Patents

Literature

72 results about "Zero liquid discharge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zero Liquid Discharge (ZLD) is a treatment process with the goal of removing all the liquid waste from a system. The focus of ZLD is to economically reduce wastewater and produce clean water that is suitable for reuse, thus saving money and being beneficial to the environment. ZLD systems employ advanced wastewater treatment technologies to purify and recycle virtually all of the wastewater produced.

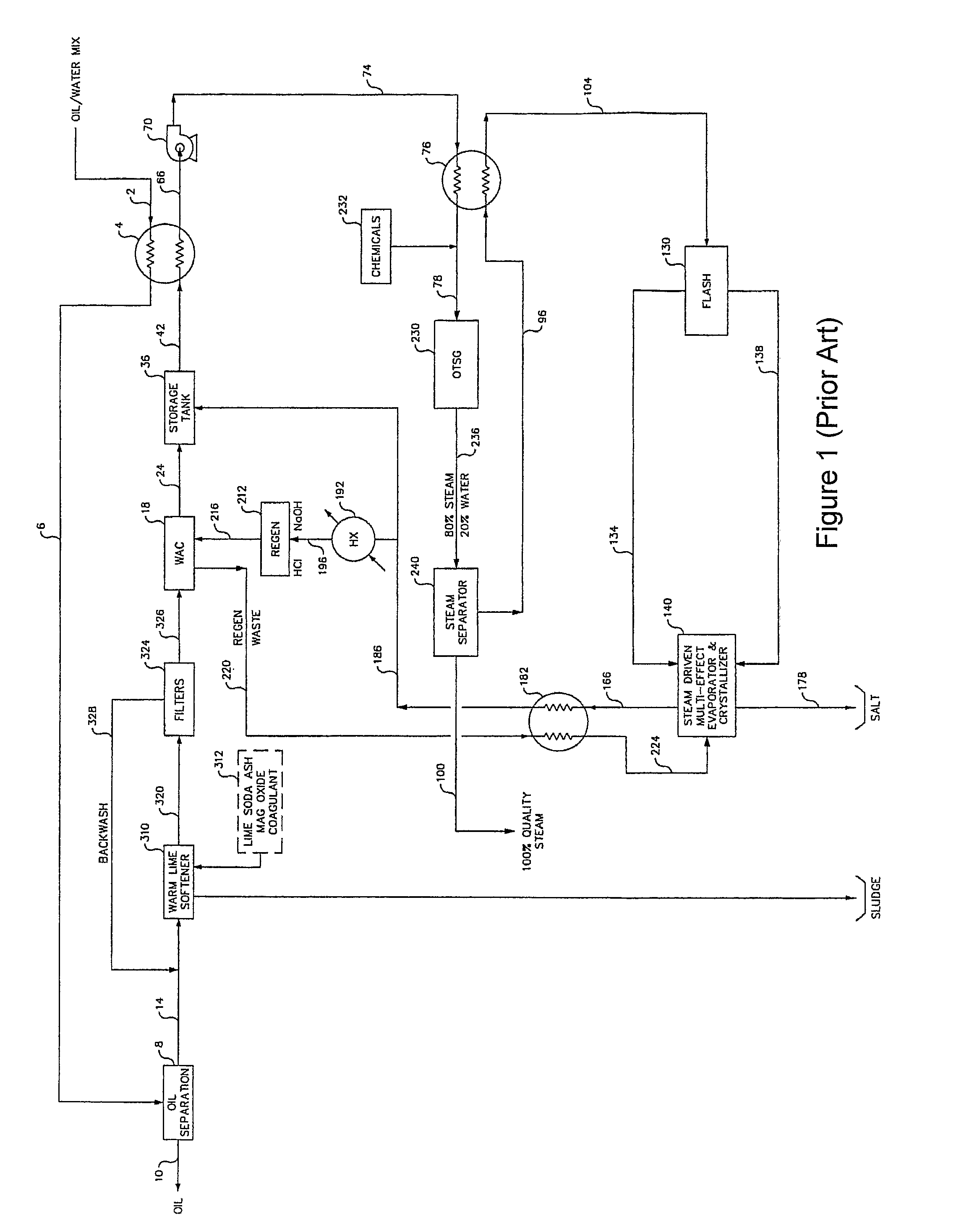

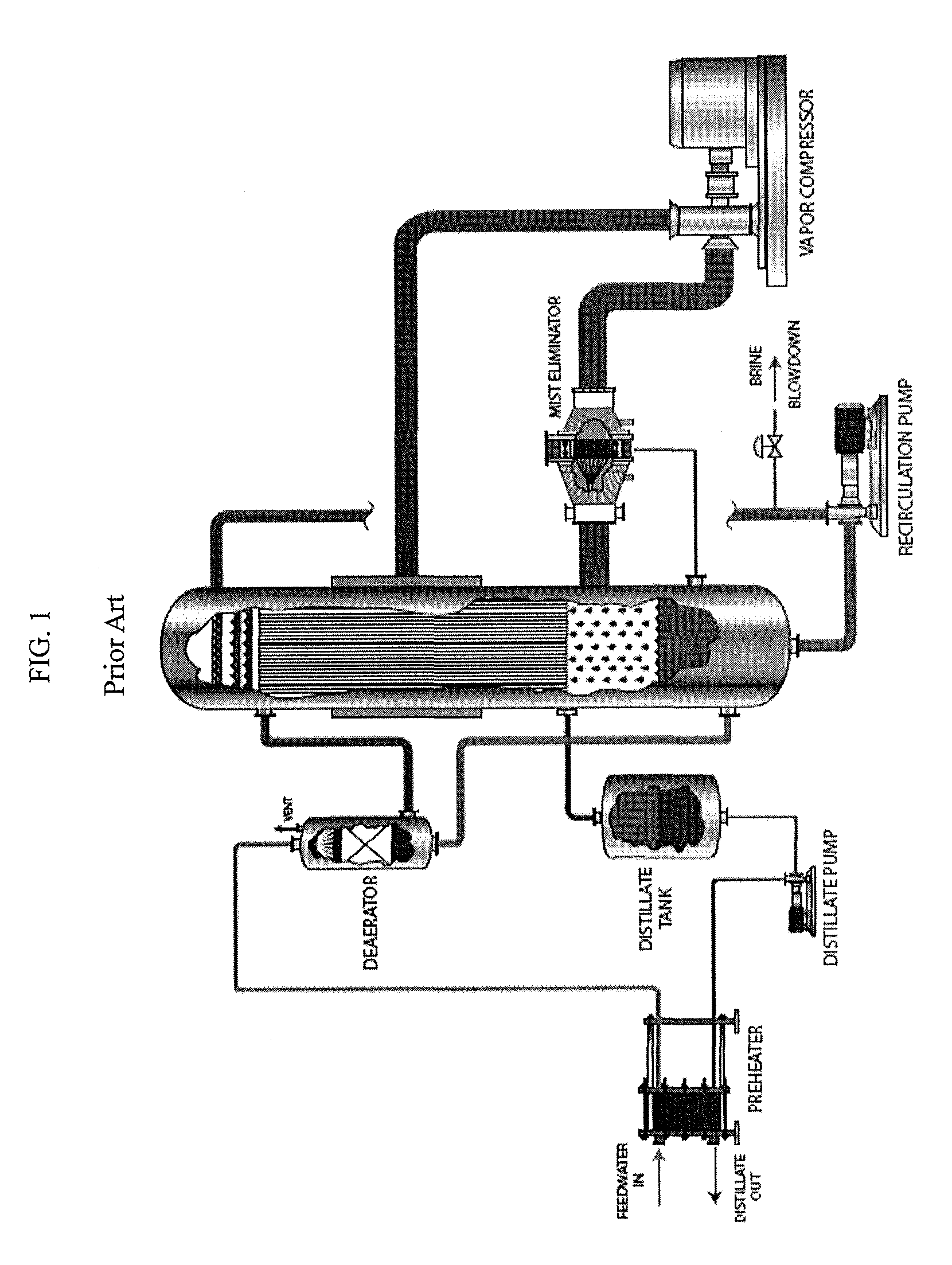

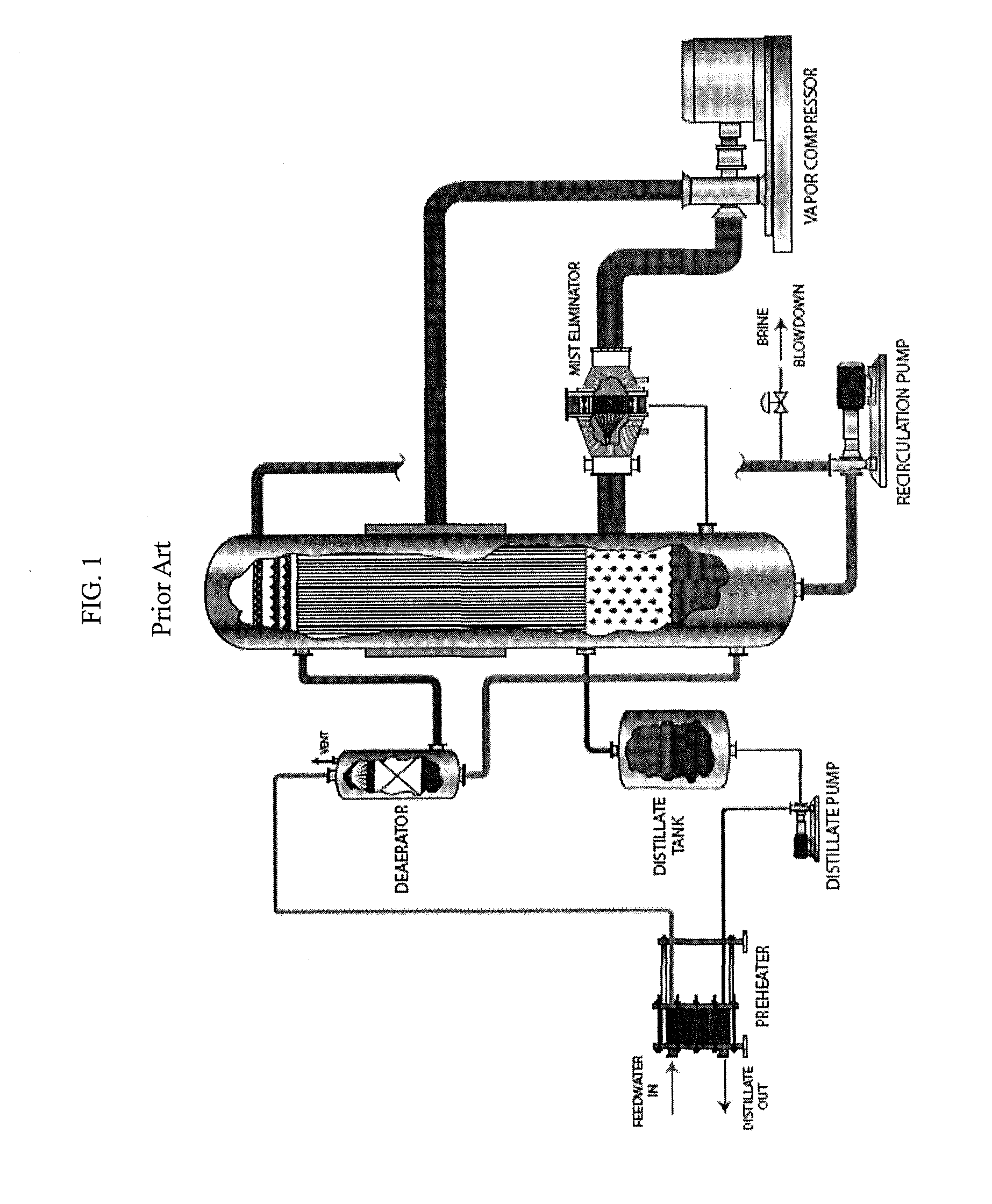

Method for Production of High Pressure Steam from Produced Water

InactiveUS20080110630A1Average power consumptionMinimize waste generationDrying using combination processesSolid sorbent liquid separationChemical treatmentDistillation

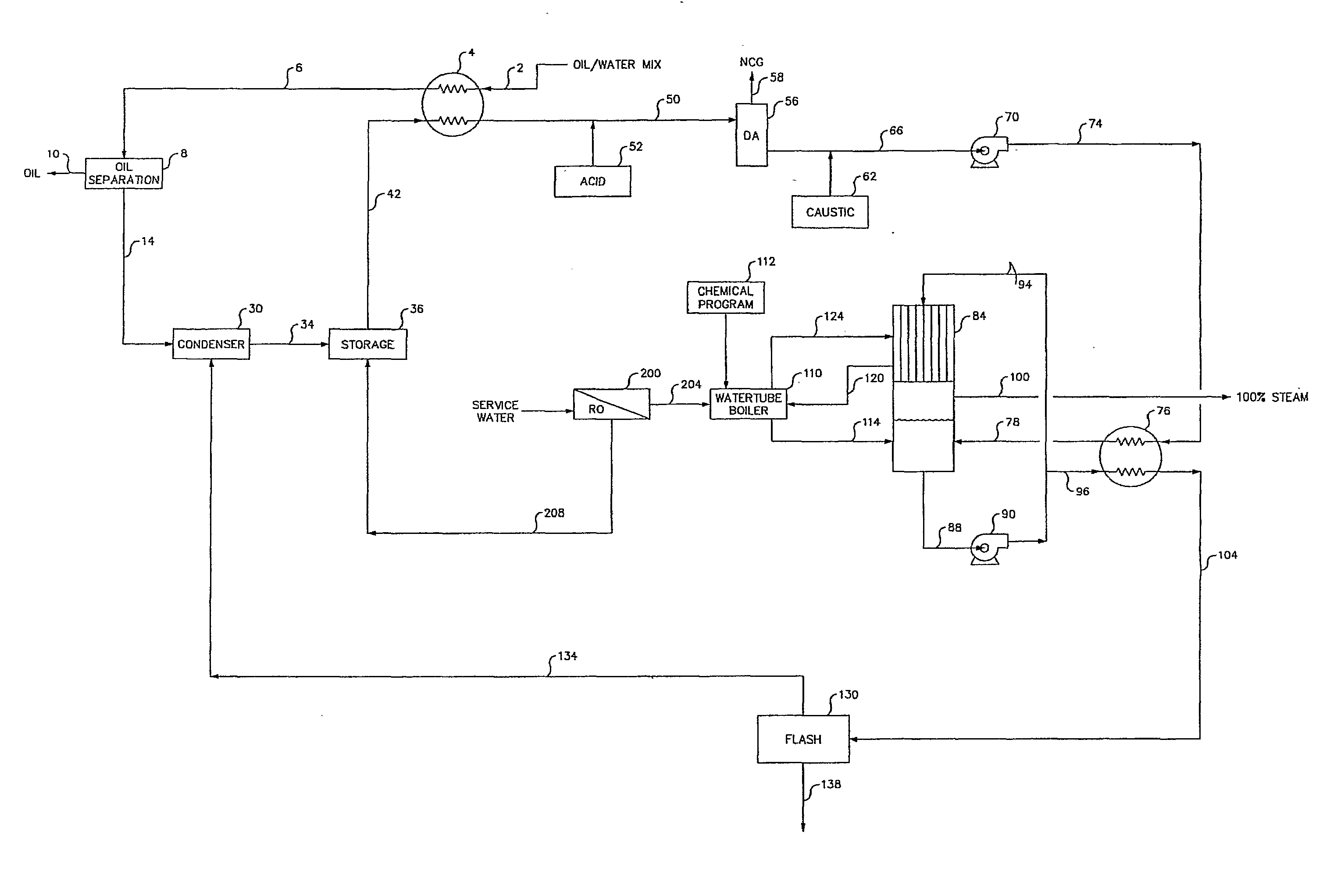

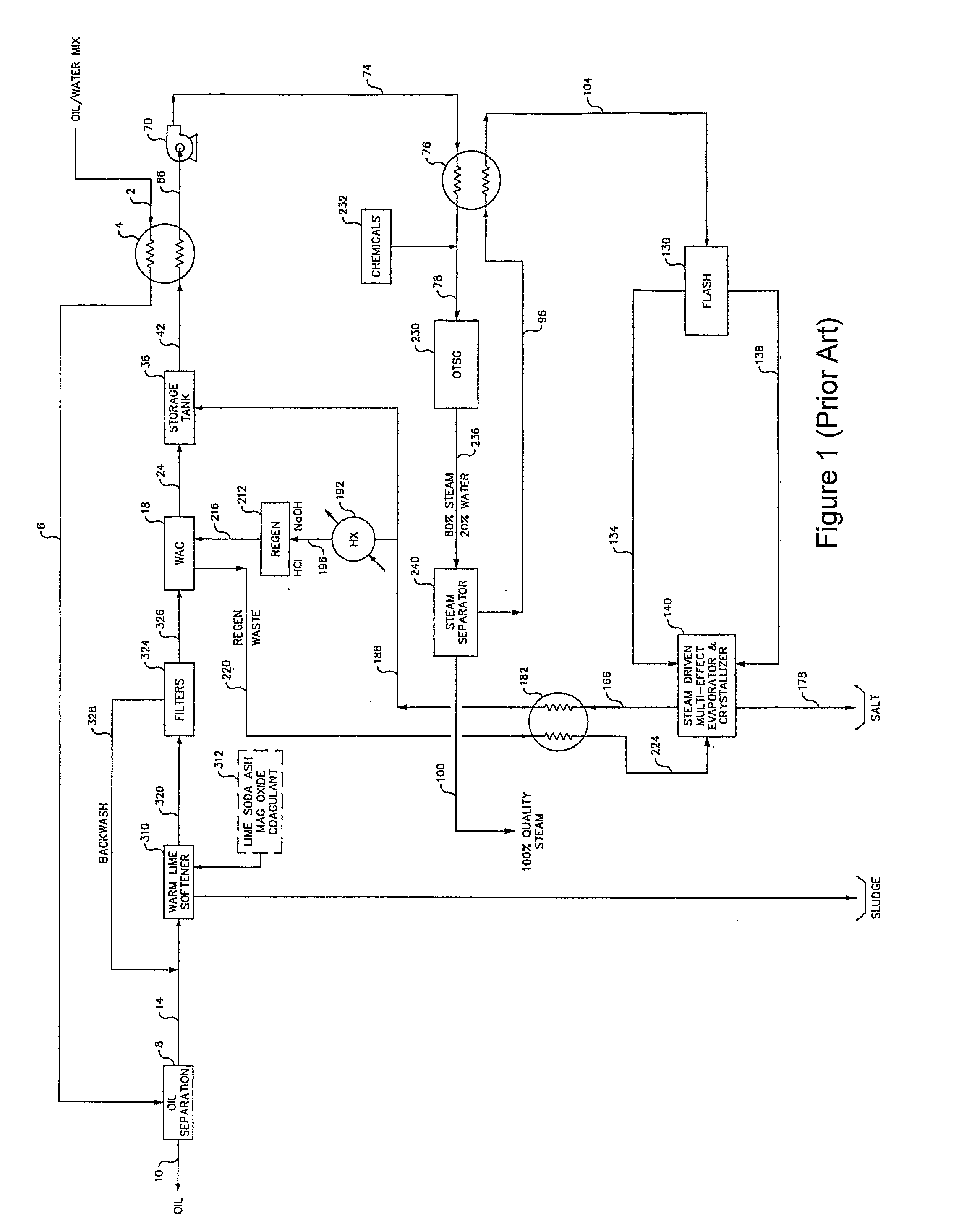

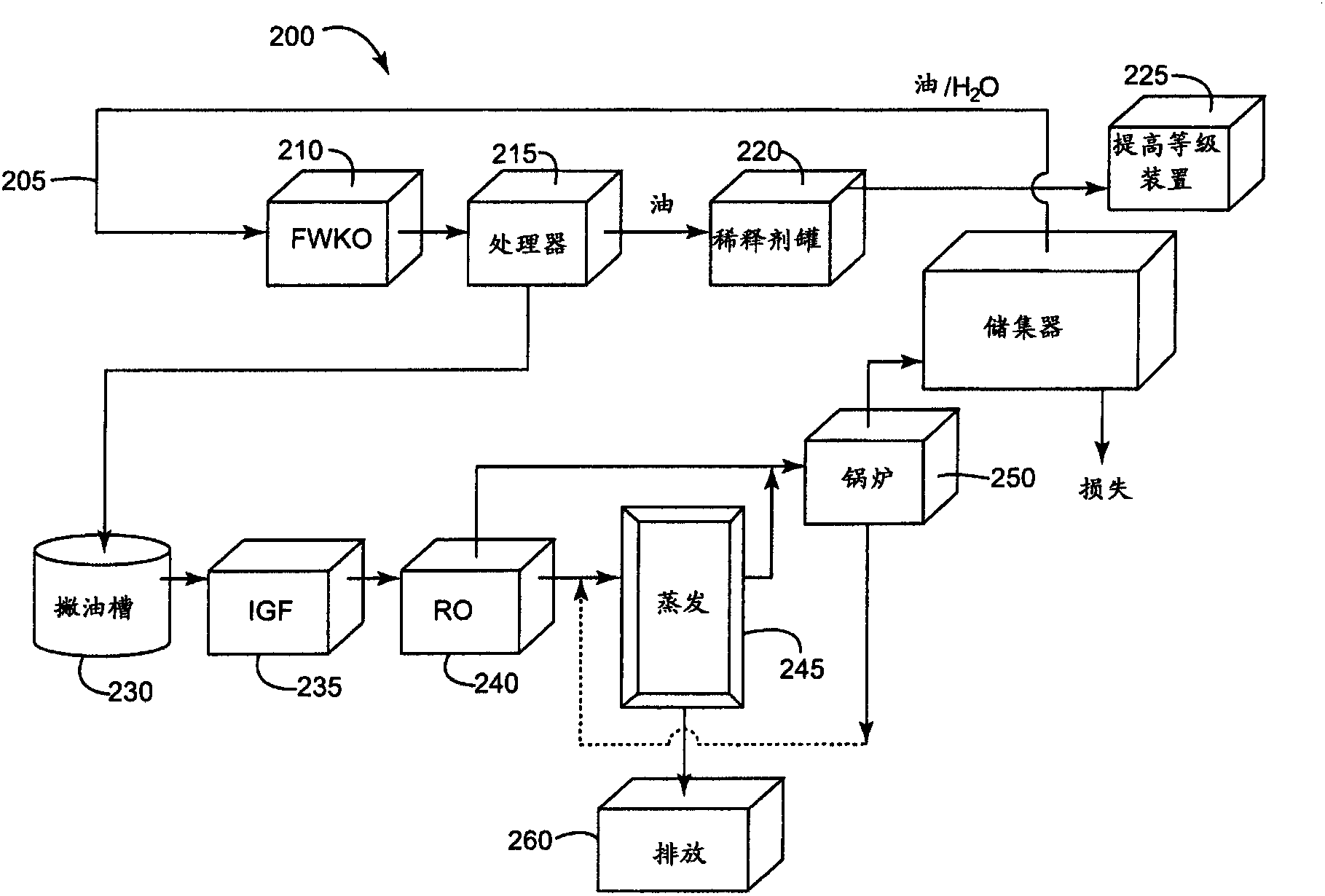

An evaporation based method for generation of high pressure steam from produced water in the heavy oil production industry. De-oiled produced water is processed through a high pH / high pressure evaporator driven by a commercial watertube boiler. The vapor produced by the evaporator is suitable for the steam assisted gravity drainage (SAGD) method being utilized by heavy oil recovery installations, without the use of once through steam generators that require extensive chemical treatment, and without requiring atmospheric distillation, which requires high power consuming compressors. Evaporator blowdown may be further treated in a crystallizing evaporator to provide a zero liquid discharge (ZLD) system and, with most produced waters, at least 98% of the incoming produced water stream can be recovered in the form of high pressure steam.

Owner:AQUATECH INT LLC

Method for production of high pressure steam from produced water

InactiveUS7591309B2Drying using combination processesSolid sorbent liquid separationChemical treatmentWater flow

An evaporation based method for generation of high pressure steam from produced water in the heavy oil production industry. De-oiled produced water is processed through a high pH / high pressure evaporator driven by a commercial watertube boiler. The vapor produced by the evaporator is suitable for the steam assisted gravity drainage (SAGD) method being utilized by heavy oil recovery installations, without the use of once through steam generators that require extensive chemical treatment, and without requiring atmospheric distillation, which requires high power consuming compressors. Evaporator blowdown may be further treated in a crystallizing evaporator to provide a zero liquid discharge (ZLD) system and, with most produced waters, at least 98% of the incoming produced water stream can be recovered in the form of high pressure steam.

Owner:AQUATECH INT LLC

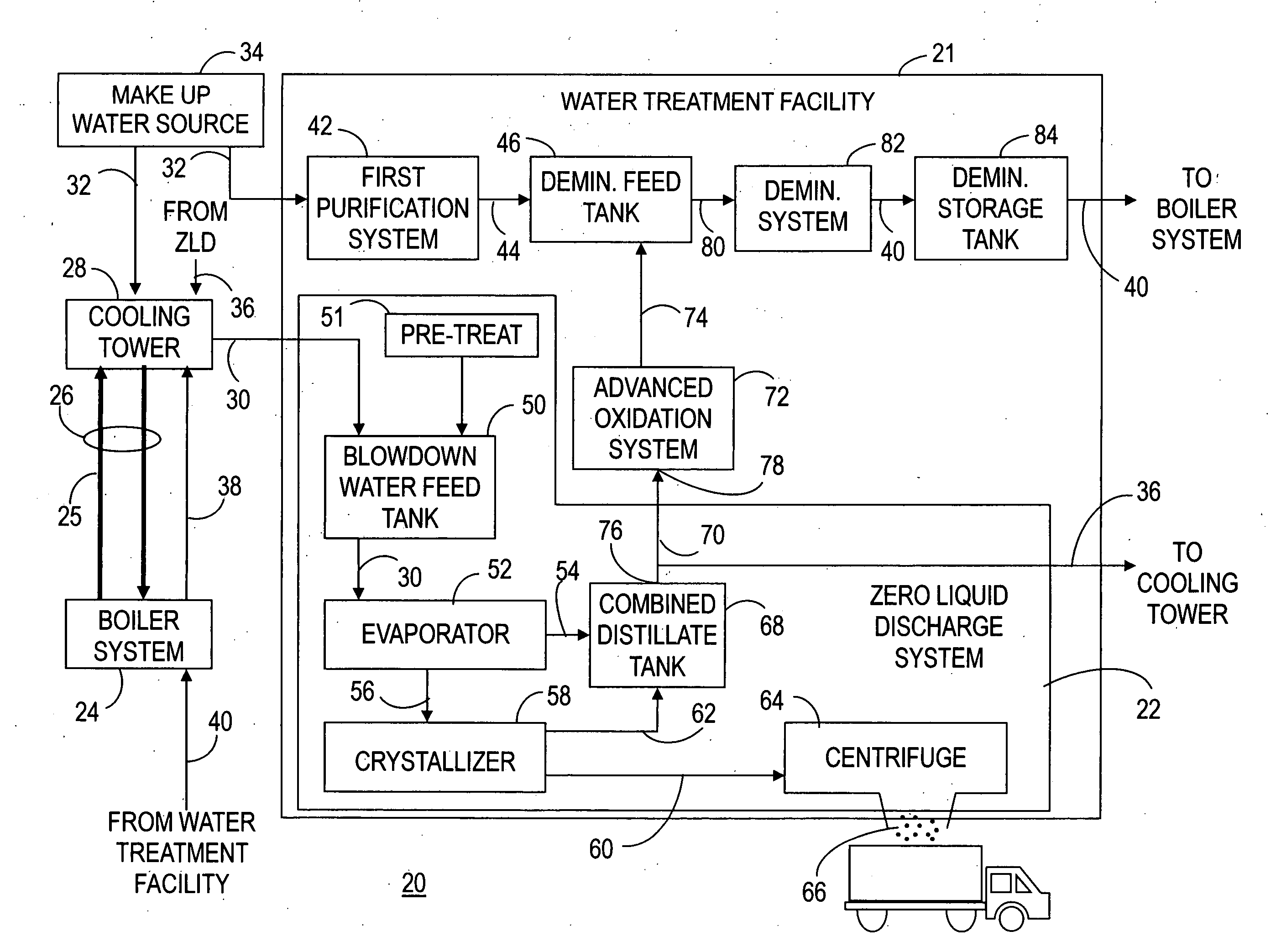

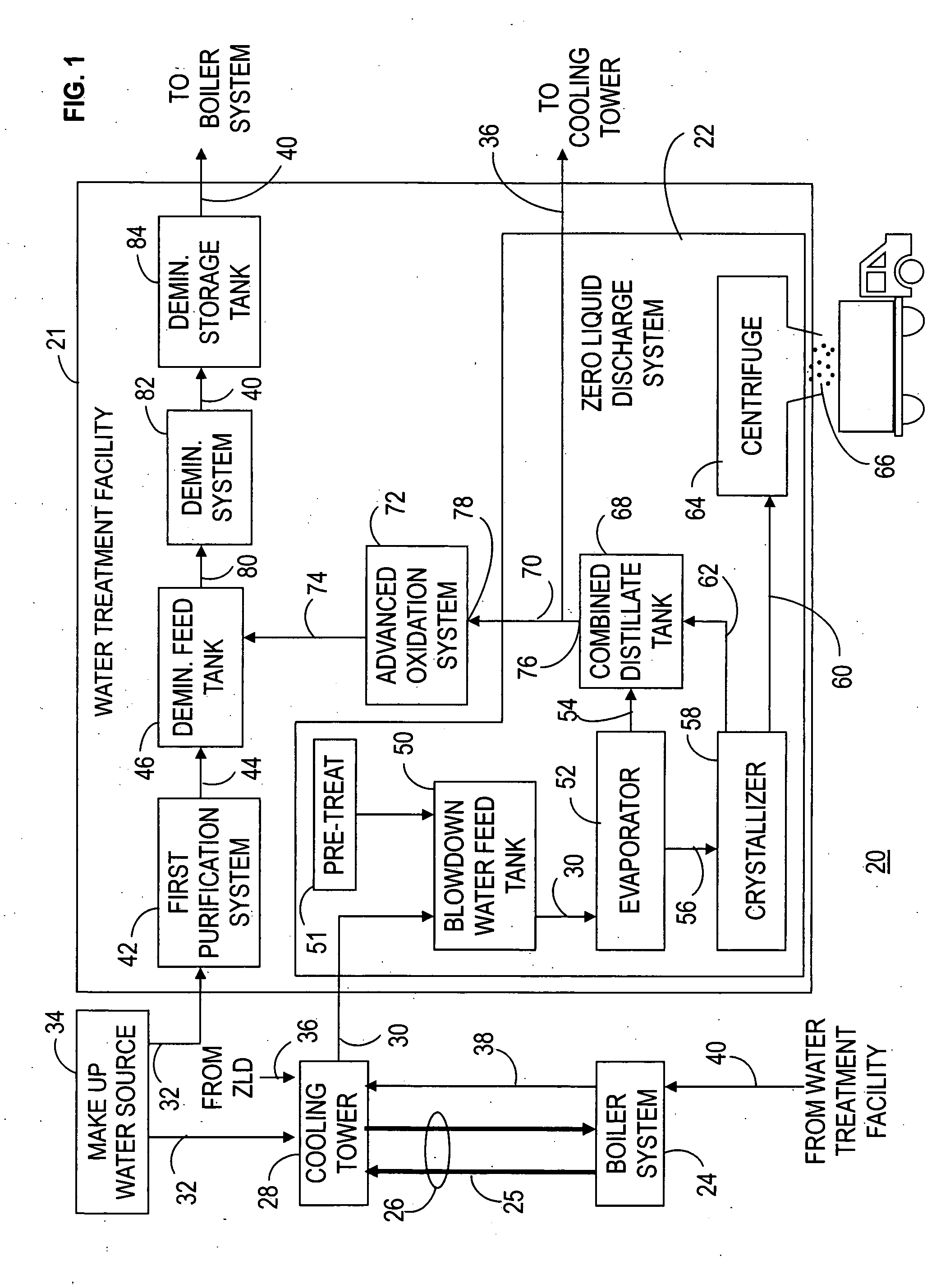

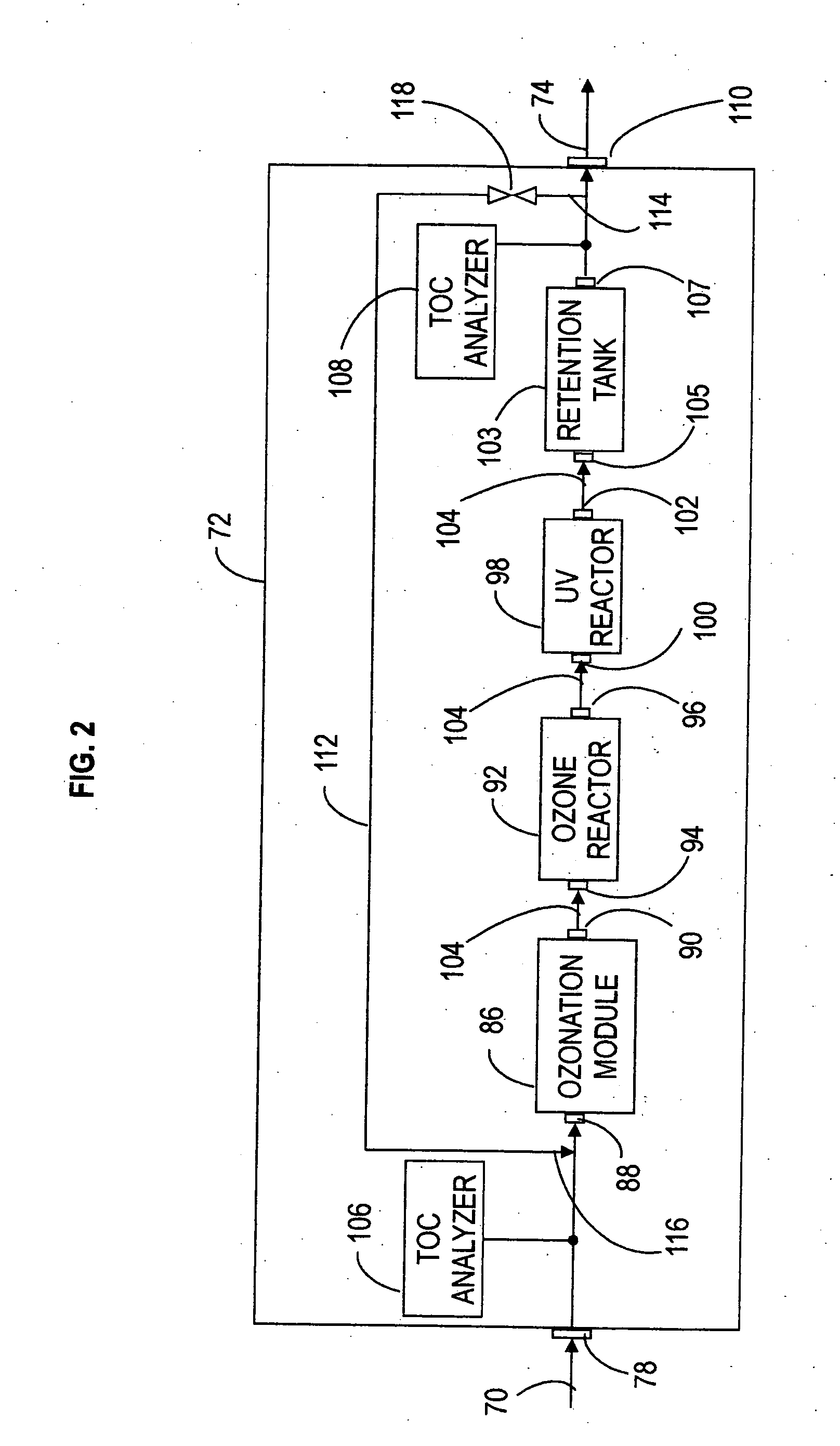

System and method of reducing organic contaminants in feed water

InactiveUS20070125719A1Reducing organic contaminantEfficient implementationWater treatment parameter controlWater/sewage treatment by irradiationHigh concentrationPower station

