemodialysis machineNephropathy

The present invention relates to systems, methods and uses for recycling at least a part of water lost during various renal replacement therapy processes, e.g. in the preparation of a fresh dialysate solution or fresh reconstitution fluid for kidney disease dialysis and hemofiltration by utilizing water from the spent fluids. The system of the invention is useful in hemodialysis and in peritoneal dialysis as well as in hemofiltration for reuse of water from filtrates and spent fluids. In addition, the system of the invention is useful in the development of a renal assist device or artificial kidney.

Owner:AQUAPORIN AS

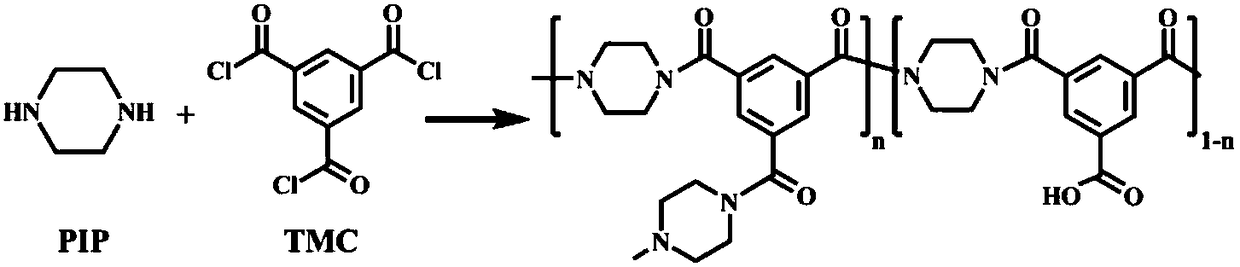

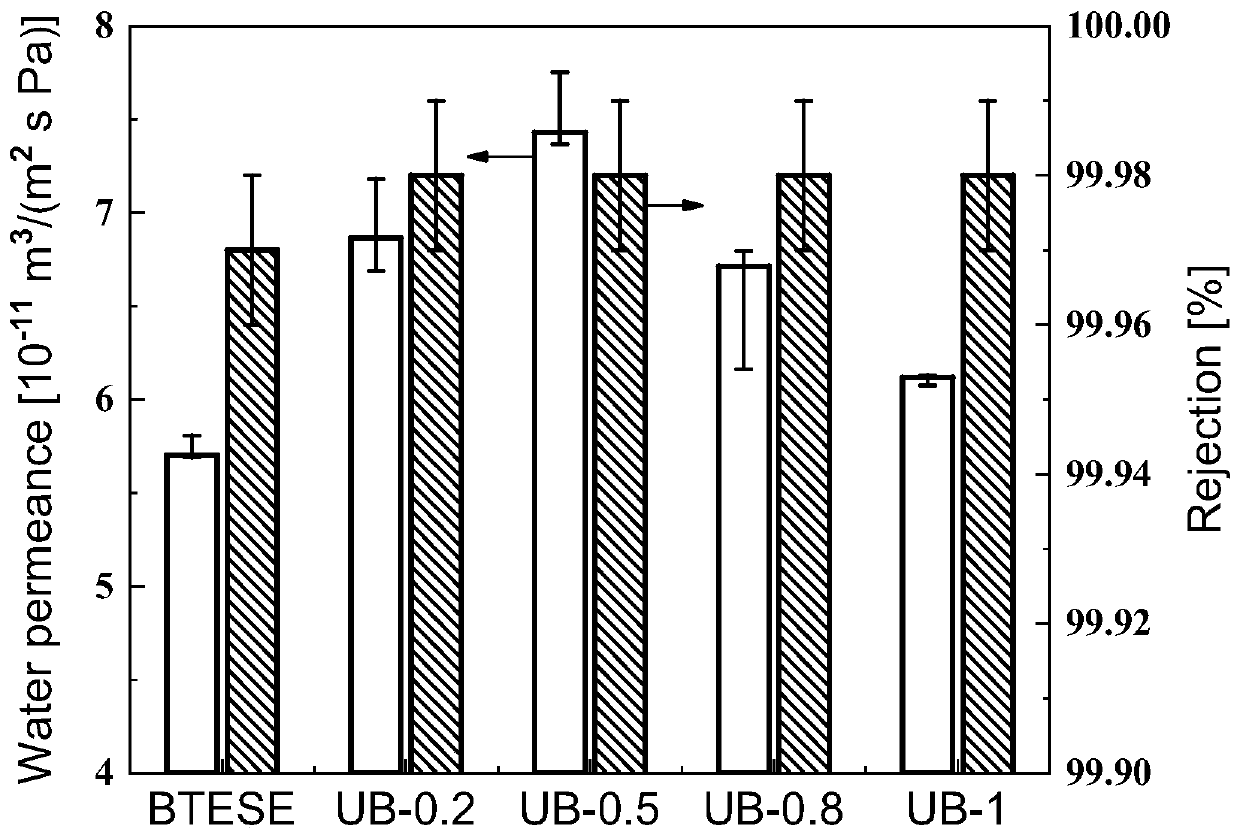

Preparation method of composite nanofiltration membrane

ActiveCN108636142AIncrease water fluxHigh Salt RejectionSemi-permeable membranesPolyamideNanofiltration

The invention provides a preparation method of a composite nanofiltration membrane. A trace amount of carbachol is added as a functional reactive monomer to a piperazine-containing aqueous phase solution for interfacial polymerization, and effective regulation and control of a polypiperazine amide structure can be realized. The crosslinking degree of polyamide is improved and at the same time thethickness of a finally formed functional layer is reduced, so that a high-performance composite nanofiltration membrane with high water flux and high salt rejection is prepared. The method has the advantages of simple and convenient operation process, and the addition amount of carbachol in the aqueous phase is small and is non-irritating to the human body, and application prospects of the composite nanofiltration membrane in large-scale production is very broad.

