UIO-66-NH2 doped organosilicon high-salinity wastewater treatment membrane and preparation method thereof

A technology of UIO-66-NH2 and uio-66-nh2, which is applied in the field of composite membranes, can solve the problems of poor film-forming properties of materials and difficulty in preparing molecular separation membranes, and achieve low cost, simple preparation methods and high rejection rates. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

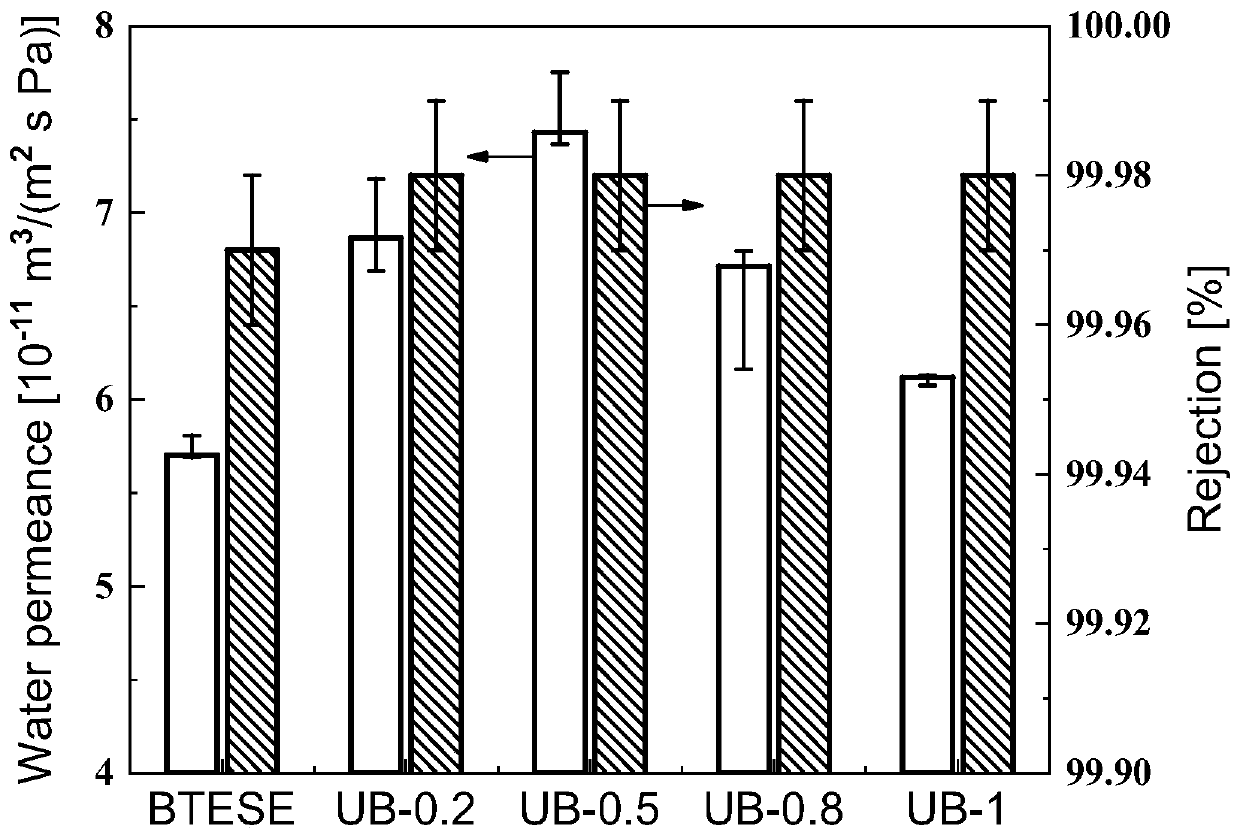

Examples

Embodiment 1

[0028] The preparation method of this implementation example is realized like this, comprises the steps:

[0029] (1) Using bis(triethoxysilyl)ethane (BTESE) as the silicon source precursor and hydrochloric acid as the catalyst, the hydrolysis polymerization reaction was carried out with water in ethanol solution. The molar ratio of BTESE, water, and hydrochloric acid was 1:60:0.2, and the solution was stirred at 40° C. for 2 hours to obtain a BTESE polymeric sol.