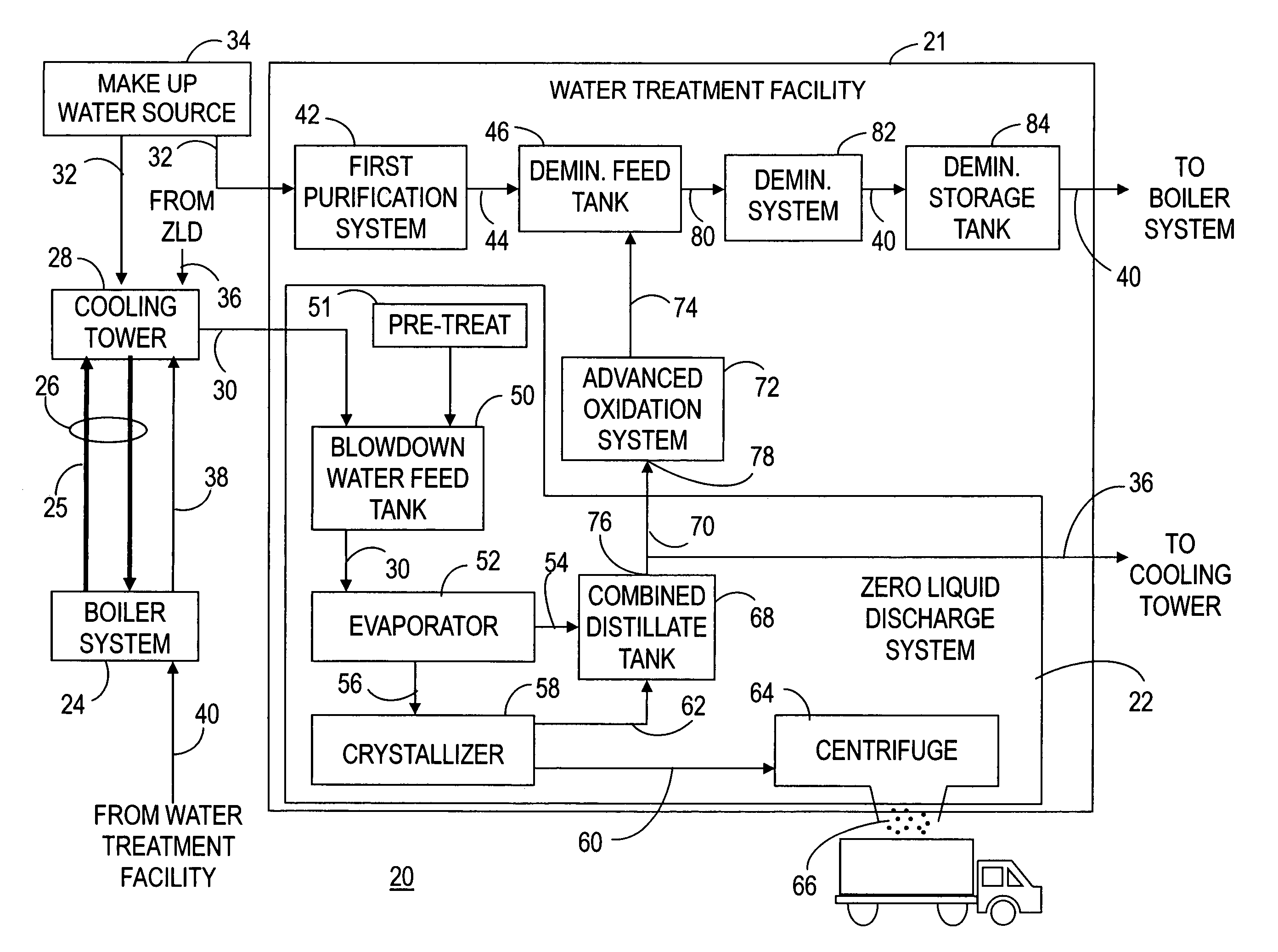

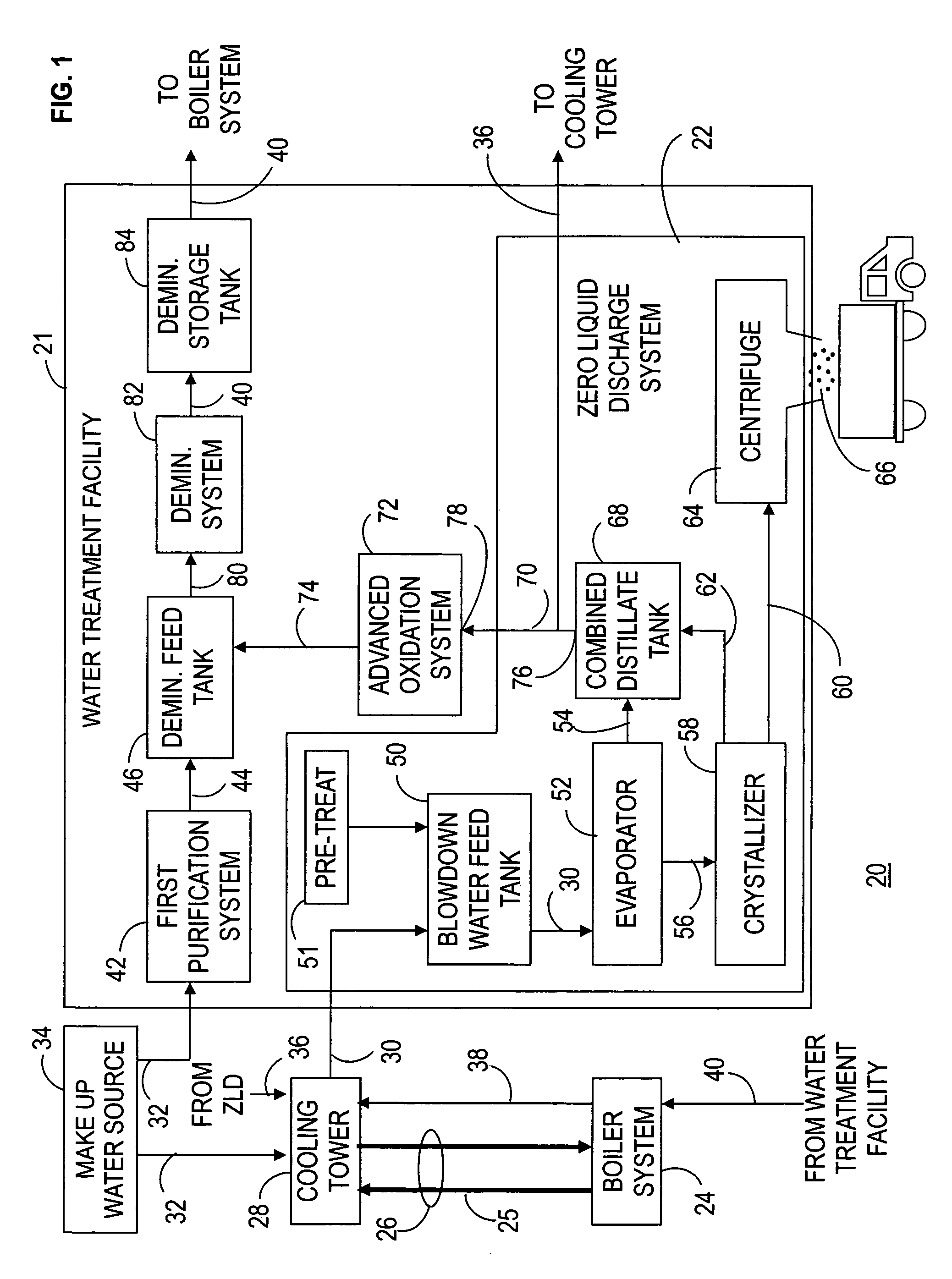

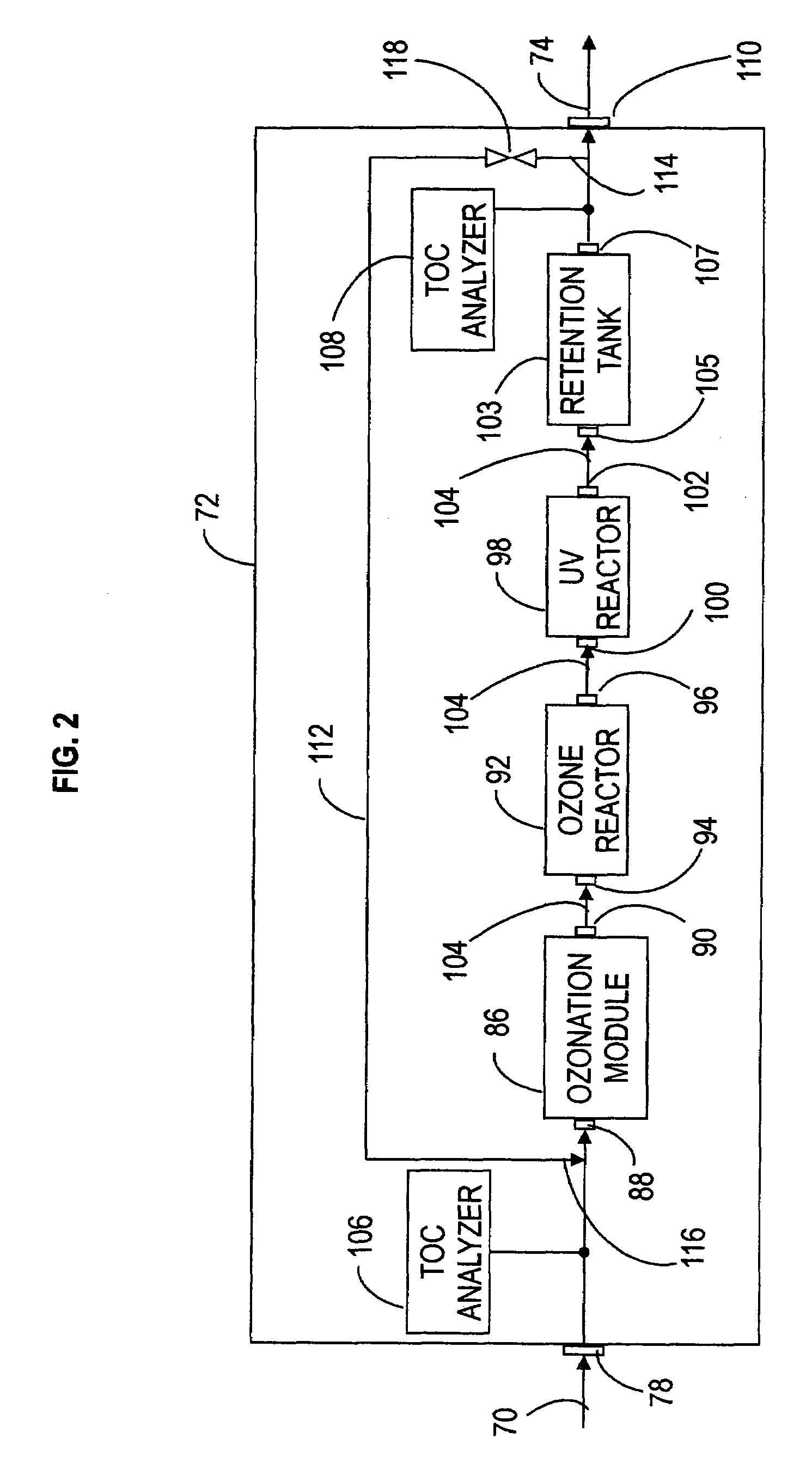

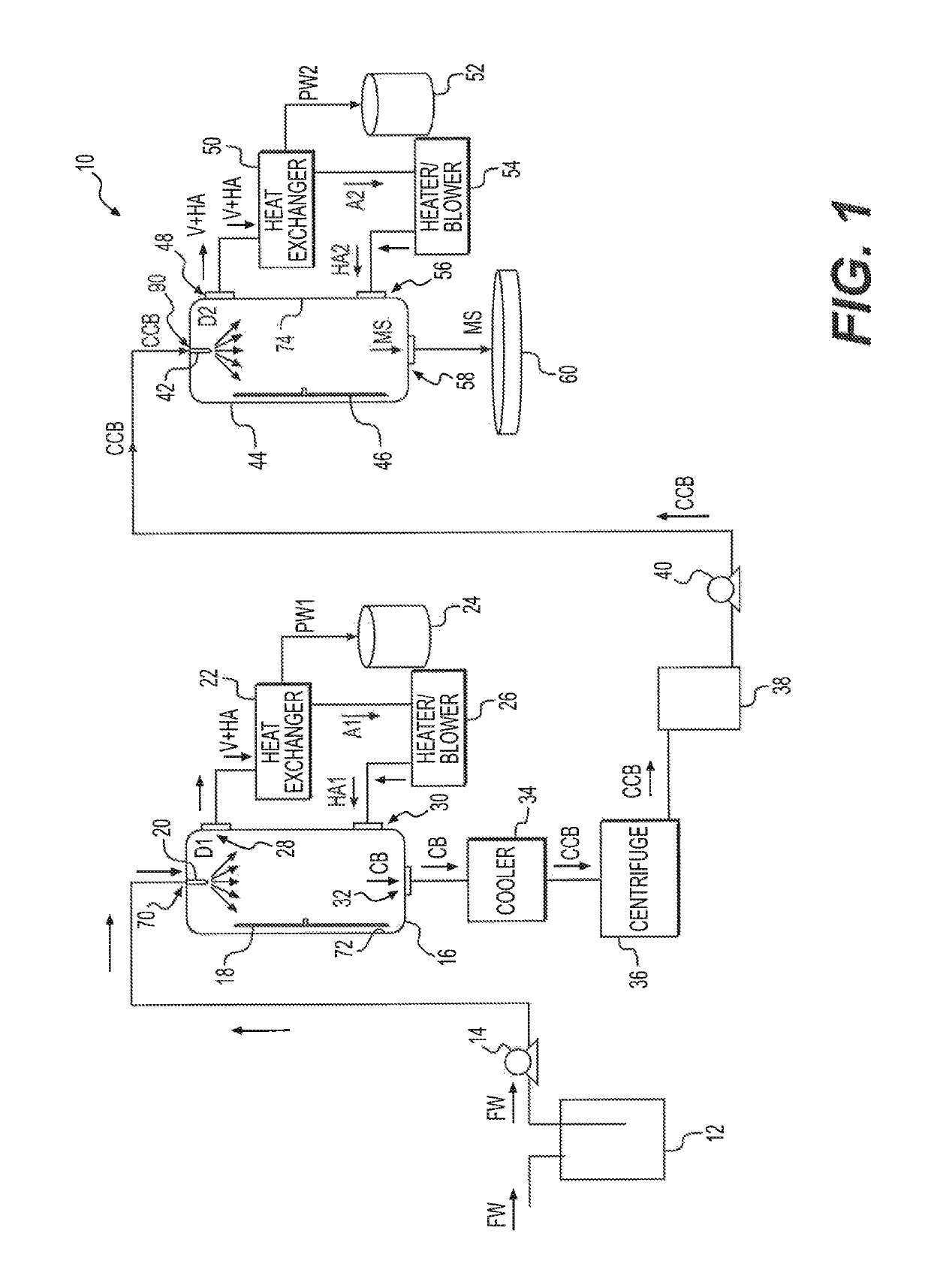

A zero liquid discharge (ZLD) power plant (20) includes an advanced oxidation system (72) for reducing contaminants in source water (70) to form feed water (40) for a boiler (24). The system (72) includes an ozonation module (86) for applying high concentration ozone to the source water (70) to form a mixed stream (104), an ozone reactor (92) in which the mixed stream is retained (104) under pressure, an ultraviolet reactor (98) downstream from the ozone reactor (92) for enhanced contaminant reduction, and a retention tank (103) downstream from the reactor (98). In one configuration, the source water (70) is evaporator distillate from an evaporator (52) that recycles cooling tower blowdown 30. The system (72) achieves organic contaminant reduction at total organic carbon (TOC) levels of less than three hundred parts per billion.

Owner:ARIZONA PUBLIC SERVICE

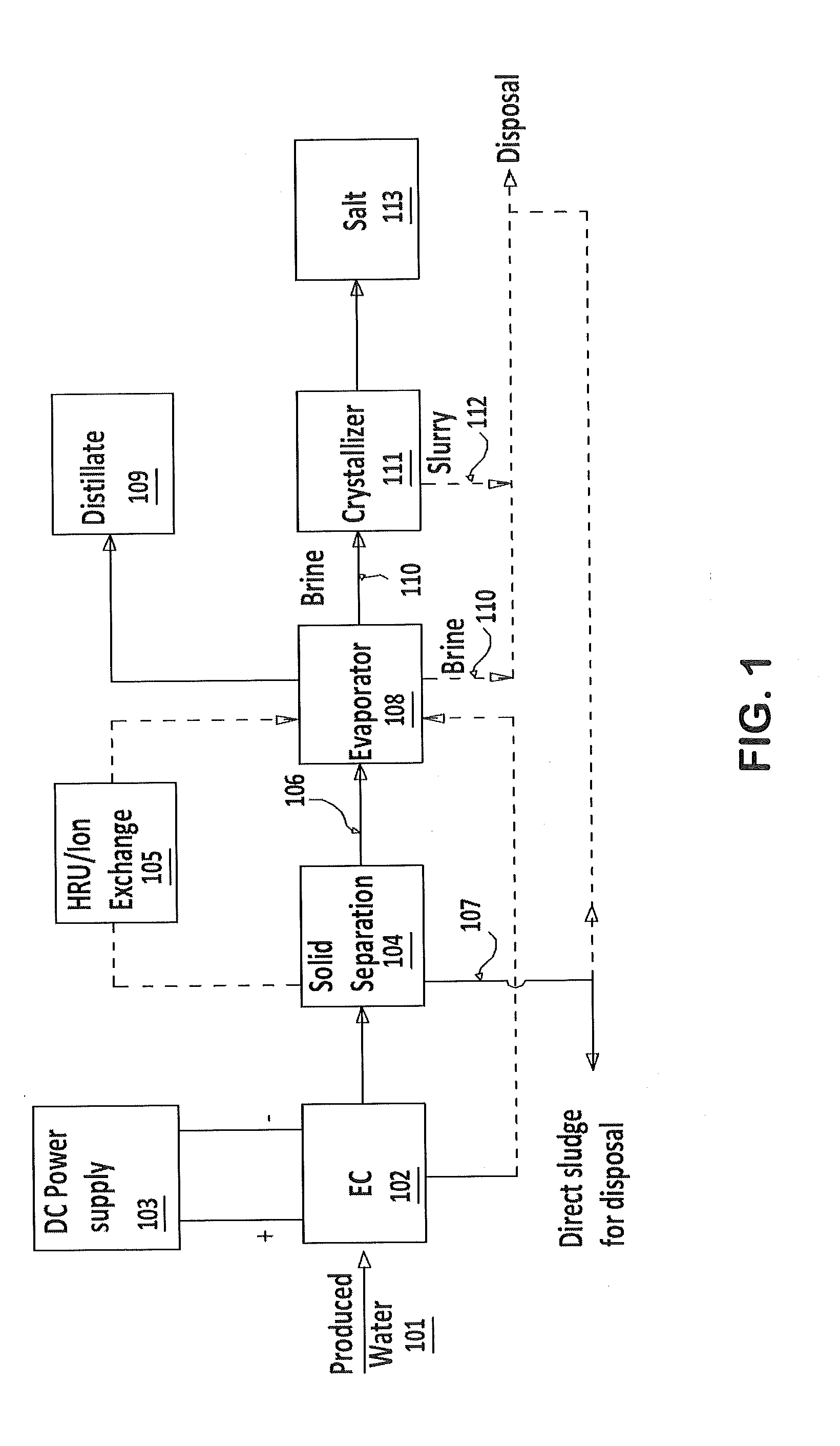

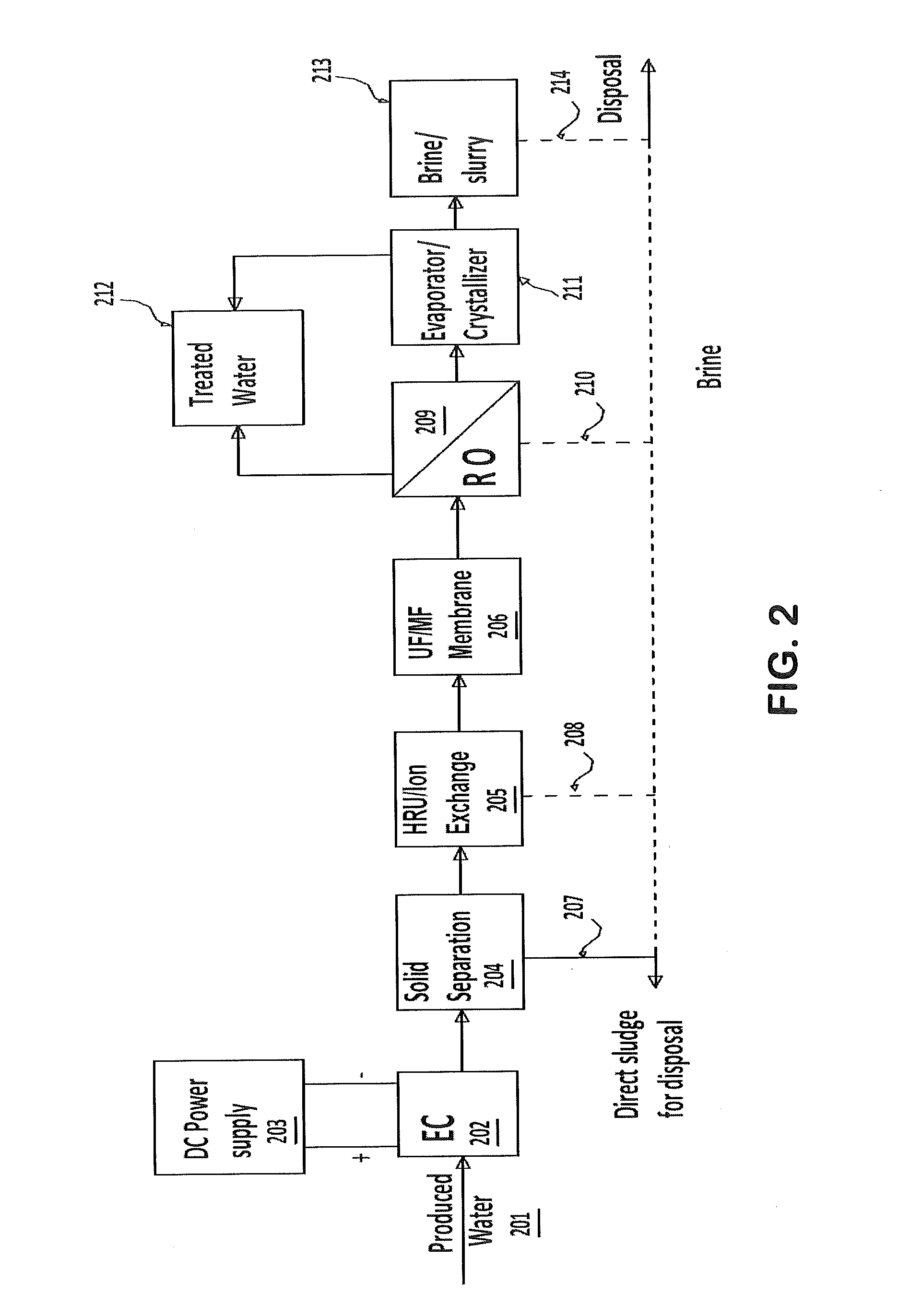

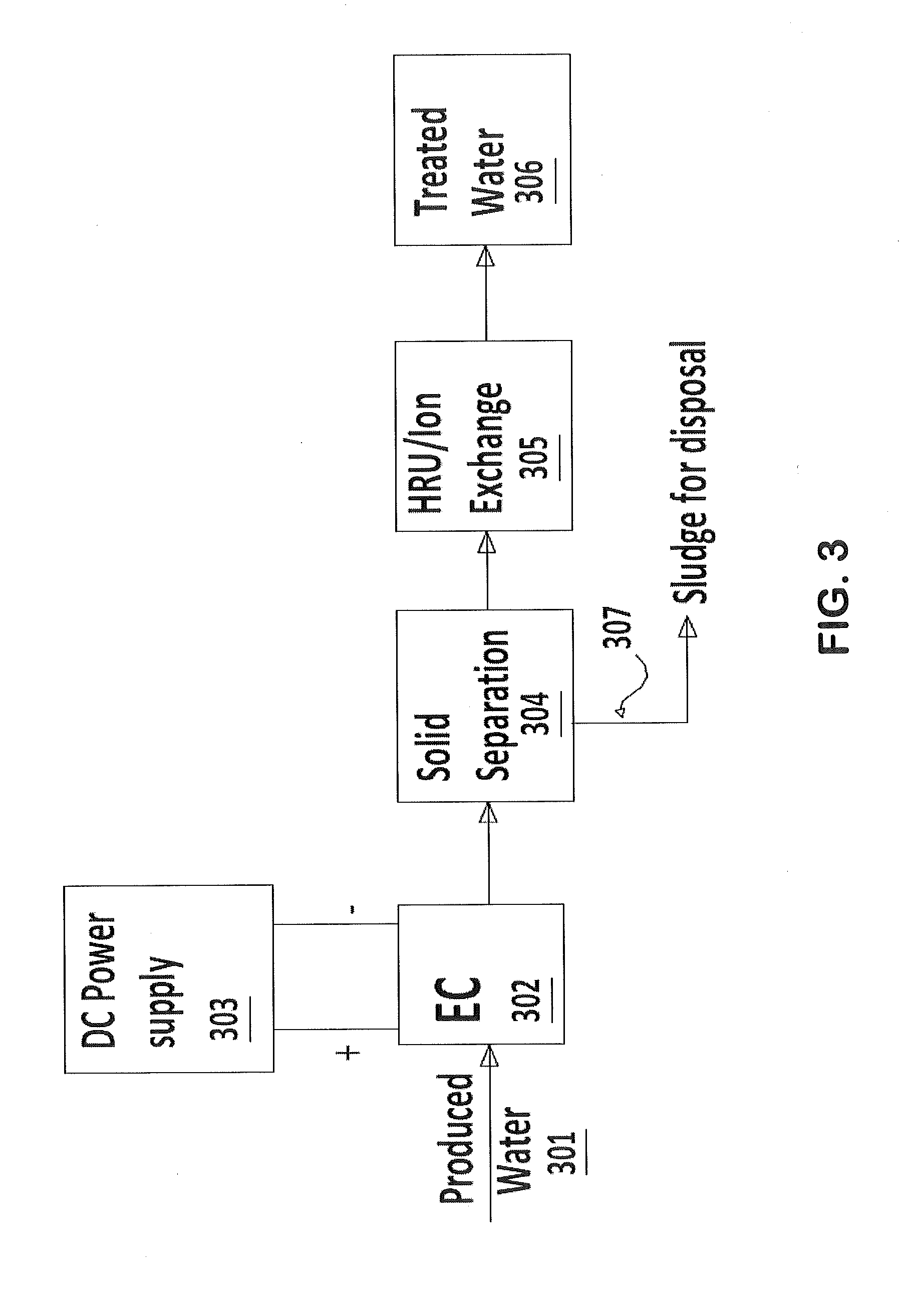

Water Treatment Process

InactiveUS20150315055A1Minimal environmental impactLow costWaste water treatment from quariesWater contaminantsElectrocoagulationHardness

A process for enhanced removal of impurities from water by an enhanced multi-step electrocoagulation process including electrocoagulation, solids separation, hardness removal, crystallization, and, optionally, reverse osmosis and evaporative purification. Embodiments of the invention may remove multiple impurities at substantial savings in time, energy, and chemical use. Zero liquid discharge options are also reported.

