Concurrent flow reverse osmosis film assembly, reverse osmosis system and method for treatment of salt containing water

A reverse osmosis membrane module, reverse osmosis membrane technology, applied in osmosis/dialysis water/sewage treatment, chemical instruments and methods, reverse osmosis, etc. cost, reduced emissions, increased operating pressure and effect of operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

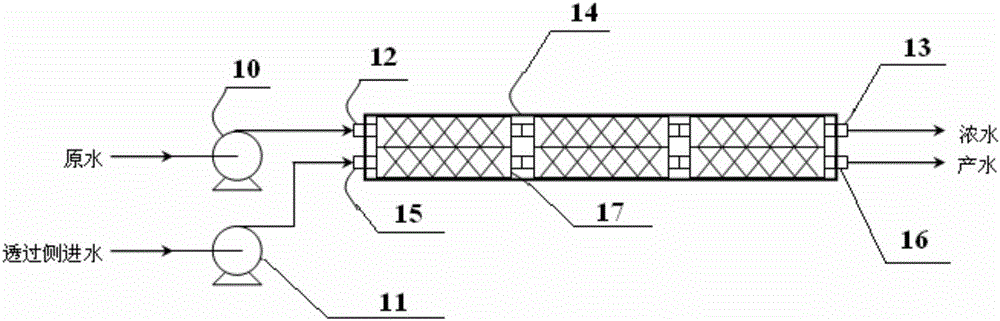

[0100] combine figure 2 with image 3 , this embodiment is used to illustrate the reverse osmosis system of the present invention and the method for treating brine using the reverse osmosis system.

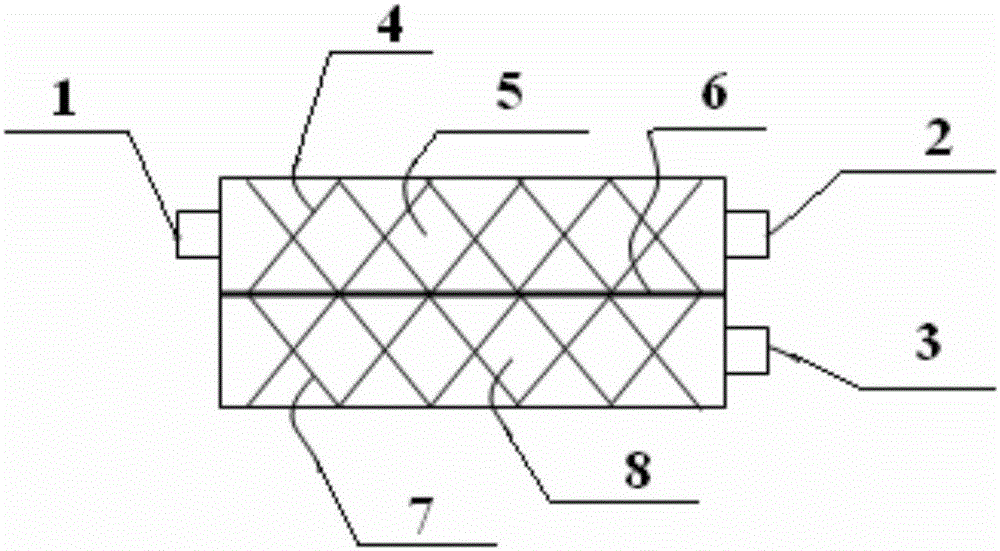

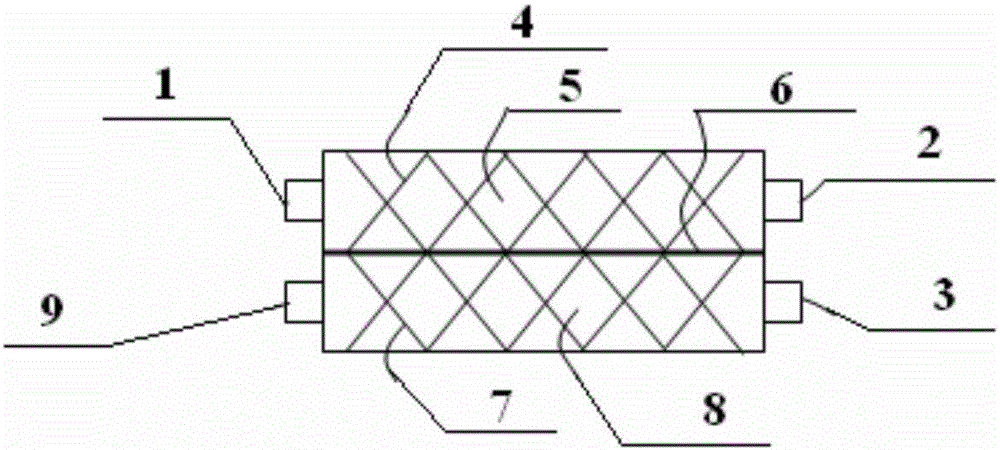

[0101] In this embodiment, the reverse osmosis system includes a membrane housing 14, three parallel flow reverse osmosis membrane modules 17 arranged in series in the membrane housing 14, a raw water pump 10 and a permeate side inlet water pump 11, wherein, for each Parallel flow reverse osmosis membrane modules, all including reverse osmosis membrane 6, concentrated water separation net 4 and fresh water separation net 7, concentrated water separation net 4 forms concentrated water flow channel 5, fresh water separation net 7 forms fresh water flow channel 8, concentrated water flow channel 5 A raw water inlet 1 and a concentrated water outlet 2 are provided, and the fresh water flow channel 8 is provided with a permeable side water inlet 9 and a produced water outlet 3 . For...

Embodiment 2

[0109] combine Figure 2-Figure 4 , this embodiment is used to illustrate the reverse osmosis system of the present invention and the method for treating brine using the reverse osmosis system.

[0110] In this embodiment, the reverse osmosis system includes two parallel-flow reverse osmosis membrane treatment units connected in series, a raw water pump 10 , a permeate side feed water pump 11 and a booster pump 20 . Among them, each parallel flow reverse osmosis membrane treatment unit is equipped with raw water inlet, concentrated water outlet, permeate side inlet and product water outlet, each parallel flow reverse osmosis membrane treatment unit includes 10 parallel membrane shells, each There are 6 parallel flow reverse osmosis membrane modules connected in series in the membrane shell, and each parallel flow reverse osmosis membrane module includes reverse osmosis membrane 6, concentrated water separation net 4 and fresh water separation net 7, concentrated water separati...

Embodiment 3

[0119] combine figure 2 , image 3 , Figure 5 , this embodiment is used to illustrate the reverse osmosis system of the present invention and the method for treating brine using the reverse osmosis system.

[0120] In this embodiment, the reverse osmosis system includes two parallel-flow reverse osmosis membrane treatment units connected in series, a raw water pump 10 , a permeate side feed water pump 11 and a booster pump 20 . Among them, each parallel flow reverse osmosis membrane treatment unit is equipped with raw water inlet, concentrated water outlet, permeate side inlet and product water outlet, each parallel flow reverse osmosis membrane treatment unit includes 10 parallel membrane shells, each There are 6 parallel flow reverse osmosis membrane modules connected in series in the membrane shell, and each parallel flow reverse osmosis membrane module includes reverse osmosis membrane 6, concentrated water separation net 4 and fresh water separation net 7, concentrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com