Owner:WANHUA CHEM GRP CO LTD

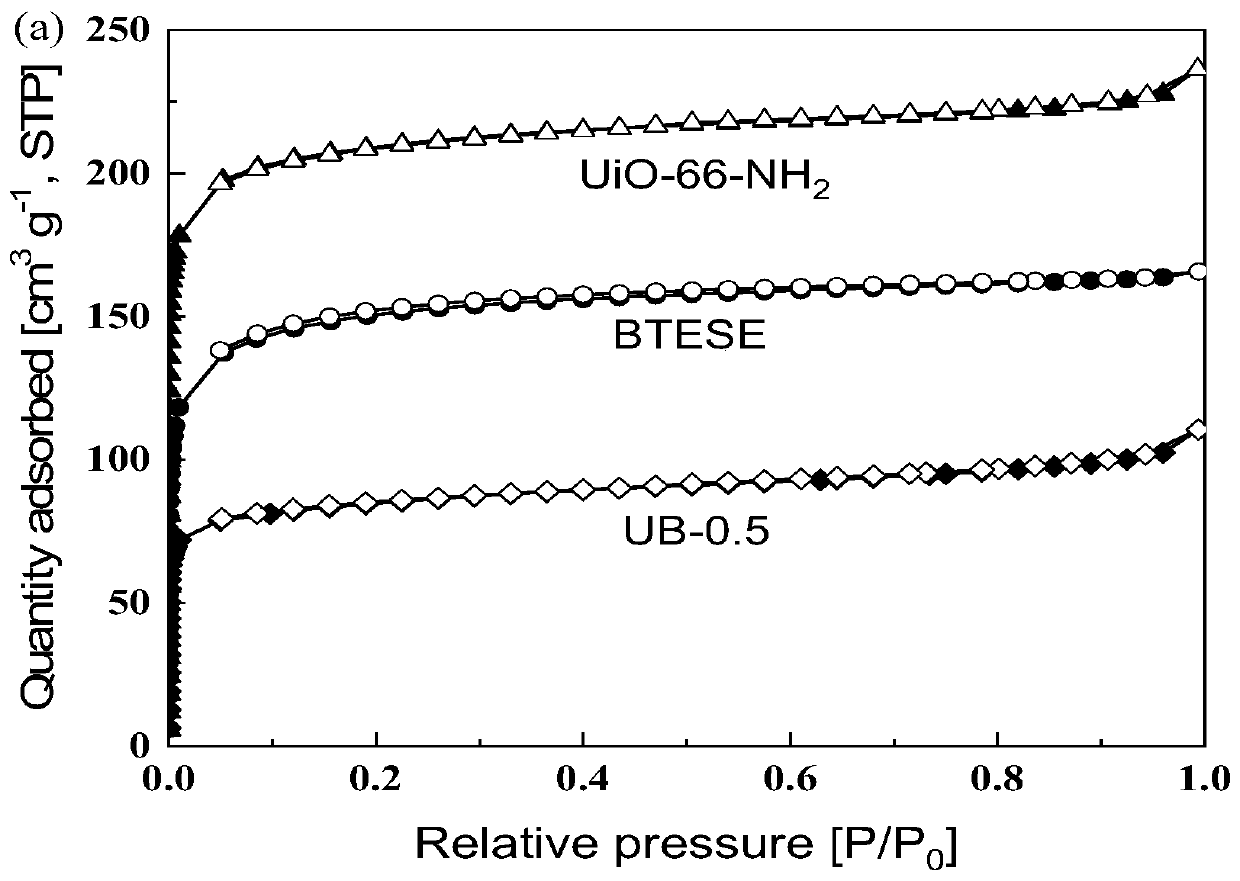

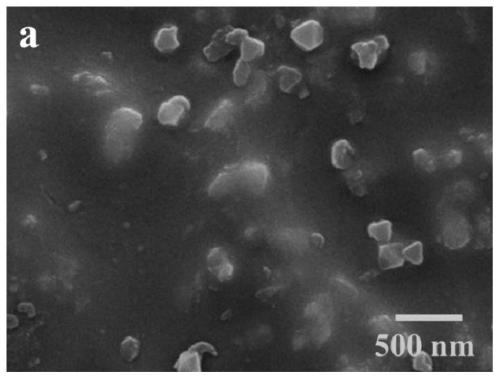

UIO-66-NH2 doped organosilicon high-salinity wastewater treatment membrane and preparation method thereof

ActiveCN111298665AReduce sensitivityReduce consumptionSemi-permeable membranesMembranesDesalinationMetal-organic framework

The invention belongs to the technical field of composite membranes, and particularly discloses a UIO-66-NH2 doped organosilicon high-salinity wastewater treatment membrane and a preparation method thereof. According to the membrane, a UIO-66-NH2 metal organic framework material is doped into polymerized organic silica sol, and a UIO-66-NH2 / organic silicon hybrid membrane is formed on the surfaceof a prefabricated ceramic support body through a dipping-pulling method. The UIO-66-NH2 / organic silicon hybrid membrane prepared by the preparation method disclosed by the invention shows high waterpermeability (reaching 1.6*10<-10>m<3> / (m<2>s Pa) and high salt rejection rate (NaCl rejection rate of greater than 99.9%) in pervaporation desalination application, and the membrane structure is stable in the treatment process of high-salt-content wastewater with TDS of more than 5wt%.