Owner:AQUATECH INT LLC

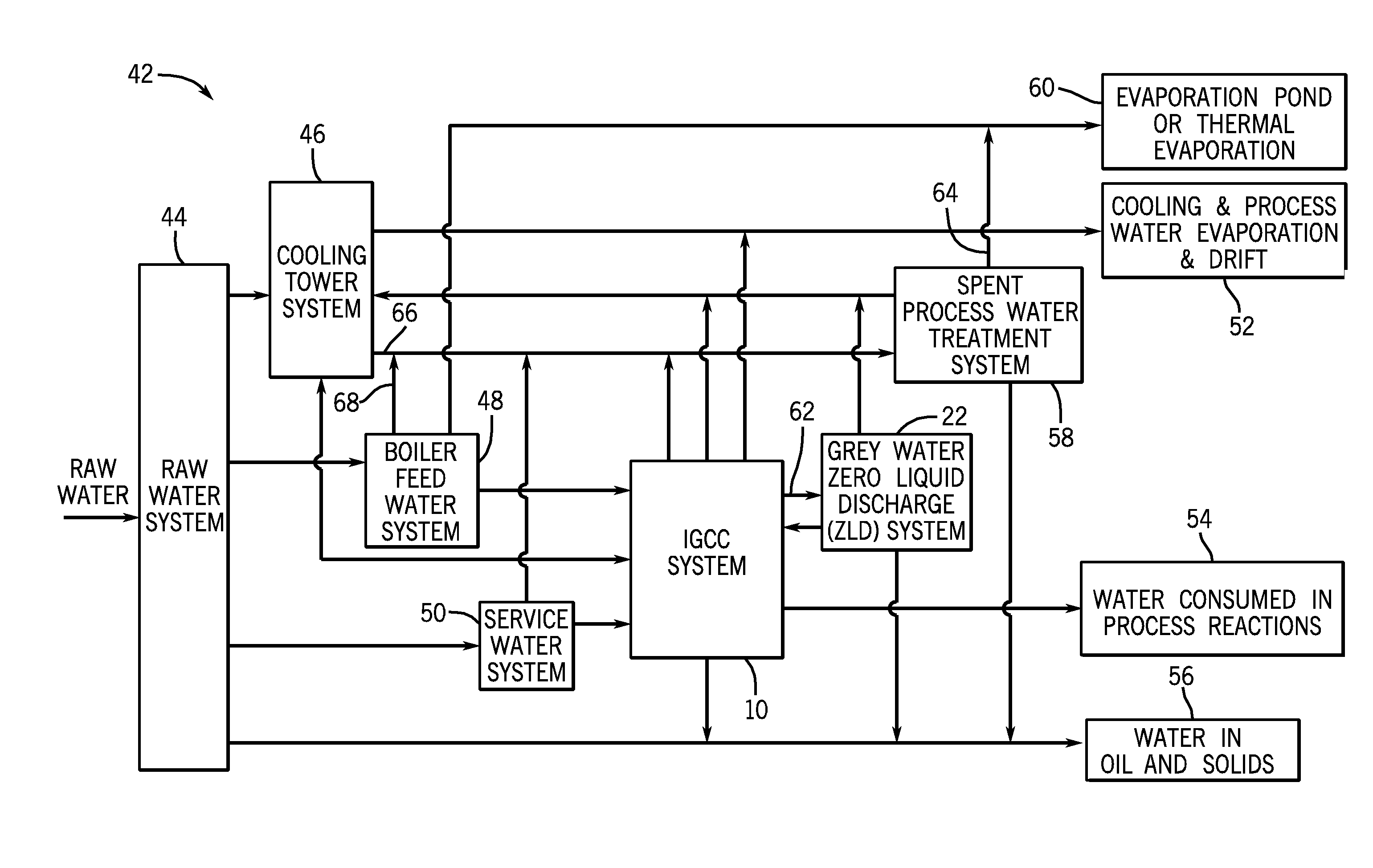

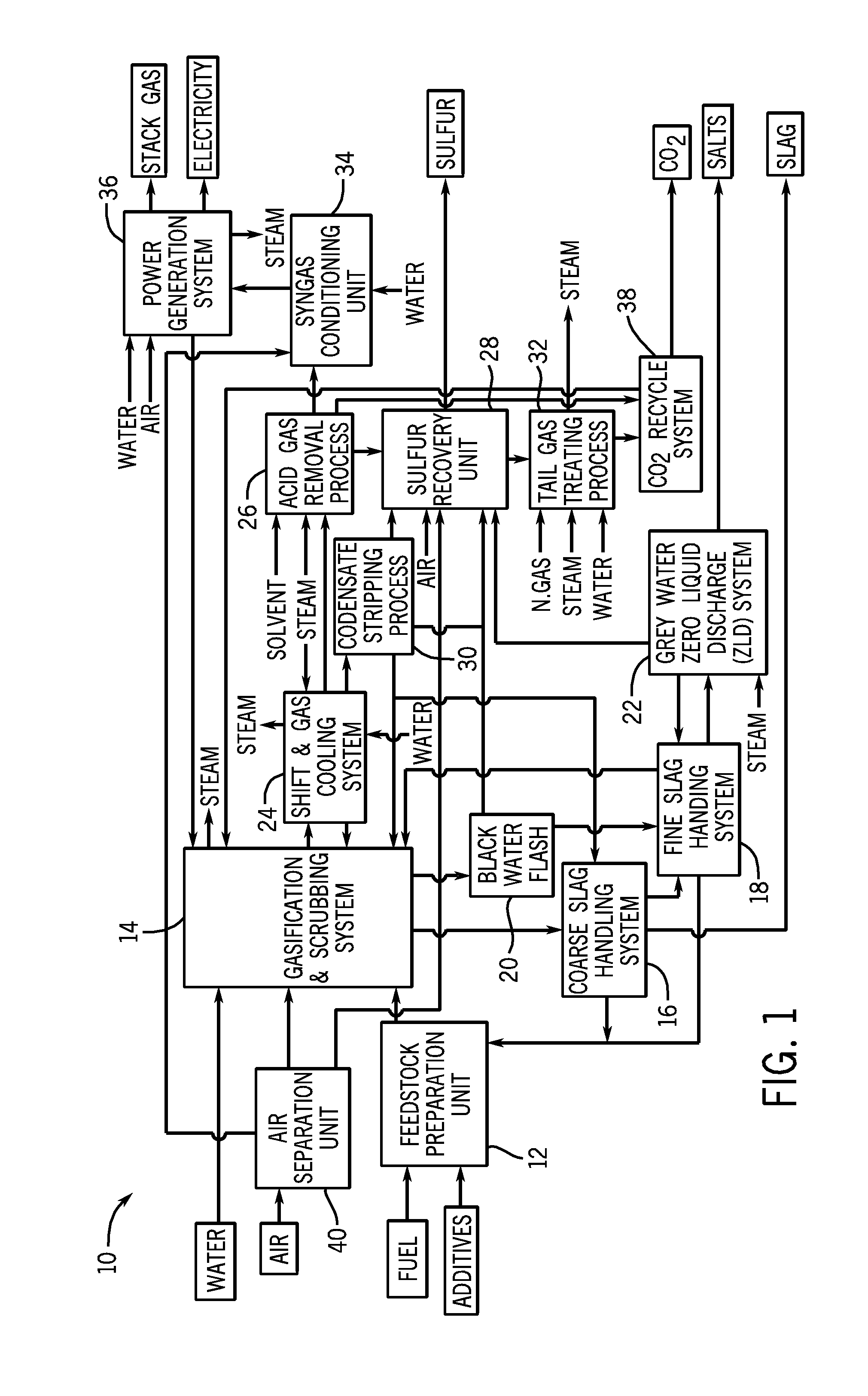

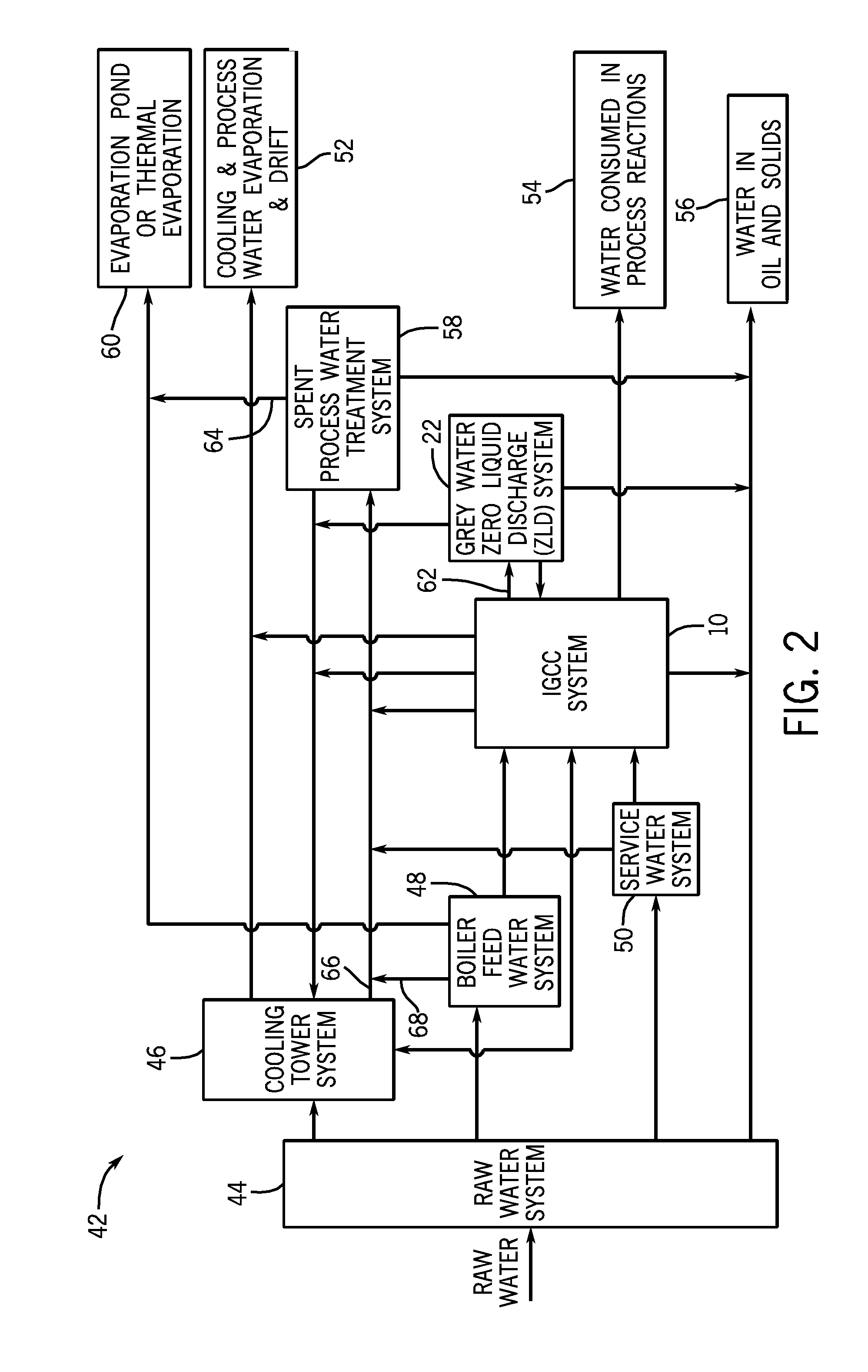

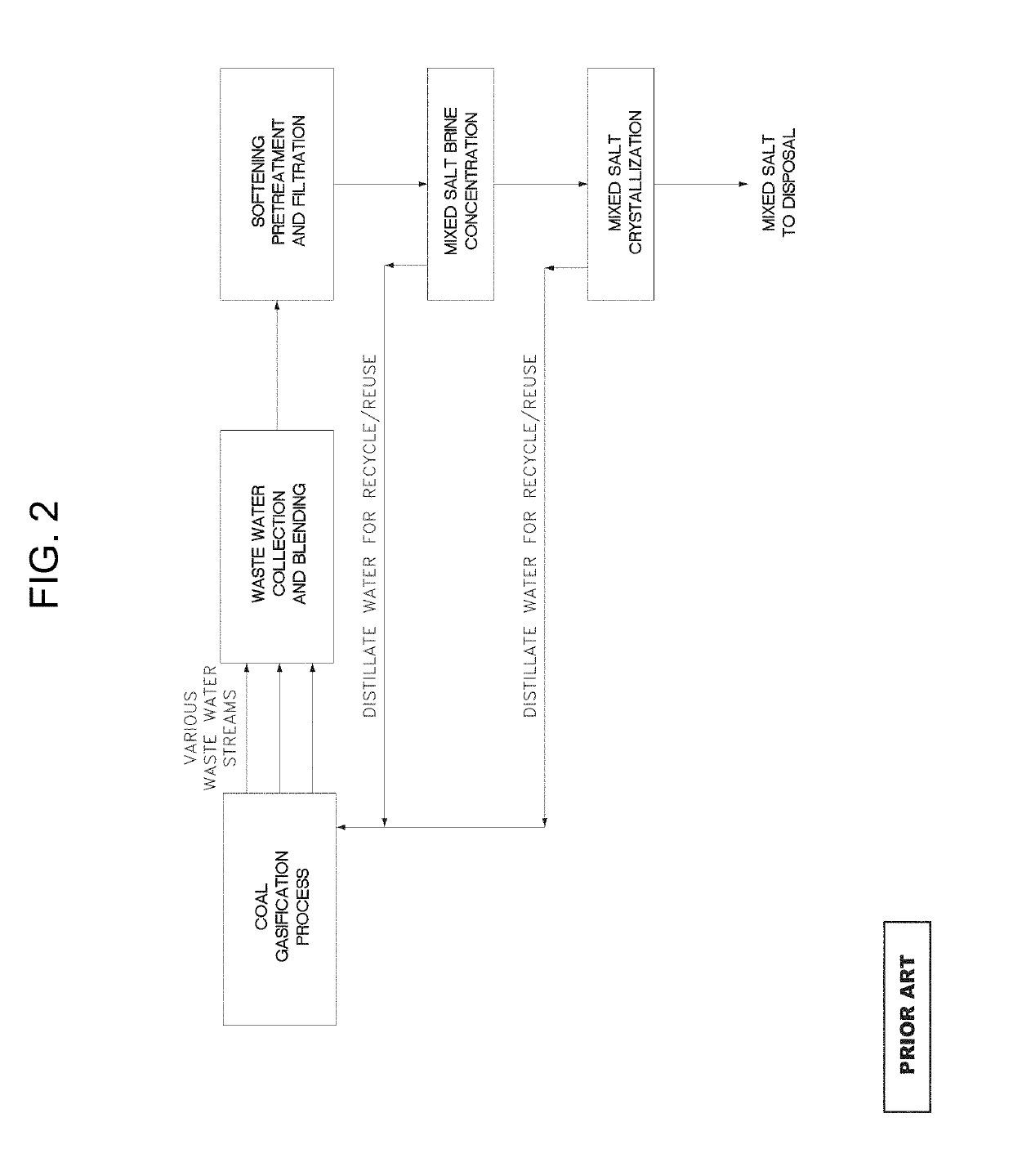

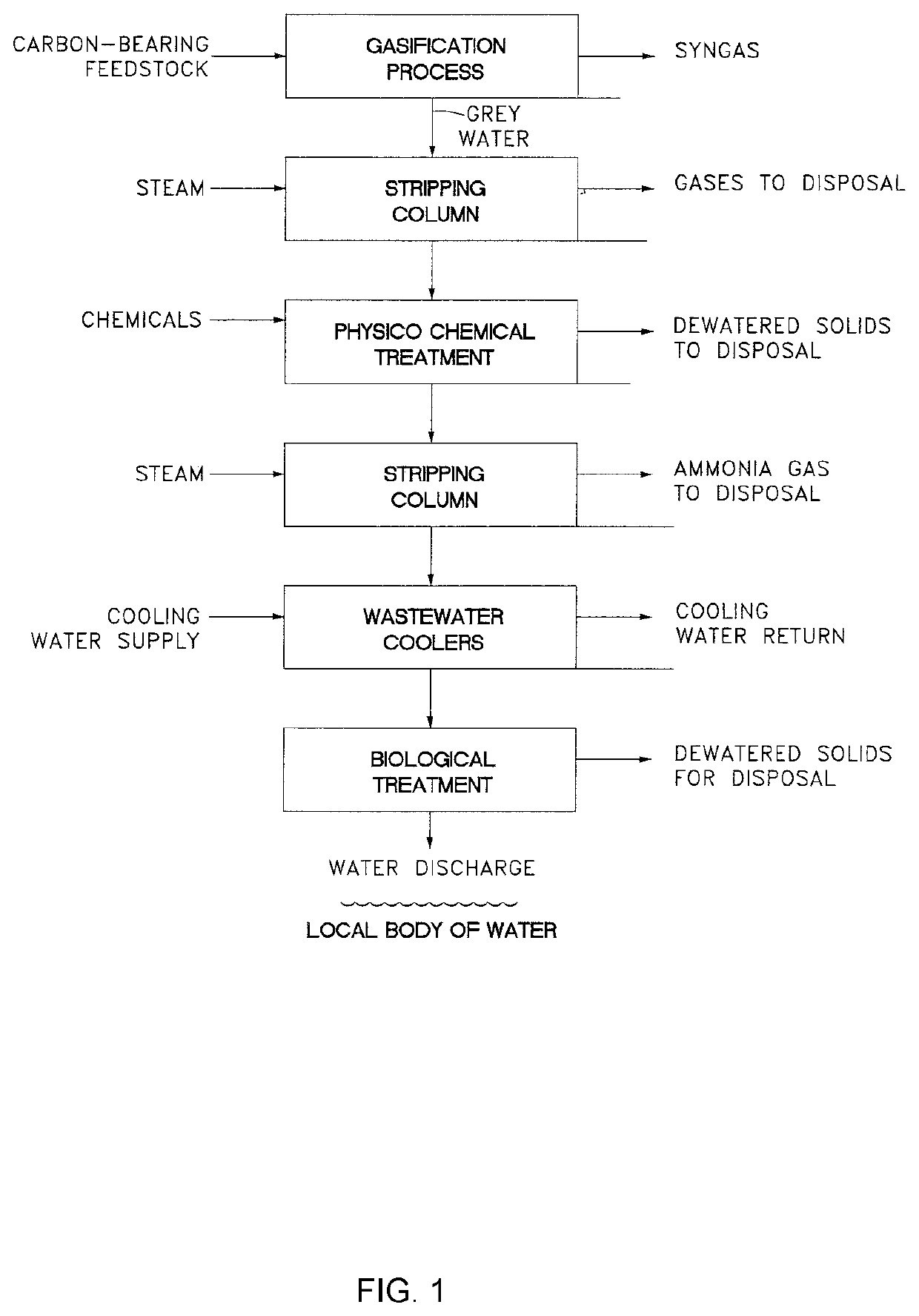

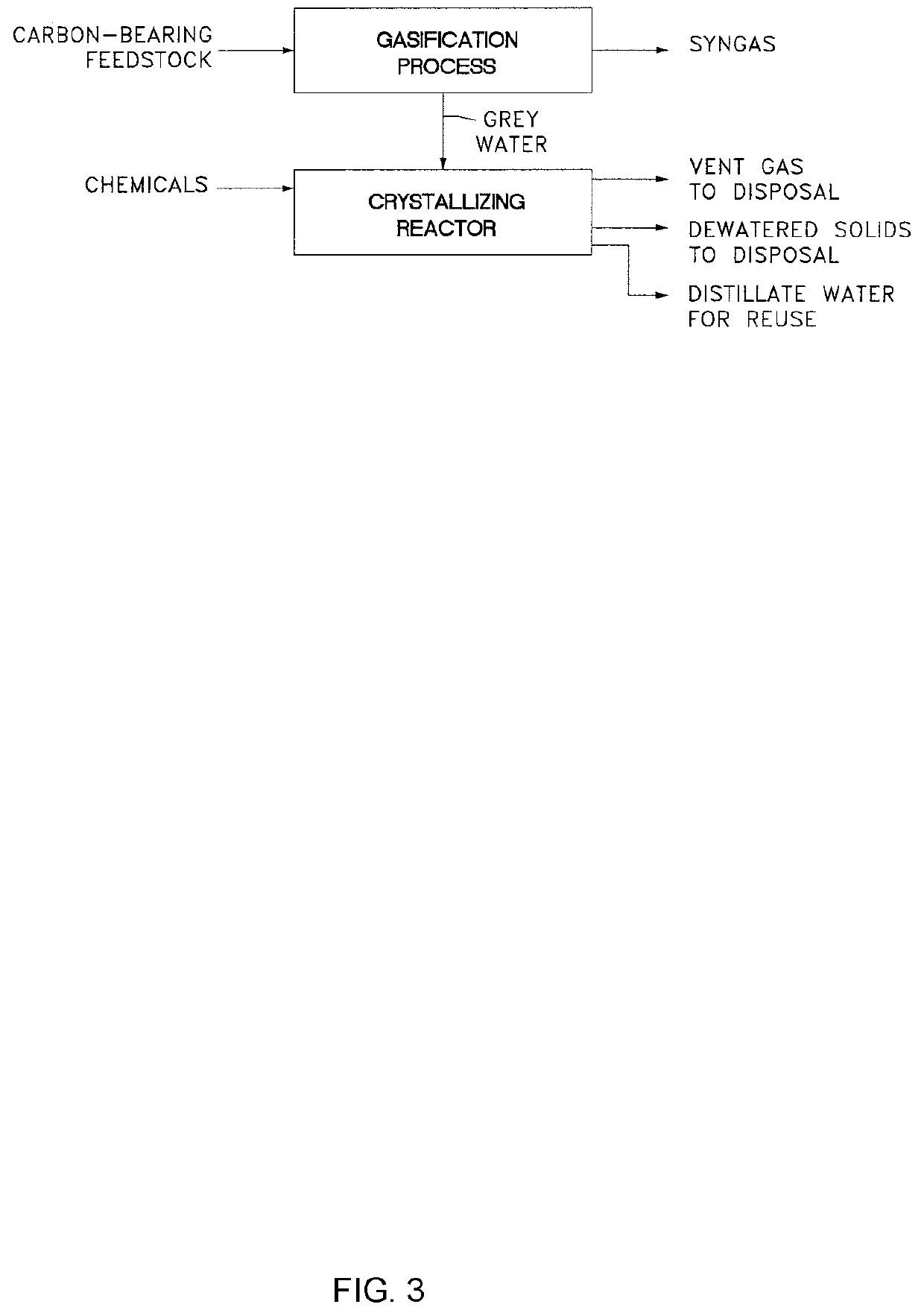

Gasification plant with total zero discharge of plant process waters

ActiveUS20110108405A1Scale removal and water softeningTreatment involving filtrationEngineeringAmmonia

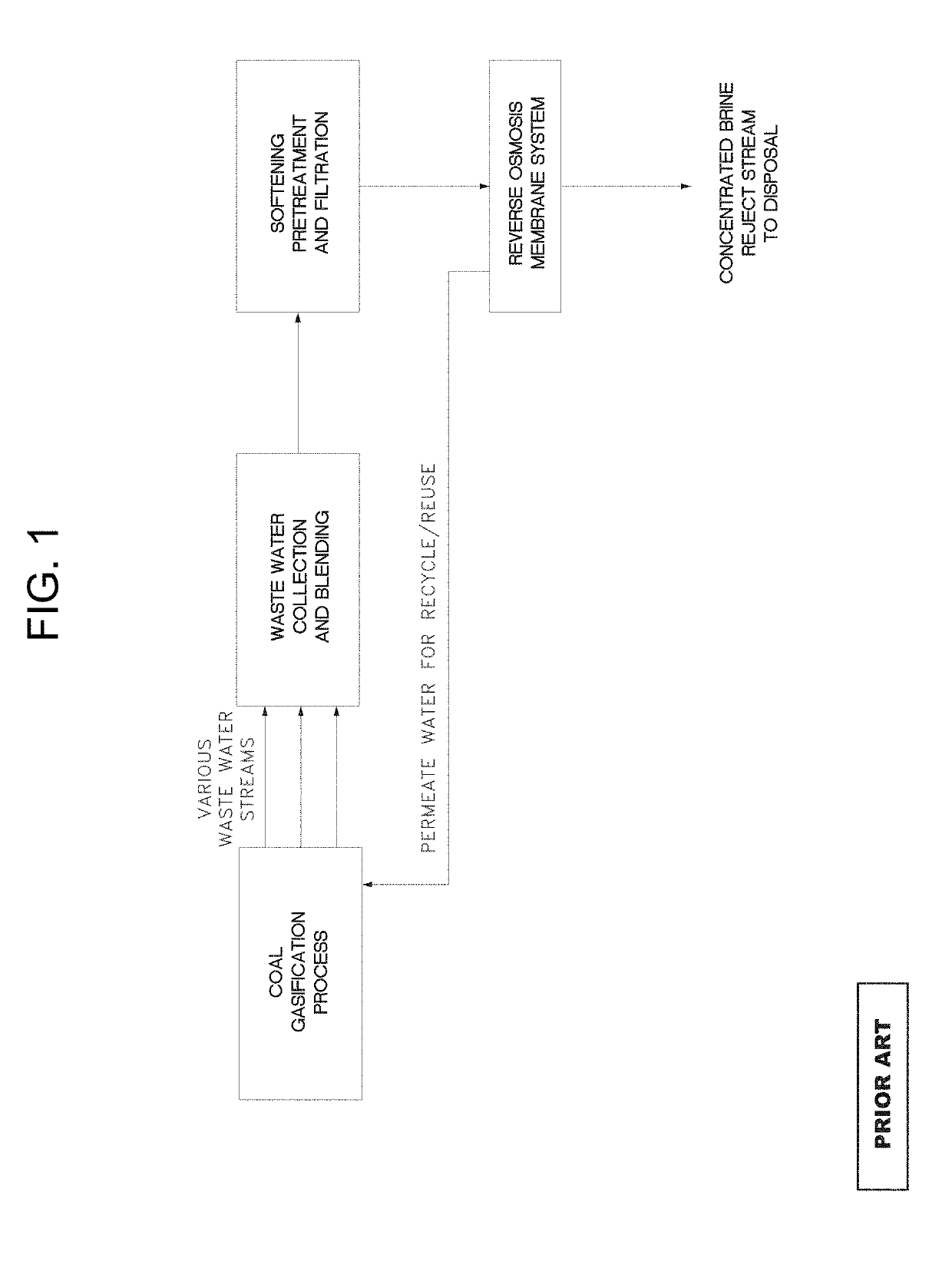

In certain embodiments, a system includes a gasification system configured to output grey water. The system also includes a grey water zero liquid discharge (ZLD) system configured to receive the grey water and to generate a first stream of distillate. The grey water ZLD system comprises an ammonia stripping system. An amount of water into and out of the grey water ZLD system is approximately equal.

Owner:AIR PROD & CHEM INC

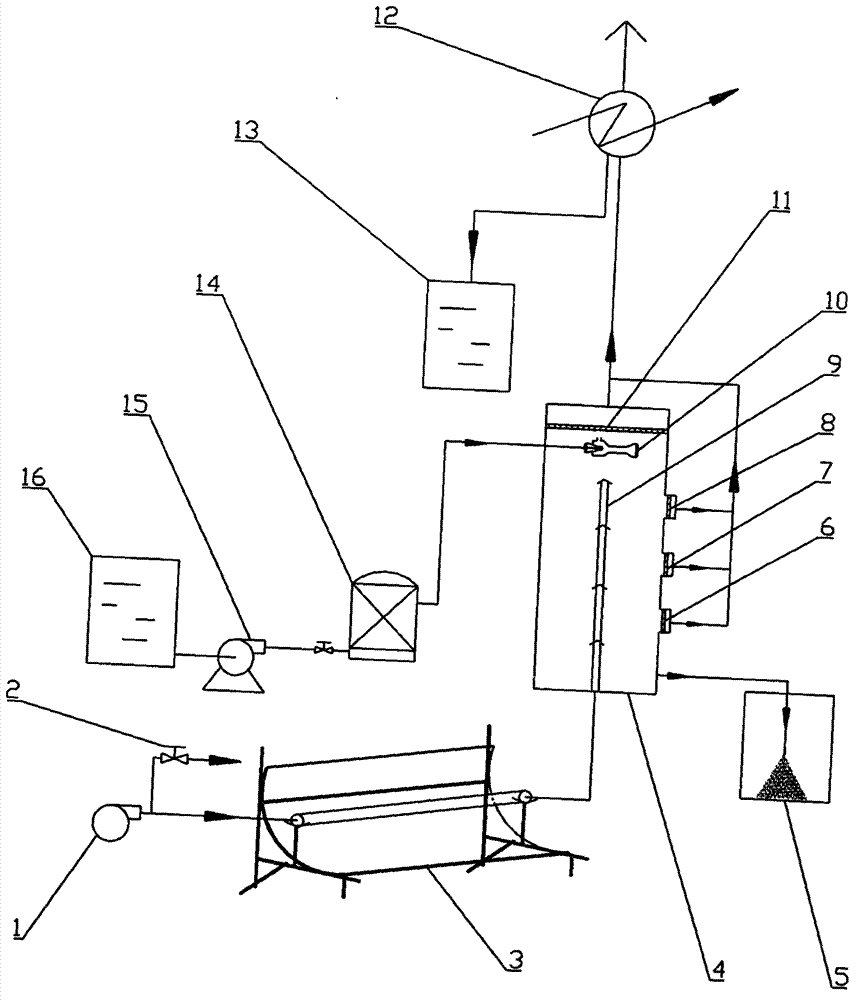

Solar zero-liquid-discharge sea water desalting plant and method

InactiveCN102730779AEfficient evaporationFast evaporationGeneral water supply conservationSeawater treatmentWater desalinationAutomatic control

The invention relates to a solar zero-liquid-discharge sea water desalting plant and method. Moisture in sea water is evaporated quickly at low energy consumption by using a liquid spray method and multistage hot air contact; 100-400 DEG C hot air is supplied by a condensation solar heat collector, micro-dimension sea water drops perform moisture diffusion and heat transfer with dry hot air many times, nano drop characteristic evaporation is implemented an atomization evaporator, the obtained high-temperature saturated moist air is cooled by a saturated moist air condenser to obtain fresh water, the rest low-temperature saturated air is exhausted, and solid crystals are taken out from the bottom of the atomization evaporator. The invention is suitable for desalting of sea water, or concentration separation or liquid-solid separation of bitters and other electrolyte water solutions. The invention has the advantages of perfect structure, strong automatic control performance and high efficiency, and fully utilizes the solar energy.

Owner:TIANJIN CHENGJIAN UNIV

Method for production of high purity distillate from produced water for generation of high pressure steam

