Preparation method of composite nanofiltration membrane

A technology of composite nanofiltration membrane and ultrafiltration membrane, which is applied in the field of nanofiltration, can solve the problems of low reactivity, insignificant change of water flux, and decrease of salt rejection rate, etc., and achieve simple addition method, broad application prospect, high salt The effect of retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

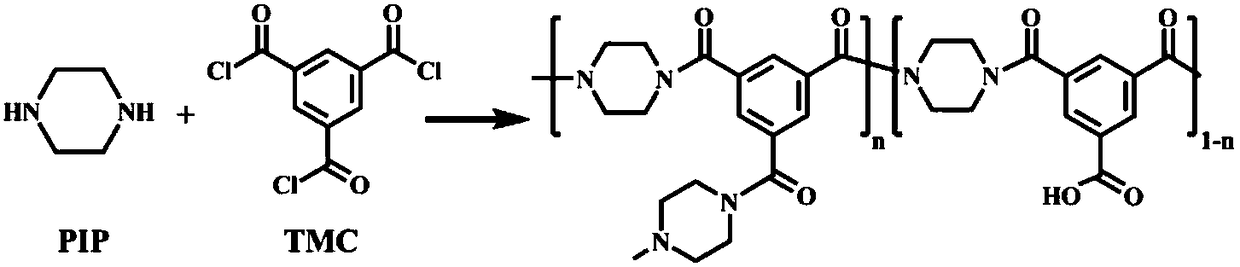

[0031] (1) Preparation of aqueous phase solution: after piperazine, carbachol and water are mixed uniformly, adding trisodium phosphate to adjust the pH of the solution is 9~11 to obtain aqueous phase solution, and the concentration of piperazine in the aqueous phase solution is 2.0wt %, the concentration of carbachol is shown in Table 1;

[0032] (2) Preparation of oil phase solution: dissolve trimesoyl chloride in n-hexane, stir to obtain oil phase solution, the concentration of trimesoyl chloride in the oil phase solution is 0.5wt%;

