Acid-resistant composite nanofiltration membrane and preparation method thereof

A composite nanofiltration membrane and filtration membrane technology, applied in chemical instruments and methods, membrane, membrane technology, etc., can solve the problems of uncompared dynamic acidic salt solution separation performance, inapplicability, and the stability of composite membranes, etc., to achieve salt cut-off The effect of improving the rate or dye rejection rate, stabilizing membrane separation performance, and improving hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

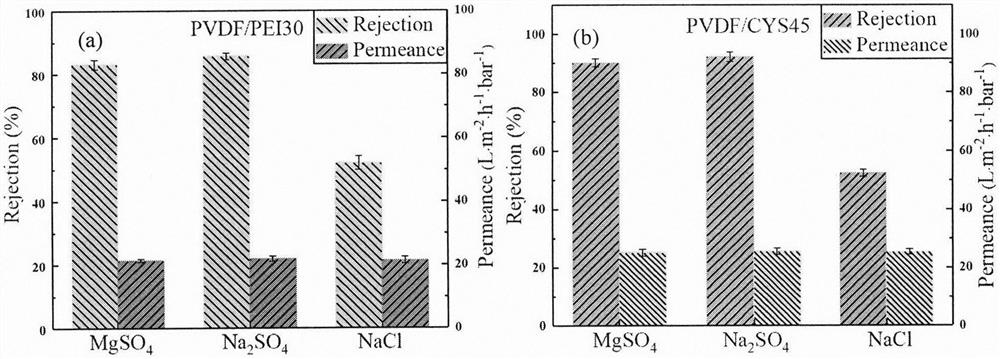

[0020] Embodiment 1: Taking the self-made PVDF ultrafiltration membrane as an example,

[0021] (1) Carboxylation of the surface of PVDF membrane: first soak the self-made PVDF ultrafiltration membrane in methanol solution for 5 minutes, then immerse it in methanol solution with BP concentration of 0.4mol / L for 1.5 hours, take it out and let it dry naturally at room temperature ; prepare a monomer solution containing 0.3g acrylic acid, 0.05g ferrous amine sulfate, and 50mL deionized water, then pass nitrogen gas for 30min to remove oxygen, and finally put the monomer solution into a ziplock bag for preservation; put the PVDF ultrafiltration membrane into the above In a ziplock bag, transfer to a UV lamp (365nm, 8W) and irradiate at room temperature for 15min, and the obtained film is marked as PVDF / AA. After taking it out, wash it with a mixture of methanol and water to remove unreacted monomers, BP and a small amount of self-polymer, and store it in deionized water for future...

Embodiment 2

[0025] (1) PVDF film surface carboxylation modification: with embodiment 1 (1);

[0026] (2) Preparation of PVDF / CYS composite nanofiltration membrane:

[0027]First, soak the carboxylated PVDF membrane in a conical flask containing EDC-NHS buffer solution, put it into a shaker and fully react it at a speed of 100r / min for 24h, then take out and put in a cystamine flask with a content of 2.5wt%. Aqueous solution, then poured into n-hexane solution containing 0.25wt% 1,3-benzenedisulfonyl chloride, 1wt% ethylene glycol methyl ether and 1wt% triethylamine, the reaction time was 45s, and the membranes were respectively marked as PVDF / CYS; After taking it out, put it into an oven for heat treatment at 70°C for 15 minutes, then wash it with ethanol, and finally put the membrane into deionized water for storage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com