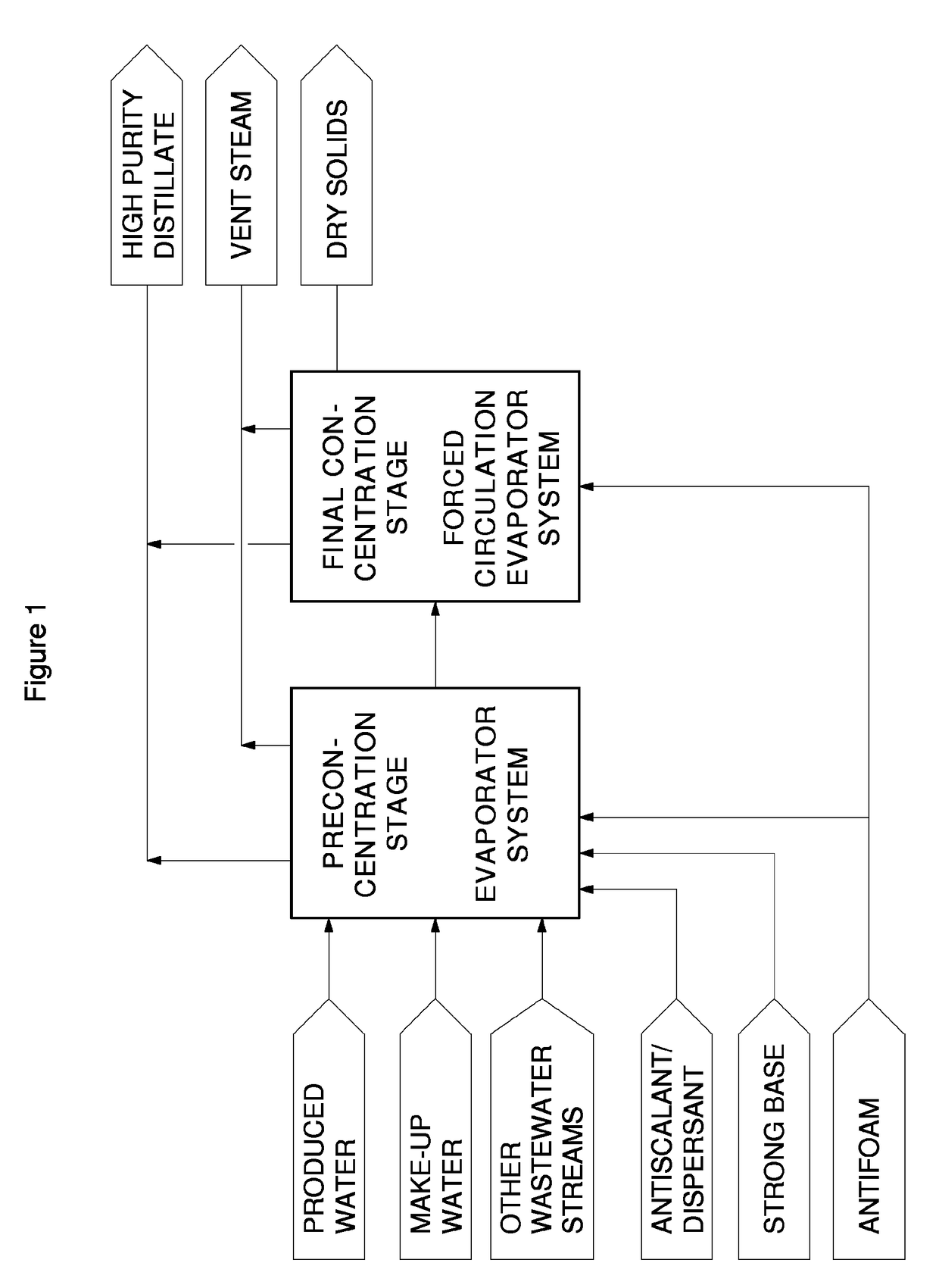

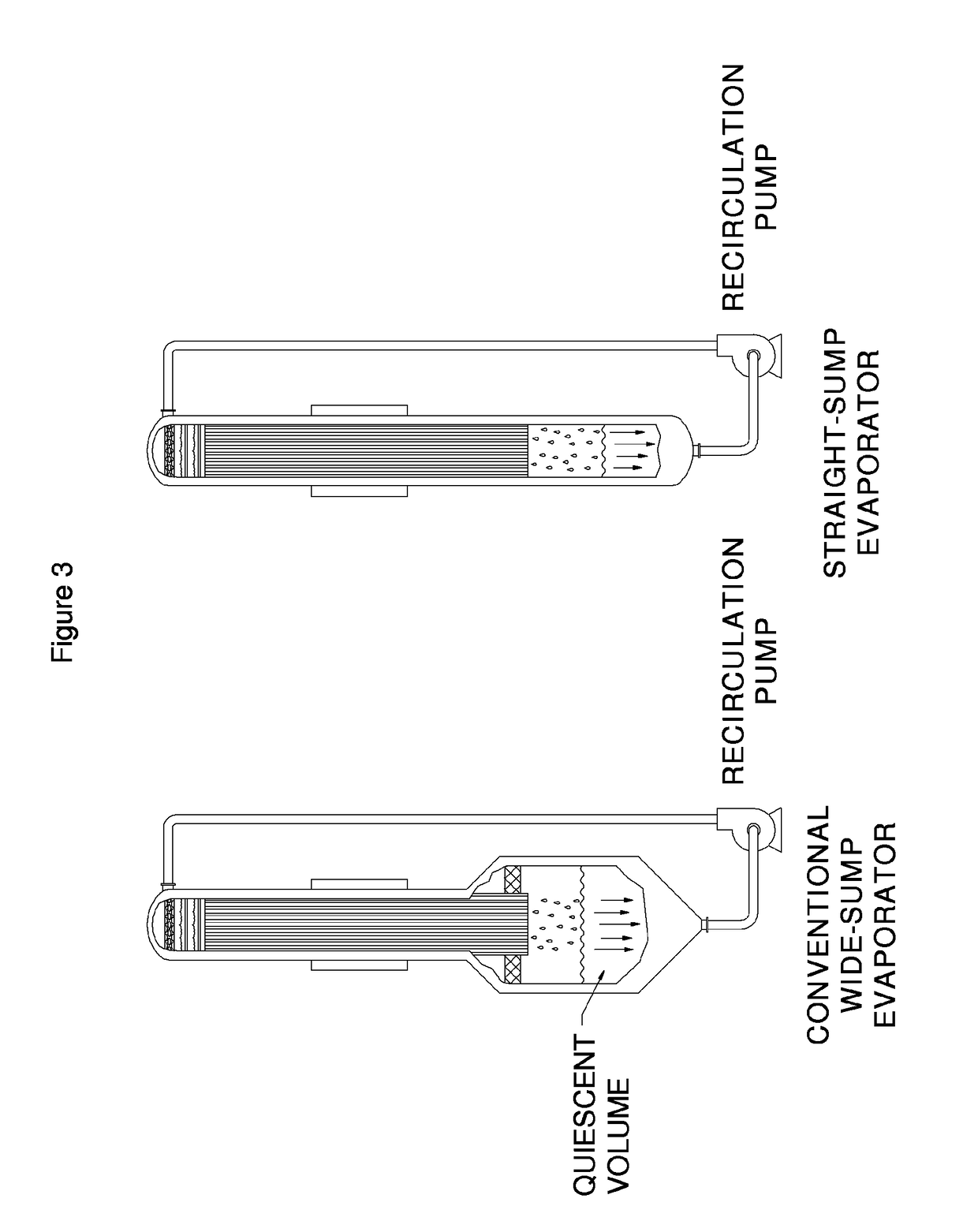

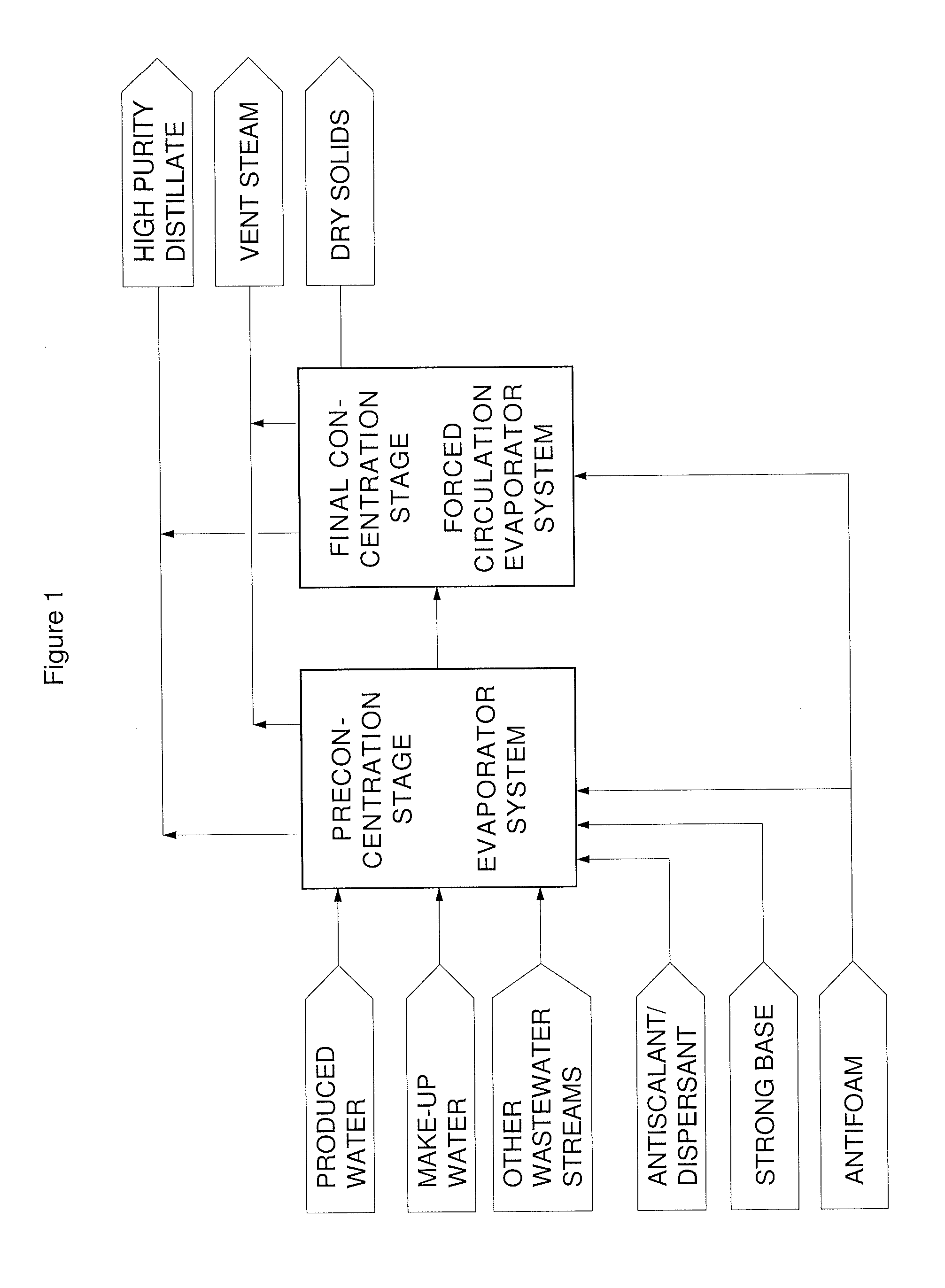

ActiveUS20110061867A1High work pressureIncrease vaporization rateUsing liquid separation agentInsulationEvaporationEngineering

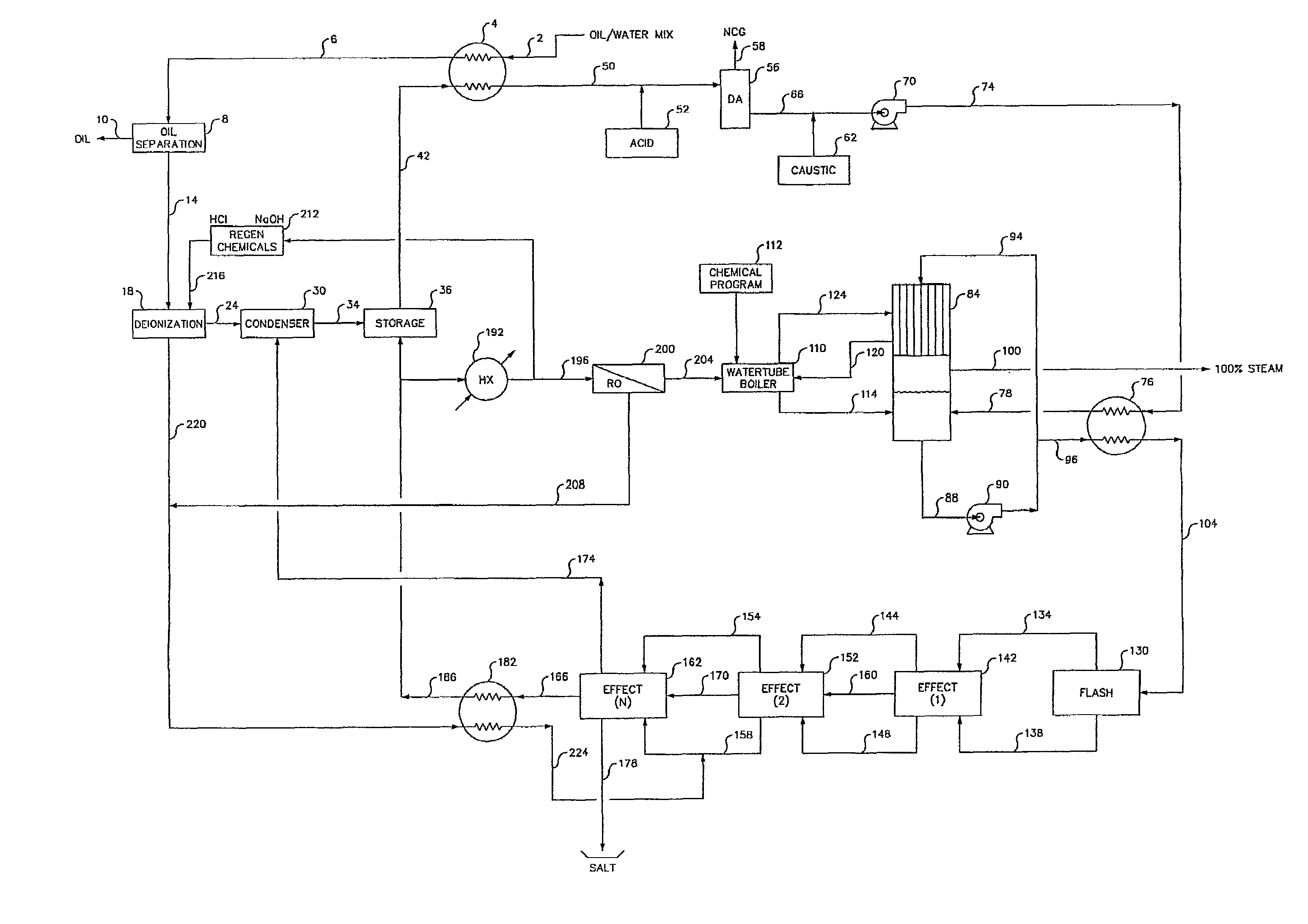

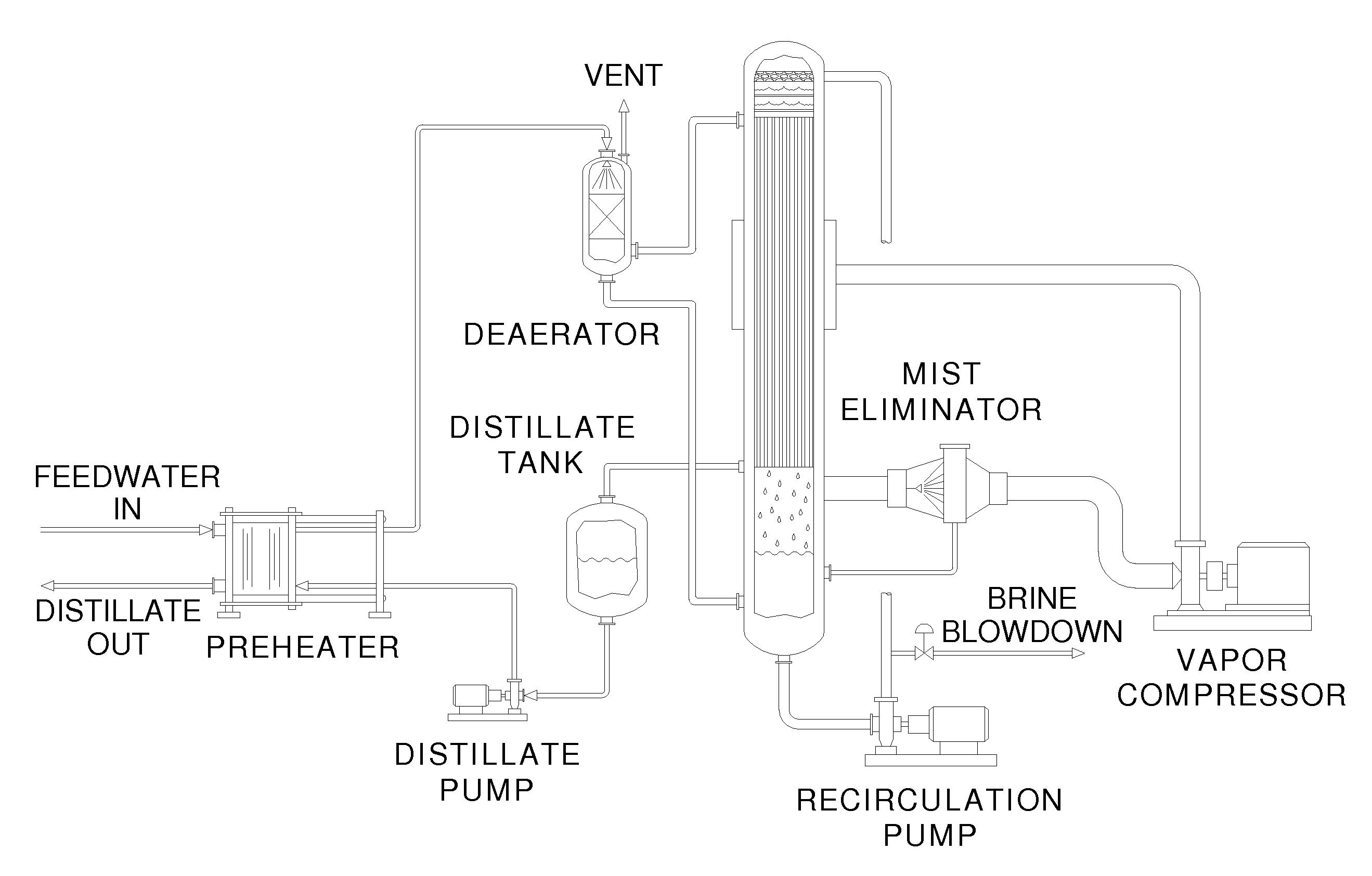

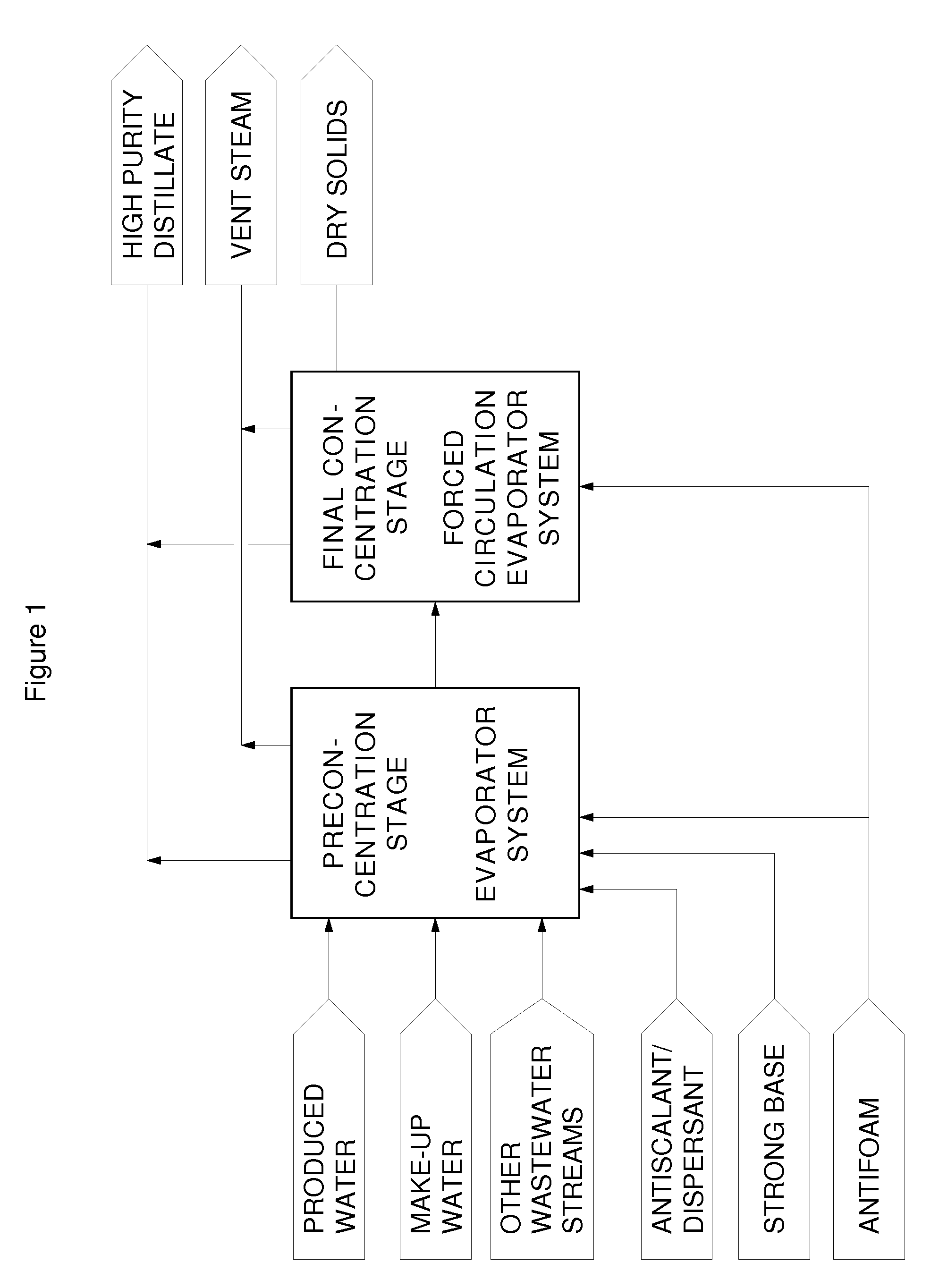

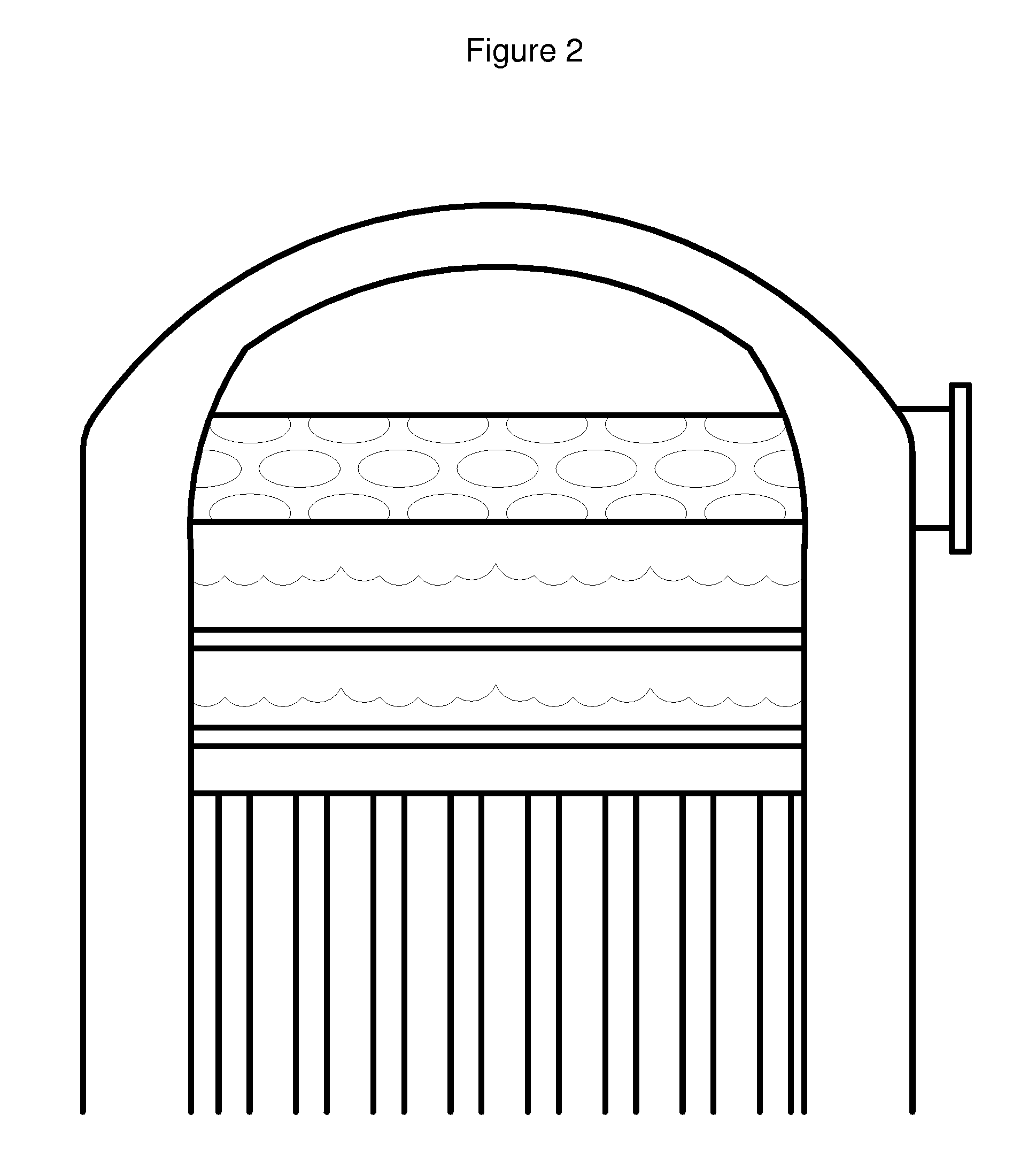

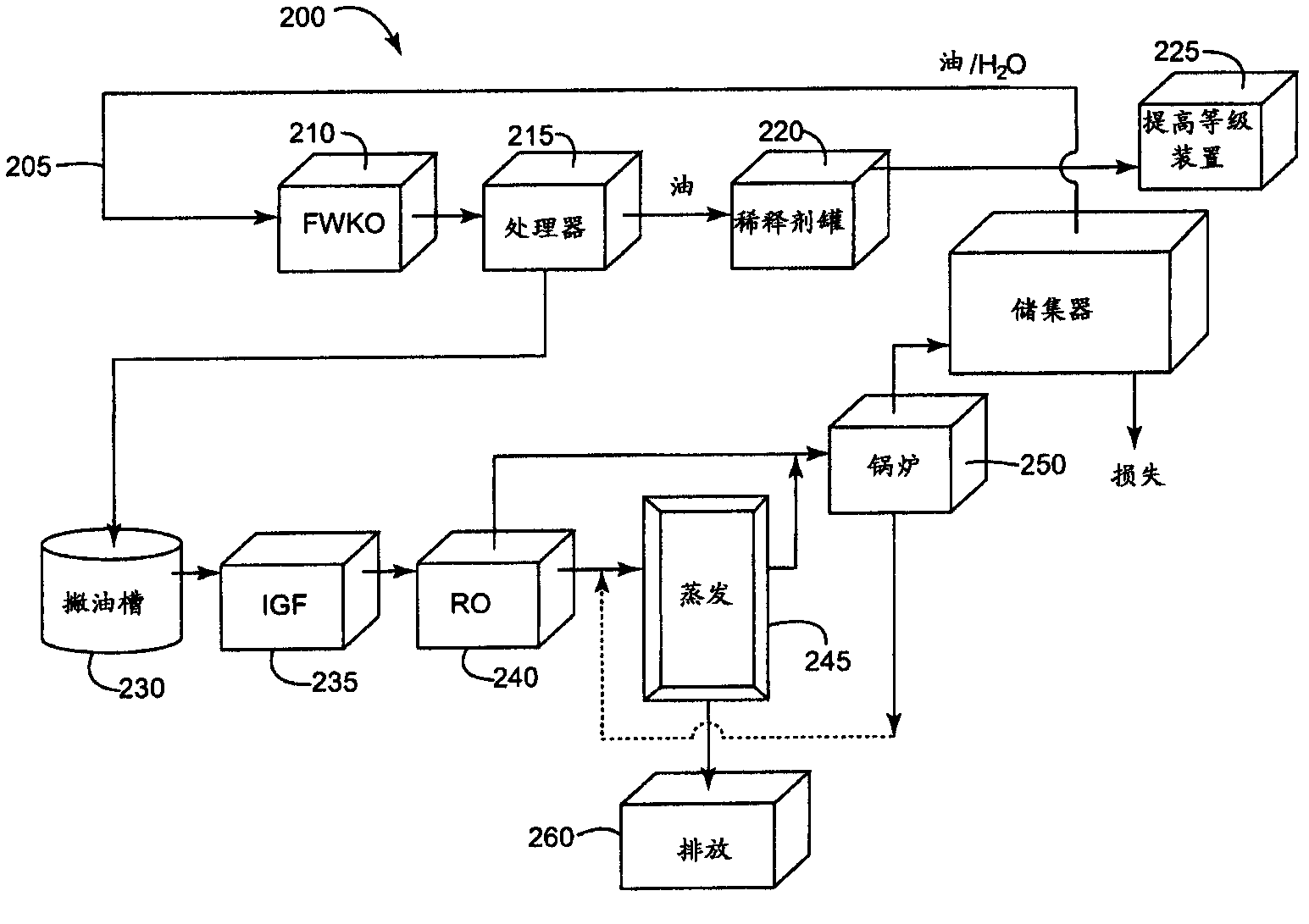

Embodiments presented herein provide an evaporation based zero liquid discharge method for generation of up to 100% quality high pressure steam from produced water in the heavy oil production industry. De-oiled water is processed in an evaporation system producing a distillate that allows steam to be generated with either drum-type boilers operating at higher pressures or once-through steam generators (OTSGs) operating at higher vaporization rates. Evaporator blowdown is treated in a forced-circulation evaporator to provide a zero liquid discharge system that could recycle>98% of the deoiled water for industrial use. Exemplary embodiments of the invention provide at least one “straight sump” evaporator and at least one hybrid external mist eliminator. Embodiments of the evaporation method operate at a higher overall efficiency than those of the prior art by producing distillate at a higher enthalpy which minimizes the high pressure boiler preheating requirement.

Owner:AQUATECH INT LLC

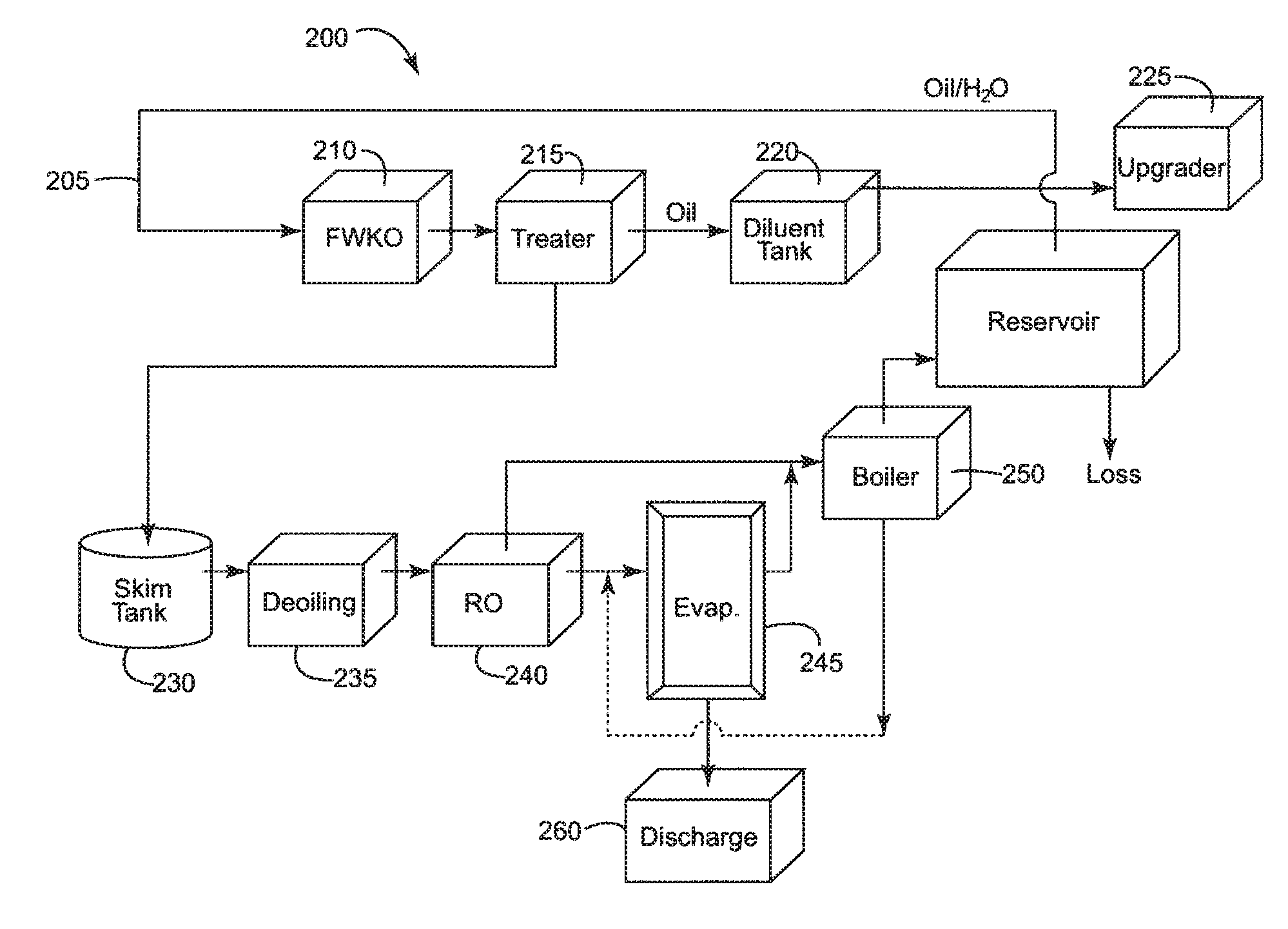

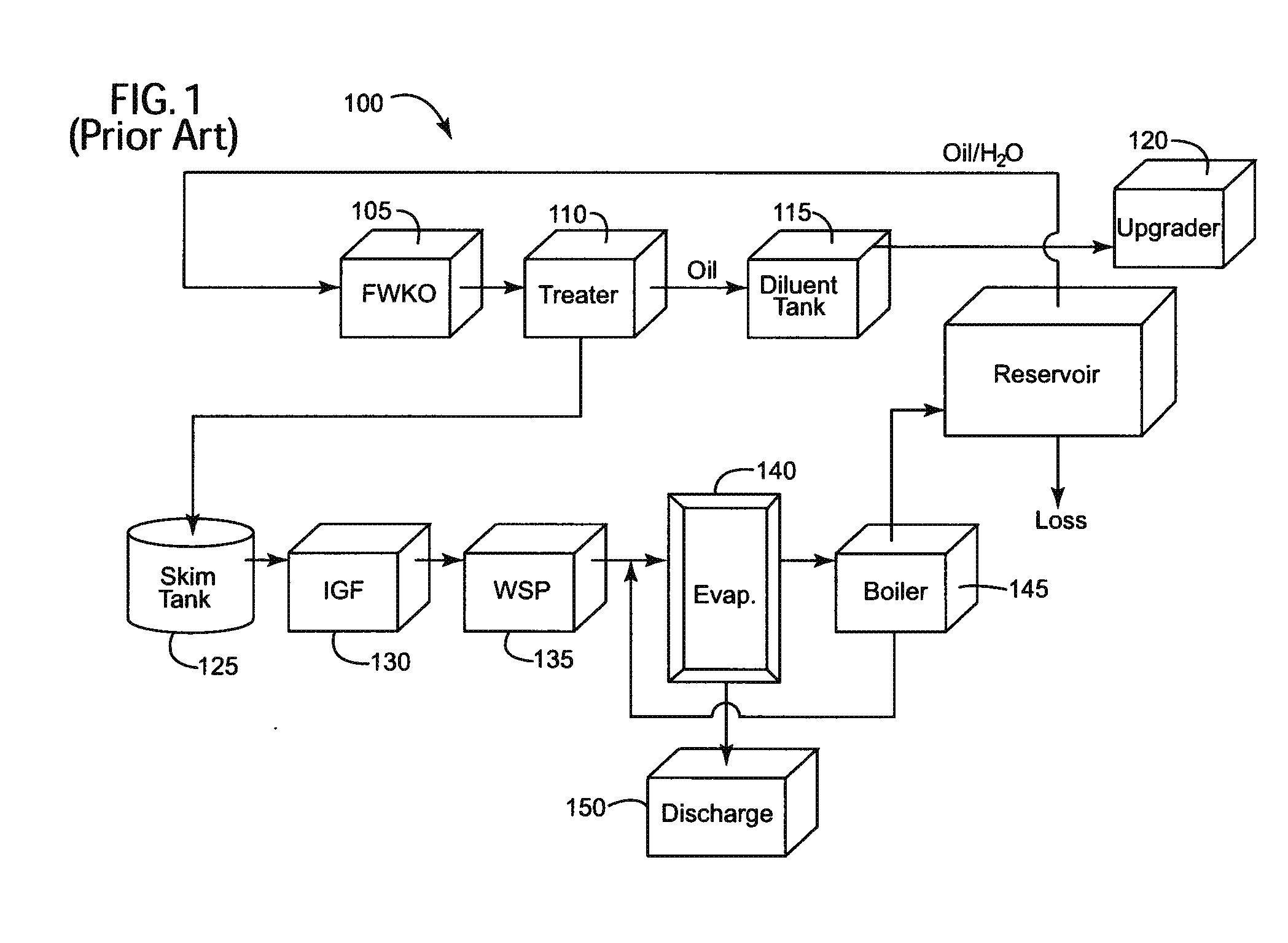

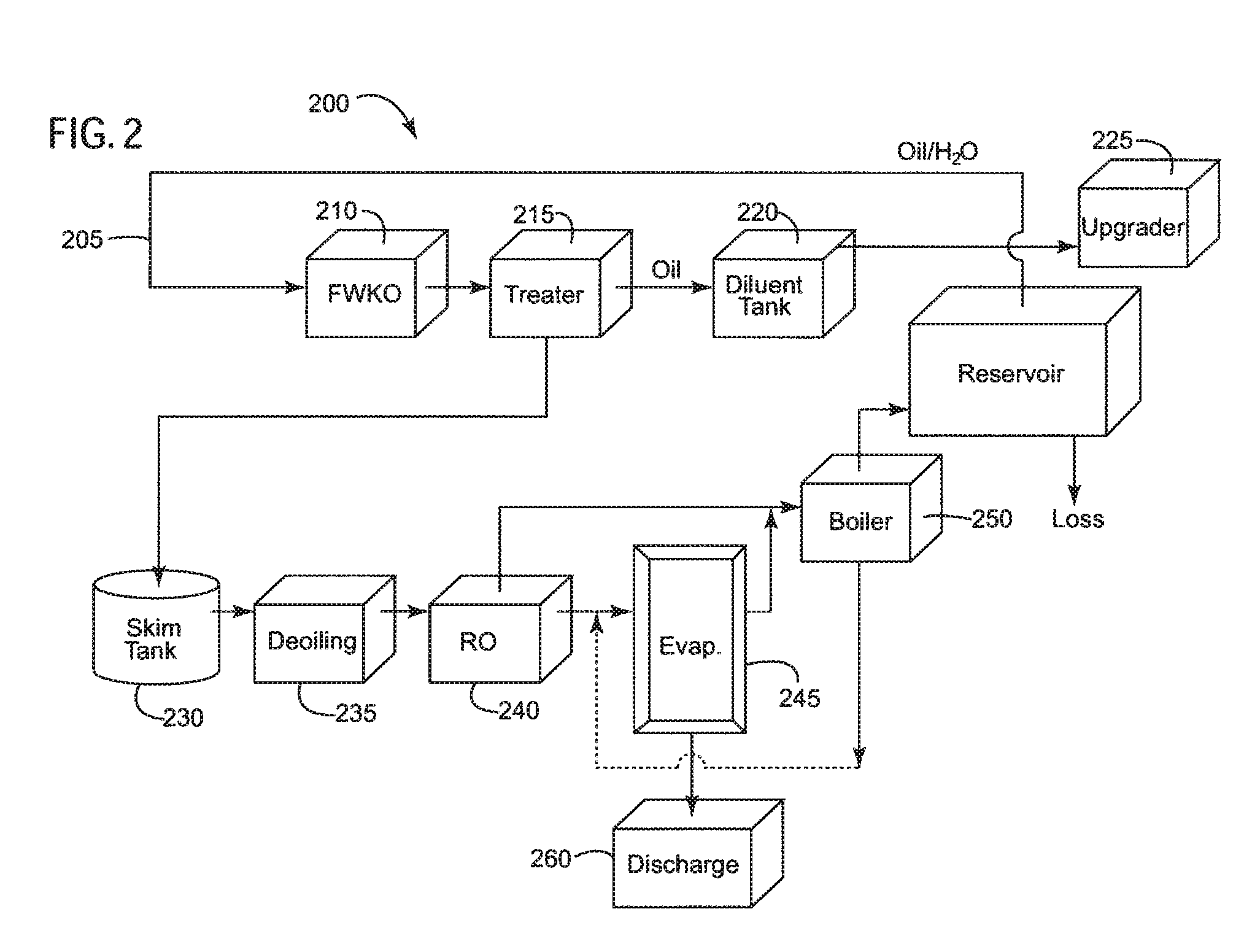

Process for treatment of produced water

InactiveUS20100294719A1Reduce amountEfficient and cost-effectiveWaste water treatment from quariesSemi-permeable membranesDistilled waterFuel oil

A process for treating produced water in heavy oil production comprises, providing an oil / water mixture gathered from an oil / water collection well, whereby oil from said oil / water mixture is separated to provide an oil product and a produced water product containing oil, dissolved gases and dissolved solutes. Said produced water product is then deoiled, and the deoiled water subsequently passes though a membrane system, resulting in permeate water and reject. The resulting permeate water is sent on to a boiler system for production of steam, and the reject is introduced into an evaporator to result in distillate water and blow down. Thereafter, the blow down may be charged into zero liquid discharge treatment; and the distillate water added to the membrane permeate.

