Distillation separation method for oily wastewater

A technology for distillation separation and waste water, which is applied in the fields of energy waste water treatment, chemical instruments and methods, heating water/sewage treatment, etc. It can solve the important indicators of the repetition rate of industrial water, does not meet the development trend of industrial waste water treatment, does not Find obvious shortcomings and other problems, and achieve excellent environmental protection treatment capabilities, reduce the spread of odors, and achieve a wider range of pH values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

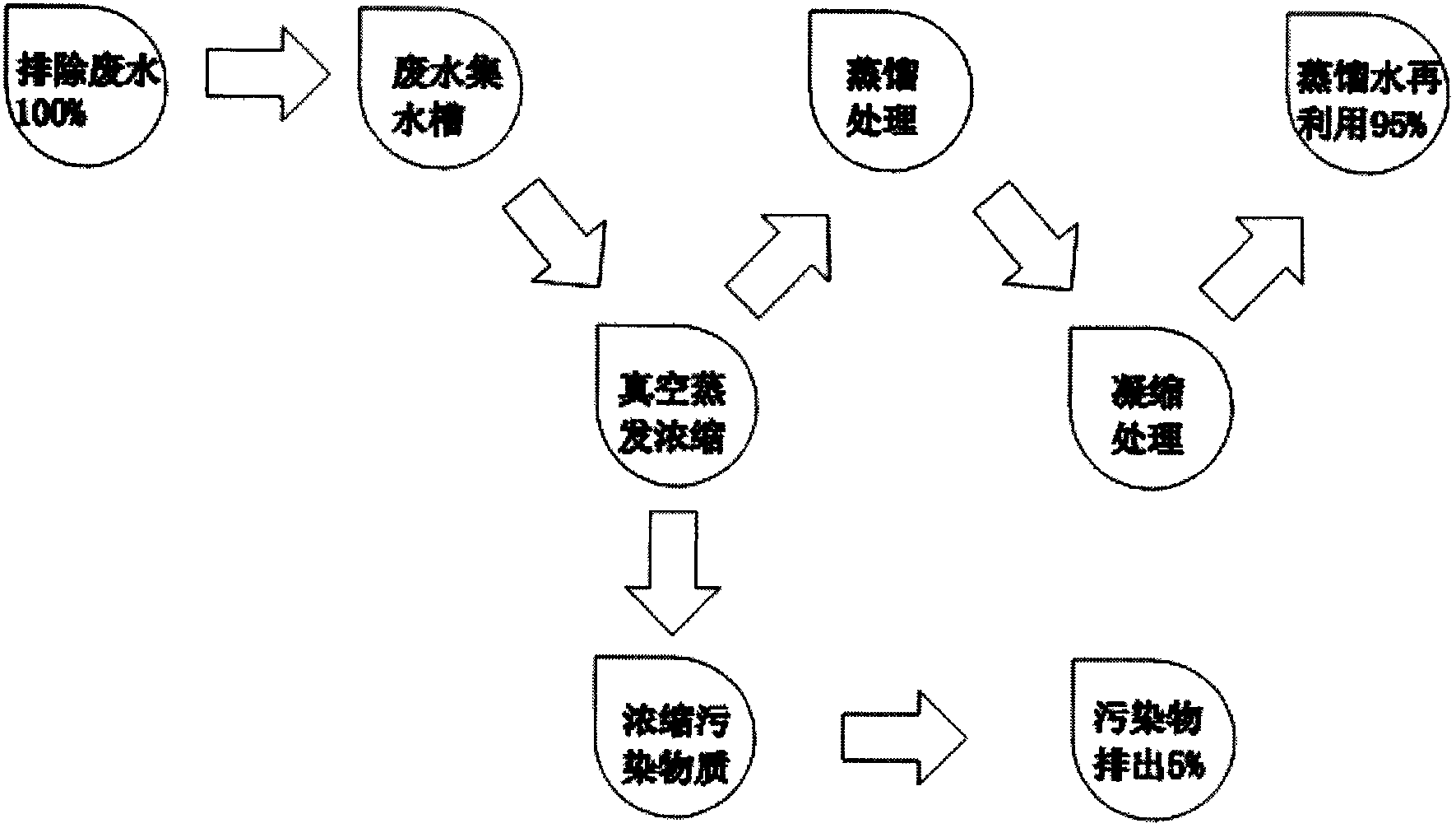

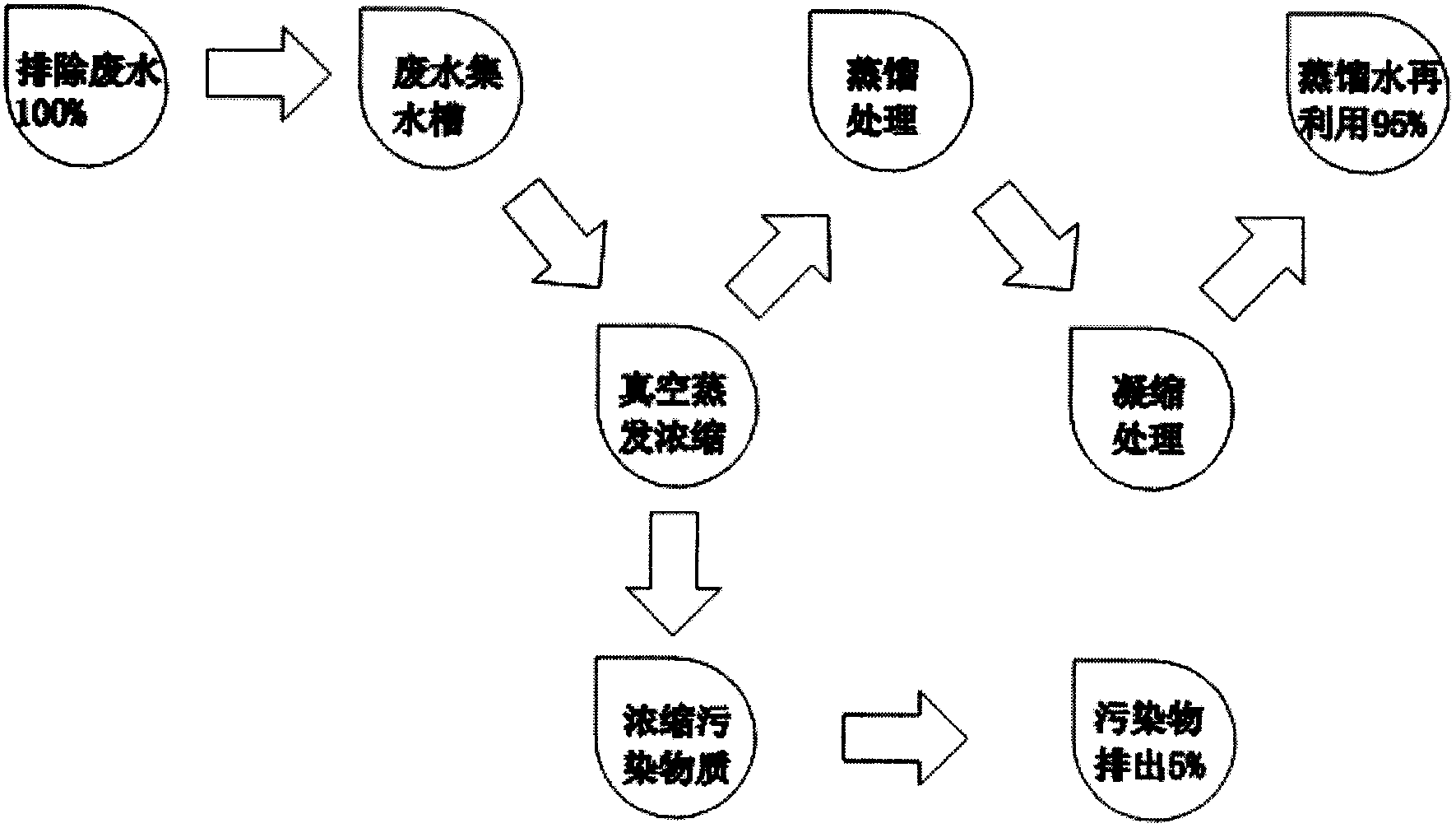

[0027] Such as figure 1 , figure 2 As shown, the steps include:

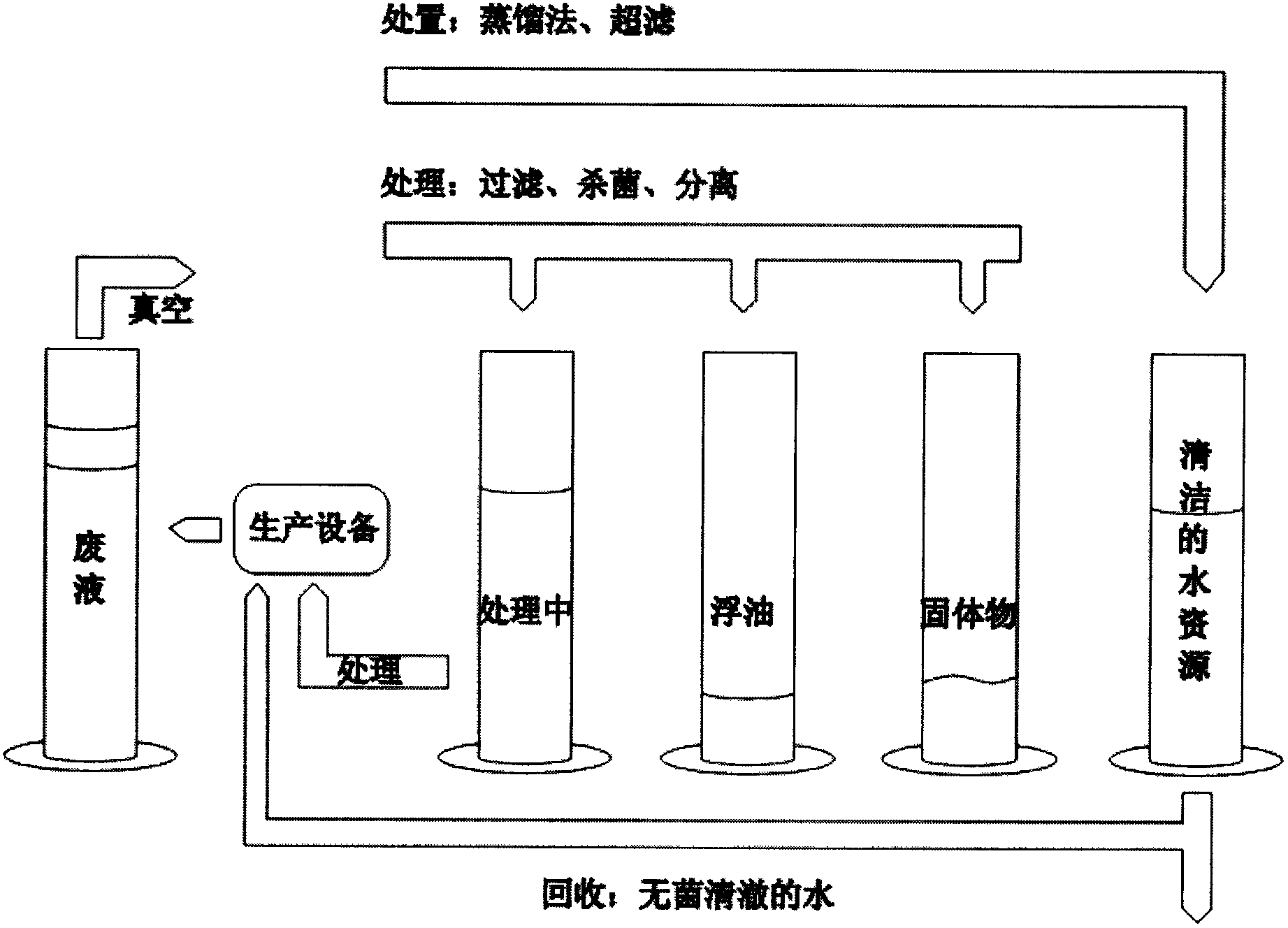

[0028] 1) Vacuum evaporation is used for vacuum evaporation of industrial wastewater, and the water in the wastewater is gasified into gas.

[0029] 2), distillation treatment, condensation treatment, the way of said distillation treatment is distillation method, the gas liquefaction by vacuum evaporation carries out distillation and condenses into distilled water, carries out ultrafiltration through ultra-strong filter, distills 90%-95% The water is condensed and discharged, while reducing waste by nearly 95%, while killing bacteria, reducing the spread of odors, and reentering clean water resources for industrial recycling.

[0030] 3) Concentrate the pollutants, concentrate 5%-10% of the waste, filter the waste to separate each waste gas, and finally discharge the waste to achieve the effect of zero emission.

[0031] 4) Pollutants are discharged, and the concentrated pollutants are discharged.

[0032] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com