Owner:CHANGZHOU UNIV

Nano microcrystalline cellulose enhanced polyvinyl alcohol forward osmosis membrane as well as preparation method and application thereof

ActiveCN104492283AHigh strengthReduce concentration polarizationSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisConcentration polarizationRoom temperature

The invention belongs to the technical field of a composite membrane, and discloses a nano microcrystalline cellulose enhanced polyvinyl alcohol forward osmosis membrane as well as a preparation method and application thereof. The preparation method of the forward osmosis membrane comprises the following steps: (1) dissolving the polyvinyl alcohol in deionized water, heating, stirring to form a uniform and transparent solution, adding additives, and stirring for uniformly dispersing the additives; (2) adding nano microcrystalline cellulose into the solution in the step (1), and uniformly stirring to form a stable membrane casting solution; (3) coating a mold with the membrane casting solution in the step (2), drying under the room temperature, and volatizing moisture to form a membrane; and (4) immersing the membrane formed in the step (3) into a glutaraldehyde solution, adding an additive into the solution to be subjected to cross-linking reaction, taking out the membrane, and drying the membrane to obtain the nano microcrystalline cellulose enhanced polyvinyl alcohol forward osmosis membrane. The forward osmosis membrane is high in strength, a supporting layer is not needed, the concentration polarization phenomenon in the application process of the positive osmosis membrane can be obviously reduced, and the water flux and the salt interception rate of the membrane can be increased.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