Owner:GENERAL ELECTRIC CO

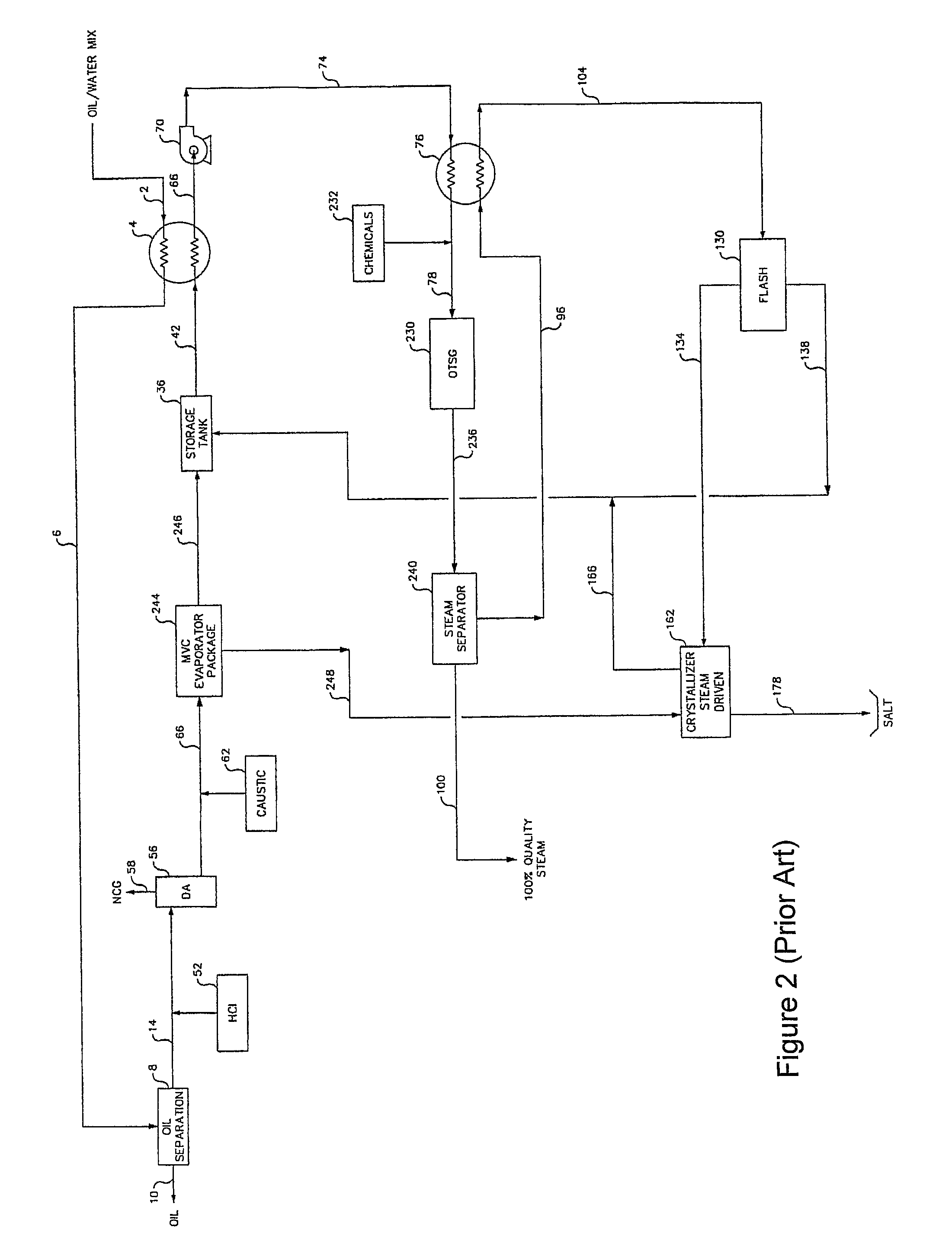

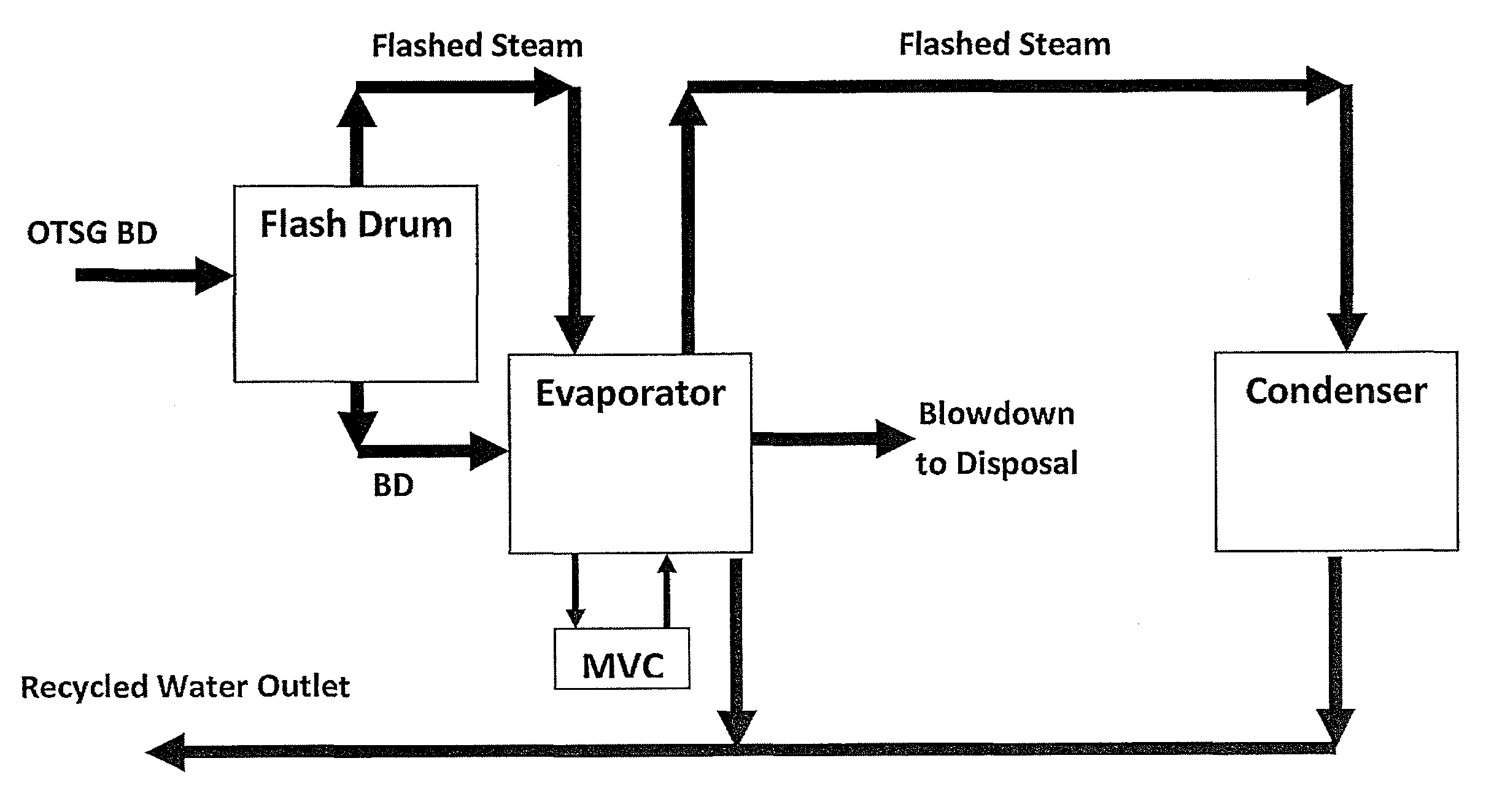

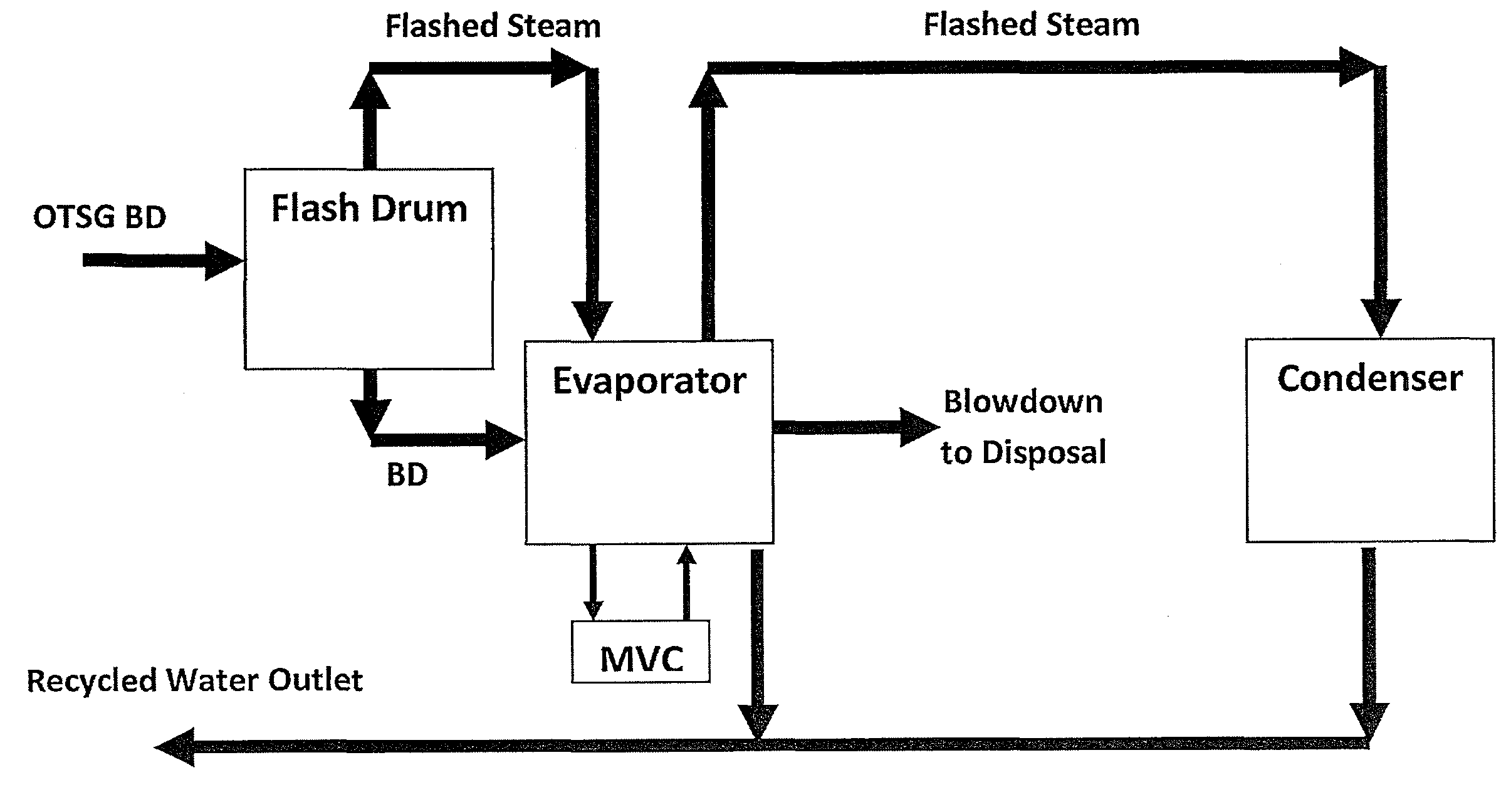

Method and apparatus for recycling water

ActiveUS9085471B2Improve economyReduce power consumptionWaste water treatment from quariesWater circulationLiquid wasteEvaporation

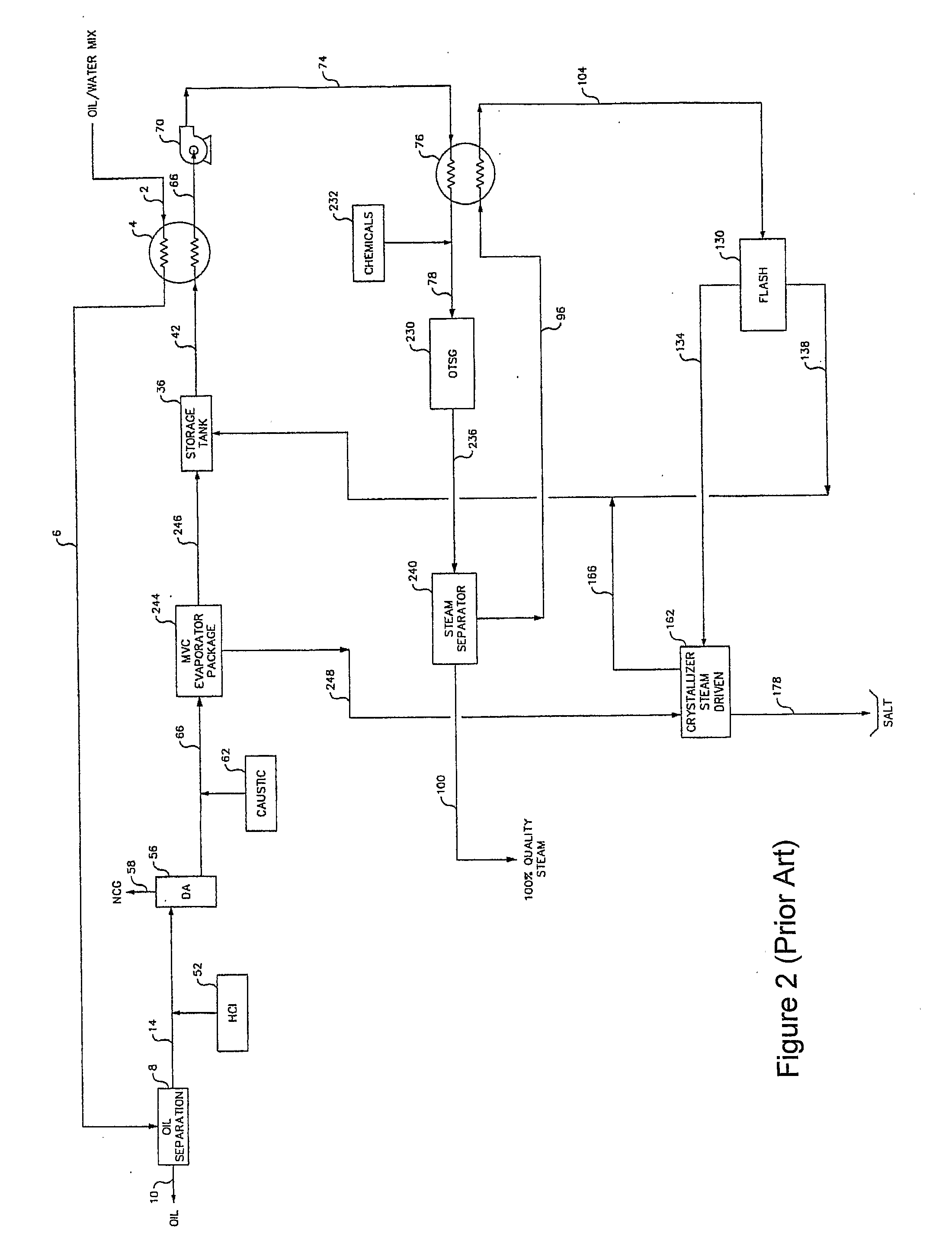

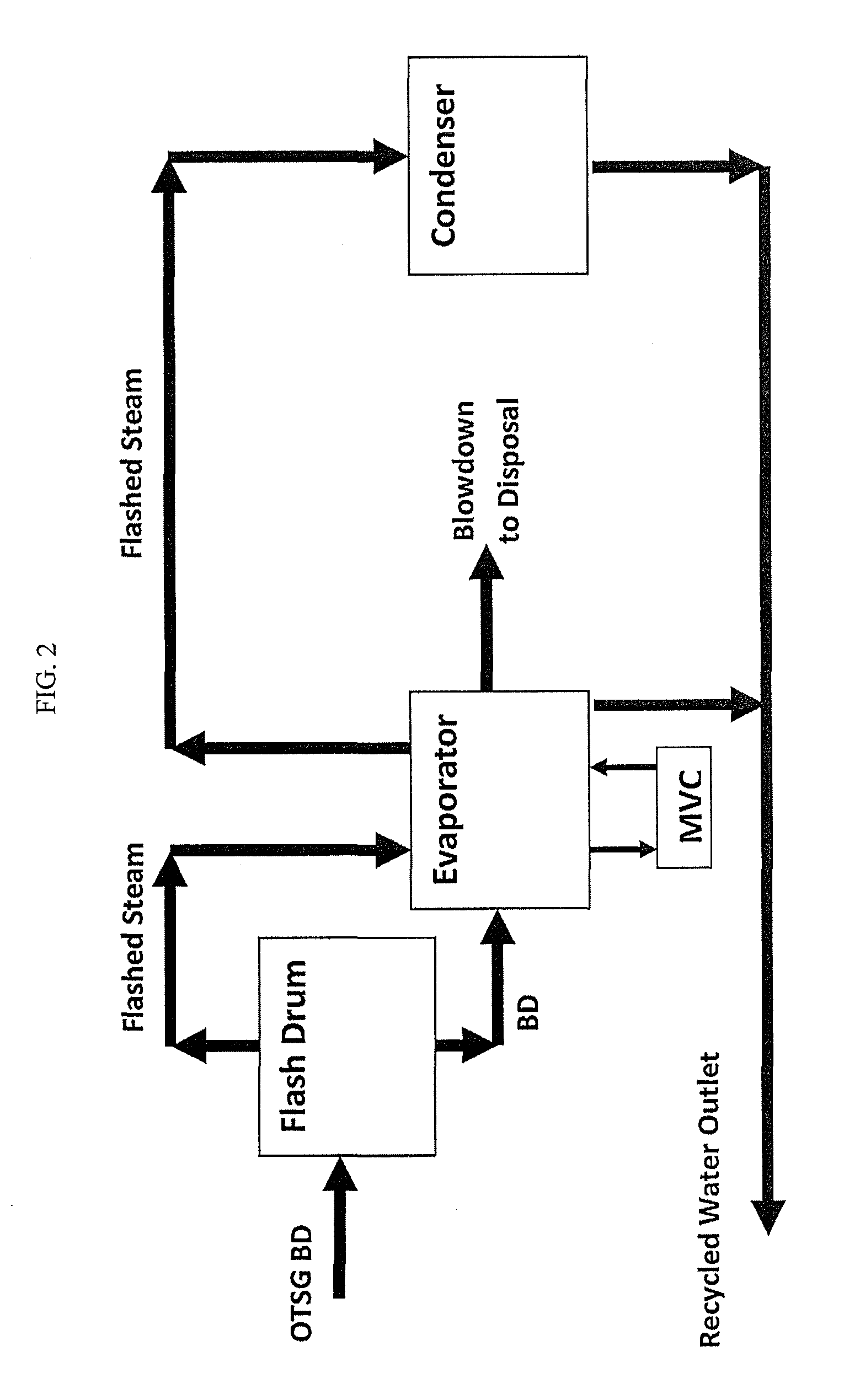

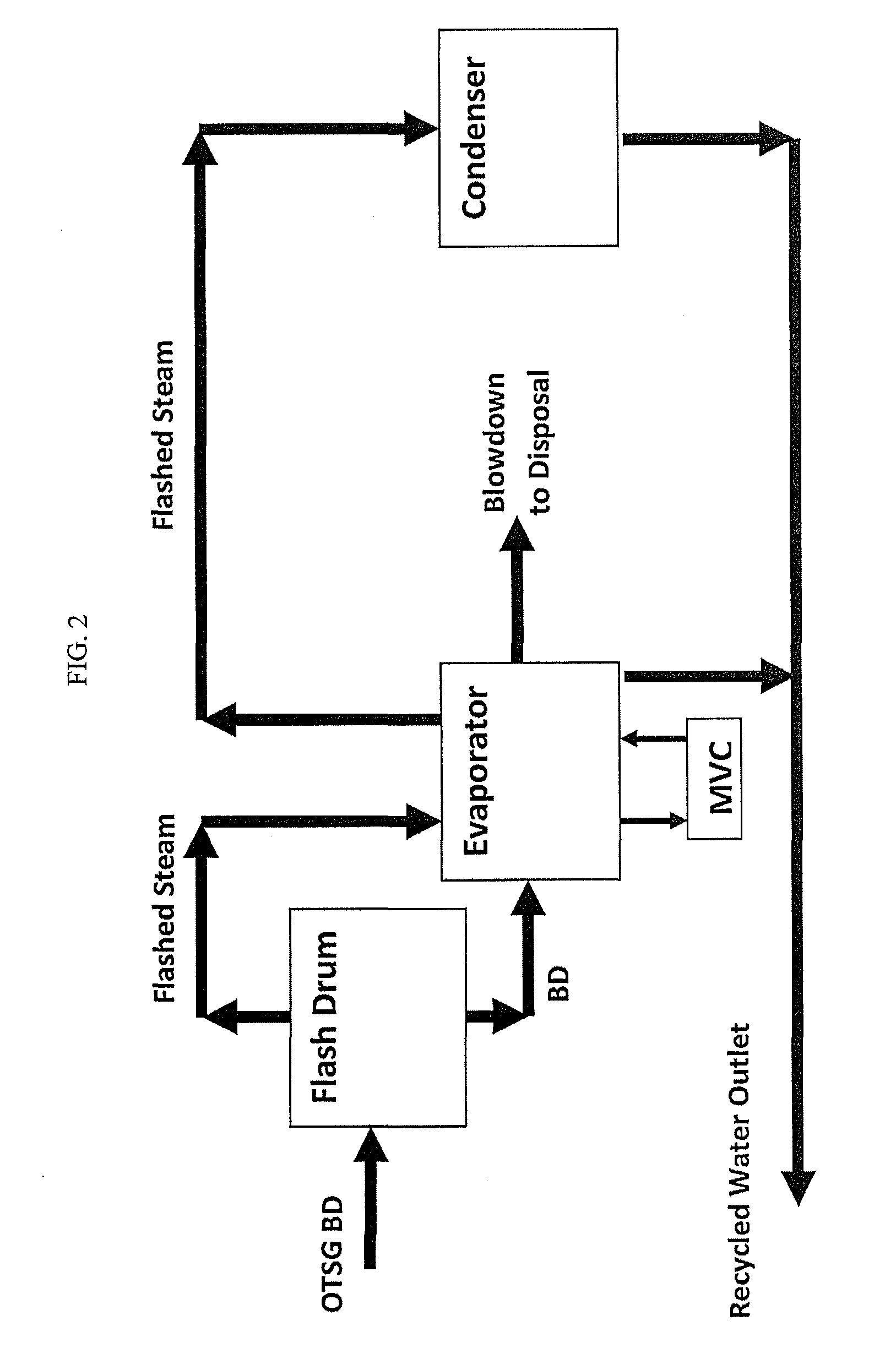

We provide an evaporation based zero-liquid discharge method for generation of steam for enhanced oil recovery (EOR) processes utilizing once-through steam generators (OTSGs). The method includes feeding the OTSG(s) with produced water, vaporizing a fraction of this water for steam injection and blowing down the balance of the water. This water, referred to as OTSG blowdown, can be flashed to produce a vapor stream and a liquid that is fed to a mechanical vapor compression (MVC) evaporative process. The latent energy contained in the vapor stream generated by the upstream flash is beneficially recycled to substantially reduce or eliminate the energy consumption of the MVC process. The evaporative process can be used to reduce the liquid waste for disposal or eliminate the need for liquid disposal by achieving zero liquid discharge.

Owner:AQUATECH INT LLC

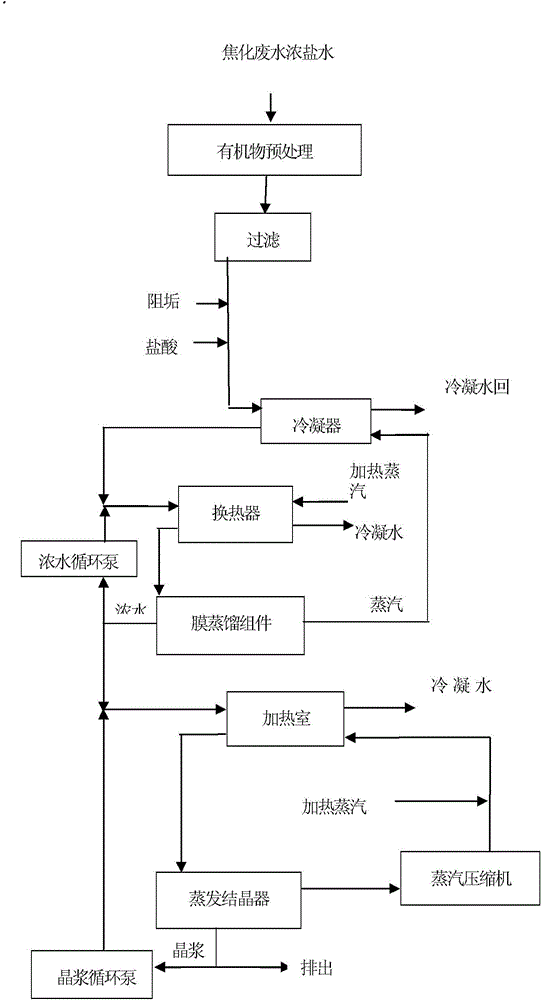

Coking wastewater strong brine recycling method

ActiveCN105236665AAchieve zero liquid dischargeImprove economyMultistage water/sewage treatmentParticulatesInorganic salts

The invention provides a coking wastewater strong brine recycling method. The coking wastewater strong brine recycling method comprises following steps: organic pretreatment, wherein coking wastewater strong brine is subjected to physicochemical treatment and biological treatment so as to remove organic matters in coking wastewater; filtering, wherein particle matters in the coking wastewater is removed via filtering; scale inhibition pretreatment, wherein pH value of the coking wastewater strong brine is adjusted to 5 to 7; and membrane distillation treatment and evaporative crystallization treatment. According to the coking wastewater strong brine recycling method, strong brine obtained via cooking wastewater reverse osmosis is subjected to membrane distillation and evaporative crystallization so as to obtain qualified water, the obtained qualified water is recycled to production systems, inorganic salts in a concentrated solution are changed into crystals, and zero liquid discharge of cooking wastewater is realized; the coking wastewater strong brine recycling method possesses both economic and environmental protection effects, and excellent social benefits and environmental benefits.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Method for production of high purity distillate from produced water for generation of high pressure steam

ActiveUS8469091B2High work pressureIncrease vaporization rateUsing liquid separation agentInsulationEngineeringFuel oil

Embodiments presented herein provide an evaporation based zero liquid discharge method for generation of up to 100% quality high pressure steam from produced water in the heavy oil production industry. De-oiled water is processed in an evaporation system producing a distillate that allows steam to be generated with either drum-type boilers operating at higher pressures or once-through steam generators (OTSGs) operating at higher vaporization rates. Evaporator blowdown is treated in a forced-circulation evaporator to provide a zero liquid discharge system that could recycle >98% of the deoiled water for industrial use. Exemplary embodiments of the invention provide at least one “straight sump” evaporator and at least one hybrid external mist eliminator. Embodiments of the evaporation method operate at a higher overall efficiency than those of the prior art by producing distillate at a higher enthalpy which minimizes the high pressure boiler preheating requirement.