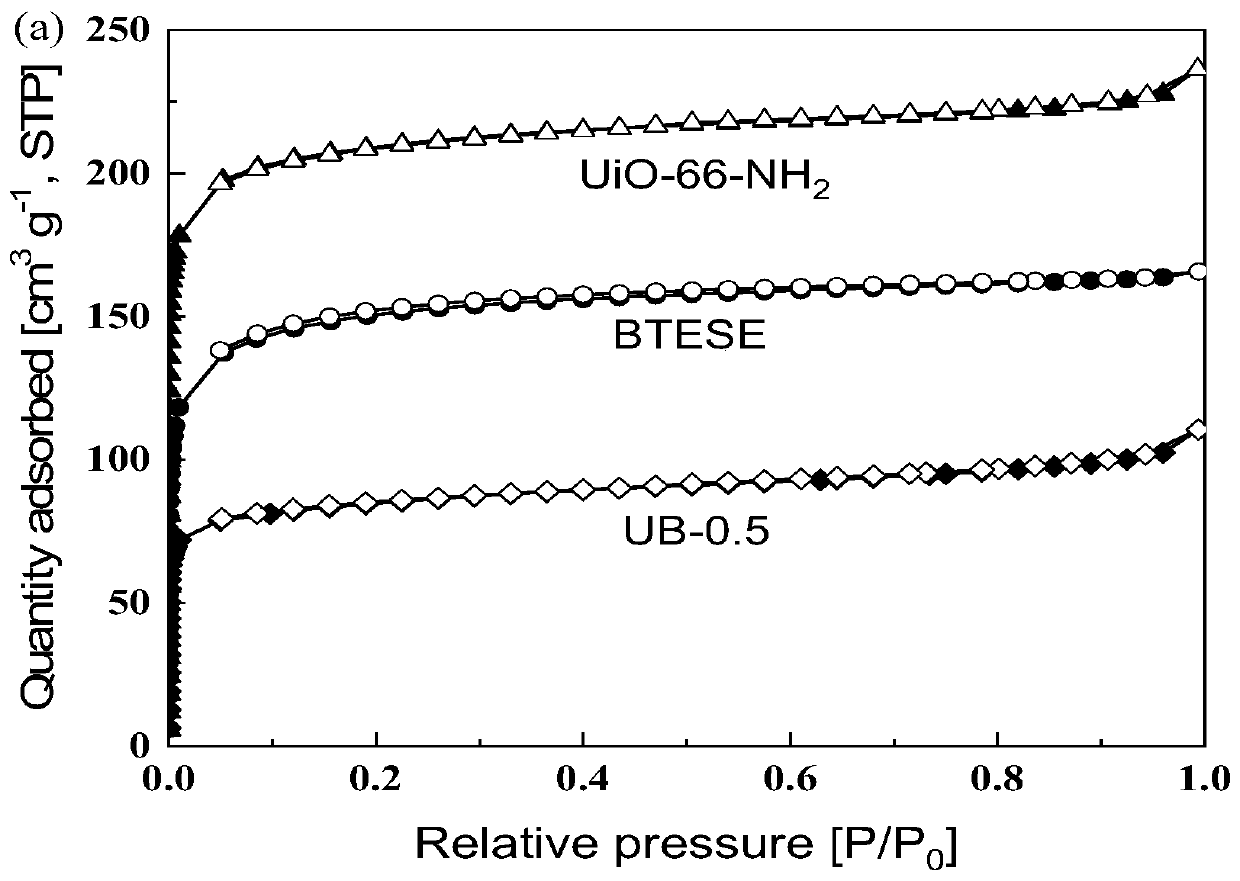

[0030] (2) ZrCl 4 and 2-amino-1,4-phthalic acid were dissolved in N,N-dimethylformamide, then ultrasonically stirred for 10min, added acetic acid, ultrasonically stirred for 10min (ZrCl 4 、BDC-NH 2 , HAC, the molar ratio of DMF is 1:1:50:500). Put the prepared mixture into a preheated oven and bake at 130° C. for 24 hours. Finally, the product UiO-66-NH was washed with N,N-dimethylformamide and methanol 2 , dried overnight at 100 °C to give UiO-66-NH 2 crystals.

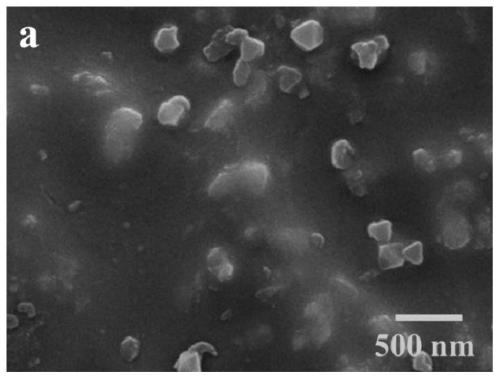

[0031] (3) UiO-66-NH 2 The crystals were ad...

Embodiment 2

[0034] The preparation method of this implementation example is realized like this, comprises the steps:

[0035] (1) Using bis(triethoxysilyl)ethylene (BTESEthy) as the silicon source precursor and hydrochloric acid as the catalyst, the hydrolytic polymerization reaction was carried out with water in ethanol solution. The molar ratio of BTESEthy, water, and hydrochloric acid was 1:60:0.2, and the solution was stirred at 40° C. for 2 hours to obtain the BTESEthy polymeric sol.

[0036] (2) ZrCl 4 and 2-amino-1,4-phthalic acid were dissolved in N,N-dimethylformamide, then ultrasonically stirred for 10min, added acetic acid, ultrasonically stirred for 10min (ZrCl 4 、BDC-NH 2 , HAC, the molar ratio of DMF is 1:1:50:500). Put the prepared mixture into a preheated oven and bake at 130° C. for 24 hours. Finally, the product UiO-66-NH was washed with N,N-dimethylformamide and methanol 2 , dried overnight at 100 °C. Get UiO-66-NH 2 crystals.

[0037] (3) UiO-66-NH 2 The cryst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com