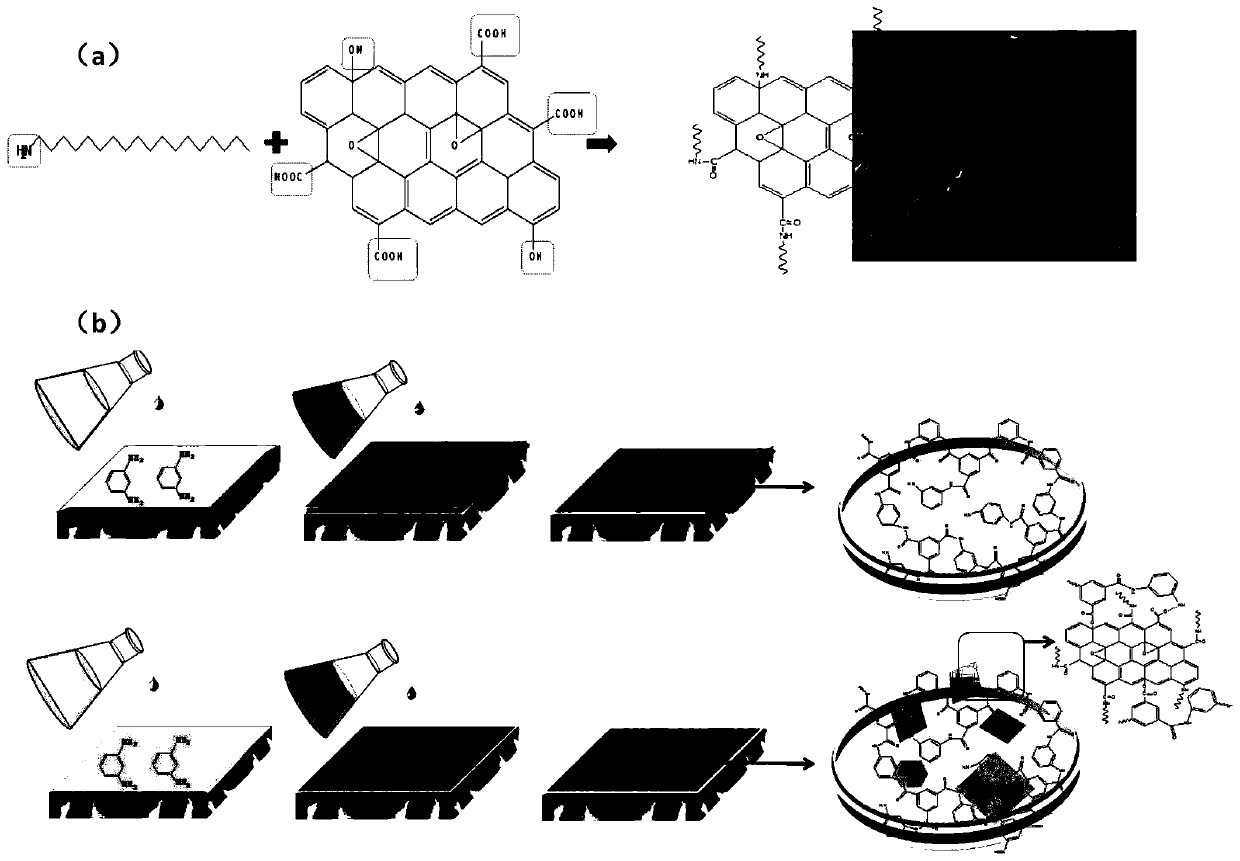

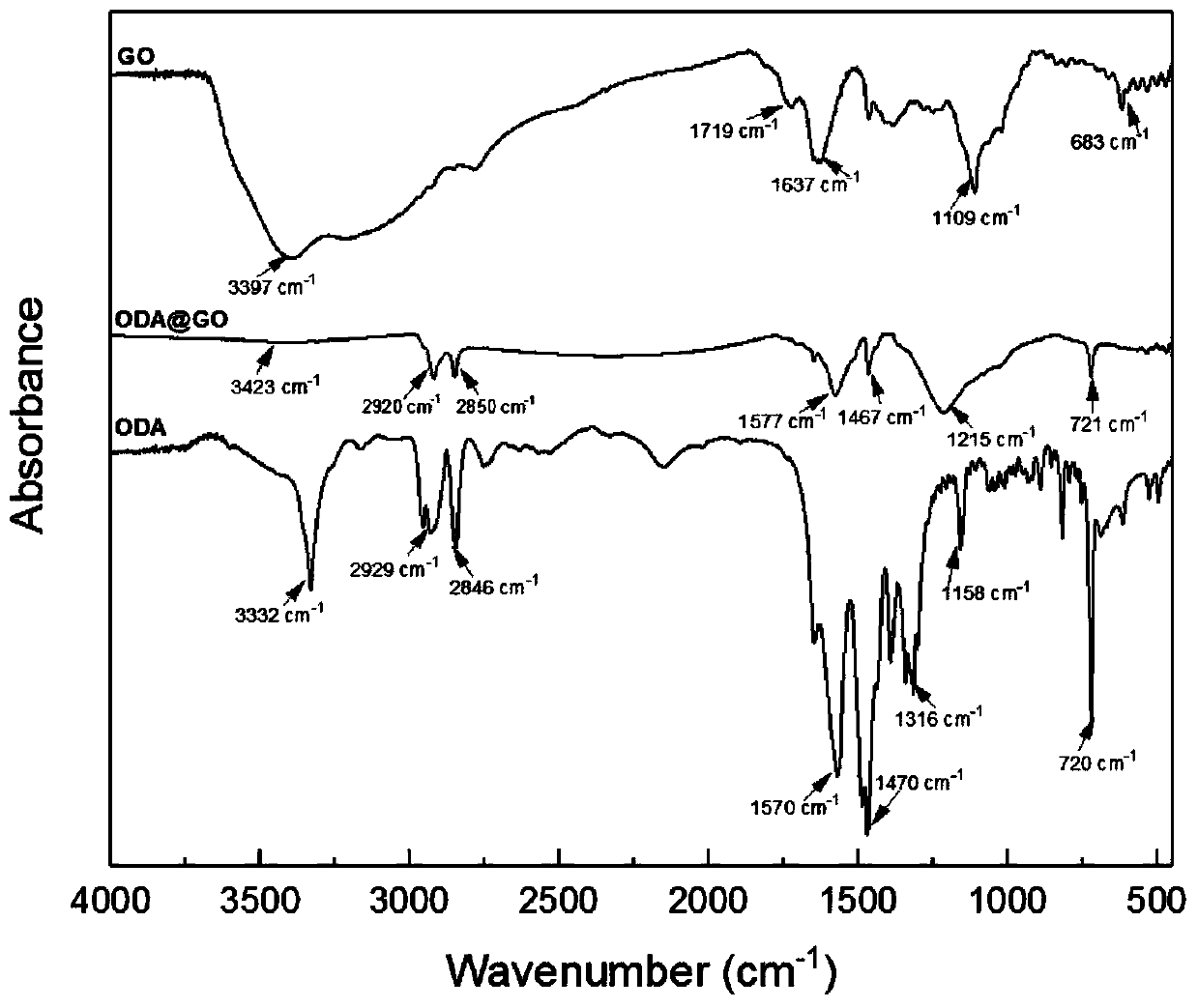

Preparation method of hydrophobic modified graphene oxide reverse osmosis membrane

ActiveCN111266017ASolve the problem of fragmentationImprove throughputReverse osmosisReverse osmosisOil phase

The invention discloses a preparation method of a hydrophobically modified graphene oxide reverse osmosis membrane. The preparation method comprises the following steps: with a polysulfone ultrafiltration membrane as a base membrane, m-phenylenediamine as a water-phase monomer, trimesoyl chloride as an oil-phase monomer, octadecylamine modified graphene oxide as an oil-phase additive and n-hexaneas an oil-phase solvent, preparing the hydrophobic modified graphene oxide reverse osmosis membrane by adopting an interfacial polymerization method. Octadecylamine modified graphene oxide is used asan oil phase additive, so that the problem of dispersion of graphene oxide in an oil phase is successfully solved, and the prepared reverse osmosis membrane has high flux and high salt rejection rate.

Owner:ZHEJIANG UNIV OF TECH

High-flux high-desalination-rate mixed matrix reverse osmosis membrane, and preparation method and application thereof

ActiveCN110141982AHigh Salt RejectionReduce mass transfer resistanceGeneral water supply conservationReverse osmosisPolymer scienceReverse osmosis

The invention discloses a high-flux high-desalination-rate mixed matrix reverse osmosis membrane, and a preparation method and application thereof. The reverse osmosis composite membrane is composed of a polysulfone supporting membrane and a functional layer; the functional layer is prepared by taking m-phenylenediamine as a water-phase monomer, taking trimesoyl chloride as an oil-phase monomer and taking an acyl chloride group-terminated hyperbranched polymer as a doping material, and the functional layer is polymerized on the supporting membrane through interfacial polymerization. Accordingto the invention, a simple and feasible treatment process is used, and a hyperbranched polymer is selected to be functionalized, so that the hyperbranched polymer can participate in interfacial polymerization. Due to highly dendritic structure of the hyperbranched polymer, the hyperbranched polymer can be used for preparing the mixed matrix reverse osmosis membrane, so that the pore number of a polyamide layer of the mixed matrix reverse osmosis membrane is increased, mass transfer resistance of water is reduced, and thus the water flux of the prepared mixed matrix reverse osmosis membrane isimproved on the basis of maintaining a high salt interception rate.