Owner:AQUATECH INT LLC

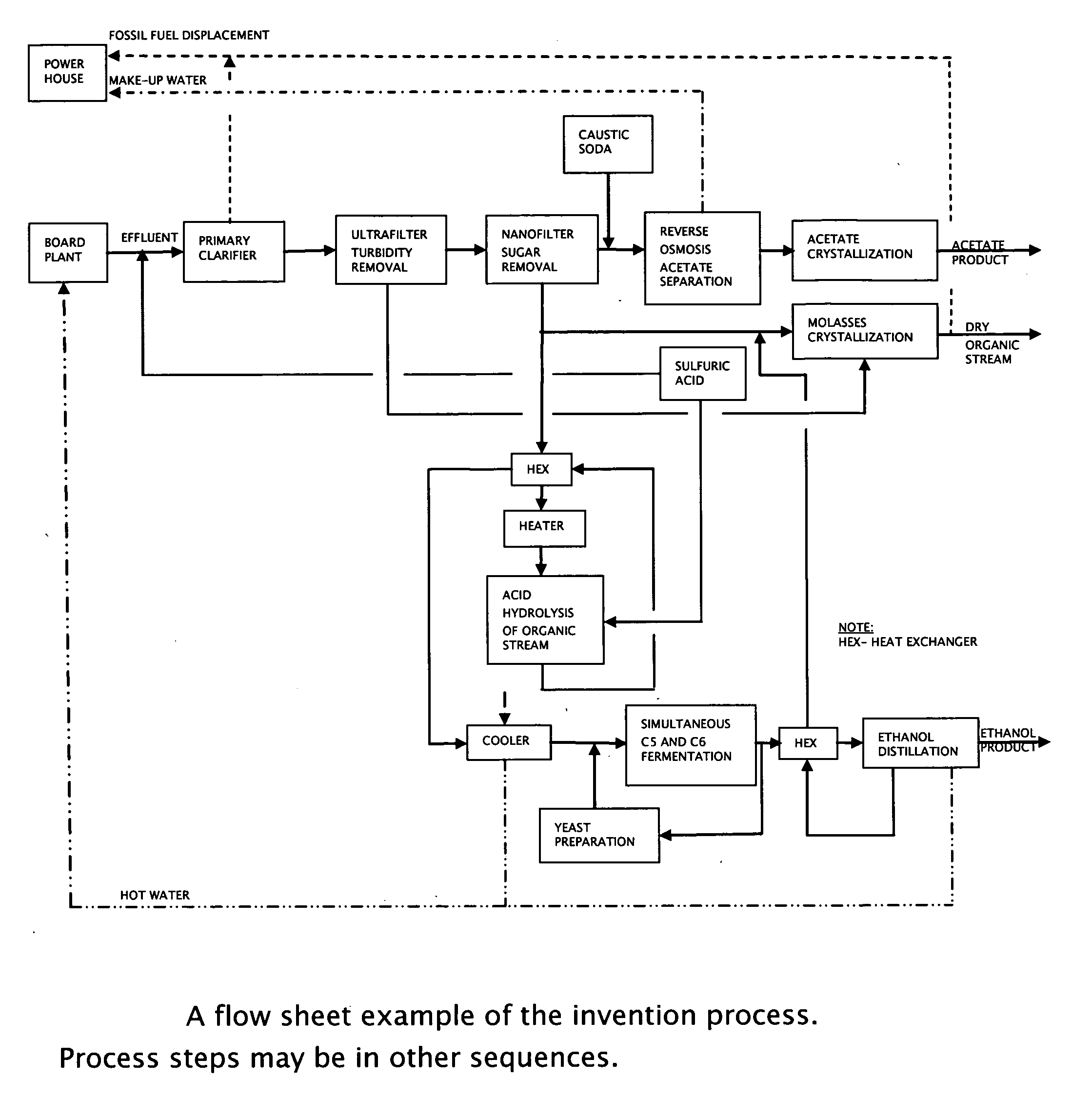

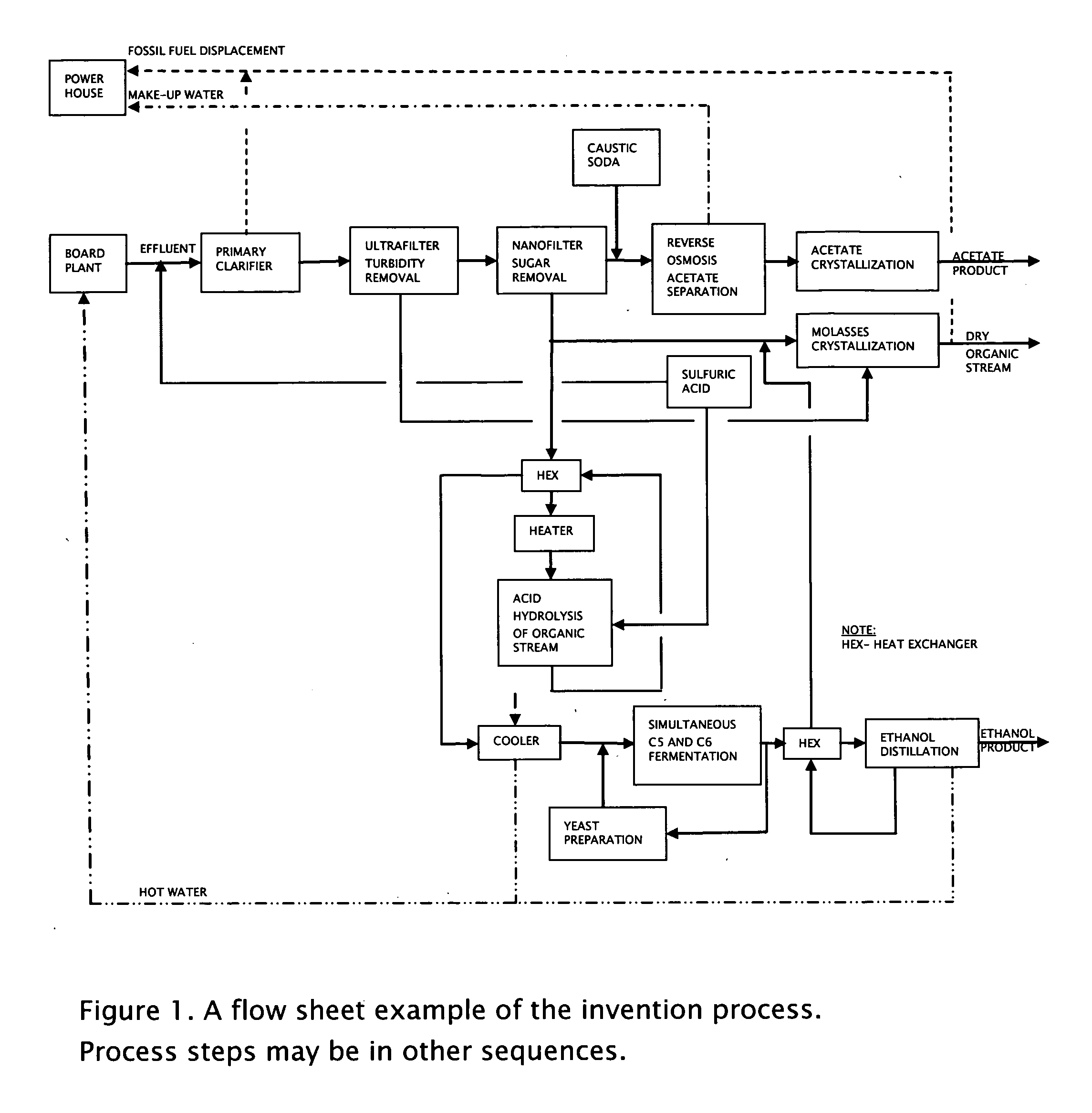

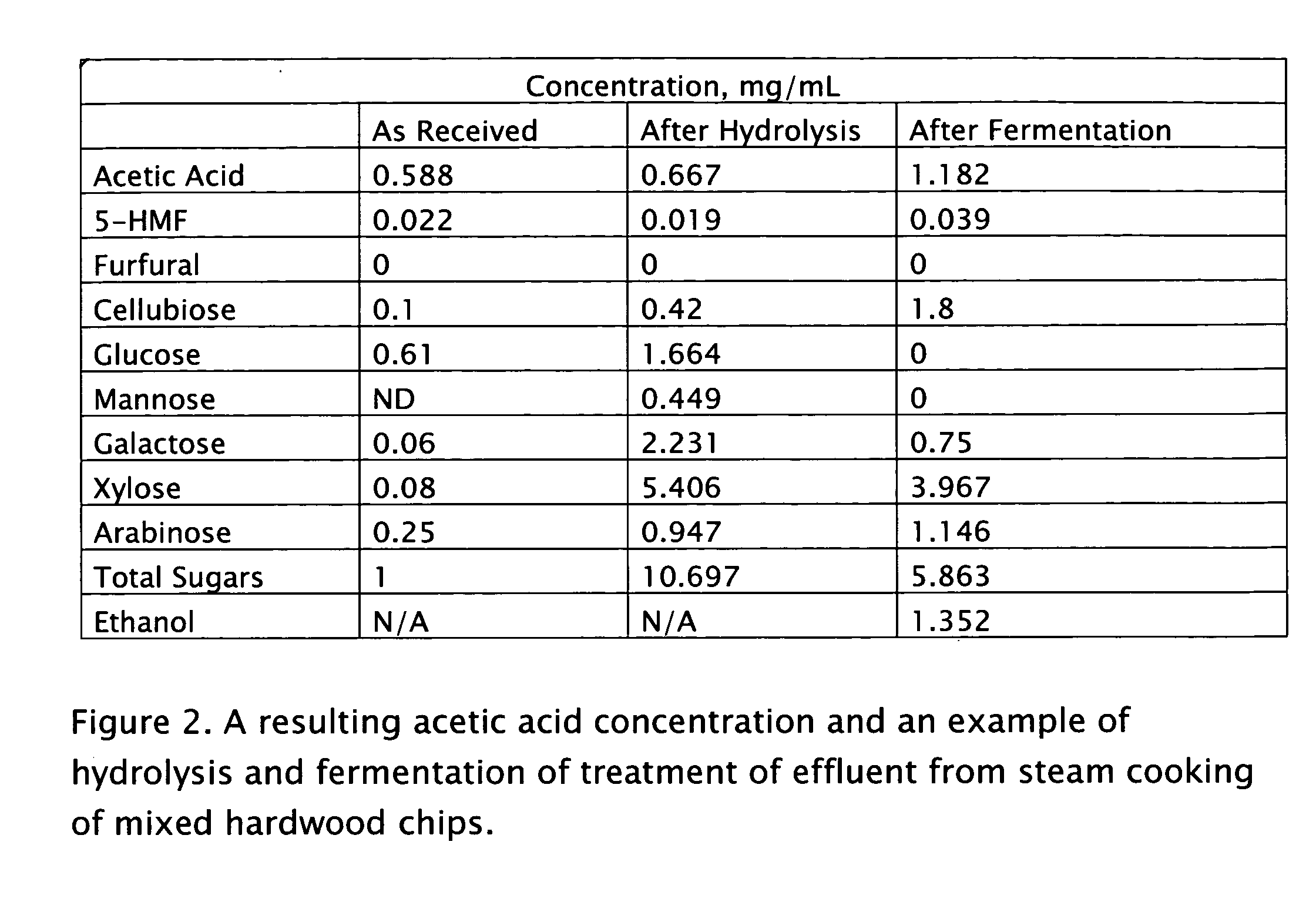

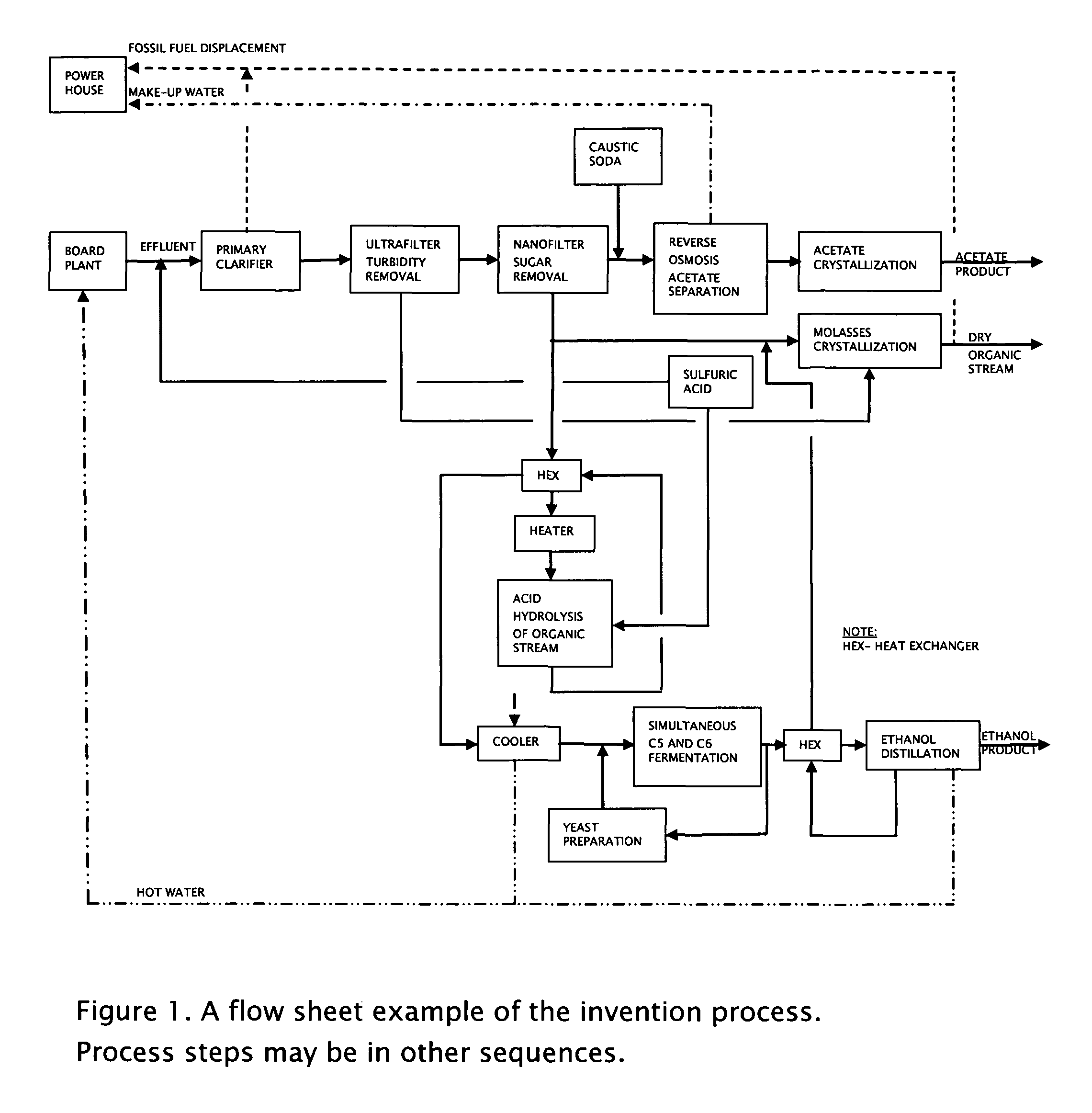

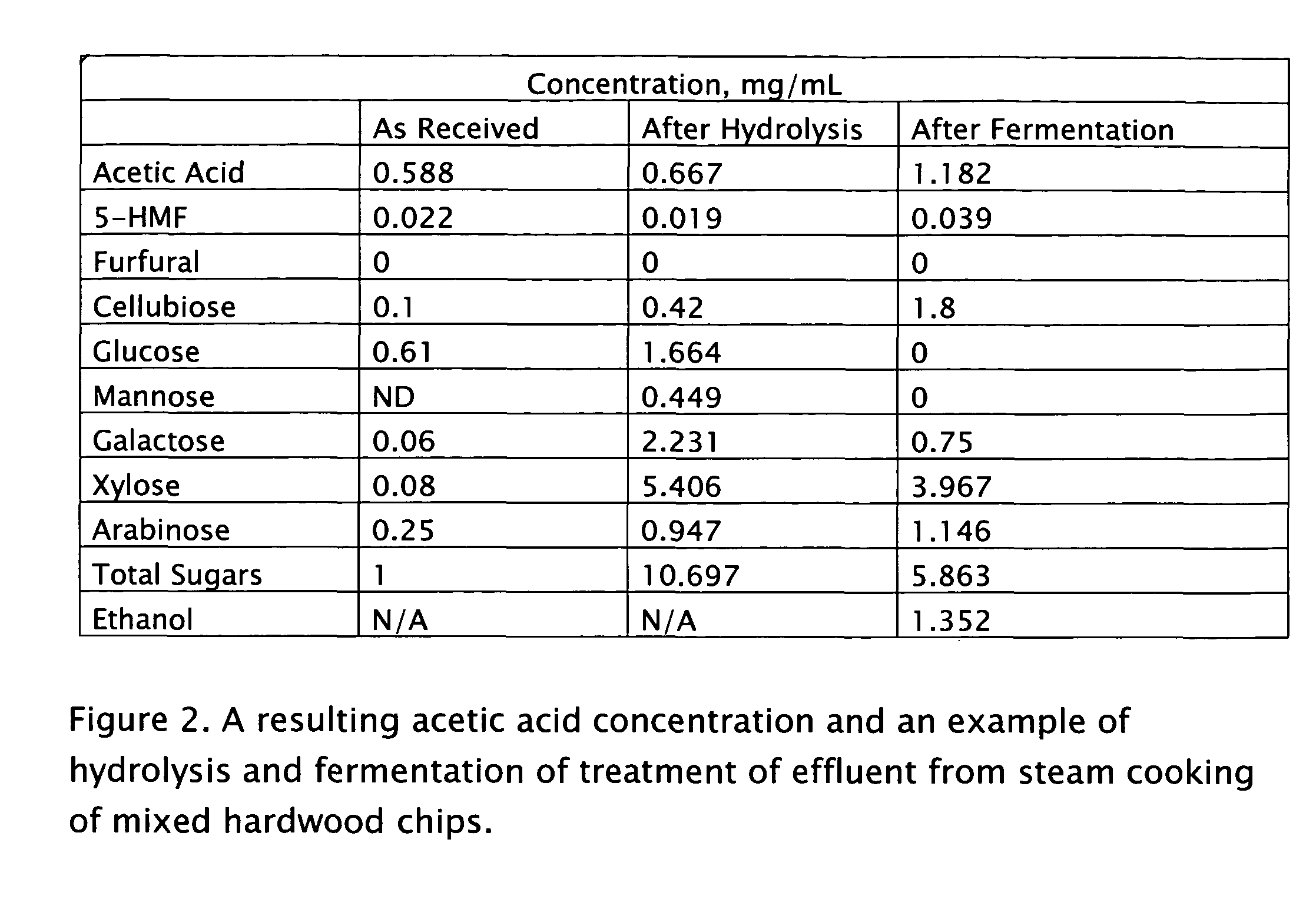

Process for obtaining biochemicals in a zero-liquid discharge plant

ActiveUS20090305374A1Minimize process energy consumptionEliminate needSugar derivativesBiofuelsFiberAcetic acid

A method is presented for the production of cellulosic ethanol, acetic acid and derivatives from the extract containing fibers and hemicelluloses after steam cooking of biomass in a host plant. The process is integrated with the host plant process to minimize the effect of loss of heat value from the extracted hemicelluloses and eliminate the need for the waste water treatment plant.

Owner:GRANBIO INTELLECTUAL PROPERTY HOLDINGS LLC

System and method of reducing organic contaminants in feed water

InactiveUS7531096B2Reducing organic contaminantEfficient implementationWater treatment parameter controlWater/sewage treatment by irradiationHigh concentrationCooling tower

A zero liquid discharge (ZLD) power plant (20) includes an advanced oxidation system (72) for reducing contaminants in source water (70) to form feed water (40) for a boiler (24). The system (72) includes an ozonation module (86) for applying high concentration ozone to the source water (70) to form a mixed stream (104), an ozone reactor (92) in which the mixed stream is retained (104) under pressure, an ultraviolet reactor (98) downstream from the ozone reactor (92) for enhanced contaminant reduction, and a retention tank (103) downstream from the reactor (98). In one configuration, the source water (70) is evaporator distillate from an evaporator (52) that recycles cooling tower blowdown 30. The system (72) achieves organic contaminant reduction at total organic carbon (TOC) levels of less than three hundred parts per billion.

Owner:ARIZONA PUBLIC SERVICE

Cooling water corrosion inhibition method

ActiveUS20080264870A1Enhanced inhibitory effectInhibits general and localized corrosionWater treatment parameter controlOther chemical processesAlloyMetallic Nickel

A method of providing corrosion inhibition to copper, nickel, aluminum, zinc, tin, lead, beryllium, carbon steel, various alloys of such metals, and galvanized coatings in evaporative cooling water applications approaching zero liquid discharge that are specifically attacked by cooling water with residuals of corrosive chemistry or ions such as ammonia / ammonium ion, chloride, high TDS, OH−, or high pH. The method includes applying azoles inhibitors (such as TTA, BTA, etc.) at residuals of 0.25 mg / L to 200 mg / L or greater (as azoles) to the cooling water application and operating with a combination of high TDS (greater than 2500 mg / L) and high pH (greater than 9.0), while maintaining low total hardness (less than 200 mg / L as CaCO3).

Owner:WATER CONSERVATION TECH INT

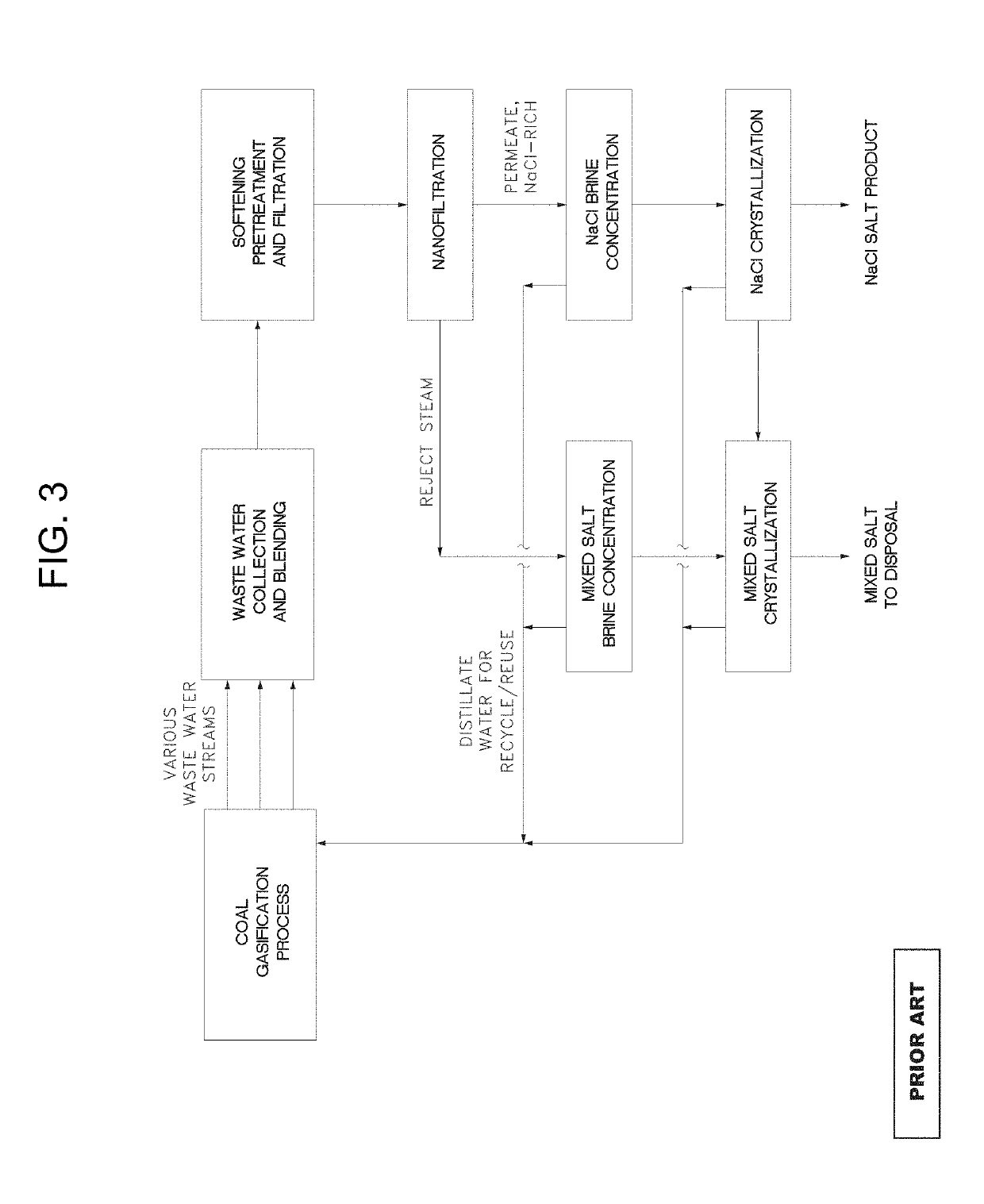

Salt production from wastewater

Many processes generate wastewater streams rich in sulfate and chloride. These salt components are traditionally not recovered and are discharged to the environment. The invention recovers pure water for recycle / reuse and simultaneously generates valuable pure salts of NaCl and Na2SO4 for beneficial reuse, eliminating the waste stream. Process consists of the sequential crystallization of salt products with an intermediate purification step in which a chemical reactant is added to elevate levels of purity. The process is configured to simultaneously achieve zero liquid discharge.

Owner:AQUATECH INT LLC

Method and apparatus for recycling water

ActiveUS20150000914A1Reducing and eliminating MVC power consumptionImprove economyWaste water treatment from quariesAuxillariesLiquid wasteEvaporation

We provide an evaporation based zero-liquid discharge method for generation of steam for enhanced oil recovery (EOR) processes utilizing once-through steam generators (OTSGs). The method includes feeding the OTSG(s) with produced water, vaporizing a fraction of this water for steam injection and blowing down the balance of the water. This water, referred to as OTSG blowdown, can be flashed to produce a vapor stream and a liquid that is fed to a mechanical vapor compression (MVC) evaporative process. The latent energy contained in the vapor stream generated by the upstream flash is beneficially recycled to substantially reduce or eliminate the energy consumption of the MVC process. The evaporative process can be used to reduce the liquid waste for disposal or eliminate the need for liquid disposal by achieving zero liquid discharge.

Owner:AQUATECH INT LLC

Cooling water corrosion inhibition method

ActiveUS7708939B2Enhanced inhibitory effectInhibits general and localized corrosionWater treatment parameter controlOther chemical processesAlloyTin

A method of providing corrosion inhibition to copper, nickel, aluminum, zinc, tin, lead, beryllium, carbon steel, various alloys of such metals, and galvanized coatings in evaporative cooling water applications approaching zero liquid discharge that are specifically attacked by cooling water with residuals of corrosive chemistry or ions such as ammonia / ammonium ion, chloride, high TDS, OH−, or high pH. The method includes applying azoles inhibitors (such as TTA, BTA, etc.) at residuals of 0.25 mg / L to 200 mg / L or greater (as azoles) to the cooling water application and operating with a combination of high TDS (greater than 2500 mg / L) and high pH (greater than 9.0), while maintaining low total hardness (less than 200 mg / L as CaCO3).