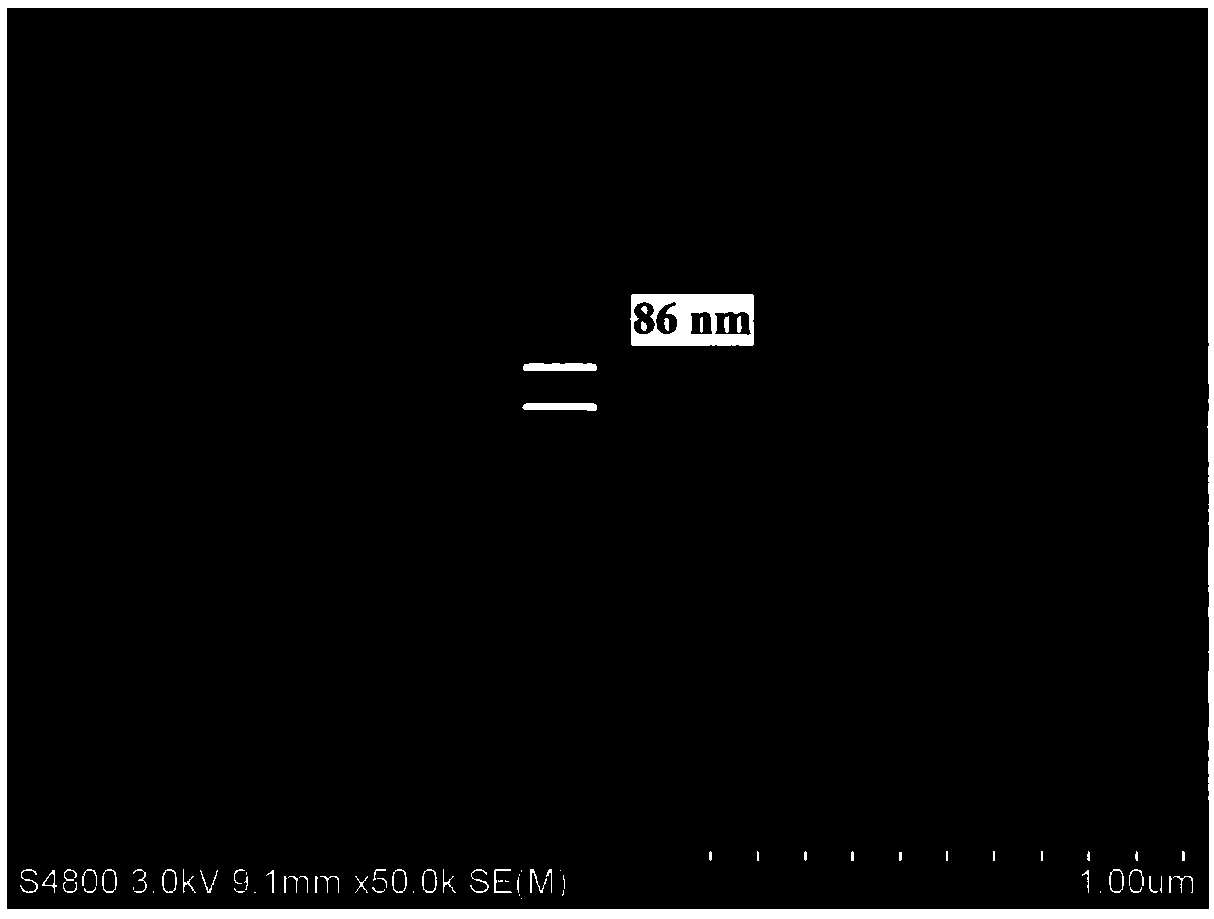

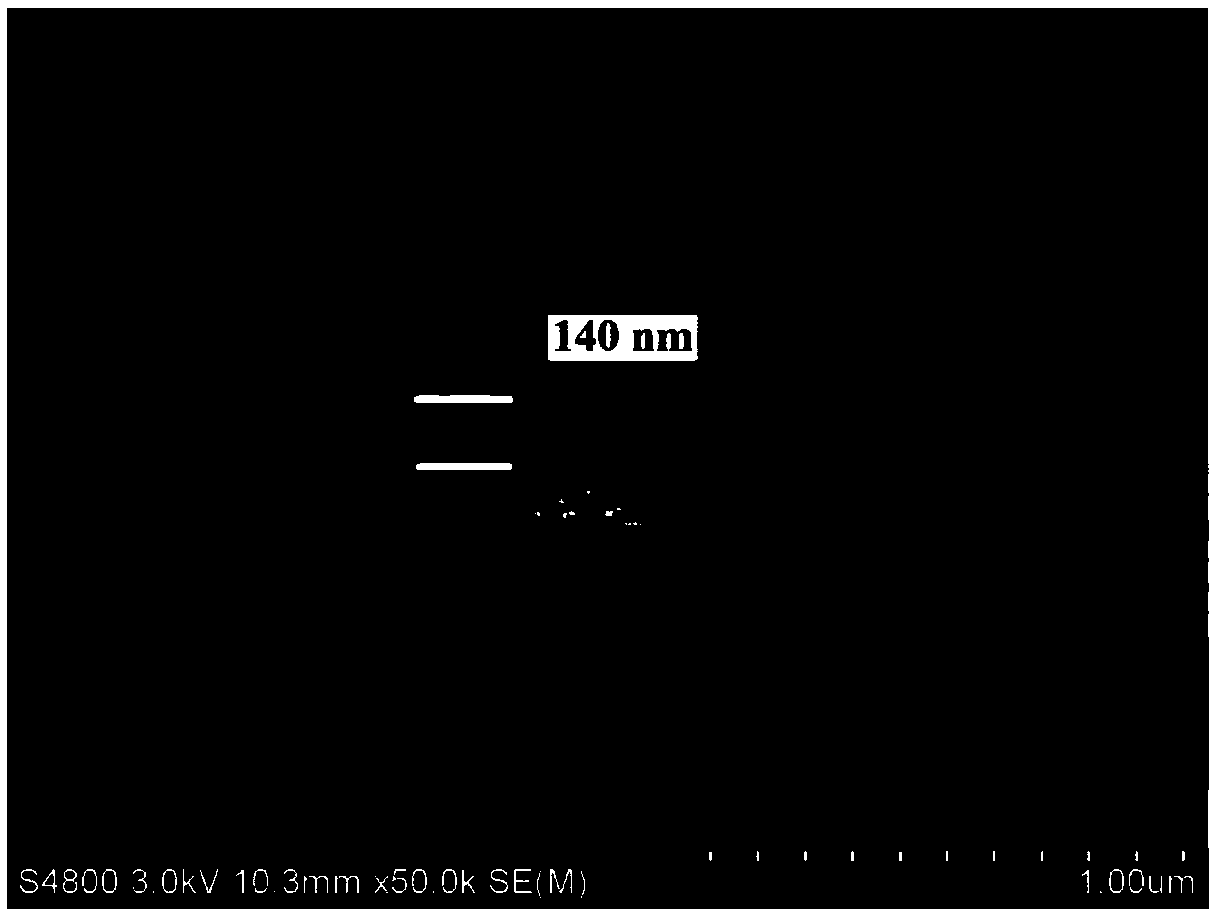

[0033] (3) Interfacial polymerization and heat treatment: directly immerse the polysulfone membrane supported by non-woven fabric (average pore size is 30nm) into the aqueous phase solution prepared in step (1), the immersion time is 1min, roll it with a rubber roller after taking it out, Remove the excess water phase solution on the surface of the polysulfone membrane, and then immerse it in the oil phase solution prepared in step (2) to carr...

Embodiment 4

[0042] Referring to Example 2, the difference between the preparation method and Example 2 is: in the aqueous phase solution prepared in step (1), the concentration of piperazine is 1.0 wt%.

Embodiment 5

[0044] Referring to Example 3, the difference between the preparation method and Example 3 is: in the aqueous phase solution prepared in step (1), the concentration of piperazine is 1.0 wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com