Owner:ZHEJIANG UNIV OF TECH

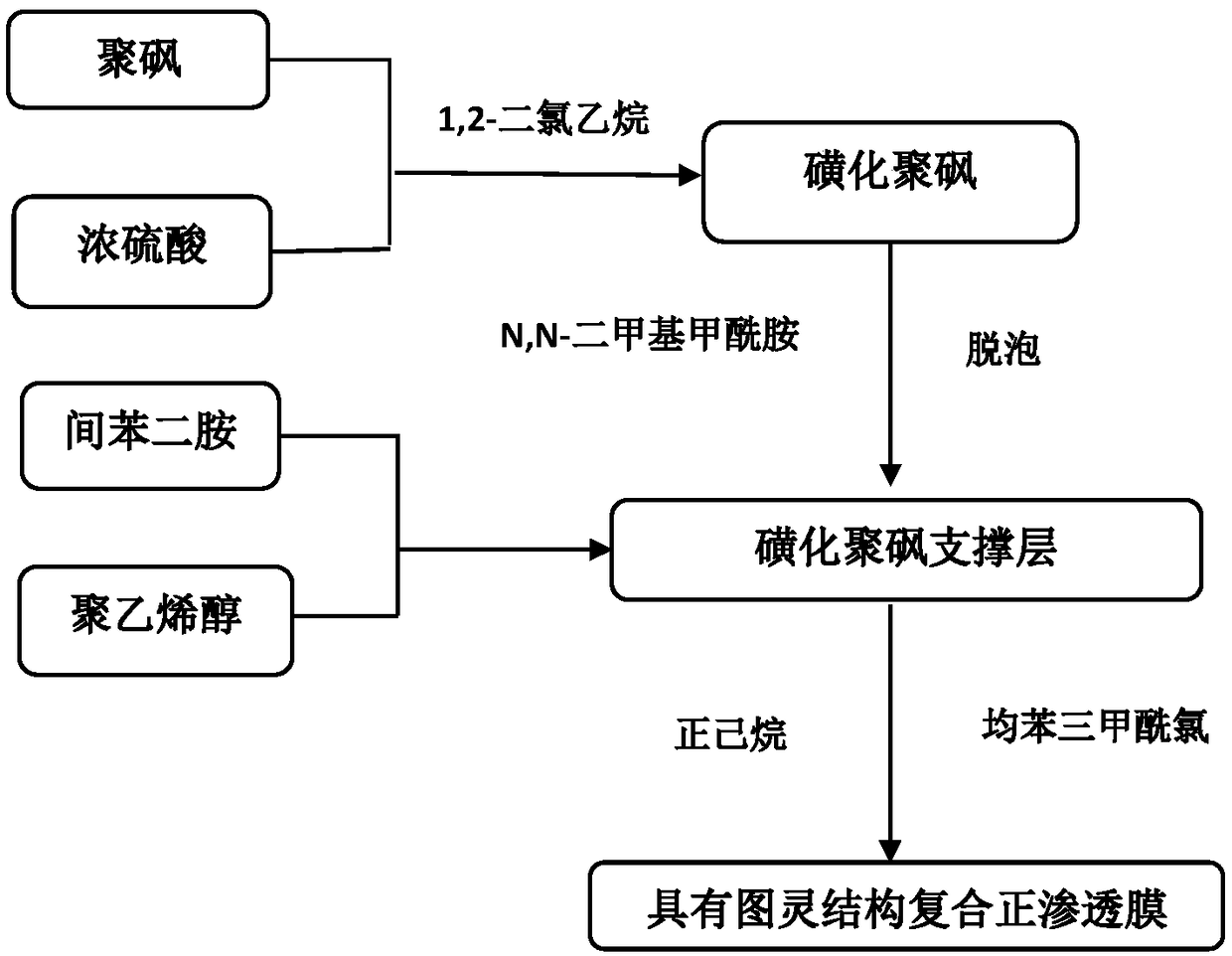

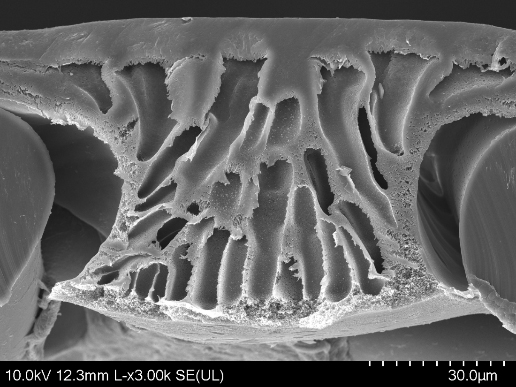

Preparation method of composite forward osmosis membrane with Turing structure

InactiveCN109012180AImprove performanceLow priceSemi-permeable membranesMembranesN dimethylformamidePolyvinyl alcohol

The invention discloses a preparation method of a composite forward osmosis membrane with a Turing structure. The method includes the steps of: (1) preparation of sulfonated polysulfone: fully mixingsulfonated polysulfone, 1, 2-dichloroethane and concentrated sulfuric acid to obtain a solid substance, washing the solid substance with deionized water and performing drying; (2) preparation of a sulfonated polysulfone support layer: mixing sulfonated polysulfone with N, N-dimethylformamide, then performing degassing, performing coating into a film and conducting cooling; and (3) preparation of asulfonated polysulfone-polyamide composite layer forward osmosis membrane: soaking a sulfonated polysulfone support layer in a mixed solution of m-phenylenediamine and polyvinyl alcohol, and conducting N2 purging; then placing the support layer in a mixed solution of trimesoyl chloride and n-hexane, and conducting drying and cooling. The existence of the Turing structure provides a lot of high water permeability sites to the forward osmosis membrane prepared according to the method, and the water permeability and salt retention rate of the membrane are greatly improved compared with the traditional forward osmosis membranes.