Owner:WATER CONSERVATION TECH INT

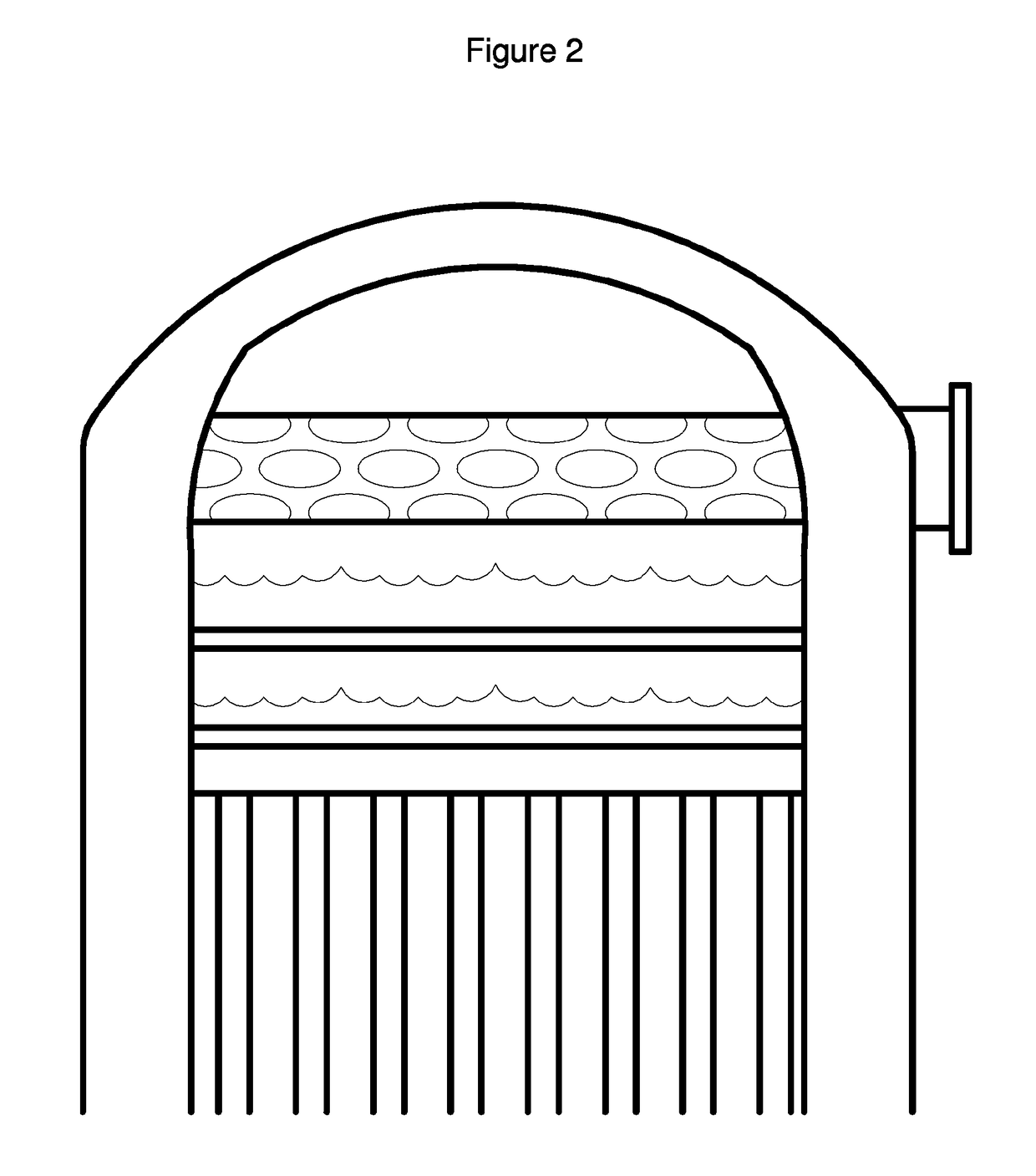

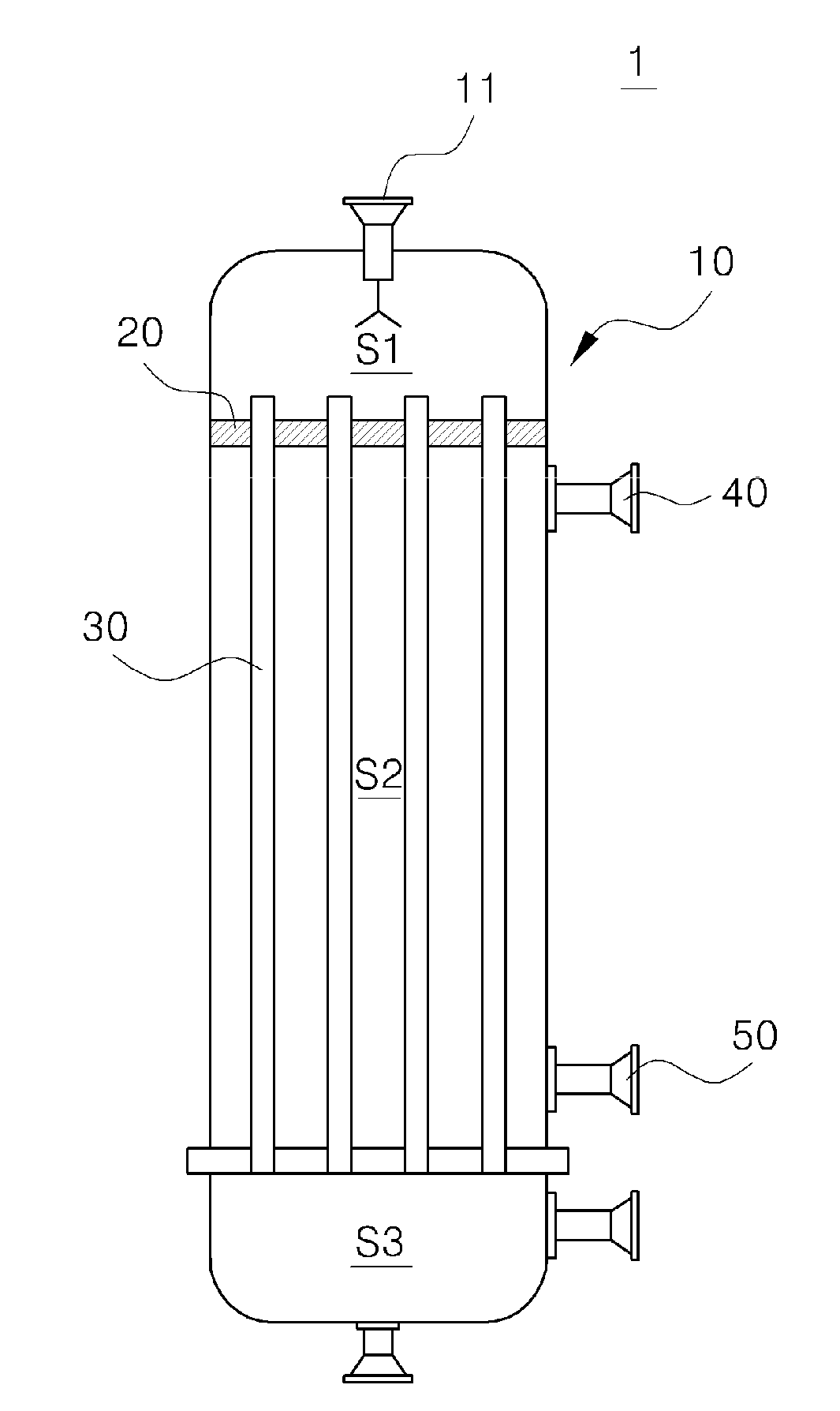

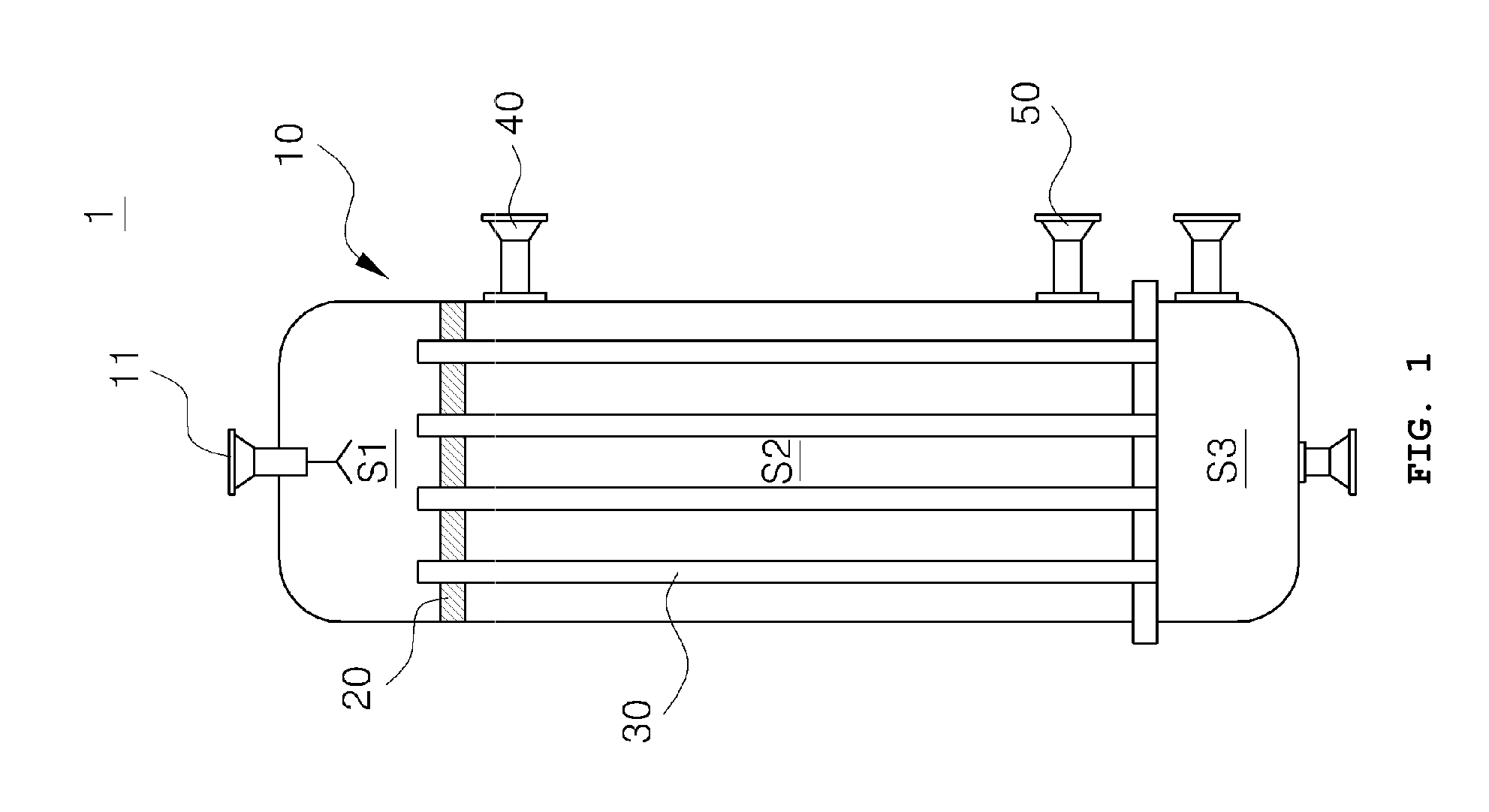

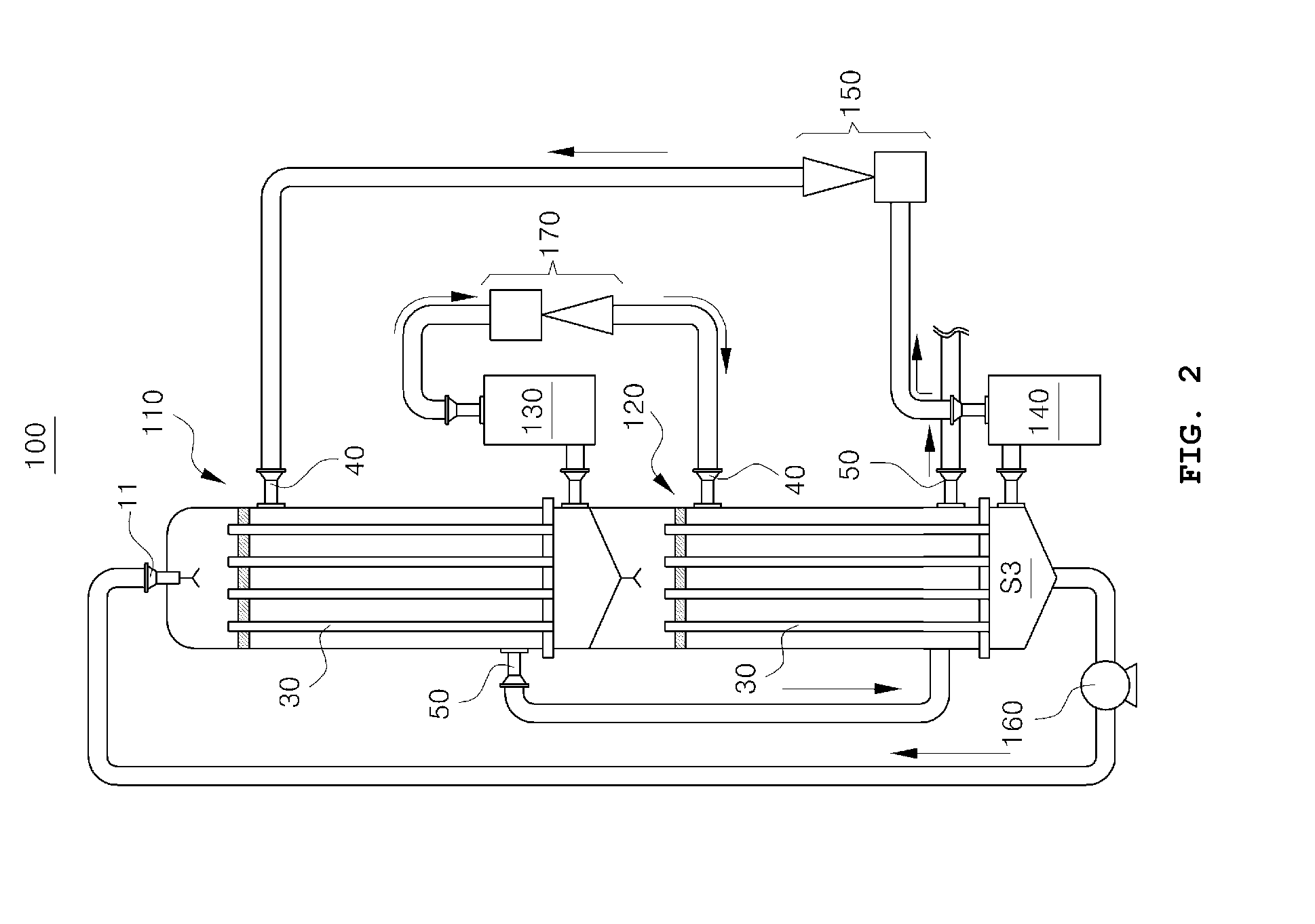

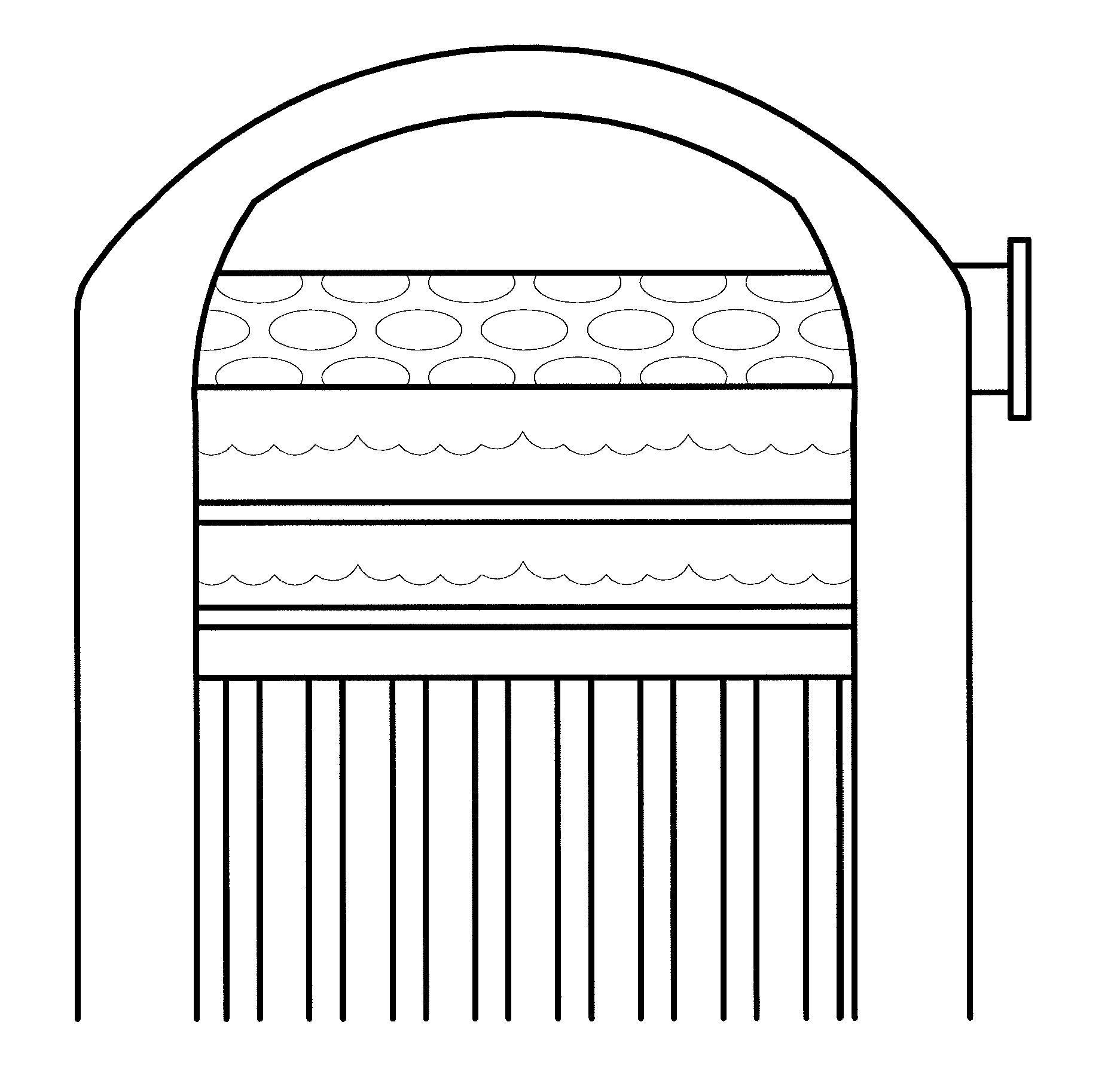

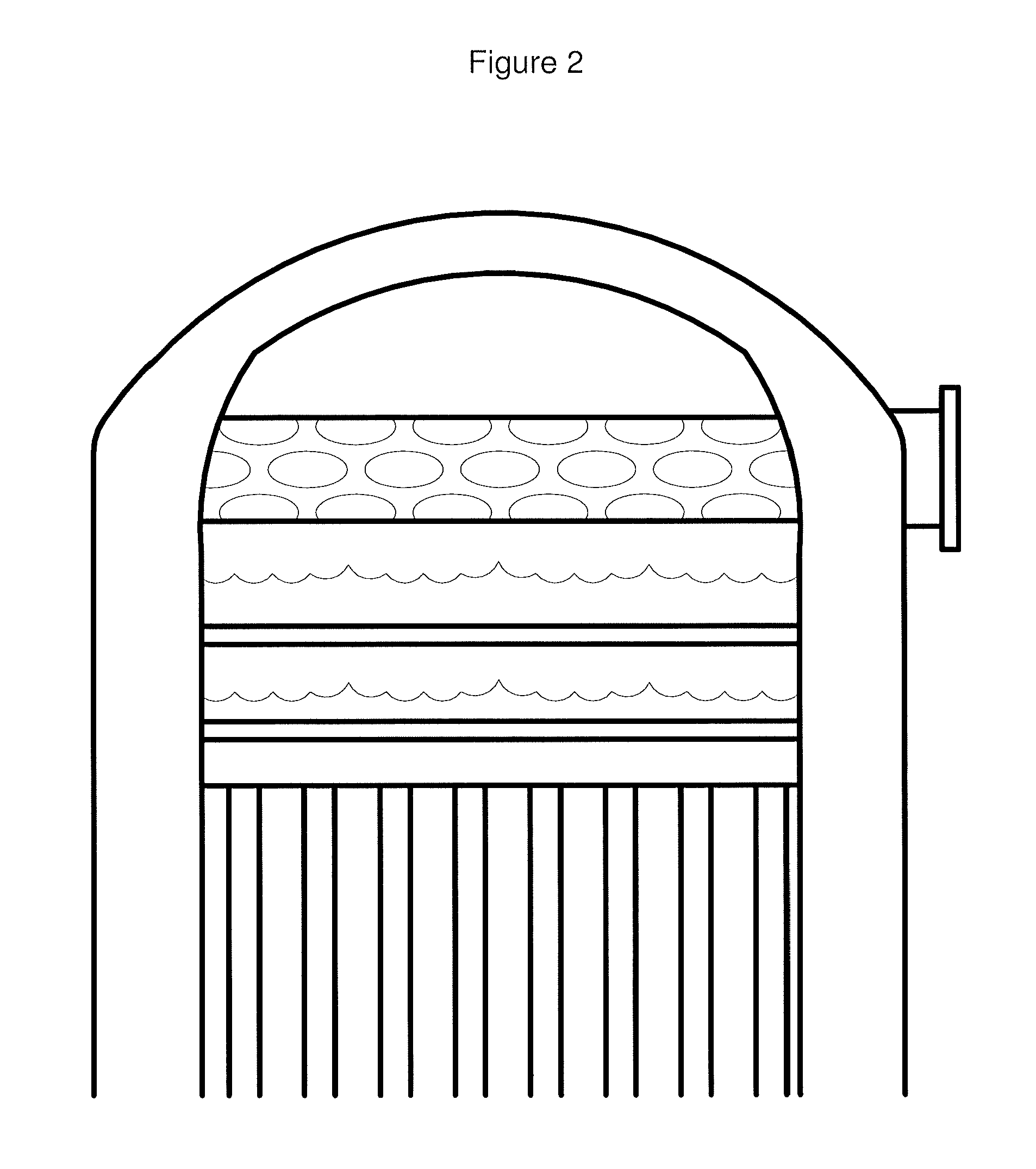

Stacked type falling film evaporator, zero liquid discharge system comprising the same, and zero liquid discharging method using the same

ActiveUS20150190727A1Improve workabilityReduce energy consumptionSludge treatmentAuxillariesWastewaterEngineering

A stacked type falling film evaporator includes a first evaporator, a second evaporator, a first vapor recovering device, a second vapor recovering device and a vapor recompressor. The first evaporator and the second evaporator respectively have evaporation tubes of a length of 5 m to 10 m, and are stacked in such a manner that wastewater passes through the first evaporator and the second evaporator in order. The first vapor recovering device collects vapor generated from the wastewater in the first evaporator and supplies the collected vapor to the second evaporator. The second vapor recovering device collects vapor generated from the wastewater in the second evaporator and supplies the collected vapor to the first evaporator. The vapor recompressor compresses the vapor collected in the second vapor recovering device before the vapor is supplied to the first evaporator.

Owner:DOOSAN HEAVY IND & CONSTR CO LTD

Process for obtaining biochemicals in a zero-liquid discharge plant

A method is presented for the production of cellulosic ethanol, acetic acid and derivatives from the extract containing fibers and hemicelluloses after steam cooking of biomass in a host plant. The process is integrated with the host plant process to minimize the effect of loss of heat value from the extracted hemicelluloses and eliminate the need for the waste water treatment plant.

Owner:GRANBIO INTELLECTUAL PROPERTY HOLDINGS LLC

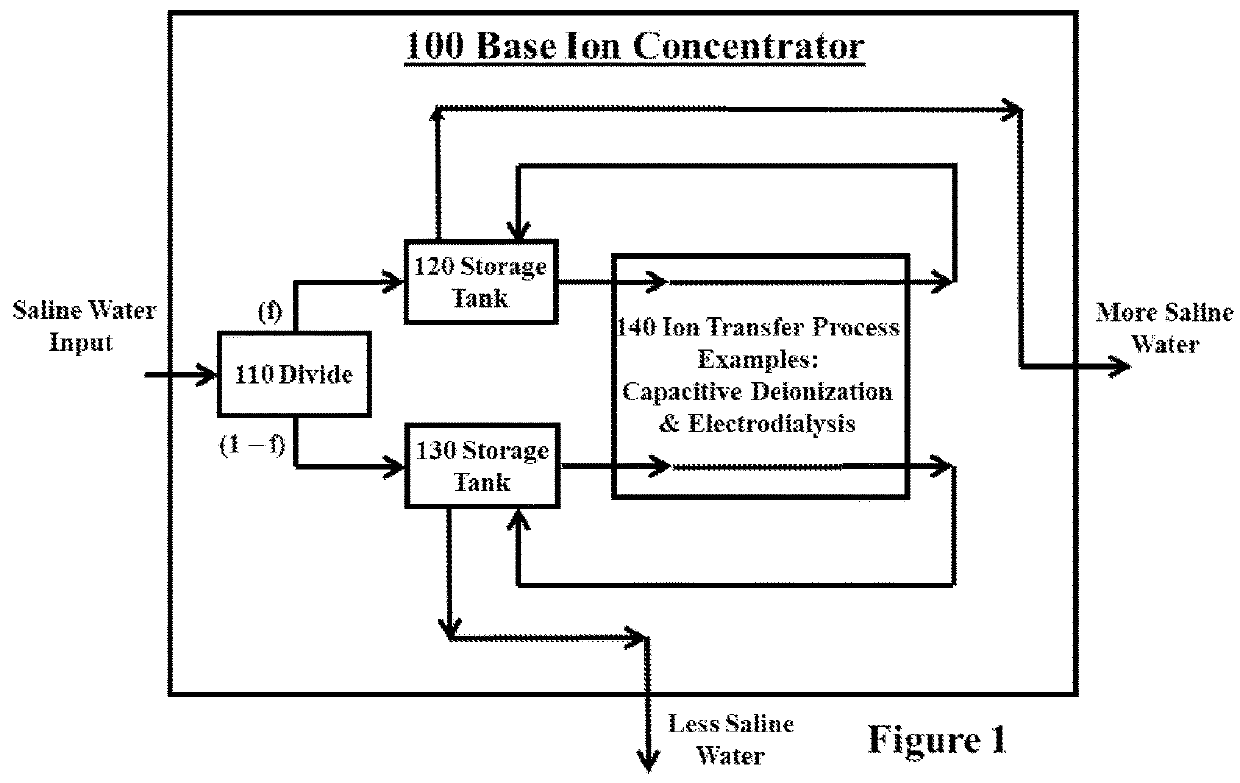

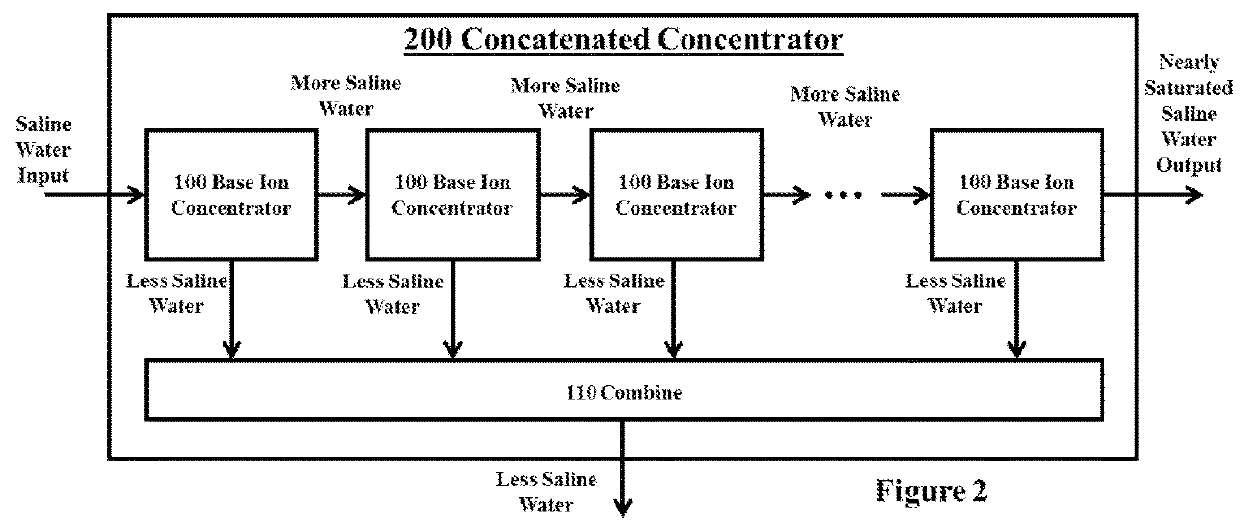

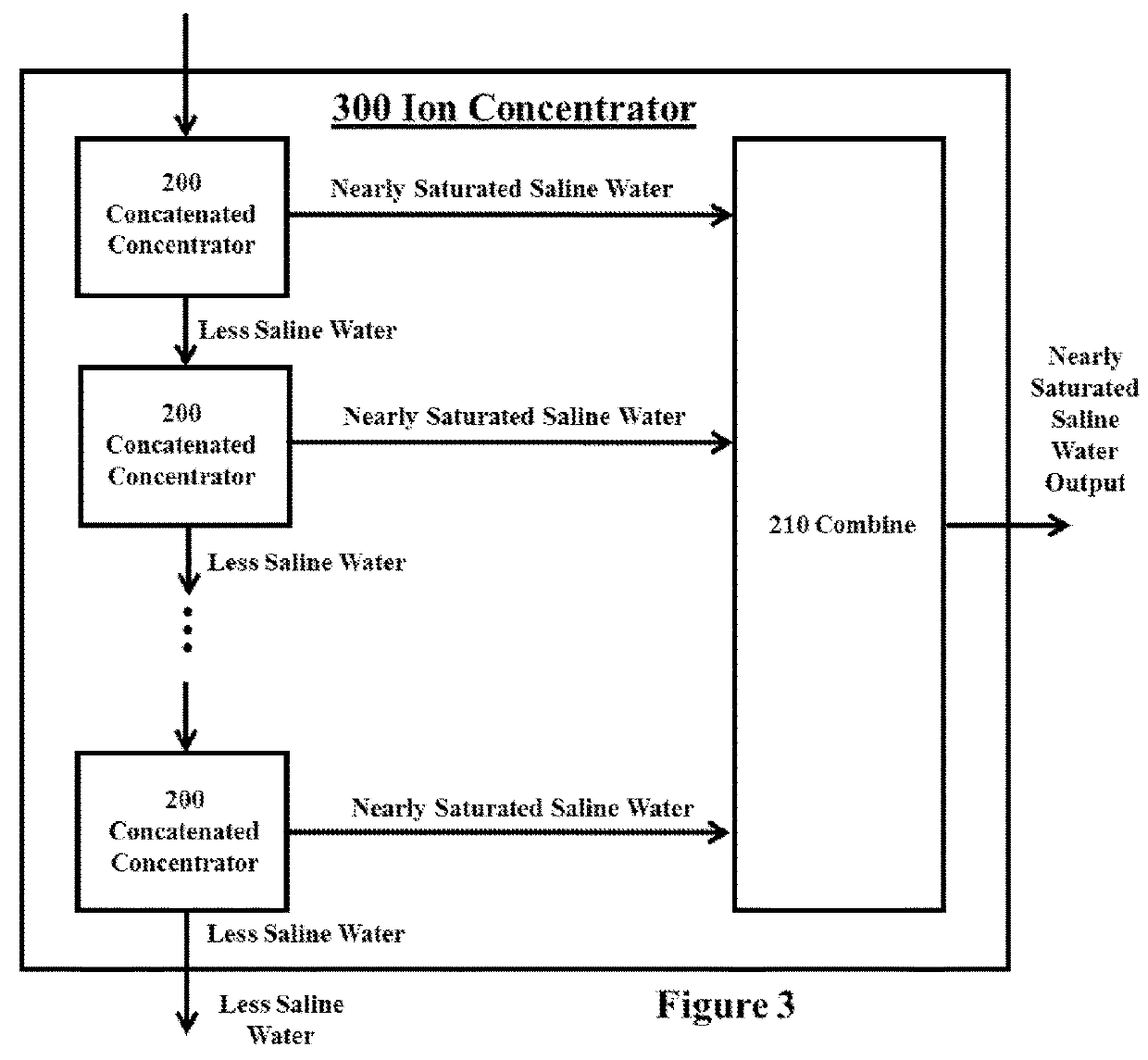

Saline Water Desalination, Concentration, and Crystallization

InactiveUS20180162758A1Prevent excessive outputGeneral water supply conservationSeawater treatmentDistillationDihydrogen oxide

Owner:CANTRELL BEN HARRISON

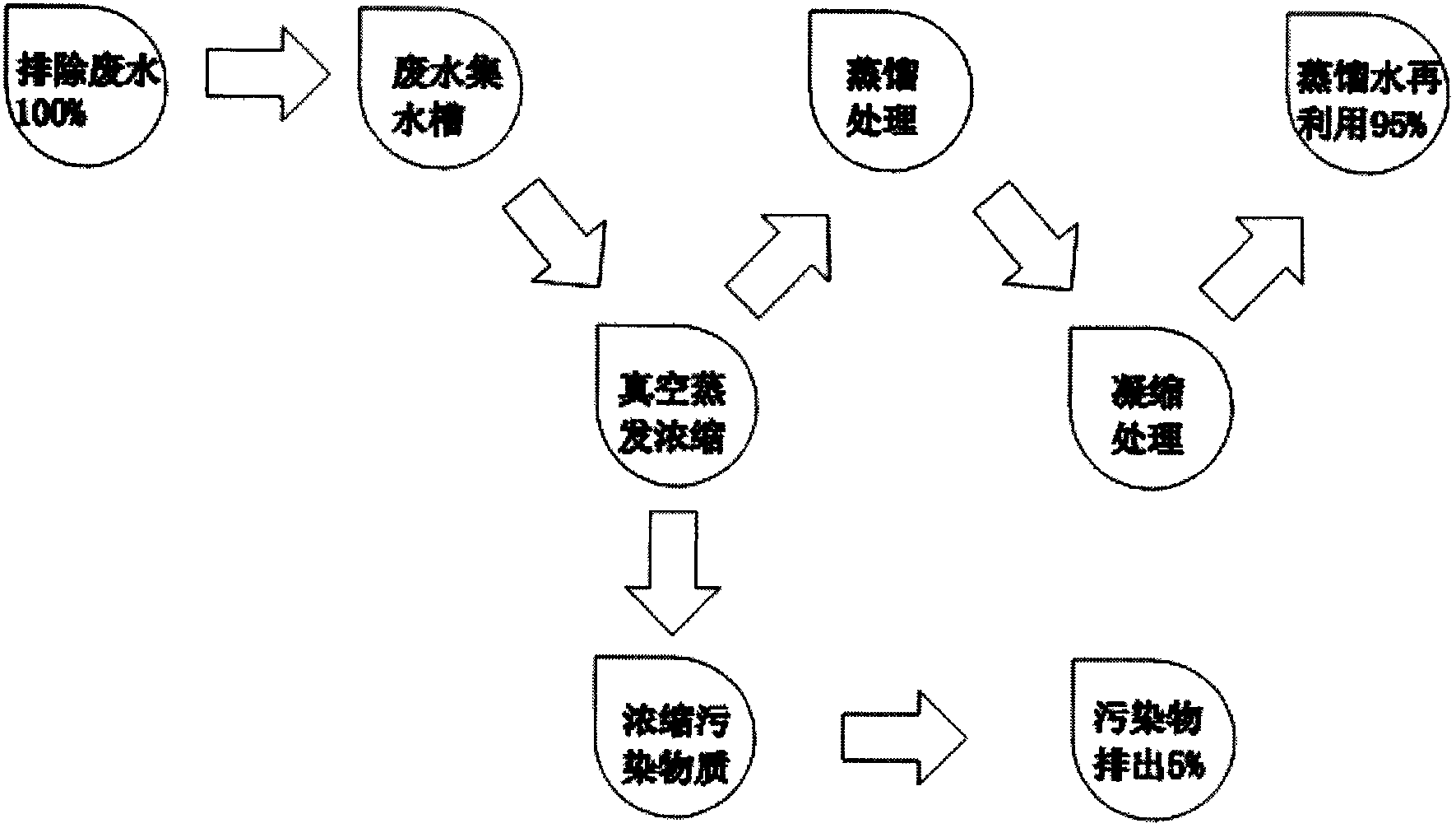

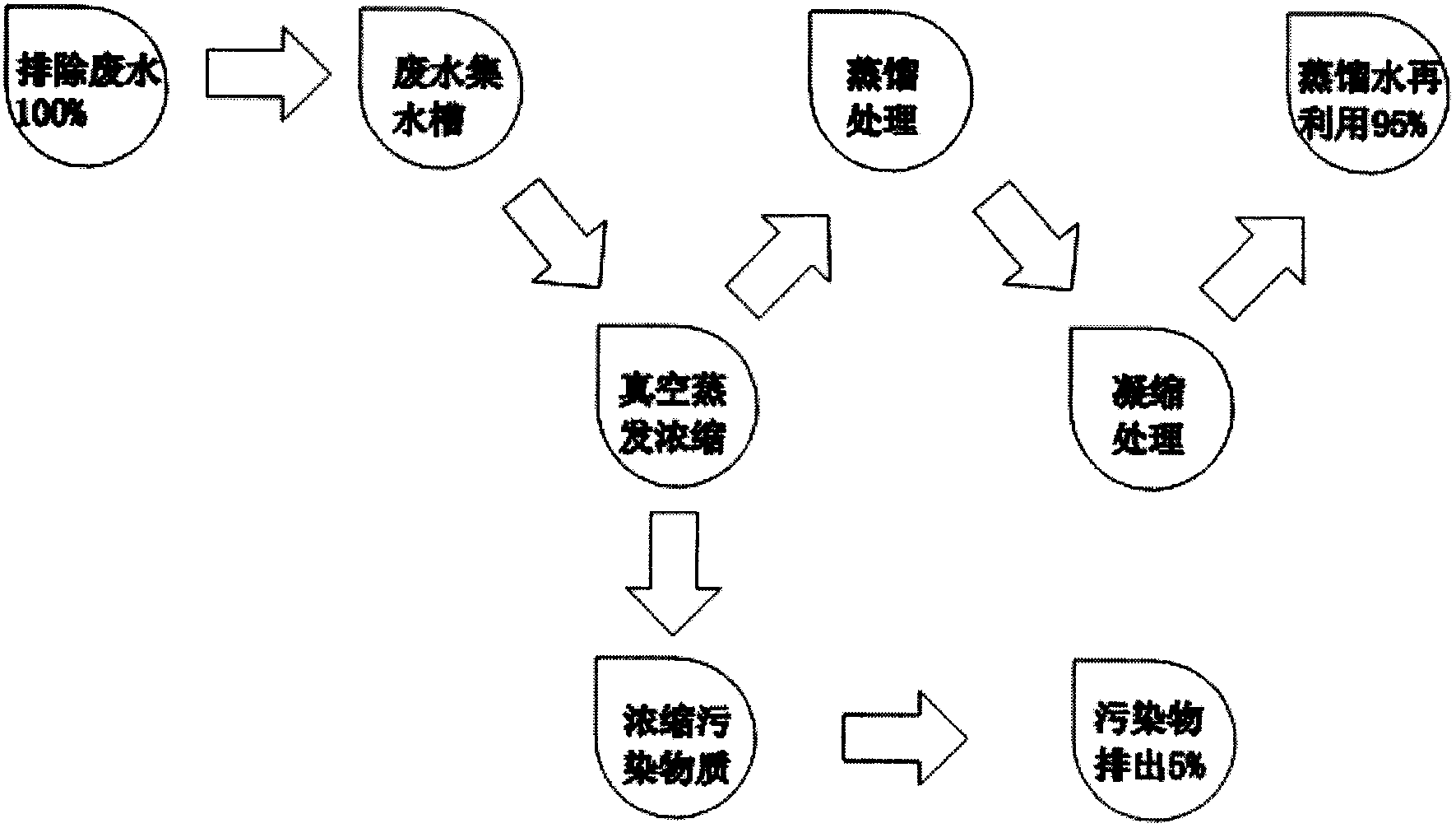

Distillation separation method for oily wastewater

InactiveCN102642882ANo emissionsReduce processing costsMultistage water/sewage treatmentEnergy based wastewater treatmentEnvironmental designIndustrial waste water

The invention discloses a distillation separation method for oily wastewater, which comprises the steps of vacuum evaporation, distillation treatment and condensation treatment, and pollutant concentration and pollutant discharge, wherein the vacuum evaporation is used for evaporating industrial wastewater in vacuum, and moisture in the wastewater is gasified into gas; the distillation treatment and the condensation treatment are used for distillating and separating the evaporated gas after being liquefied, and the separated water is distillated to obtain 90-95% of water through concentration and then is industrially recycled; the pollutants left after wastewater evaporation are concentrated so as to concentrate out 5-10% of waste; and the concentrated pollutants are discharged. Breakthrough zero liquid discharge and zero pollution are realized; and the treatment cost is reduced, and a clean water treatment process is used for producing clean water. According to the method disclosed by the invention, sewage discharge and recording in government departments are not needed, evaporation and concentration are carried out at a low temperature in a vacuum state, and the environmental design is safe, so that 24-hour fully automatic operation and an automatic cleaning function are realized.