Owner:TIANJIN UNIV

Method for preparing polyvinylidene fluoride composite cellulose acetate forward osmosis membrane

ActiveCN102580562BImprove heat resistanceImprove cold resistanceSemi-permeable membranesConcentration polarizationFiltration

The invention relates to a method for preparing a polyvinylidene fluoride composite cellulose acetate forward osmosis membrane. The conventional product has a serious inside concentration polarization phenomenon and low actual flux. The method comprises the following steps of: preparing a polyvinylidene fluoride cast membrane solution from polyvinylidene fluoride and additive; preparing a cellulose acetate cast membrane solution from cellulose acetate, cellulose triacetate and molecular sieve; and uniformly coating the polyvinylidene fluoride cast membrane solution on a non-woven fabric to obtain a hydrophilic polyvinylidene fluoride micro-filtration base membrane, drying or naturally drying in air to form a dry hydrophilic polyvinylidene fluoride membrane, uniformly coating the cellulose acetate cast membrane solution on the dry hydrophilic polyvinylidene fluoride membrane, and thus obtaining the composite forward osmosis membrane. The forward osmosis membrane prepared by the method has high mechanical strength and solvent tolerance, high water flux and high salt intercepting rate, and can be applied in the fields of desalting of seawater and brine, softening of hard water, first-aid water bags and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

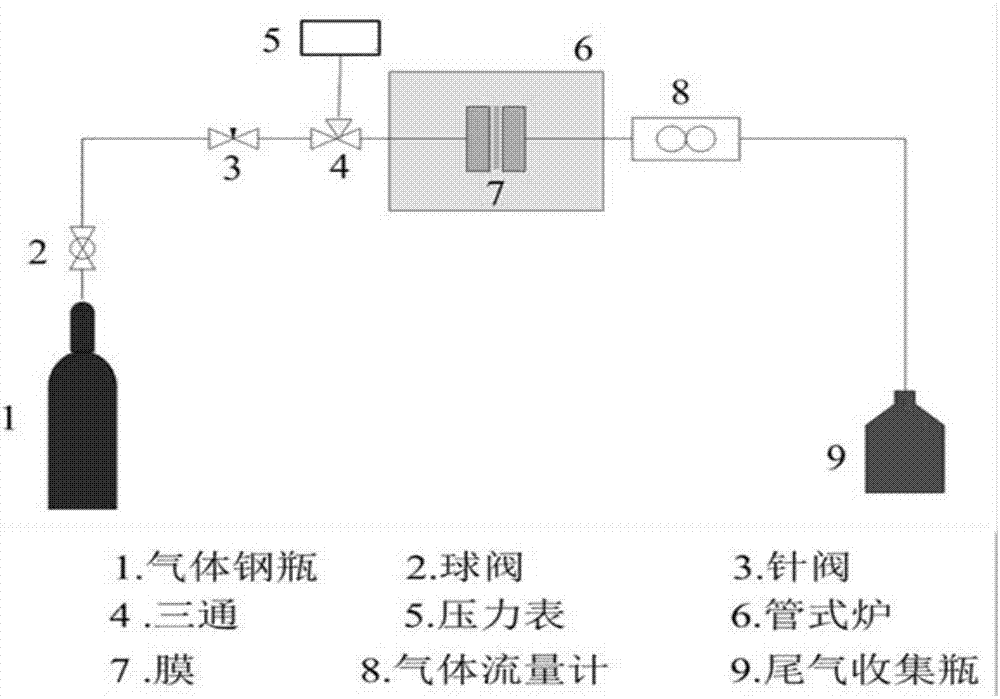

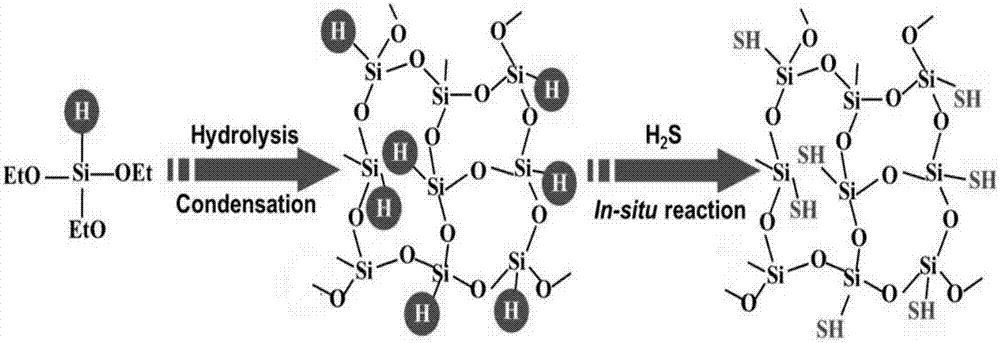

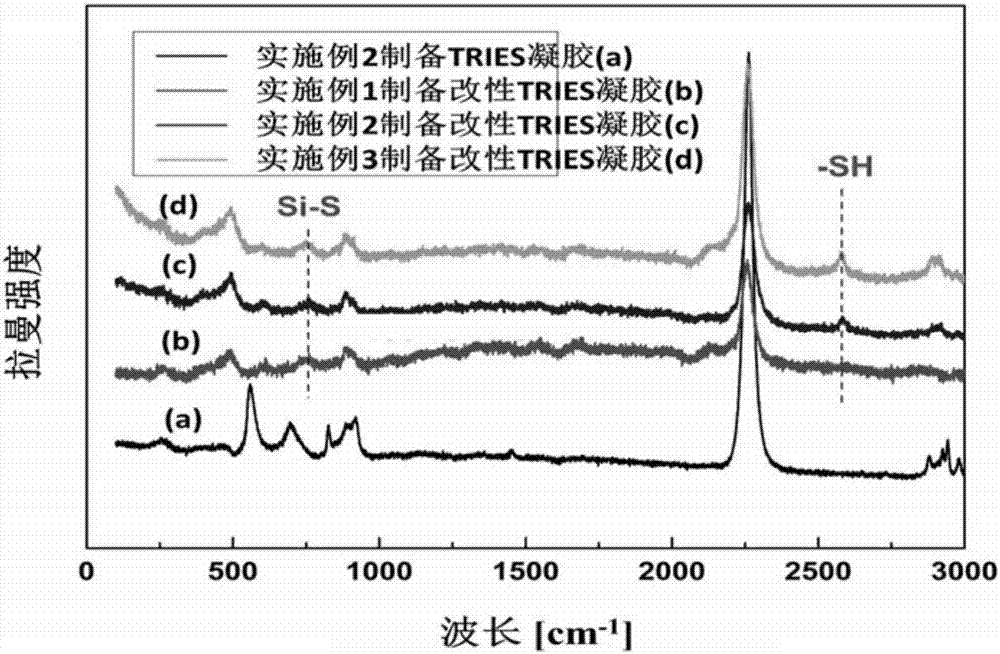

Sulfhydrylation-modified TRIES separating membrane and preparation method and purpose thereof

The invention belongs to the field of preparation of an inorganic membrane material, and especially relates to a sulfhydrylation-modified TRIES separating membrane and a preparation method and a purpose thereof. a TRIES sol is prepared by a sol-gel method, a support diaphragm of an alpha-Al2O3 material is coated with the TRIES sol, then is calcined under high temperature inert atmosphere to obtain the TRIES separating membrane, H2S and H2 mixing gas is introduced under high temperature condition, and in-situ sulfhydrylation modification is carried out for 1 hour to obtain the sulfhydrylation-modified TRIES separating membrane. The sulfhydrylation-modified TRIES separating membrane is used for the field of reverse osmosis desalination, and presents good separating performance.

Owner:CHANGZHOU UNIV

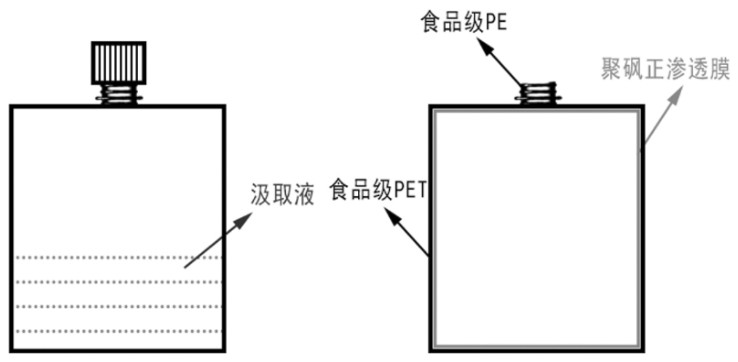

Dopamine and polyvinyl alcohol compounded modified polysulfone forward osmosis membrane as well as preparation method and application thereof

ActiveCN112516821AHigh mechanical strengthImprove anti-pollution performanceSemi-permeable membranesPolyesterPolymer science

The invention discloses a dopamine and polyvinyl alcohol compounded modified polysulfone forward osmosis membrane as well as a preparation method and application thereof. The forward osmosis membranecomprises: a supporting layer which is a polyester screen supporting layer; a porous bottom layer which is a polysulfone porous bottom layer; and an active layer which is a polyamide active layer modified by dopamine and polyvinyl alcohol. According to the forward osmosis membrane disclosed by the invention, under the condition of maintaining a high salt rejection rate, a polysulfone porous bottomlayer prepared by a phase inversion method and a dopamine and polyvinyl alcohol modified active layer are combined, so that the water flux and the salt rejection rate are greatly improved. The composite forward osmosis membrane is used for preparing an emergency water bag. The water bag is simple to prepare, easy to carry and reusable, can be applied to the field of emergency rescue, and is particularly used for solving the problem that trapped people lack drinking water due to mines, earthquakes, natural disasters and the like.