Owner:SHENZHEN FRANCOOL TECH

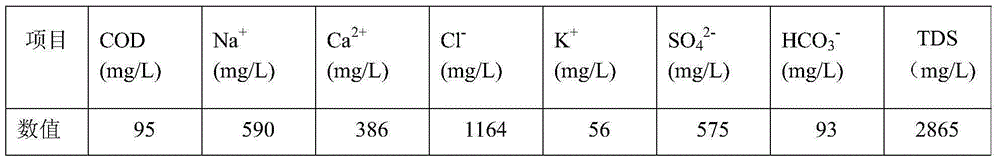

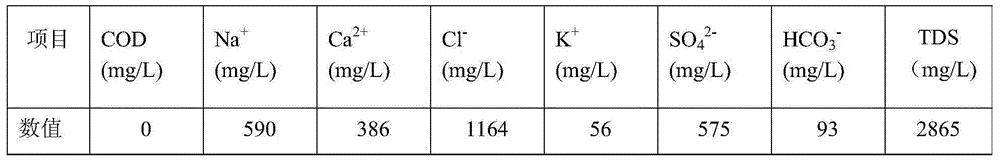

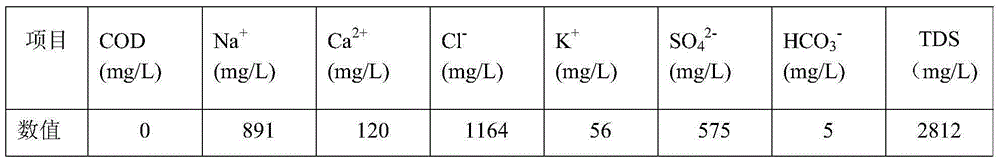

Treatment method and treatment system for salt-containing water

InactiveCN106554103AReduce processing costsRealize comprehensive utilizationMultistage water/sewage treatmentSoftened waterSalt water

The invention relates to the field of water treatment and discloses a treatment method and a treatment system for salt-containing water. The treatment method comprises the steps of: (1) softening the salt-containing water with strong-acid cation-exchange resin to remove at least a part of bivalent cations and replace the bivalent cations by monovalent cations to produce strong-acid cation-exchange softened water; (2) performing reverse osmosis separation to the strong-acid cation-exchange softened water to concentrate the monovalent cation salt in the strong-acid cation-exchange softened water to obtain a reverse osmosis product water and reverse osmosis concentrated water being rich in monovalent cation salt; and (3) regenerating the strong-acid cation-exchange resin which is used for the treatment of the salt-containing water in the step (1) by means of a regenerating agent, wherein at least a part of the regenerating agent is prepared from the reverse osmosis concentrated water. The treatment method can achieve zero-liquid emission, and greatly reduces the comprehensive treatment cost of the salt-containing water.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Method for production of high purity distillate from produced water for generation of high pressure steam

ActiveUS20130269934A1High work pressureIncrease vaporization rateEnergy industryFluid removalFuel oilProcess engineering

Embodiments presented herein provide an evaporation based zero liquid discharge method for generation of up to 100% quality high pressure steam from produced water in the heavy oil production industry. De-oiled water is processed in an evaporation system producing a distillate that allows steam to be generated with either drum-type boilers operating at higher pressures or once-through steam generators (OTSGs) operating at higher vaporization rates. Evaporator blowdown is treated in a forced-circulation evaporator to provide a zero liquid discharge system that could recycle >98% of the deoiled water for industrial use. Exemplary embodiments of the invention provide at least one “straight sump” evaporator and at least one hybrid external mist eliminator. Embodiments of the evaporation method operate at a higher overall efficiency than those of the prior art by producing distillate at a higher enthalpy which minimizes the high pressure boiler preheating requirement.

Owner:AQUATECH INT LLC

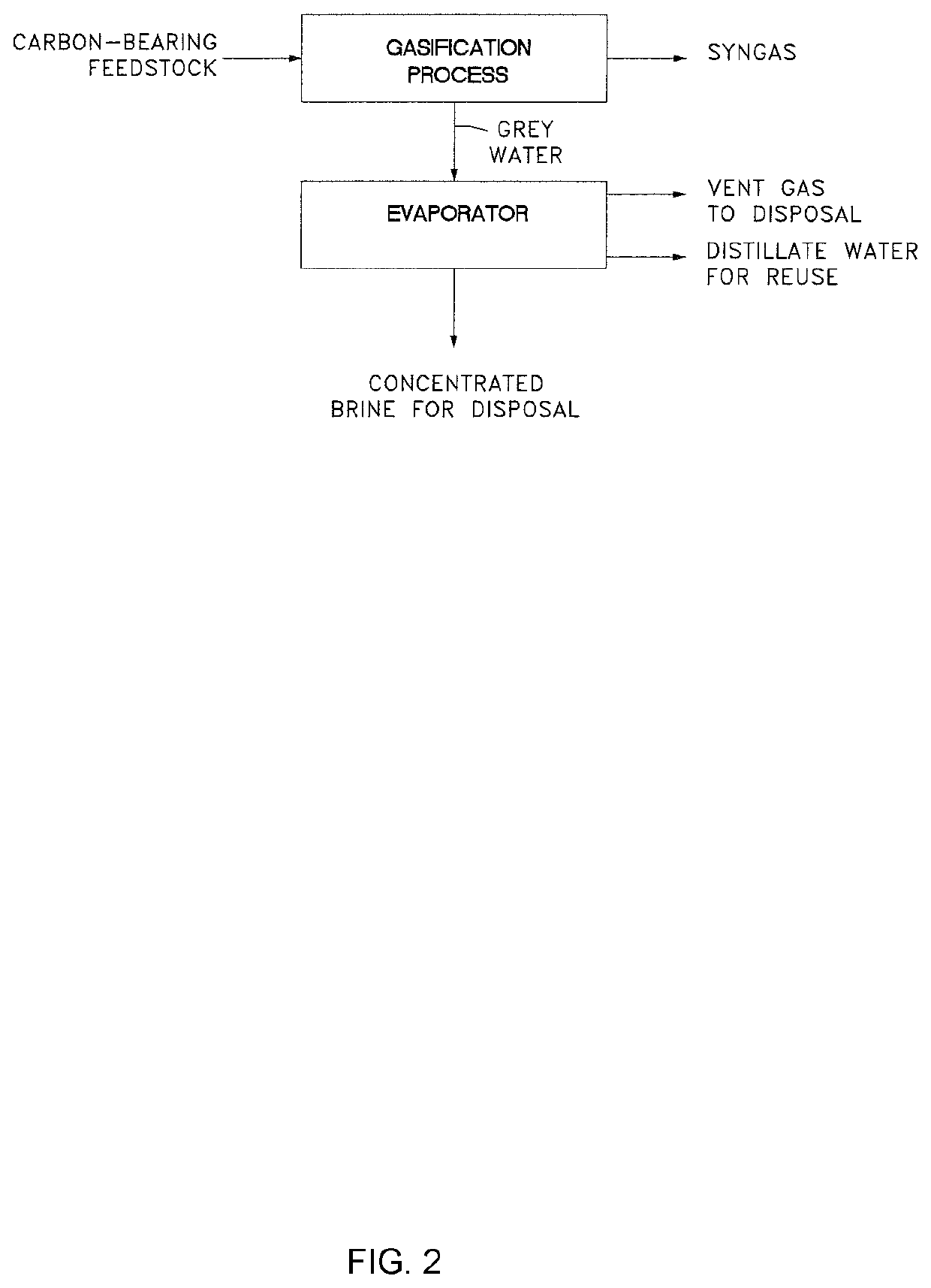

Method and Apparatus for Gasification Wastewater Treatment

InactiveUS20200048128A1Reduce solubilityImprove concentrationTreatment involving filtrationEnergy based wastewater treatmentFluid phaseGreywater

We provide an evaporation based method for water recovery from gasification wastewater to achieve zero liquid discharge. Grey water from a gasification system is processed by an evaporation system which recovers >99% of the influent water and generates a solid phase in a crystallizing reactor. The crystallizing reactor converts dissolved solids present as highly soluble species into alternative chemical forms that are amenable to precipitation and removal from the liquid phase to achieve zero liquid discharge.

Owner:AQUATECH INT LLC

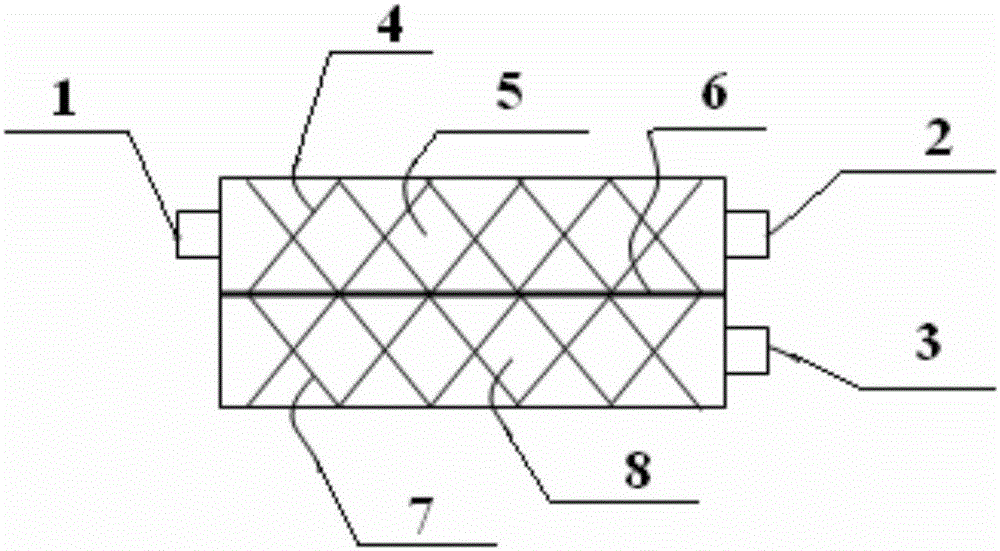

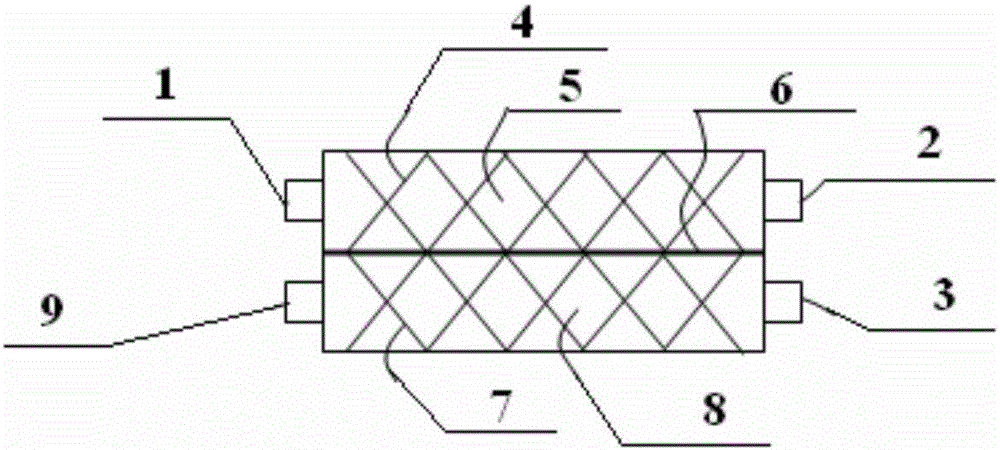

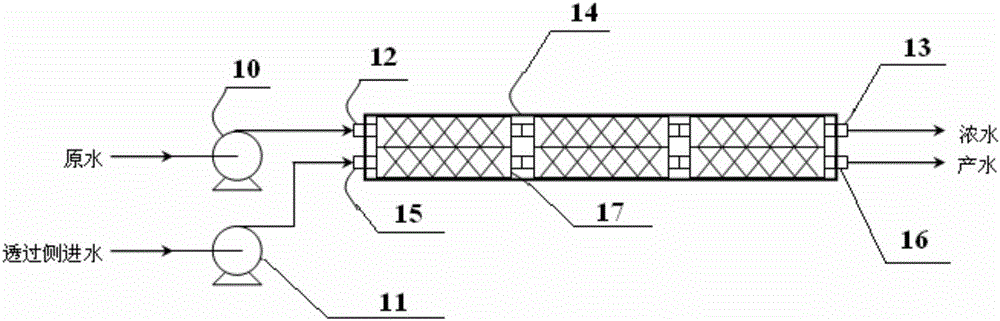

Concurrent flow reverse osmosis film assembly, reverse osmosis system and method for treatment of salt containing water

InactiveCN106554052AEmission reductionImprove recycling efficiencyReverse osmosisWater/sewage treatment bu osmosis/dialysisWater resourcesWater flow

The invention relates to the field of water treatment and discloses a concurrent flow reverse osmosis film assembly, a reverse osmosis system and a method for treatment of salt containing water. The concurrent flow reverse osmosis film assembly comprises a reverse osmosis film, a concentrated water separating net and a fresh water separating net. A concentrated water flow channel is formed by the concentrated water separating net, and a fresh water flow channel is formed by the fresh water separating net. A raw water inlet and a concentrated water outlet are formed in the concentrated water flow channel, and a permeation side water inlet and a water producing outlet are formed in the fresh water flow channel. By using the concurrent flow reverse osmosis film assembly and the reverse osmosis system for the treatment of the salt containing water, the operating pressure and the running cost do not need to be improved, but the concentration limitation of an existing reverse osmosis system can be broken through; and the discharge quantity of final concentrated saltwater of the system is greatly reduced, the recycling efficiency of water resource can be improved, and the comprehensive treatment cost for achieving zero liquid discharge can be greatly lowered.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

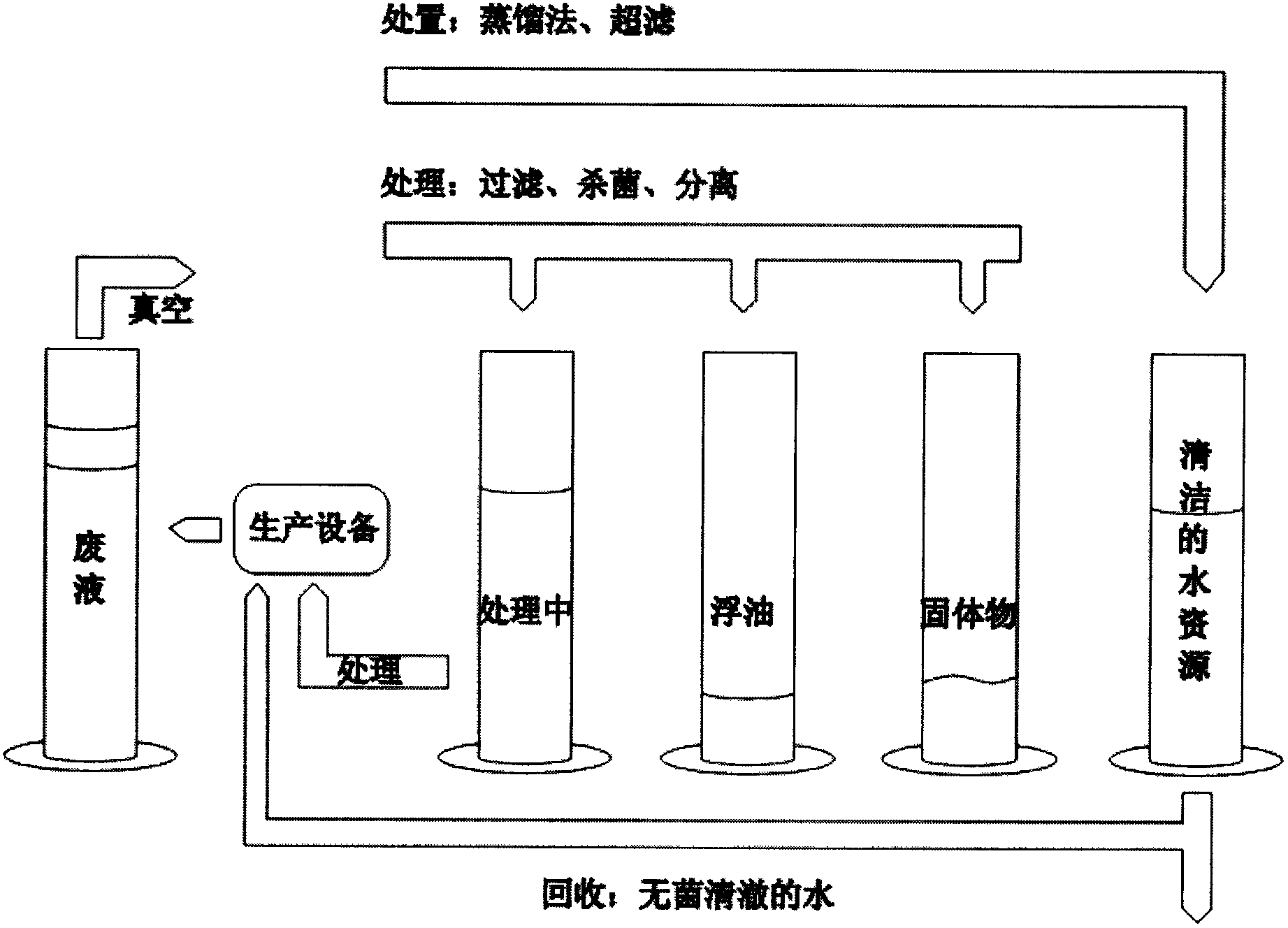

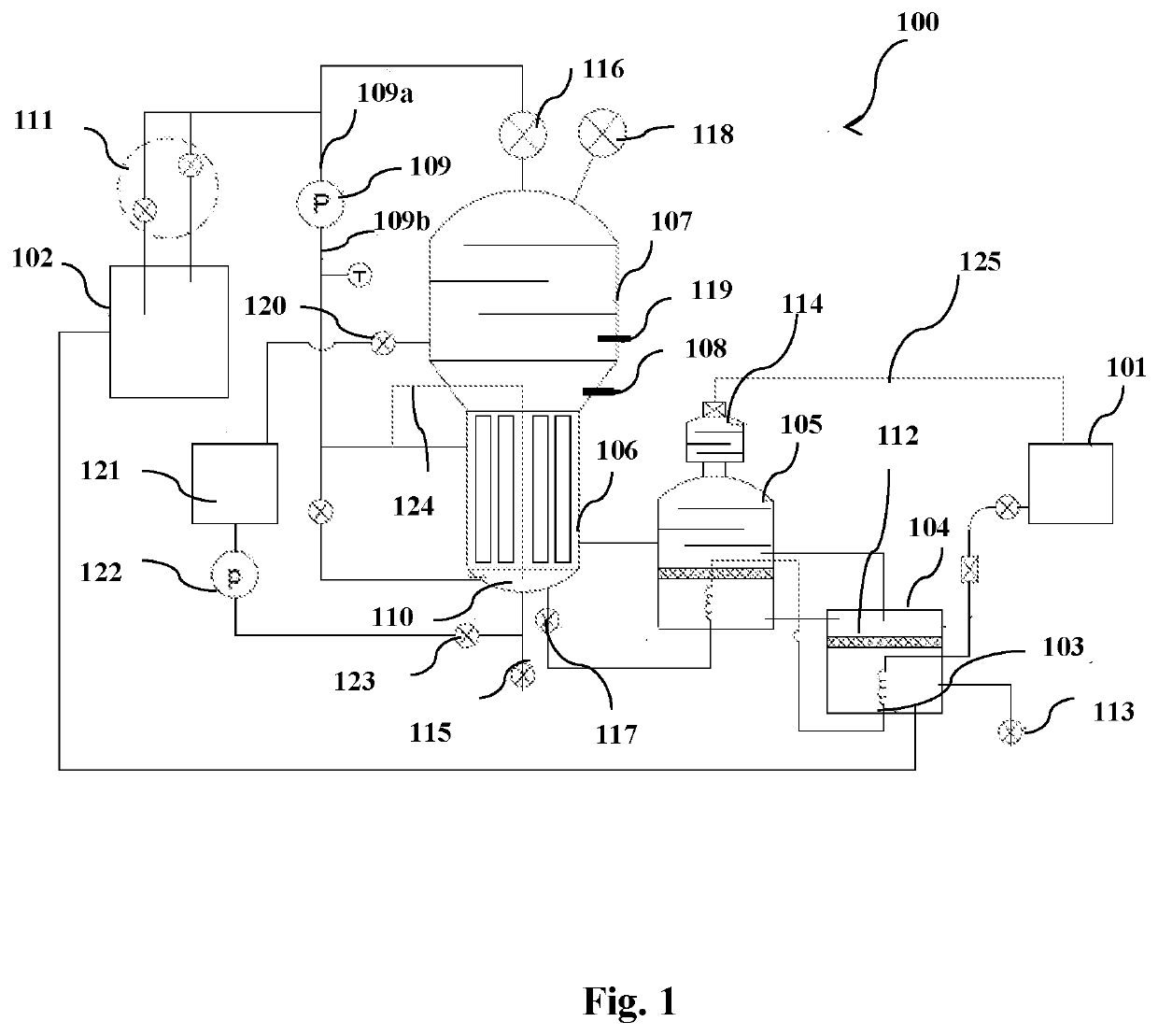

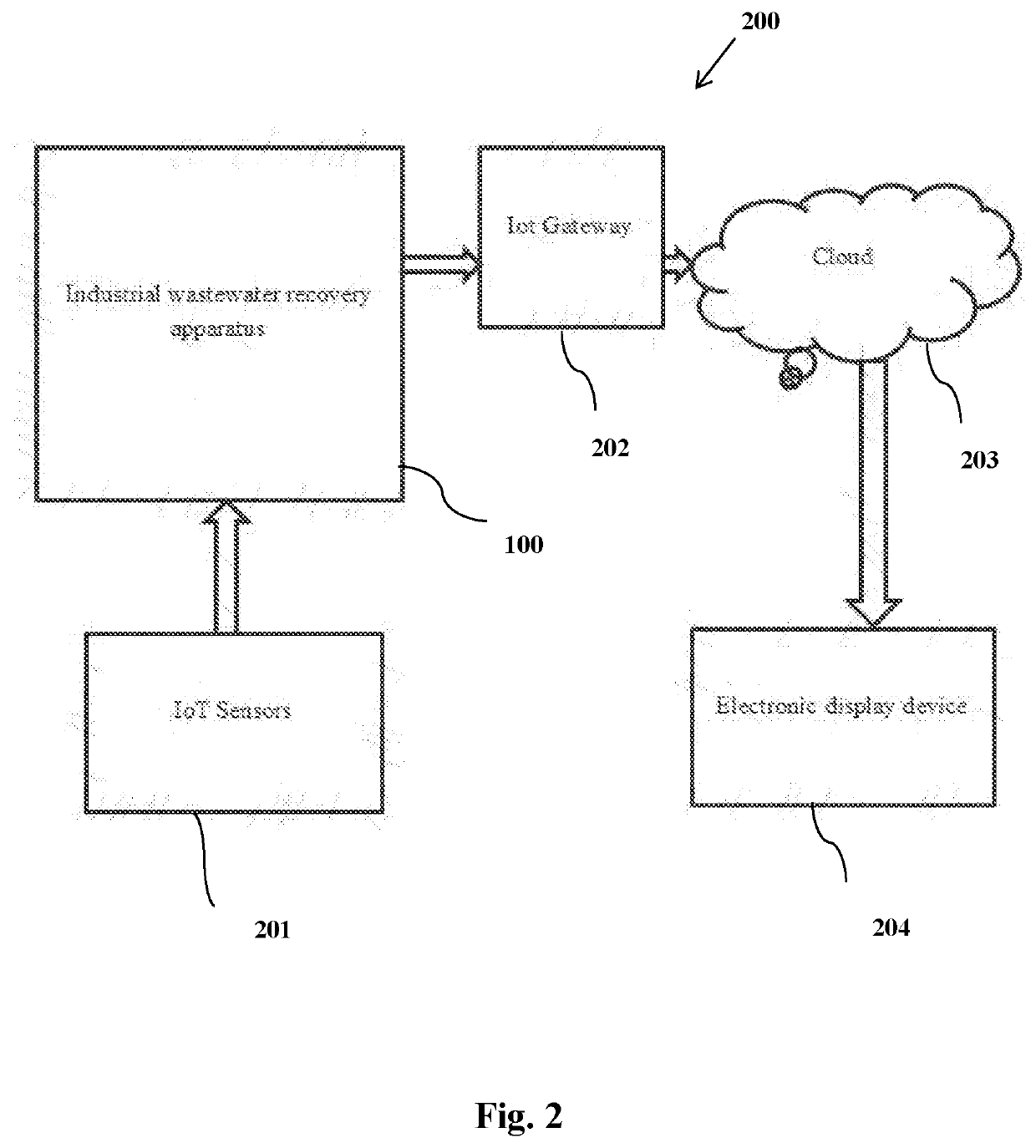

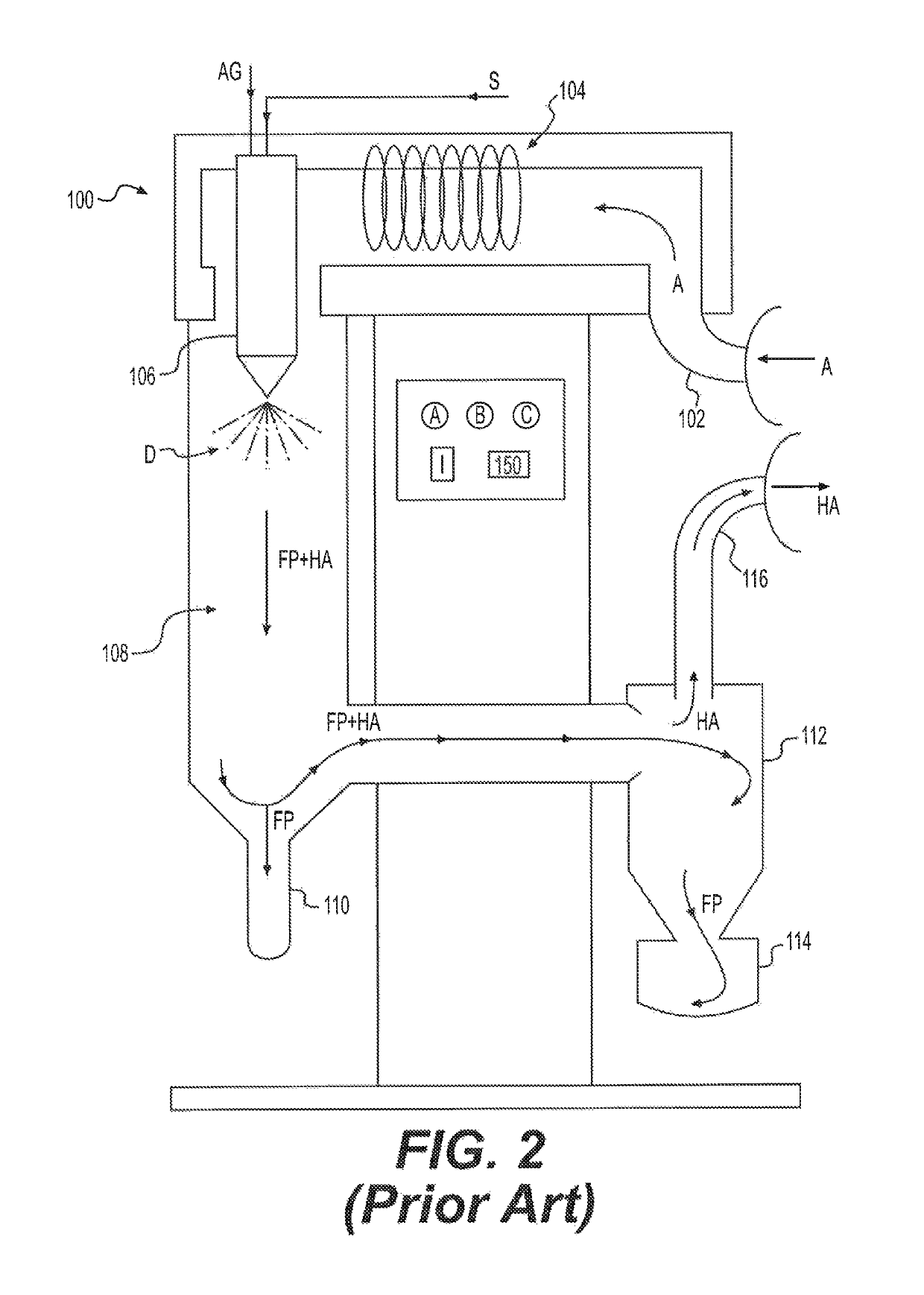

Industrial wastewater recovery apparatus aiming at zero liquid discharge (ZLD)

ActiveUS20200009471A1Low costEasy to operateDistillation regulation/controlLiquid suspension thickening by filtrationIndustrial waste waterDisplay device

The present invention provides an industrial wastewater recovery apparatus (100) aiming at Zero Liquid Discharge (ZLD). The apparatus (100) provides two stages in pre-heating the spiral coil pipe (103) containing wastewater and also conserves the heat by using the two heat exchangers (104, 105). The apparatus (100) agitates the surface wastewater to increase the rate of evaporation for faster heating. The apparatus (100) provides two stages in condensation of distilled water and also provides real-time monitoring of the water quality. The apparatus (100) provides automatic cleaning in the various parts during the operations. Further, a plurality of IoT sensor (201) monitor the real time parameters of the industrial wastewater recovery apparatus (100) and data is available to the user on the electronic display device (204).

Owner:MEGHANATHAN DHARMENDRA

Method for deeply treating inorganic high-salt industrial wastewater and realizing zero liquid discharge

InactiveCN106477775AReduce fouling propertiesRealize comprehensive utilizationTreatment involving filtrationWater softeningIndustrial waste waterSlag

The invention discloses a method for deeply treating inorganic high-salt industrial wastewater and realizing zero liquid discharge. The method comprises the following steps: treating alkaline waste residues, chemically removing hardness, precipitating and separating, carrying out double-membrane concentration and recycling according to different quality. The method disclosed by the invention has the beneficial effects that all the high-salt wastewater can be recycled and the zero liquid discharge is realized; calcium-containing alkaline waste residues (such as carbide slag and lime powder), carbonate-containing alkaline waste residues, waste gas containing carbon dioxide and the like are industrial wastes and comprehensive utilization of treating wastes by wastes is realized; the hardness is technically removed and the total hardness is reduced to be lower than or equal to 4mmol / L; scaling properties of the wastewater are reduced and the industrial wastewater is convenient to concentrate through low-pressure reverse osmosis; and particularly, according to different water quality of the high-salt industrial wastewater, different hardness removing materials and methods are adopted and the hardness removing cost is low.

Owner:SHAANXI JINTAI CHLOR ALKALI CHEM CO LTD

Zero Liquid Discharge Method for High Silica Solutions

InactiveUS20140326674A1Improve performanceReduce power consumptionWaste water treatment from quariesSludge treatment by de-watering/drying/thickeningHardnessSilica gel

Disclosed are zero liquid discharge (ZLD) processes that utilize naturally occurring or supplemental silicate in the water supply for removing magnesium and calcium hardness from aqueous alkaline streams in the form of a silica gel, thereby allowing separation of a low hardness supernant for recycling.

Owner:CHEMTREAT

Process For Treatment Of Produced Water

InactiveCN102428041AWaste water treatment from quariesFatty/oily/floating substances removal devicesWaste productProduct gas

A process for treating produced water in heavy oil production comprises, providing an oil / water mixture gathered from an oil / water collection well, whereby oil from said oil / water mixture is separated to provide an oil product and a produced water product containing oil, dissolved gases and dissolved solutes. Said produced water product is then deoiled, and the deoiled water subsequently passes though a membrane system, resulting in permeate water and reject. The resulting permeate water is sent on to a boiler system for production of steam, and the reject is introduced into an evaporator to result in distillate water and blow down. Thereafter, the blow down may be charged into zero liquid discharge treatment; and the distillate water added to the membrane permeate.

Owner:GENERAL ELECTRIC CO

Desalination system with mineral recovery

ActiveUS10280095B1Readily apparentGeneral water supply conservationSeawater treatmentWater useWater desalination

The desalination system with mineral recovery is a system for desalinating water using spray drying, which allows for both the production of purified water and the recovery of mineral salts. The desalination system with mineral recovery is a two-stage system for zero-liquid discharge (ZLD) desalination of feed water. The feed water may be, for example, seawater, reverse osmosis (RO) brine (i.e., the waste brine from a RO process), nano-filtration (NF) reject, multistage flash (MSF) brine, or the like. The first stage receives the feed water and uses a spray drying process to produce concentrated brine and a first volume of purified water. The concentrated brine is fed to the second stage, which also uses a spray drying process to produce a second volume of purified water and a volume of recovered mineral salts.

Owner:KUWAIT INST FOR SCI RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com