Owner:XIAN UNIV OF SCI & TECH

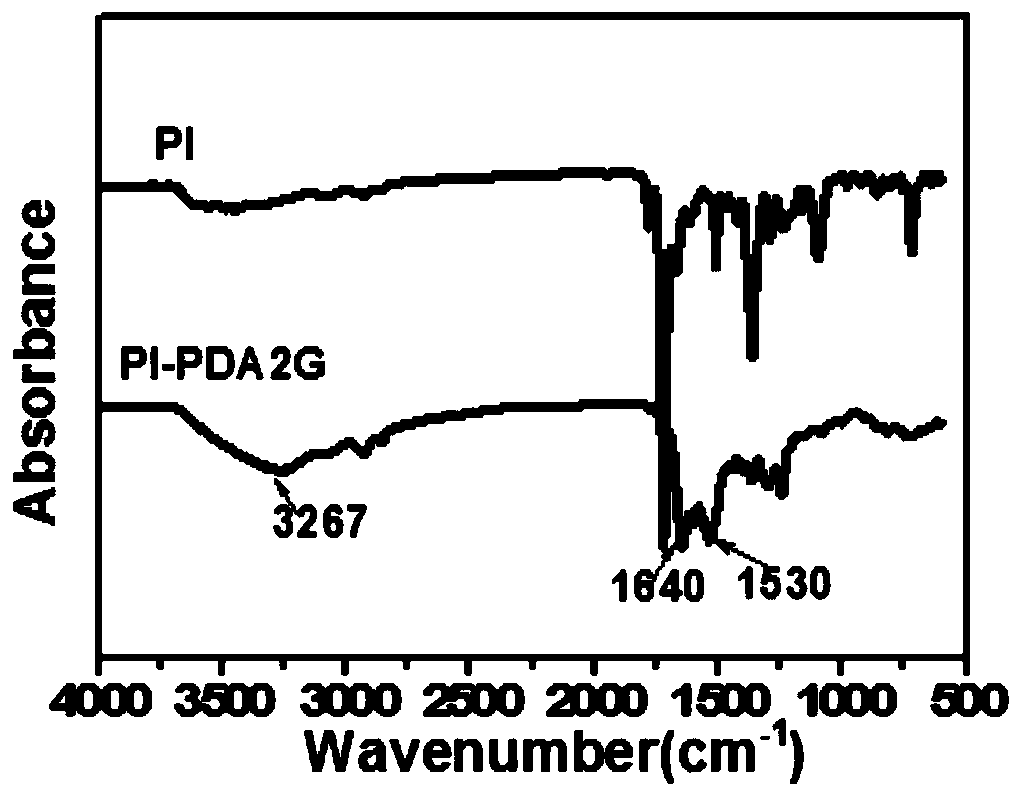

A kind of preparation method of dopamine and glucose modified cross-linked polyimide nanofiltration membrane

InactiveCN107413210BUnique cross-network pore structureImprove hydrophilicitySemi-permeable membranesCoated membranePolymer science

The invention relates to a preparation method of a dopamine and glucose modified cross-linking polyimide nanofiltration membrane. The method comprises the following steps: 1, preparing a polyimide nanofiltration base membrane; 2, preparing an alkanolamine solution of hexamethylene diamine, and putting the polyimide nanofiltration base membrane into the prepared alkanolamine solution of the hexamethylene diamine for cross-linking modification; 3, immersing cross-linking polyimide into a dopamine buffer solution, and performing coating modification; 4, preparing an acyl chloride solution, and immersing the dopamine-coated membrane into the acyl chloride solution; 5, preparing a glucose solution, and immersing the membrane into the glucose solution, so as to obtain a polyimide composite nanofiltration membrane. The prepared polyimide composite nanofiltration membrane has the advantages of obvious hydrophily increase, large permeation flux, high rejection rate of inorganic salt, high separation efficiency of an organic solvent, and the like.

Owner:宁波聚仁新材料科技有限公司

A kind of composite forward osmosis membrane and preparation method thereof

InactiveCN105289334BEvenly distributedNo chemical changesSemi-permeable membranesTrappingPolymer solution

The present invention relates to a composite forward osmosis membrane and a preparation method thereof. The composite forward osmosis membrane comprises an ion exchange resin doped polymer support layer and a polyamide active layer compounded on the polymer support layer surface, wherein a mass ratio of the ion exchange resin to the polymer in the polymer support layer is (0.1-25):(5-40). The preparation method comprises: doping ion exchange resin micro-particles in a polymer solution, preparing a composite forward osmosis membrane support layer containing the ion exchange resin by using a non-solvent induction phase separation method, and compounding an active layer adopting polyamine and poly acyl chloride on the surface of the composite forward osmosis membrane support layer containing the ion exchange resin by using an interfacial polymerization method so as to prepare the composite forward osmosis membrane, wherein the prepared composite forward osmosis membrane can be adopted as the osmosis membrane for seawater desalination and other processes. Compared with the method in the prior art, the method of the present invention has advantages of economy, high efficiency, high water flux, high salt trapping rate, and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

Hydrophobically modified distillation membrane material of high throughout and high salt rejection rate and application thereof

InactiveCN102228801BImprove stabilityIncrease water fluxEnergy based wastewater treatmentWater/sewage treatment by heatingProtein solutionFruit juice

The invention discloses a hydrophobically modified distillation membrane material of high throughout and high salt rejection rate and its application. For the material of the invention, ultrafiltration or microfiltration membrane materials are employed as the basic membrane material, the surface of which is subjected to cleaning and etching pretreatment by means of drying and plasmas. Then the surface of the basic membrane material is modified with a modification material by gas phase, liquid phase or plasma modification, thus obtaining the hydrophobically modified distillation membrane material of high throughout and high salt rejection rate. The invention discloses a novel hollow fiber membrane material with hydrophobic surface modification, and the membrane material is characterized by high throughout, high salt rejection rate and high stability. The distillation membrane material provided in the invention can be used for direct contact membrane distillation or sweeping gas membrane distillation or vacuum membrane distillation, and is applicable to the treatment of seawater, reverse osmosis concentrated wastewater and industrial wastewater, and the concentration of biomass solution, protein solution and fruit juice.

Owner:何涛 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com